Aluminum-tin-zirconium-molybdenum-chromium intermediate alloy and preparation method thereof

An intermediate alloy, molybdenum-chromium technology, applied in the field of metal materials, can solve problems such as unstable product performance and difficulties in the intermediate process of producing titanium alloys, and achieve the effects of easy control, improved uniformity and stability, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

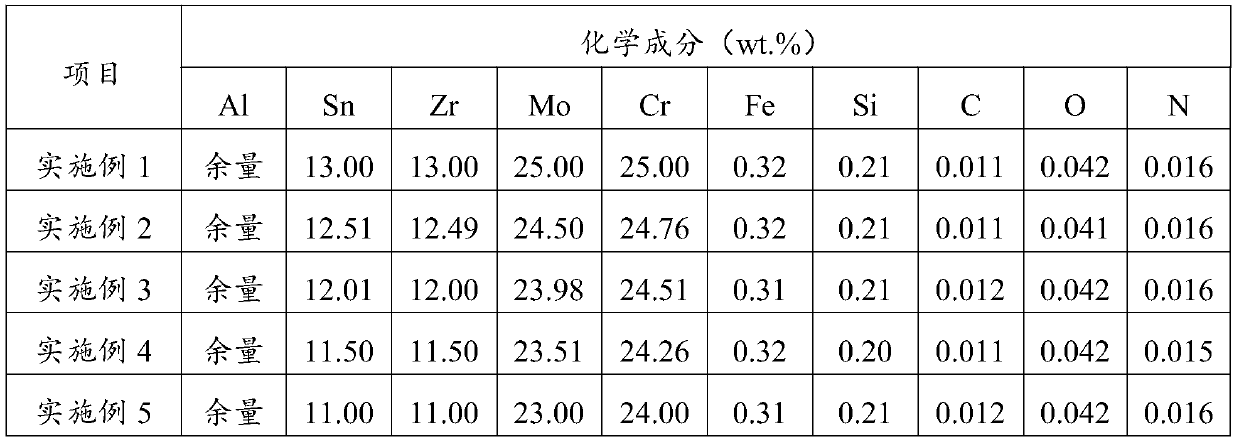

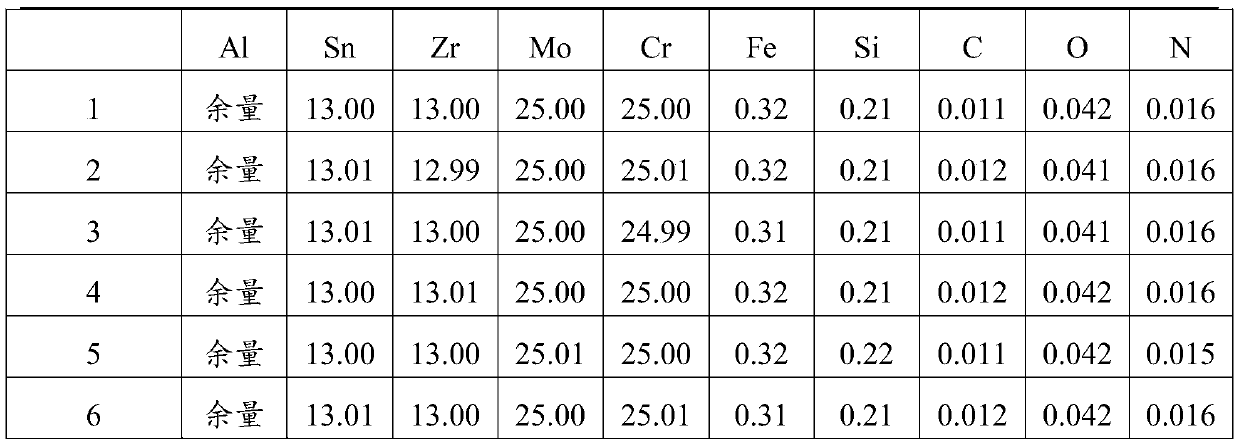

Examples

preparation example Construction

[0032] The present invention provides the preparation method of the aluminum-tin-zirconium-molybdenum-chromium master alloy described in the above technical solution, comprising the following steps:

[0033] Mixing the first aluminum source and the molybdenum source to carry out an aluminothermic reaction to obtain an aluminum-molybdenum primary alloy;

[0034] The aluminum-molybdenum primary alloy, tin, zirconium, chromium and the second aluminum source are mixed and vacuum smelted to obtain an aluminum-tin-zirconium-molybdenum-chromium intermediate alloy.

[0035] In the present invention, the first aluminum source and the molybdenum source are mixed to carry out an aluminothermic reaction to obtain an aluminum-molybdenum primary alloy. Before mixing the first aluminum source and the molybdenum source, the present invention preferably dries the first aluminum source and the molybdenum source; the drying temperature is preferably 100-120°C, more preferably 105-115°C, and the ...

Embodiment 1

[0048] 1. Aluminothermic reaction smelting process

[0049] (1) Dry the aluminum powder and molybdenum trioxide at a drying temperature of 110°C and a drying time of 12h.

[0050] (2) According to the mass fraction of molybdenum trioxide in molybdenum trioxide and the aluminum consumption of molybdenum trioxide in the chemical reaction, calculate the quality of raw materials in the aluminothermic smelting process: aluminum powder 13.98kg, molybdenum trioxide 19.05kg.

[0051] (3) The aluminum powder and molybdenum trioxide were respectively charged into the mixer for 4min at a rate of 120r / min.

[0052] (4) Preheating the mixed aluminum powder and molybdenum trioxide to a furnace temperature of 43°C respectively, smelting by ignition, the reaction temperature is 1650°C to 1720°C, the reaction time is 29 to 35 seconds, and the furnace is released after 24 hours to obtain aluminum molybdenum. Grade 65 alloy.

[0053] 2. The ratio of vacuum melting process

[0054] After obtai...

Embodiment 2

[0072] 1. Aluminothermic reaction smelting process

[0073] (1) Dry the aluminum powder and molybdenum trioxide at a drying temperature of 110°C and a drying time of 12h.

[0074] (2) According to the mass fraction of molybdenum trioxide in molybdenum trioxide and the aluminum consumption of molybdenum trioxide in the chemical reaction, the quality of raw materials in the aluminothermic smelting process is calculated: aluminum powder 13.70kg, molybdenum trioxide 18.68kg.

[0075] (3) The aluminum powder and molybdenum trioxide were respectively charged into the mixer for 4min at a rate of 120r / min.

[0076] (4) Preheating the mixed aluminum powder and molybdenum trioxide to a furnace temperature of 43°C respectively, smelting by ignition, the reaction temperature is 1650°C to 1720°C, the reaction time is 29 to 35 seconds, and the furnace is released after 24 hours to obtain aluminum molybdenum. Grade 65 alloy.

[0077] 2. The ratio of vacuum melting process

[0078] After o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com