Proportion design method for SMA (stone mastic asphalt) mixture

A design method and mixture technology, which is applied in the field of road and bridge engineering, can solve the problems of unstable SMA mixture quality, hindering the large-scale application of SMA, and uneven distribution of fiber agglomeration, so as to simplify the mixing production process and reduce asphalt smoke Emissions and the effect of improving economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The embodiment of the present invention provides a method for designing the ratio of SMA mixture, comprising the following steps:

[0041] Step 1: adjust the proportion of mineral material, and select 3 preliminary test gradations with different thicknesses from the primary selection gradation range in Table 1, and the preliminary test gradation is as shown in Table 2;

[0042] Table 1 Primary grading range

[0043]

[0044] Table 2 Primary gradation

[0045] Sieve hole(mm)

16

13.2

9.5

4.75

2.36

1.18

0.6

0.3

0.15

0.075

1# Grading

100

89.7

63.9

30.3

24.1

20.3

14.5

13.2

11.9

11.4

2# Grading

100

90

64.7

28.7

22.3

19.1

14

12.9

11.7

11.2

3# Grading

100

90.8

67.3

26.5

19.7

17.2

13.2

12.4

11.5

11.1

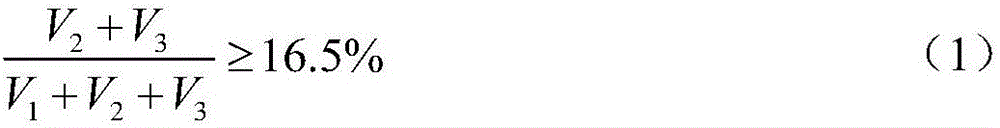

[0046] Step 2: Calculate the theoretical minimum asphalt ratio according to the following formula with the target void rat...

Embodiment 2

[0059] The embodiment of the present invention provides a kind of SMA mixture, comprises: the SBS modified asphalt (I-D) of 1 weight part, the aggregate of 16.07 weight parts, the limestone mineral powder of 1.79 weight part (asphalt ratio=SBS modified asphalt / (set material+limestone slag)=5.6%) and 0.005 parts by weight of Evotherm M1 surfactant; wherein the aggregate is taken from the basalt produced in Chengde, Hebei, and the gradation is shown in Table 4.

[0060] The SMA mixture is prepared by the following method: Step 1: take a certain amount of SBS modified asphalt, take by weighing 0.5% surfactant with the weighed amount of the SBS modified asphalt (I-D) and add to the Stir in the SBS modified asphalt for 5 minutes, and then place it in an oven at 165°C for drying for later use; Step 2: Take the aggregate that is 16.07 times the weighted amount of the SBS modified asphalt described in step 1 and dry it at 155°C Keep the temperature in the dry box for 4 hours, then add...

Embodiment 3

[0064] The embodiment of the present invention provides a kind of SMA mixture, comprises: the SBS modified bitumen (I-D) of 1 weight part, the aggregate of 16.43 parts by weight, the limestone mineral powder of 1.43 parts by weight (asphalt ratio=SBS modified bitumen / (set Material+limestone ore powder)=5.6%) and the Evotherm M1 surfactant of 0.006 weight part;

[0065] The SMA mixture is prepared by the following method: Step 1: take a certain amount of SBS modified asphalt, take by weighing 0.6% surfactant with the weighed amount of the SBS modified asphalt (I-D) and add it to the Stir in the SBS modified asphalt for 10 minutes, and then place it in an oven at 155°C for drying for later use; Step 2: Take the aggregate that is 16.43 times the weighted amount of the SBS modified asphalt described in step 1 and dry it at 145°C Keep the temperature in the dry box for 4 hours, then add it to the mixing pot at 145°C and dry mix it for 90s; Step 3: Add the asphalt prepared at consta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com