Graphene conduction oil additive and preparation method thereof

A heat-conducting oil and additive technology, applied in the petroleum industry, chemical instruments and methods, heat-exchange materials, etc., can solve the problems of heat-conducting oil being easily cracked, easy to burn, polymerized and deteriorated, etc., to improve heat transfer efficiency, prolong service life, The effect of improving usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

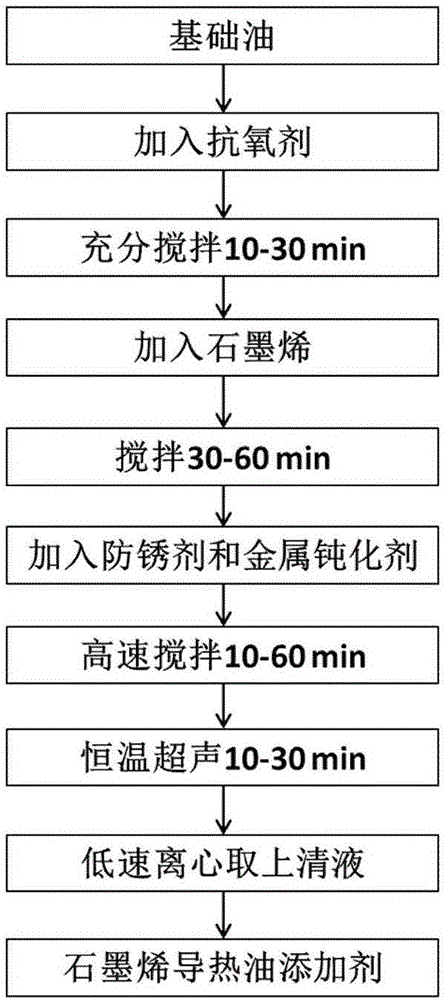

Method used

Image

Examples

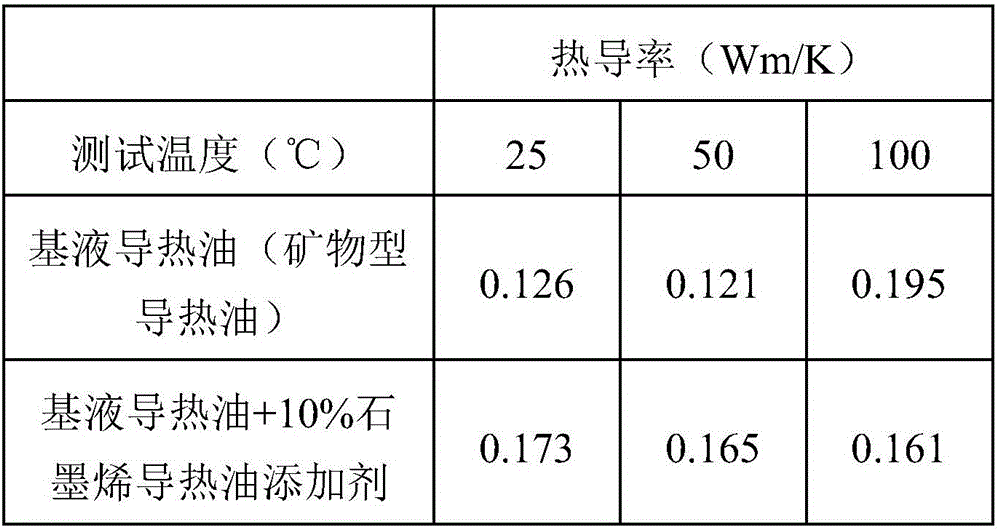

Embodiment 1

[0029] (1) Graphene heat-conducting oil additive, gets raw material and comprises by weight percentage:

[0030] 5% graphene, 90% base fluid heat transfer oil, 0.03% metal passivator, 0.5% antirust agent, 3% antioxidant;

[0031] Among them: graphene is single-layer or multi-layer fluorinated graphene, with a specific surface area of 160m 2 / g, the thermal conductivity of the powder is 50W / mK, the diameter of a single graphene sheet is between 10 microns and 30 microns, and the thickness of a graphene sheet is 0.34 nanometers to 5 nanometers. Base liquid heat transfer oil choose mineral heat transfer oil, metal passivator choose N,N'-disalicylidene propylenediamine, antioxidant choose tetrakis[β-(3,5-di-tert-butyl-4-hydroxy phenyl) propionate] pentaerythritol ester.

[0032] (2) the preparation method of graphene heat conduction oil additive, comprises the steps:

[0033] Fully stir the base liquid heat transfer oil and antioxidant at a temperature of 55°C for 20 minutes,...

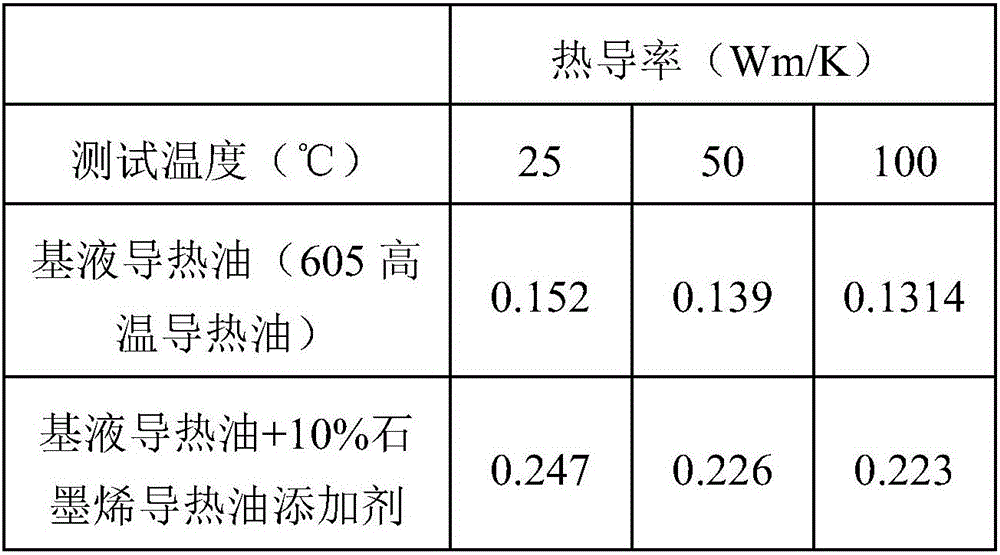

Embodiment 2

[0038] (1) Graphene heat-conducting oil additive, gets raw material and comprises by weight percentage:

[0039] Graphene 15%, base fluid heat transfer oil 80%, metal passivator 0.03%, rust inhibitor 0.3%, antioxidant 3%;

[0040] Among them: graphene is single-layer and multi-layer graphene prepared by oxidation-reduction method, with a specific surface area of 400m 2 / g, the thermal conductivity of the powder is 150W / mK, the diameter of a single graphene sheet is between 5 microns and 200 microns, and the thickness of the graphene sheet is 0.6 nanometers to 10 nanometers; use 605 high-temperature heat transfer oil; use p-benzene Diamine antioxidant; use N,N'-disalicylidene propylenediamine metal deactivator.

[0041](2) the preparation method of graphene heat conduction oil additive, comprises the steps:

[0042] Fully stir the base liquid heat transfer oil and antioxidant at a temperature of 55°C for 20 minutes, then add graphene and mechanically stir for 40 minutes, ad...

Embodiment 3

[0047] (1) Graphene heat-conducting oil additive, gets raw material and comprises by weight percentage:

[0048] Graphene 1%, base fluid heat transfer oil 98%, metal passivator 0.05%, rust inhibitor 0.5%, antioxidant 0.1%;

[0049] Among them: graphene is single-layer or multi-layer graphene prepared by chemical growth method, with a specific surface area of 450m 2 / g, the thermal conductivity of the powder is 200W / mK, the diameter of a single graphene sheet is between 0.1 micron and 20 microns, and the thickness of the graphene sheet is 0.34 nanometers to 5 nanometers; use synthetic heat transfer oil; use sulfur Dipropionate diester antioxidant; use N,N'-disalicylidene propylenediamine metal deactivator.

[0050] (2) the preparation method of graphene heat conduction oil additive, comprises the steps:

[0051] Fully stir the base liquid heat transfer oil and antioxidant at a temperature of 60°C for 10 minutes, then add graphene and mechanically stir for 30 minutes, add ru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Film diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com