Slurry-homogenizing process for positive electrode slurry of lithium ion battery, positive electrode plate and lithium ion battery

A lithium-ion battery and positive electrode slurry technology, which is applied to battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve the problems of affecting the uniformity of the slurry, poor stability of the slurry, and difficulty in dispersing the slurry , to enhance the bonding effect, solve the problem of difficult dissolution of the binder, and reduce the baking temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

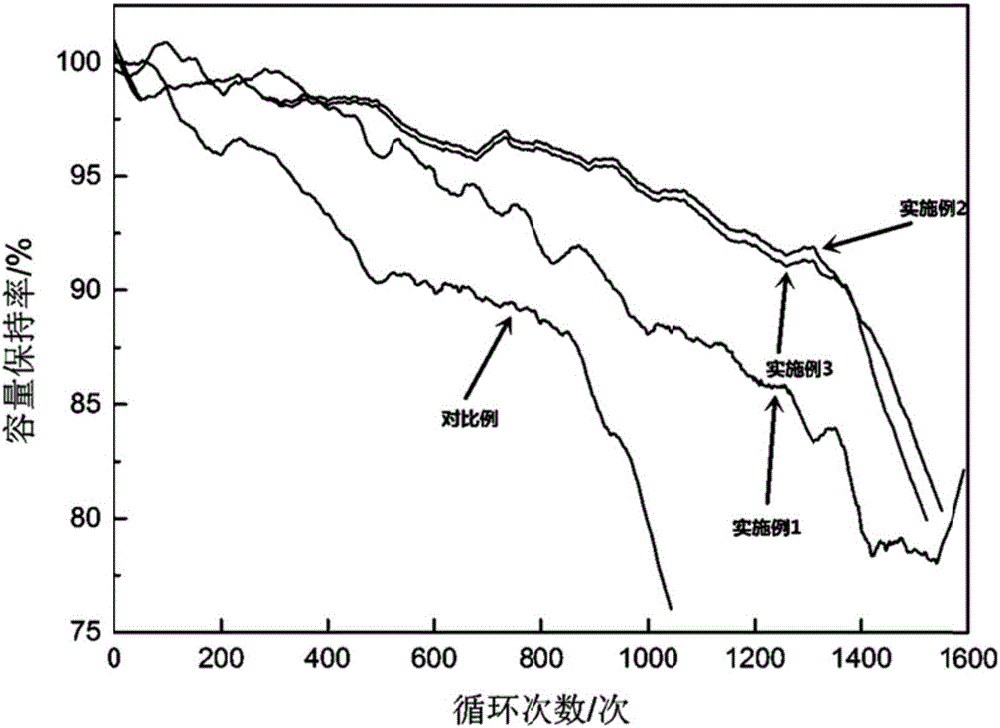

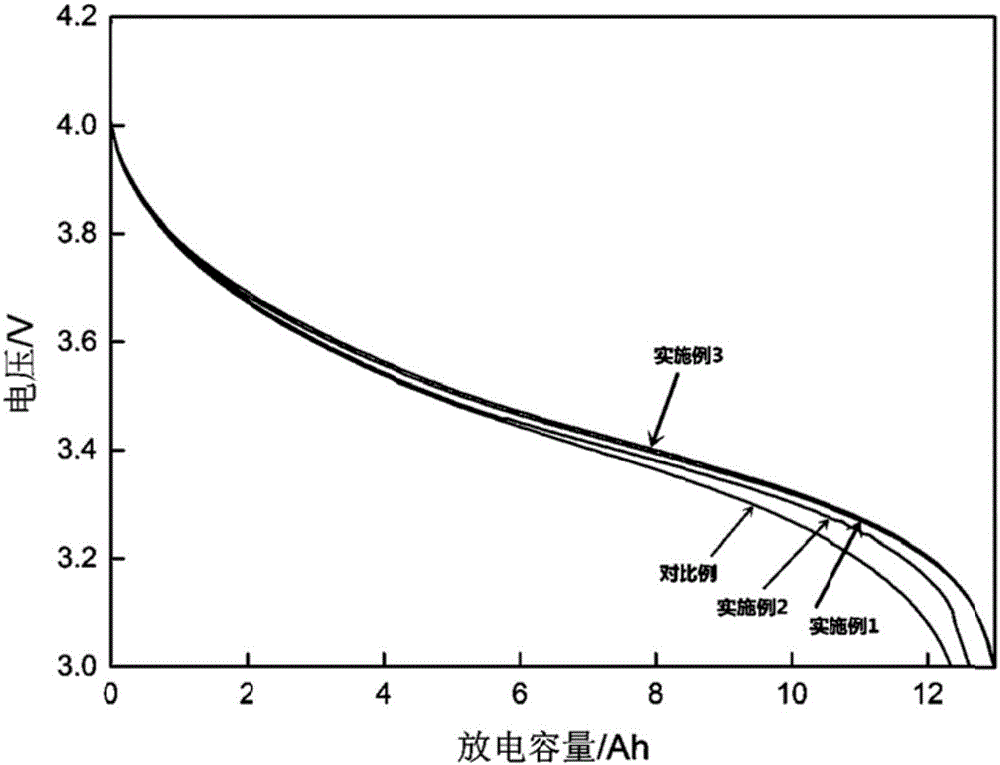

Embodiment 1

[0030] A homogenization process for lithium-ion battery cathode slurry, comprising the following steps:

[0031] a) Preparation of glue solution: mix the binder and solvent at a weight ratio of 1:5, stir and disperse at 50°C at a speed of 30Hz for 4 hours to prepare a binder glue solution, and then put the binder glue solution in Vacuum storage at -85KPa;

[0032] b) Stirring with a V-shaped mixer: After mixing the positive active material and the conductive agent, stir in a V-shaped mixer at a speed of 20 Hz for 40 minutes;

[0033] c) Pre-mixing and stirring: Add the positive electrode active material and conductive agent treated in step b into the homogenizer, and then add 40wt% of the binder solution and 20wt% of the remaining solvent into the homogenizer to Stir at a speed of 10 rpm and 300 rpm for 10 minutes, scrape the material after the end, then stir for 20 minutes at a speed of 15 rpm and 1000 rpm, and scrape the material after the end;

[0034] d) High-speed stirr...

Embodiment 2

[0041] A homogenization process for lithium-ion battery cathode slurry, comprising the following steps:

[0042]a) Preparation of glue solution: mix the binder and solvent at a weight ratio of 1:10, stir and disperse at a temperature of 50-60°C at a speed of 30-50Hz for 4-6 hours to prepare a binder glue solution, and then The adhesive glue solution is stored in vacuum at a vacuum degree of -85 ~ -100KPa;

[0043] b) Stirring with a V-shaped mixer: Mix the positive electrode active material and the conductive agent and stir in a V-shaped mixer at a speed of 20-40Hz for 40-60 minutes;

[0044] c) Pre-mixing and stirring: Add the positive electrode active material and conductive agent treated in step b into the homogenate mixer, and then add 40-60wt% of the binder solution and 20-40wt% of the remaining solvent into the homogenate In the mixer, stir at a speed of 10-15 rpm and 300-800 rpm for 10-20 minutes, scrape the material after the end, then stir for 20-30 minutes at a spee...

Embodiment 3

[0052] A homogenization process for lithium-ion battery cathode slurry, comprising the following steps:

[0053] a) Preparation of glue solution: Mix the binder and solvent at a weight ratio of 1:7, stir and disperse at 60°C at a speed of 50Hz for 6 hours to prepare a binder glue solution, and then put the binder glue solution in Vacuum storage at -100KPa;

[0054] b) Stirring with a V-shaped mixer: After mixing the positive electrode active material and the conductive agent, stir in a V-shaped mixer at a speed of 40 Hz for 60 minutes;

[0055] c) Pre-mixing and stirring: Add the positive electrode active material and conductive agent treated in step b into the homogenizer, and then add 60wt% of the binder solution and 40wt% of the remaining solvent into the homogenizer to Stir at a speed of 15 rpm and 800 rpm for 20 minutes, scrape the material after the end, then stir for 30 minutes at a speed of 20 rpm and 1500 rpm, and scrape the material after the end;

[0056] d) High-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com