Nanometer running-in agent

A nano-grinding and mixture technology, applied in additives, lubricating compositions, petroleum industry, etc., can solve the problems of clogging of precision filters, easy deterioration, poor compatibility, etc. obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Weigh the following raw materials for use: heavy alkylbenzene 15KG, alkylnaphthalene 15KG, borated polyisobutenyl succinimide 20KG, dialkyl molybdenum dithiophosphate 20KG, oil modified phenolic resin 1KG, hydroxyl silicone oil emulsion 3051KG , butter 1KG, detergent LD-11KG. It is prepared according to the following steps: (1) put the heavy alkylbenzene in the blending kettle, heat to 60°C, and stir for 10 minutes; (2) add borated polyisobutenyl succinimide, and continue to stir for 30 minutes Minutes; (3) Add dialkyl molybdenum dithiophosphate, and circulate and stir for 120 minutes, then add oil-modified phenolic resin, hydroxyl silicone oil emulsion 305, tallow, and detergent LD-1, and keep the temperature at 60°C for 60 minutes. Then slowly lower the temperature to below 40°C, fill the bucket, and seal the lid.

Embodiment 2

[0012] Weigh the following raw materials for use: heavy alkylbenzene 20KG, alkylnaphthalene 20KG, borated polyisobutenyl succinimide 50KG, dialkyl molybdenum dithiophosphate 40KG, oil modified phenolic resin 2KG, hydroxyl silicone oil emulsion 3054KG , butter 4KG, detergent LD-14KG. It is prepared according to the following steps: (1) put the heavy alkylbenzene in the blending kettle, heat to 60°C, and stir for 10 minutes; (2) add borated polyisobutenyl succinimide, and continue to stir for 30 minutes Minutes; (3) Add dialkyl molybdenum dithiophosphate, and circulate and stir for 120 minutes, then add oil-modified phenolic resin, hydroxyl silicone oil emulsion 305, tallow, and detergent LD-1, and keep the temperature at 60°C for 60 minutes. Then slowly lower the temperature to below 40°C, fill the bucket, and seal the lid.

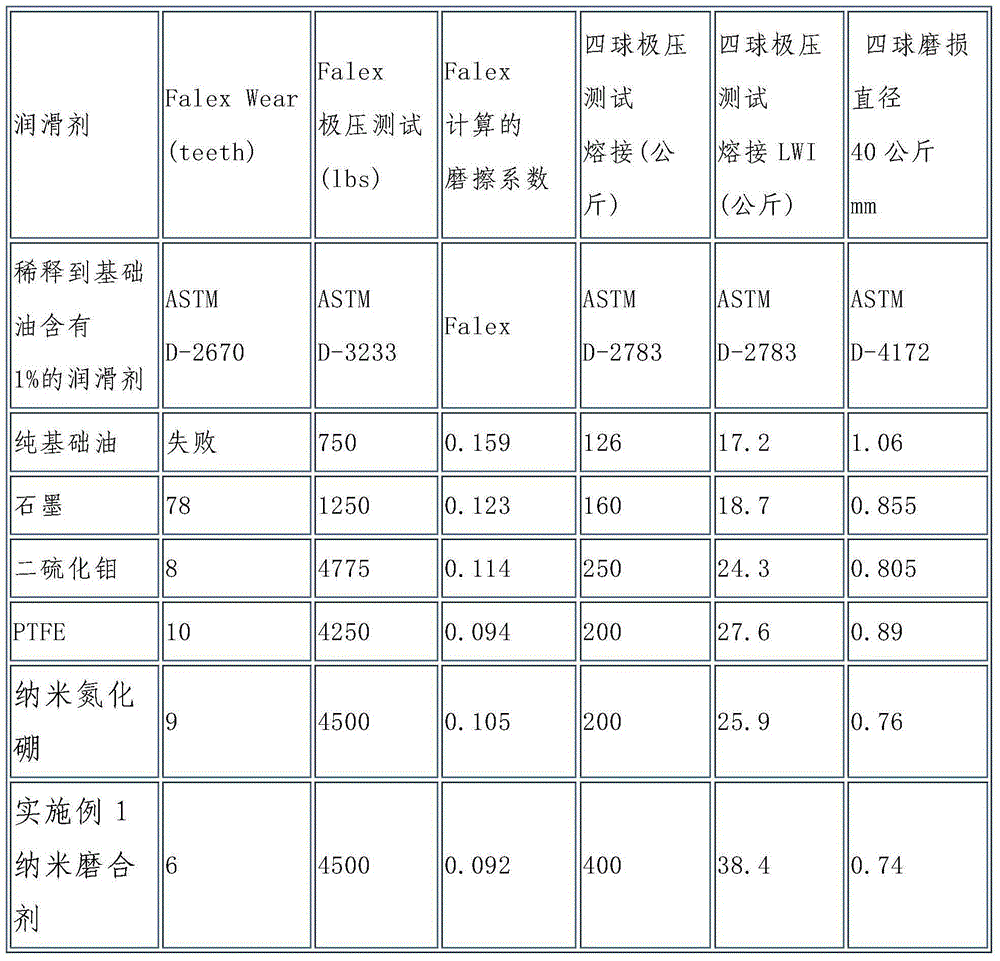

[0013] Embodiment 1 nanometer running-in agent performance comparison (comparison table with other solid lubricants)

[0014]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com