Patents

Literature

40results about How to "Avoid impact wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

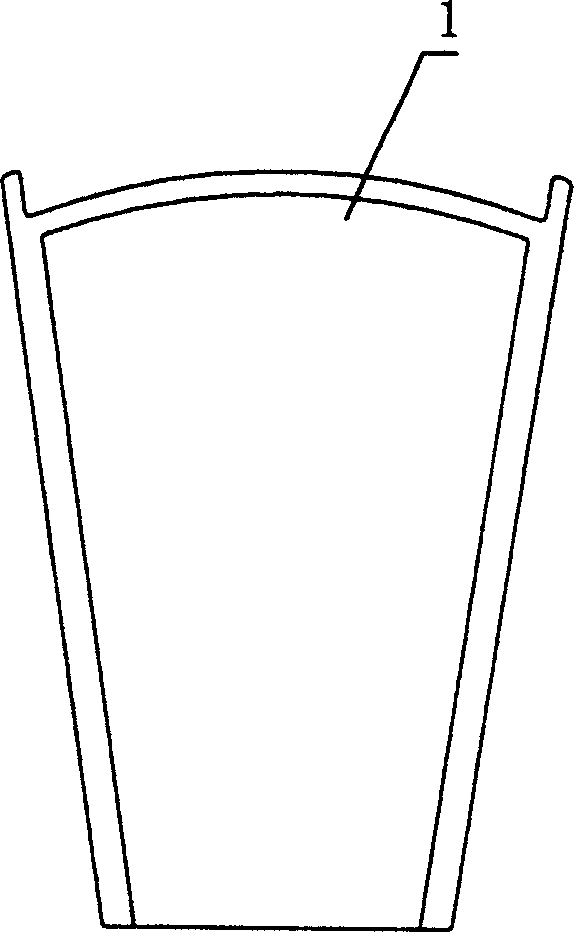

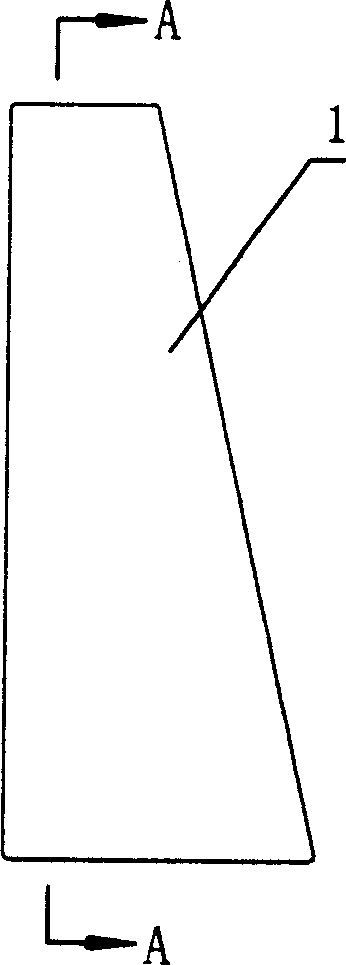

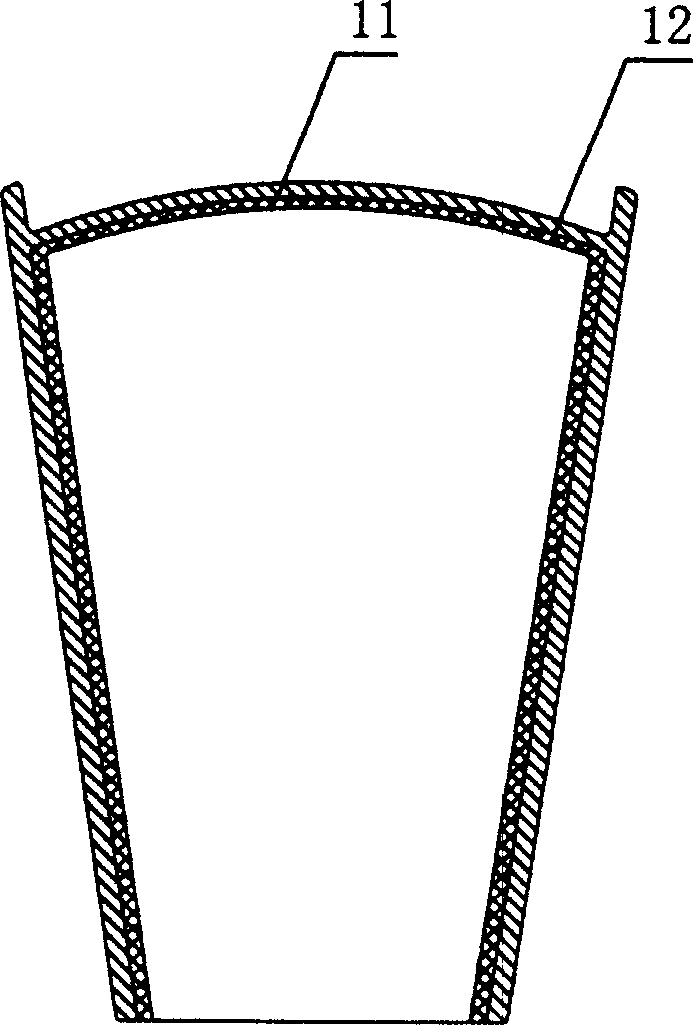

Spherical hammer head of combined crusher and manufacturing method thereof

InactiveCN101940968AWear resistanceReduce tangential forceFoundry mouldsFoundry coresMetallic materialsStructural engineering

The invention discloses a spherical hammer head of a combined crusher and a manufacturing method thereof. The hammer head comprises a spherical hammer end (1) and a hammer handle (2); the spherical hammer end (1) and the hammer handle (2) are combined into the integral hammer head through a connecting rod (3); the spherical hammer end is cast by adopting an alloy high-chromium cast iron losing die; and the hammer handle is made of No. 45 round steel by a metal processing and cutting method. The spherical hammer head of the crusher has the advantages of abrasion resistance, good toughness, quick replacement of the spherical hammer end and long-term use of the hammer handle, improves the production efficiency, saves the metal material, and is particularly suitable for manufacturing hammer heads of reversible small and medium hammer crushers.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

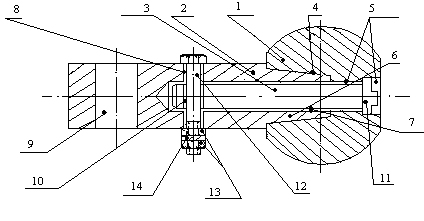

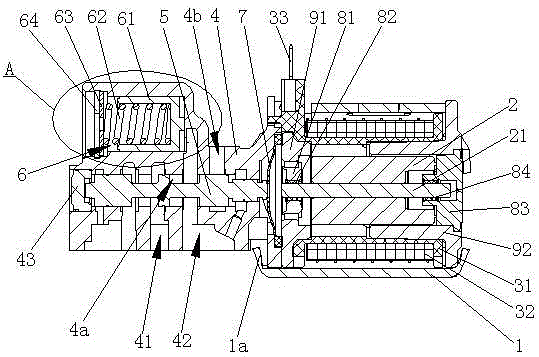

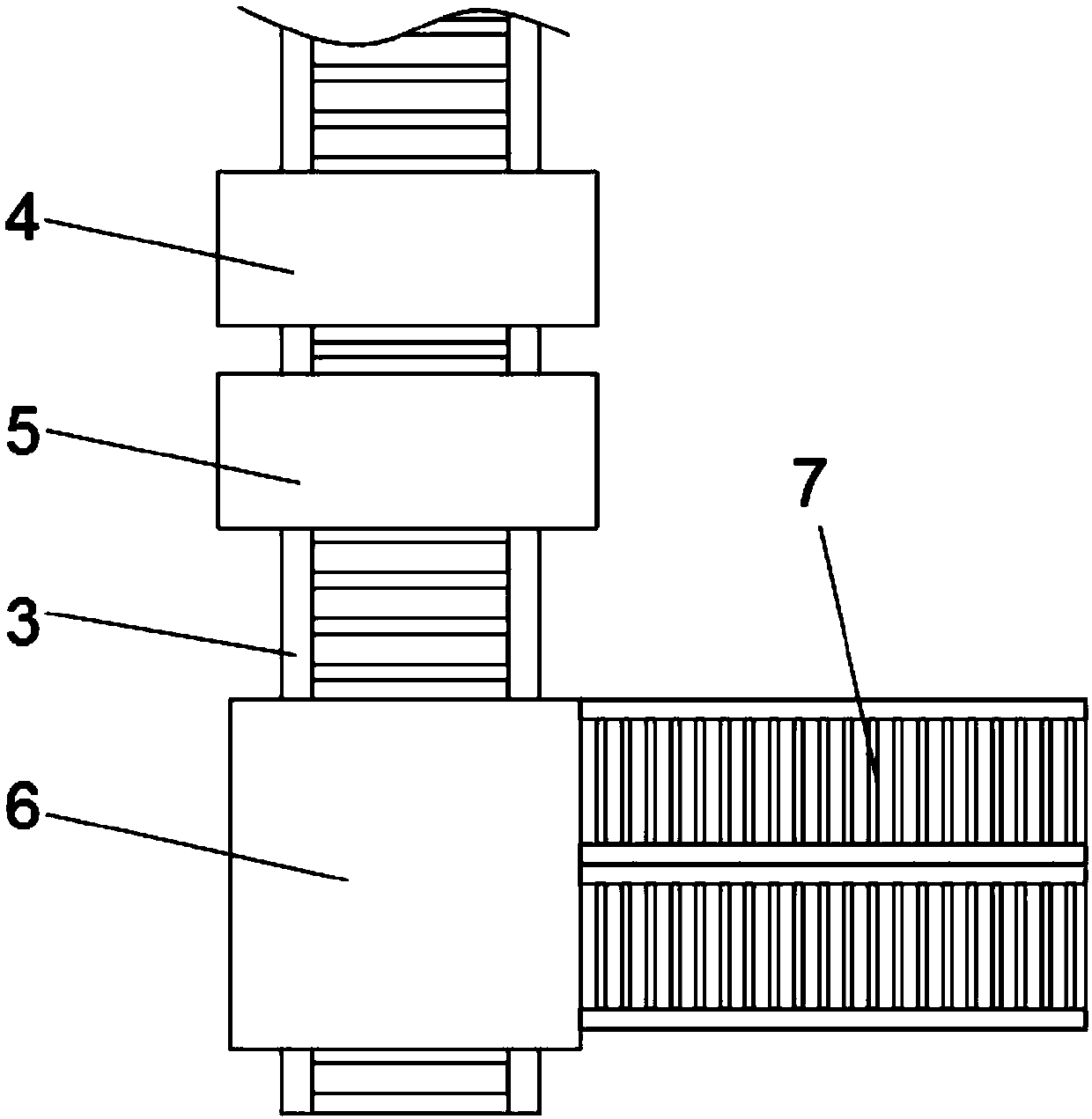

Electromagnetic valve of automatic gearbox

ActiveCN105202177ARealize opening and closing controlSimple designOperating means/releasing devices for valvesGearing controlEngineeringElectromagnetic valve

The invention discloses an electromagnetic valve of an automatic gearbox. The electromagnetic valve comprises an outer housing, a movable iron core and an electromagnetic coil component assembled inside the outer housing, wherein the movable iron core is assembled at the center of the electromagnetic coil component; an ejector rod is arranged at the center of the movable iron core; a valve body is assembled at the front part of the outer housing; a pressure inlet and a pressure outlet are formed in the valve body; a pressure cavity is formed in the valve body; a valve element is arranged inside the pressure cavity; the front end of the ejector rod is matched with the valve element; a pressure storage chamber is further arranged inside the valve body, and is communicated with the pressure cavity; a piston, a spring, a gasket and a clamp spring are arranged inside the pressure storage chamber; one end of the spring is propped against the gasket, and the other end of the spring is propped against the piston; the clamp spring is placed on the outer side of the gasket, and is in clamping fit with the valve body. The electromagnetic valve has the advantages that the structure is simple, and the stability is good; besides, the electromagnetic valve is integrated with the pressure storage structure, so that the defect of the lag of oil pressure adjustment is eliminated, and the adjustment is more sensitive.

Owner:XINGYU ELECTRON NINGBO CO LTD

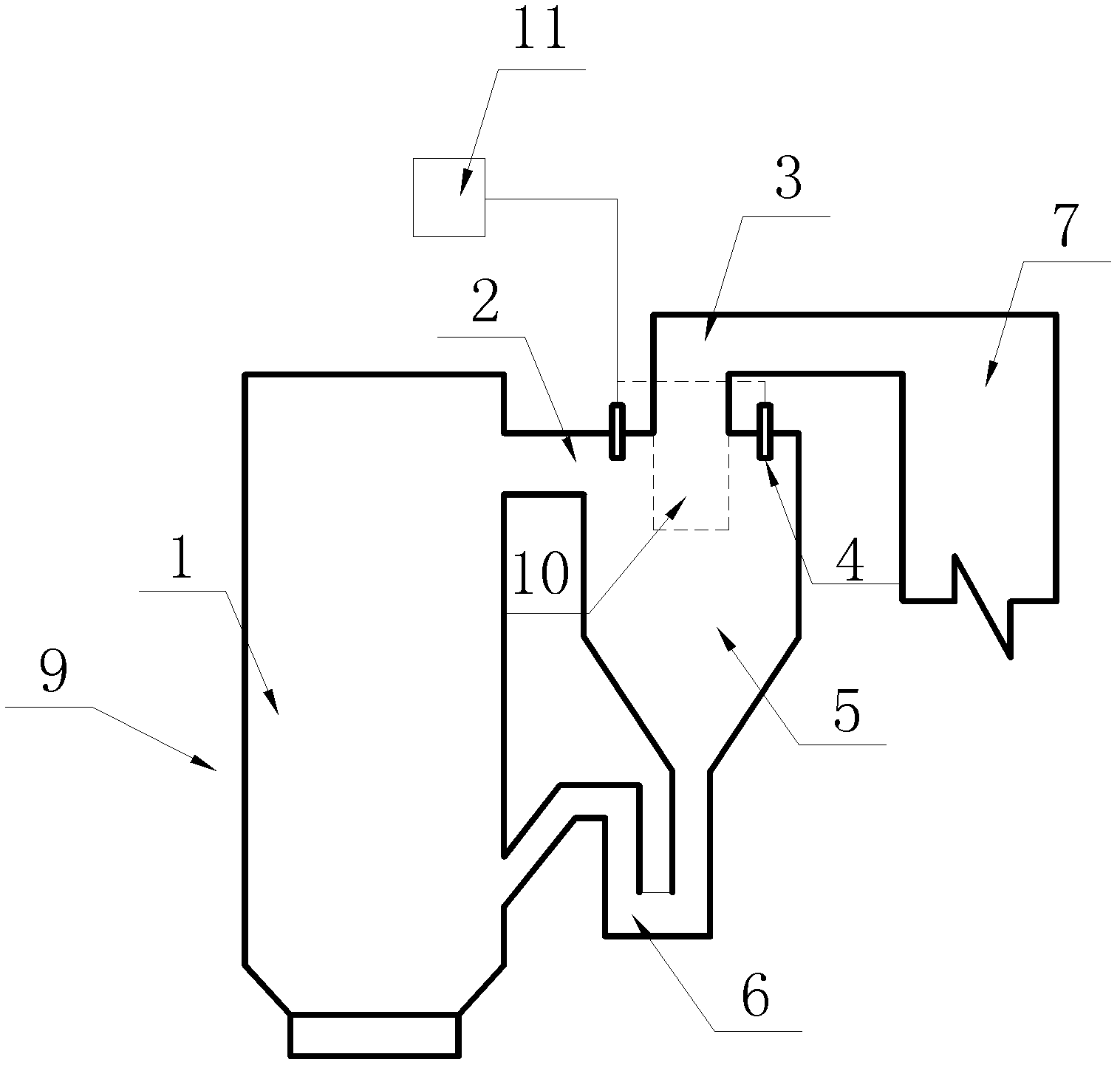

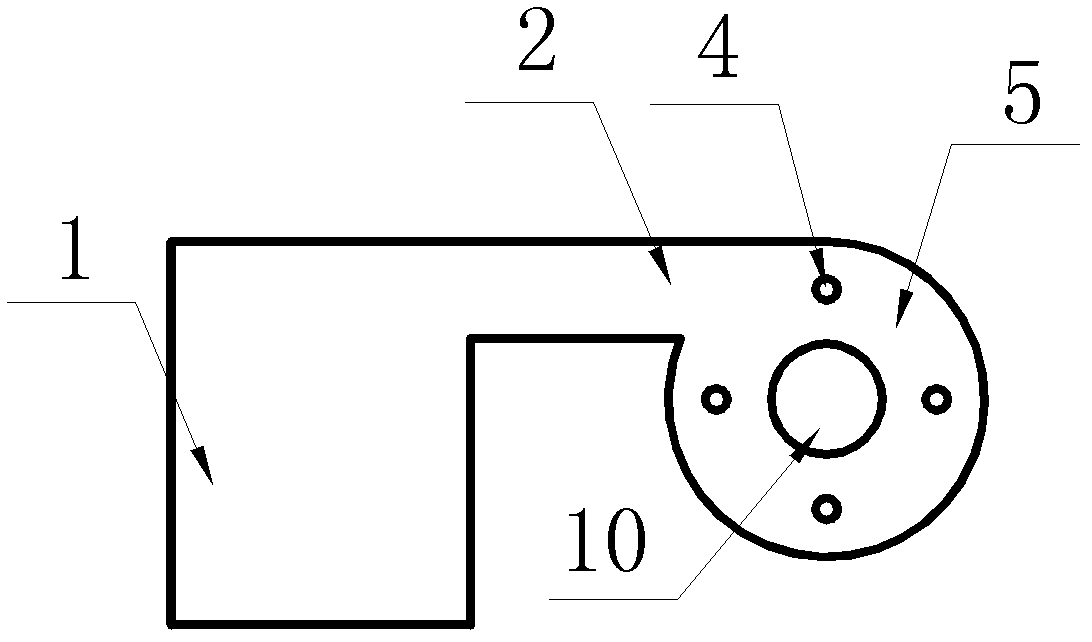

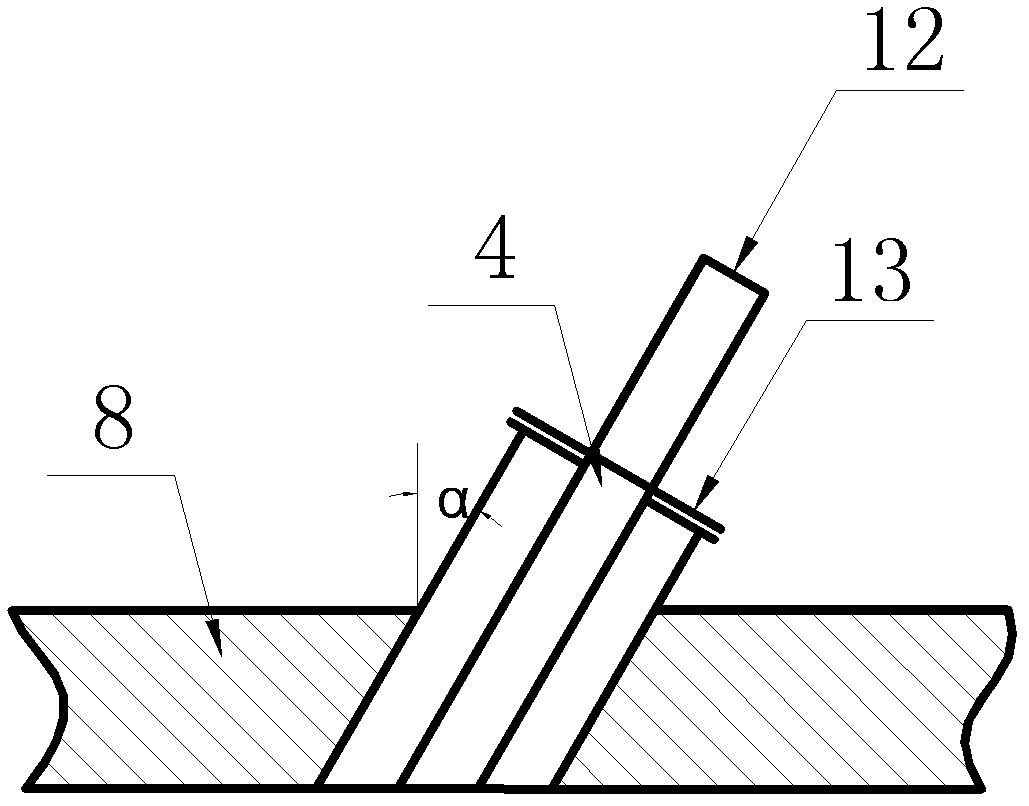

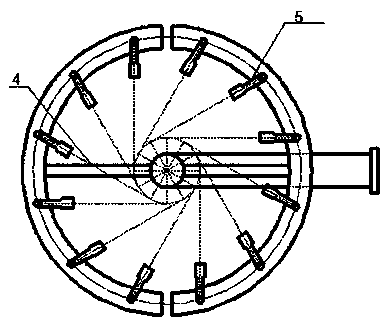

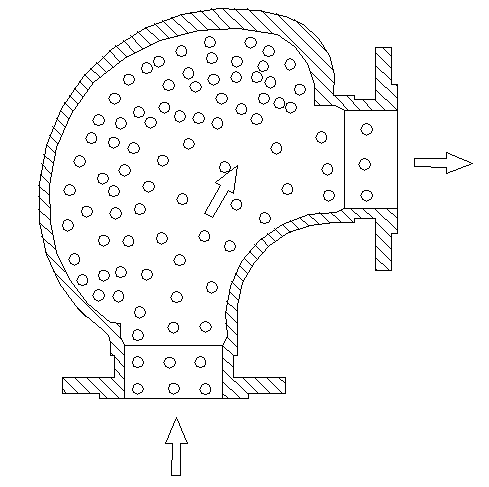

Selective non-catalytic reduction denitration system of circulating fluidized bed boiler

The invention discloses a selective non-catalytic reduction denitration system of a circulating fluidized bed boiler, belonging to the technology of flue gas denitration. The system comprises a hearth, a reducing agent and atomization air proportion conveying system, a cyclone separator, a material return system and a tail flue, and is characterized in that: multiple atomization nozzles are uniformly arranged on the upper top plate of the separator on the periphery of a core cylinder of the cyclone separator; the openings of the atomization nozzles face downwards; and an angle of 0-60 degrees is formed between the reducing agent spraying direction and the vertical direction. According to the invention, by adopting reasonable spraying position and angle and nozzle number for the selective non-catalytic reducing agent, the mixing degree of the reducing agent and NOx in flue gas is increased, the denitration reaction is promoted, the efficiency and feasibility of the selective non-catalytic reduction denitration are improved, the leakage of the reducing agent is reduced, and the industrial application of the selective non-catalytic reduction denitration method is facilitated.

Owner:TSINGHUA UNIV +1

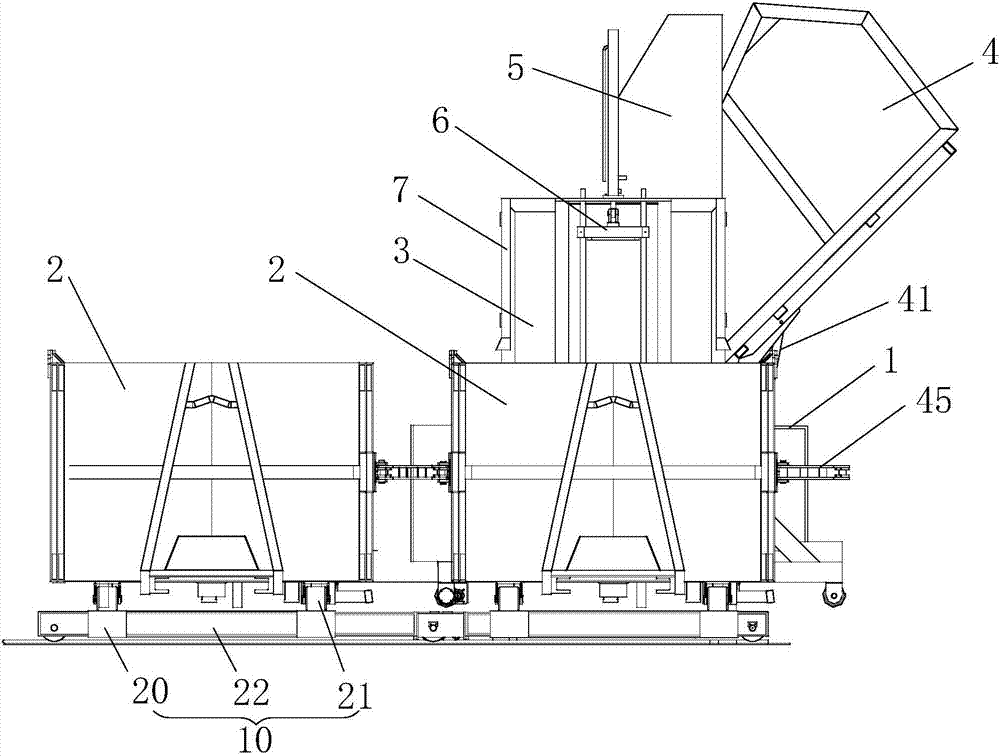

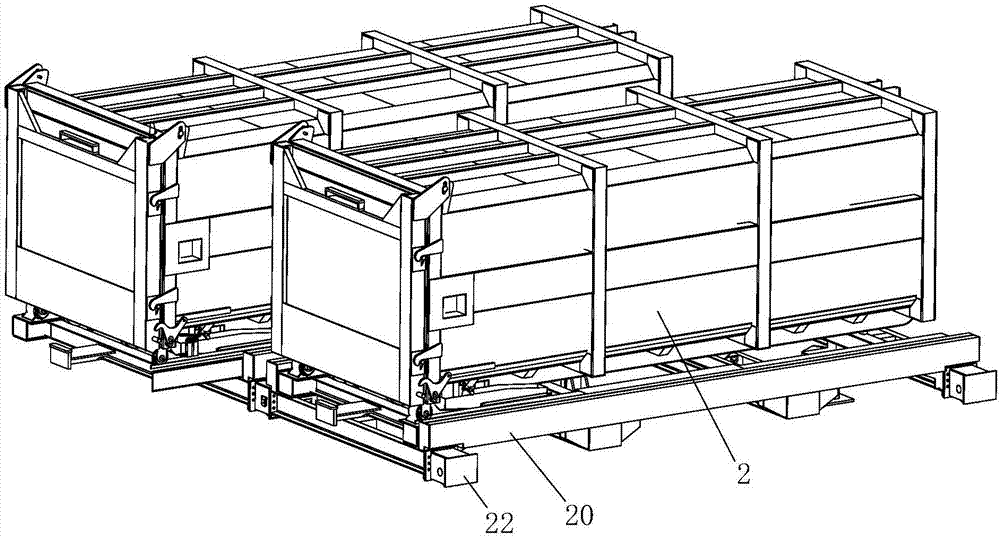

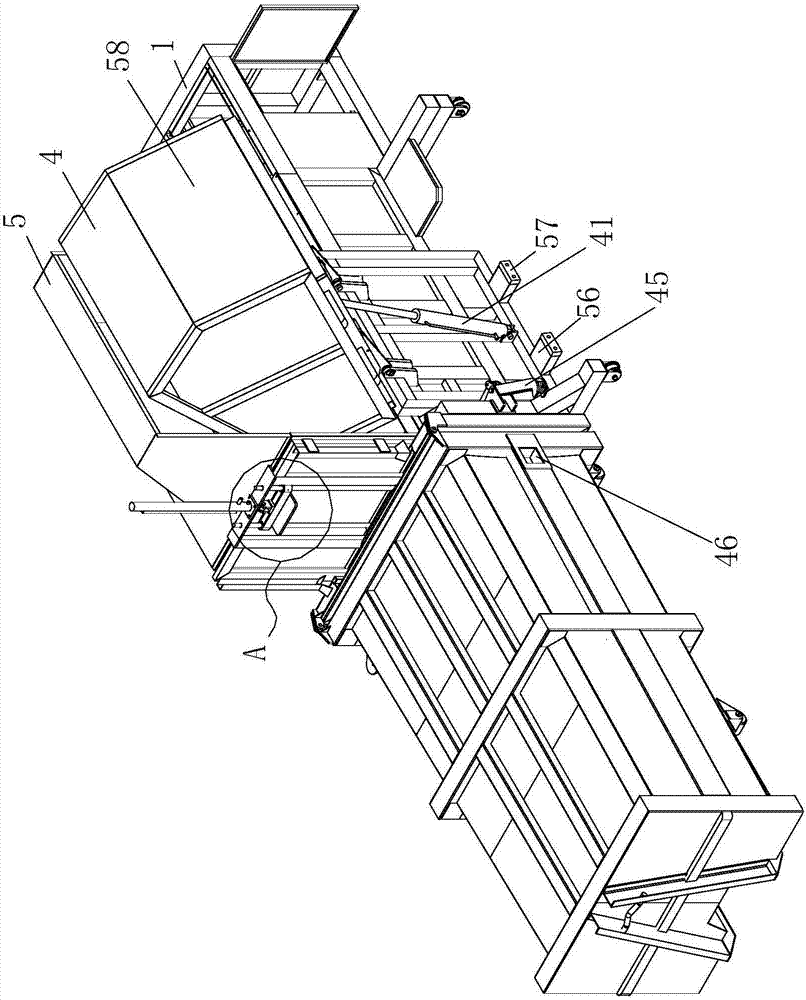

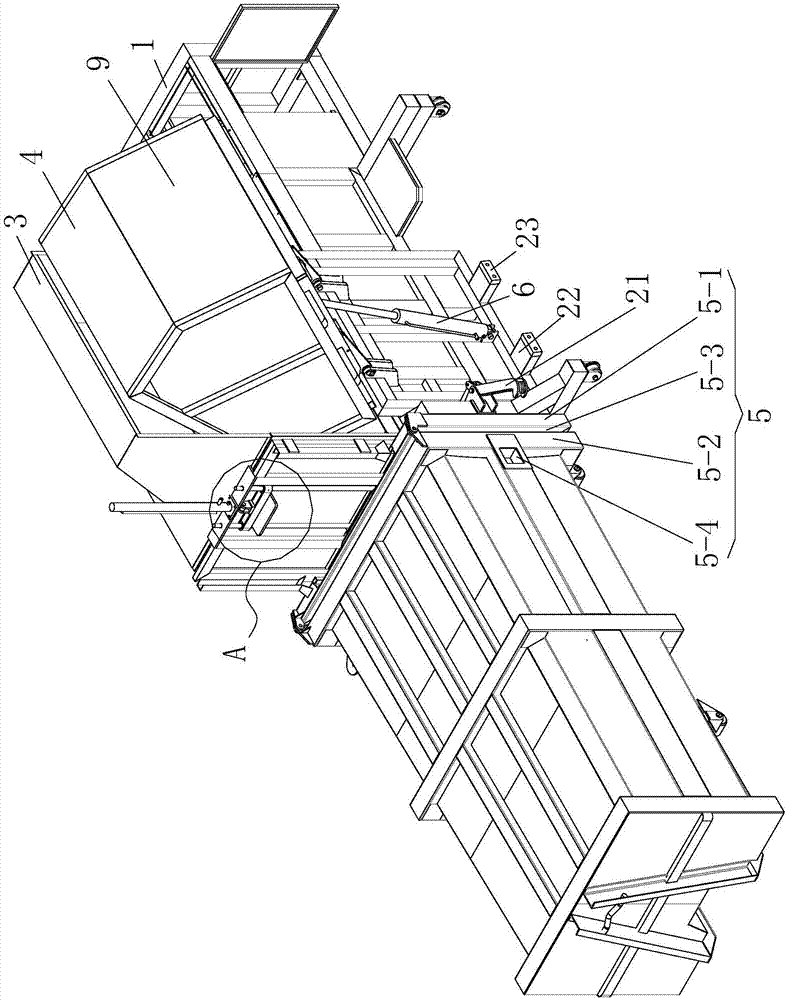

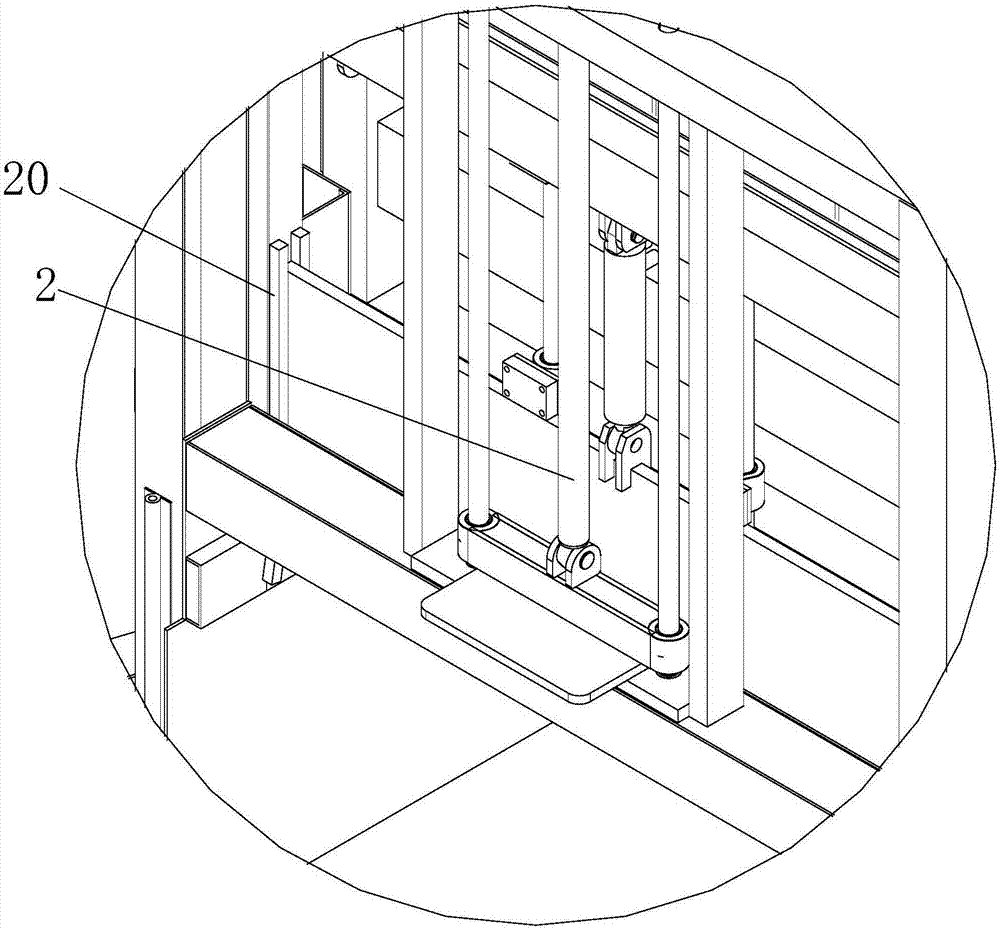

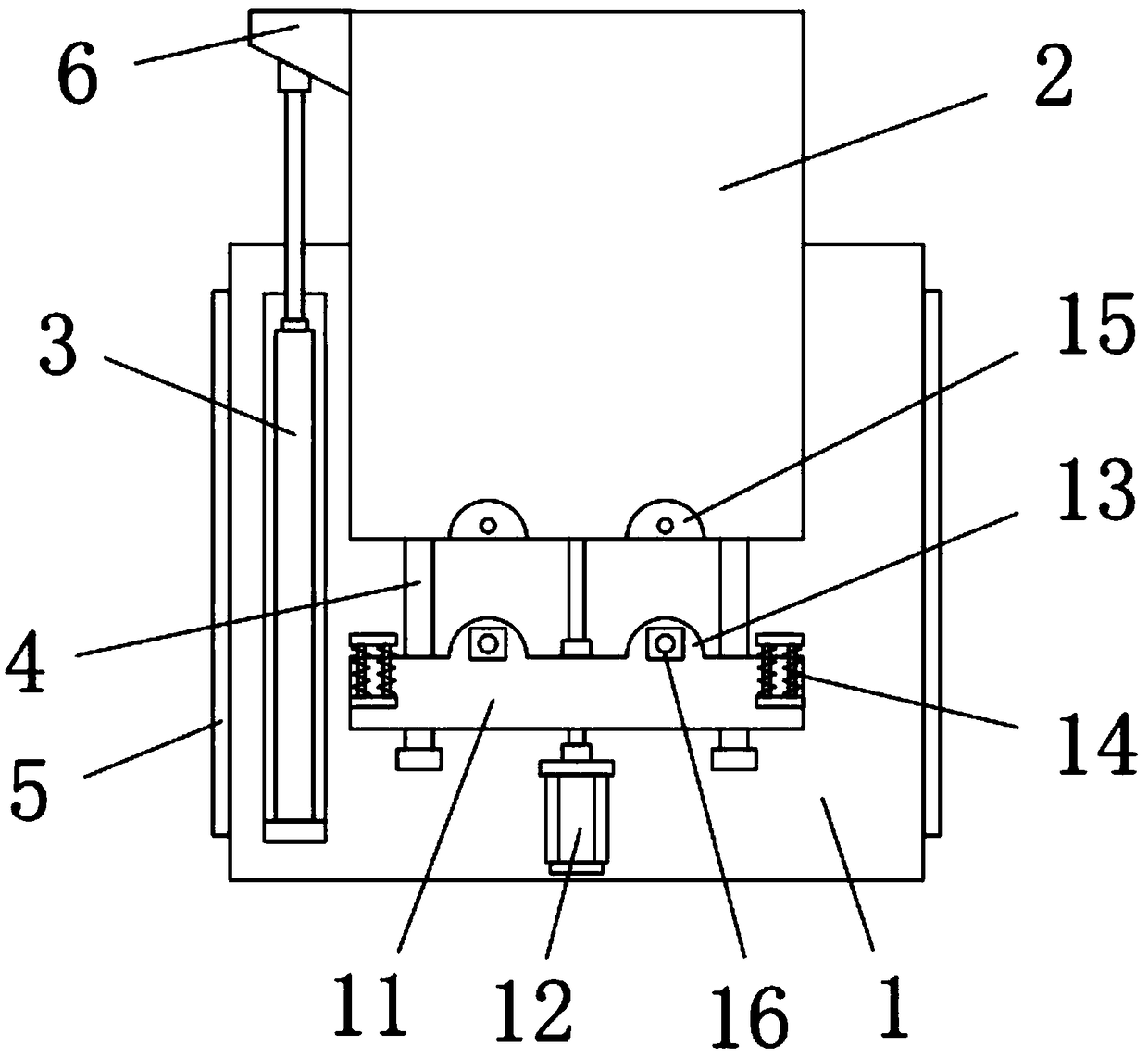

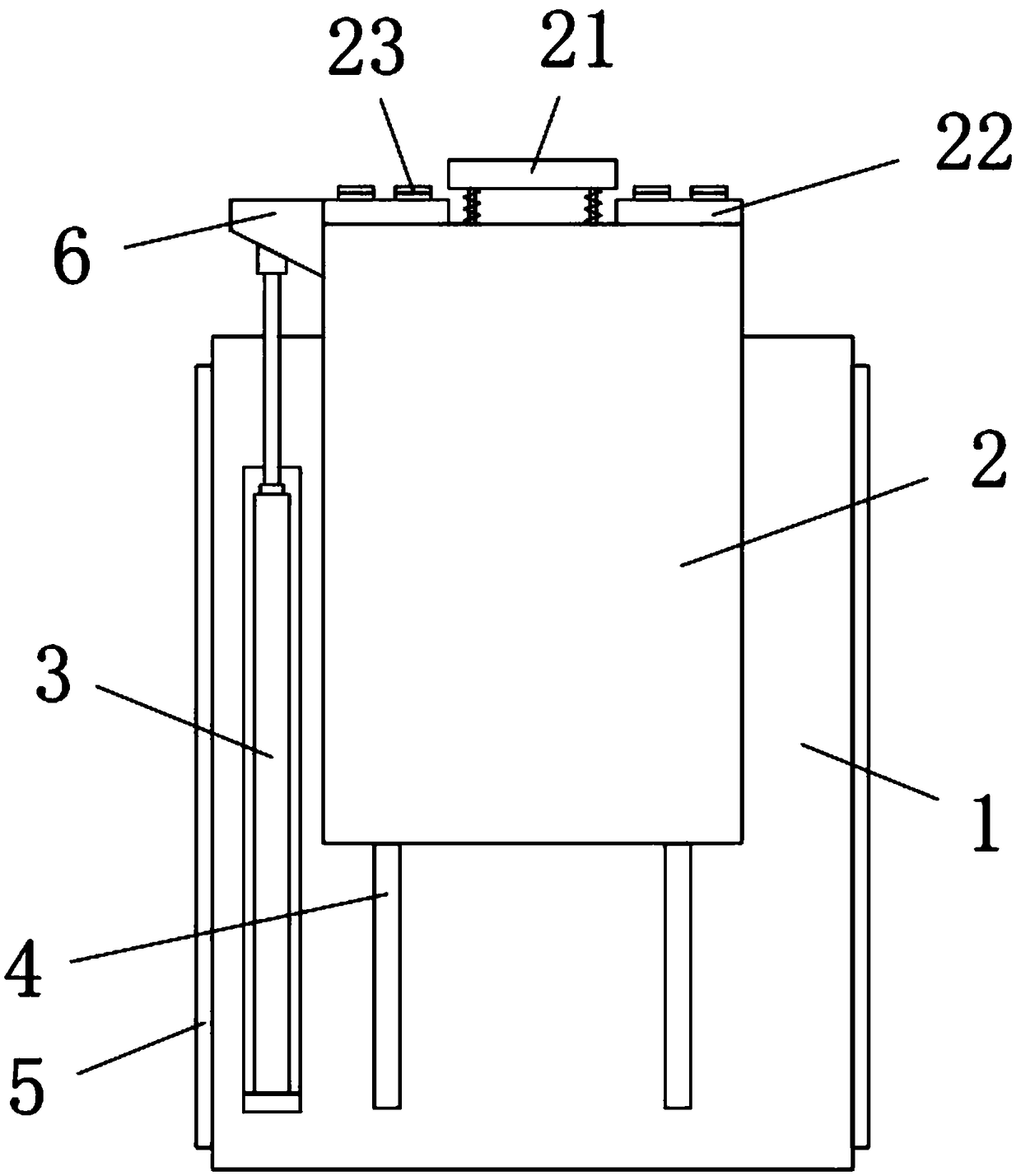

Horizontal automatic garbage compressor

The invention relates to a horizontal automatic garbage compressor, which has a detachably connected frame and a collection box; a temporary storage room is provided inside the frame, and a tipping bucket is hinged at one end of the frame near the collection box; The hopper cover; the temporary storage room is equipped with a pushing mechanism for pushing garbage, and the output port of the temporary storage room is equipped with a box door pulling mechanism; the box door pulling mechanism includes a lifting mechanism and the sides of the box door arranged on the left and right sides of the lifting mechanism Guide groove; the collection box includes a box body and a box door; the box door is connected to the opening end of the box body; a guide mechanism is provided under the collection box, and the inlet end of the collection box has a small door that is tightly held, and the inner edge of the box door of the collection box Inlaid with a sealing ring; the inner side of the lifting mechanism is equipped with a single cylinder door lifting device; the lower part of the frame is equipped with a "U"-shaped ramp. The invention has the characteristics of simple structure, convenient operation, etc., and can prevent secondary pollution caused by domestic sewage generated after compression.

Owner:唐亚琴

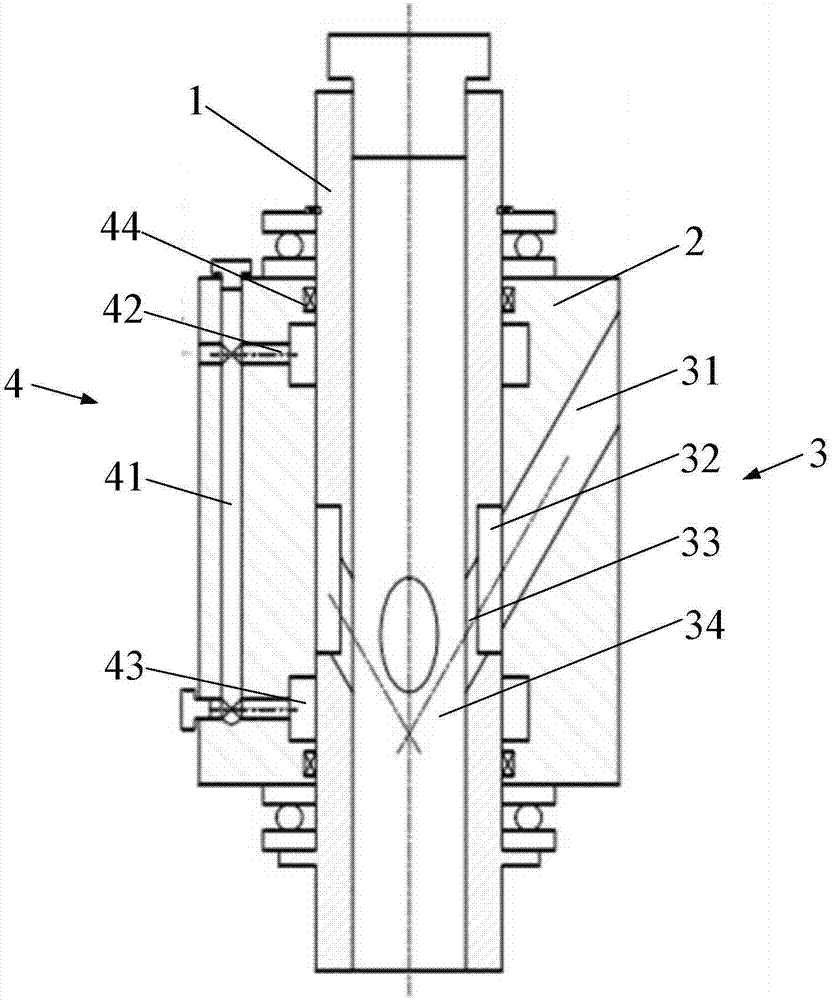

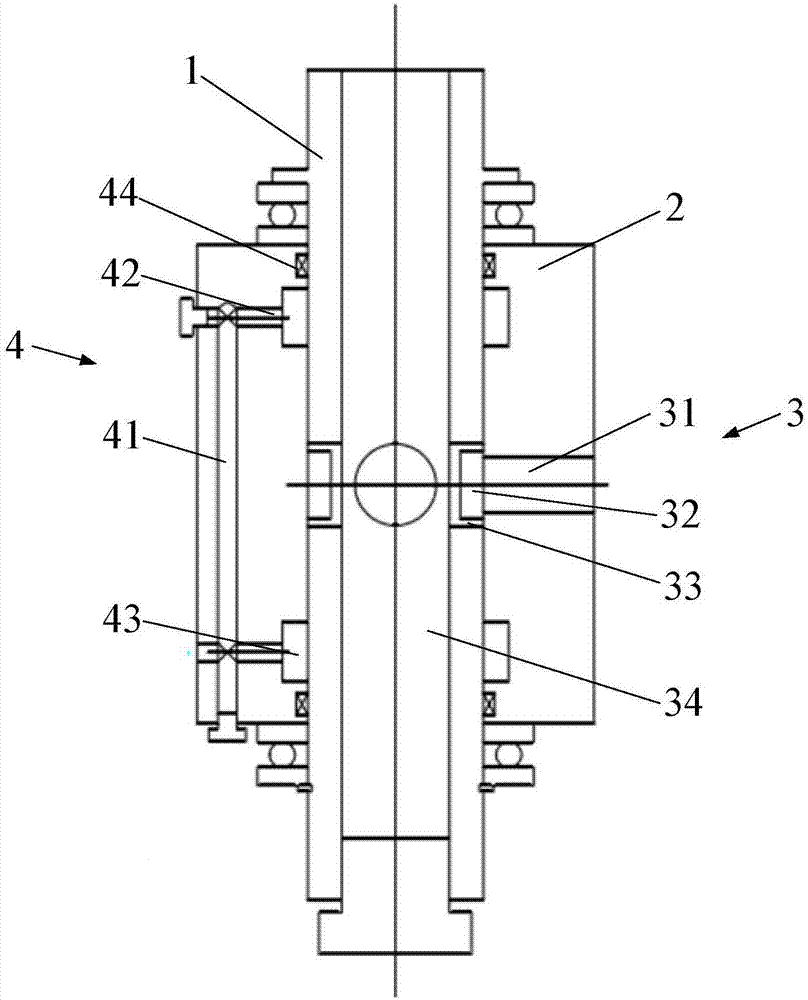

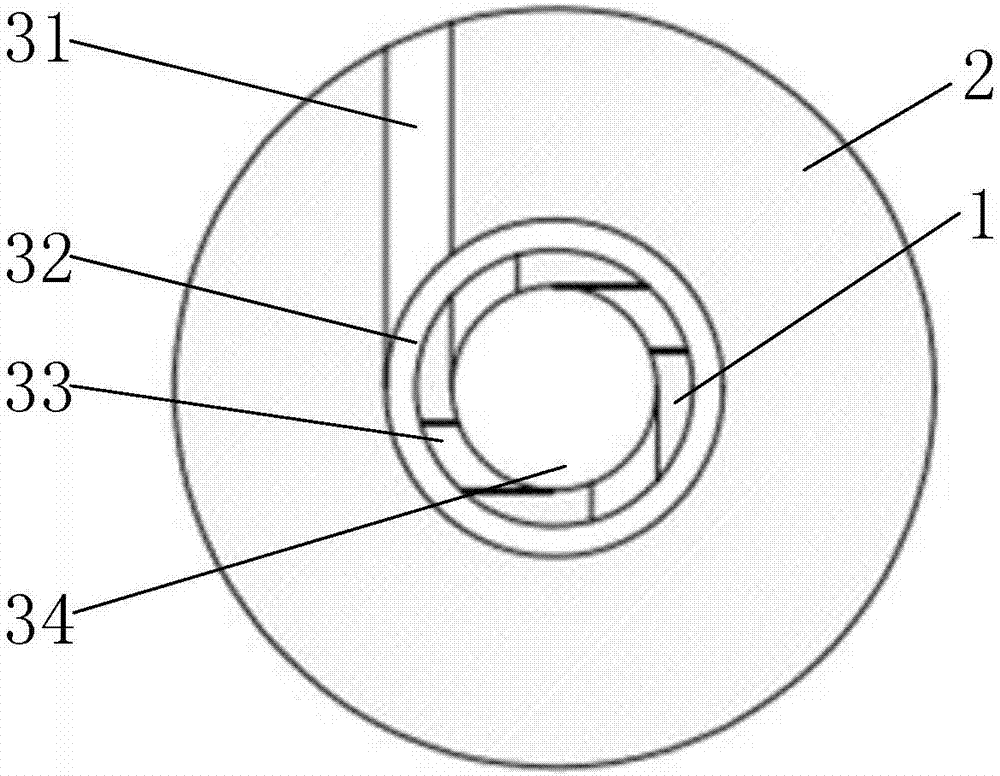

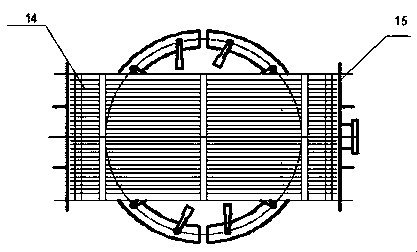

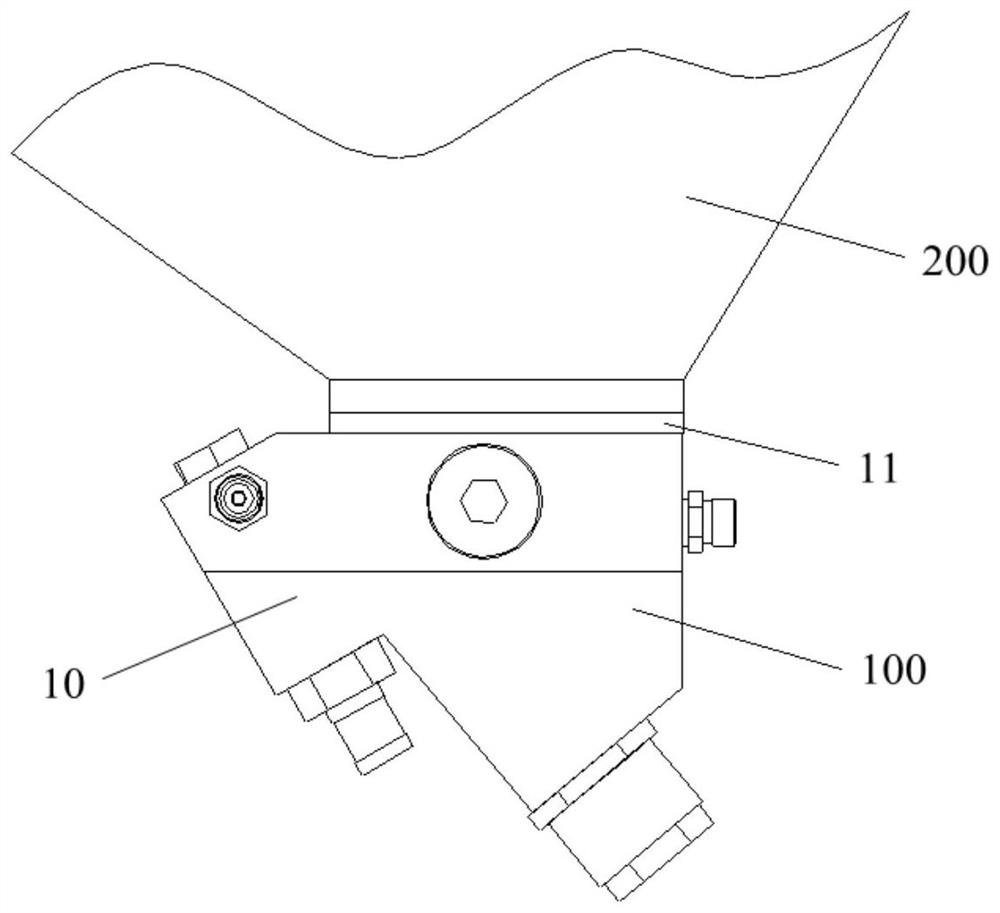

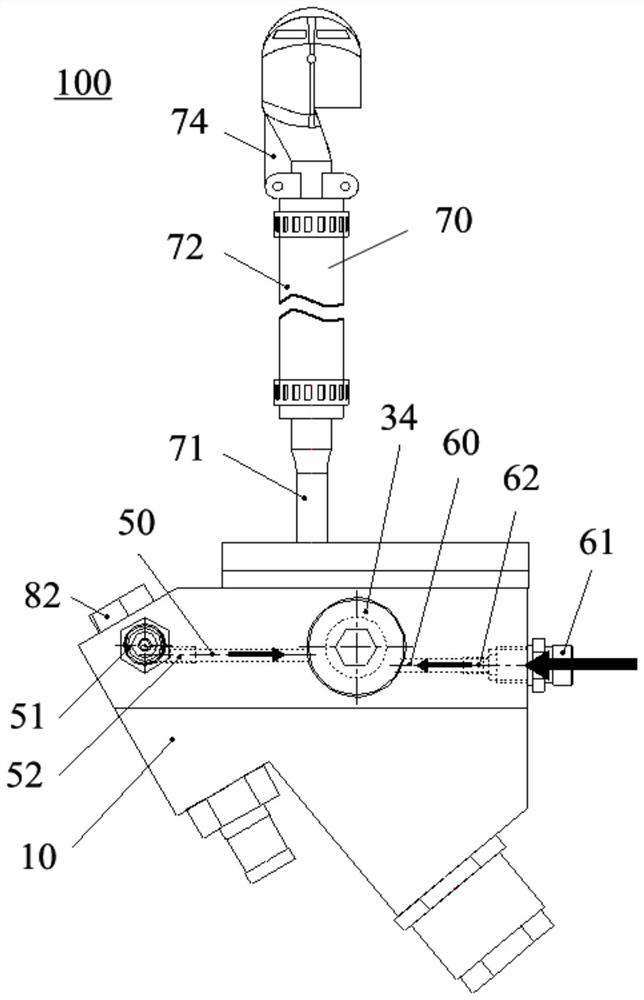

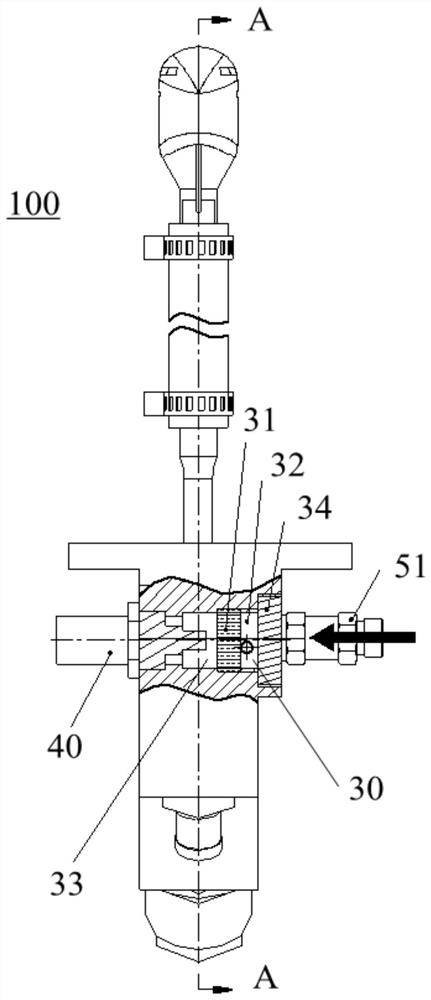

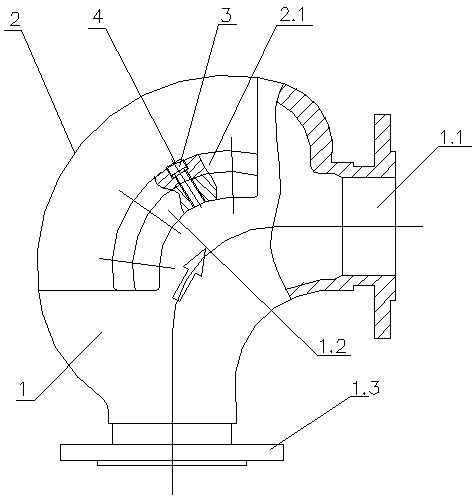

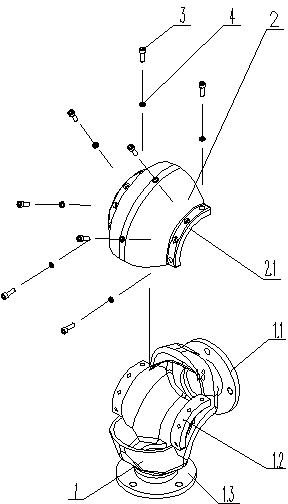

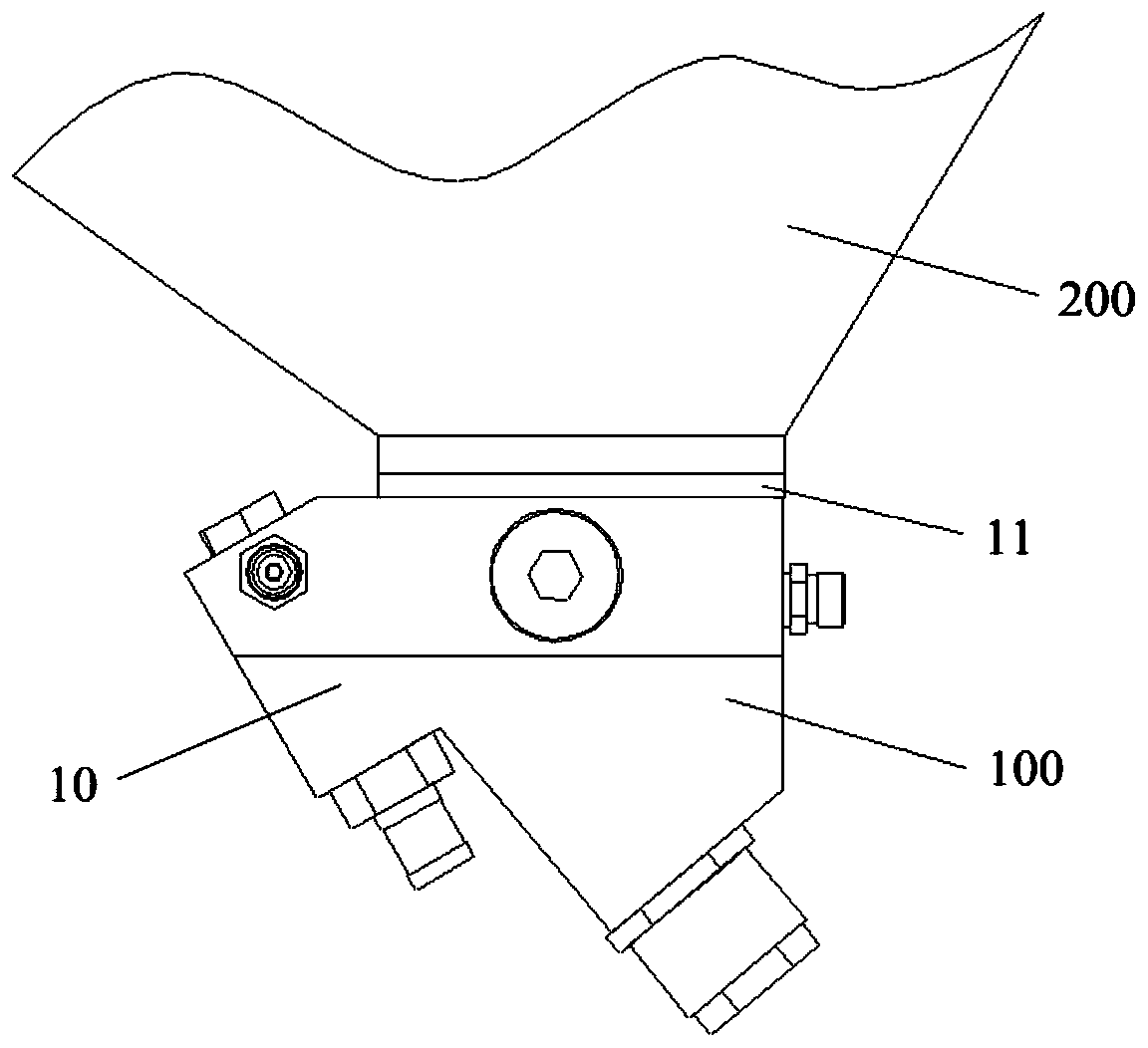

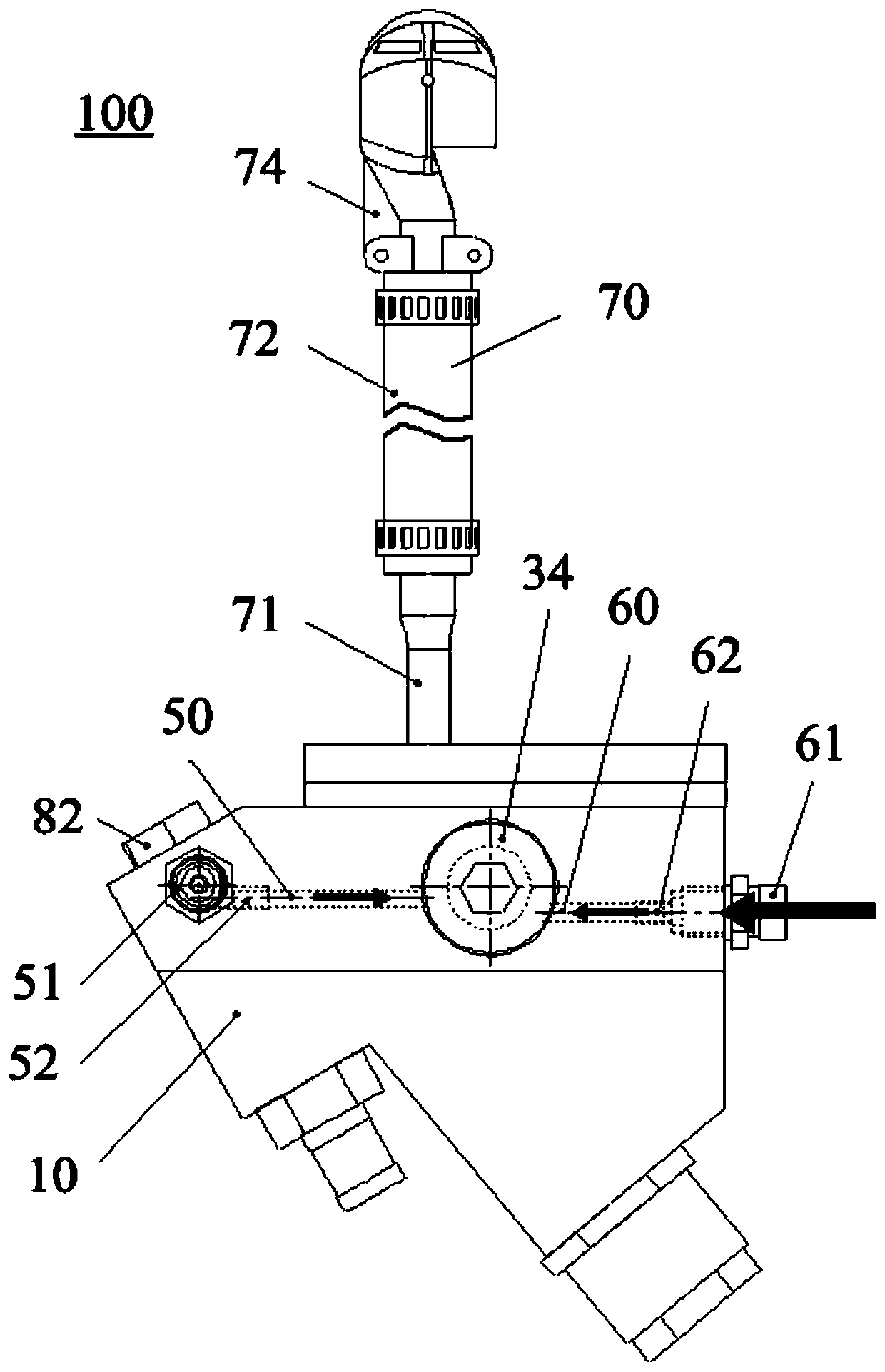

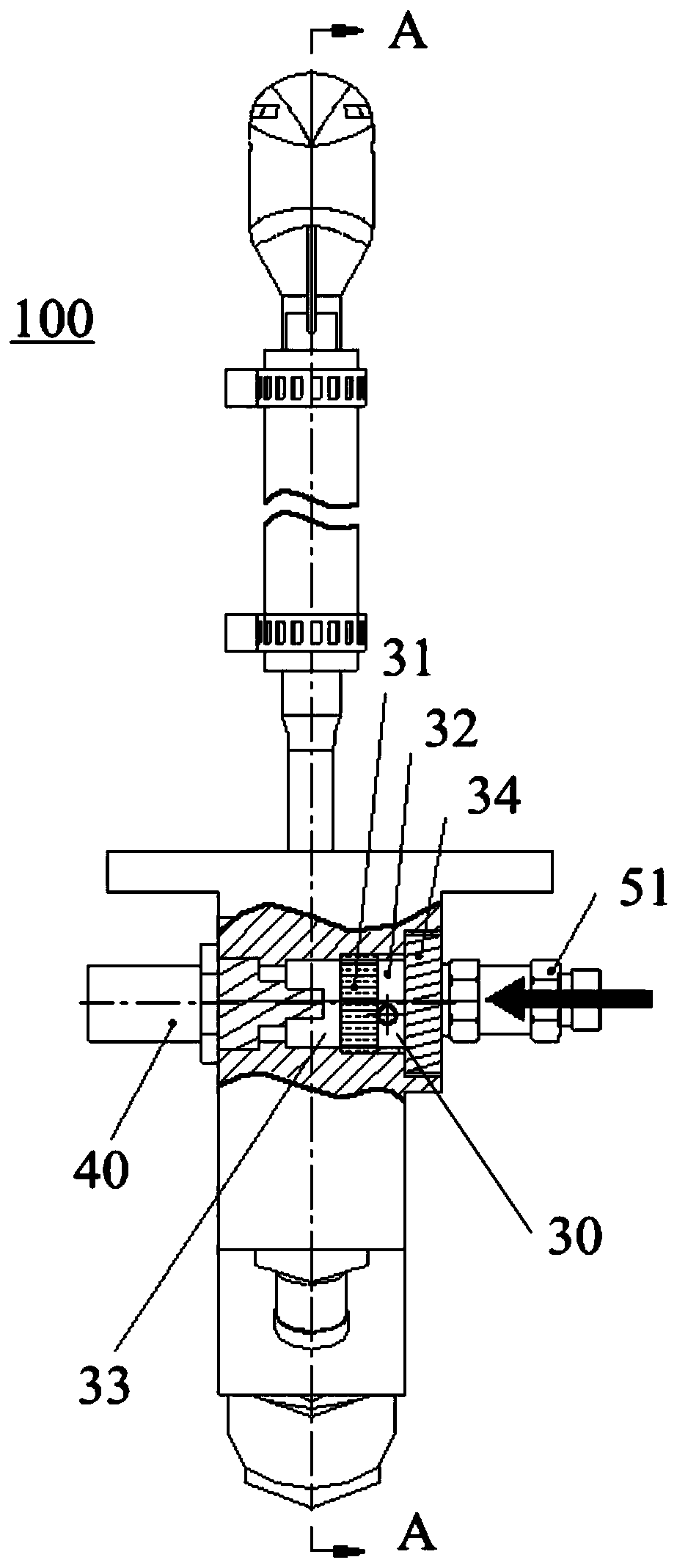

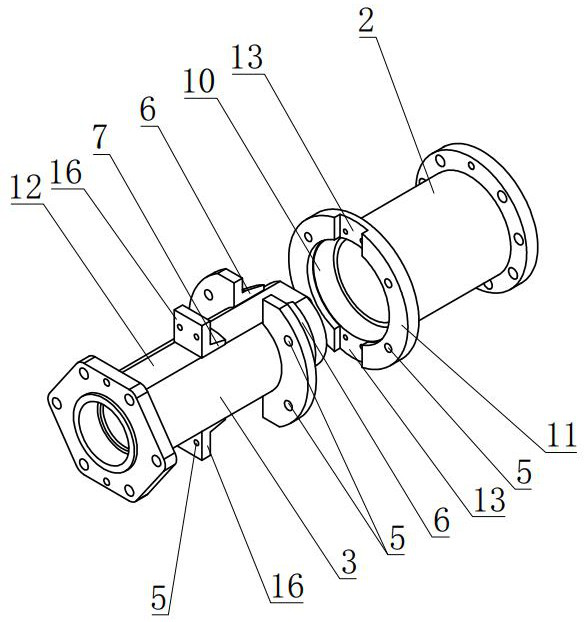

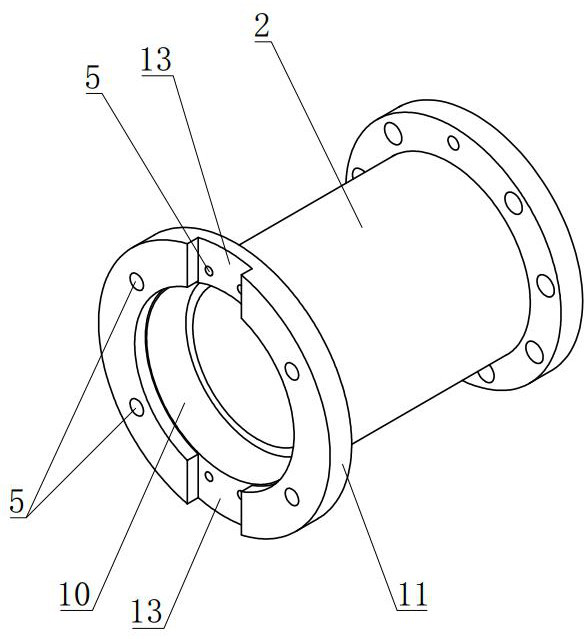

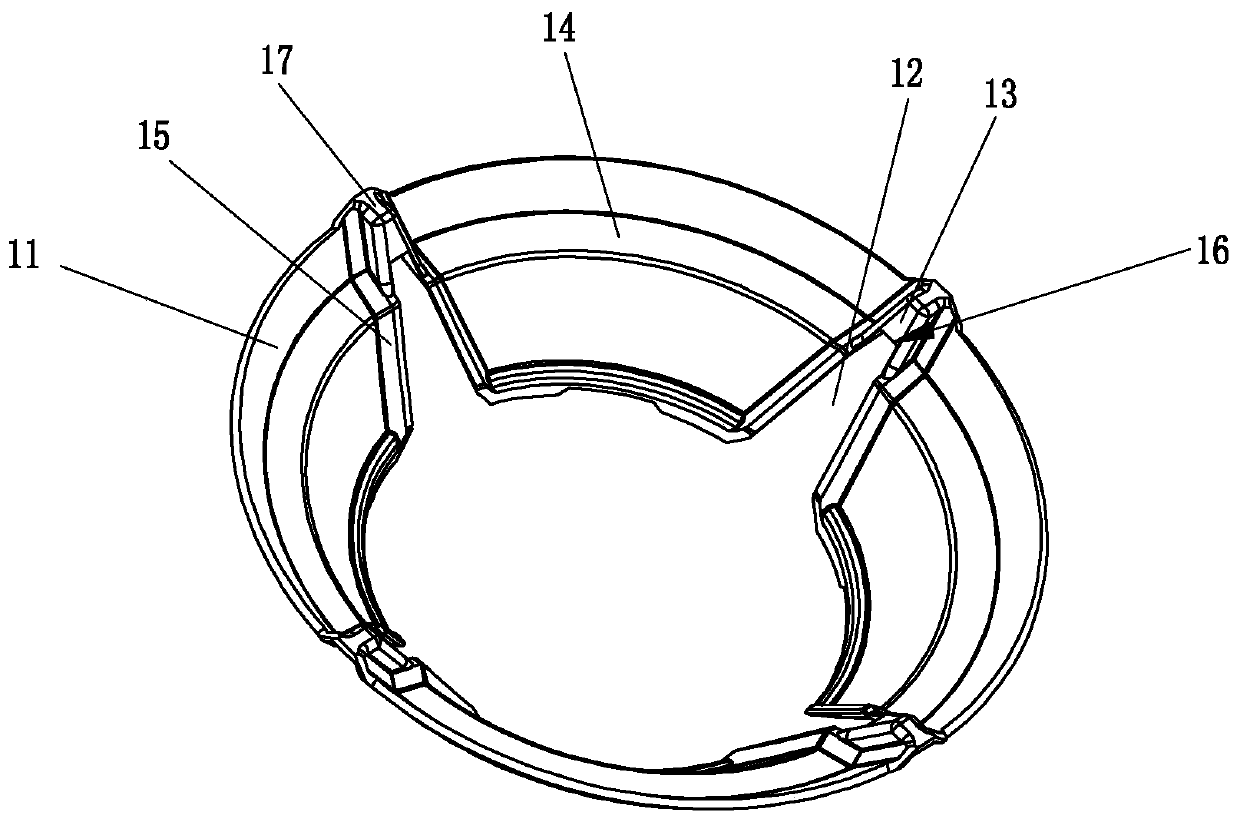

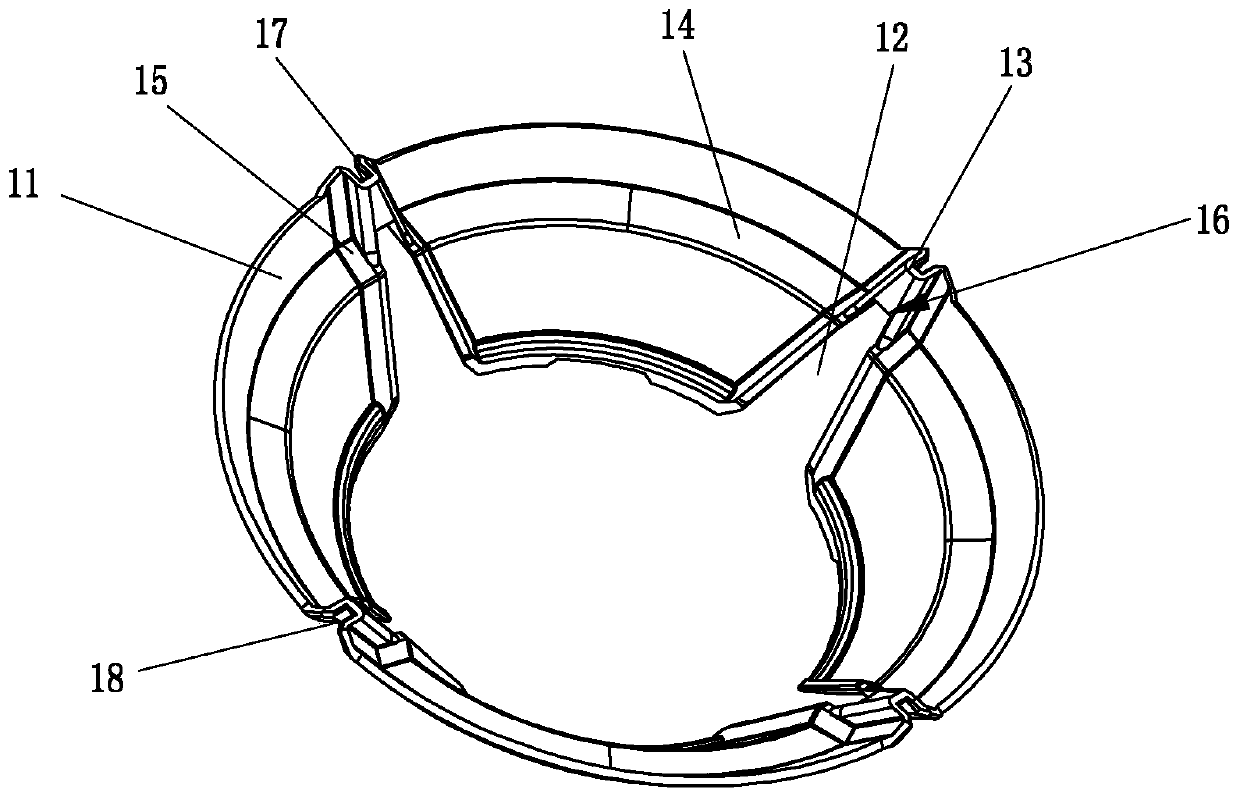

Rotating connector used for conveying two-phase flow containing solid abrasives

ActiveCN107283325AEnsure flow stabilityEnsure safetyGrinding/polishing apparatusMechanical engineeringRotational joint

The invention provides a rotating connector used for conveying a two-phase flow containing solid abrasives. The rotating connector used for conveying the two-phase flow containing the solid abrasives comprises an inner shaft, an outer sleeve arranged on the inner shaft in a sleeving manner, and a material conveying assembly arranged on the inner shaft and the outer sleeve in a penetrating manner; the outer sleeve is provided with a high pressure sealing assembly used for conveying high pressure fluid to a gap between the inner shaft and the outer sleeve; and the injecting pressure of the high pressure fluid is larger than the conveying pressure of the two-phase flow of the high pressure abrasives. The rotating connector used for conveying the two-phase flow containing the solid abrasives is especially used for the work condition of the two-phase flow containing abrasive particles, and has the beneficial effects that abrasion is small and flowing stability is good.

Owner:CHINA RAILWAY CONSTR HEAVY IND

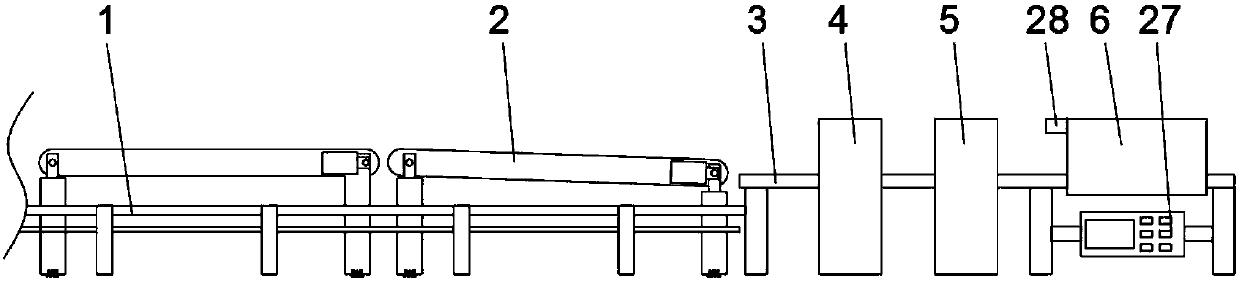

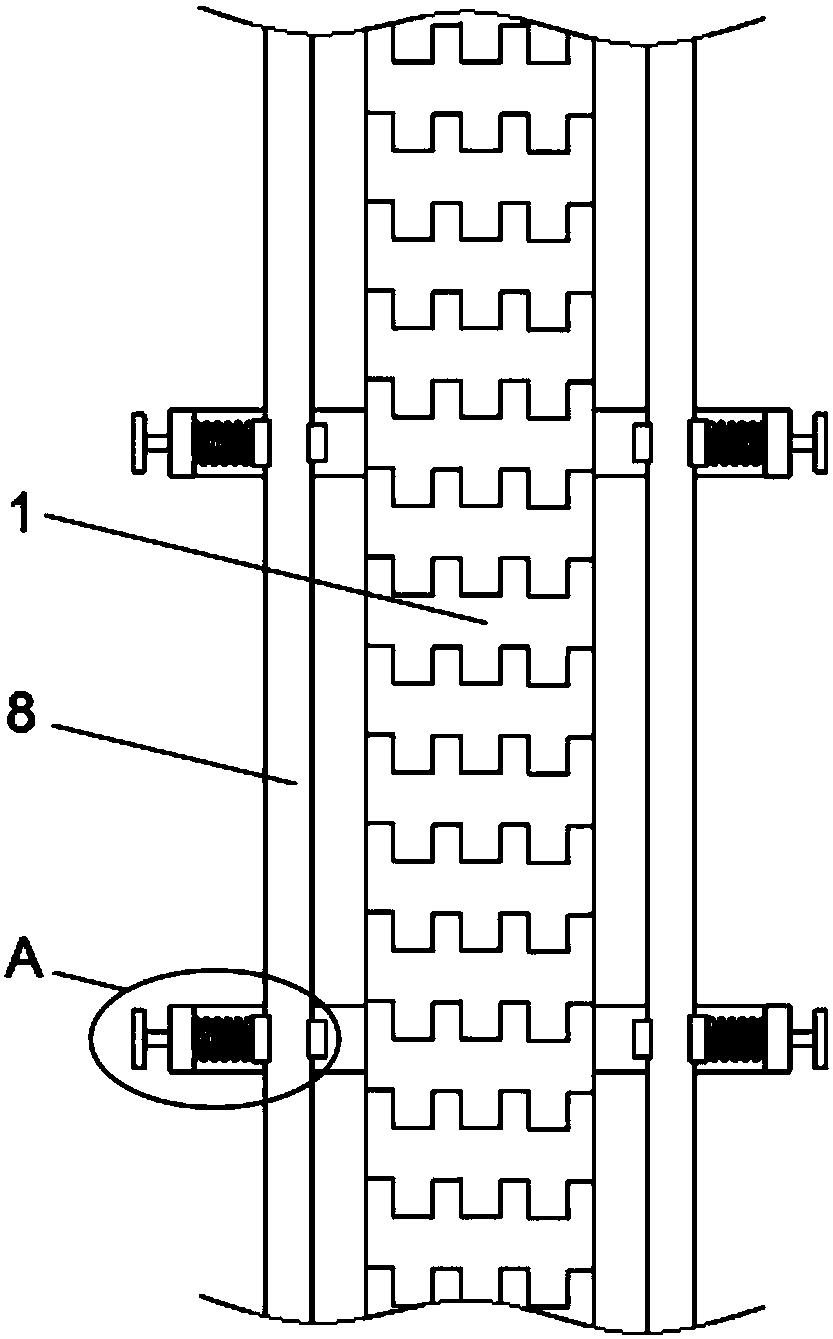

Combined conveyor belt with automatic identification system

ActiveCN109867106AEasy to disassembleEasy to install and disassembleConveyor partsMechanical conveyorsCartonConveyor belt

Owner:GUANGDONG JIALONG FOOD

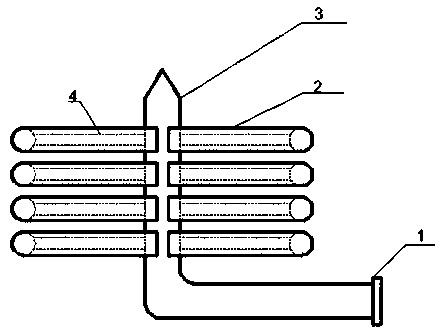

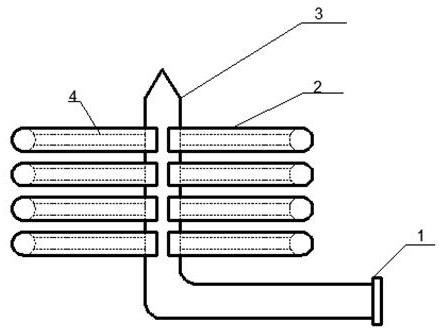

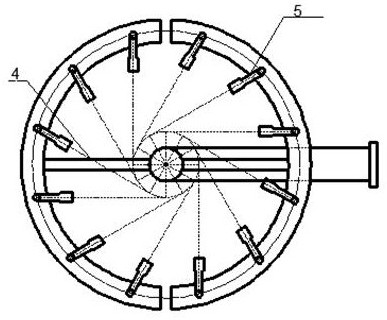

Air inlet device for variable-diameter carbonization tower

ActiveCN109775728AImprove air intake efficiencyImprove uniformityProductsReagentsSpray nozzleCarbonization

The invention discloses an air inlet device for a variable-diameter carbonization tower. The air inlet device comprises a main air inlet pipe which extends into the carbonization tower, multiple branch air pipes evenly distributed in the axial direction of the main air inlet pipe in a layer shape and an air blowing device arranged at the bottom of the carbonization tower. Multiple spray nozzles are evenly distributed on the branch air pipes, and gas discharged into the carbonization tower from the spray nozzles spirally ascends under the effect of the air blowing device. According to the air inlet device for the carbonization tower, the distribution uniformity of gas discharged into the carbonization tower is improved, the gas discharged out from the spray nozzles does not directly impacta heat exchange water tank above the air inlet device, impact and wear of a tube bundle in the heat exchange water tank are reduced, and the service life of the device is prolonged.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

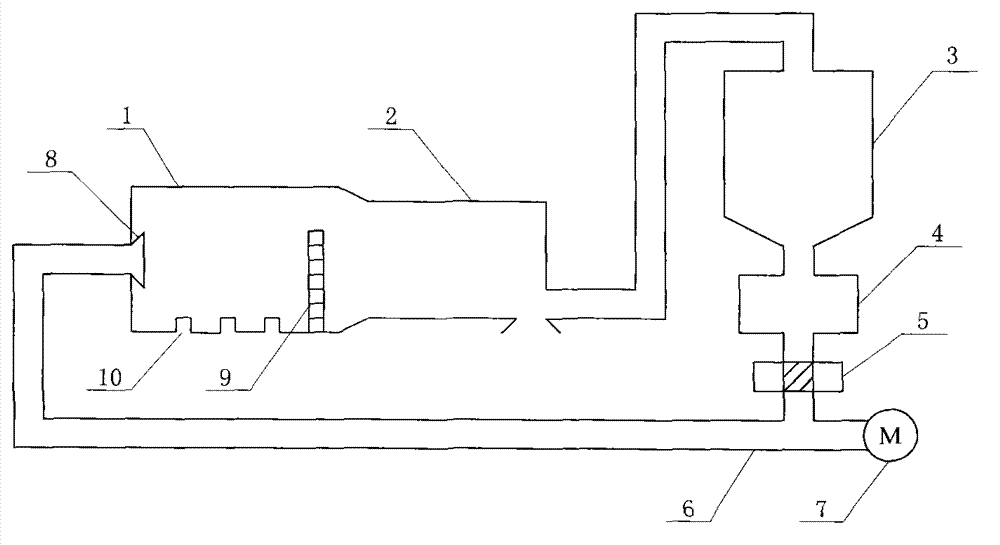

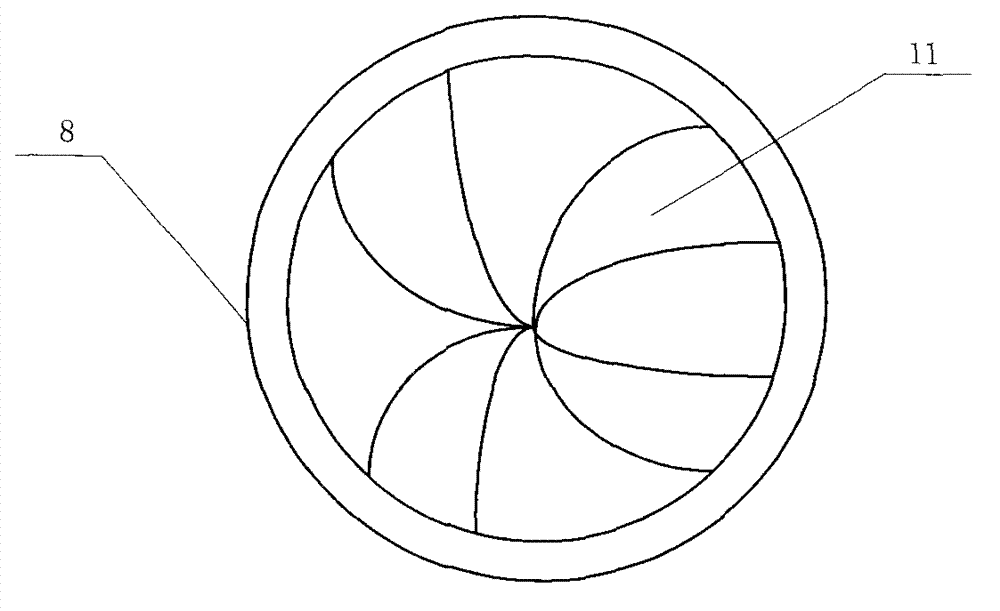

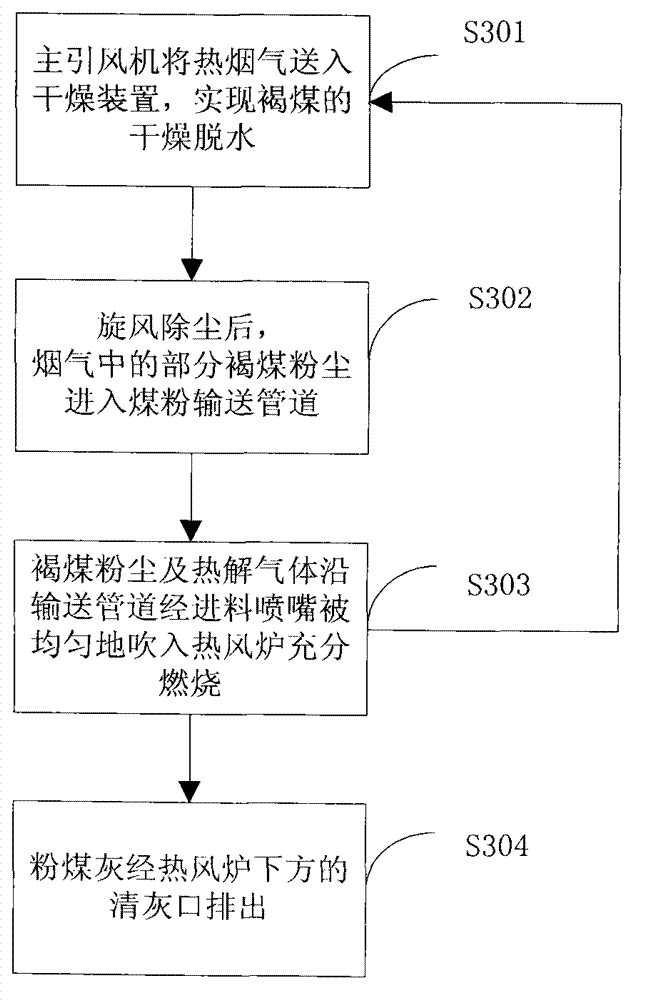

Closed circulating heat supply device for lignite drying and upgrading and heat supply method

InactiveCN102927810AReduce consumptionEmission reductionHeating arrangementAir blowerCyclonic spray scrubber

The invention discloses a closed circulating heat supply device for lignite drying and upgrading and a heat supply method. A hot blast furnace is connected with a drying device to provide a heat source of the initial stage for the in-furnace combustion of the lignite; under the action of a main induced draft fan, hot smoke enters the drying device to realize the drying and dehydration of raw coal; the hot smoke and lignite pyrolytic gas guided out by the drying device are sent into a cyclone dust extractor; after cyclone dust extraction, a part of the lignite dust in the smoke subsides downwards to enter a stirring cage and then is sent to a closed pulverized coal conveying pipeline through a feeder; and under the action of an air blower, the lignite dust and the pyrolytic gas are evenly and dispersedly blown into the hot blast furnace for sufficient combustion through a nozzle through the conveying pipeline in a spiral manner. The closed circulating heat supply device is reasonable in design, safe, reliable and stable in running during large-scale application, and has the effects of realizing the recycle of the lignite dust and the pyrolytic gas, effectively overcoming the problem that the traditional smoke heat supply and upgrading process is high in energy consumption, high in pollution and the like and meeting the environmental requirements of saving energy and reducing emission.

Owner:ZHEJIANG UNIVERSITY OF MEDIA AND COMMUNICATIONS

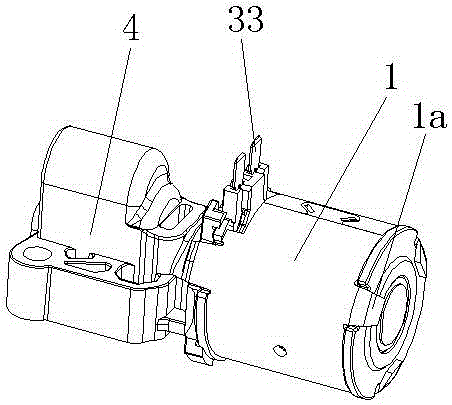

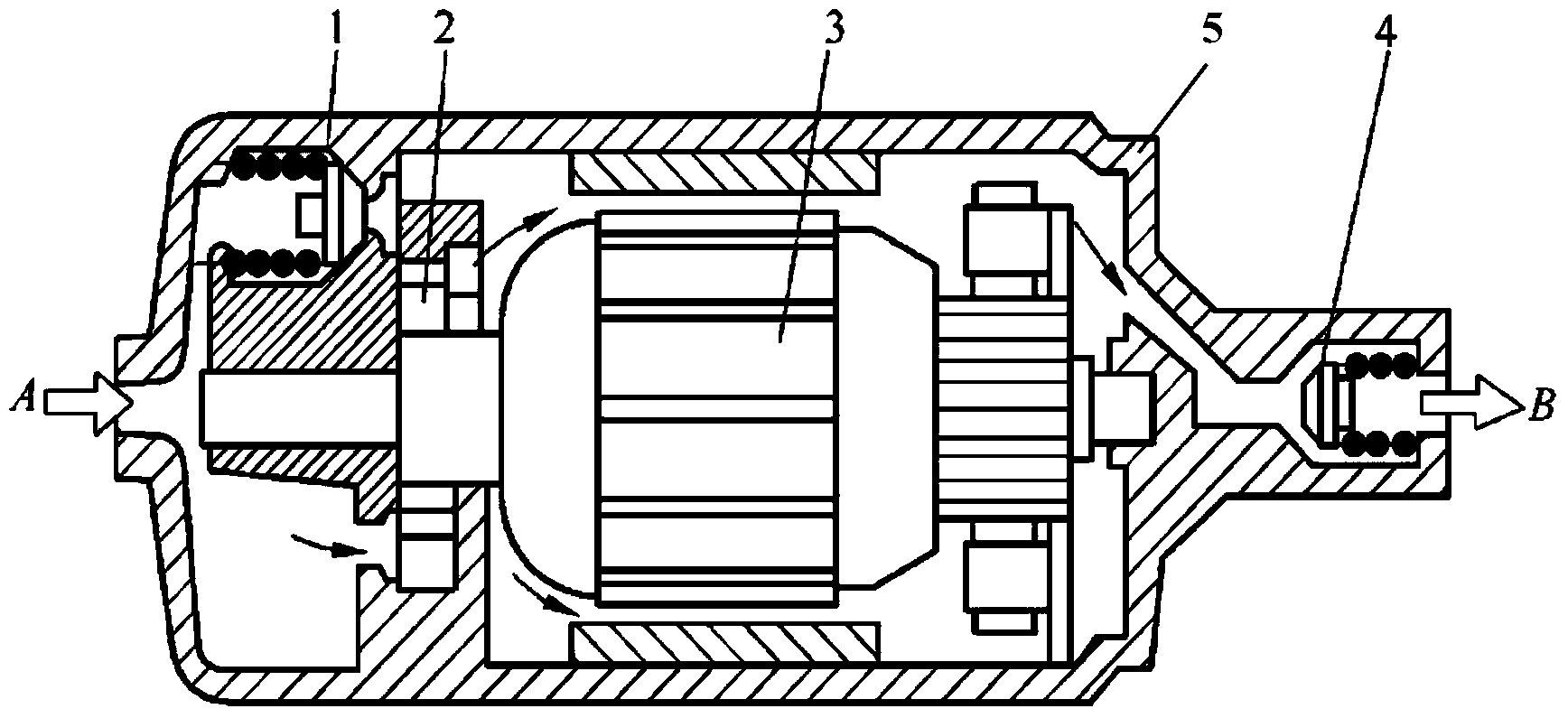

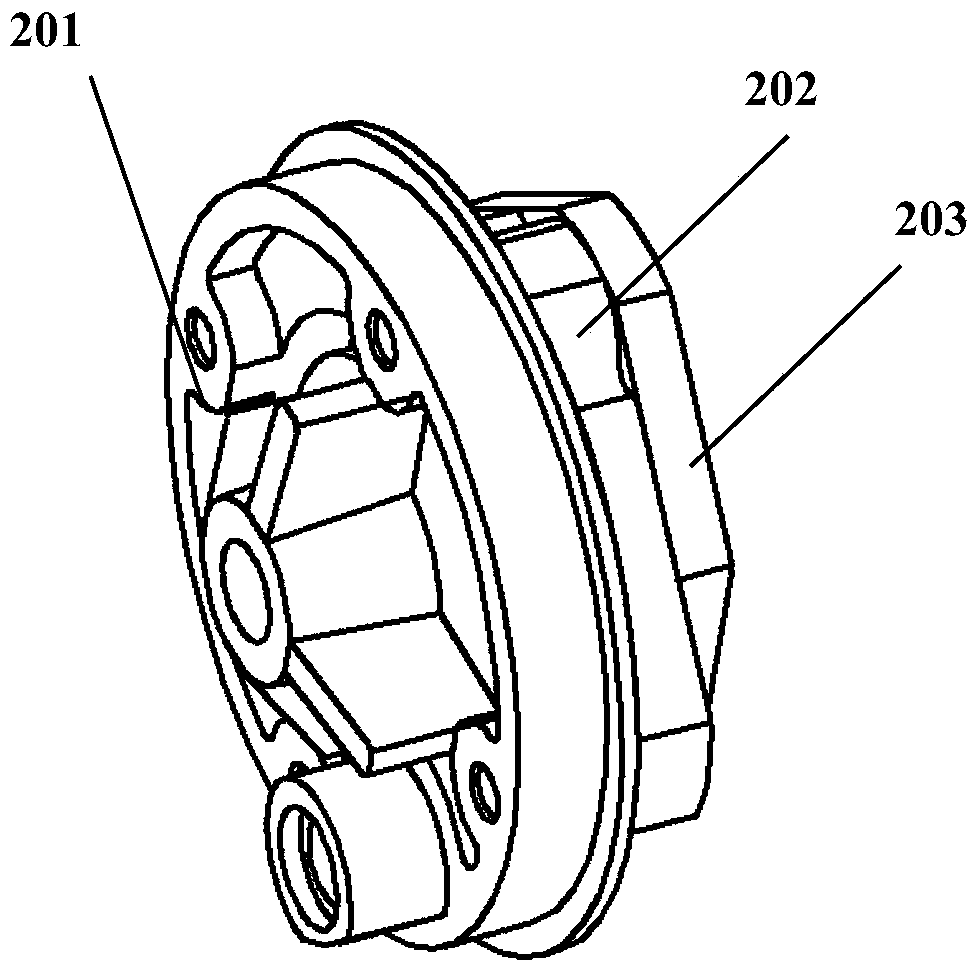

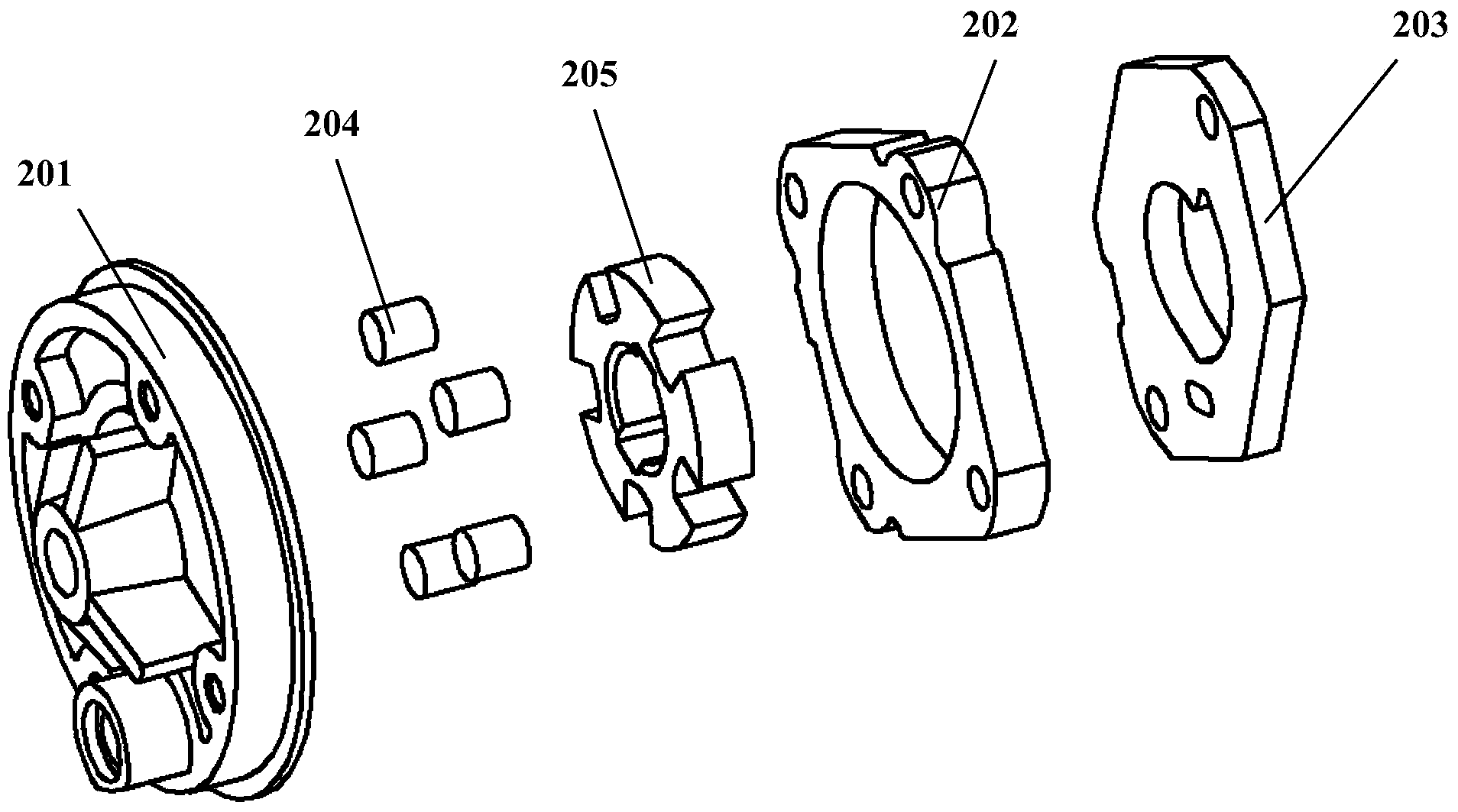

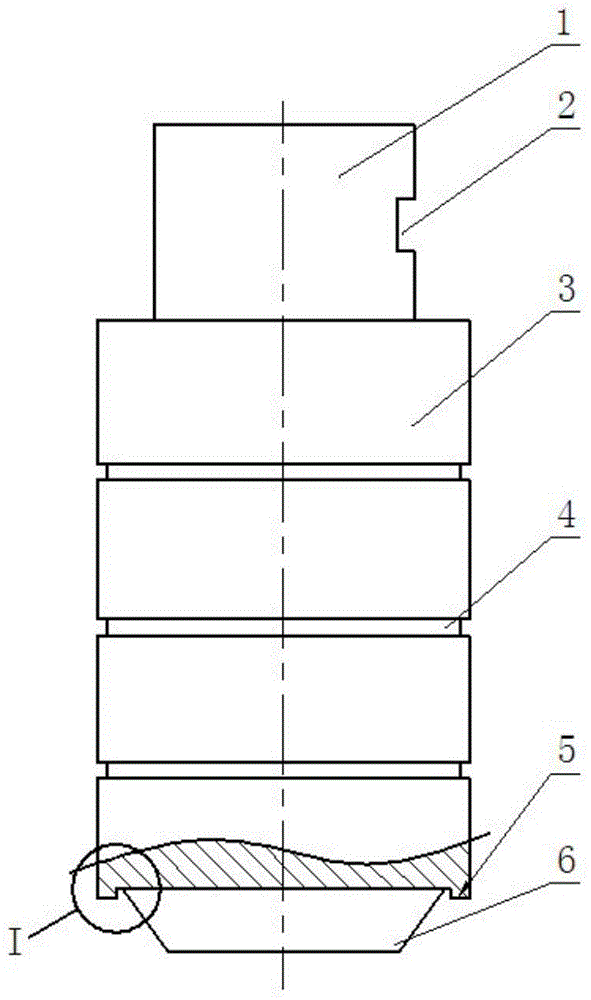

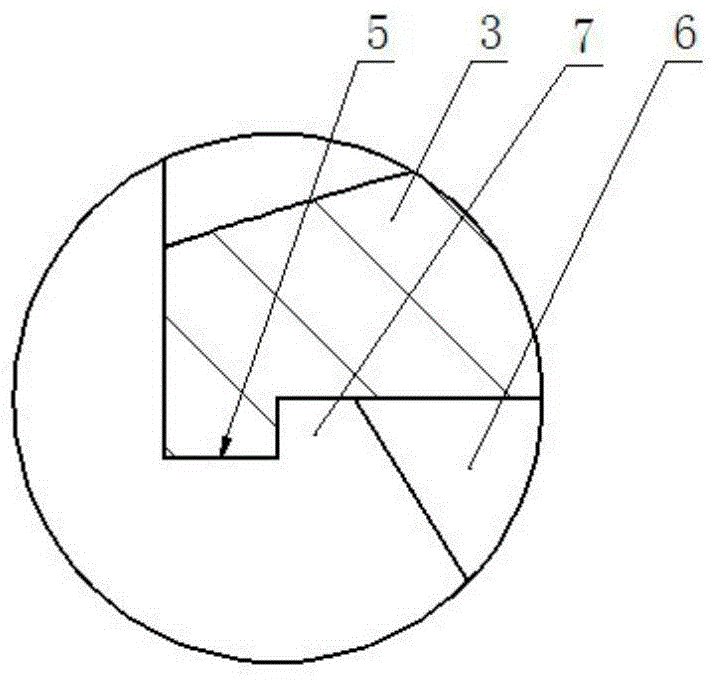

Stator magnetic pole type electric roller vane pump

InactiveCN103527475AReduce oil leakageIncreased pump volumetric and mechanical efficiencyRotary piston pumpsRotary piston liquid enginesDrive motorRelief valve

The invention discloses a stator magnetic pole type electric roller vane pump, which comprises a pump shell, wherein the pump shell is provided with an oil inlet and an oil outlet; a direct current(DC) drive motor is arranged in the pump shell; a relief valve and a roller pump are arranged between the oil inlet and the DC drive motor; an one-way valve is arranged in the oil outlet; the roller pump comprises an oil intake end, a stator, a rotor, a plurality of rollers and a port plate, wherein the stator is arranged between the cap of the oil intake end and the port plate; the rotor is arranged in the stator; an U-shaped groove is formed in the edge of the rotor and the rollers are arranged in the U-shaped groove. The stator magnetic pole type electric roller vane pump, disclosed by the invention, has the beneficial effects that the impact abrasion to the sidewall of the stator caused by the rollers in the roller pump due to the action of start centrifugal force is avoided; the tight contact among the magnetic sidewall of the stator, the rollers and the groove of the rotor can relieve oil fluid leakage, thereby increasing volumetric efficiency and mechanical efficiency of the pump; the ability of resisting external load sudden change is greatly augmented; the reliability is improved, meanwhile, the service time of the pump is prolonged and low costs of good quality products are realized.

Owner:WENZHOU PUMP VALVE ENG RES INSTOF LANZHOU UNIV OF TECH +1

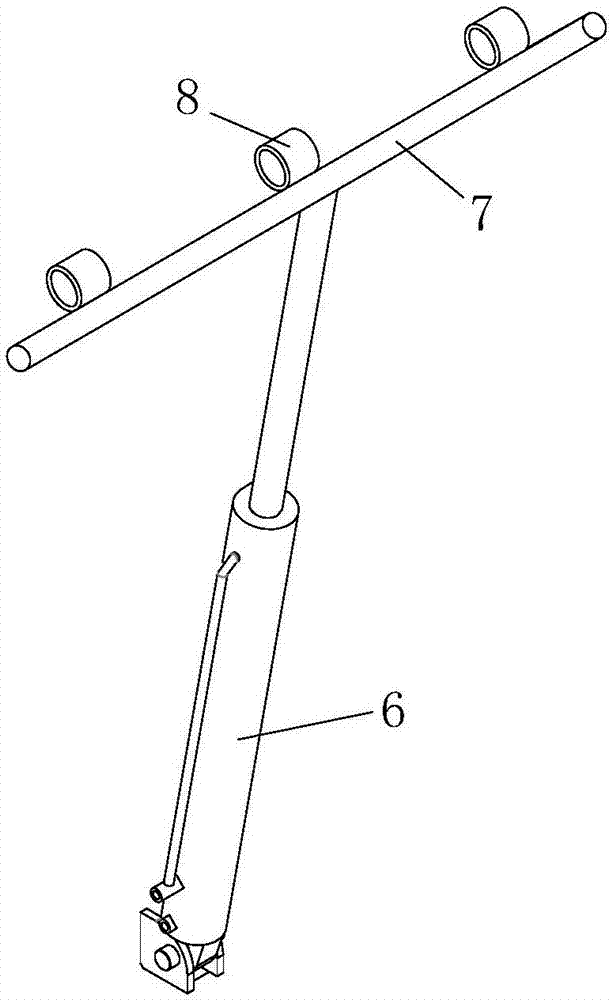

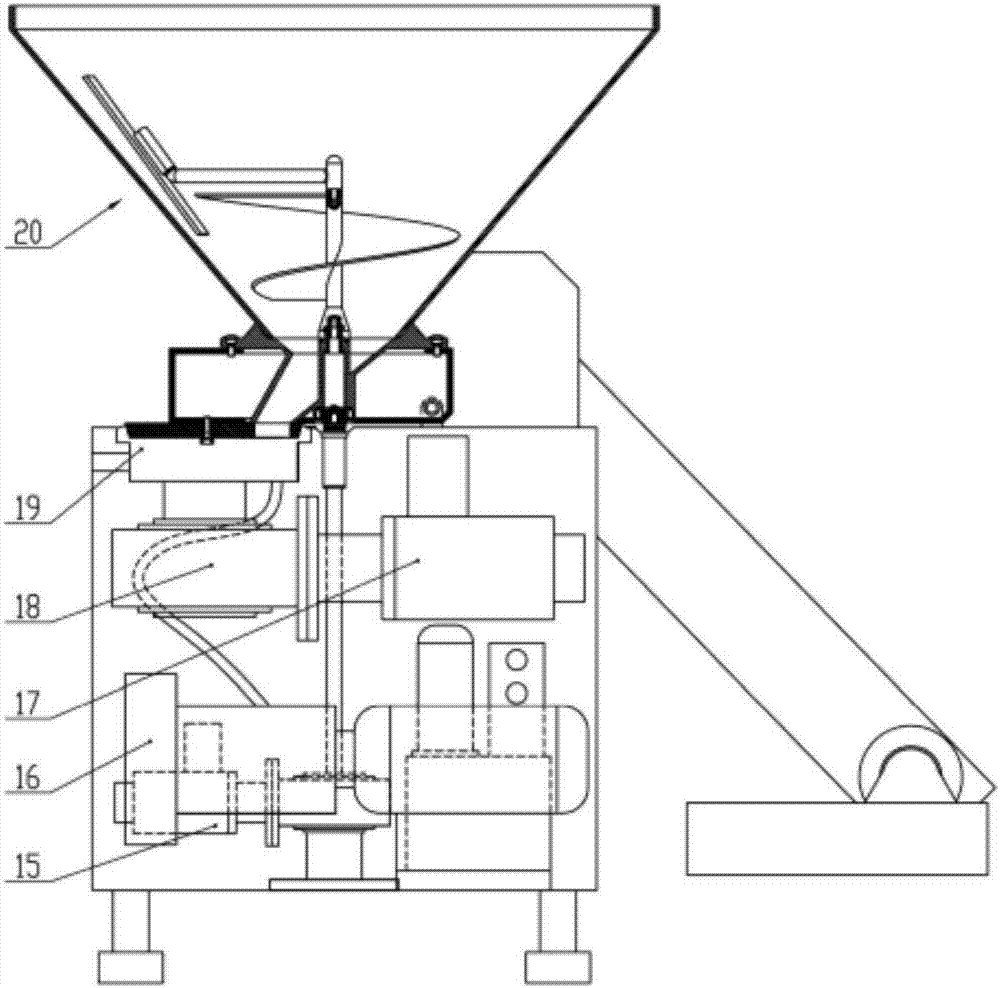

Main engine tipping bucket oblique angle type lifting door stable type garbage compression equipment

InactiveCN107352203AMaintain balanceImprove performanceRefuse transferringLoading/unloadingEngineeringOblique angle

The invention relates to a dumping bucket oblique angle door-lifting stable garbage compression equipment of the main engine, which has a frame, a lifting oil cylinder, a hopper cover, a dumping bucket and a container; the frame and the container are provided with a lifting oil cylinder; the hopper cover is fixedly installed on the top of the frame The tipping bucket is set corresponding to the position of the hopper cover, and the two sides of the tipping bucket are hinged on the frame; the connection between the container and the frame is detachable; the tipping bucket is turned over by a power mechanism fixed on the frame at one end; the power mechanism includes symmetrical hinges The oil cylinder on the frame; the piston rod of the oil cylinder is connected with a cross bar; the cross bar is hinged on the dumping bucket through at least two rings fixed on the cross bar; the outside of the dumping bucket is a slope; The included angle is 30-75°; there is a door-lifting device inside the lifting cylinder at the output port of the frame. The invention has the advantages of reliable turning action, high fault tolerance, high reliability of the system, and the turning is conveniently controlled through the power mechanism.

Owner:唐亚琴

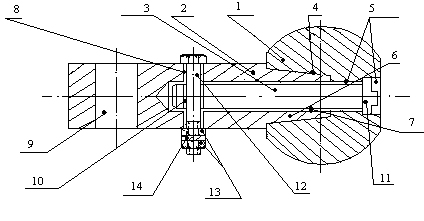

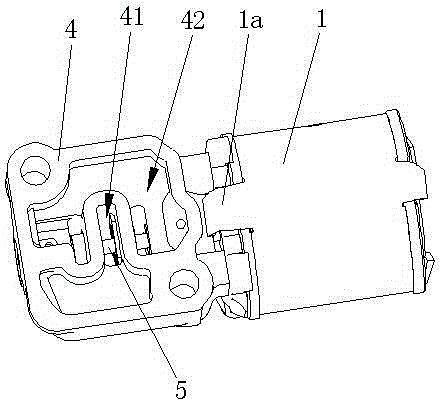

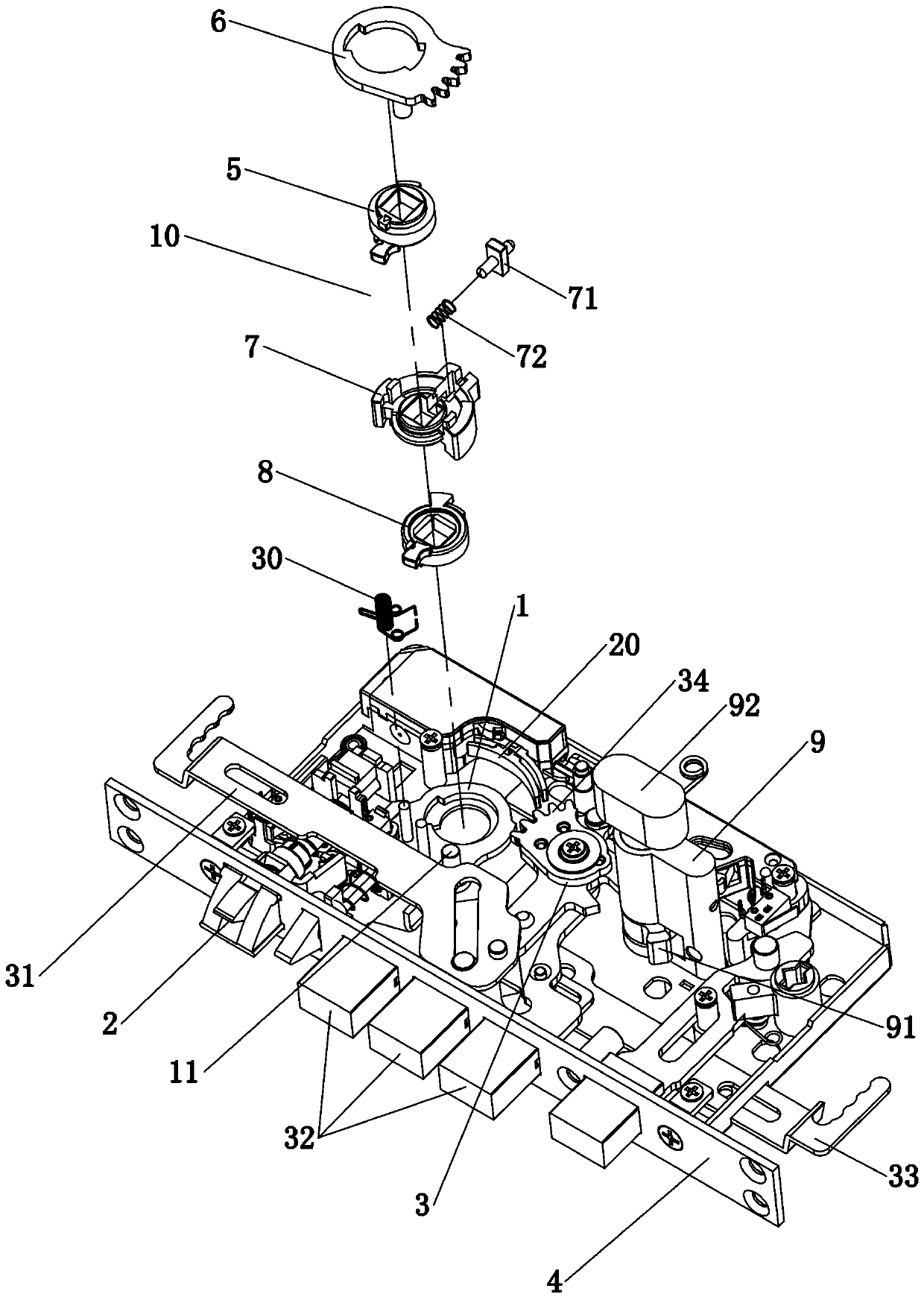

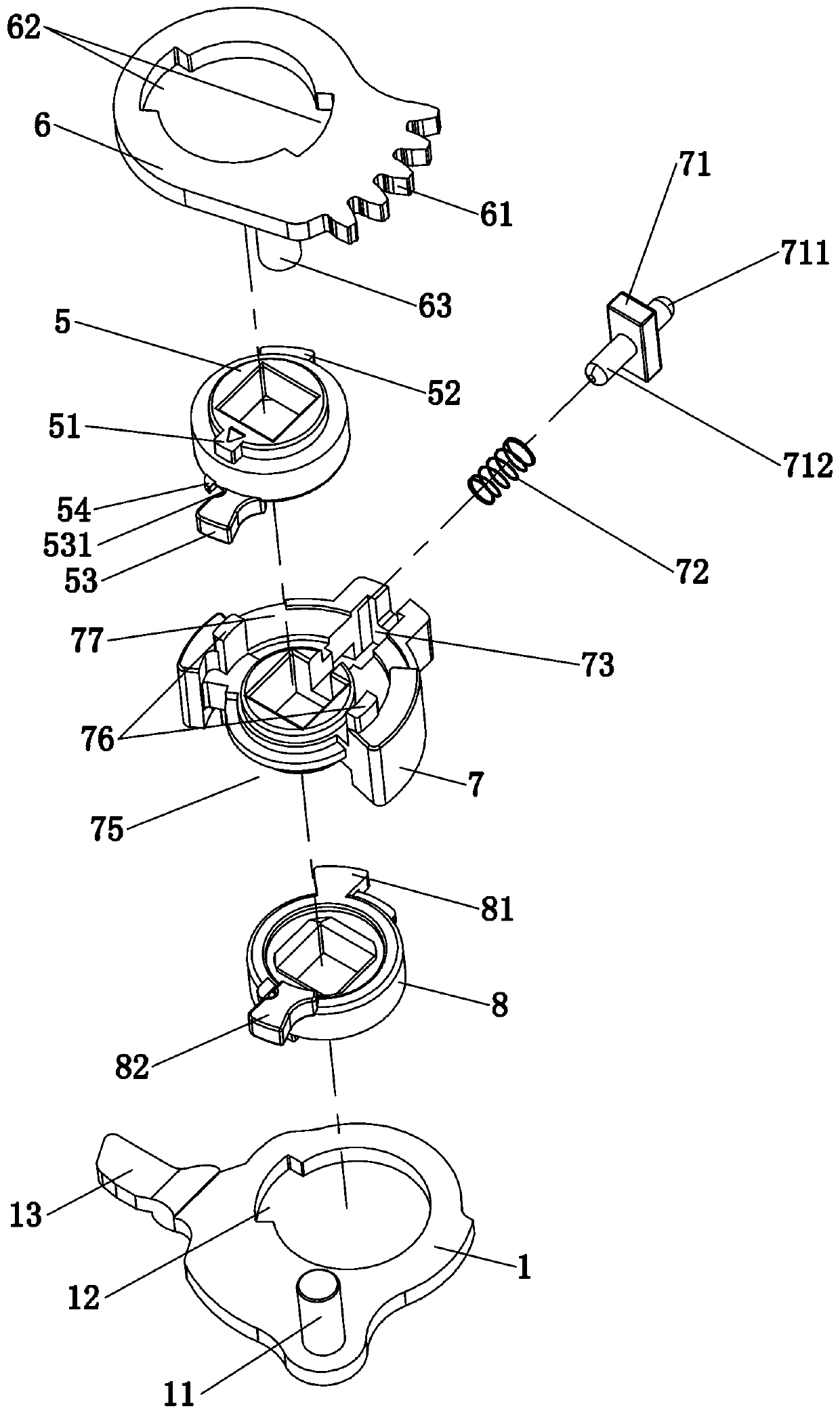

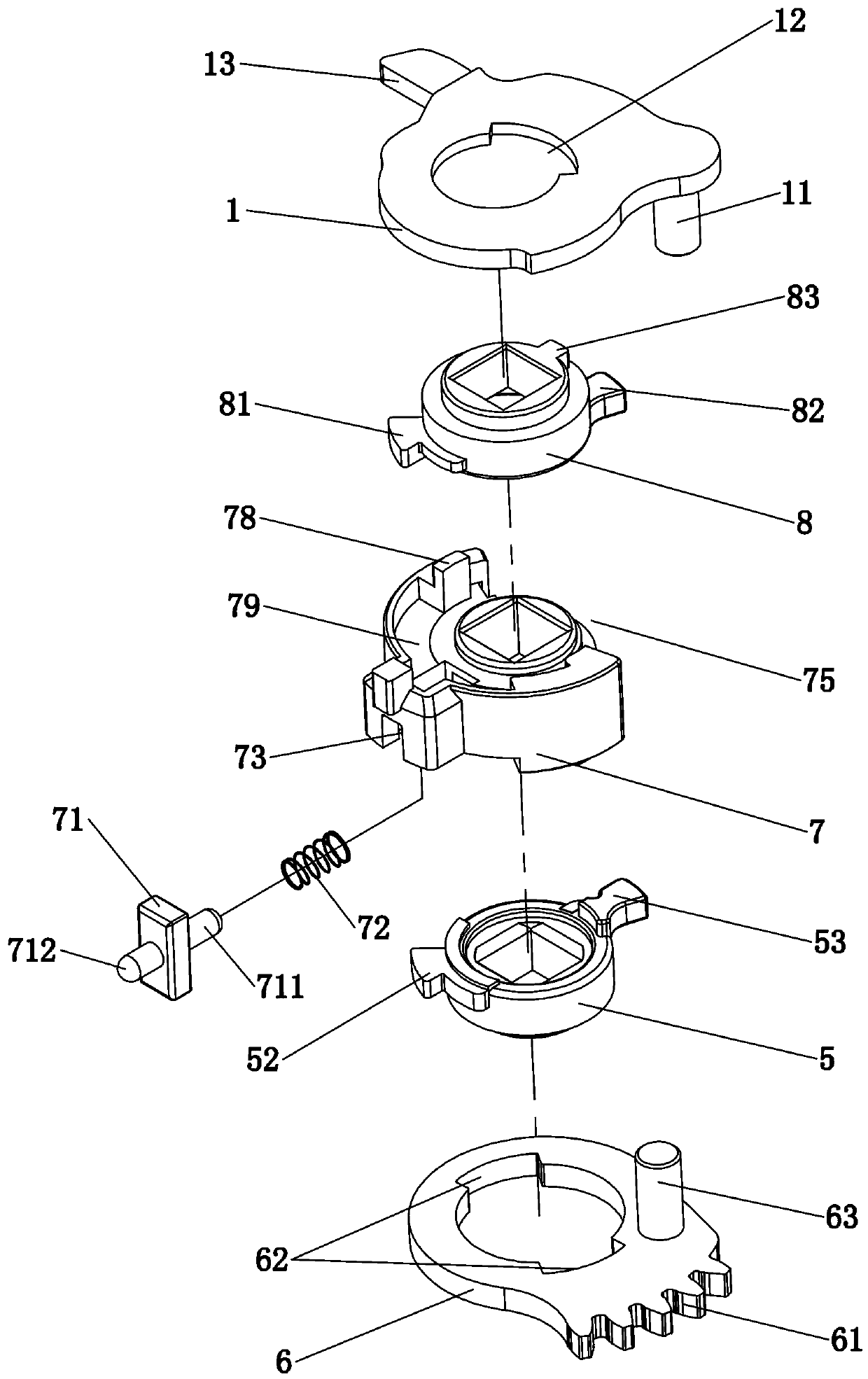

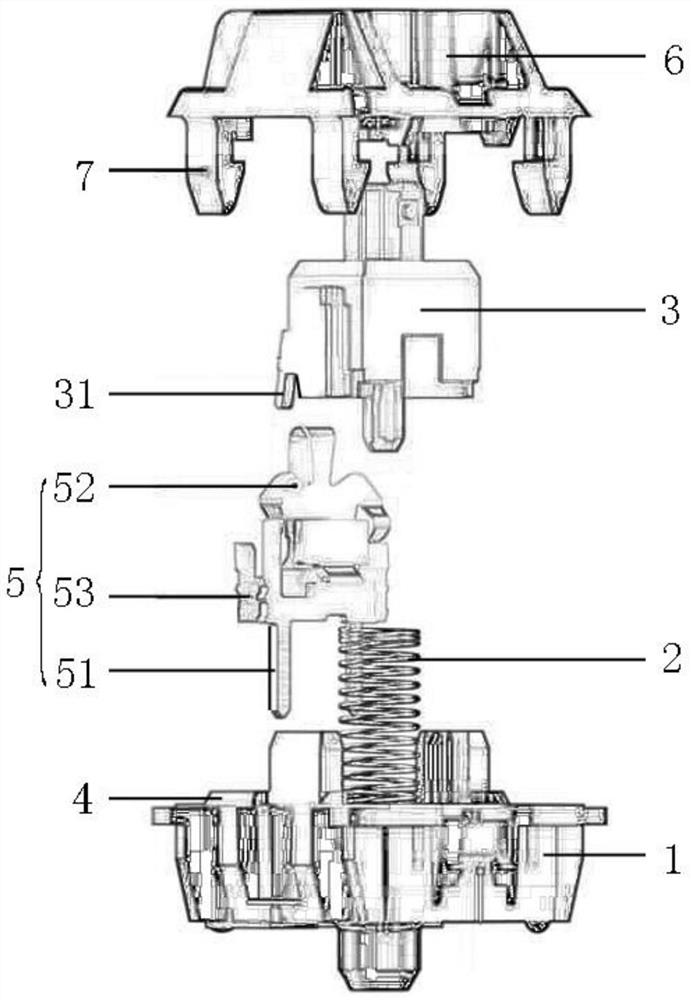

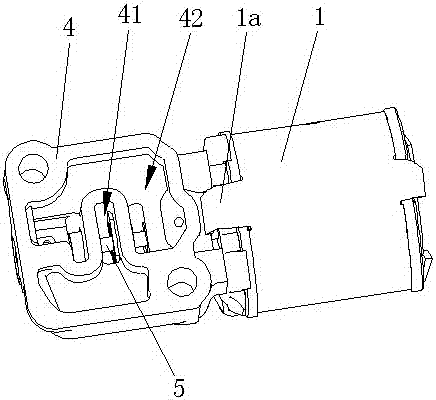

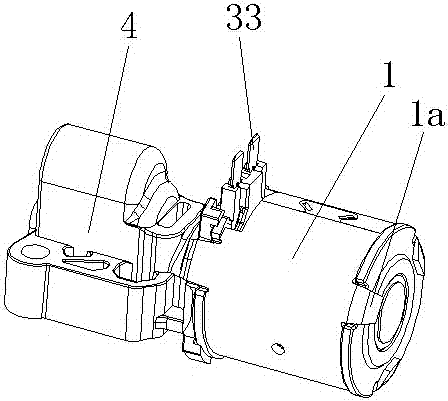

Door lock engagement and disengagement shifting fork device

PendingCN110185318AAvoid holding handsAvoid door handle linkageNon-mechanical controlsEngineeringMechanical engineering

The invention relates to a door lock engagement and disengagement shifting fork device, wherein a front drive shifting block and a front shifting arm are arranged on the outer circumference of a frontshifting fork; a rear drive shifting block and a rear shifting arm are arranged on the outer circumference of a rear shifting fork; front and rear sides of a middle shifting fork are respectively provided with front and rear arc chutes; the front drive shifting block extends into the front arc chute, and the rear drive shifting block extends into the rear arc chute; the middle shifting fork is provided with a engagement and disengagement groove that disconnects the front arc chute from the rear arc chute; when a engagement and disengagement block enters the engagement and disengagement grooveand is blocked from the front drive shifting block and the rear drive shifting block, the front drive shifting block also has a sliding space between the front arc chute; and the rear drive shiftingblock also has a sliding space between the rear arc chute. When the rear shifting fork and the middle shifting fork are controlled to rotate and unlock by an indoor handle, the rear shifting fork andthe middle shifting fork can rotate relative to the front shifting fork to work; the indoor handle is prevented from being in linkage with the outdoor handle when the door is opened in the door, so that a user can unlock through the indoor handle of under the condition that the outdoor handle is blocked and cannot rotate; and product safety is thereby improved.

Owner:ZHONGSHAN ROYALWAND HARDWARE

Sand spreading device for locomotive

The invention provides a sanding device for a locomotive, which comprises a sanding main body, a plurality of sanding nozzles and a plurality of sanding nozzles, the air inlet cavity is arranged in the sanding main body and is respectively communicated with the sanding runner and the locomotive sand box, and a heater is arranged in the air inlet cavity; the first air inlet flow channel and the second air inlet flow channel are respectively communicated with the air inlet cavity; the sanding air cavity is communicated with the first air inlet flow channel, a sanding air nozzle is arranged in the sanding air cavity, and the spraying direction of the sanding air nozzle faces the sand outlet of the sanding flow channel; wherein in the first working state, the normal-pressure sanding air sourceenters the sanding air cavity and enters the sanding flow channel through the first air inlet flow channel to be stirred, and sand grains are blown out under the combined action of the sanding air nozzle, so that sanding operation is carried out; and in the second working state, the normal-pressure air source enters the air inlet cavity through the second air inlet flow channel and enters the locomotive sand box and the sanding flow channel after being heated by the heater, so that sand grains are kept loose and dry.

Owner:HUNAN LIANCHENG TRACK EQUIP CO LTD +1

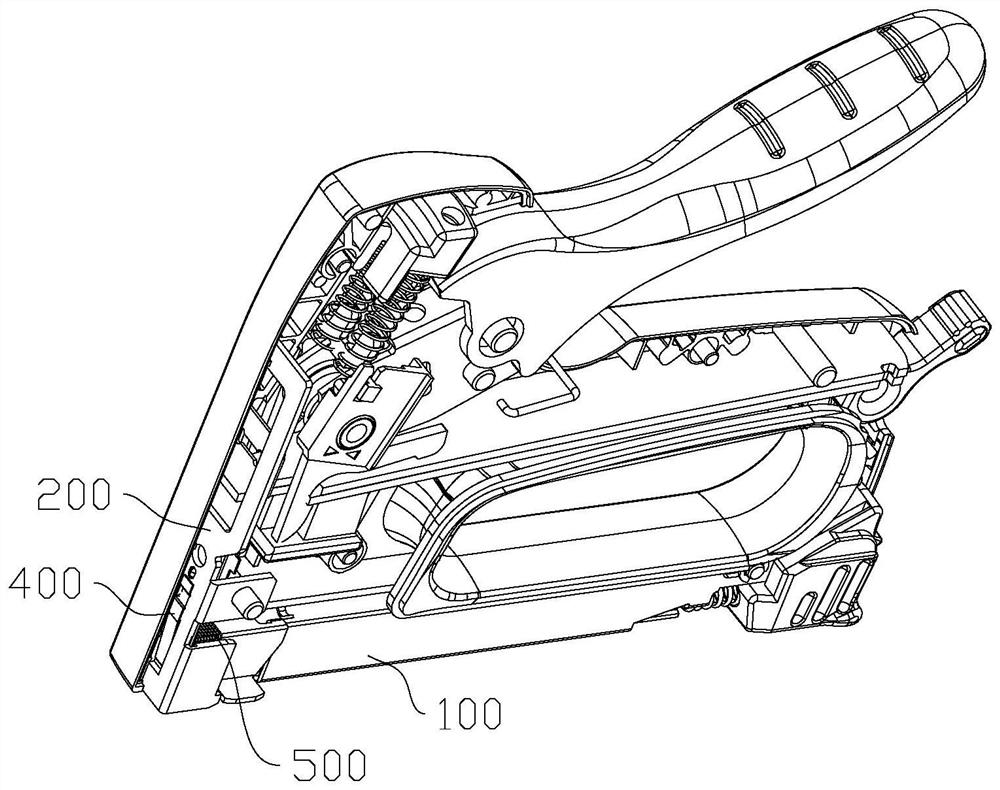

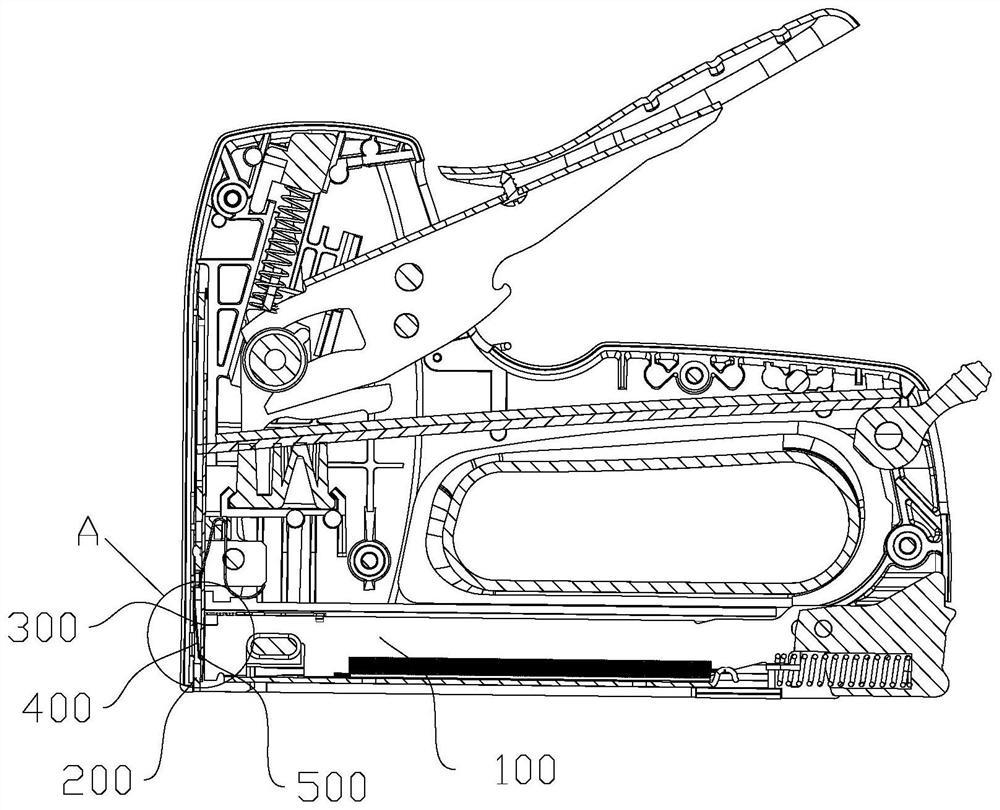

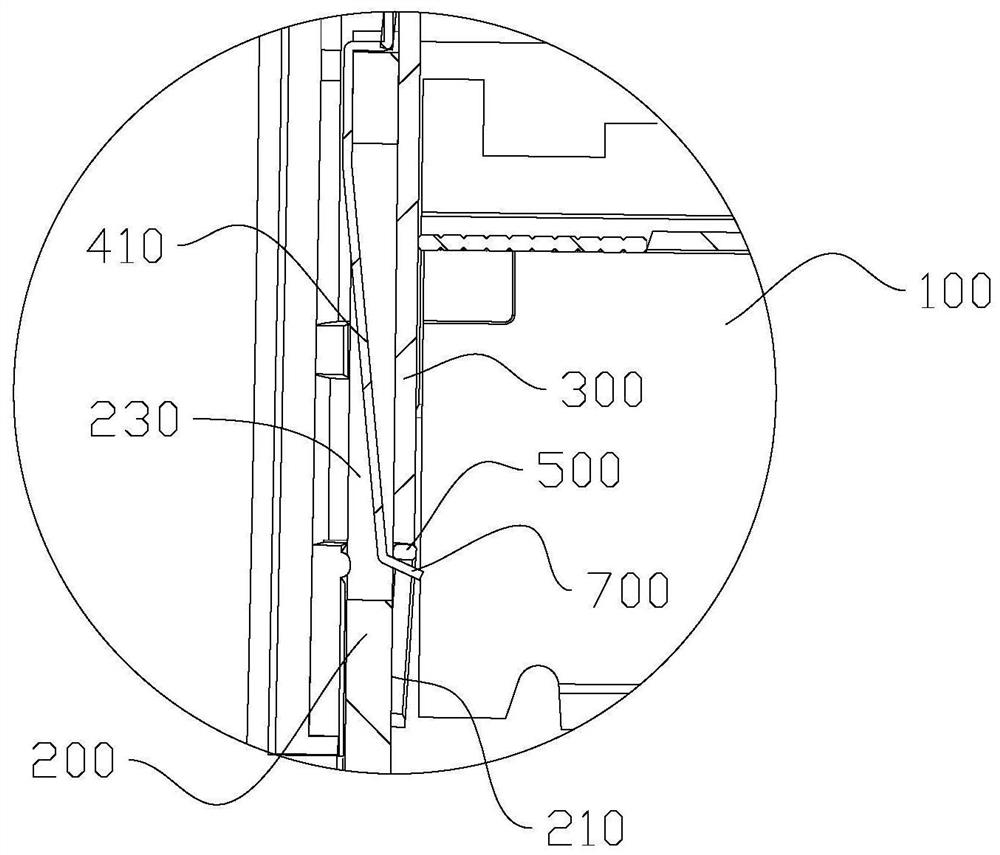

Nail gun

The invention discloses a nail gun. The nail gun solves the technical problem that in the prior art, the nailing quality of a nail gun is unstable. The nail gun comprises a shell and a driving mechanism. A nail feeding guide rail, a rushing sheet guide rail, a rushing sheet and an alignment piece are further arranged in the shell. A nail outlet gap which is used for holding a U nail is formed between the ends of the rushing sheet guide rail and the nail feeding guide rail, and the driving mechanism drives the rushing sheet to move downwards in the nail outlet gap so as to rush out the U nail. When nailing is conducted, the alignment piece is matched with the rushing sheet to align the U nail in the nail outlet gap to be attached to the rushing sheet guide rail, and therefore the U nail can be discharged in the mode of being attached to the rushing sheet guide rail.

Owner:HANGZHOU KELONG ELECTRICAL APPLIANCE TOOLS

Backflow-type detachable wear-resisting elbow

InactiveCN103423542ASimple structureReasonable structurePipe protection against damage/wearSiphonsEngineeringWear resistance

The invention discloses a backflow-type detachable wear-resisting elbow comprising a housing, a top cover, a bolt and a gasket. The housing is a right-angle bent tube member, a notch is formed on the outer wall of the bent tube member for mounting the top cover in a sealing manner, and the housing and the top cover are connected to form a detachable structure through the bolt and the gasket. The housing and the top cover form an upward-convex-shaped spiral case, the top end of the spiral case is located on the upper wall of the neck of an outlet and are connected through an arc, and the tail end of the spiral case is connected with the outer wall of the neck of an inlet transitionally. The spiral-case-shaped inner wall allows a small part of inputted particle material to wriggle and backflow along the inner wall curve, the low-speed backflow particle material forms a barrier to protect the inner wall of the spiral case, and impact and wear on the inner wall of the spiral case by the inputted particle material are avoided. According to the structure, operating environment of the top cover can be improved greatly, so that the purpose of wear resistance is achieved; by the aid of the detachable structure, the top cover can be maintained or changed conveniently, so that maintenance cost is reduced.

Owner:江苏旺能锅炉制造有限公司

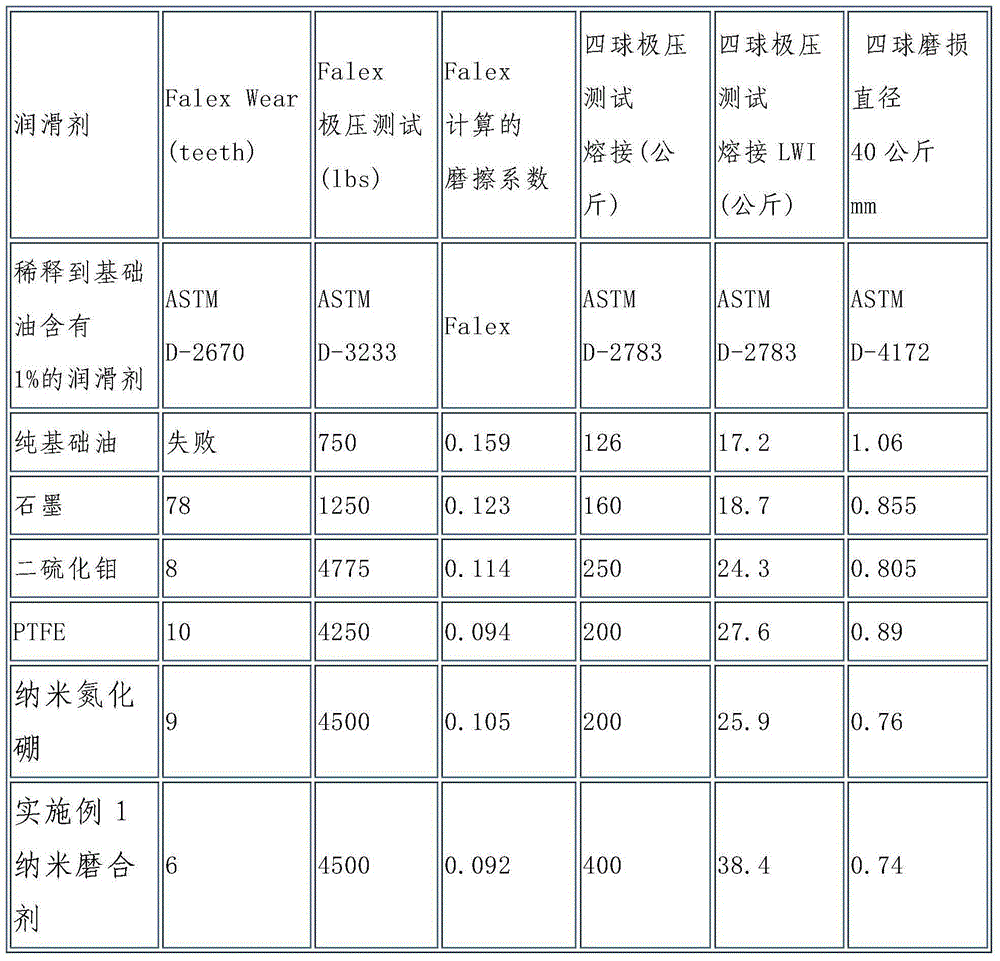

Nanometer running-in agent

InactiveCN105199812AOvercome limitationsOvercome the limitations of immiscibilityAdditivesBeef TallowPetroleum

A disclosed nanometer running-in agent is composed of the following compositions in percent by weight: 10-20 parts of heavy alkyl benzene, 10-20 parts of alkyl naphthalene, 20-50 parts of boronized polyisobutylene succinimide, 20-40 parts of molybdenum dialkyldithiophosphate, 1-2 parts of oil-modified phenolic resin, 1-4 parts of hydroxyl silicone oil emulsion 305, 1-4 parts of beef tallow, and 1-4 parts of detergent LD-1. The agent is prepared according to the following steps: (1) putting heavy alkyl benzene into a blending kettle, heating to 60 DEG C, and stirring for 30 min; (2) then adding boronized polyisobutylene succinimide, and continuing to stir for 30 min; (3) then adding molybdenum dialkyldithiophosphate, cyclically stirring for 120 min, then adding oil-modified phenolic resin, hydroxyl silicone oil emulsion 305, beef tallow and the detergent LD-1, keeping a constant temperature of 60 DEG C for 60 min, and then slowly cooling to 40 DEG C or less, loading a barrel, and capping, so as to obtain the agent. Compared with the prior art, the agent possesses the substantial advantages that the agent is applicable to lubrication systems of various vehicles, ships, petroleum chemical machinery, mine machinery and other large-scale equipment, and possesses multiple functions of reducing wear, reducing oil consumption, restoring wear surface, improving bearing capability, reducing noise and the like.

Owner:胡波

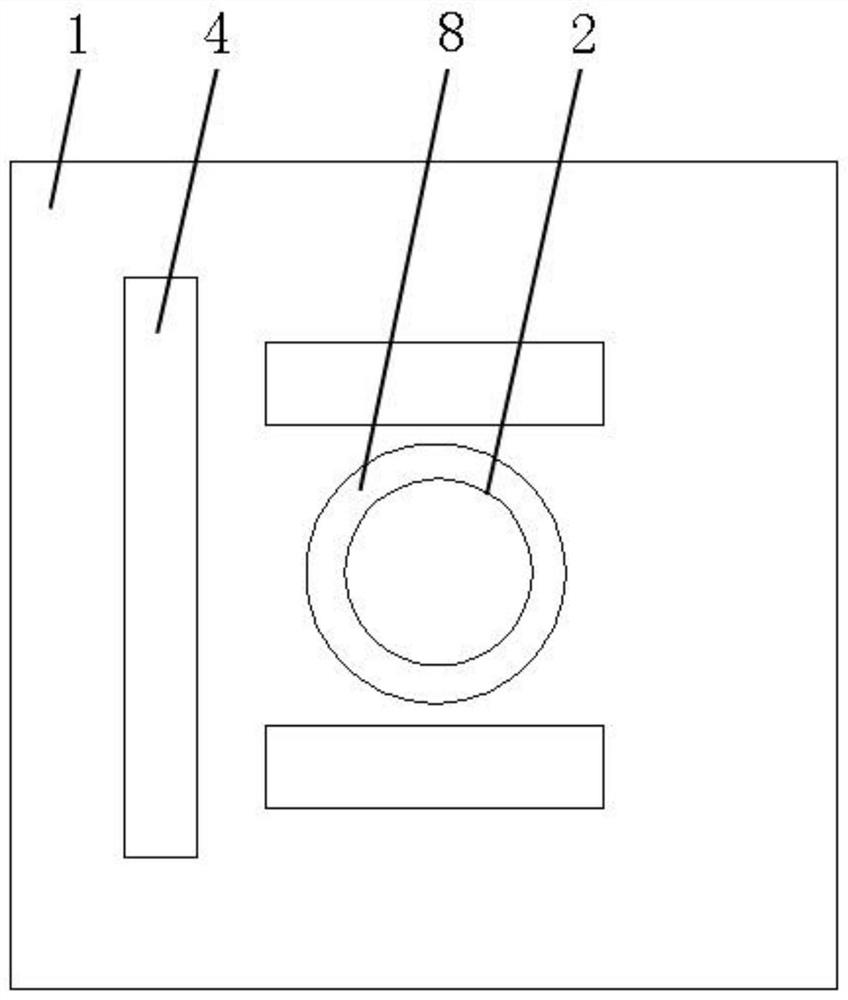

Server, control key and magnetic induction triggering structure

InactiveCN111834151AAvoid impact wearHall effect is obviousElectric switchesKey pressingControl theory

The invention discloses a magnetic induction triggering structure. The structure comprises a base, a spring vertically arranged on the surface of the base, a shaft core arranged at the top end of thespring and used for moving in the vertical direction under the pressing effect, and a magnetic induction switch arranged on the surface of the base and used for triggering a preset output signal through the Hall effect when the shaft core is vertically pressed downwards to a preset distance. The invention provides a magnetic induction triggering structure. The Hall effect is utilized to trigger the key to output signals in the mode that the shaft core approaches the magnetic induction switch under the pressing effect. Key triggering control is achieved, the shaft core does not need to be in physical contact with the magnetic induction switch, so that the magnetic induction switch is prevented from being impacted and abraded, the service life can be prolonged, meanwhile, the shaft core andthe magnetic induction switch do not need to be in face-to-face friction abutting connection, the triggering delay and springback hysteresis phenomena can be reduced as much as possible, and the switch triggering sensitivity is improved. The invention also discloses a control key and a server, which have the above beneficial effects.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

Sanding device for locomotive

The invention provides a sanding device for a locomotive, which comprises a sanding main body, a plurality of sanding nozzles and a plurality of sanding nozzles, the air inlet cavity is arranged in the sanding main body and is respectively communicated with the sanding runner and the locomotive sand box, and a heater is arranged in the air inlet cavity; the first air inlet flow channel and the second air inlet flow channel are respectively communicated with the air inlet cavity; the sanding air cavity is communicated with the first air inlet flow channel, a sanding air nozzle is arranged in the sanding air cavity, and the spraying direction of the sanding air nozzle faces the sand outlet of the sanding flow channel; wherein in the first working state, the normal-pressure sanding air sourceenters the sanding air cavity and enters the sanding flow channel through the first air inlet flow channel to be stirred, and sand grains are blown out under the combined action of the sanding air nozzle, so that sanding operation is carried out; and in the second working state, the normal-pressure air source enters the air inlet cavity through the second air inlet flow channel and enters the locomotive sand box and the sanding flow channel after being heated by the heater, so that sand grains are kept loose and dry.

Owner:HUNAN LIANCHENG TRACK EQUIP CO LTD +1

Discharge plate of automatic mill

The present invention discloses discharge plate for automatic mill. The discharge dustpan plate includes dustpan plate body comprising casing of carbon steel and in the shape of dustpan, and protective antiwear layer of rubber material covering the inner surface of casing. The present invention has no wear of quartzite on the carbon steel casing, no iron dust contamination of product, high quality of ground quartzite and reduced dustpan plate weight.

Owner:王成敬

Mobile platform

InactiveCN108714879AImprove stabilityGuaranteed stabilityWork benchesMechanical engineeringEngineering

The invention discloses a mobile platform. The mobile platform comprises a fixed platform body, a workbench, a forward moving cylinder and a reset positioning assembly; the fixed platform body is provided with a sliding rail, the forward moving cylinder is arranged on the fixed platform body, and the forward moving cylinder drives the workbench to slide back and forth along the slide rail; the reset positioning assembly is arranged on the rear side of the workbench to improve the stability of the operation; the reset positioning assembly includes a slide seat, and the position of the slide seat can be adjusted according to the reset position of the workbench; and the slide seat is provided with a matching boss and a buffer part to enable the process of resetting the workbench and matchingwith the sliding seat to be buffered to avoid impact abrasion, and the matching boss is matched with a positioning groove to fix the workbench to ensure the stability of processing on the workbench and improve the product precision.

Owner:苏州康普雷森精密机械有限公司

Punch used for stamping die

InactiveCN106541027AAvoid crackingAvoid superficial strainShaping toolsMechanical engineeringLubrication

The invention relates to a punch used for a stamping die. The upper part of a body of the punch is integrally and coaxially provided with a handle section. The lower part of the body of the punch is integrally and coaxially provided with a transition section. The outer edge of the lower end surface of the body is integrally and downwardly provided with an annular boss. An annular groove is formed between the annular boss and the transition section. The outer edge of the body is uniformly and coaxially provided with multiple annular grooves at intervals. The punch used for the stamping die has following beneficial effects: due to the fact that the lower end surface of the body of the punch is integrally and downwardly provided with the annular boss, and the annular groove is formed between the annular boss and the transition section, the annular groove can store cooling liquid so that crack or surface strain of the punch caused by excessive heat can be avoided, thereby prolonging service lifetime; good cooling and lubrication effects of the punch are ensured; crack or surface strain caused by excessive heat is avoided; and the punch is featured by being high in location precision and long in service lifetime.

Owner:TIANJIN HAOXIN PRECISION MOLD

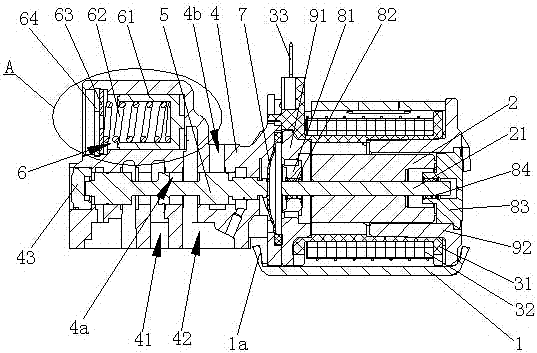

Solenoid valve for automatic transmission

ActiveCN105202177BRealize opening and closing controlSimple designOperating means/releasing devices for valvesGearing controlAutomatic transmissionSolenoid valve

The invention discloses an electromagnetic valve of an automatic gearbox. The electromagnetic valve comprises an outer housing, a movable iron core and an electromagnetic coil component assembled inside the outer housing, wherein the movable iron core is assembled at the center of the electromagnetic coil component; an ejector rod is arranged at the center of the movable iron core; a valve body is assembled at the front part of the outer housing; a pressure inlet and a pressure outlet are formed in the valve body; a pressure cavity is formed in the valve body; a valve element is arranged inside the pressure cavity; the front end of the ejector rod is matched with the valve element; a pressure storage chamber is further arranged inside the valve body, and is communicated with the pressure cavity; a piston, a spring, a gasket and a clamp spring are arranged inside the pressure storage chamber; one end of the spring is propped against the gasket, and the other end of the spring is propped against the piston; the clamp spring is placed on the outer side of the gasket, and is in clamping fit with the valve body. The electromagnetic valve has the advantages that the structure is simple, and the stability is good; besides, the electromagnetic valve is integrated with the pressure storage structure, so that the defect of the lag of oil pressure adjustment is eliminated, and the adjustment is more sensitive.

Owner:XINGYU ELECTRON (NINGBO) CO LTD

Air intake device of variable diameter carbonization tower

The invention discloses an air intake device of a variable-diameter carbonization tower. The air intake device includes a main air intake pipe extending into the carbonization tower, a plurality of branch air pipes uniformly distributed in layers along the axial direction of the main air intake pipe, The gas blowing device arranged at the bottom of the carbonization tower has a plurality of nozzles evenly distributed on the branch air pipe, and the gas discharged into the carbonization tower from the nozzles is spirally raised under the action of the gas blowing device; the carbonization tower provided by the invention The air intake device improves the uniformity of gas distribution in the carbonization tower, and the gas discharged from the nozzle does not directly impact the heat exchange tank installed above the air intake device, reducing the impact and wear on the tube bundles in the heat exchange tank and improving the service life of the equipment.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

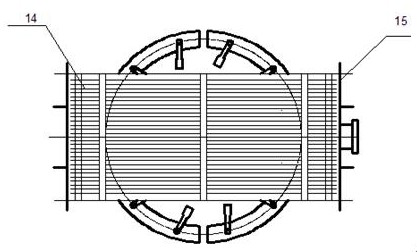

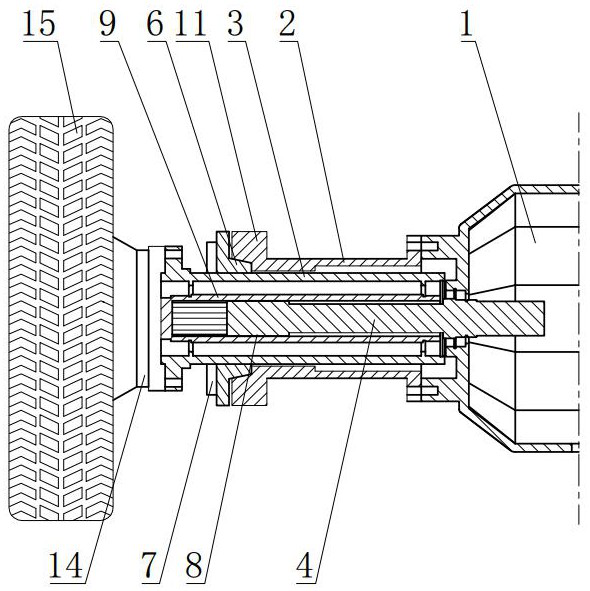

Axle for plant protection machine

ActiveCN114342899AAvoid impact wearPrevent circumferential rotationInsect catchers and killersAgricultural engineeringStructural engineering

The invention discloses a plant protection machine axle which comprises an axle housing, fixing sleeves are mounted on the left side and the right side of the axle housing, sliding sleeves are slidably mounted in the fixing sleeves, a taper hole is formed in the end, away from the axle housing, of each fixing sleeve, the taper holes expand outwards, the sliding sleeves penetrate through the taper holes and extend outwards, taper tiles are inserted into the taper holes, and the outer side faces of the taper tiles abut against the fixing sleeves. A clamping sleeve is arranged at the end, away from the axle housing, of the fixed sleeve, a taper hole is formed in the clamping sleeve, an opening in the end, close to a wheel, of the taper hole is large, an opening in the end, away from the wheel, of the taper hole is small, and a limiting edge extending in the length direction of the sliding sleeve is arranged on the outer wall of the sliding sleeve and is a transversely-extending plane. Limiting grooves are formed in the fixing sleeves and open towards the wheels, top plates are clamped in the limiting grooves, inserting plates are arranged on the top plates, and the inserting plates are inserted in the taper holes. According to the novel axle, the connecting strength of the fixed sleeve and the sliding sleeve can be guaranteed, and the fixed sleeve and the sliding sleeve are prevented from being collided and abraded when a vehicle runs.

Owner:山东广为智能科技有限公司

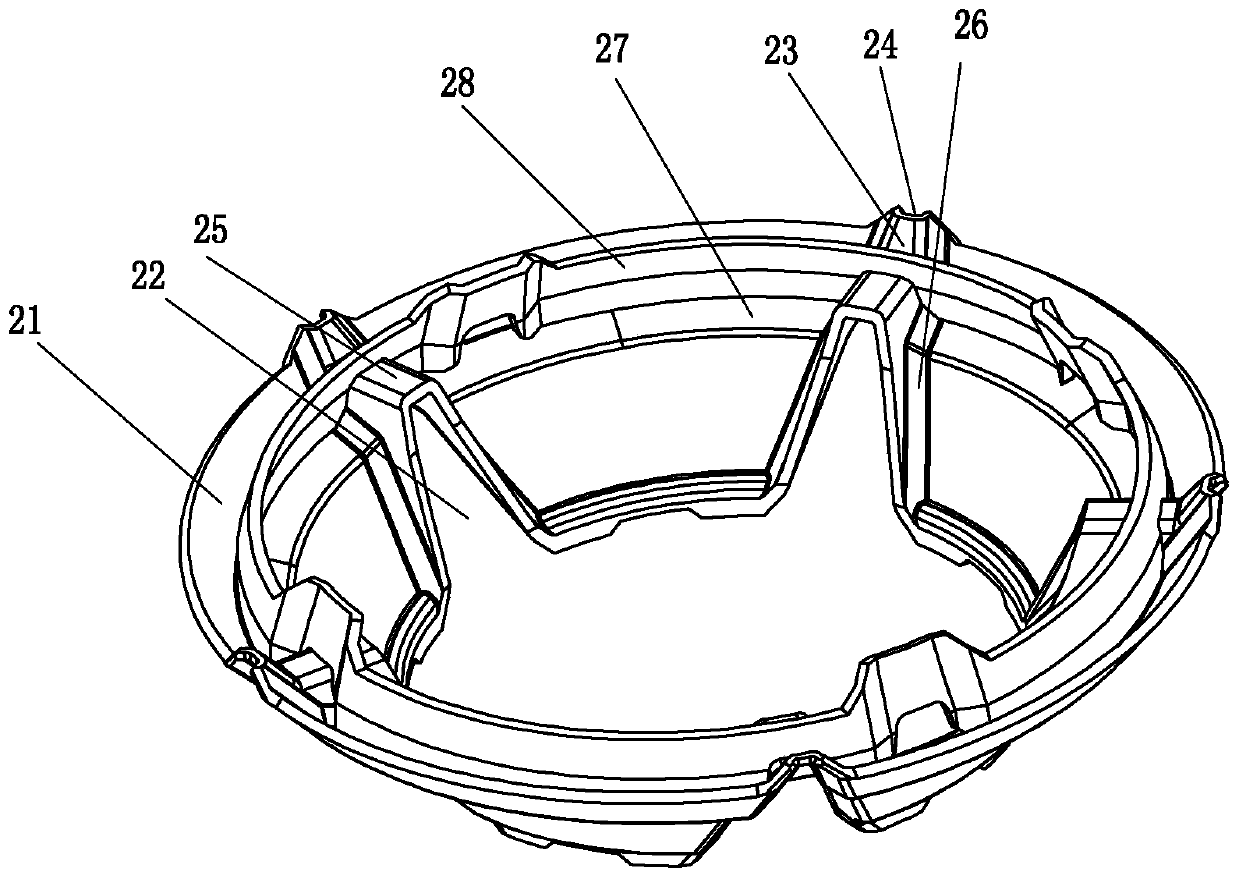

Energy gathering disk

PendingCN110822500AAvoid impact wearHigh strengthStoves/ranges topsGaseous fuel burnerSupport surfaceEngineering

The invention discloses an energy gathering disk. According to the energy gathering disk, the top of a through inserting groove with an opening formed in the bottom side is connected through connecting sections, the connecting sections are bulged inwards in the radial direction, and supporting surfaces are formed on the bottom surfaces of the connecting sections, so that the strength of a disk body is enhanced, traditional point contact pressing is replaced by surface contact pressing, the inner diameters of the tips of the inner sides of the connecting sections are reduced, all the connectingsections can be favorably pressed against cookware supporting feet, the mounting stability of the energy gathering disk is improved, the collision abrasion of the supporting feet can be prevented, the service life of the disk body can be prolonged, and the energy gathering disk can adapt to various models of grates.

Owner:沈科泽

Multifunctional equipment platform

The invention discloses a multifunctional equipment platform which comprises a fixed table, a working table, a forward moving cylinder, a resetting and positioning assembly and a forward moving and positioning assembly. The forward moving cylinder drives the working table to slide front and back along a slide rail; the forward moving and positioning assembly and the resetting and positioning assembly are arranged on the front side and the rear side of the working table; the forward moving and positioning assembly is provided with a buffer plate and a vacuum sucker, so that the working table isbuffered during the process of forward moving in place and is prevented from being impacted and worn, after in place, the vacuum sucker is adsorbed onto a component at a stroke terminal of the frontside of the working table so as to be positioned, and workpieces are conveniently loaded and unloaded or carried to the next station; the resetting and positioning assembly comprises a sliding seat; the position of the sliding seat can be adjusted according to the reset position of the working table; a matched lug boss and a buffer part are arranged on the sliding seat, so that the process of resetting the working table to be matched with the sliding seat is buffered, and the impact wear is avoided; and the matched lug boss and a positioning slot are matched so as to fix the working table, sothat the stability in processing on the working table is ensured, and the product accuracy is improved.

Owner:苏州康普雷森精密机械有限公司

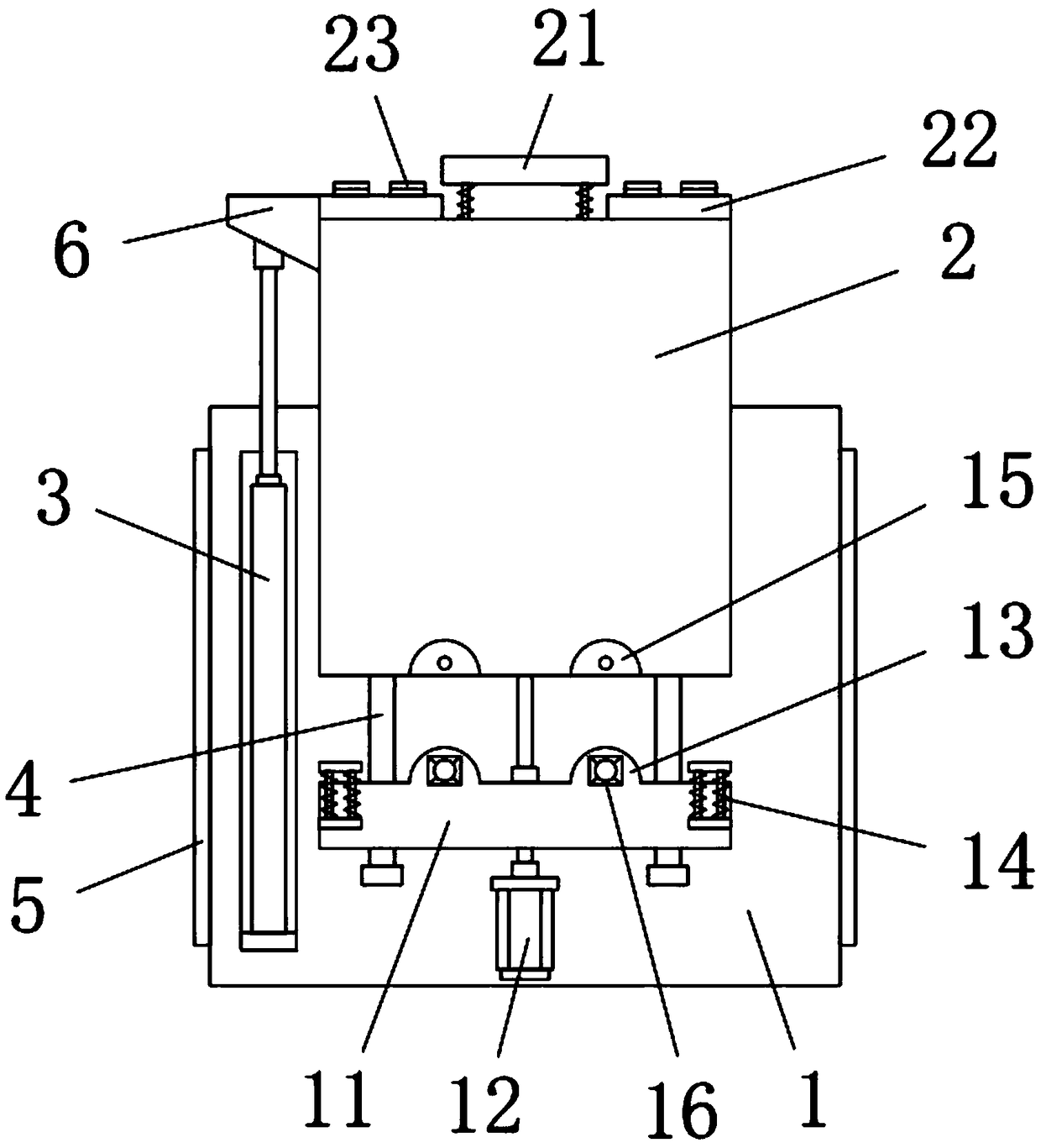

Vacuum quantitative filling machine

InactiveCN107380500APrevent oxidationIsolate running soundLiquid materialElectric machineryEngineering

The invention discloses a vacuum quantitative filling machine comprising a main case. A hopper is arranged on the main case; a locking handle is arranged between the main case and the hopper; a main motor connected with a pump body is arranged on the main case; a torsion motor is connected to the pump body; a storage box is arranged on the main case; a vacuum pump is arranged on one side of the storage box, and an air inlet is formed in the one side of the vacuum pump; an electrical box is arranged on the main case; the main case is further covered with a protecting body and a pedal plate; and a connecting piece is arranged in the connection position of the main motor and the pump body. Automatic quantitative portioning and automatic twisting can be achieved, and fat oxidization can be effectively prevented; by additionally arranging the protecting body on the main case, the operation sound of the device is effectively isolated; and the connecting piece is arranged in the connecting position of the main case and the pump body, so that the noise of machine impacting is effectively reduced, device damage and impacting abrasion which are caused by machine impacting are avoided, and operation of the vacuum pump is guaranteed to the maximum extent.

Owner:湖南嘉圣农业科技发展有限公司

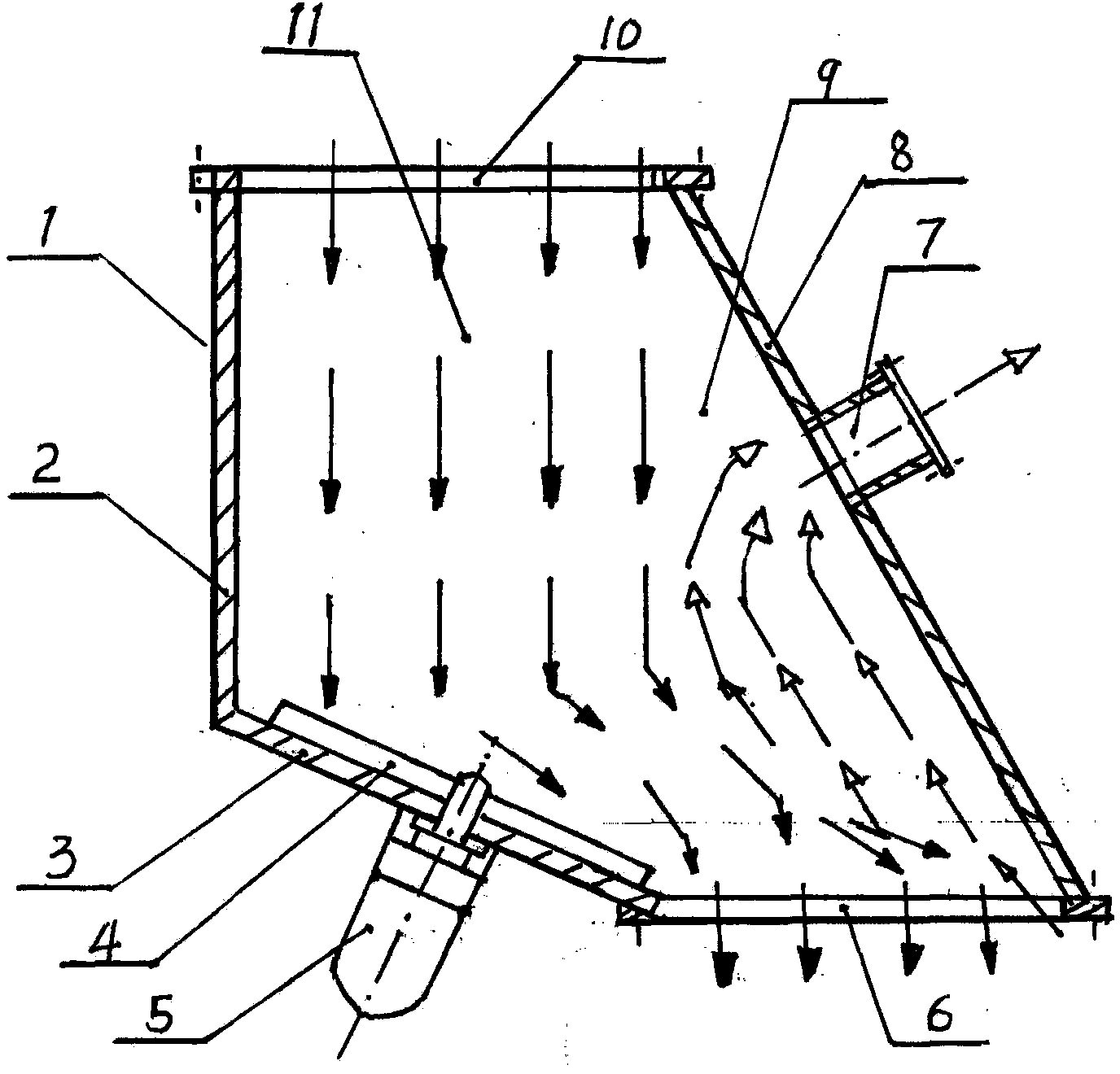

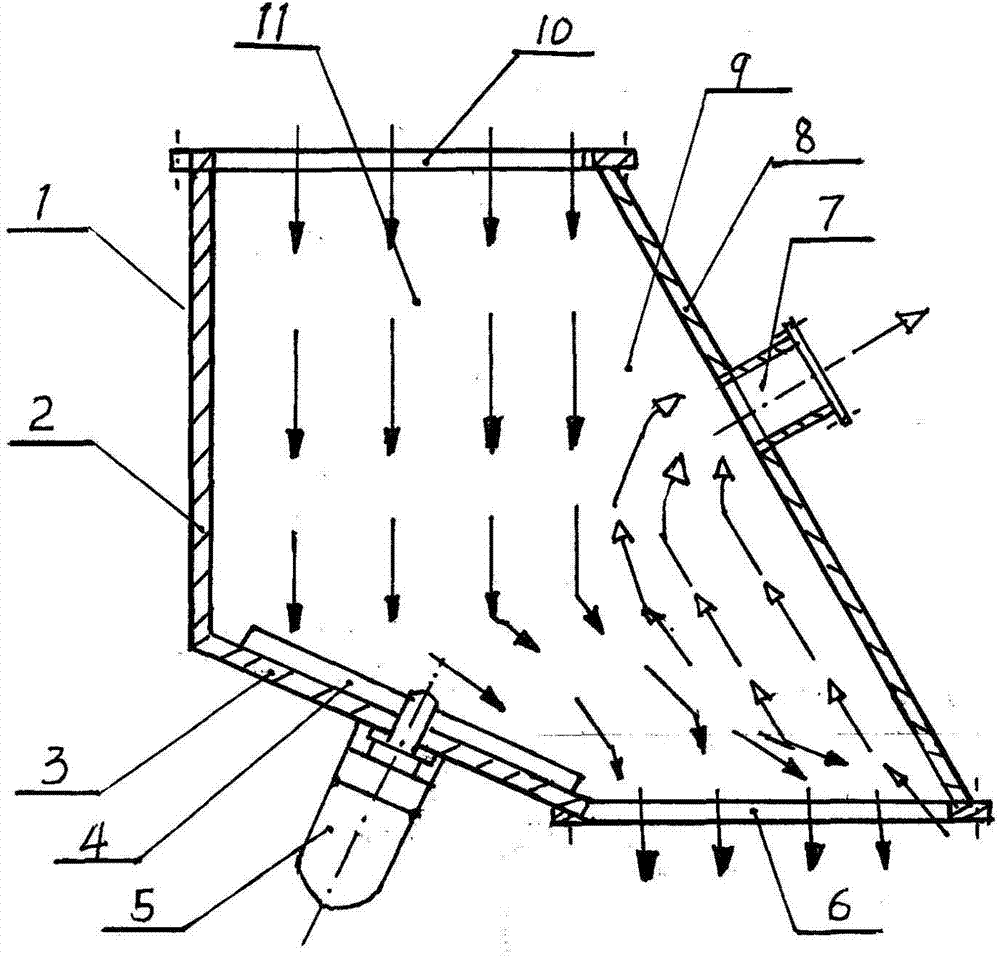

'Three-prevention' blanking pipe

ActiveCN103449155AReduce wearPrevent material cloggingConveyor partsEngineeringMechanical engineering

The invention belongs to the field of material conveying machinery, and provides a 'three-prevention' blanking pipe. The 'three-prevention' blanking pipe is mainly characterized in that a pipe body of the blanking pipe is a pentahedral pipe body and is provided with three vertical side plates, one inclined side plate and one inclined lower plate; a rotary blade is arranged above the inclined lower plate; and a dust collecting mouth is formed in the inclined side plate. Compared with the existing material articulated chute, the 'three-prevention' blanking pipe has the remarkable advantages of novel structure, ingenious design, capability of effectively solving three disadvantages of the material articulated chute, wear prevention, blockage prevention and raising dust prevention.

Owner:张玉伟

Adsorption type working platform

The invention discloses an adsorption type working platform which comprises a fixed table, a workbench, a forward moving cylinder and a forward moving positioning assembly. The fixed table is providedwith a sliding rail, the forward moving cylinder is arranged on the fixed table, the forward moving cylinder drives the workbench to slide front and back along the sliding rail, and the front side ofthe workbench is provided with the forward moving positioning assembly for improving operation stability. The forward moving positioning assembly is provided with a buffer plate and a vacuum adsorption head. The workbench is buffered in the forward in-place moving process, impact abrasion is avoided, a workpiece is adsorbed to a component on the trip destination of the front side of the workbenchafter in place for positioning, the workpiece can be fed or discharged or carried to a next station conveniently, stability of machining on the workbench is ensured, and product precision is improved.

Owner:苏州康普雷森精密机械有限公司

'Three-prevention' blanking pipe

ActiveCN103449155BAvoid cloggingFree from direct impact wearConveyor partsEngineeringMechanical engineering

The invention belongs to the field of material conveying machinery, and provides a 'three-prevention' blanking pipe. The 'three-prevention' blanking pipe is mainly characterized in that a pipe body of the blanking pipe is a pentahedral pipe body and is provided with three vertical side plates, one inclined side plate and one inclined lower plate; a rotary blade is arranged above the inclined lower plate; and a dust collecting mouth is formed in the inclined side plate. Compared with the existing material articulated chute, the 'three-prevention' blanking pipe has the remarkable advantages of novel structure, ingenious design, capability of effectively solving three disadvantages of the material articulated chute, wear prevention, blockage prevention and raising dust prevention.

Owner:张玉伟

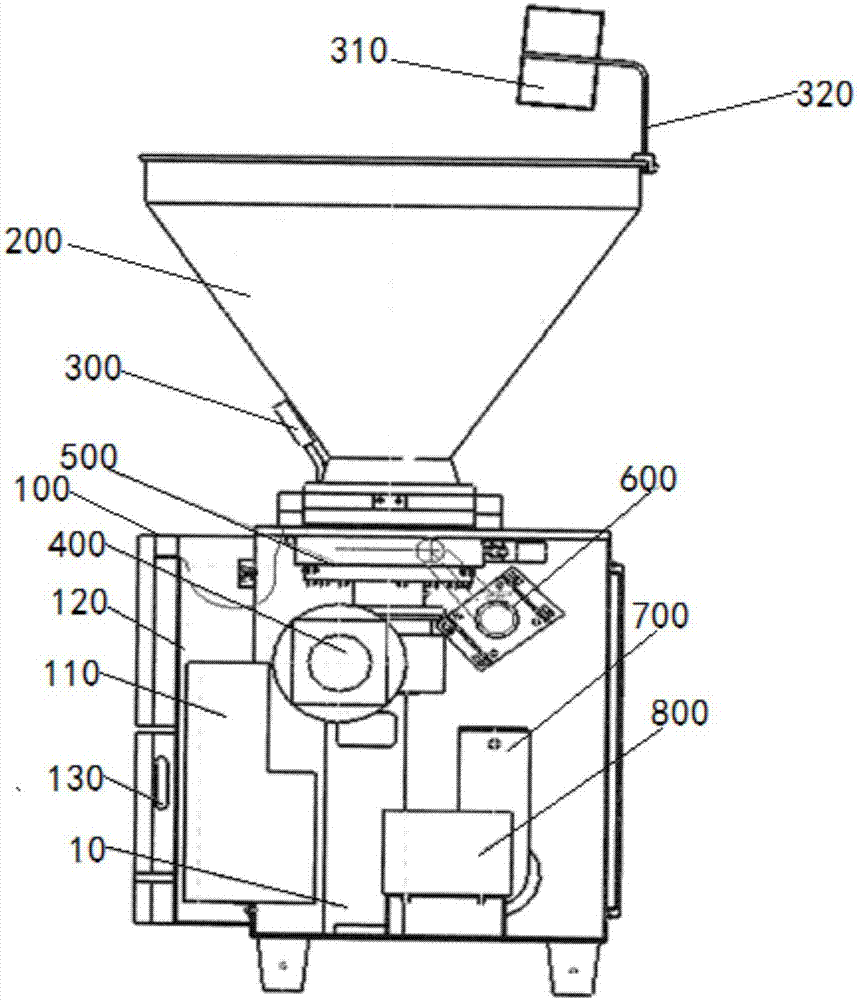

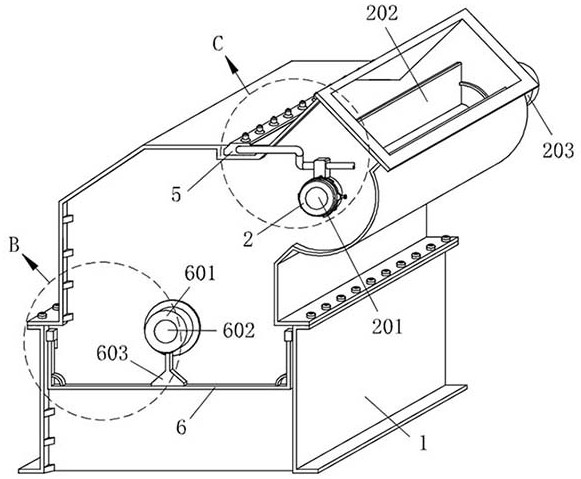

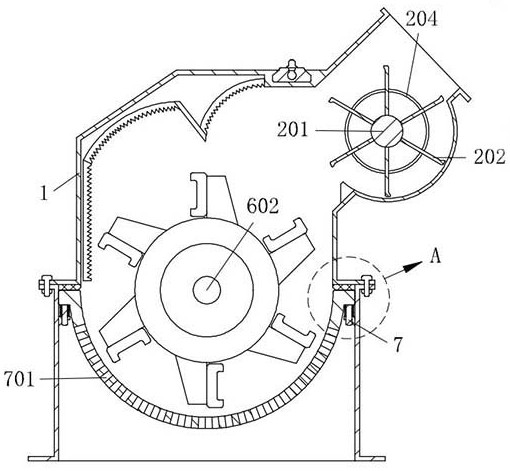

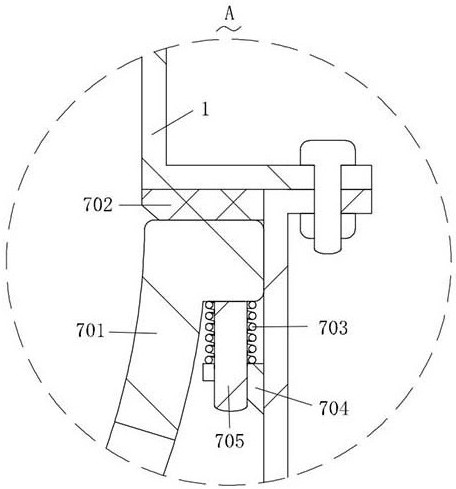

Horizontal fine crusher with material control assembly

The invention relates to the technical field of fine crushers, in particular to a horizontal fine crusher with a material control assembly, which comprises a fine crusher body, a feeding mechanism is mounted on the fine crusher body, a protection mechanism is mounted on the feeding mechanism, a control mechanism is connected to the protection mechanism, a dust removal mechanism is mounted on the fine crusher body, and the dust removal mechanism is connected to the control mechanism. A discharging mechanism is mounted on the fine crusher body, and a shaking mechanism is connected to the fine crusher body; the feeding amount can be controlled through the feeding mechanism, stone bullets are prevented from being ejected, under the action of the protection mechanism and the control mechanism, one-way rotation control over the feeding mechanism is facilitated, material overflow caused by reverse rotation is prevented, follow-up cleaning is facilitated, the dust removal mechanism is controlled through work of the feeding mechanism, and the dust removal efficiency is improved. And through cooperation of the discharging mechanism and the shaking mechanism, fine crushed gravel can be well guided out, and the discharging mechanism is prevented from being stuck and blocked.

Owner:徐州铭山路桥机械设备制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com