Patents

Literature

43results about How to "Reduce tangential force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rolling bearing

InactiveUS20030040442A1Reaction can be suppressedImprove fatigue strengthLiquid carbonaceous fuelsThickenersAlternatorRolling-element bearing

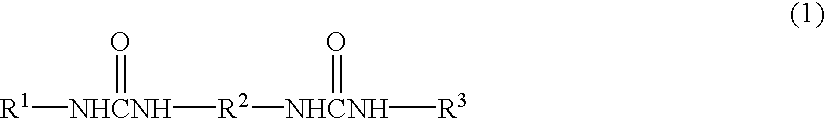

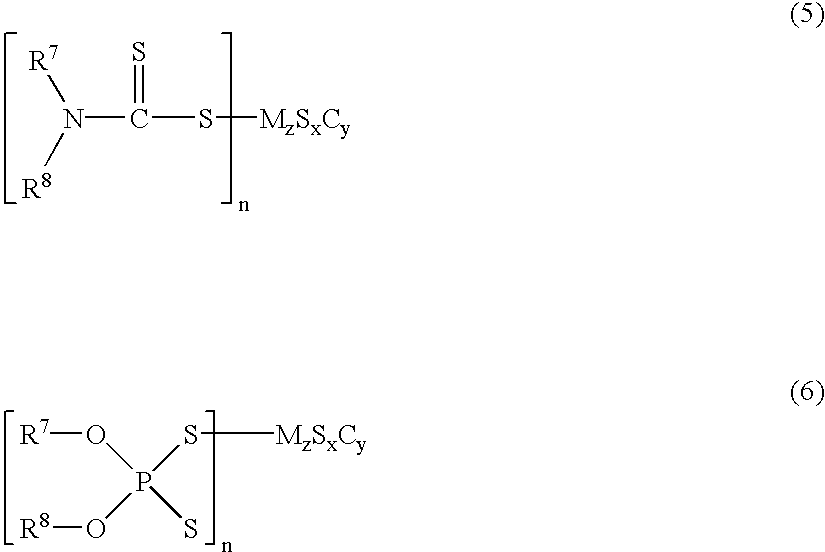

The invention aims to provide a rolling bearing that secures a sufficient bearing life economically even when used under such conditions that water from the outside or water formed by moisture condensation may seep into the lubricant or the bearing is affected by the vibrations, and particularly a rolling bearing suited to the electric parts and accessaries of au automobile engine, such as an alternator. To accomplish the object, the hydrogen ion exponent pH of the grease sealed into the inside of the bearing is adjusted in a range of from 7 to 13. For the same purpose, the hydrogen ion exponent pH of the grease is adjusted in a range of from 5 to 13 where a prescribed amount of an organic metal salt or ADTC is added to the grease, where a prescribed amount of an inorganic compound having an average particle size of 2 squarem or smaller is added to the grease, or where a diurea compound containing an aromatic amine or a mixture of the diurea compound is added to the grease as a thickener.

Owner:NSK LTD

Spherical hammer head of combined crusher and manufacturing method thereof

InactiveCN101940968AWear resistanceReduce tangential forceFoundry mouldsFoundry coresMetallic materialsStructural engineering

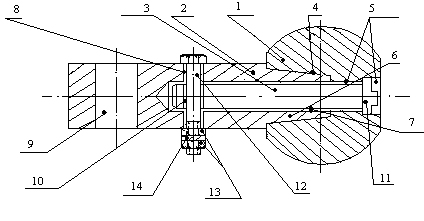

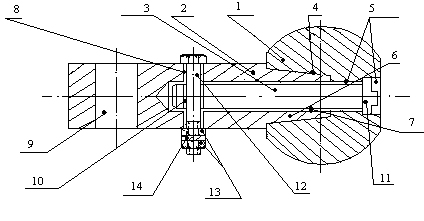

The invention discloses a spherical hammer head of a combined crusher and a manufacturing method thereof. The hammer head comprises a spherical hammer end (1) and a hammer handle (2); the spherical hammer end (1) and the hammer handle (2) are combined into the integral hammer head through a connecting rod (3); the spherical hammer end is cast by adopting an alloy high-chromium cast iron losing die; and the hammer handle is made of No. 45 round steel by a metal processing and cutting method. The spherical hammer head of the crusher has the advantages of abrasion resistance, good toughness, quick replacement of the spherical hammer end and long-term use of the hammer handle, improves the production efficiency, saves the metal material, and is particularly suitable for manufacturing hammer heads of reversible small and medium hammer crushers.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

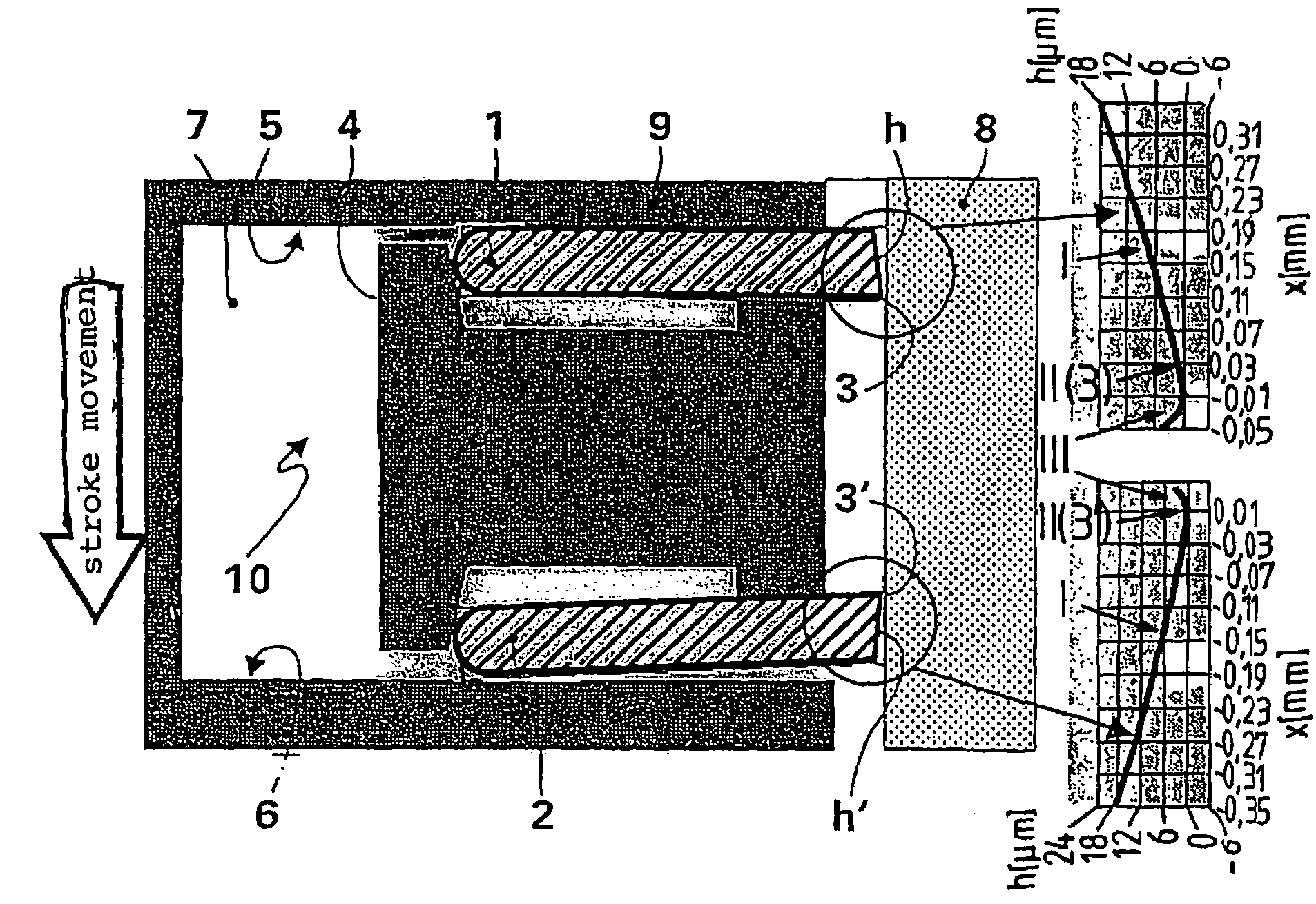

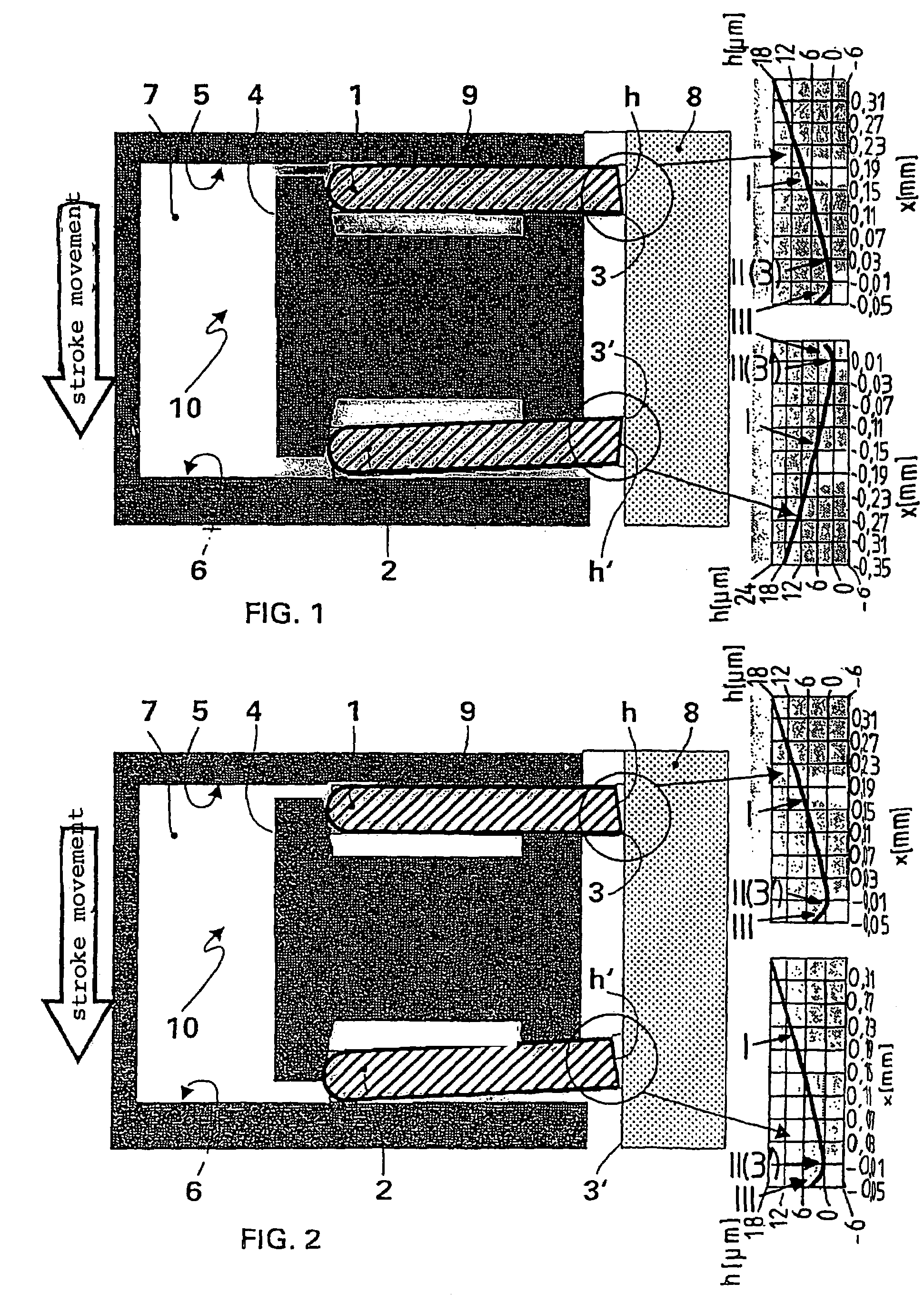

Multipart oil wiping ring for pistons of internal combustion engines

ActiveUS7306232B2Good oil control effectReduce wearPiston ringsBraking action transmissionCombustionExternal combustion engine

A multipart oil wiping ring for pistons of internal combustion engines comprises two steel strip-type lamellae with parallel sides, the running surfaces of which are provided with a convexly asymmetric shape having a vertex line that extends across the circumference of the lamellae, and a bracing spring located between the lamellae. The bracing spring presses the lamellae in an axial direction against one respective side of an annular groove in the piston and in a radial direction against the cylinder wall.

Owner:MAHLE GMBH

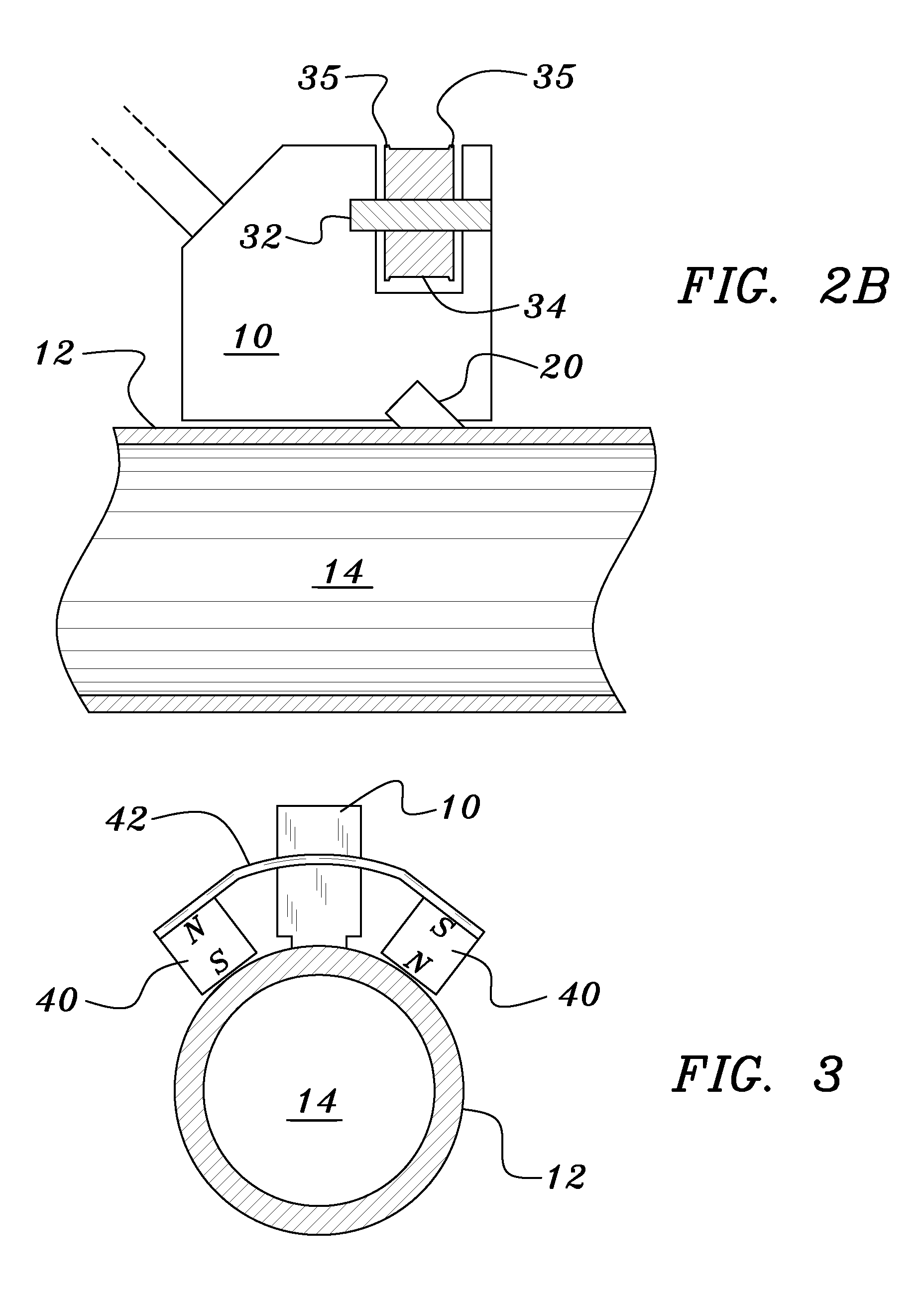

Flowmeter transducer magnetic clamping

InactiveUS8151651B1Reduce tangential forceIncrease pressureVolume/mass flow measurementHaberdasheryMagnetic tension forceCoupling

Owner:ONICON INC

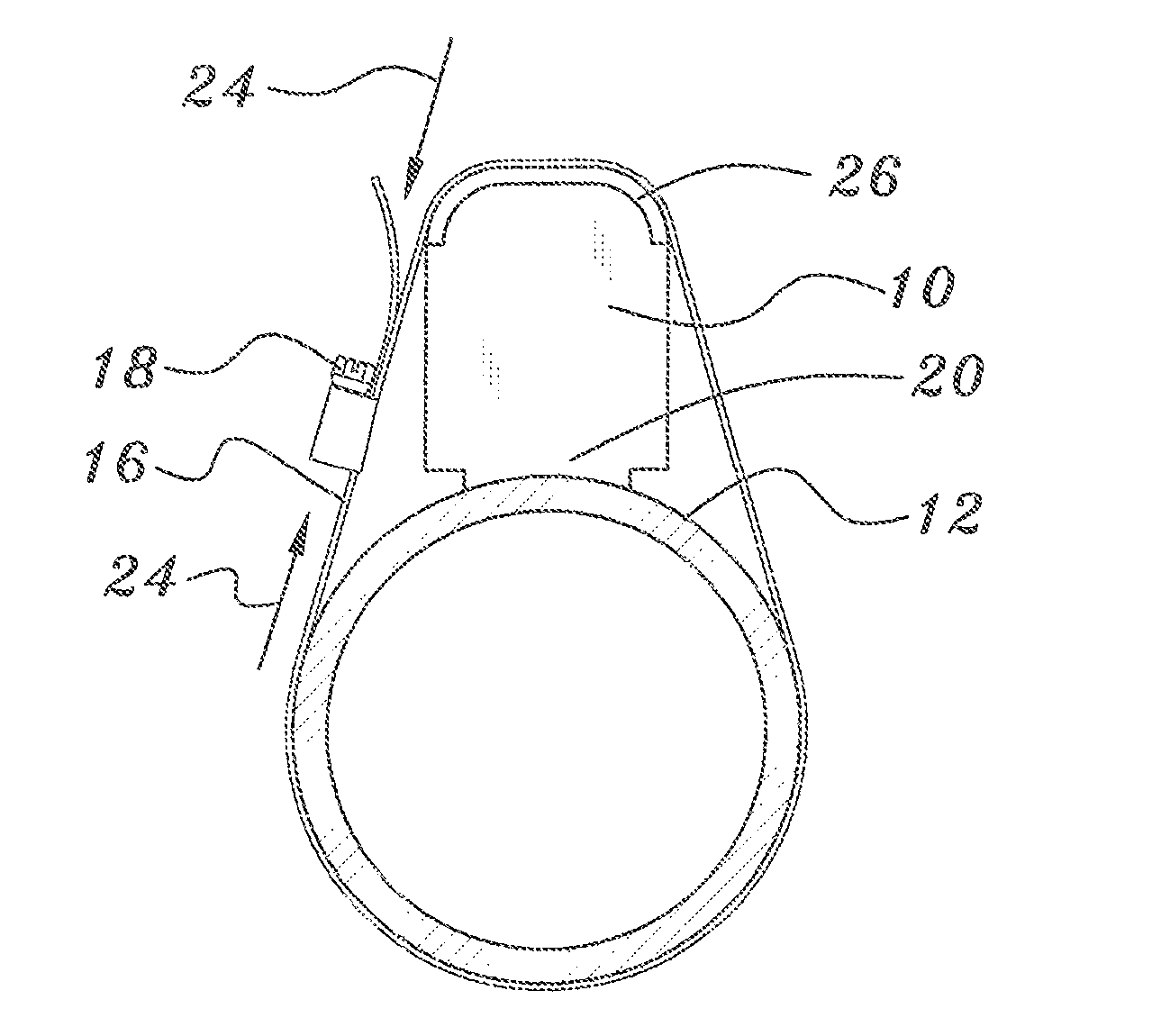

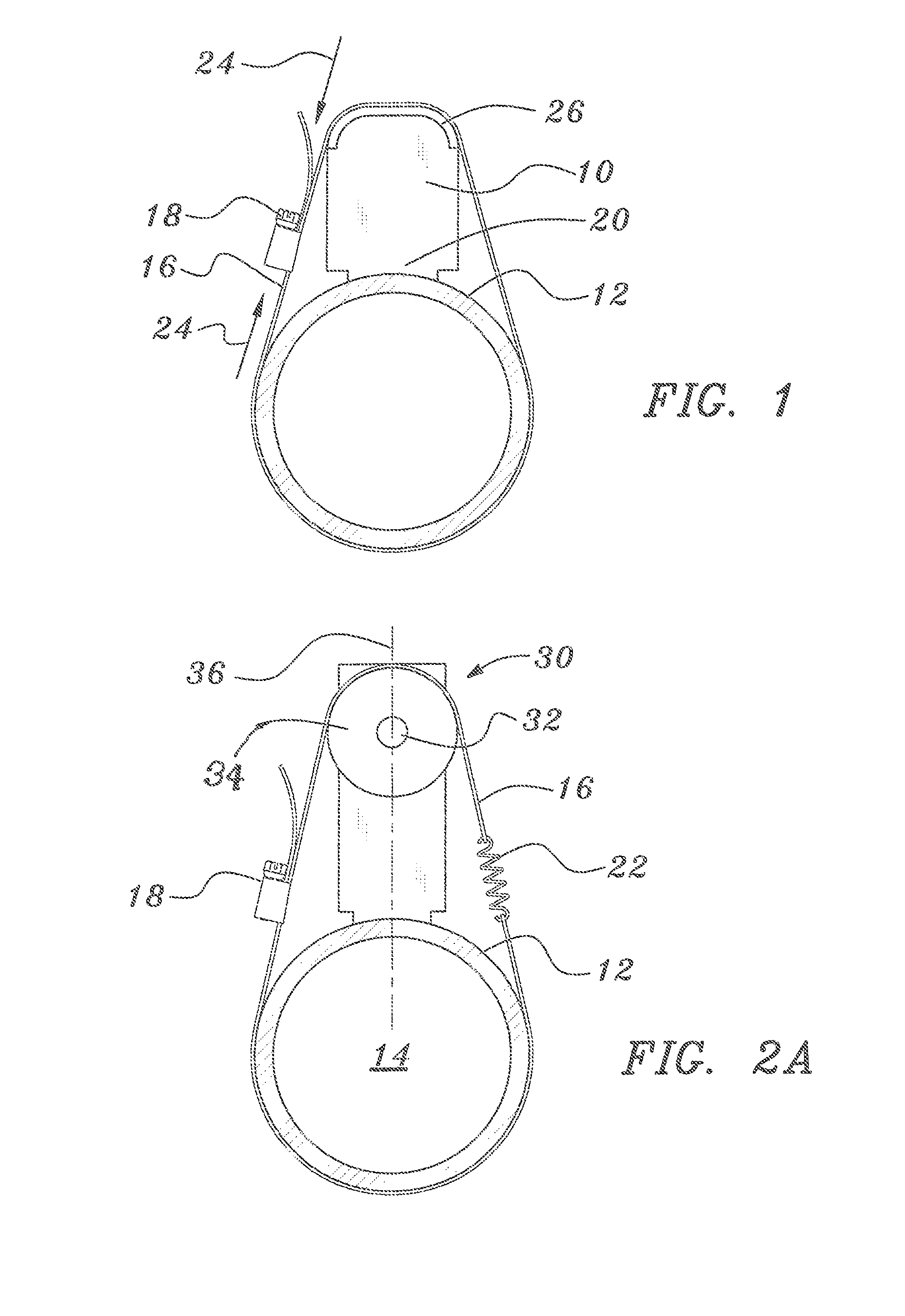

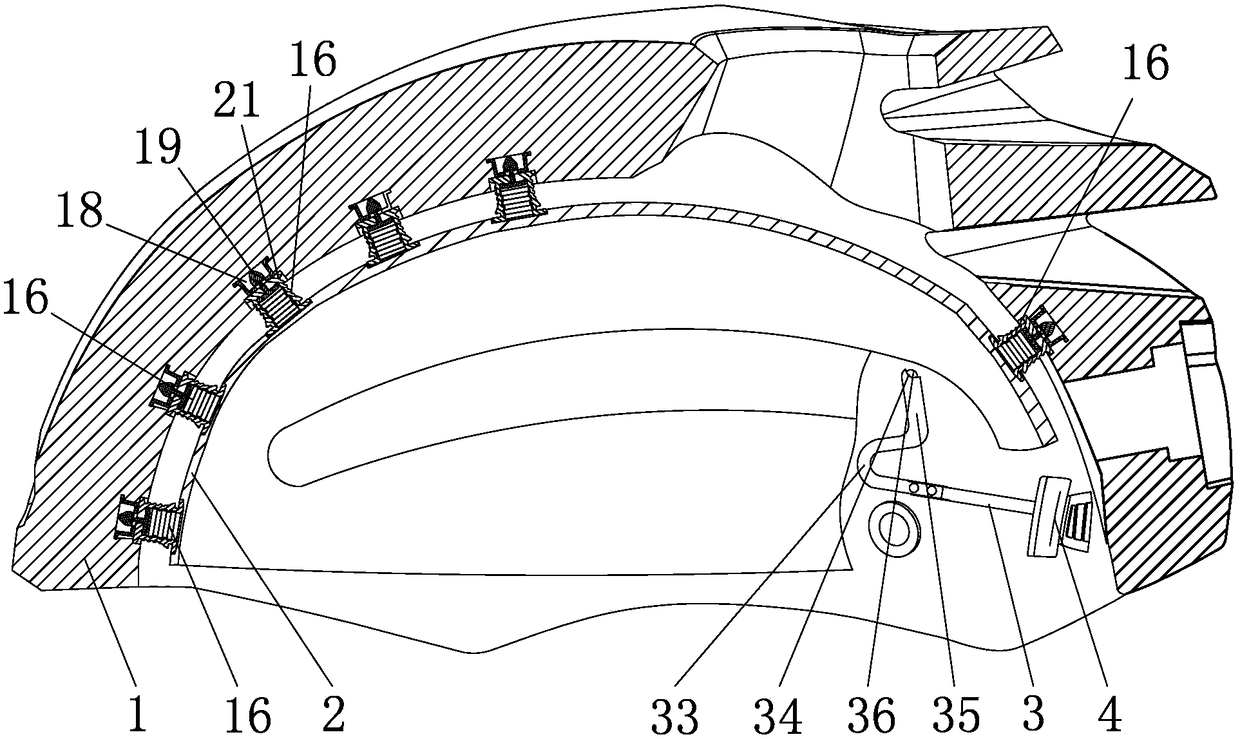

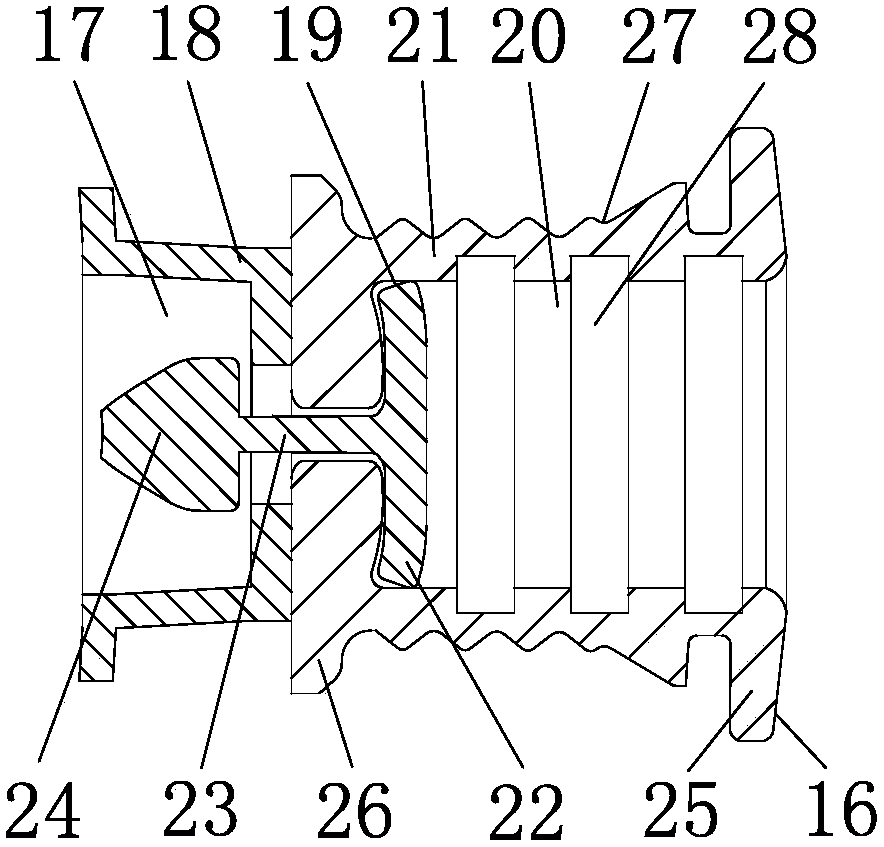

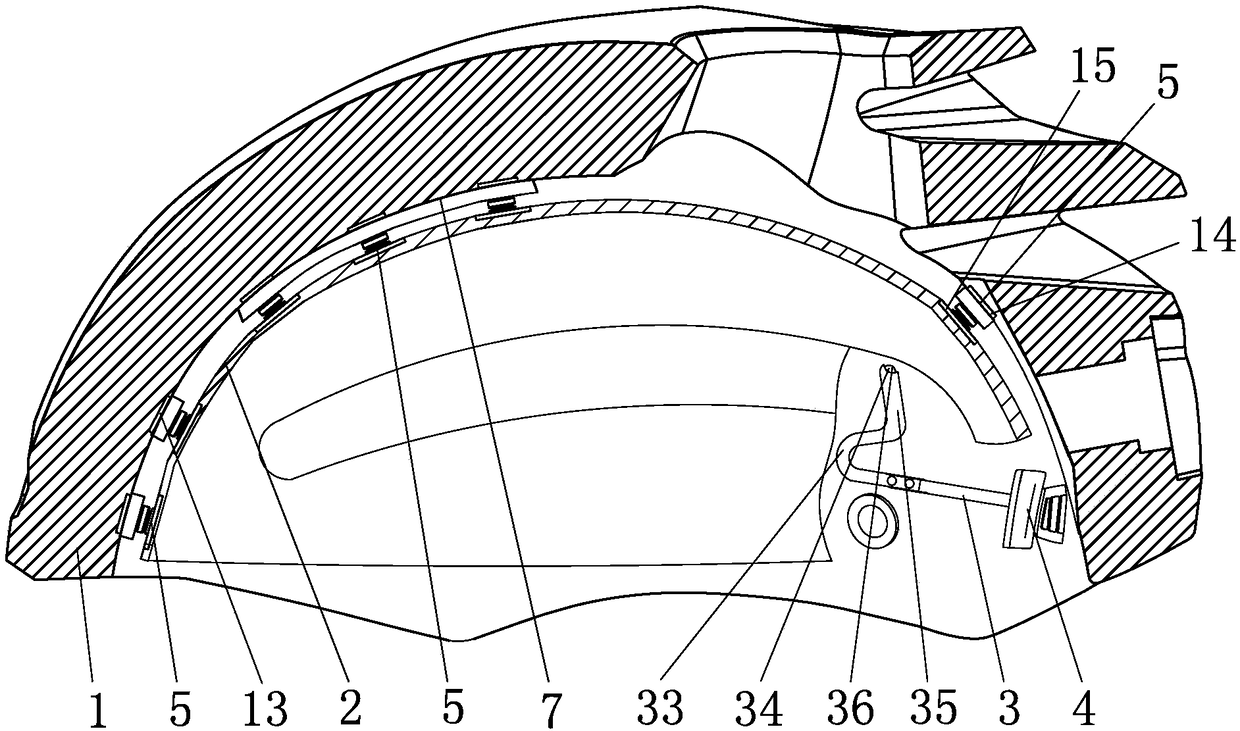

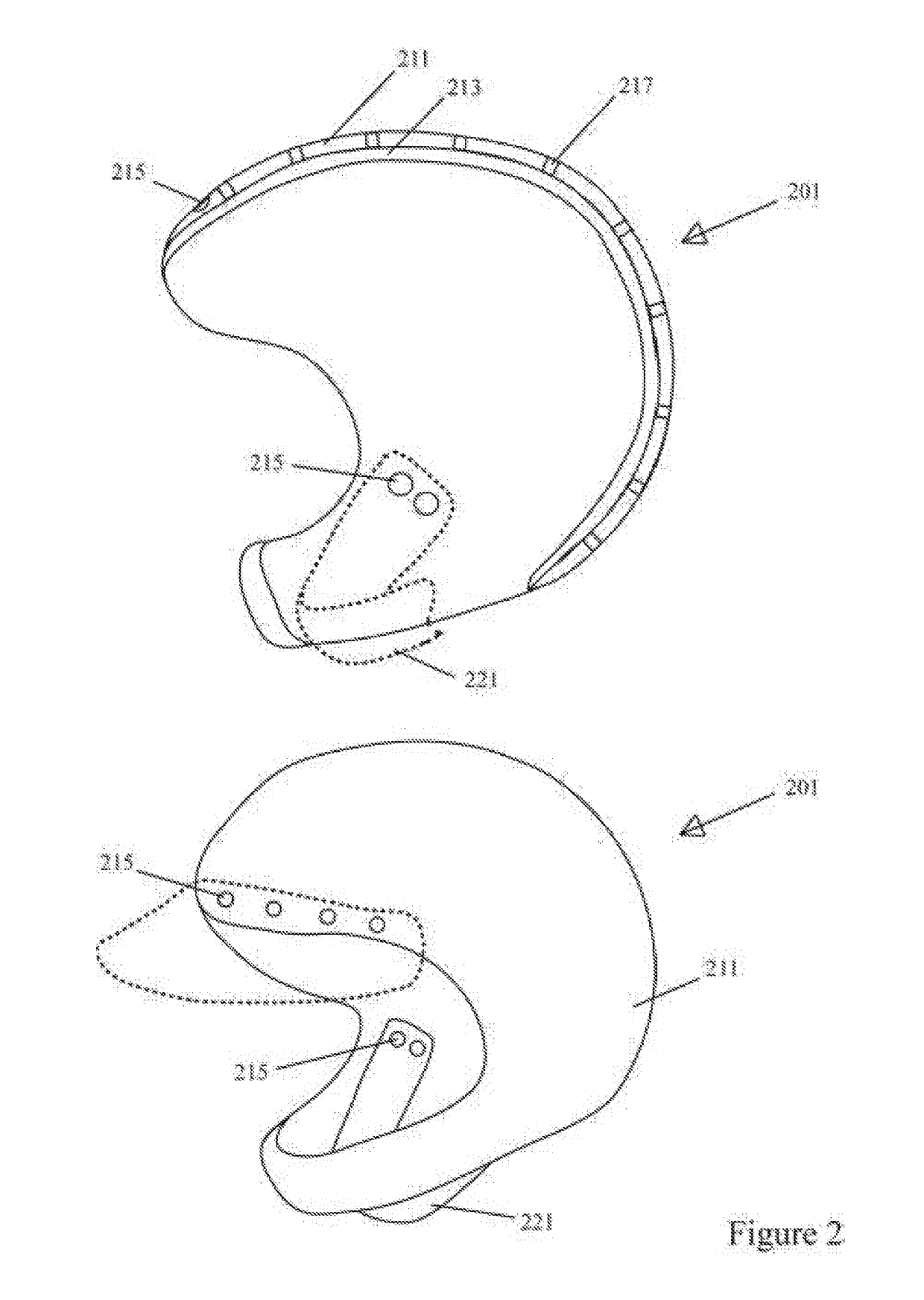

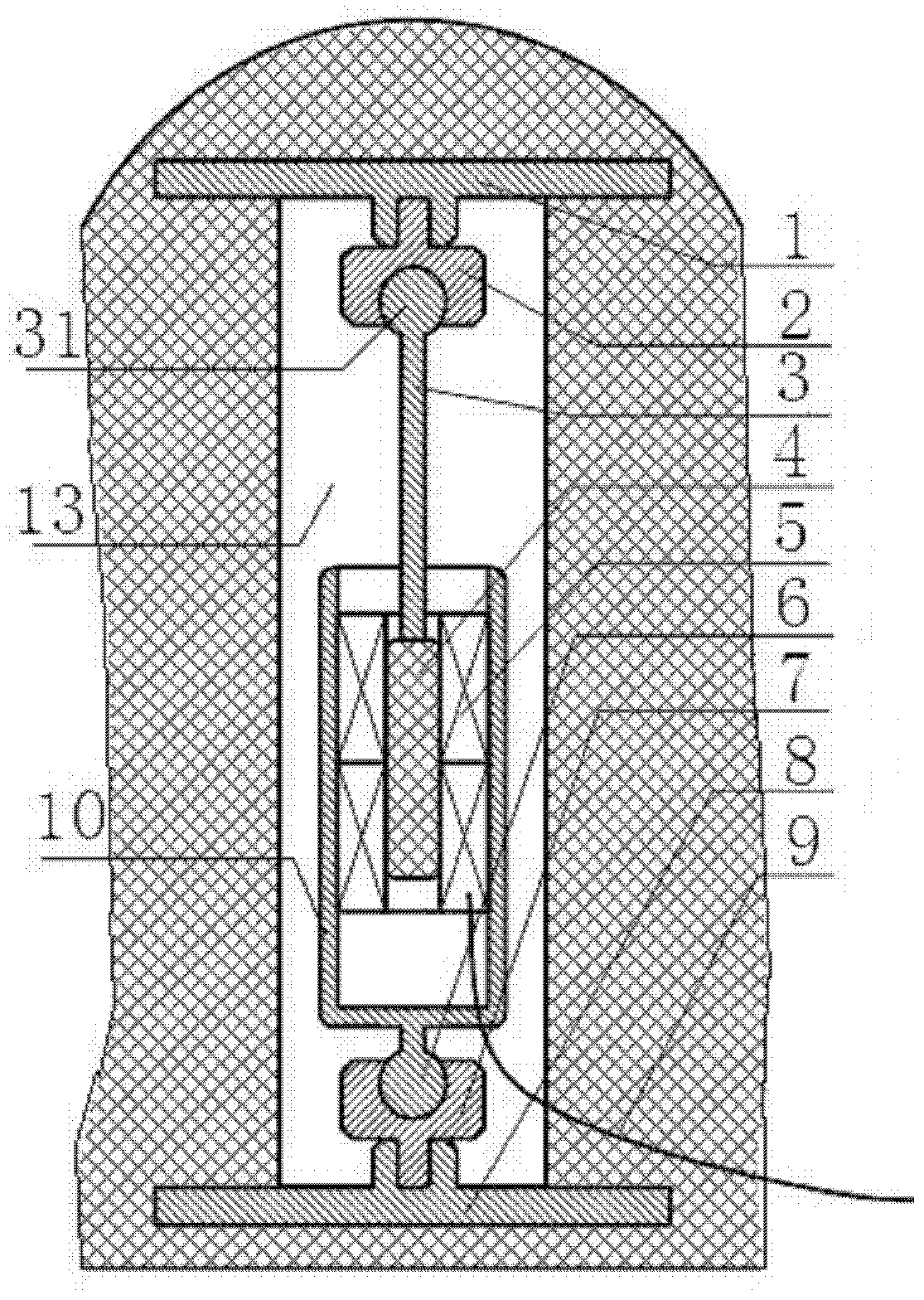

Rotary impact cushioning safety helmet

ActiveCN108294394AReduce tangential forceIncreased anti-rotational damping forceHelmetsHaberdasheryCushioningEngineering

The invention discloses a rotary impact cushioning safety helmet. The rotary impact cushioning safety helmet comprises a shell and an elastic lining in the shell, a gap is formed between the shell andthe elastic lining, and a rotary impact cushioning device which makes the shell rotate relative to the elastic lining is arranged between the shell and the elastic lining. When the safety helmet is impacted by external force, the upward component force in the external force, which tangentially acts on the shell, makes the shell tend to rotate relative to the elastic lining. By means of the rotaryimpact cushioning safety helmet, through the tangential deformation of the rotary impact cushioning device, the shell can rotate by a certain angle relative to the elastic lining on the premise thatthe elastic lining relatively stays still, and accordingly, the cushioning effect that the impact of the external force on a user is greatly reduced is achieved.

Owner:古正煇

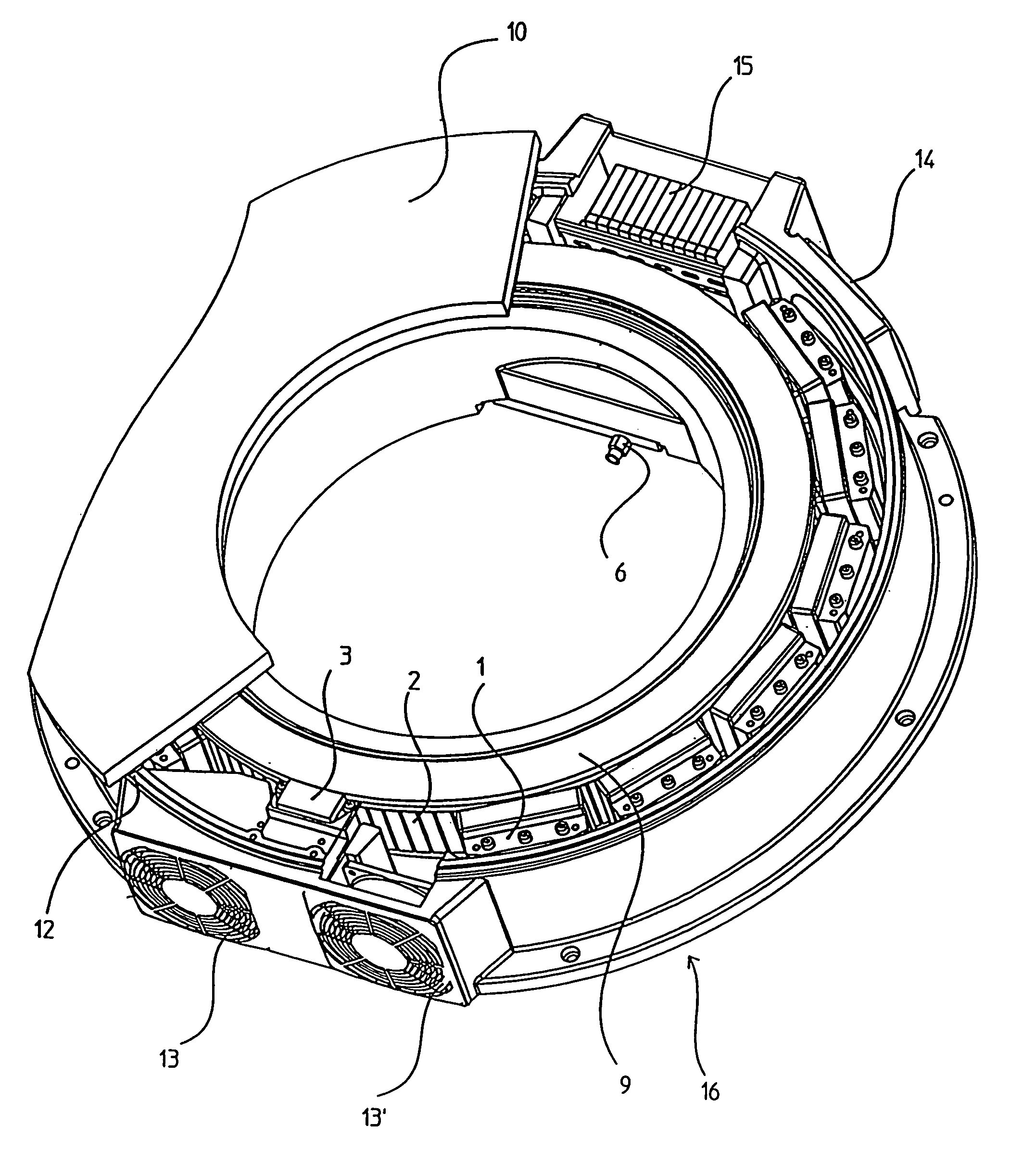

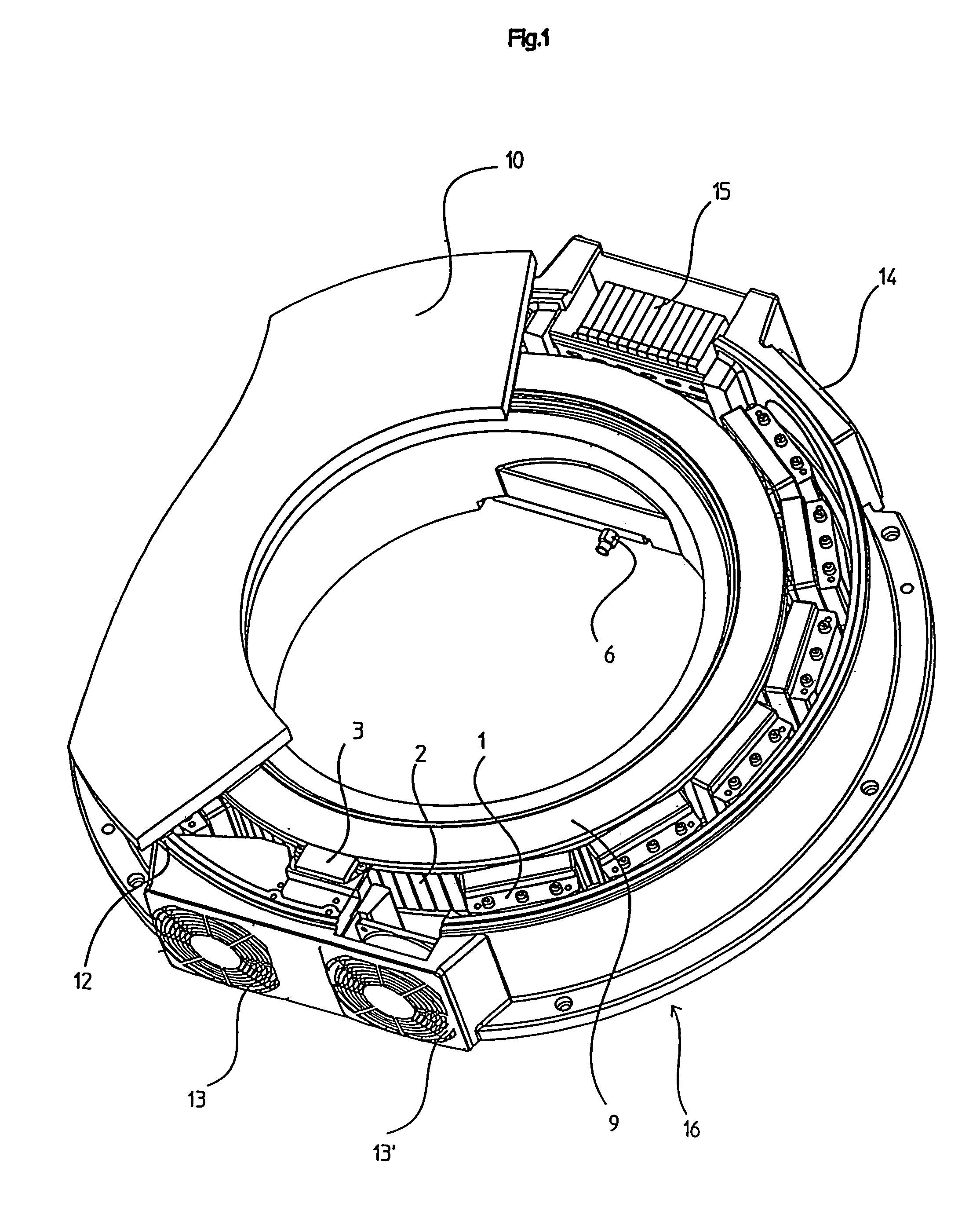

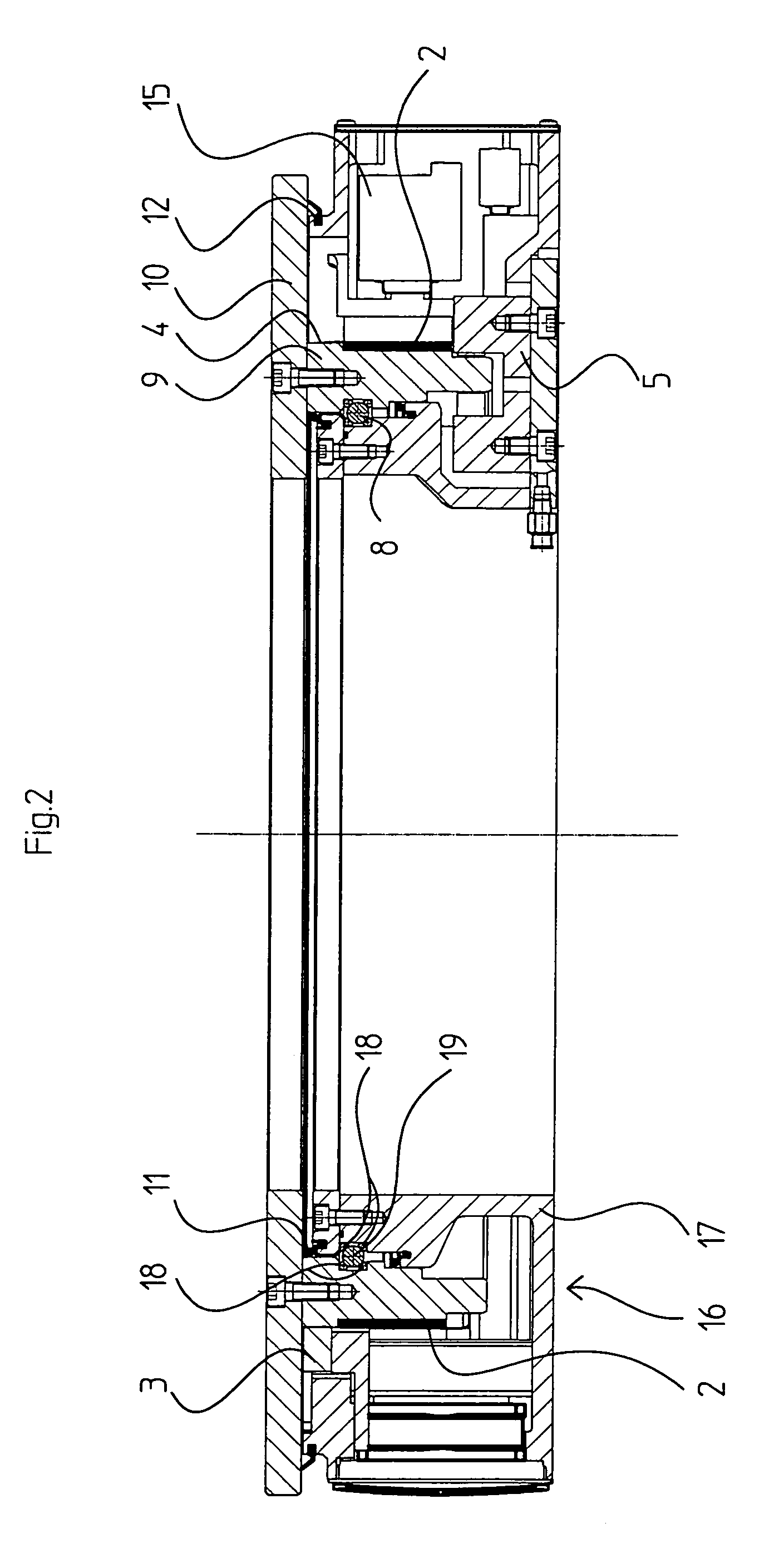

Rotary indexing table

ActiveUS7154243B2Low economic effortReduce power consumptionPrecision positioning equipmentElectric controllersEngineeringDriven element

Owner:WEISS SONDERMASCHENTECHN

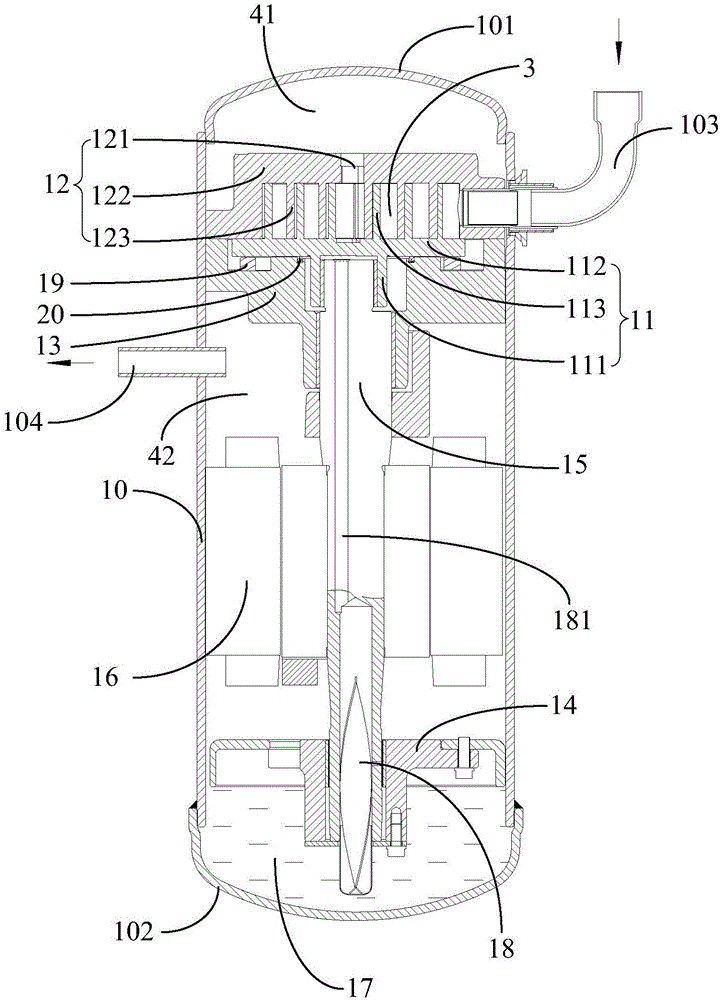

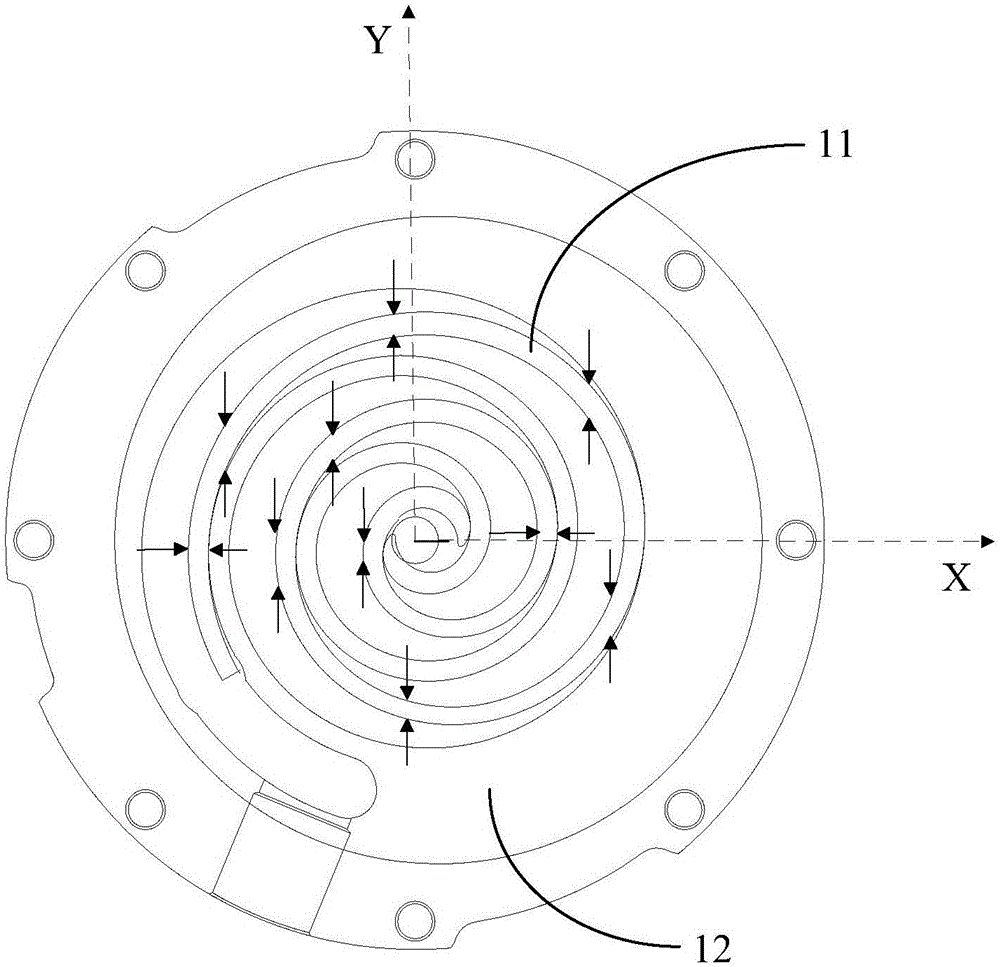

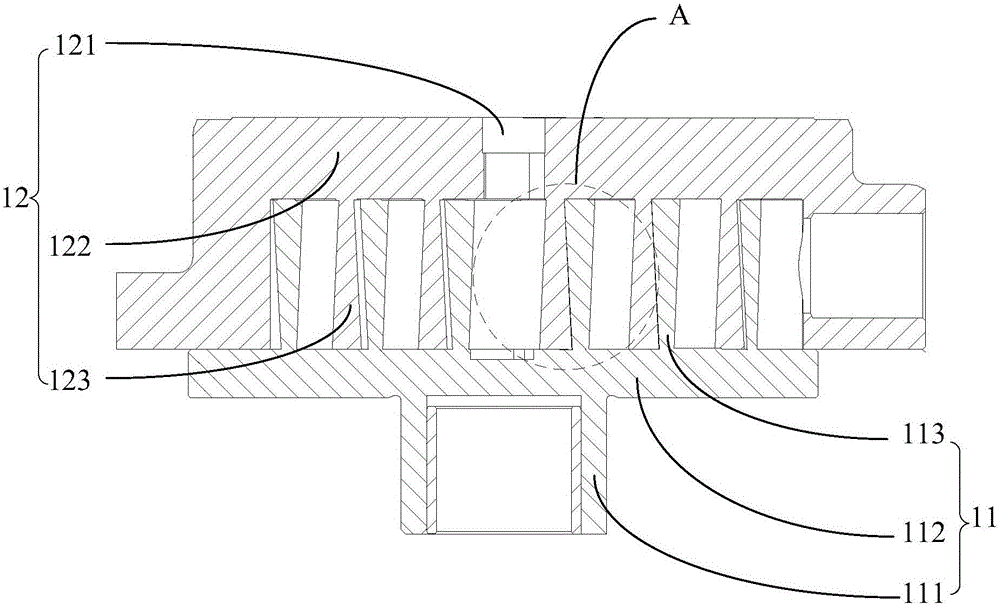

Scroll plate, scroll compressor and air conditioner

InactiveCN106438369AReduce frictional power consumptionImprove reliabilityRotary piston pumpsRotary piston liquid enginesEngineeringMechanical engineering

The invention discloses a scroll plate of a scroll compressor. The scroll plate comprises a plate body, and a scroll tooth projected on the plate body, wherein the wall thickness of the scroll tooth is gradually changed in the projection direction of the scroll tooth. The invention further discloses a scroll compressor with the scroll plate, and an air conditioner provided with the scroll compressor. The scroll plate can reduce the force thereof in the radial direction and the axial direction, so that the friction power consumption of the scroll compressor is reduced, and the reliability of a crankshaft bearing is improved.

Owner:GUANGDONG MIDEA ENVIRONMENTAL TECH CO LTD

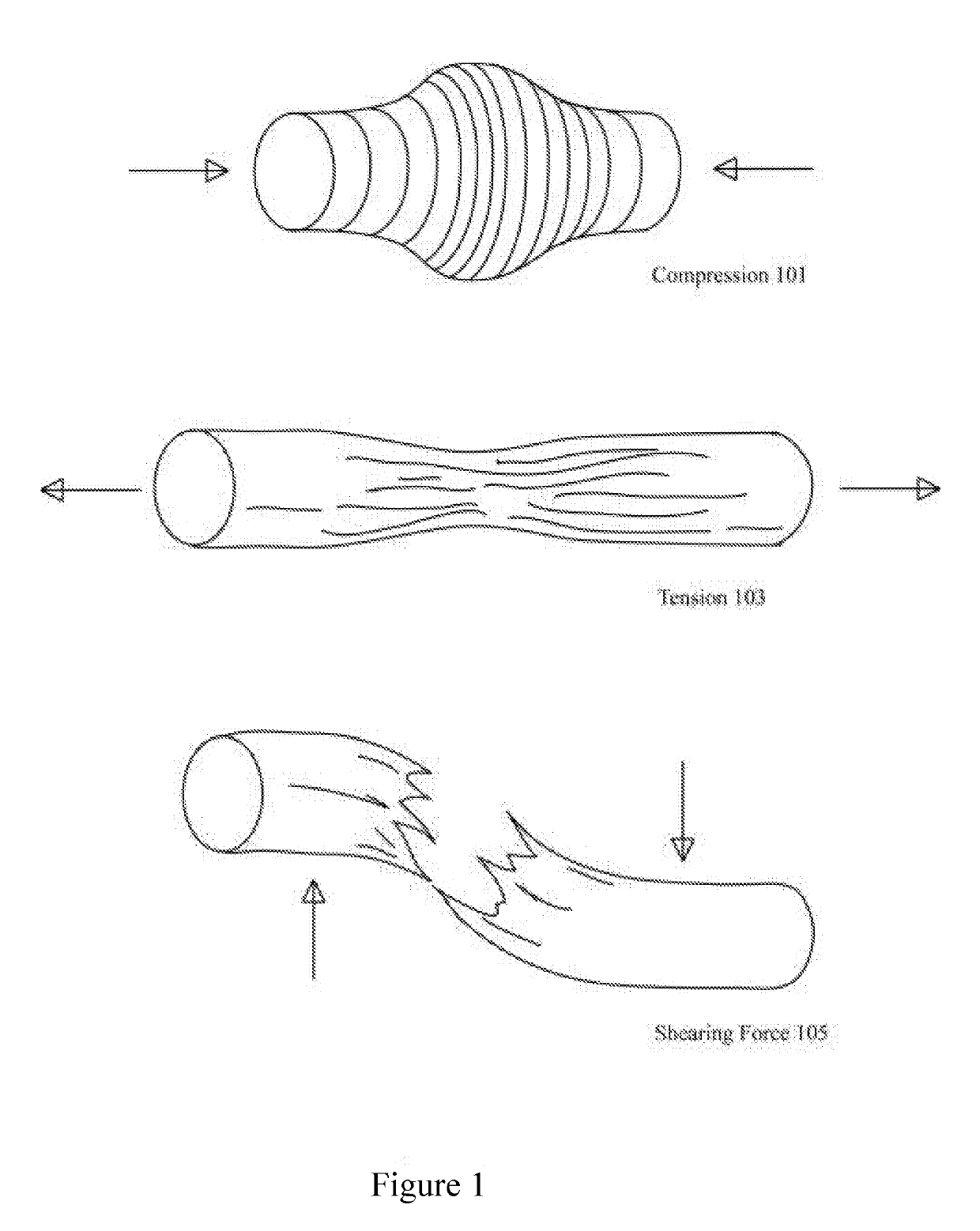

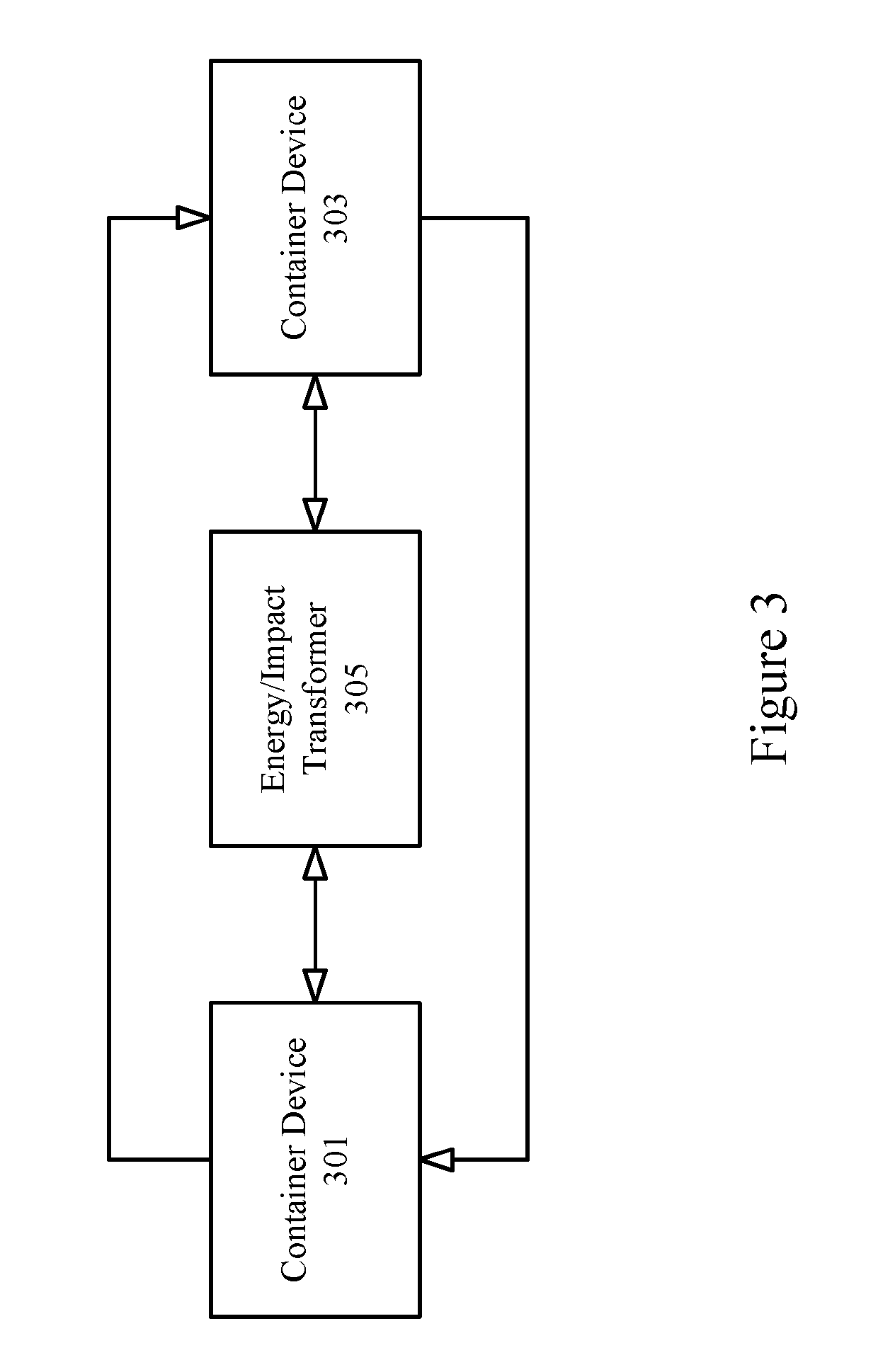

Outer padding assembly for biomechanics aware headgear

Protective gear includes an outer shell layer connected to a middle shell layer through an outer energy and impact transformer layer. A padding assembly can be provided over the outer shell layer. The padding assembly can include a padding layer configured to absorb forces normal to the outer shell. The padding assembly can be coupled to the outer shell via an interface layer that allows the padding layer to slide over the outer shell layer in response to tangentially applied forces. The interface layer and associated sliding motion can reduce the tangential forces transmitted through the padding layer to the outer shell while still allowing normal forces to be absorbed. The protective gear may be formed as helmets or body protection for various activities and protect users from not only impact and penetrative forces, but rotational and shear forces as well.

Owner:BRAINGUARD TECH

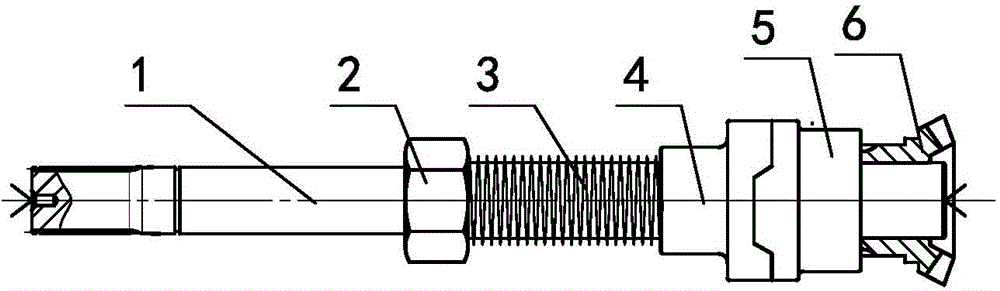

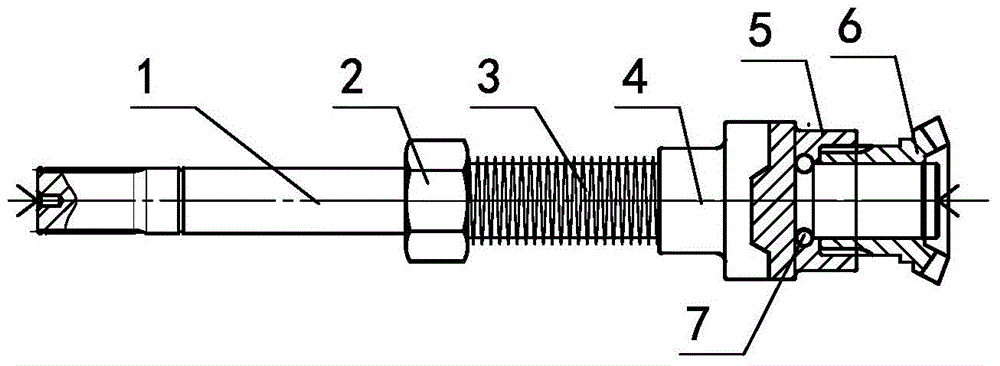

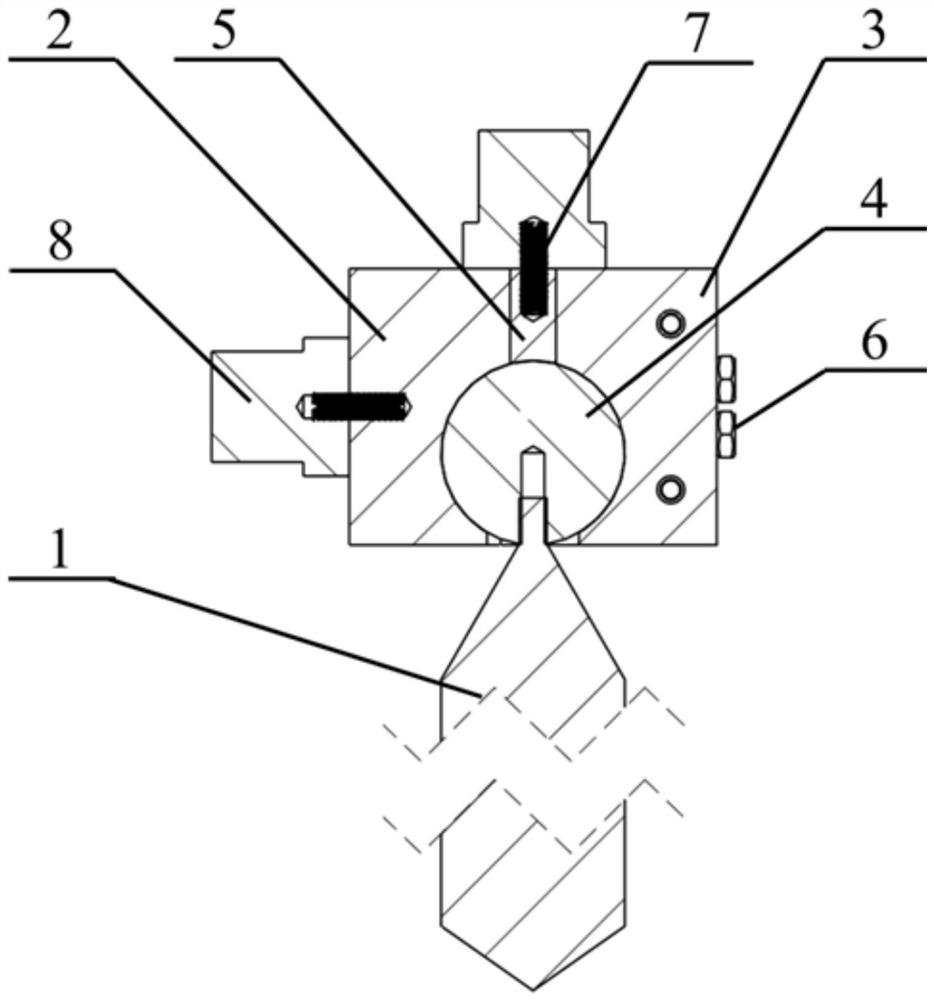

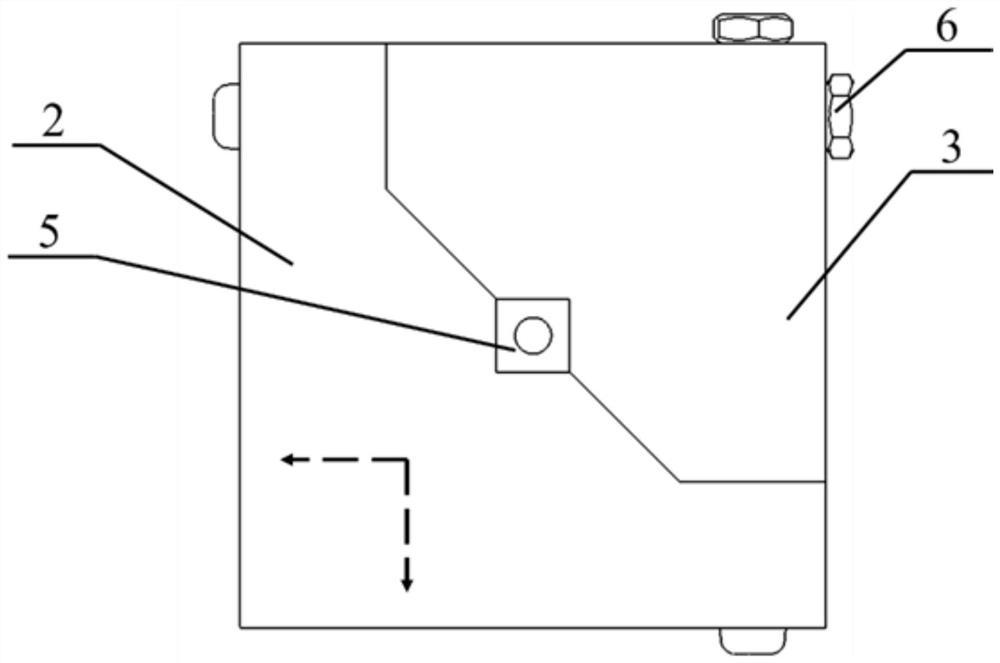

Overload protection clutch used for shaft connection

InactiveCN105351382ASimple structureIncrease the force contact areaSlip couplingAutomatic clutchesEngineeringConical teeth

The invention relates to an overload protection clutch used for shaft connection, and belongs to the technical field of connectors. The overload protection clutch used for shaft connection comprises a horizontal shaft and conical teeth arranged on the shaft in a penetrating mode, and the shaft and the conical teeth are independent; the shaft is sleeved with a nut in a threaded connection mode; a first clutch body used for axial power transmission is installed on the part, on the right side of the nut, of the shaft, the part, between the first clutch body and the nut, of the shaft is sleeved with a spring, the left end of the spring abuts against the nut, and the right end of the spring abuts against the first clutch body; a second clutch body capable of freely rotating around the shaft is installed on the part, on the right side of the first clutch body, of the shaft and connected with the first clutch body in a matched mode through a clutch claw; the second clutch body and the shaft are transversely positioned through built-in balls, and the left ends of the conical teeth are connected with the second clutch body through a spline. The overload protection clutch used for shaft connection is simple in structure and large in stress contact area, the tangential force is reduced, transmission is more stable, and overload protection is achieved.

Owner:CHONGQING HANYUAN MACHINERY

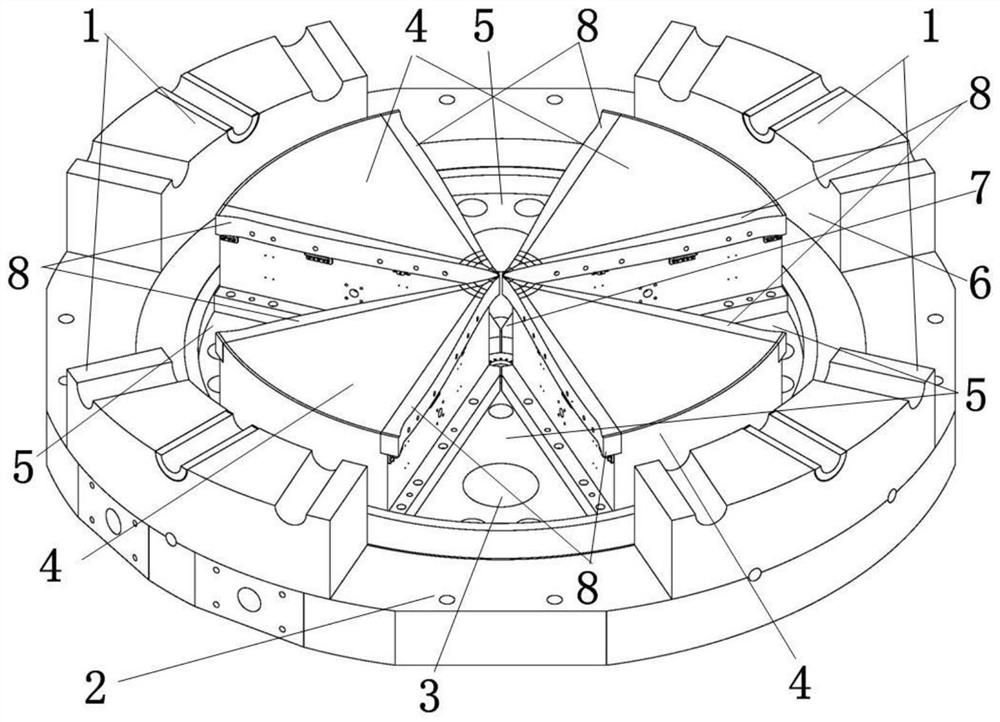

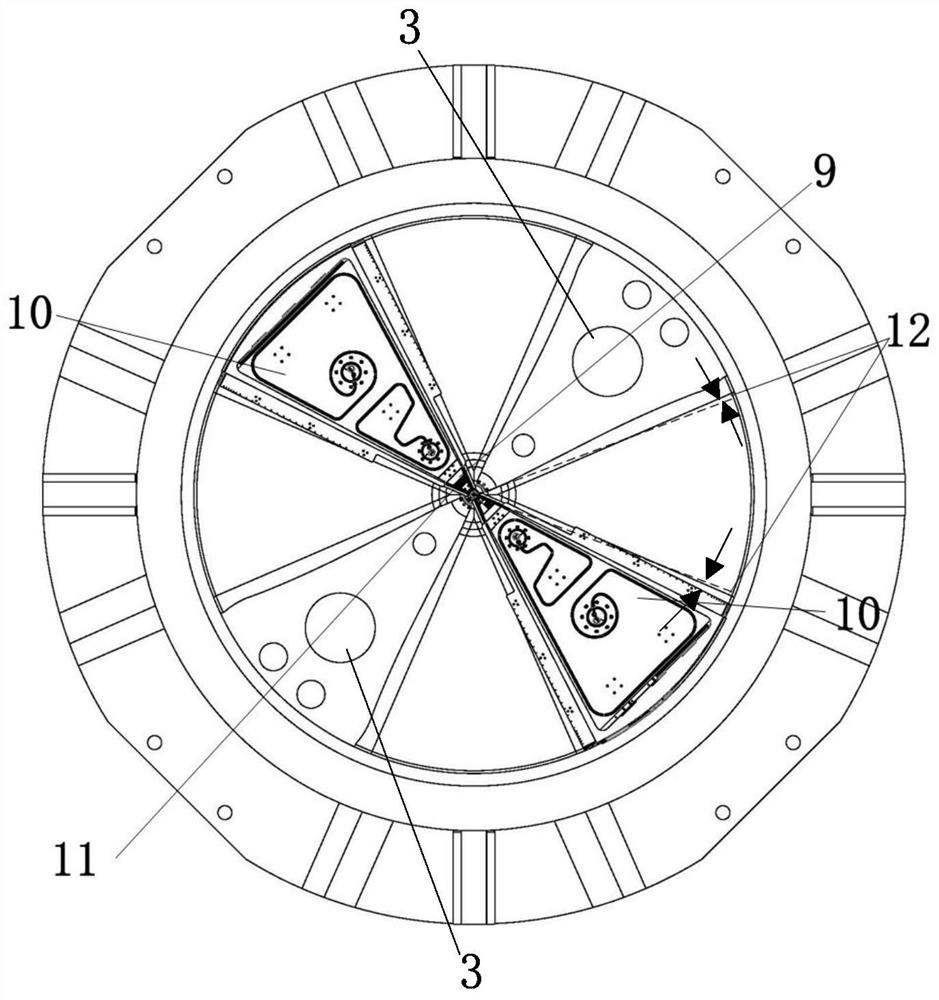

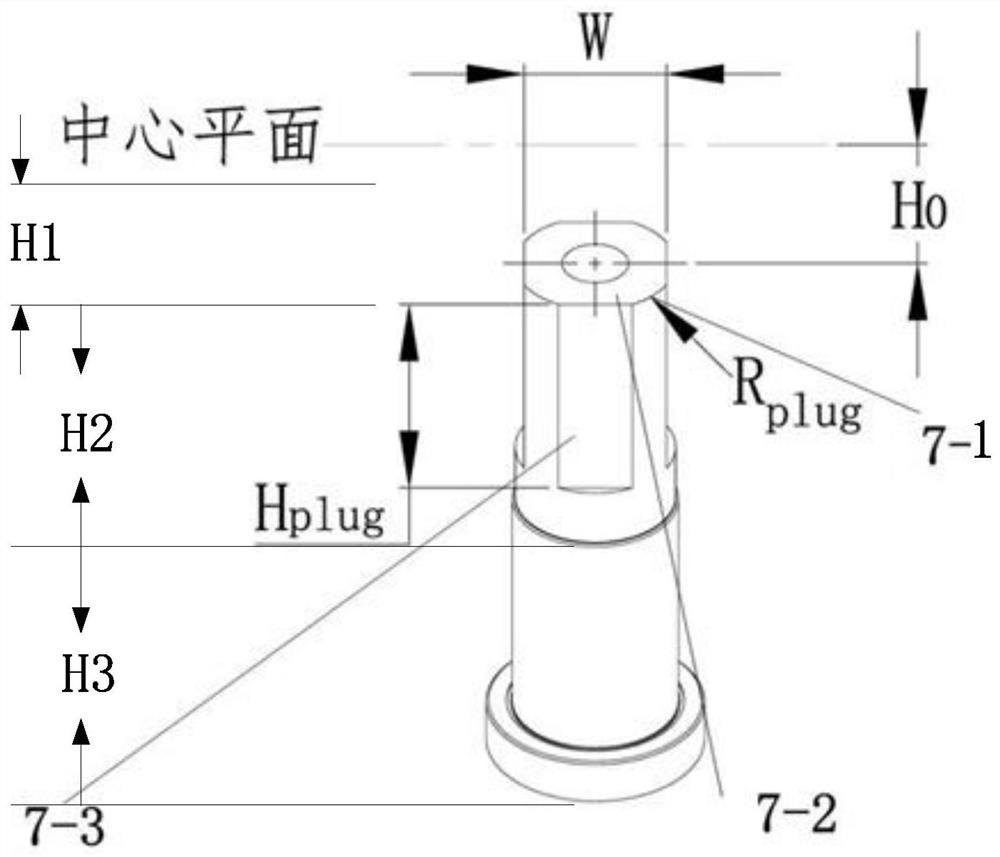

Compact medium-energy negative-hydrogen high-current isochronous cyclotron straight-side fan main magnet

ActiveCN112216468AImprove the problem of high frequency ignitionImprove running stabilityElectromagnets without armaturesNuclear energy generationCentral planeEngineering

The invention discloses a compact medium-energy negative-hydrogen high-current isochronous cyclotron straight-side fan main magnet which is characterized in that the intersection point of two straightsides of each straight-side fan-shaped magnetic pole does not radially coincide with the central point of a cover plate, and the intersection point is positioned on the circumference of the central area of the cover plate; the circle center of the arc at the tail part of each straight-side fan-shaped magnetic pole is strictly overlapped with the center of the cover plate, and the radius at the fan-shaped magnetic pole side of each straight-side fan-shaped magnetic pole is smaller than the curvature radius of the arc at the tail part of the fan-shaped magnetic pole; the reduction of the large-radius angular width of a panel is enough larger than the arc length of the magnetic pole of the main magnet increased at the large radius, so that the total angular width of the magnetic pole at thelarge radius and the panel is reduced compared with an existing structure, namely, alpha is reduced, and accordingly, the modulation degree and the focusing force are increased; alpha is the proportion of the fan-shaped magnetic pole of the magnet and the panel on the central plane and in the circumferential direction. By adjusting the proportional relation between the radius of the fan-shaped magnetic pole and the curvature radius of the arc at the tail of the fan-shaped magnetic pole and combining the modes of adjusting the magnetic pole panel outline and the like, magnetic field variable-gradient focusing is convenient to introduce.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

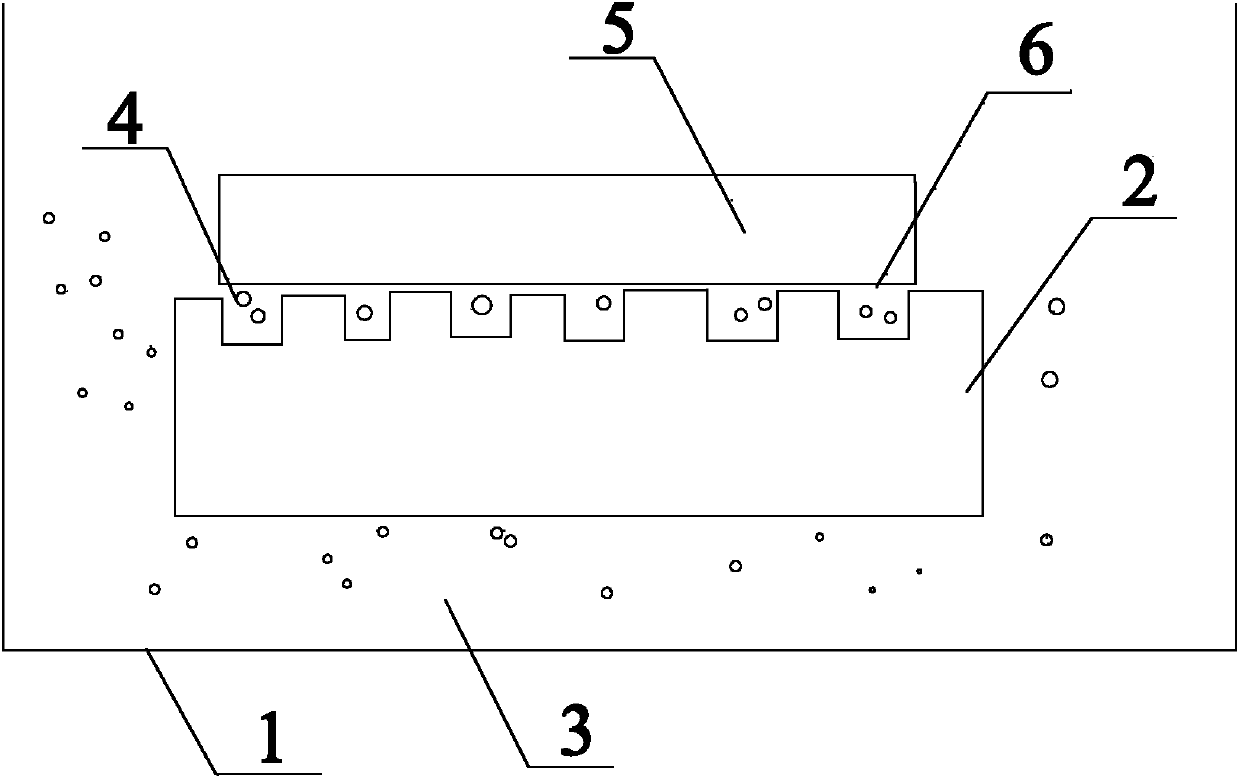

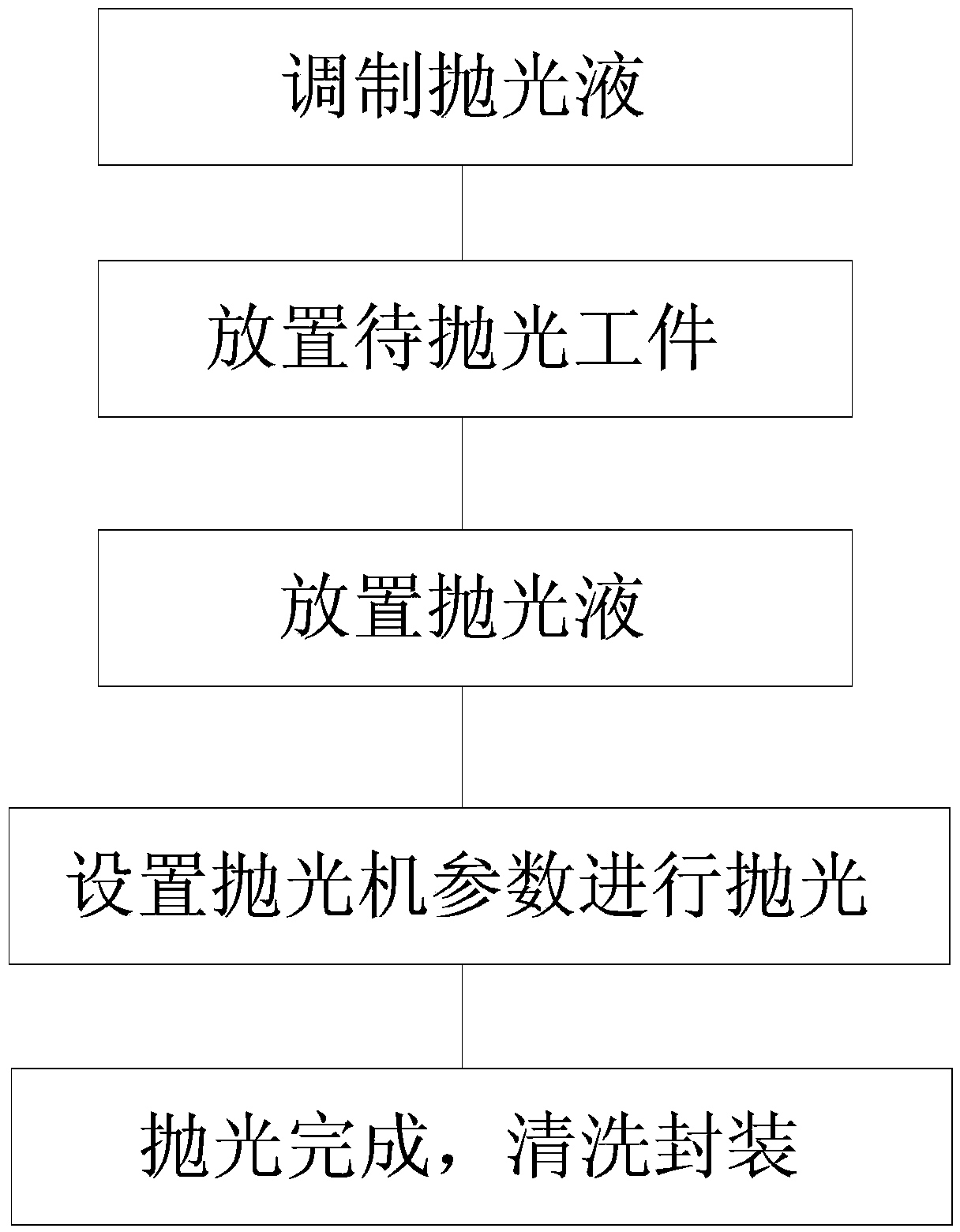

Novel float polishing equipment and polishing method

InactiveCN103737452ASolve the plating problemMake the most of chemistryOptical surface grinding machinesPolishingSurface roughness

The invention provides novel float polishing equipment and a polishing method. The problem that the surface roughness and the precision of optical elements are low after the optical elements are polished by a common method in the prior art is solved. The polishing method comprises the following steps of adding water in polishing powder to obtain polishing liquid; keeping PH (power of hydrogen) of the polishing liquid in a range of 5.5-7; gently placing a workpiece to be polished on an abrasive disk and guaranteeing that the workpiece to be polished is matched with the surface of the abrasive disk; pouring the polishing liquid in a polishing plate; immersing the workpiece to be polished and the lower surface of the abrasive disk by using the polishing liquid; keeping the pressure of the polishing plate in a range of 0.07-0.12Mpa and keeping the rotating speed of the abrasive disk in a range of 10-30rpm; automatically and circularly feeding the polishing liquid to polish the workpiece to be polished; taking out the workpiece after the workpiece is polished; and cleaning and packaging the workpiece. By using the novel float polishing equipment and the polishing method, the surface roughness of optical elements can be improved to 1 nanometer Rz-0.5 nanometer Rz, the cost is reduced, and the efficiency is improved.

Owner:王成

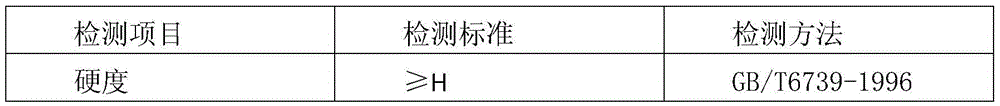

Anticorrosive coating for LED lamps

InactiveCN108285704AGood weather resistanceGood acid and alkali resistanceAnti-corrosive paintsZinc nitrideGas phase

The invention discloses anticorrosive coating for LED lamps. The anticorrosive coating comprises the following raw materials in parts by mass: 20-30 parts of waterborne acrylic resin, 10-20 parts of fluorosiloxane, 5-15 parts of zinc nitride, 1-2.5 parts of glass fiber, 5-12 parts of kaolin, 10-15 parts of far infrared ceramic nanoparticles, 1-5 parts of gaseous titanium dioxide, 10-30 parts of asolvent, 0.5-1.5 parts of a wetting and dispersing agent, 2-3 parts of an MOK-2015 leveling agent and 15-25 parts of a curing agent, wherein the solvent is a mixture of glycerol, coconut oil and ethylformate; the wetting and dispersing agent is the MOK-2030 dispersing agent; the curing agent is a waterborne isocyanate curing agent; the glass fiber is sodium calcium glass fiber with the particle size of 50-150 nm; and the sizes of the far infrared ceramic nanoparticles are 100-150 nm. Coating formed by the anticorrosive coating has excellent mechanical properties and a protective function, andalso has good waterproof and anticorrosive characteristics while radiating temperature reduction is achieved; and the anticorrosive coating is simple and convenient in production process and convenient to use.

Owner:FOSHAN YINNUOWEI BIOTECH CO LTD

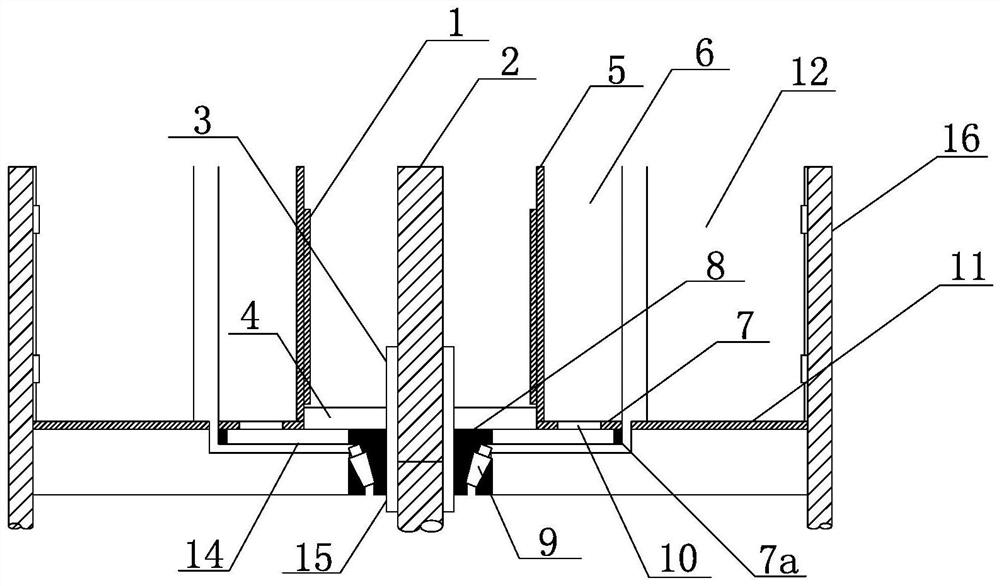

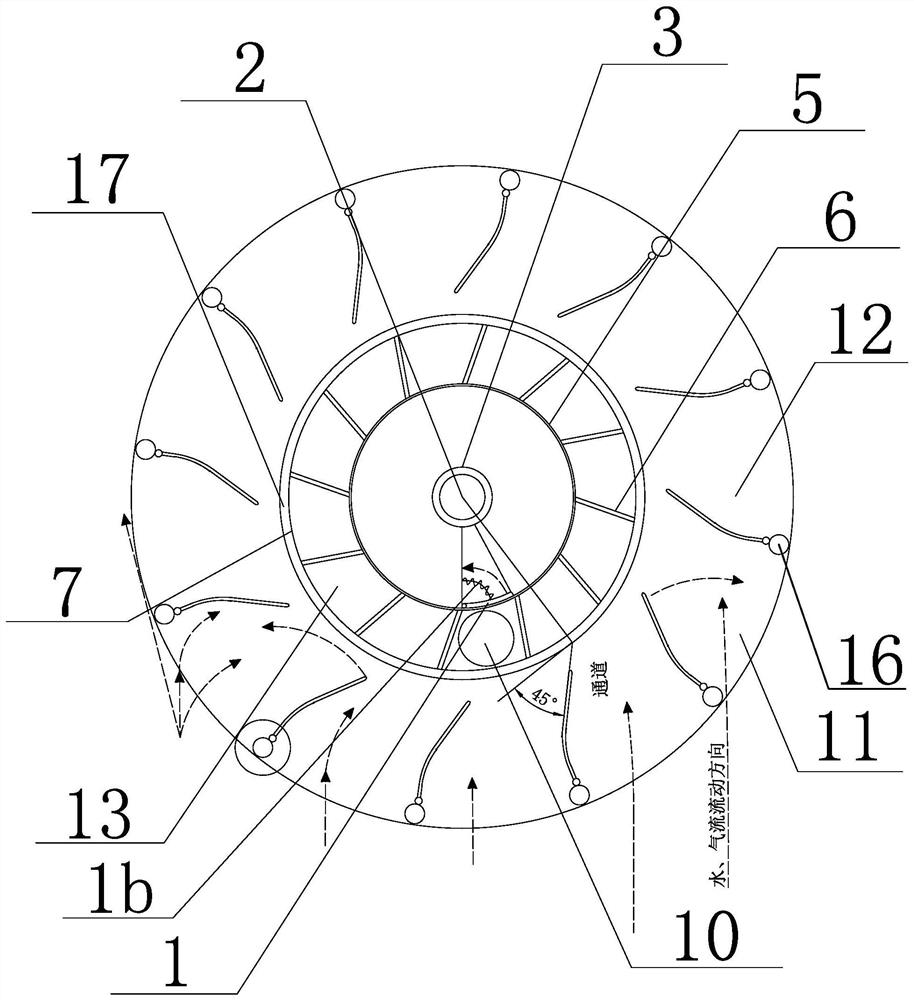

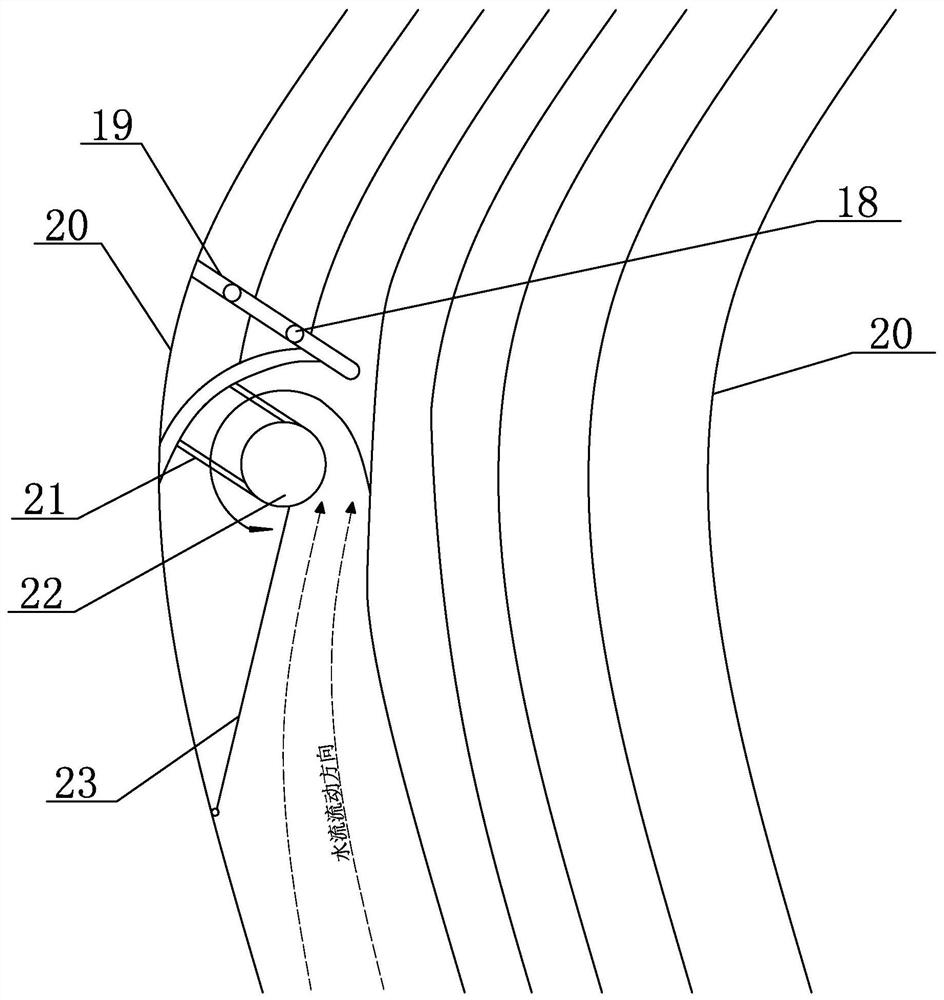

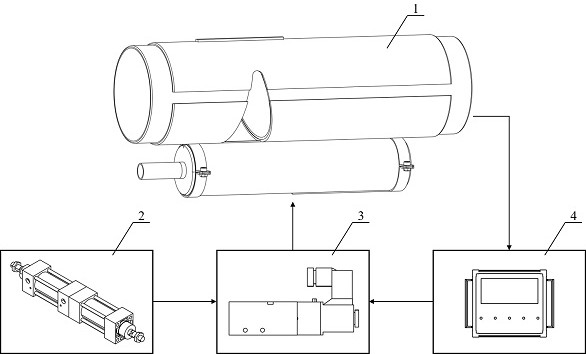

Universal multi-stage vertical shaft hydraulic and wind power conversion machine for driving power generation device

PendingCN112628081AReduce tangential forceGuaranteed stabilityHydro energy generationWind motor combinationsStatorTurbine blade

The invention relates to a device for converting water energy, water flow including non-dammed rivers, lakes, seas, oceans and artificial canal weirs, surges, wave energy and wind energy into mechanical energy, in particular to a universal multi-stage vertical shaft hydraulic and wind power conversion machine for driving a power generation device. The universal multi-stage vertical shaft hydraulic and wind power conversion machine comprises flow guide plates, a rotor disc, a stator disc and a main shaft, wherein the included angle between each flow guide plate and the tangent line of the inner circle of the stator disc is 45 degrees, so that water energy and wind energy are guided to turbine blades to generate torque, wind and water can enter from a channel between every two adjacent flow guide plates in any direction of the device, and the upstream area and the windward area of the device account for 90% or above of the total area; and meanwhile, due to the angle of the turbine blades, the wind and the water with large thrust still push the rotor disc to rotate until the flow guide plates deflect to the downstream position and the downwind position under the continuously increased thrust, and the water and the wind become flowing water and wind, so that the device is prevented from being excessively stressed.

Owner:黄始征

Soft wearable robot for elbow movement function rehabilitation

ActiveCN113633512AAlleviate tangential slidingEvenly distributed assist forceChiropractic devicesHuman bodyEngineering

The invention discloses a soft wearable robot for elbow movement function rehabilitation. The soft wearable robot comprises a soft wearable robot body assembly, an air cylinder, an electromagnetic proportional valve and a controller; the soft wearable robot body assembly is composed of an outer elbow sleeve, an inner elbow sleeve, a flexible bending sensor and a soft actuator assembly; and the soft actuator assembly comprises a flexible pipe, a first end sealing piece, a second end sealing piece, an air guide pipe, a woven mesh sleeve, a first end fastening piece, a second end fastening piece, a first limiting layer, a second limiting layer, a joint extension layer and a third limiting layer. The three limiting layers form a limiting structure with the elasticity modulus gradually changed on the two sides, so that the motion characteristic of the soft actuator assembly conforms to the motion characteristic of the elbow of the human body, tangential sliding between the soft actuator assembly and the skin of the elbow joint of the human body is relieved, and auxiliary force distribution is more uniform; and the joint extension layer of the soft body actuator assembly has certain axial ductility, so that the discomfort of a user is reduced.

Owner:SOUTHEAST UNIV

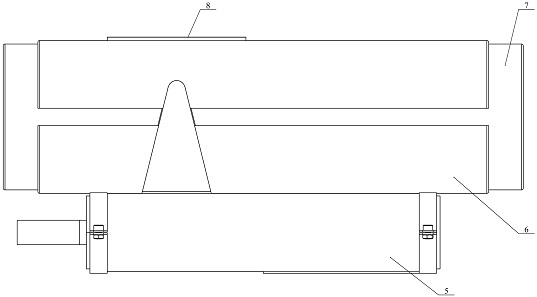

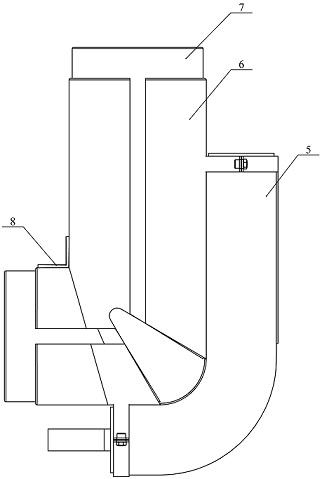

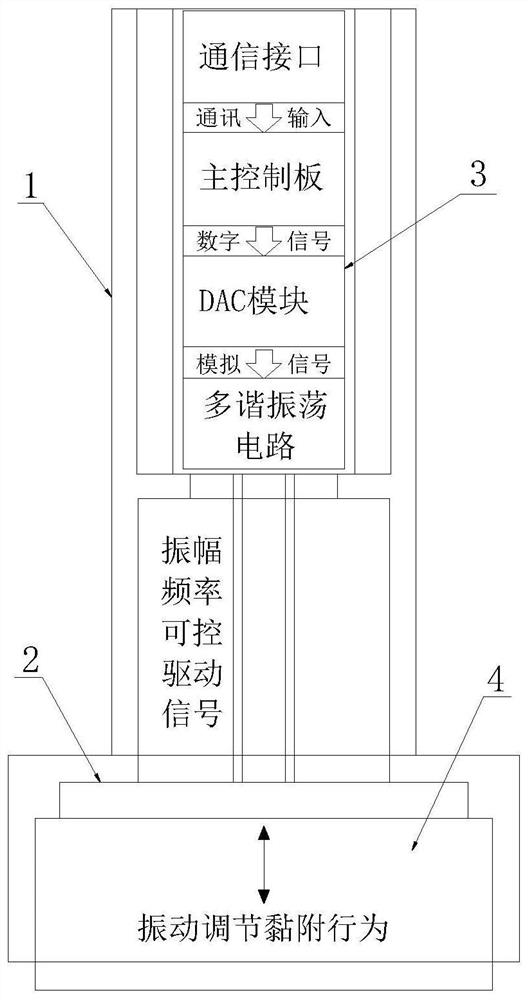

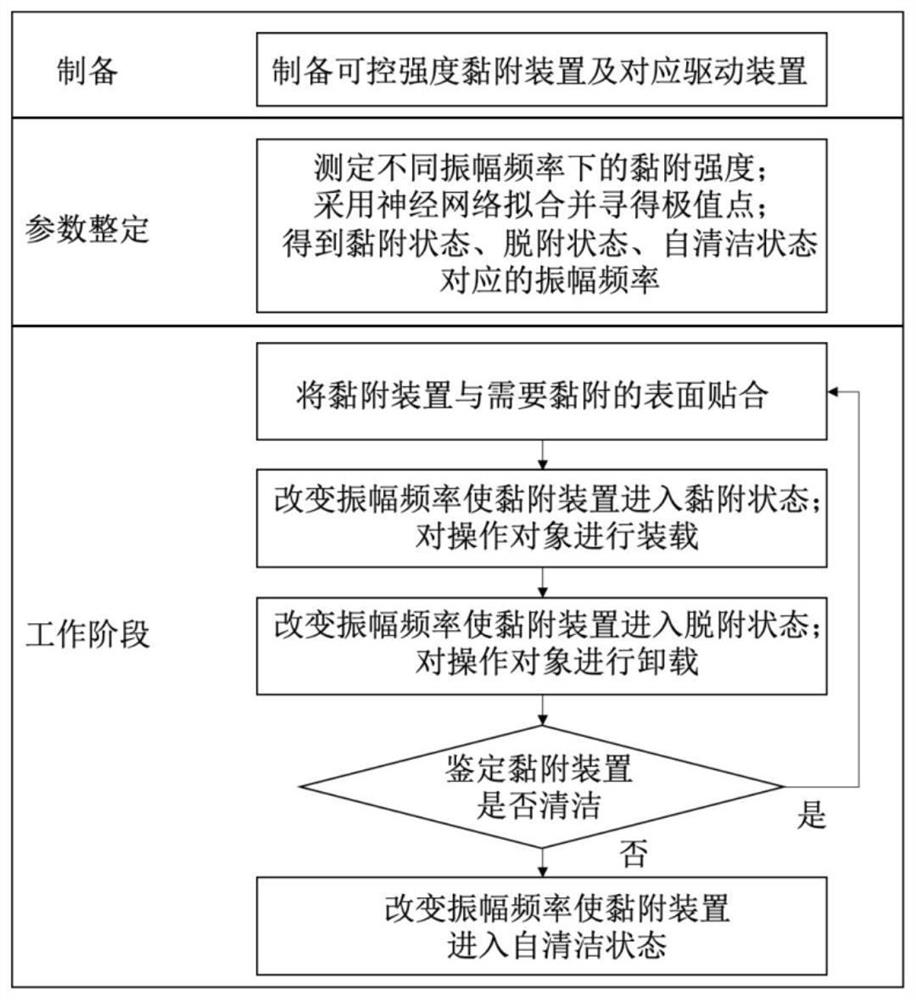

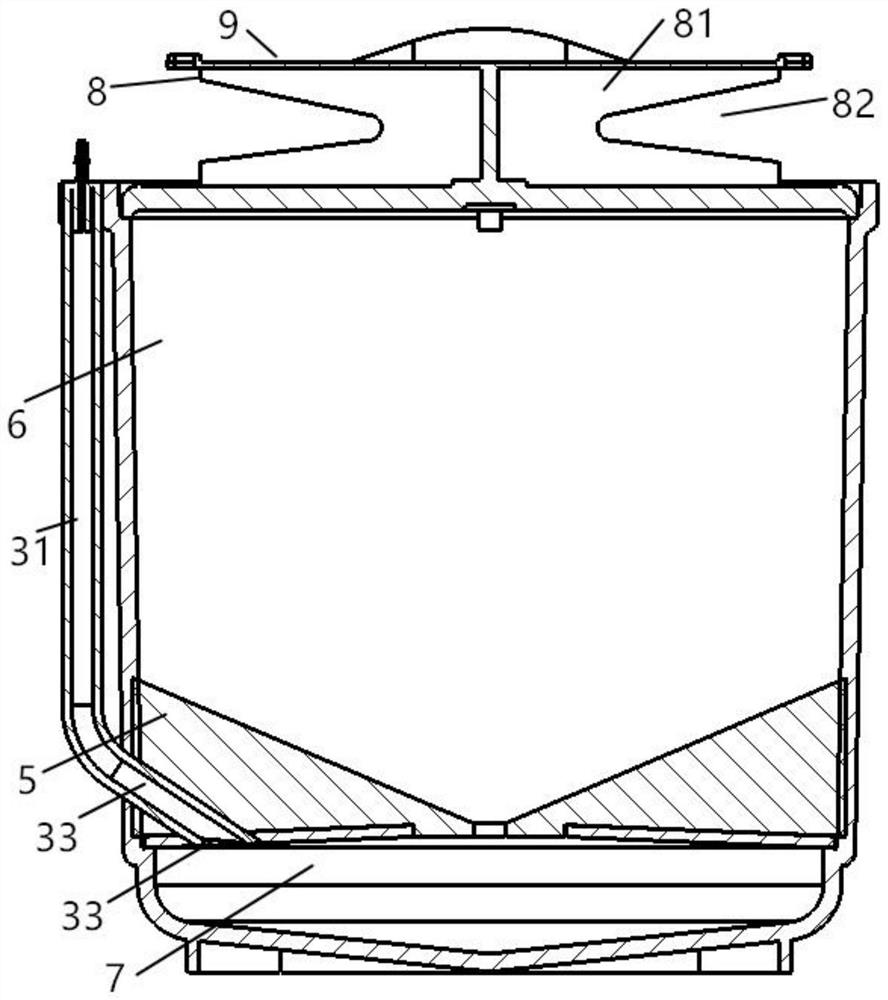

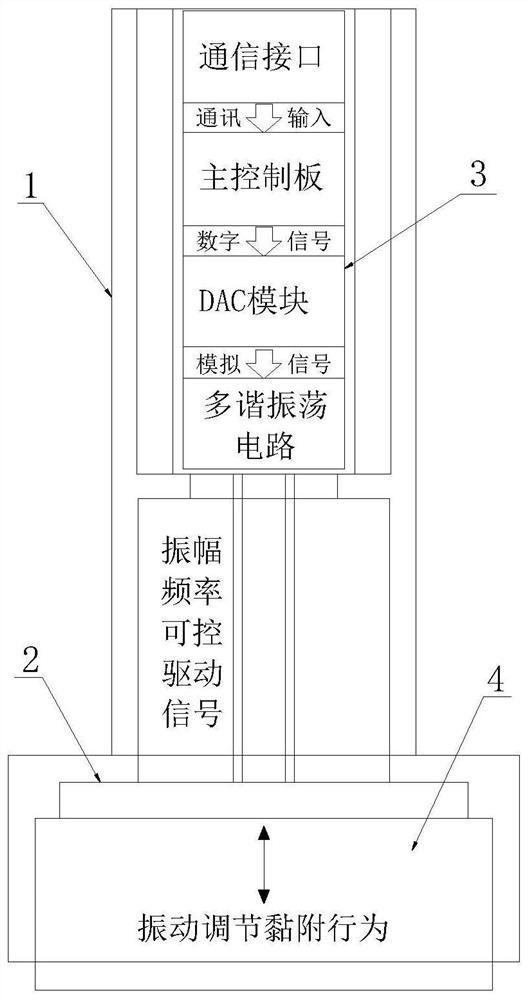

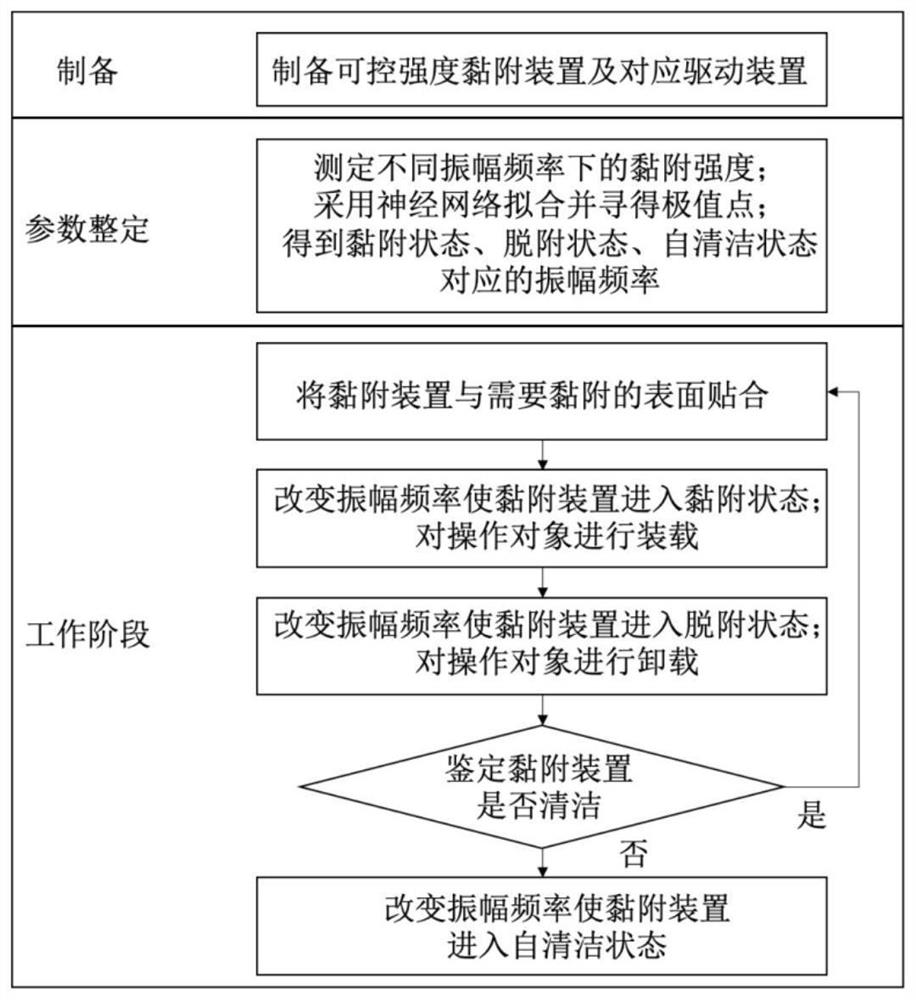

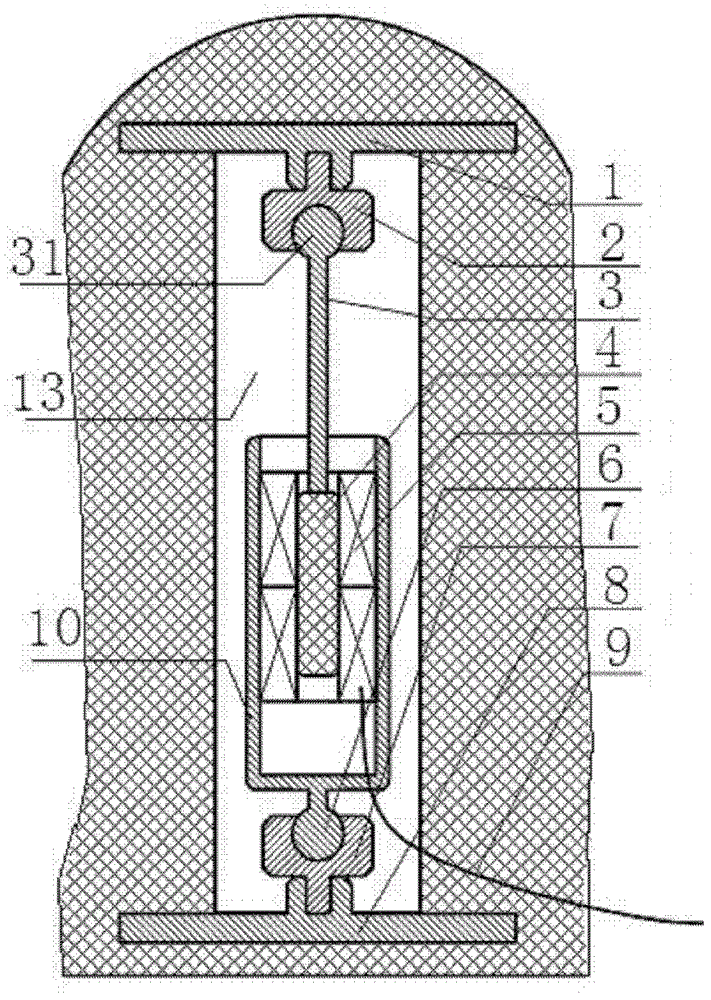

Strength-controllable adhesion device and regulation and control method thereof

ActiveCN112727876AChange the adhesive strengthReduce tangential forceMechanical oscillations controlMaterial gluingCommunication interfaceVibration amplitude

The invention relates to a strength-controllable adhesion device. The adhesion device comprises a supporting piece for supporting the strength-controllable adhesion device, an adhesion unit arranged at one end of the supporting piece, a micro-vibration excitation generation module arranged between the supporting piece and the adhesion unit and a micro-vibration excitation adjusting and amplifying module arranged in the supporting piece; one end, far away from the supporting piece, of the adhesion unit makes contact with an adhesion interface; one end of the micro-vibration excitation generation module is fixedly connected with the supporting piece, the other end is fixedly connected with the adhesion unit, and the micro-vibration excitation generation module drives the adhesion unit to generate micro-vibration; a communication interface is arranged on the micro-vibration excitation adjusting and amplifying module, and the micro-vibration excitation adjusting and amplifying module is connected with the micro-vibration excitation generation module to adjust the vibration frequency and amplitude of the micro-vibration excitation generation module. The invention also relates to a regulation and control method of the device. According to the method, the micro-vibration frequency and amplitude can be adjusted according to the requirements, and stable adhesion strength adjustment of a target adhesion object can be realized, so that quick switching of adhesion and detachment is completed. The problems that existing adhesion fails difficultly and the strength between adhesion interfaces cannot be regulated and controlled can be effectively solved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method for manufacturing rubber sealing ring of dam gate

InactiveCN103256387AAvoid safety accidentsSimple structureEngine sealsVulcanizationMechanical engineering

Owner:成都太微电子科技有限公司 +1

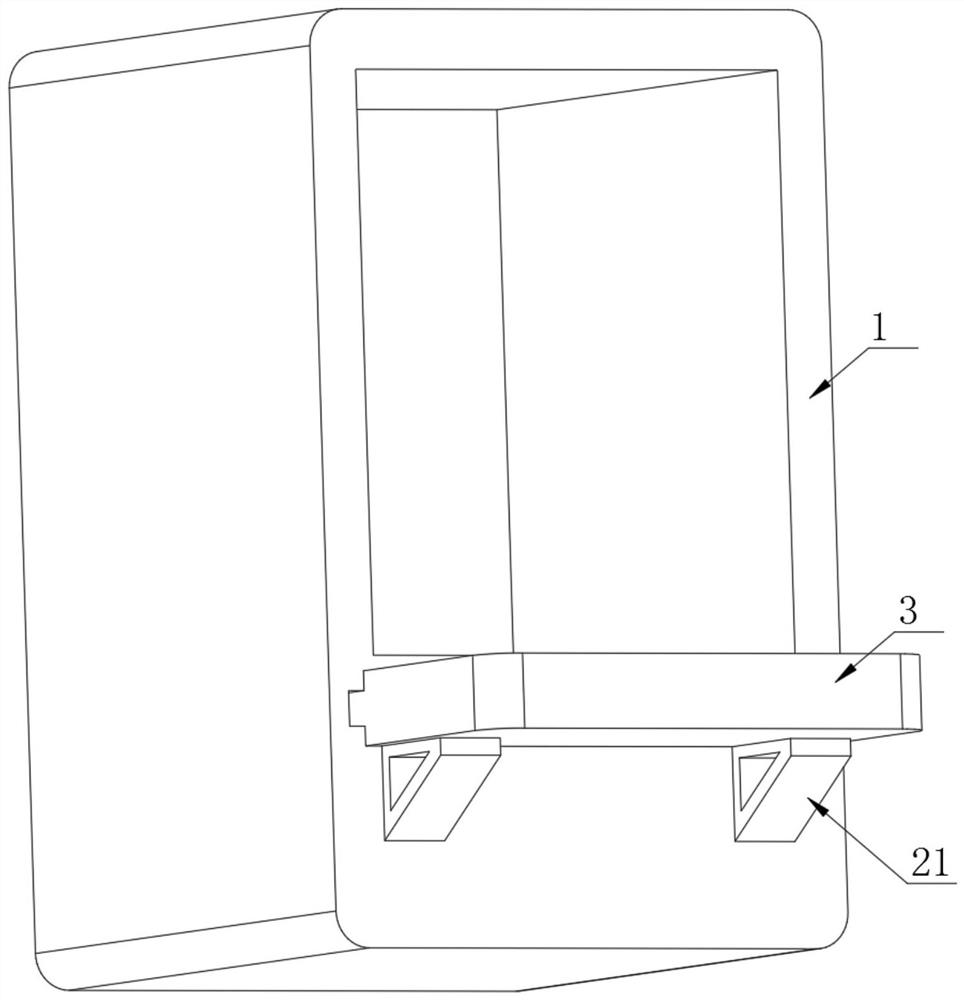

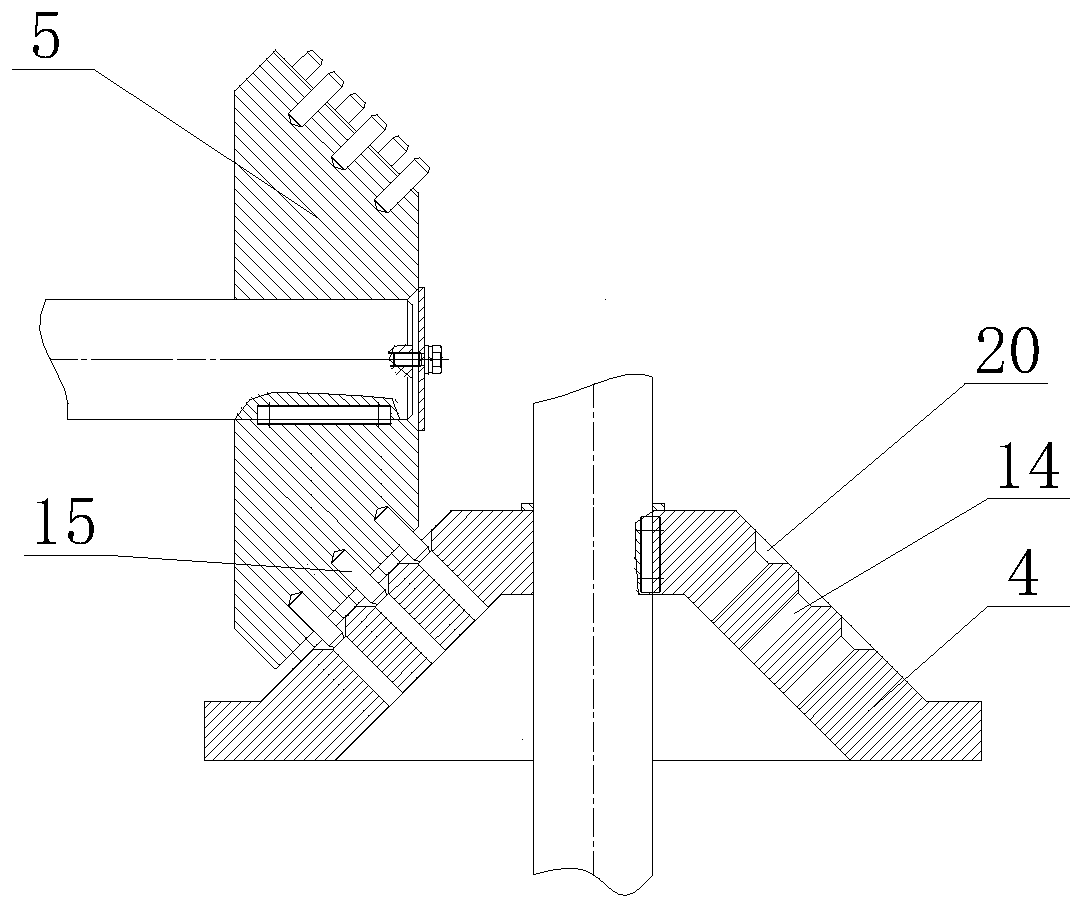

Connection structure between elevator and floor during parking of building construction elevator

PendingCN113682935APlay a supporting roleReduce tangential forceElevatorsBuilding liftsFloor levelArchitectural engineering

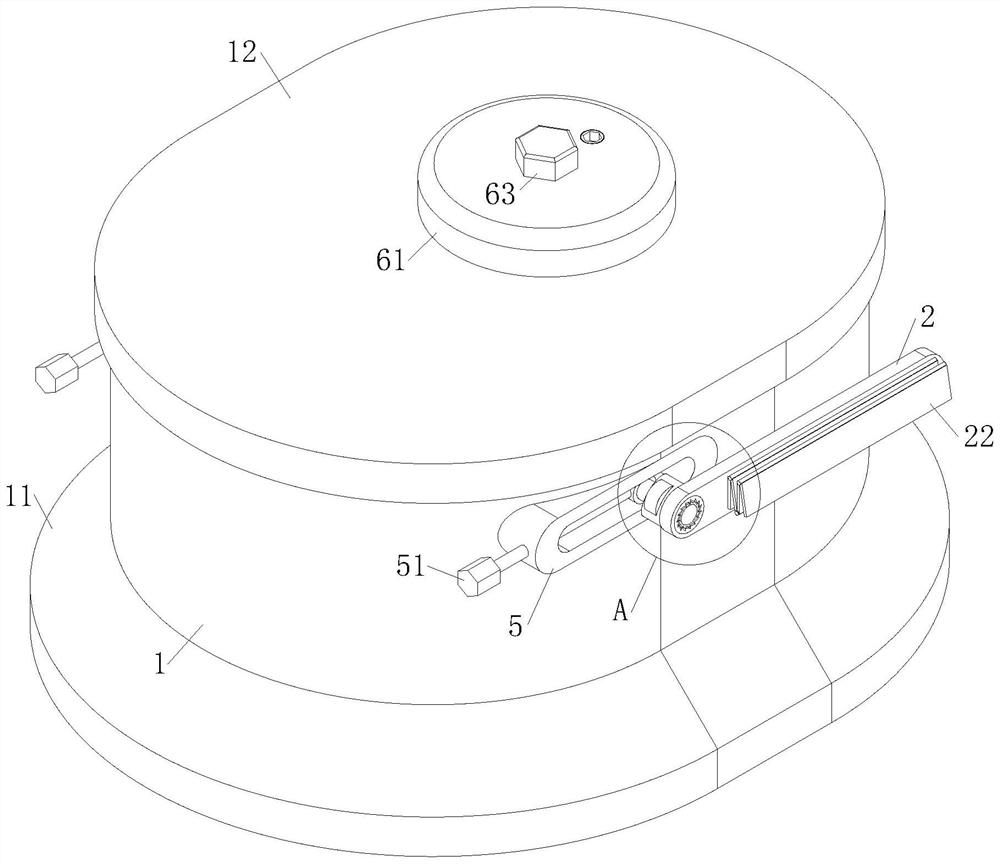

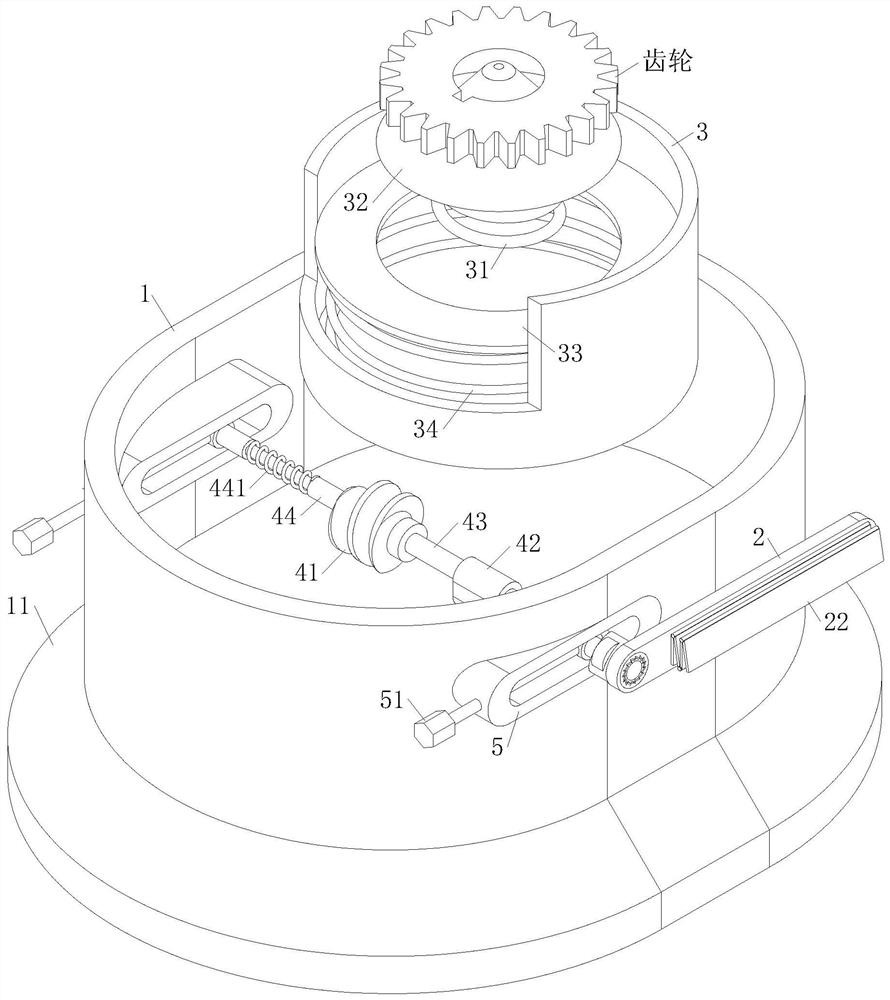

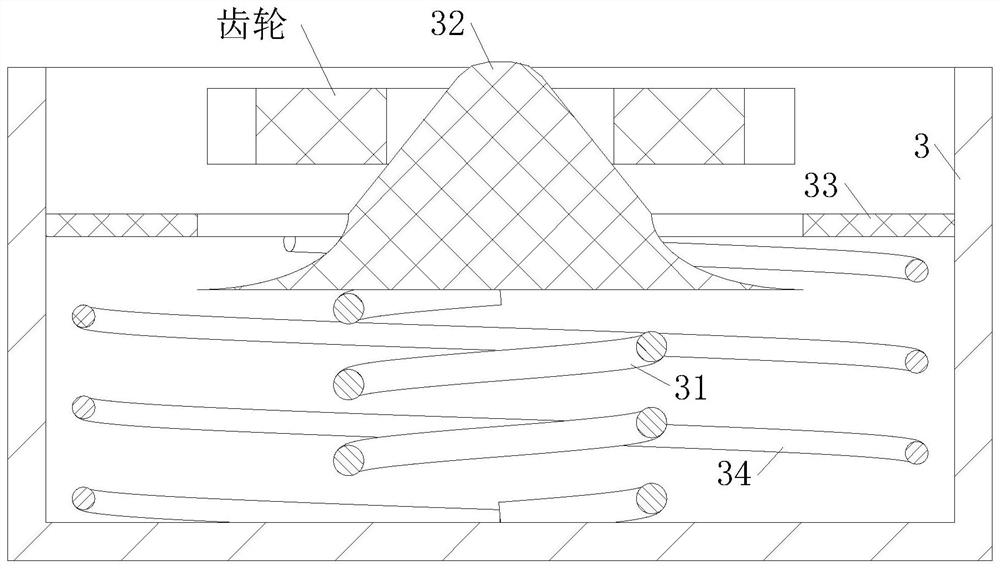

The invention relates to a connecting structure between an elevator and a floor during parking of a building construction elevator. The connecting structure between the elevator and the floor during parking of the building construction elevator comprises a lift car, a worm, a butt strap, two shells and two fixing structures with the same structure, wherein the two fixing structures with the same structure are arranged in the shell; each fixing structure comprises a connecting block, a threaded sleeve, a worm gear, a threaded rod, a moving block, two toothed plates, a first spring, two connecting plates, two sliding blocks and two clamping structures with the same structure; the two clamping structures with the same structure are symmetrically arranged; and each clamping structure comprises a first rotating shaft, a gear, a rotating rod, a clamping block, multiple telescopic rods and multiple second springs. According to the connecting structure between the elevator and the floor during parking of the building construction elevator provided by the invention, through a series of actions, the clamping blocks are embedded in clamping grooves, so that the connection between the butt strap and the lift car is more stable, and the condition of relative sliding between the butt strap and the lift car is avoided.

Owner:中铁城建集团第一工程有限公司

A kind of heat-dissipating coating for LED lamp and preparation method thereof

The invention discloses a cooling coating for a light-emitting diode (LED) lamp and a preparation method thereof. The coating comprises the following components by weight percent: 30-55% of acrylic resin, 10-20% of amino resin, 5-10% of aluminium nitride, 2-15% of carbon fiber, 3-8% of pigment, 5-15% of mica, 1-2% of anti-settling agent, 10-20% of solvent, 1-2% of dispersant and 0.5-2% of flatting agent. The preparation method comprises the following steps: during preparation, mixing and grinding raw materials, and then dispersing the raw materials by a disperser; controlling the fineness of the coating within 15-30mu m, filtering and removing impurities, thereby obtaining the cooling coating. The cooling coating for the LED lamp disclosed by the invention has high radioactivity and high heat conductivity, and is sprayed on the surface of an LED apparatus; the temperatures on the surfaces of the apparatuses such as an LED lamp aluminum substrate and a cooling shell can be greatly reduced by the formed coating; the coating has the characteristics of excellent mechanical property and protection function, good waterproofness and weather fastness, and the like.

Owner:SOUTH CHINA UNIV OF TECH

Novel external meshing back cone plunger type biomass ring mold forming machine

The invention discloses a novel external meshing back cone plunger type biomass ring mold forming machine. The forming machine comprises a case, a driving device, a ring mold body, a pressure roller body, a ring mold shaft, a pressure roller shaft, a reversing shaft and a driving shaft. A driven bevel gear is arranged at the top end of the ring mold shaft. A driving bevel gear meshing with the driven bevel gear is arranged on the driving shaft. The driving shaft, the reversing shaft and the ring mold shaft are connected through a gear transmission system. The driving shaft rotates to drive thepressure roller shaft and the ring mold shaft to rotate. The pressure roller body is arranged at the bottom end of the pressure roller shaft. The ring mold body is arranged on the ring mold shaft. The pressure roller body is provided with a plurality of compression male molds. The ring mold body is provided with a plurality of forming holes. When the ring mold shaft and the pressure roller shaftrotate, the compression male molds mesh with the forming holes positionally, and materials are extruded by the compression male molds out of the forming holes and discharged. The problem of serious abrasion between the existing product forming molds and pressure rollers is overcome, energy conservation and high efficiency can be ensured, the production cost is reduced, meanwhile, abrasion of the pressure roller and forming mold is reduced, and the service life is prolonged.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY

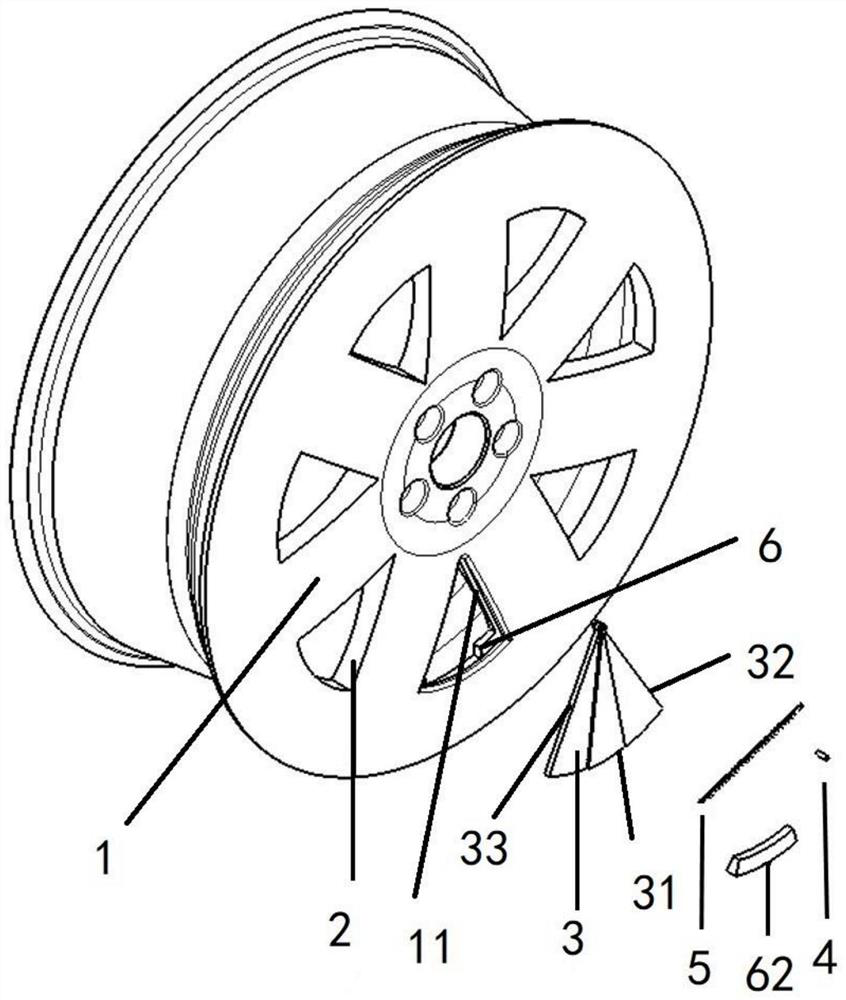

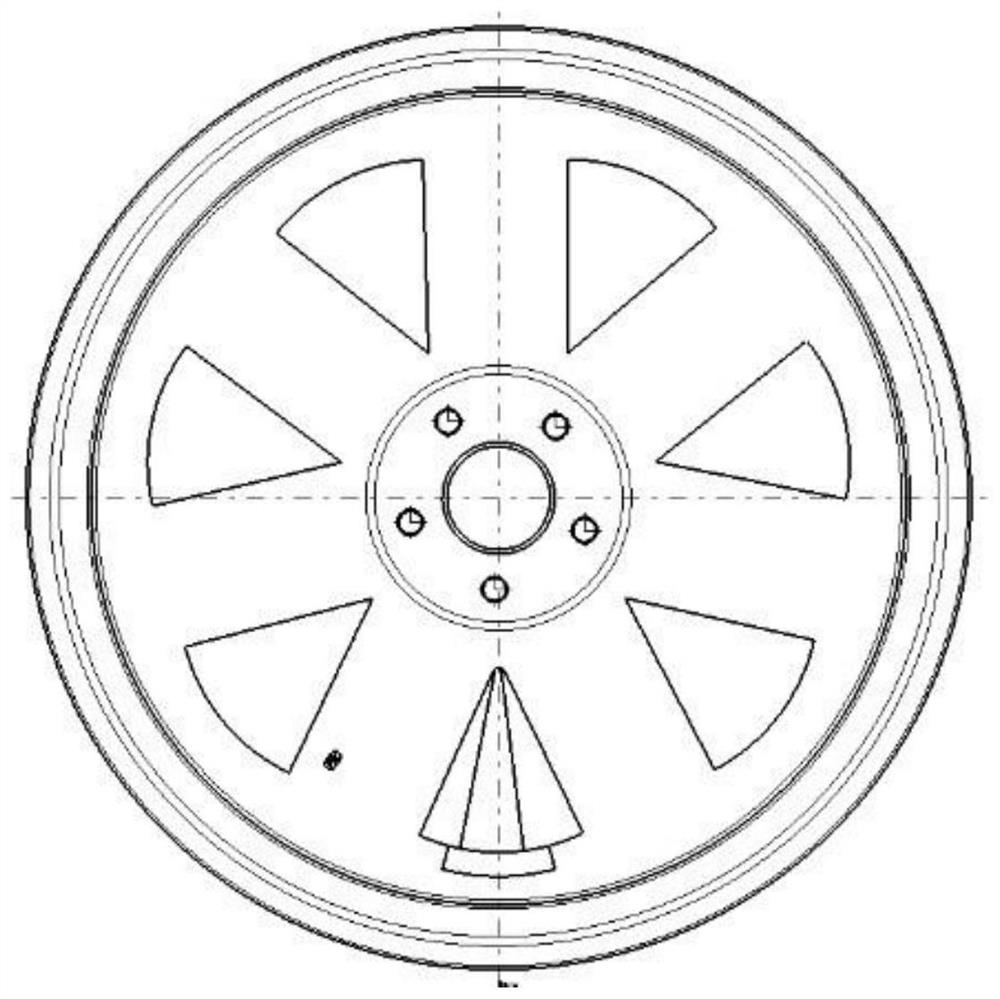

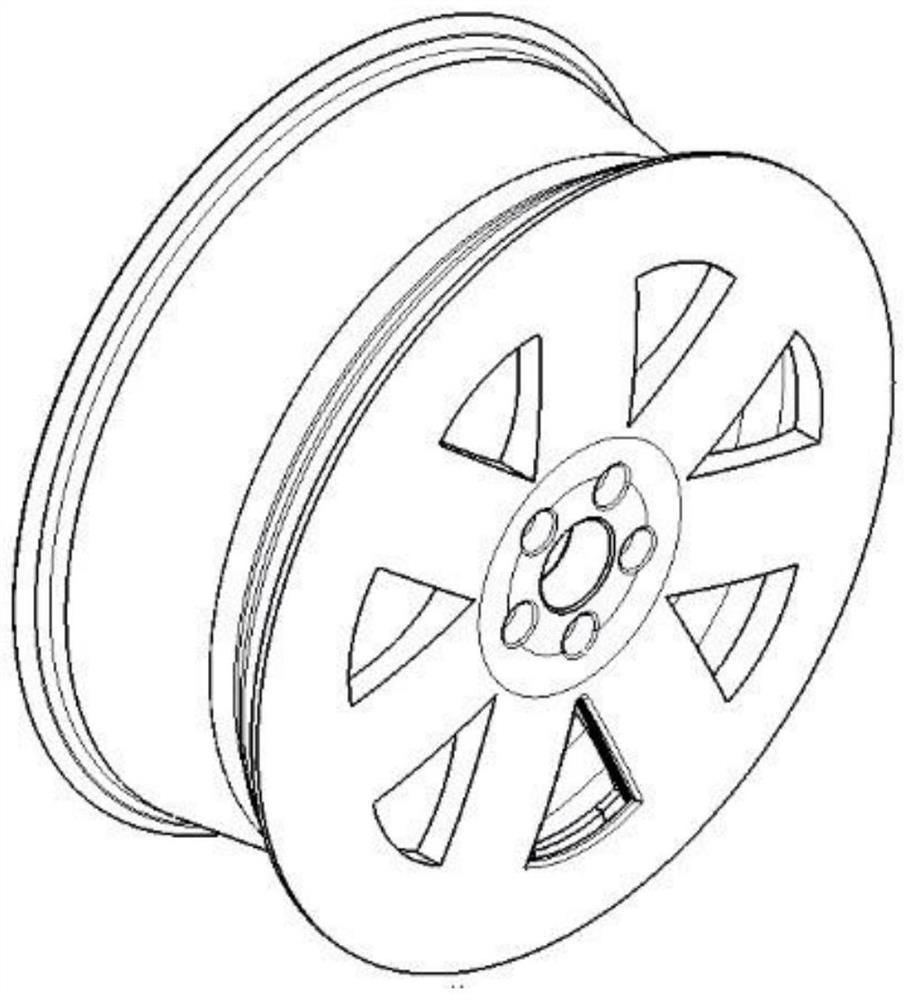

Wheel rim assembly and vehicle for automatically adjusting wind resistance

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

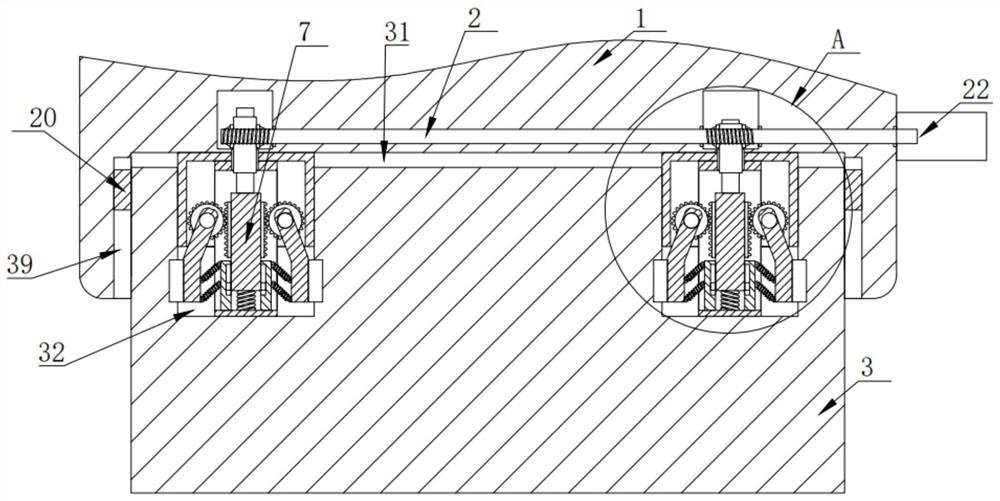

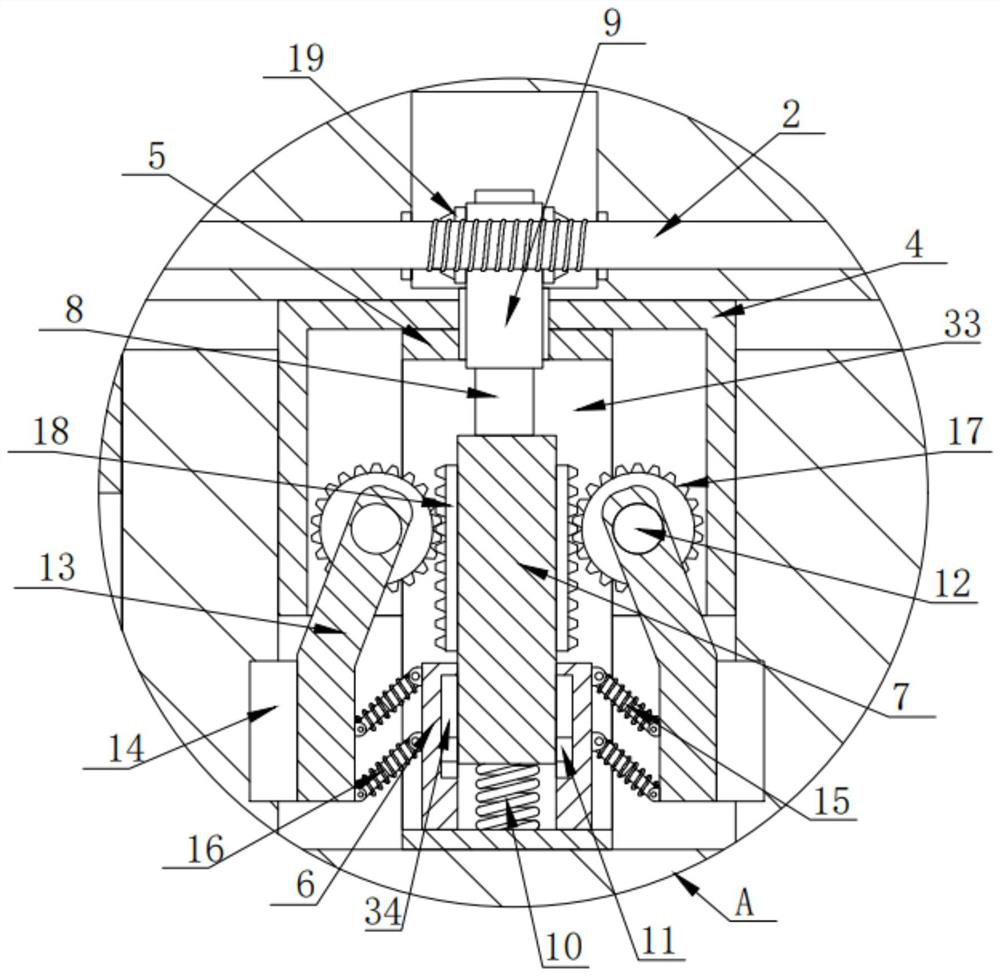

Intelligent portable detector for tooth strength of transmission gear

ActiveCN113029557ASmall structure sizeImprove applicabilityMachine part testingMechanical componentsGear wheel

The invention relates to the technical field of gear detection, in particular to an intelligent portable detector for the tooth strength of a transmission gear, which comprises a detection table, a pressing rod and an inductor. As the strength of a plastic gear in a mechanical component is lower than that of a metal part, and the strength condition of the plastic gear is difficult to directly observe like that of the metal gear in the maintenance process of the mechanical component, the gear needs to be sent to a professional testing device of a detection mechanism for testing the tooth strength of the plastic gear, and direct detection of a small number of gears is inconvenient. Therefore, a worm shaft is driven to rotate through a pressing rod arranged in the detection table, a motor driving mode in detection is replaced, the strength of a gear installed in a clamping cylinder is tested, the structural size of the gear detector is reduced, the applicability of the detector is improved through the clamping cylinder for adjusting the position and a worm shaft, and the use effect of the intelligent portable detector for the tooth strength of a transmission gear is improved.

Owner:ZHEJIANG JIEZHONG SCI & TECH CO LTD

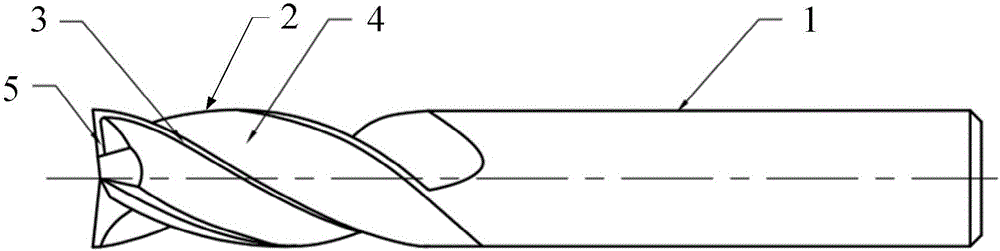

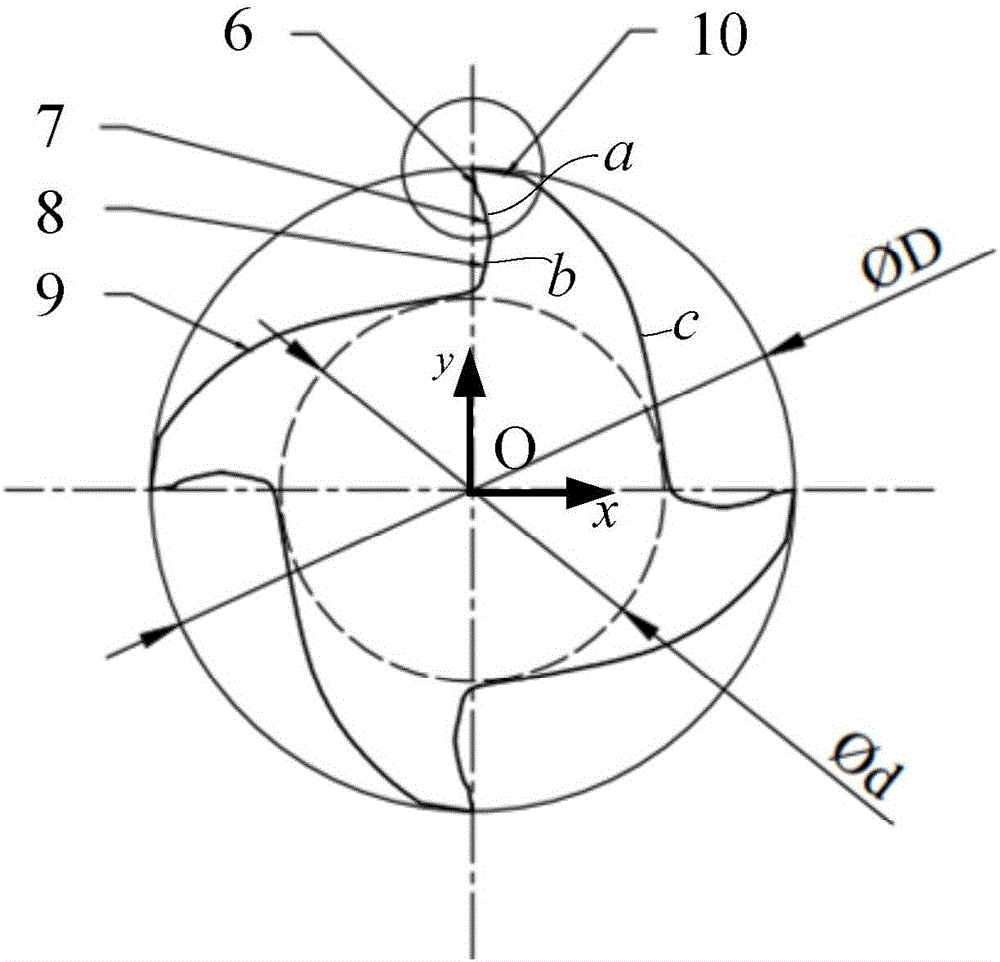

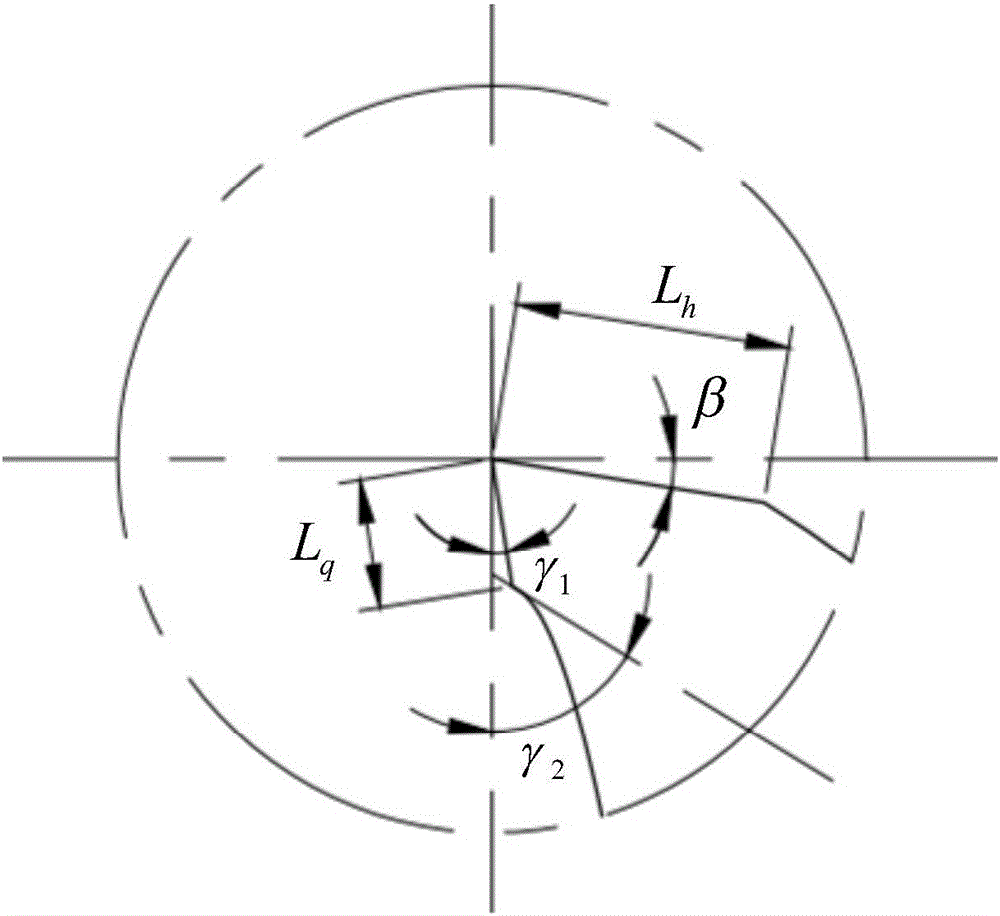

End mill with special groove and micro edge structure based on bionics

ActiveCN104400100BGuaranteed StrengthGuaranteed chip removal capabilityMilling cuttersSection planeBionics

The invention provides a bionics-based end mill with a special groove profile and a micro blade structure. The cutting edge part comprises peripheral cutting teeth and a chip pocket, the tooth number of the peripheral cutting teeth is 4, the peripheral cutting teeth consist of a first front mill surface, a second front mill surface and a rear mill surface, the radial profile of the first front mill surface is linear, the radial profile of the second front mill surface is in the shape of a parabola, and the coordinates of all points on the radial profile of the second front mill surface meet a parabola equation; the radial profile of the rear mill surface is linear; the chip pocket comprises the two parts of a main groove and an auxiliary groove, the main groove is connected with the second front mill surface, the radial profile of the main groove is in the shape of a parabola, the coordinates of all points on the radial profile of the main groove meet the parabola equation, the auxiliary groove projects outwards and is connected with the main groove and the rear mill surface, and the coordinates of all points on the radial profile of the auxiliary groove meet an equation: y=ax3+bx2+cx+d. The end mill has excellent strength and can inhibit the production of zigzag chips during titanium alloy processing. The cutting process is smoother, the workpiece surface quality is improved, and the service life of the mill is prolonged.

Owner:SHANDONG UNIV

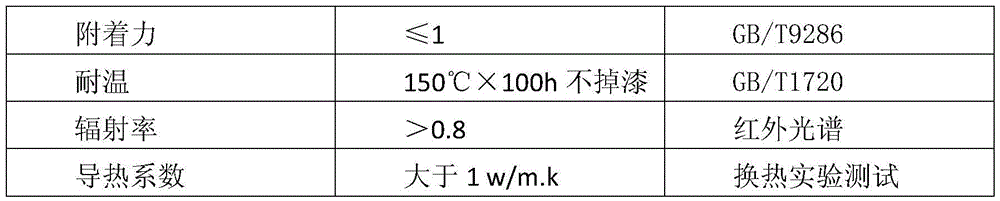

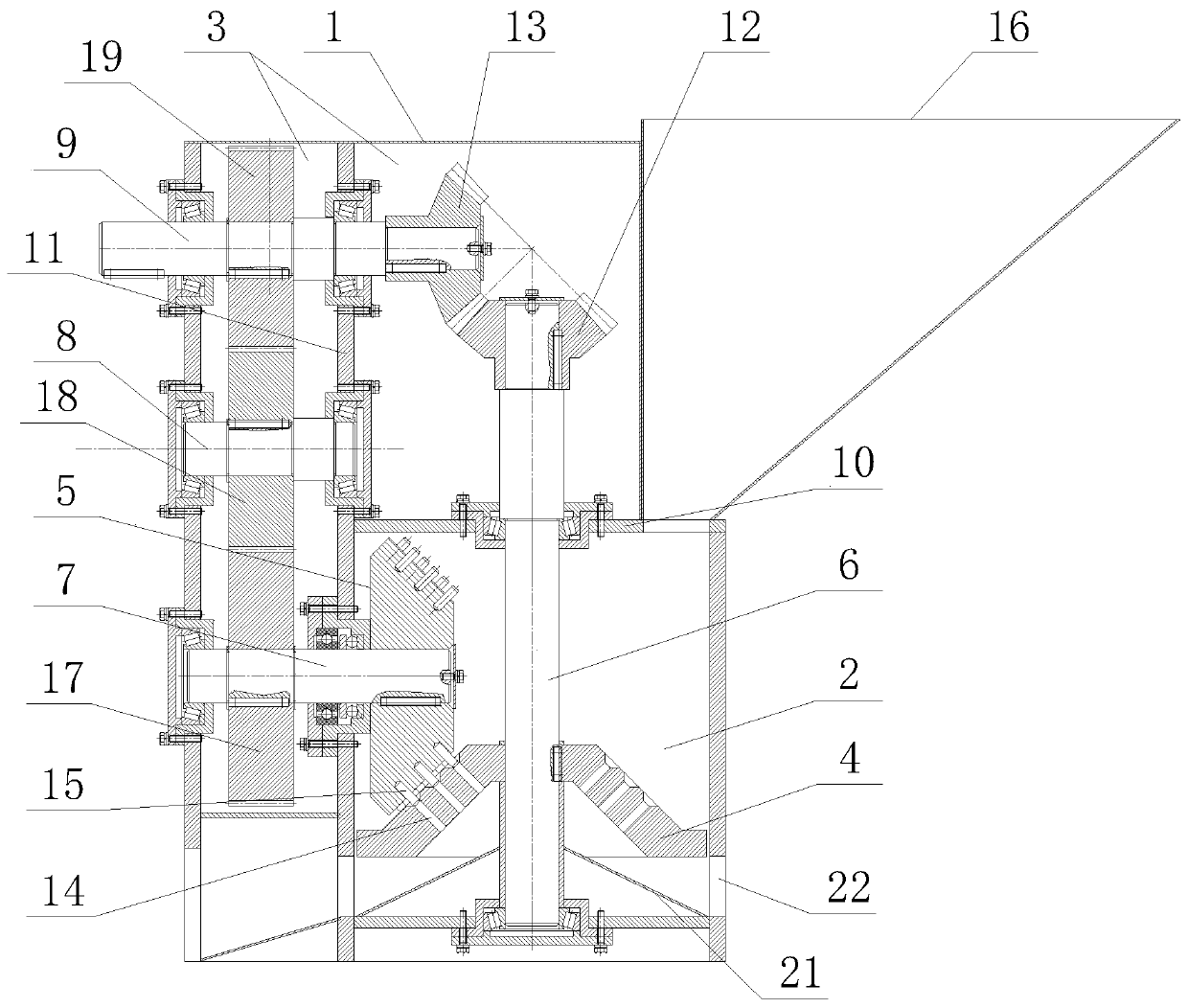

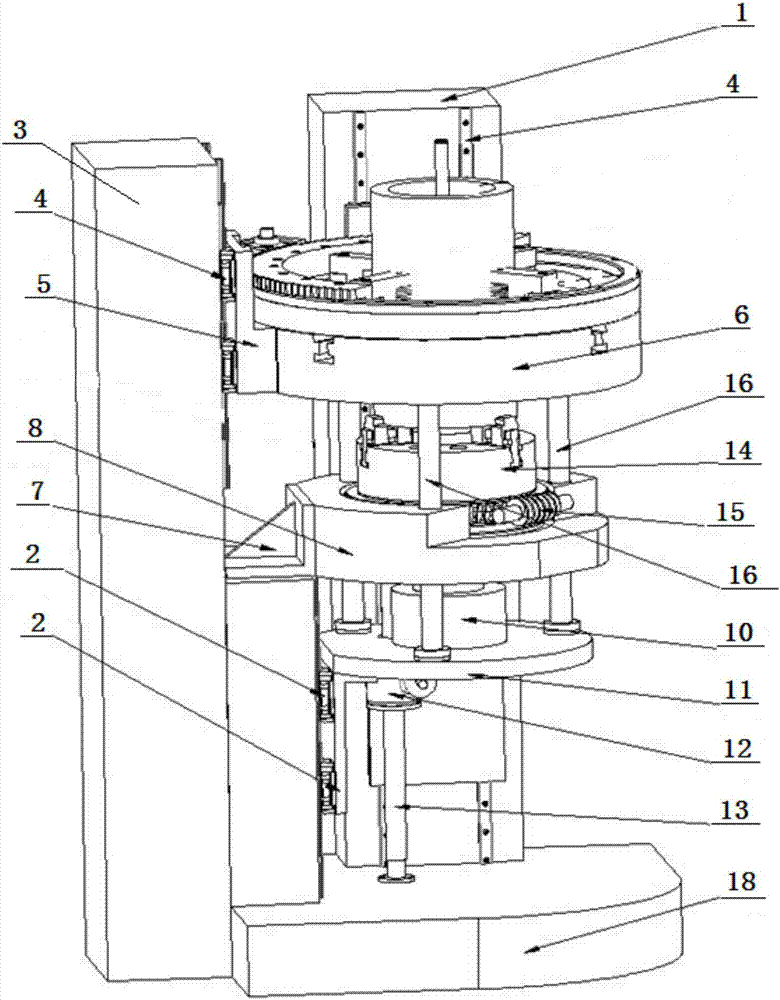

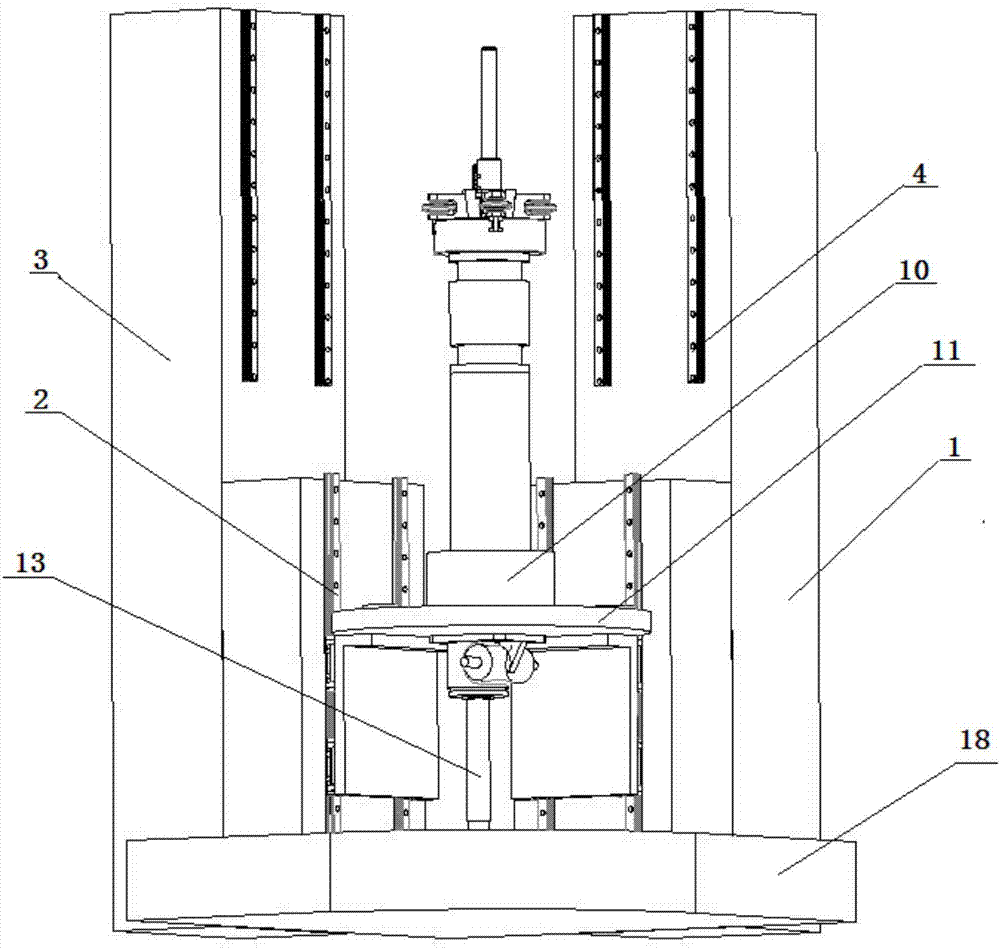

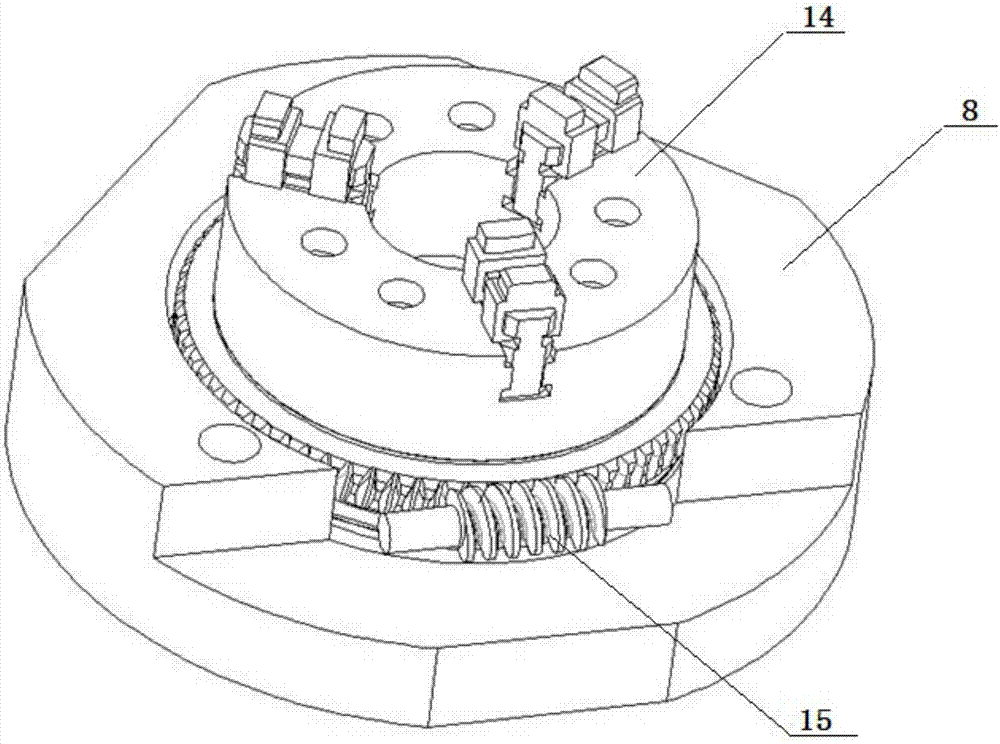

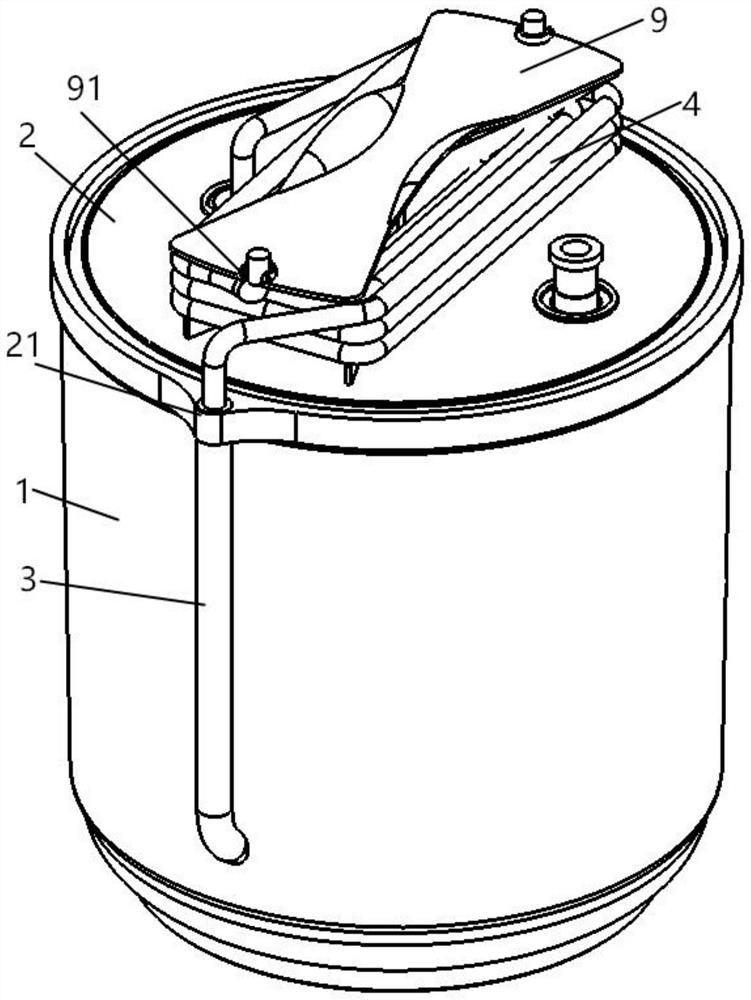

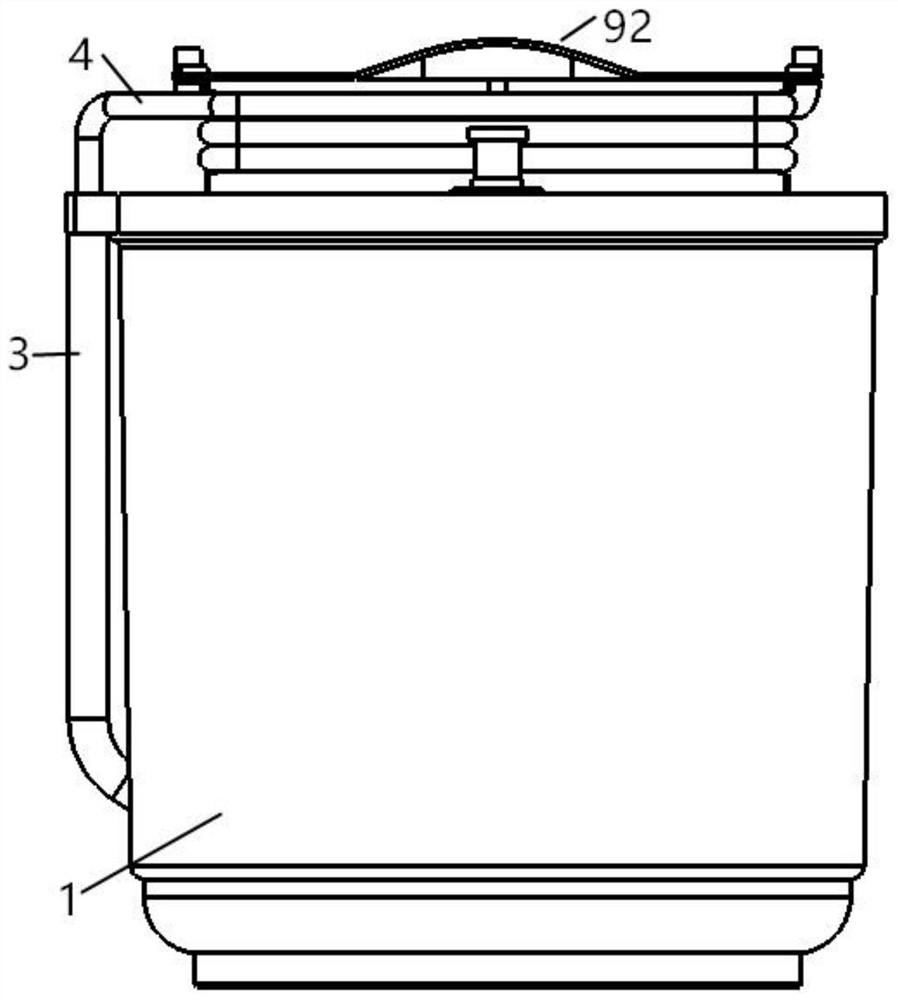

A pair of wheel spinning equipment for forming large thin-walled cylindrical parts

The invention relates to opposite roller spinning equipment, in particular to opposite roller spinning equipment for forming a large thin-walled cylindrical part, and aims to solve the problems that existing die spinning equipment is high in cost, poor in universality and long in manufacturing period as a core die is needed. A chuck substrate fixing base is installed on a rack between an internal rotation guide rail and an external rotation guide rail, a chuck substrate is installed on the chuck substrate fixing base, an external rotation mechanism fixing base is installed on the external rotation guide rail in a sliding mode, and an external rotation disc is installed on the external rotation mechanism fixing base; a bottom plate is installed on an internal rotation guide rail, a lifting motor is installed at the lower end of the bottom plate, one end of a lifting lead screw penetrates through the bottom plate, and the other end of the lifting lead screw is connected with a base; an internal rotation device fixing base is installed on the bottom plate, a worm and gear assembly is installed on the chuck substrate, a three-claw chuck is installed on the worm and gear assembly, multiple pull rods are connected with the external rotation disc, the chuck substrate and the base, an internal rotation device is installed in the internal rotation device fixing base, and the external rotation device is installed in the external rotation disc. The opposite roller spinning equipment is suitable for carrying out opposite roller spinning on the large thin-walled cylindrical part.

Owner:HARBIN INST OF TECH

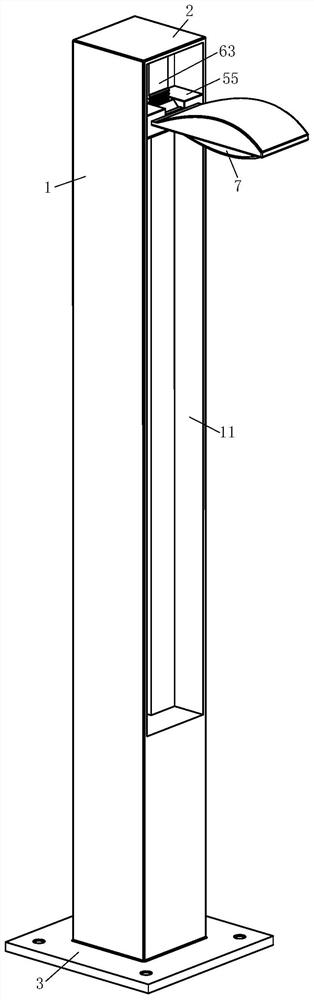

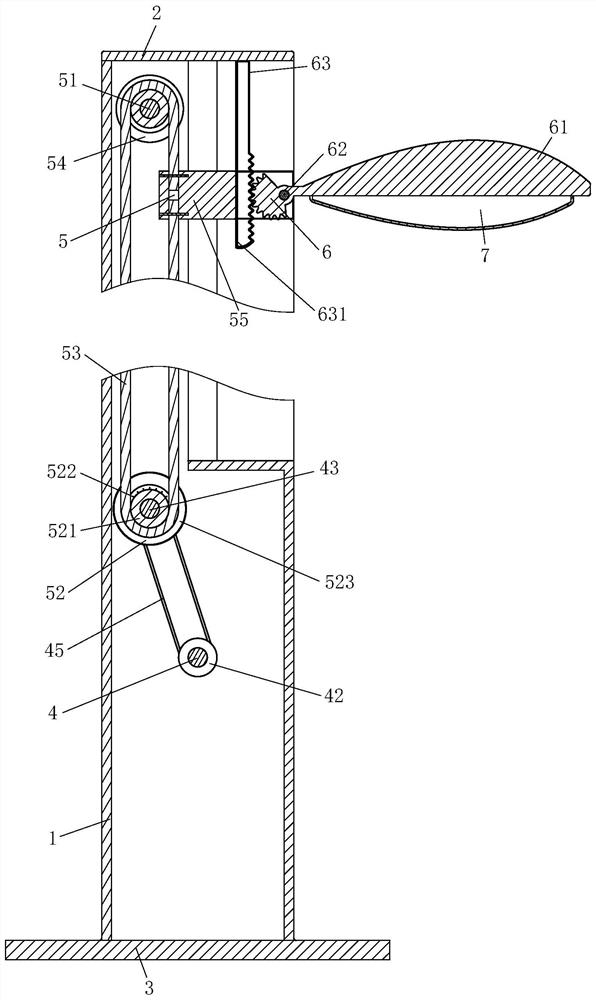

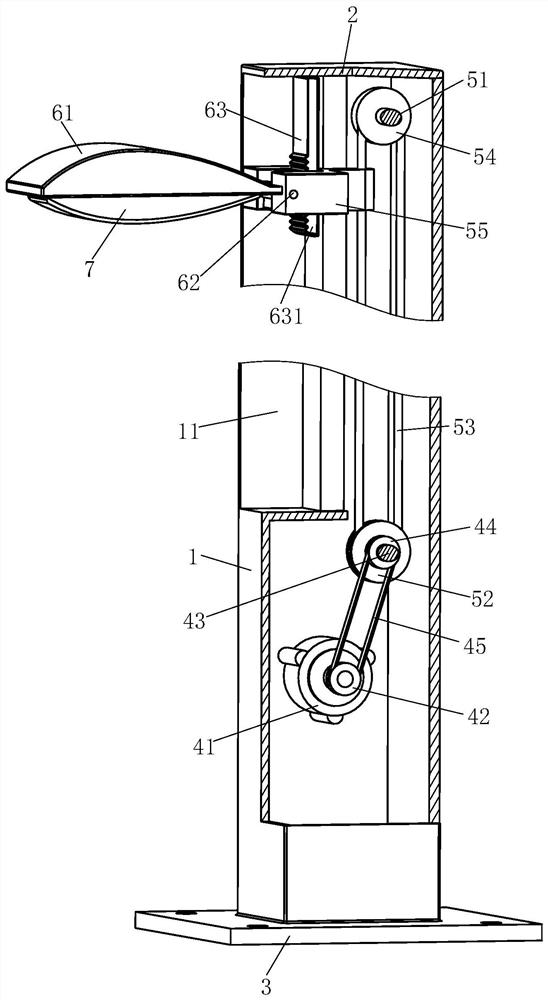

Direction-adjustable sensor mounting seat and mounting method thereof

PendingCN114812647ANot affected by errorsMeet the use requirementsMeasurement apparatus componentsEngineeringMechanical engineering

Owner:NORTHWEST INST OF NUCLEAR TECH

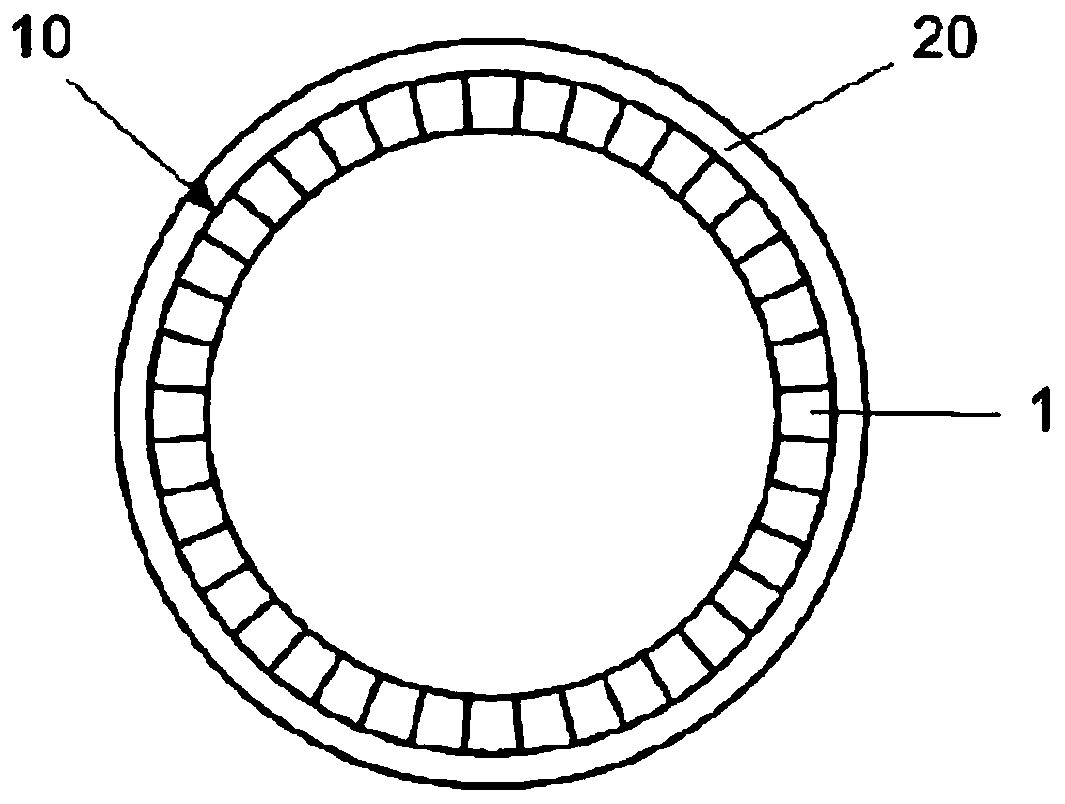

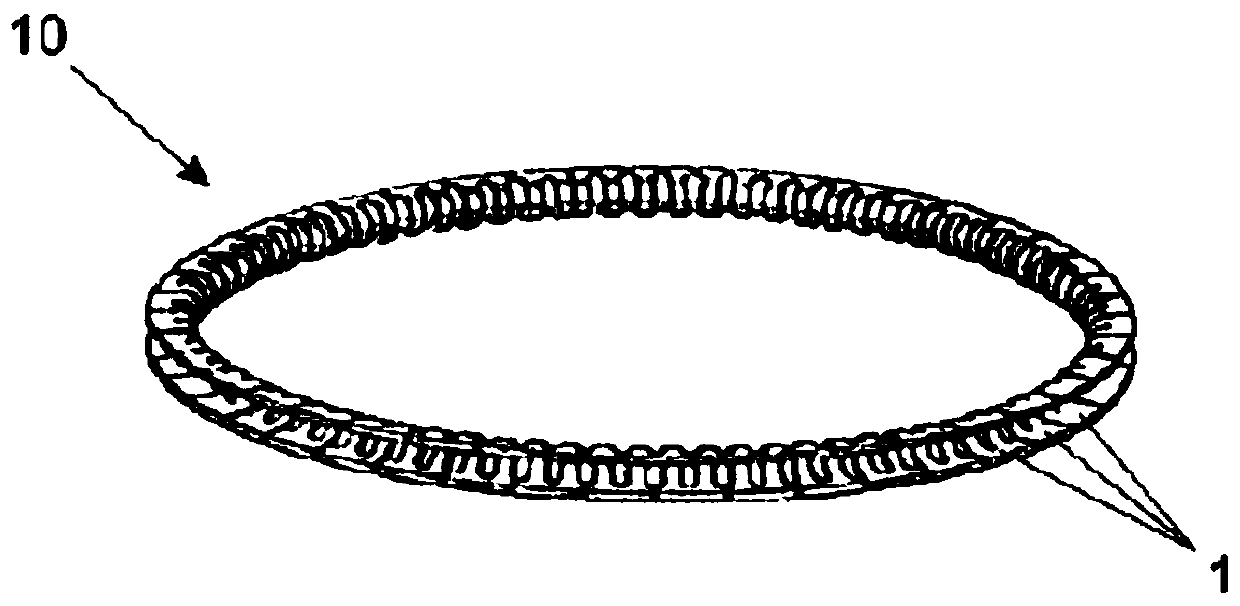

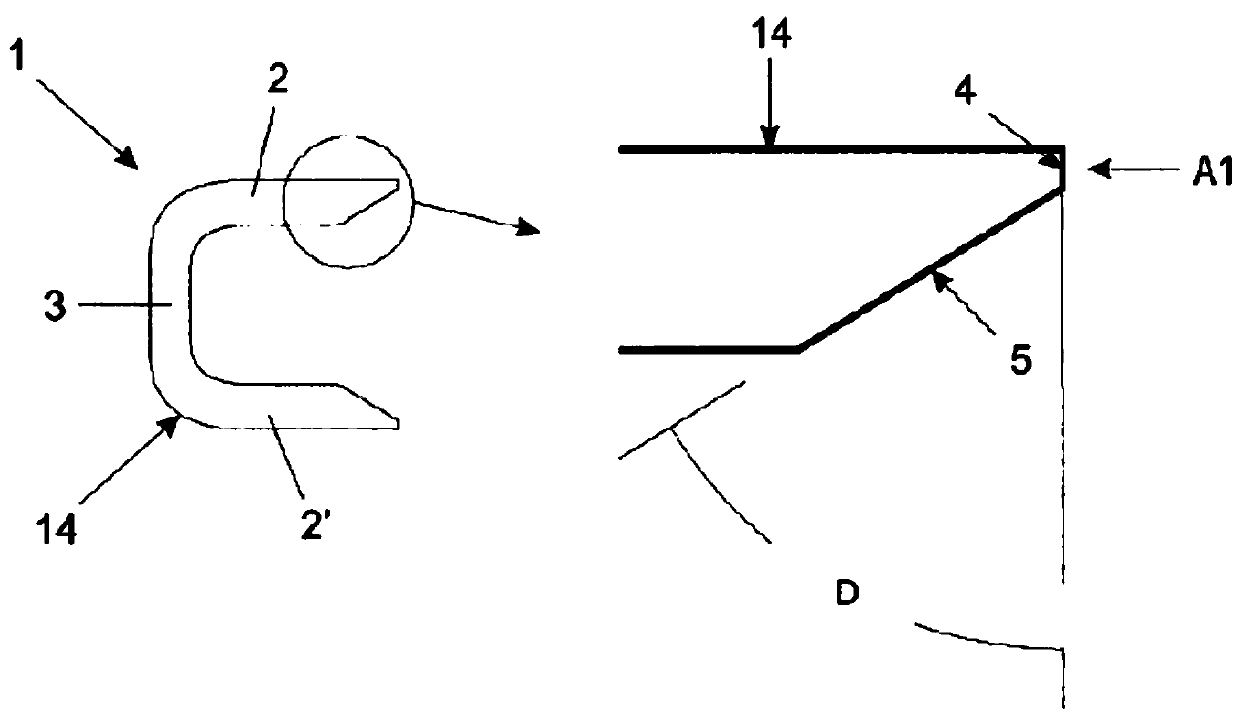

One piece oil control ring for internal combustion engine

InactiveCN109790925AAppropriate thicknessReduce consumptionPiston ringsEngineeringExternal combustion engine

The present invention relates to a one piece oil control ring (10) for an internal combustion engine capable of readily conforming to a cylinder liner (20) by virtue of the excellent flexibility of the ring (10), comprising a first surface (4) substantially parallel to the internal surface of the cylinder liner, wherefrom there extends a second substantially inclined surface (5), and comprising atempered martensitic matrix capable of receiving a nitrided layer (12), having high hardness, ensuring excellent resistance to wear and, consequently, high durability of the ring.

Owner:MAHLE METAL LEVE +1

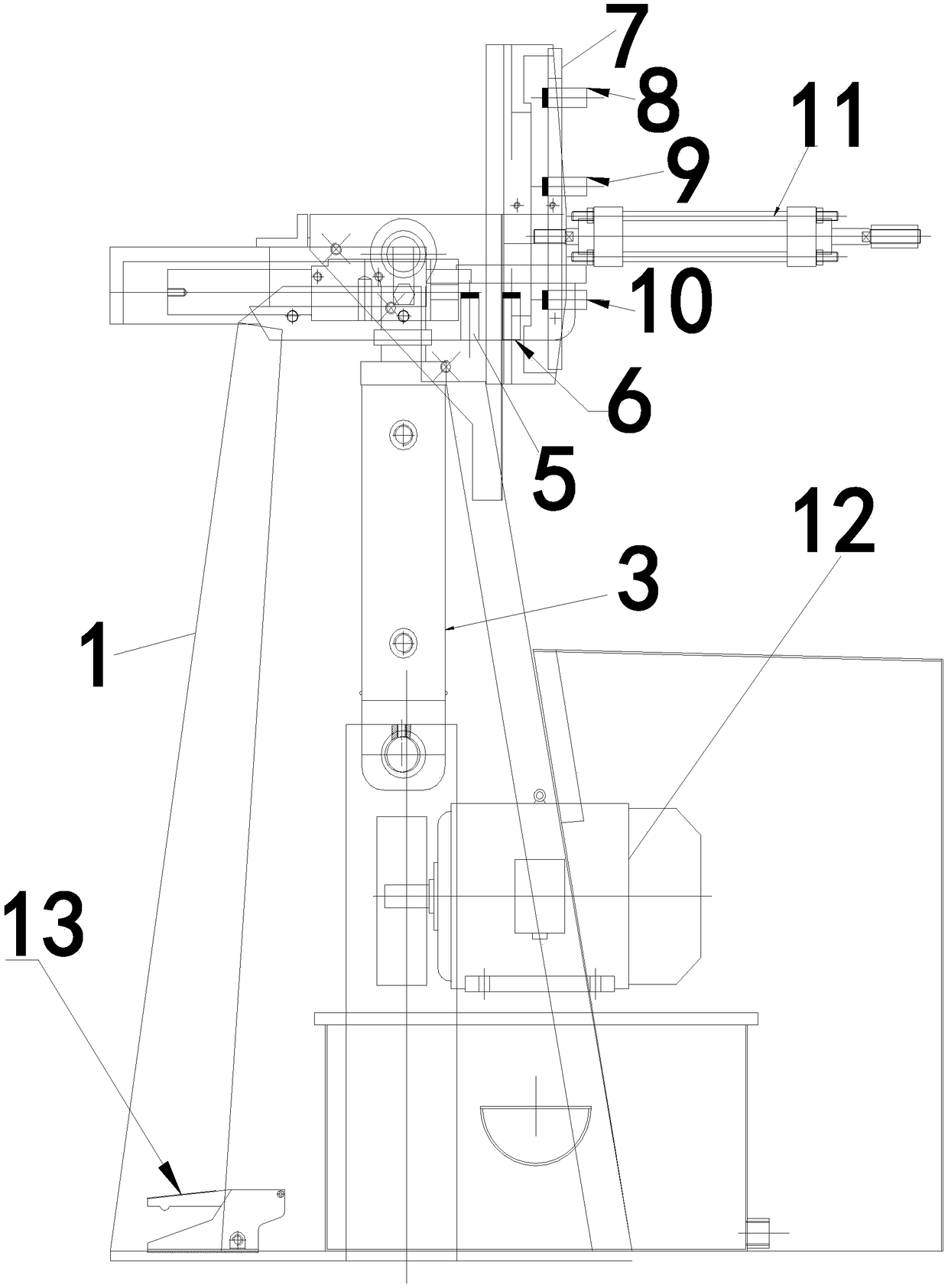

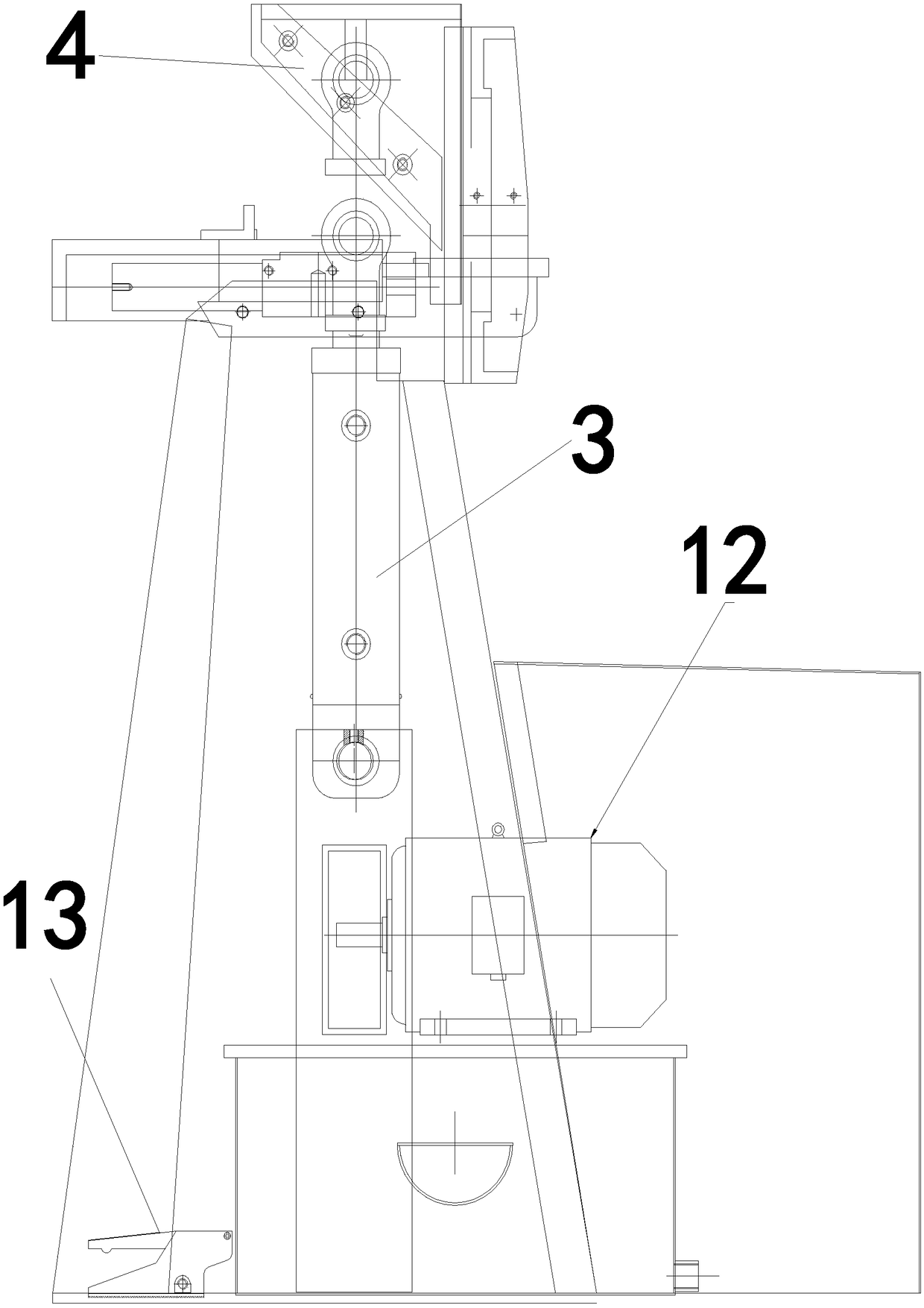

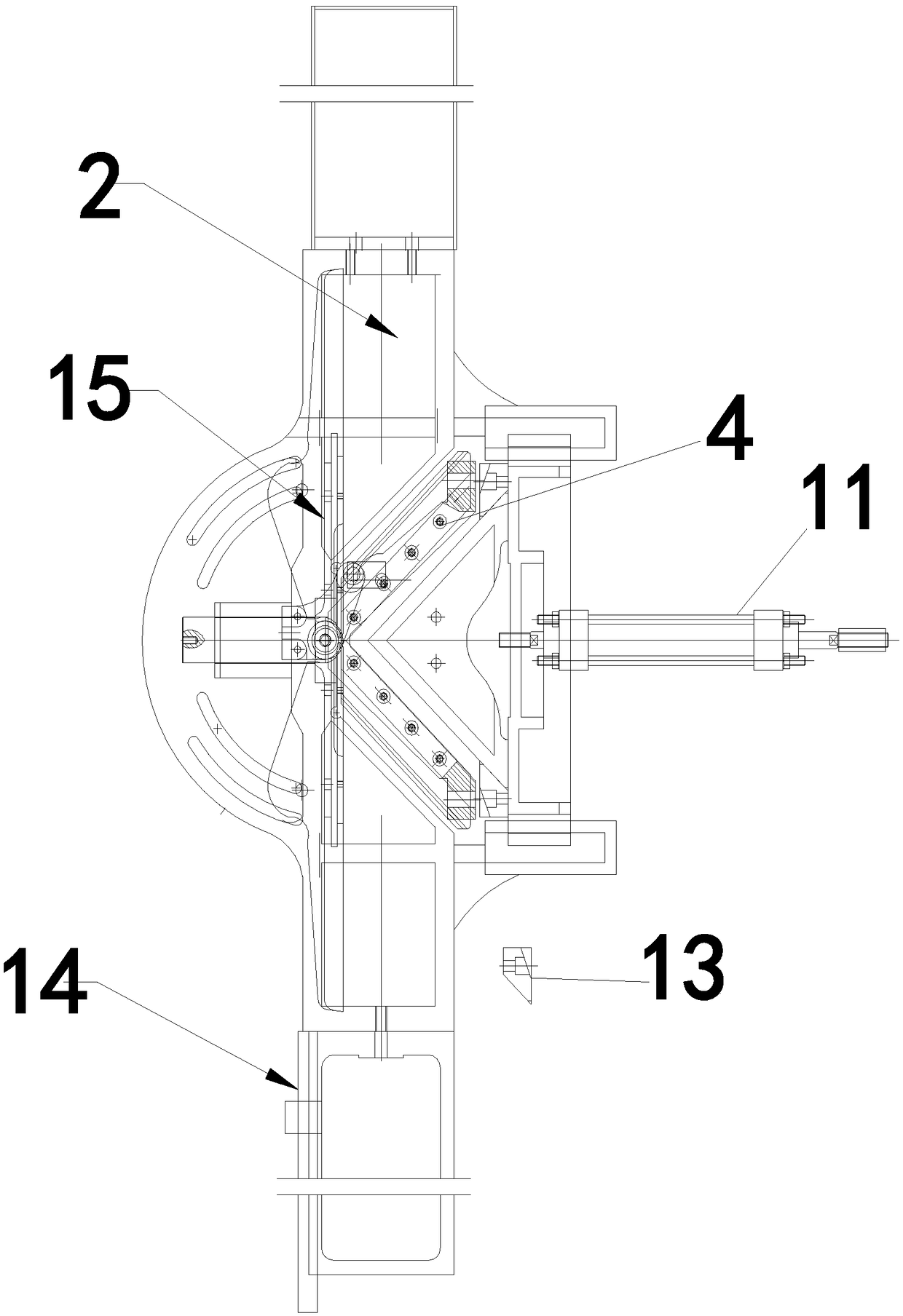

An automatic hydraulic angle cutting machine for photo frame production and its realization method

ActiveCN106541456BSimple structureLow costProfiling/shaping machinesHydraulic cylinderHydraulic pump

The invention discloses an automatic hydraulic angle cutter for producing a picture frame. The automatic hydraulic angle cutter comprises a framework, a longitudinal hydraulic cylinder, a beveling knife, a left inductive switch and a right inductive switch, wherein the side edge of the framework is provided with a mounting plate; the mounting plate is provided with a top limit inductive switch, a middle touch inductive switch and a bottom limit inductive switch in sequence from top to bottom; a transverse hydraulic cylinder is arranged below the middle touch inductive switch; the transverse hydraulic cylinder is connected with the beveling knife; a motor hydraulic pump is connected with the longitudinal hydraulic cylinder and the transverse hydraulic cylinder respectively; a controller is arranged in an electric control cabinet; the controller is connected with the longitudinal hydraulic cylinder, the transverse hydraulic cylinder, the motor hydraulic pump, the left inductive switch, the right inductive switch, the top limit conductive switch, the middle touch inductive switch and the bottom limit inductive switch respectively. The invention also discloses a realization method of the automatic hydraulic angle cutter for producing the picture frame. The automatic hydraulic angle cutter for producing the picture frame has the characteristics of being simple in structure, low in manufacturing cost, tidy in section, high in production efficiency, high in degree of automation, and the like.

Owner:DONGYANG MINGSHUO MACHINERY EQUIP MFG CO LTD

Cell separation cup with high extraction purity

PendingCN114292732AAvoid damageEliminate remaining problems in gapsBioreactor/fermenter combinationsBiological substance pretreatmentsMechanical engineeringCell isolation

The invention discloses a cell separation cup with high extraction purity. According to the technical scheme, the suction cup comprises a cup body, a cup cover, a suction pipe, a sterile pipe and a separation body arranged in the cup body, the separation body divides the interior of the cup body into an upper space and a lower space, and the top of the separation body is connected with the sterile pipe in a welded mode; the straw comprises a vertical section arranged outside the cup body and a bent section capable of penetrating through the wall of the cup body and the separation body to enter the lower space, and the bottom of the bent section is flush with the bottom of the separation body. According to the scheme provided by the invention, the suction tube can be prevented from damaging cells during centrifugation, residual cells in gaps are avoided, and the collection purity is improved.

Owner:太仓艺斯高医疗器械科技有限公司

A controllable strength adhesion device and its regulation method

ActiveCN112727876BChange the adhesive strengthReduce tangential forceMechanical oscillations controlMaterial gluingCommunication interfaceVibration amplitude

The invention relates to a controllable-strength adhesion device, which includes a support member providing support for the controllable-strength adhesion device; an adhesion unit is arranged at one end of the support member, and the end of the adhesion unit away from the support member is in contact with the adhesion interface; The micro-vibration excitation generation module between the units, one end of the micro-vibration excitation generation module is consolidated with the support, and the other end is consolidated with the adhesion unit, and the micro-vibration excitation generation module drives the adhesion unit to generate micro-vibration; The excitation adjustment amplification module is provided with a communication interface, and the micro-vibration excitation adjustment amplification module is connected with the micro-vibration excitation generation module to adjust its vibration frequency and amplitude. It also relates to the regulation method of the device, the method can adjust the frequency and amplitude of the micro-vibration according to the demand, and can realize the adjustment of the stable adhesion strength to the target adherent, so as to complete the fast switching between adhesion and desorption. The invention can effectively solve the existing problems of difficult adhesion failure and uncontrollable strength between adhesion interfaces.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

A kind of manufacturing method of dam gate rubber sealing ring

InactiveCN103256387BAvoid safety accidentsSimple structureEngine sealsVulcanizationMechanical engineering

Owner:成都太微电子科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com