One piece oil control ring for internal combustion engine

A one-piece, internal combustion engine technology applied in the field of oil control rings that can solve problems such as no revealed solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

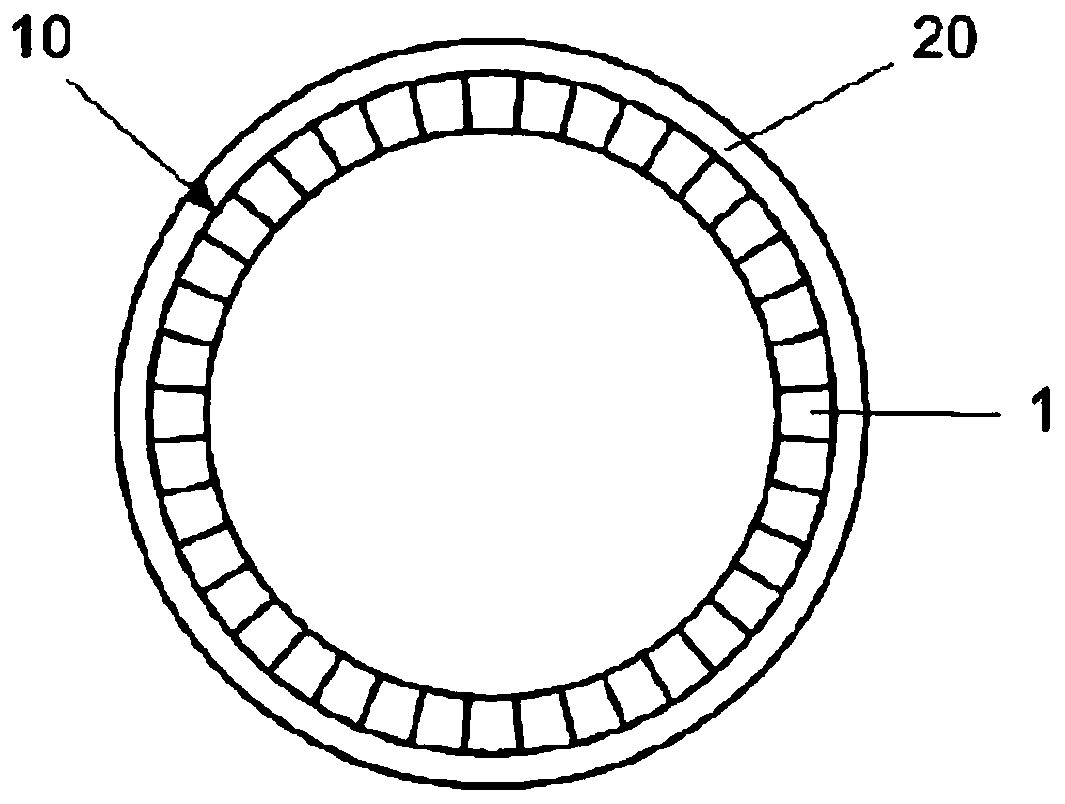

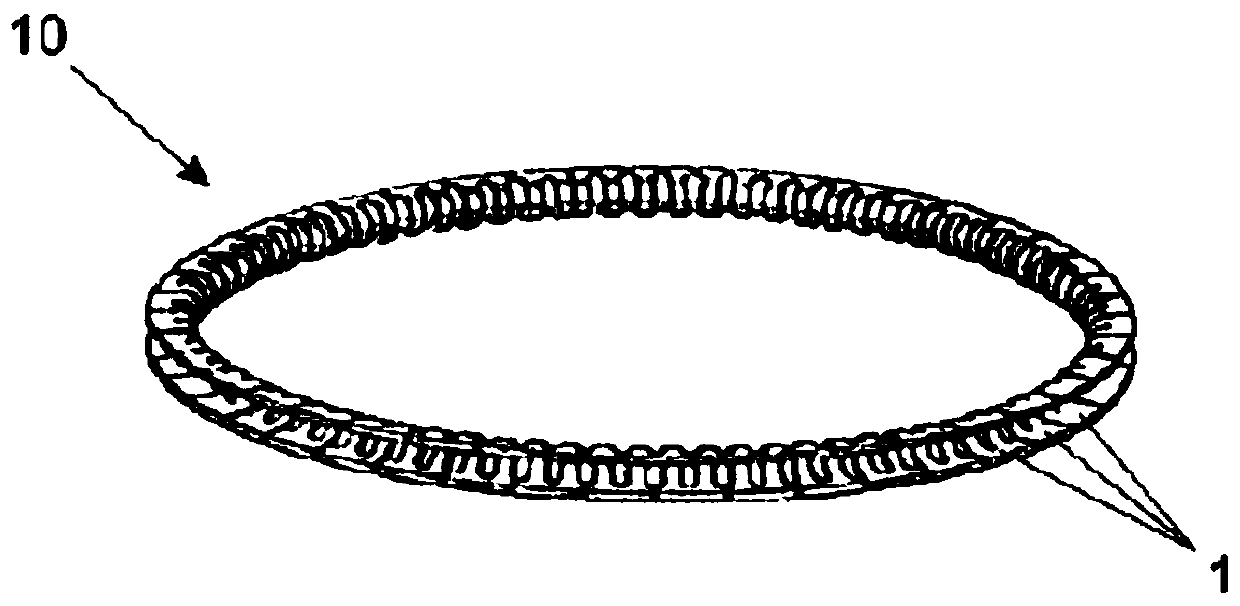

[0029] According to a preferred embodiment, and as in figure 1 with figure 2 As can be seen in , the subject one-piece oil control ring 10 of the present invention comprises a body formed of a plurality of operably associated segments 1, each segment having a degree of freedom of movement relative to the rest, Giving the ring 10 great flexibility, and thus great adaptability or moldability to the form of the cylinder liner 20, ensures that a proper oil film is maintained under a wide variety of engine operating conditions.

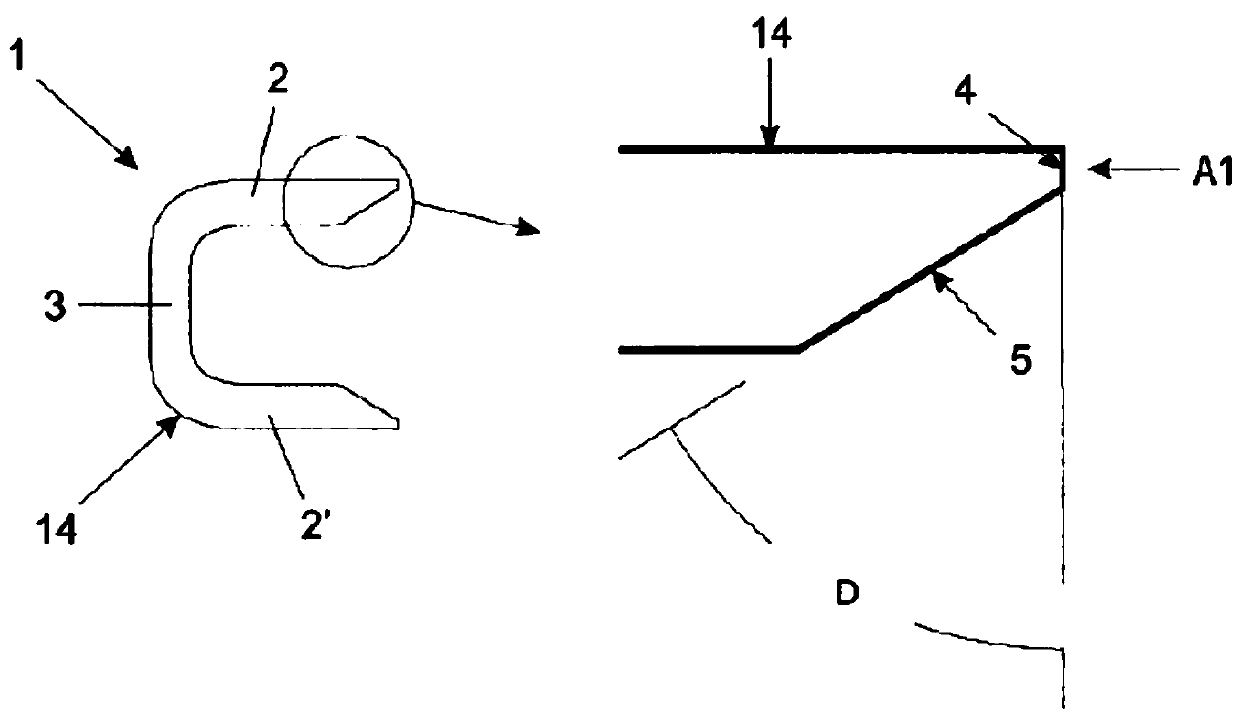

[0030] image 3 One of the segments 1 forming the body of the ring 10 is shown, comprising a cross-section having a substantially "C"-shaped form defining an upper part 2 and a lower part corresponding to the free extremities of the "C" 2', and a center portion 3 corresponding to the base of the "C". The upper part 2 and the lower part 2' are oriented towards the inner surface of the cylinder liner 20 when the ring 10 is mounted in the groove of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com