A pair of wheel spinning equipment for forming large thin-walled cylindrical parts

A technology of spinning equipment and thin-walled cylinder, which is applied in the field of wheel spinning equipment for forming large-scale thin-walled cylindrical parts, can solve the problems of high cost, poor versatility, long manufacturing cycle, etc. Tangential force, the effect of improving the rigidity of the screw

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

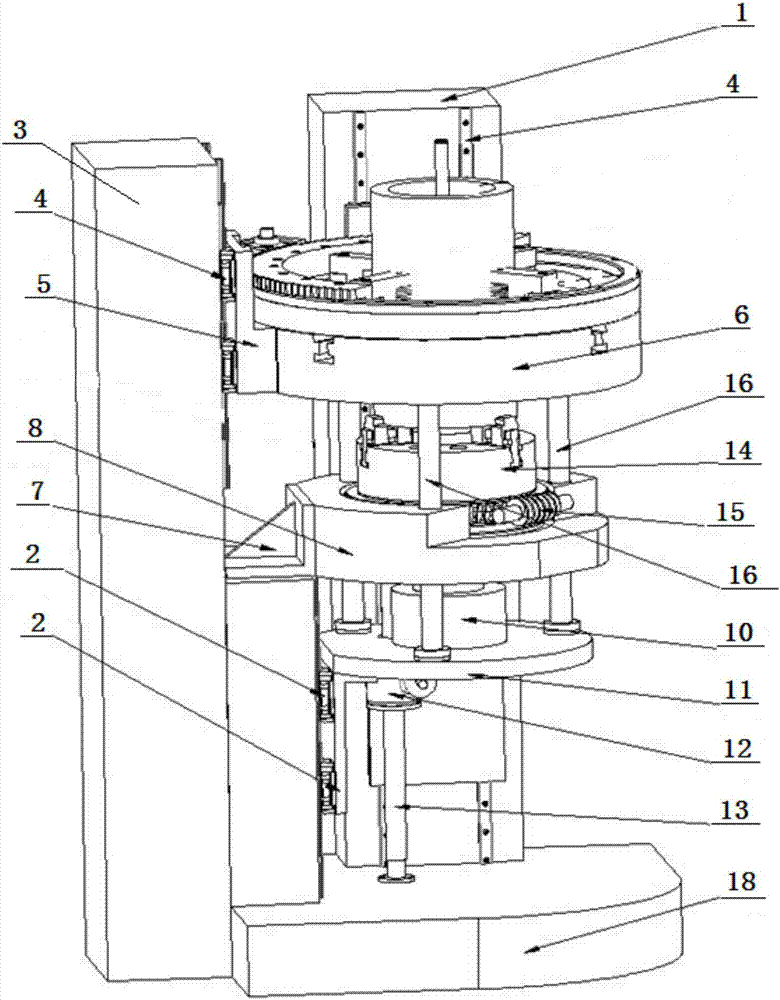

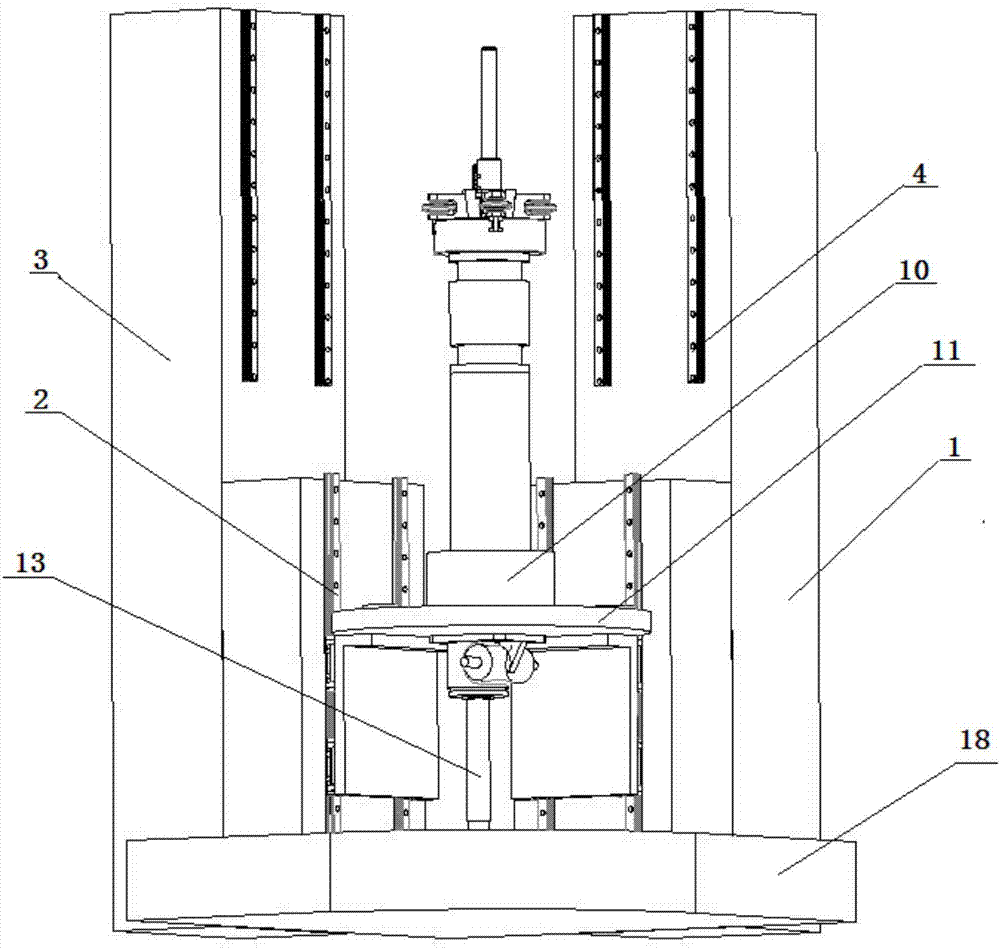

[0030] Specific embodiment one: combine 1 to Figure 14 Describe this embodiment, a wheel spinning equipment for forming large thin-walled cylindrical parts in this embodiment includes a first vertical frame 1, an inner rotation guide rail 2, a second vertical frame 3, an outer rotation guide rail 4. Outer rotation mechanism fixing seat 5, outer rotating disk 6, chuck base fixing seat 7, chuck base 8, base 18, bottom plate 11, lifting screw 13, lifting motor 12, inner rotation device fixing seat 10, Three-jaw chuck 14, worm gear assembly 15, multiple pull rods 16, internal rotation device and external rotation device;

[0031] The first vertical frame 1 and the second vertical frame 3 are installed on the base 18 at 90° with each other, and the inner rotation guide rail 2 is installed on the bottom of the first vertical frame 1 and the second vertical frame 3. The rotary guide rail 4 is installed on the top of the first vertical frame 1 and the second vertical frame 3, and th...

specific Embodiment approach 2

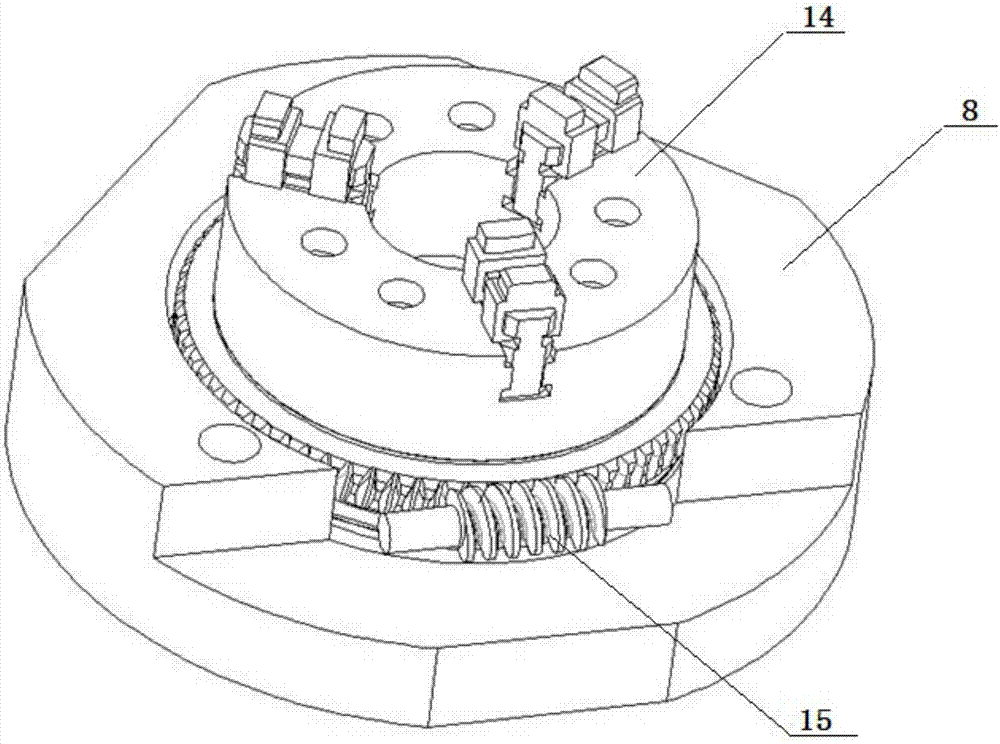

[0033] Specific implementation mode two: combination Figure 4 to Figure 9 Describe this embodiment, a kind of internal rotation device used for large-scale thin-walled tubular part counter-wheel spinning equipment in this embodiment includes internal rotation wheel seat guide sleeve A-1-1, internal rotation wedge guide sleeve A -1-4, inner rotation transition sleeve A-1-5, inner rotation upper beam A-1-6, inner rotation feed screw A-1-7, inner rotation motor A-1-8, inner rotation deceleration Device A-1-9, internal rotation cone wedge A-2-2, multiple internal rotation wheel seats A-2-3, multiple internal rotation wheels A-2-4 and multiple internal rotation wheel shafts A -3-2.

[0034] The inner-rotating conical wedge A-2-2 is set on the inner-rotating feed screw A-1-7, and a plurality of inner-rotating wheel seats A-2-3 are evenly distributed in a ring and installed on the inner-rotating conical wedge A On -2-2, each internal rotation wheel seat A-2-3 is vertically rotatab...

specific Embodiment approach 3

[0036] Specific implementation mode three: combination Figure 4 to Figure 9 Describe this embodiment, the inner turning wheel seat A-2-3 of this embodiment of this embodiment is a U-shaped structure, the upper and lower ends of the inner turning wheel A-2-4 are fitted with the tapered roller bearings at the head and tail sections of the turning wheel shaft A-3-3 constitutes an interference fit. Such an arrangement facilitates the provision of a spinning working environment and space for the rotary wheel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com