Direction-adjustable sensor mounting seat and mounting method thereof

A technology of sensors and mounts, which is applied in the field of adjustable sensor mounts, can solve problems such as inability to obtain effective inversion parameters, inability to correct bolt installation errors, and directional errors in measurement results, so as to facilitate mass processing, Accurately adjust the effect of reliable curing and reduce the requirements of processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described in detail below in conjunction with the accompanying drawings

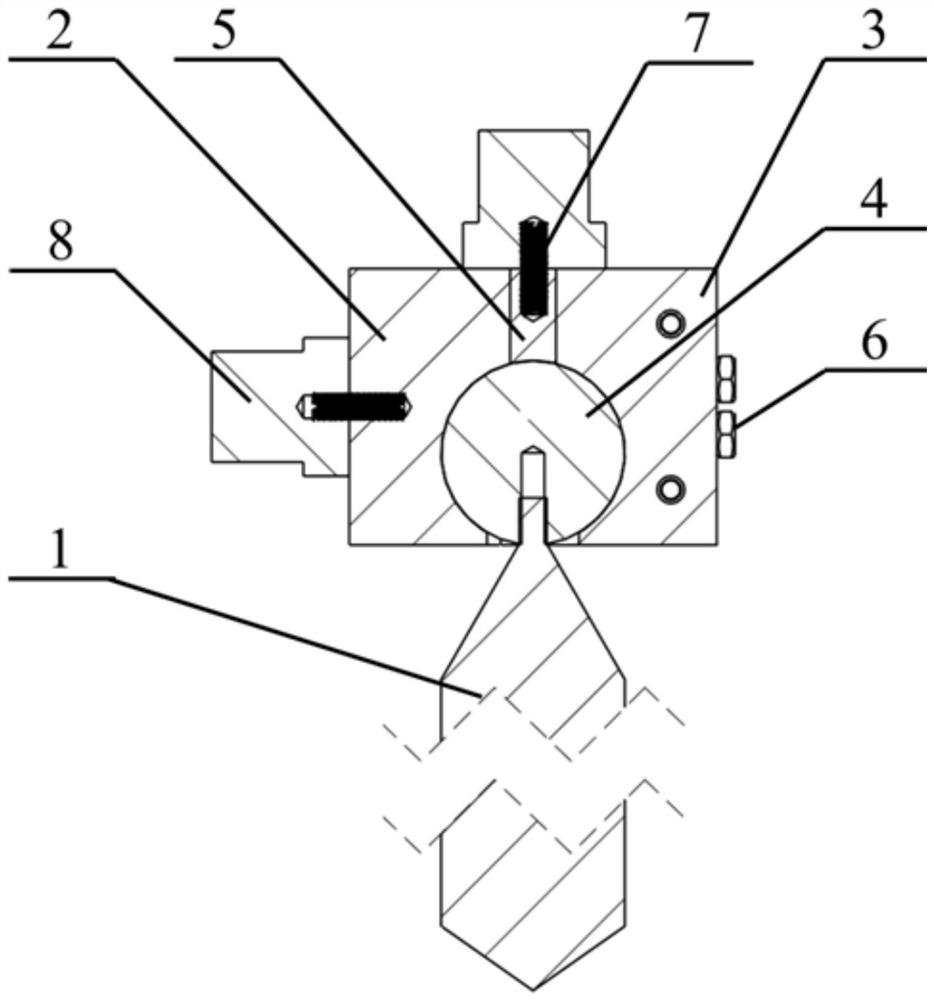

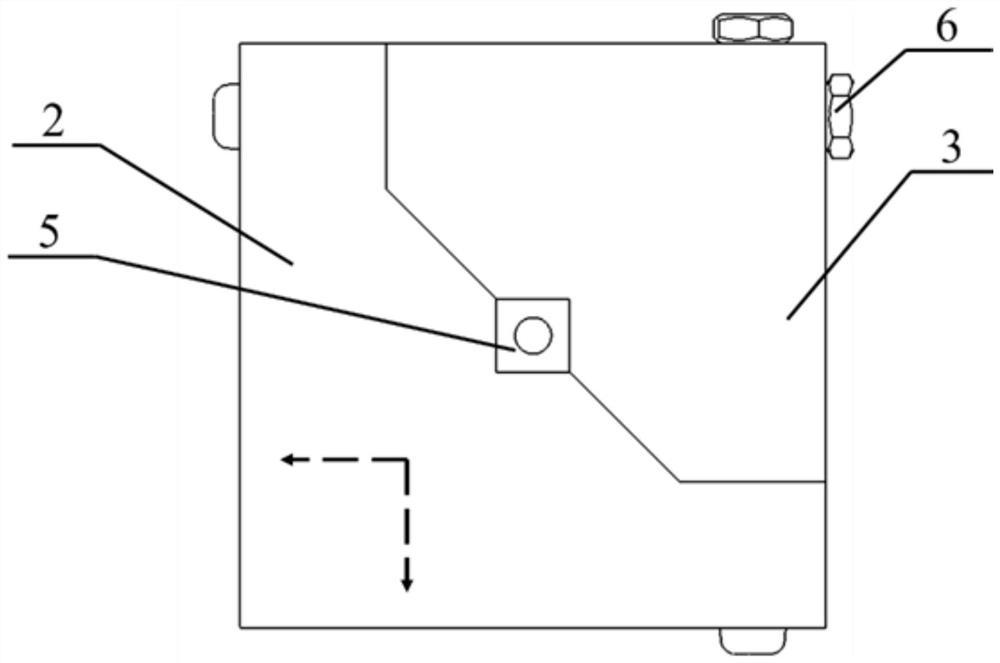

[0056] like figure 1 , figure 2 As shown in the figure, the present invention provides an orientable sensor mounting seat. The overall structure includes an anchor rod 1 and a positioning unit. The positioning unit includes a first module 2, a second module 3, a spherical base 4, a positioning pin 5, and a bolt. Assembly 6 and three connecting screws 7.

[0057] The top of the anchor rod 1 is provided with threads, which are fixedly connected with the screw holes at the bottom of the spherical base 4 through threads. The lower part of the threads of the anchor rod 1 is provided with a conical transition section. This structural design increases the angle adjustment range of the mounting seat.

[0058] The first module 2 and the second module 3 are fixedly connected by bolt assemblies 6 to form a cube structure, and the tightening direction of the bolt assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com