Patents

Literature

34results about How to "Easy to process in large batches" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

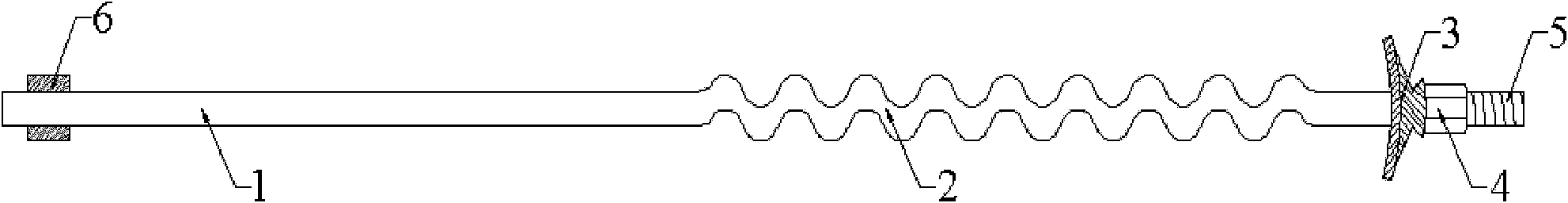

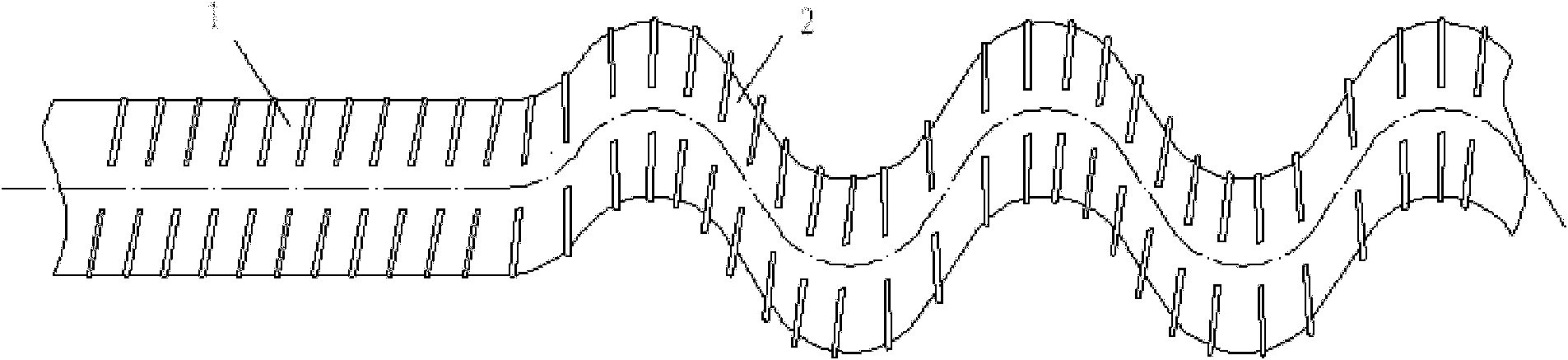

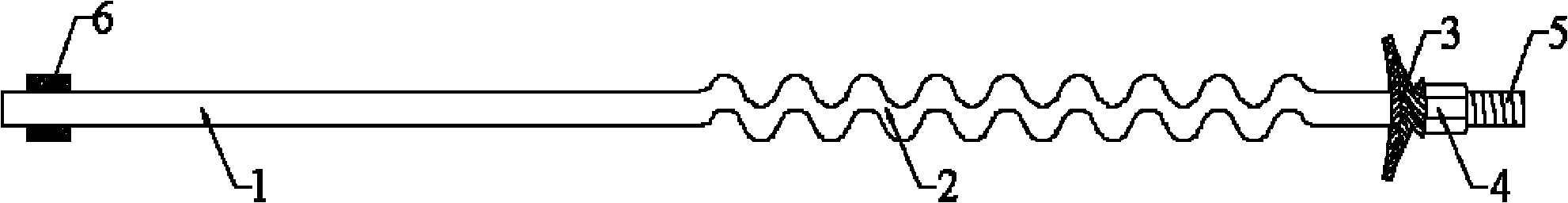

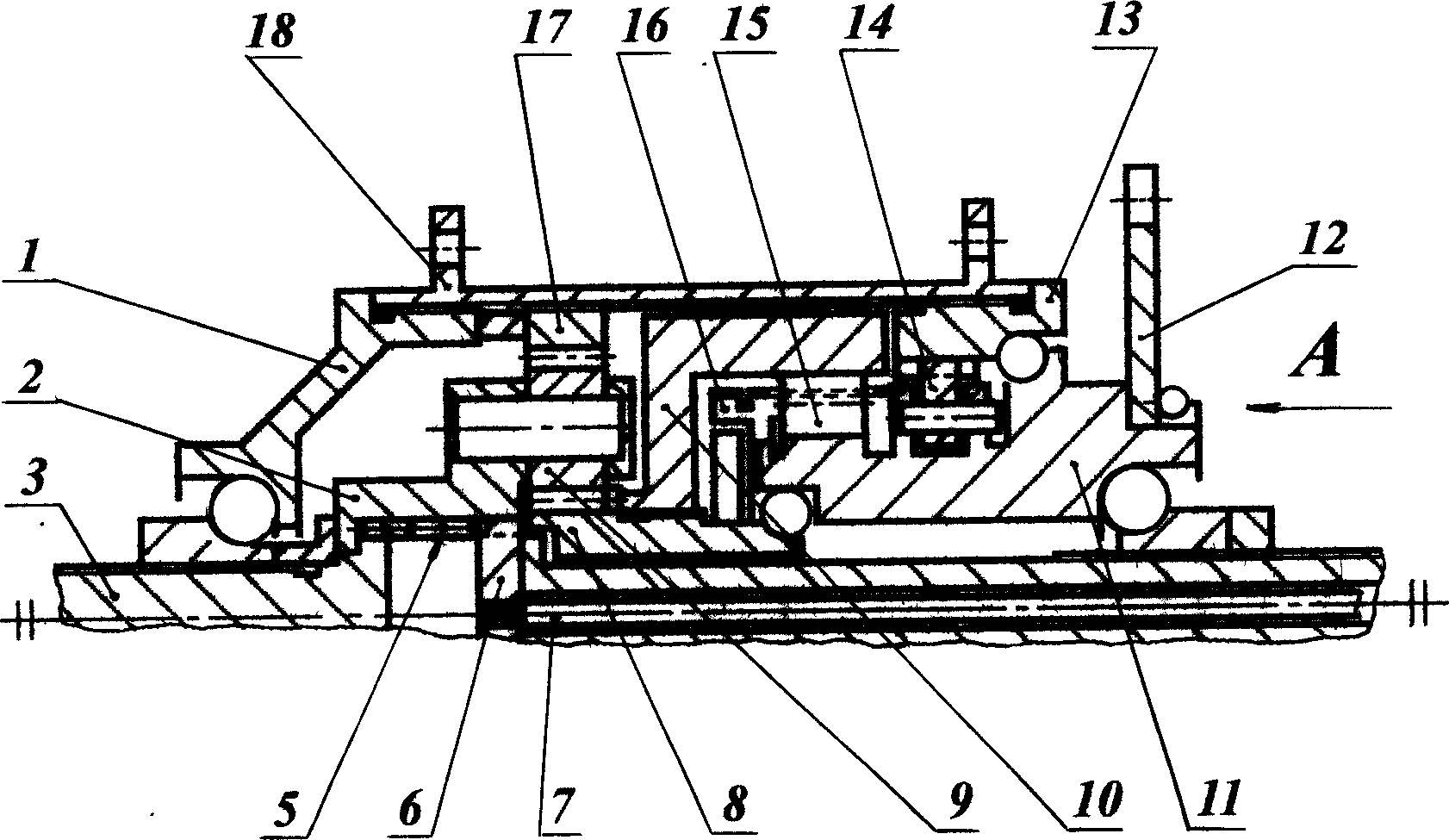

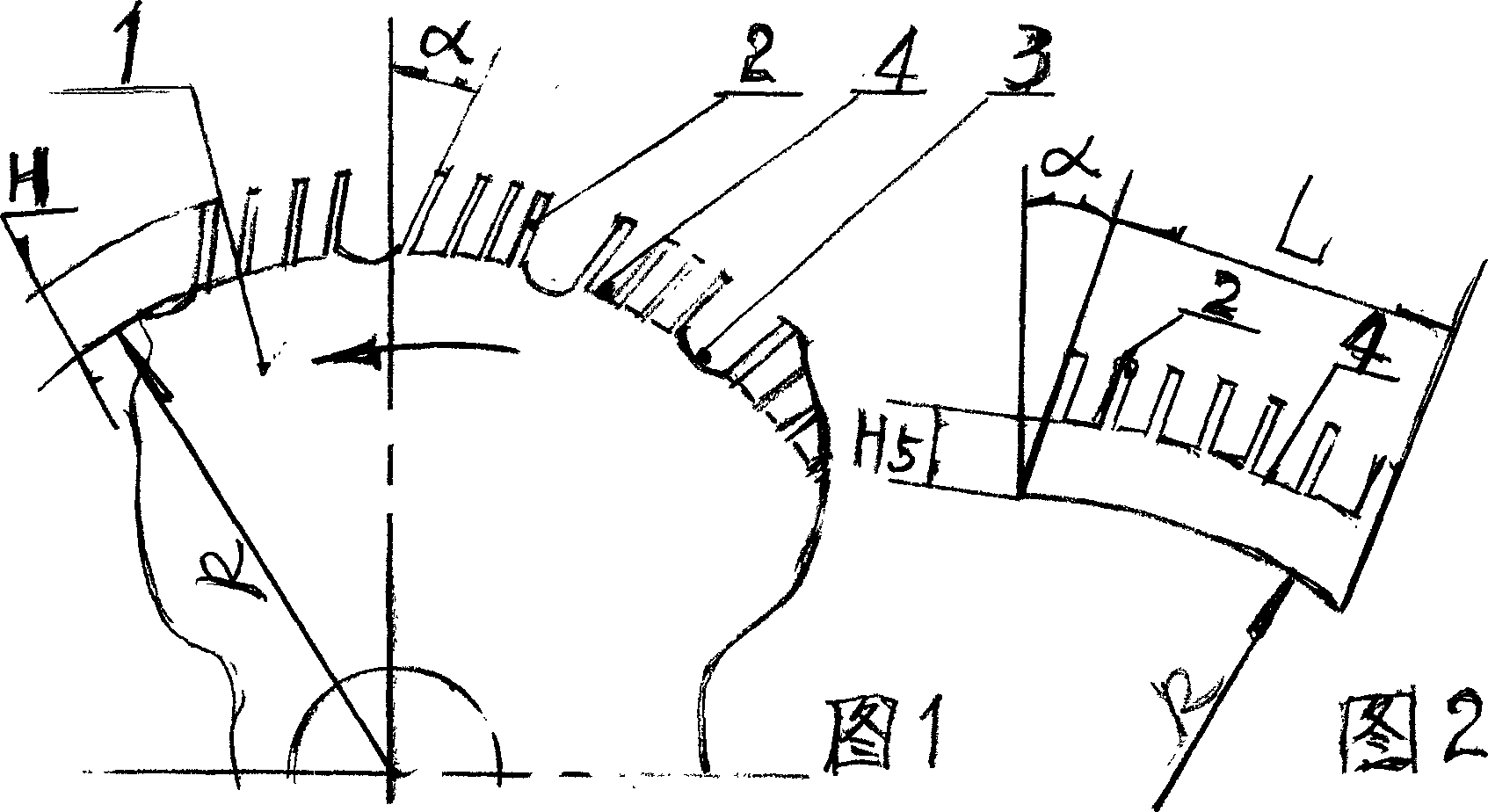

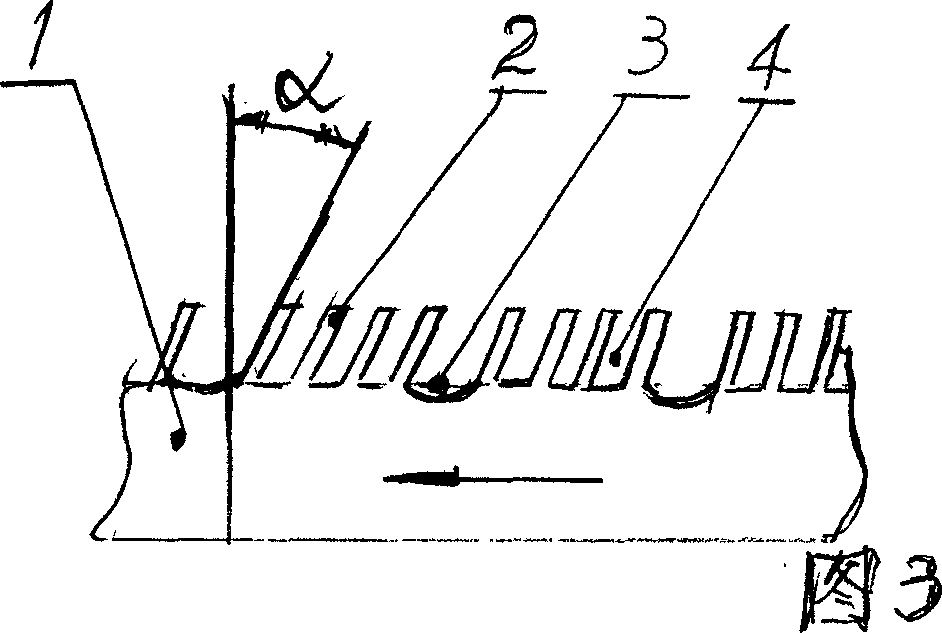

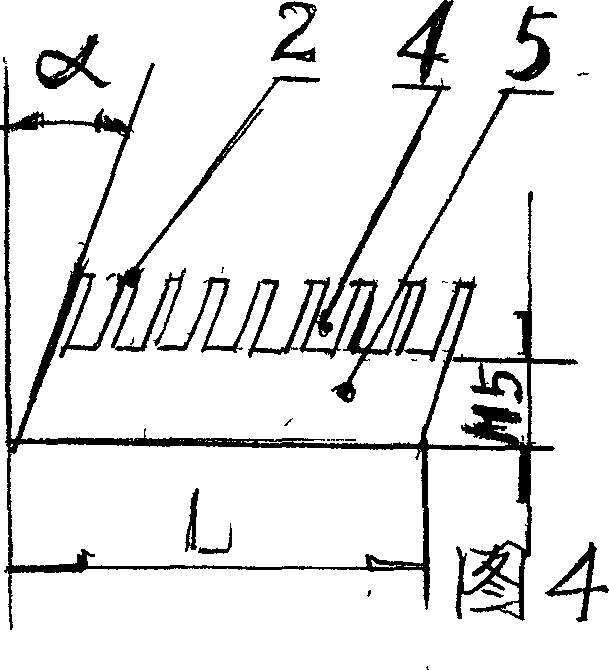

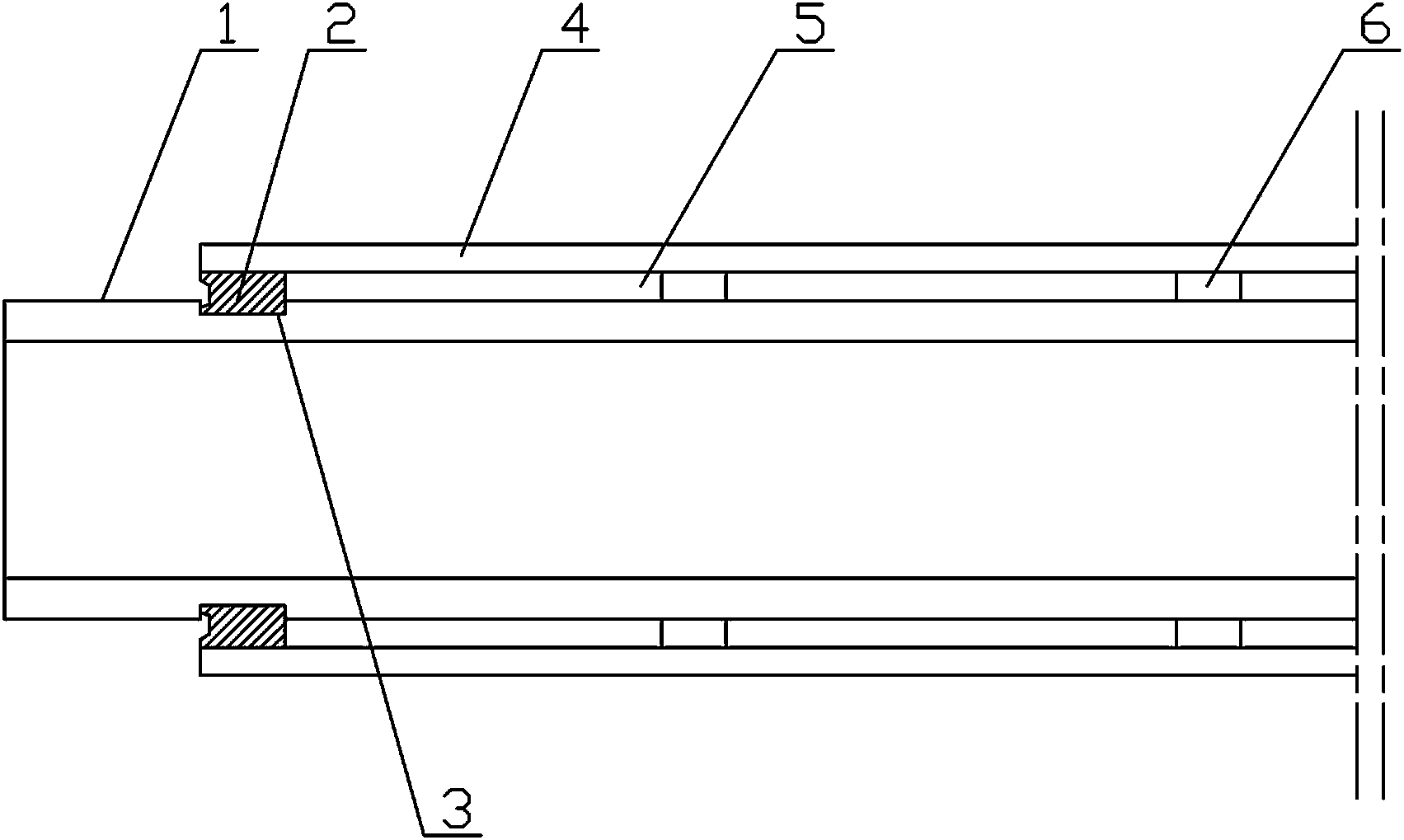

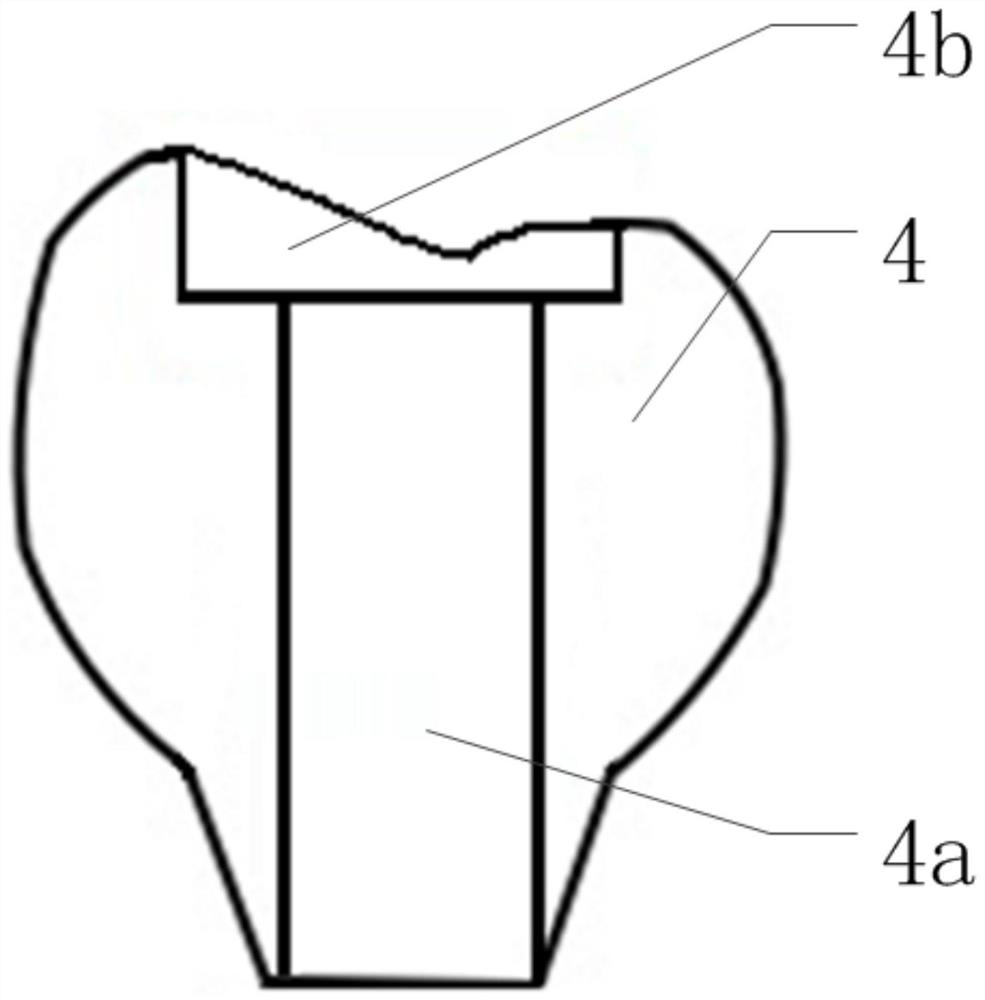

Coordinated-deformation energy-absorption anchor rod suitable for mining high-stress large-deformation rock mass

InactiveCN101929347ASimple structureEasy to process in large batchesAnchoring boltsGround pressureEnergy absorption

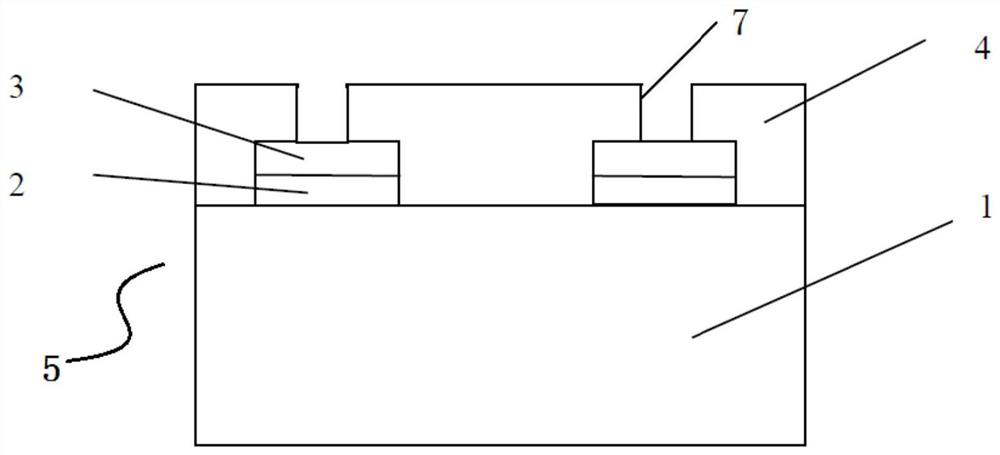

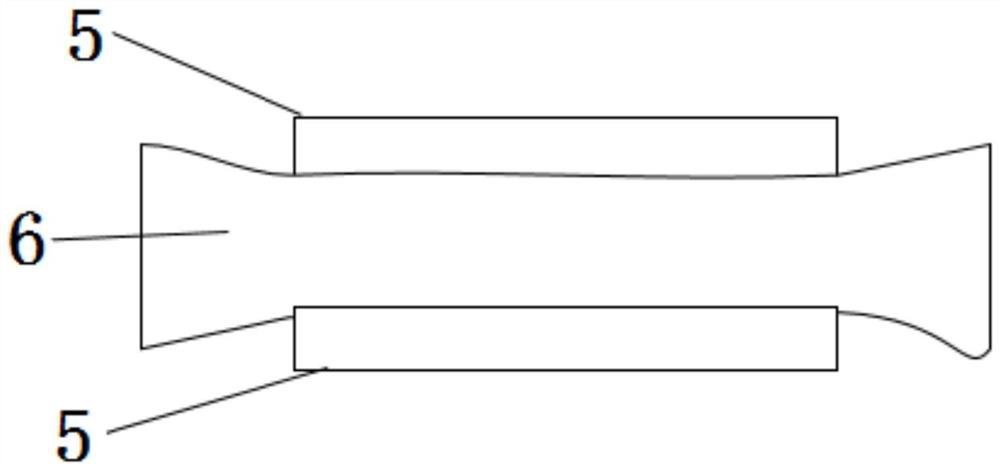

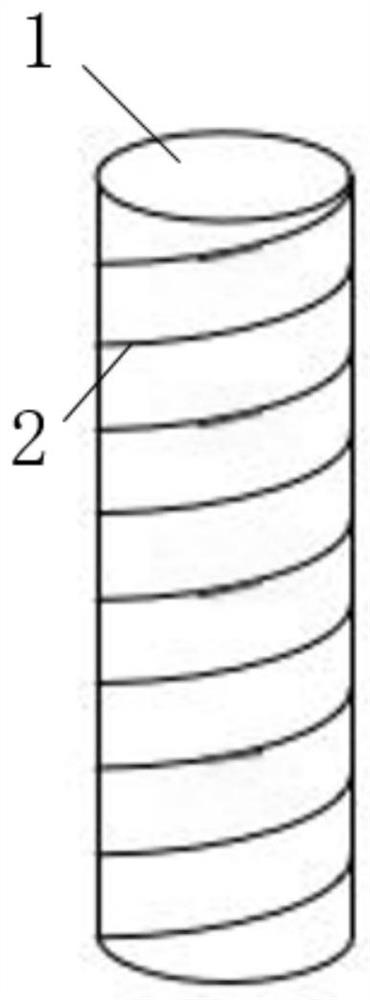

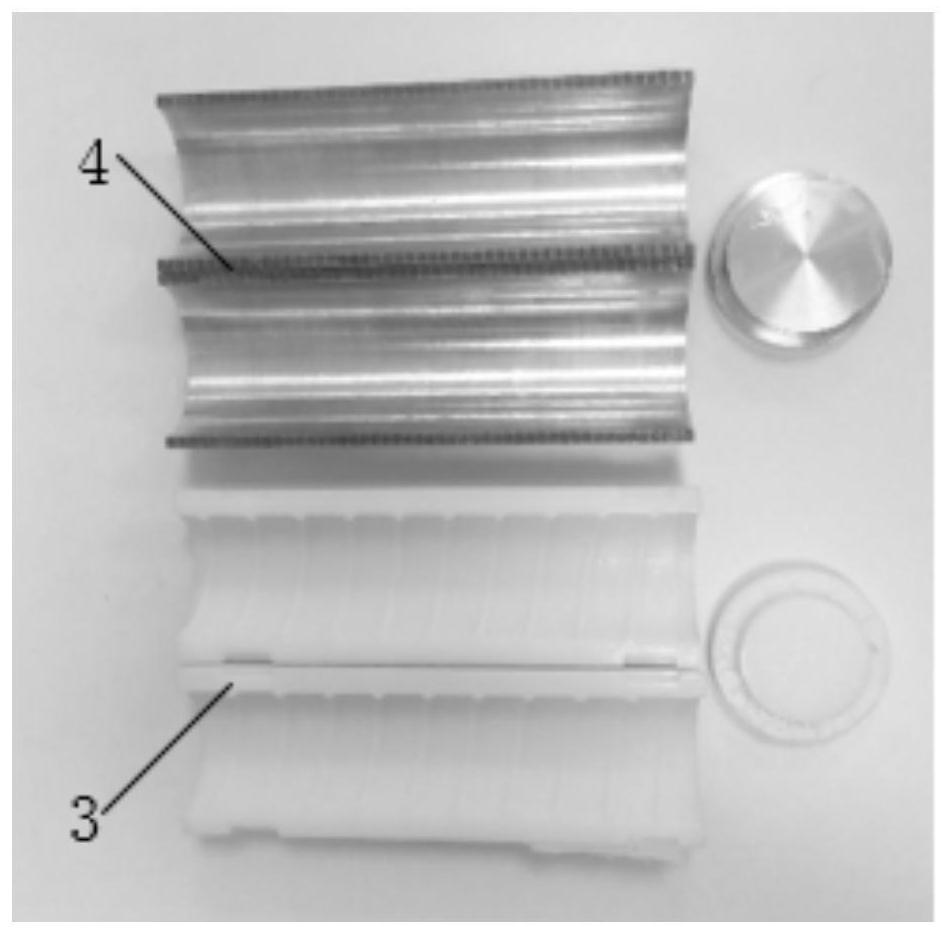

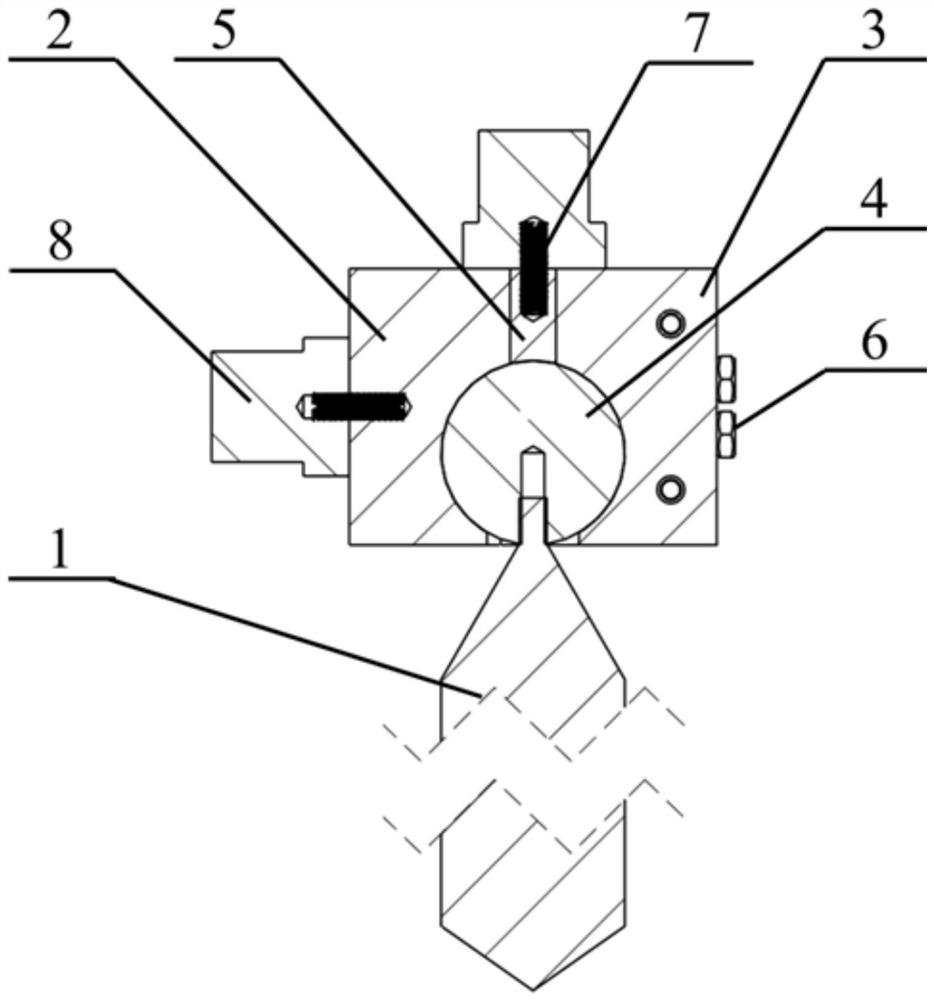

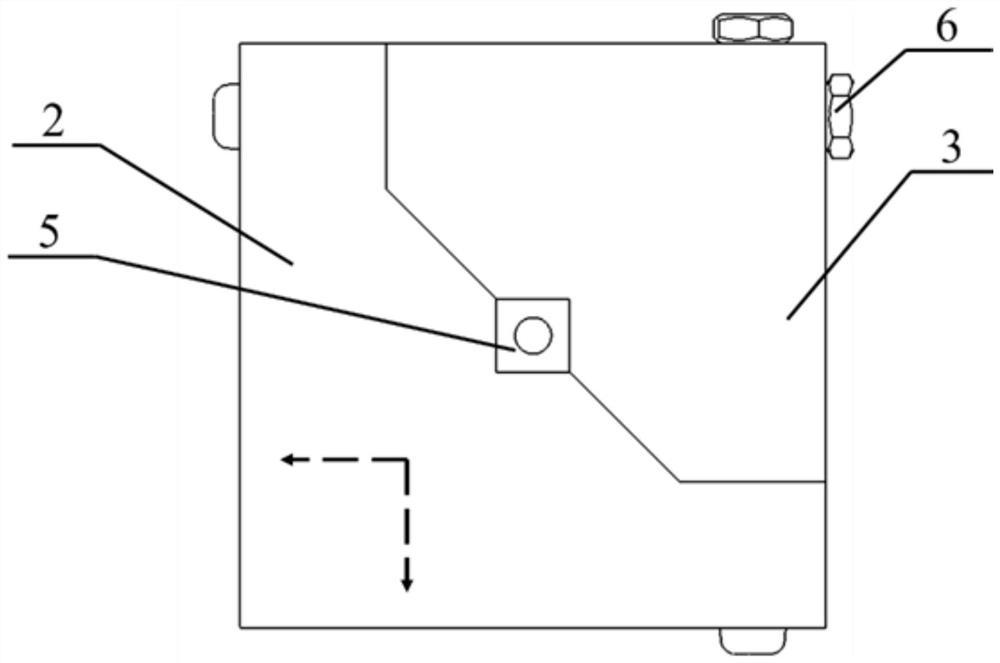

The invention discloses a coordinated-deformation energy-absorption anchor rod suitable for mining a high-stress large-deformation rock mass. The rod body of the anchor rod mainly comprises an elongated anchoring section straight rod body (1) and an energy-absorption section bending rod body (2), wherein one end, close to the energy-absorption section bending rod body, of the rod body is provided with a threaded section (5); a fastening nut (4) is screwed on the threaded section (5); and a steel pallet (3) is sleeved between the fastening nut (4) on the threaded section (5) and the energy-absorption section bending rod body. The anchor rod is mainly characterized in that: a wavelike bending energy-absorption section in a specific length and a specific shape is mechanized on a long straight threaded steel rod body in a heat treatment mode; the energy-adsorption section restrictively allows a wall rock to deform properly and simultaneously absorb the deformation energy of the rock mass until reaching total allowable deformation quantity meeting a design requirement. In the process, the supporting force of the anchor rod is increased gradually; and finally, after the bending section is completely straightened and a yielding effect controlled by a high-stress roadway ground pressure is achieved, the anchor rod becomes a high-strength rigid resin anchor rod for providing greater supporting force for a supported wall rock mass.

Owner:CENT SOUTH UNIV

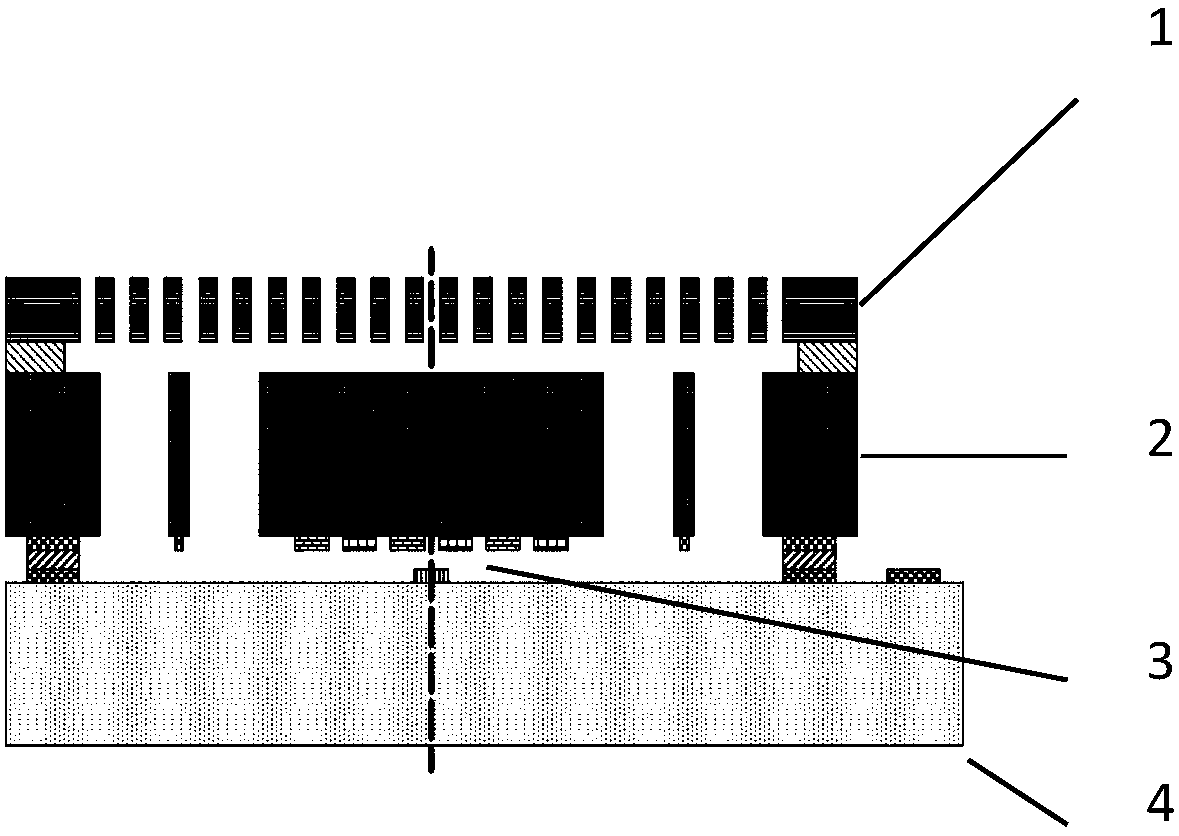

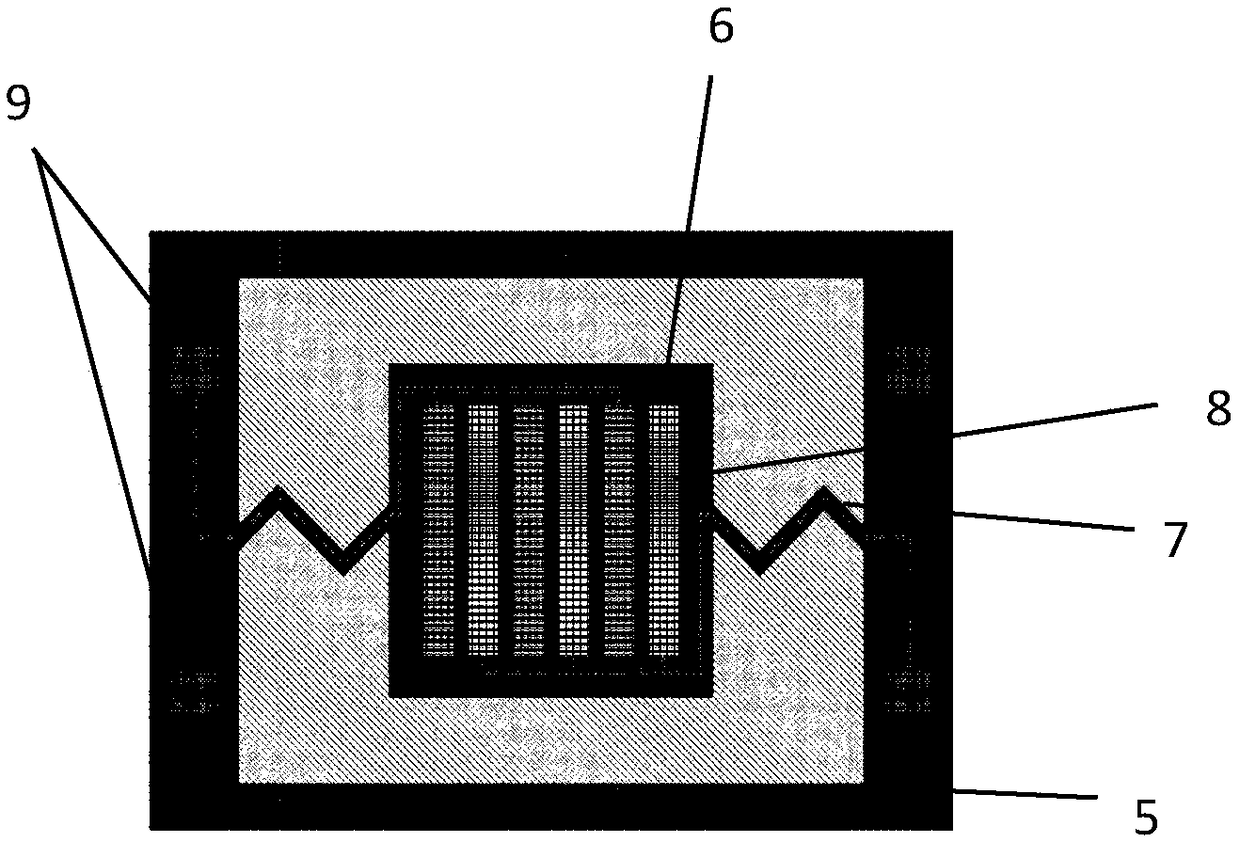

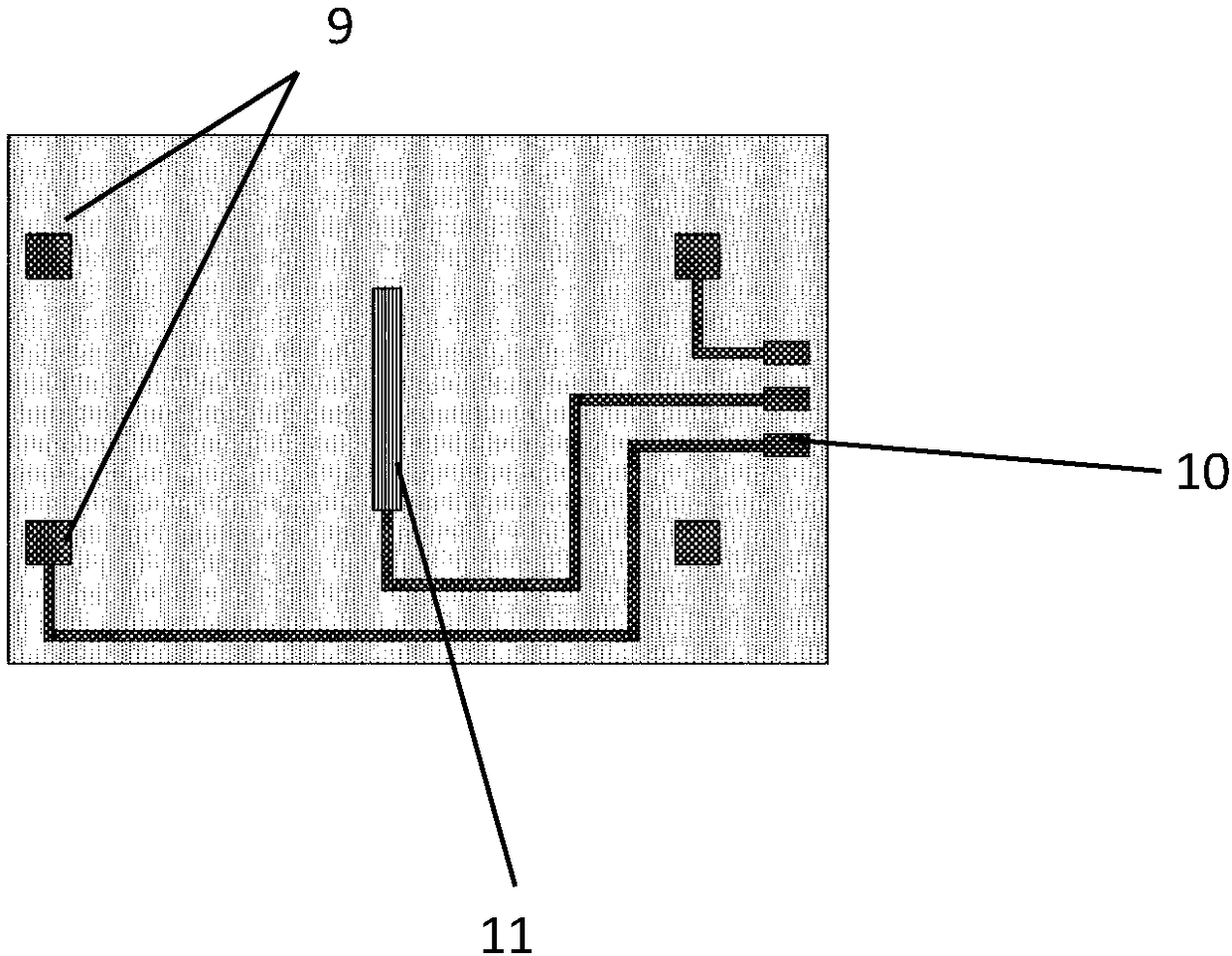

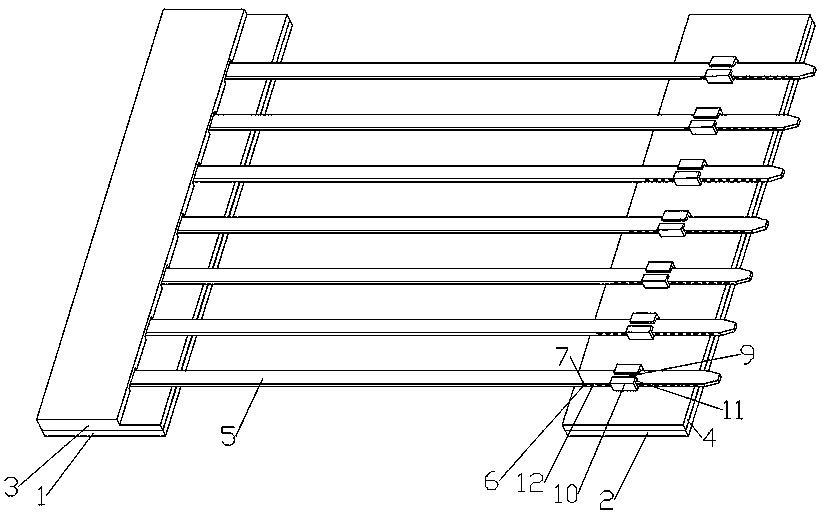

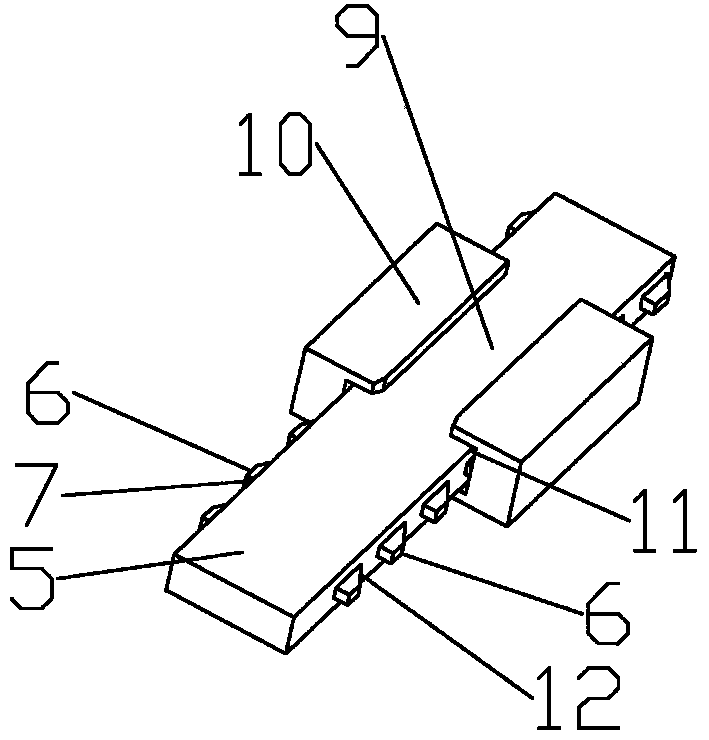

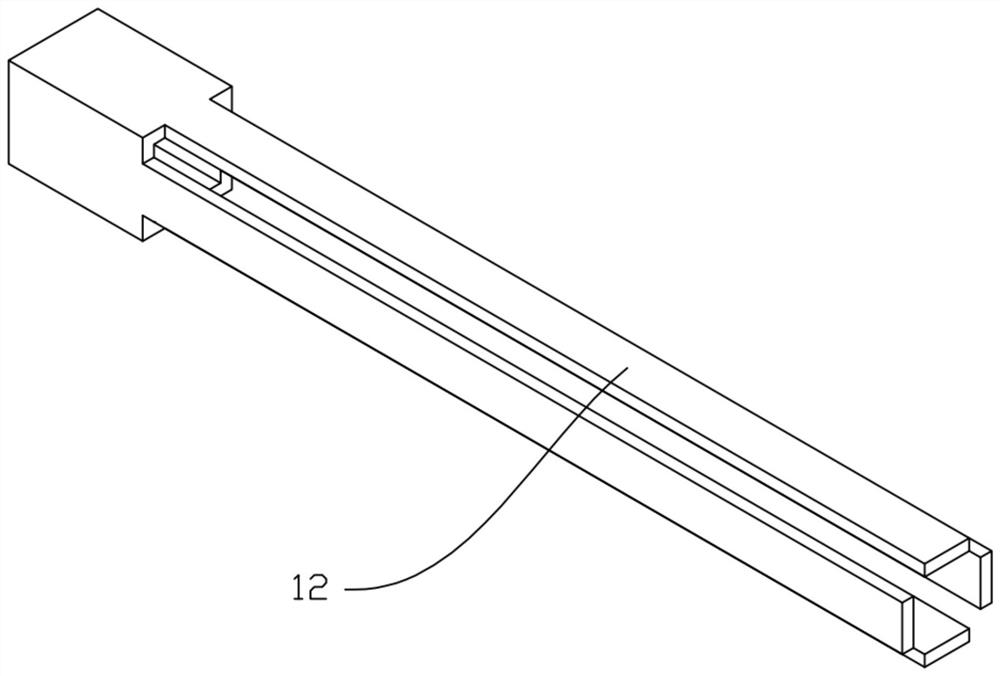

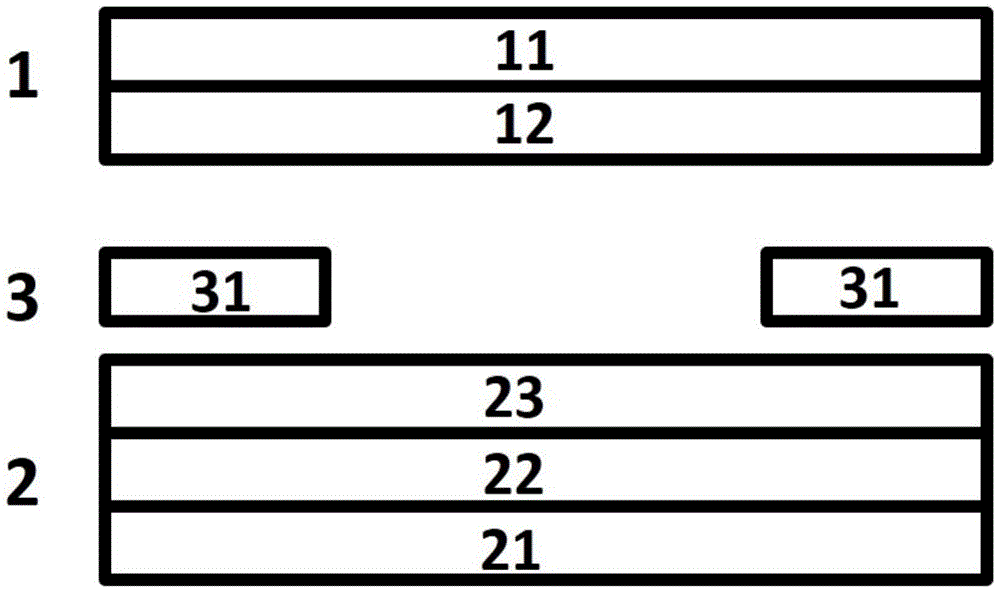

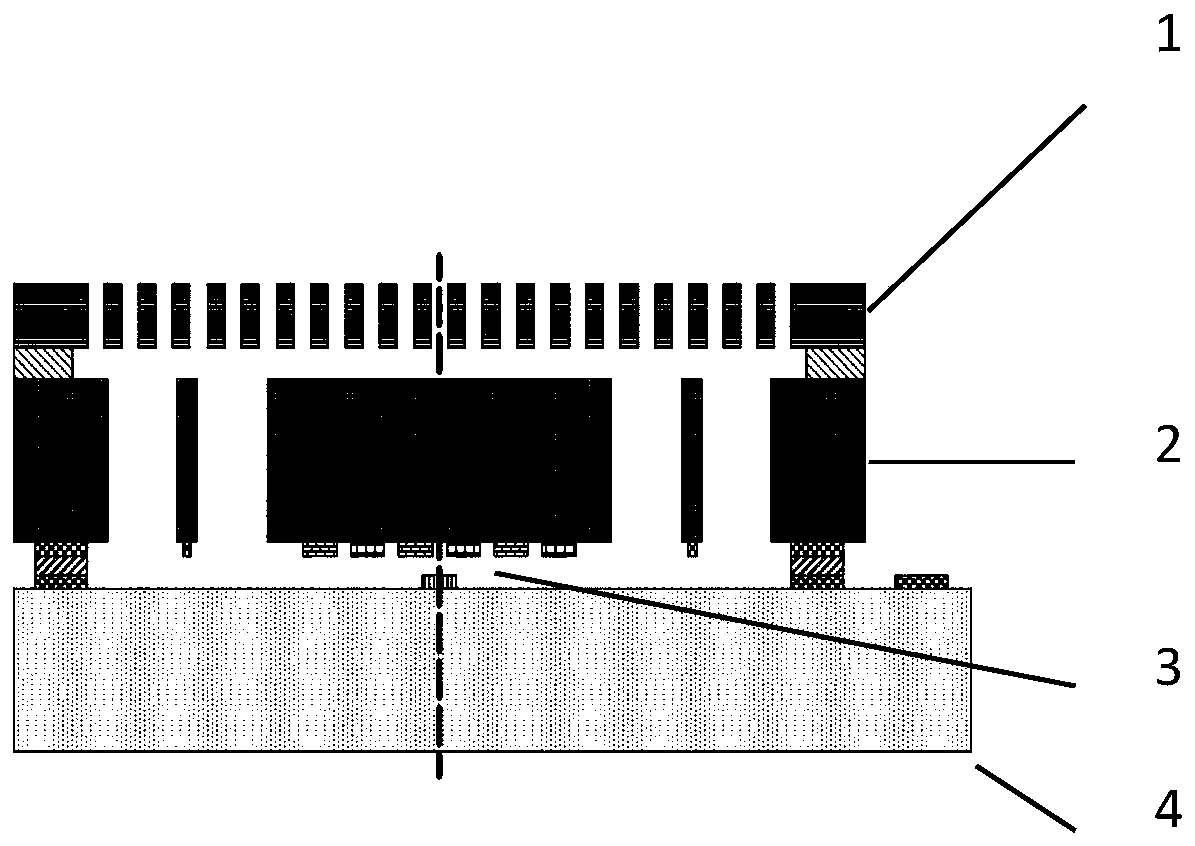

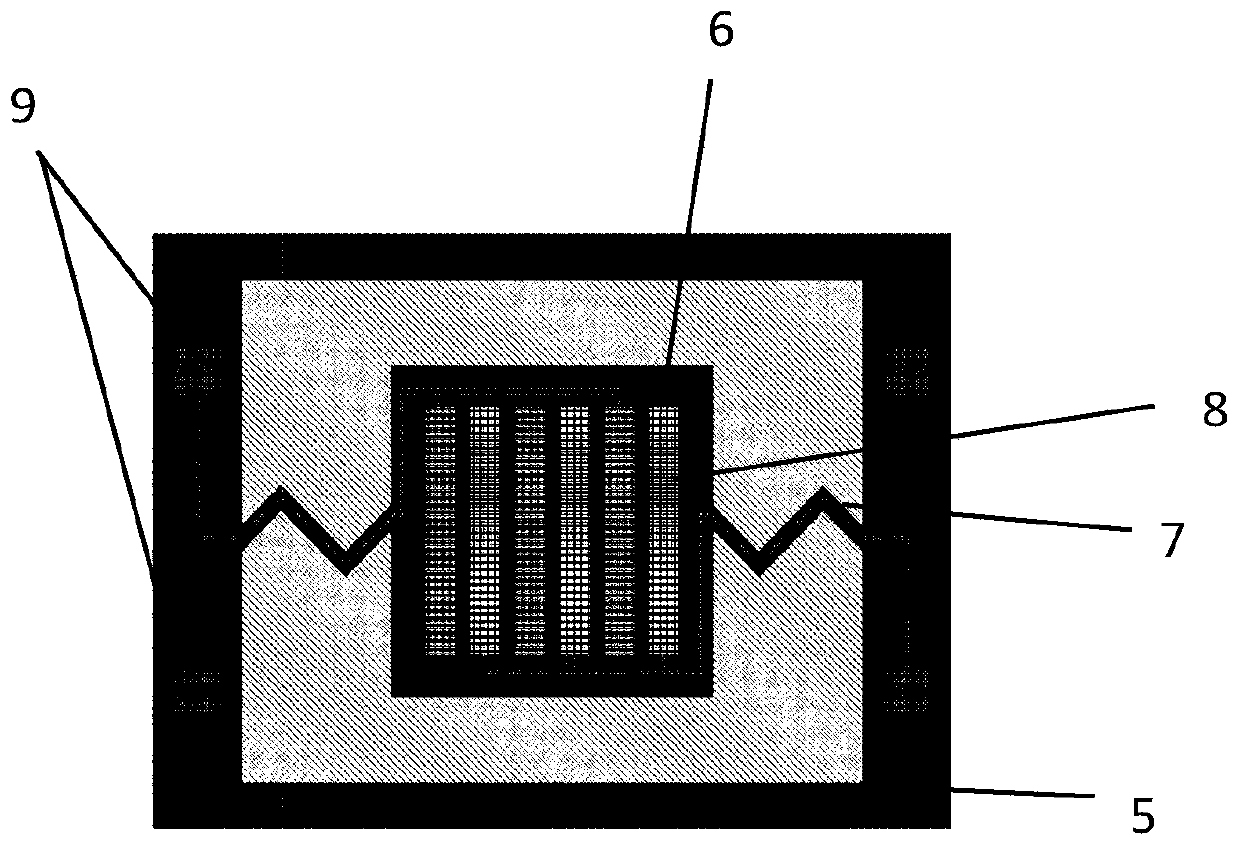

Gravitational acceleration sensor

ActiveCN108152862AImprove consistencyEasy to implementGravitational wave measurementGravitational forceCapacitance

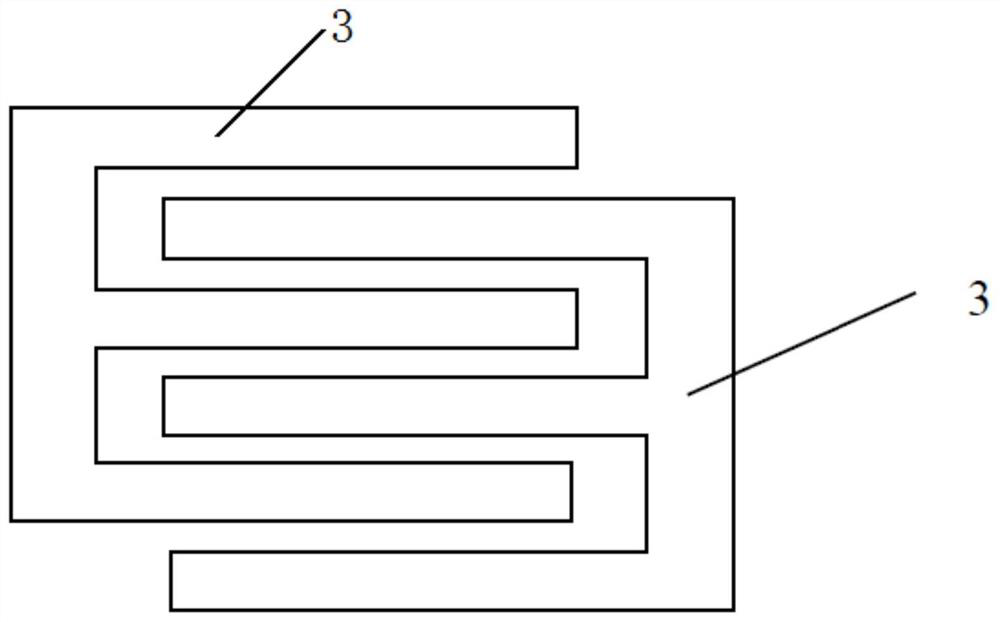

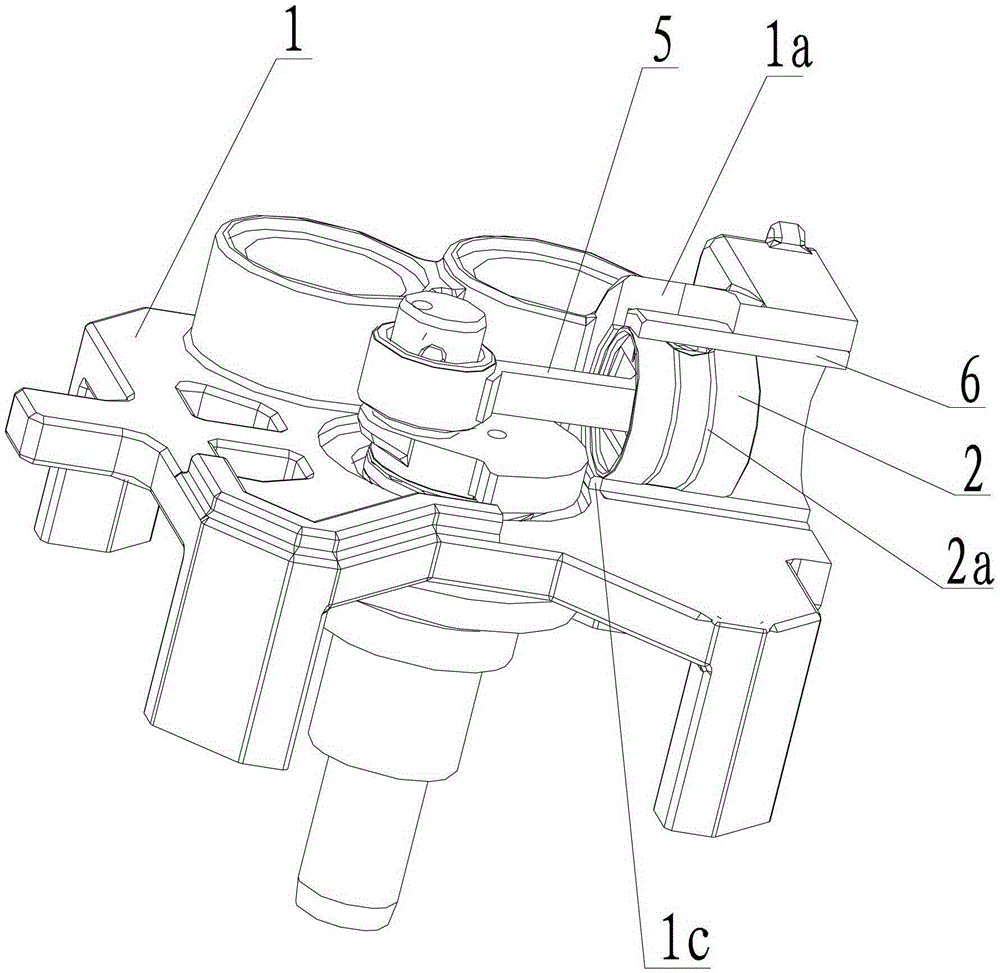

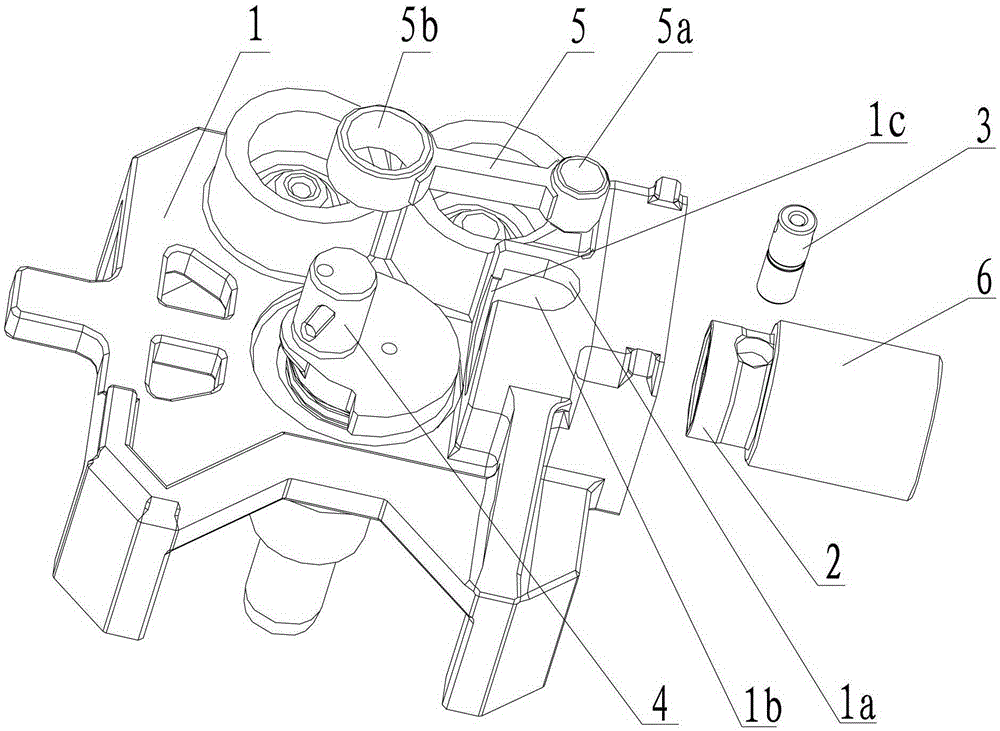

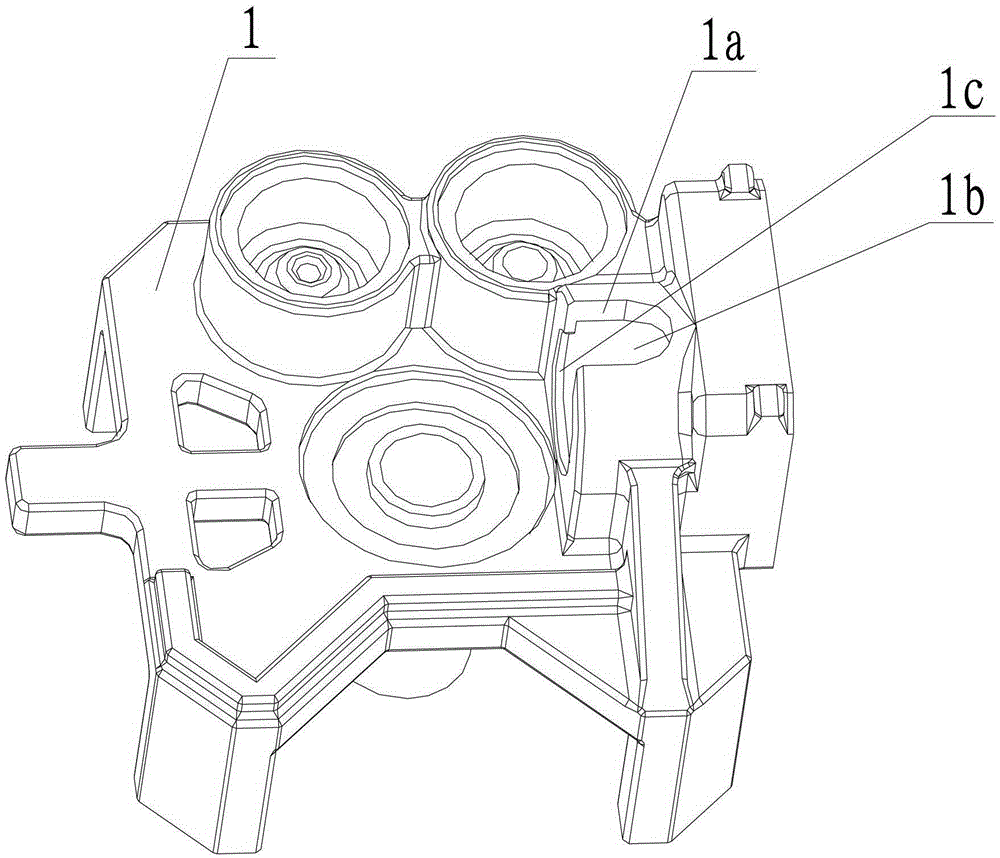

The invention discloses a gravitational acceleration sensor which comprises a spring mass block structure, a displacement sensing assembly, an upper cover plate structure and a lower cover plate structure. The spring mass block structure comprises a housing frame, an examining weight and a spring structure, and under constraint of the spring structure, the examining weight moves under the effect of an external force; the displacement sensing assembly comprises a driving period array pole plate and a picking period array pole plate, the position of the driving period array pole plate is opposite to that of the picking period array pole plate in an interlaced way, and a capacitor is formed; and when a gravitational acceleration component parallel to the direction of the driving period arraypole plate or the picking period array pole plate changes, the examining weight moves so that the area of the pole plates opposite to each other of the capacitor changes, the change quantity of the capacitor is detector to determine the change quality of the gravitational acceleration component in the direction, and when the gravitational acceleration sensor works in the direction of axis-Z, sagging displacement of the examining weight includes one or more array period(s) under the effect of the gravity. Thus, three-component gravity measurement can be realized.

Owner:HUAZHONG UNIV OF SCI & TECH

Wound closure device

The invention discloses a wound closure device, which comprises a left adhesive strip and a right adhesive strip which are respectively distributed along both sides of a wound. The left adhesive strip and the right adhesive strip are respectively and fixedly provided with a left support belt and a right support belt; a plurality of locking devices connected with the left support belt and the right support belt are distributed on the left support belt and the right support belt; each locking device comprises a connecting band and a connecting device matched with the corresponding connecting band; a plurality of fixture blocks are respectively distributed in rows at both sides of each connecting band; one ends of the connecting bands are fixedly arranged onto the left support belt; the connecting devices are arranged on the right support belt; each connecting device comprises a muff-coupling part with an insertion hole; necks are respectively configured at both sides of the insertion hole of each muff-coupling part corresponding to the fixture blocks; one side, which faces the corresponding muff-coupling part, of each fixture block is provided with a first oblique plane; one side, which faces the left support belt, of each neck is provided with a second oblique plane matched with the corresponding first oblique plane; one side, which is far away from the corresponding muff-coupling part, of each fixture block is provided with a first stopping plane; one side of, which is far away from the left support belt, each neck is provided with a second stopping plane matched with the corresponding first stopping plane. According to the wound closure device disclosed by the invention, a centipede foot-like scar is not left after the wound is closured, drugs can be conveniently applied, and moreover, a better ventilation effect can be kept for the wound.

Owner:宋方昆

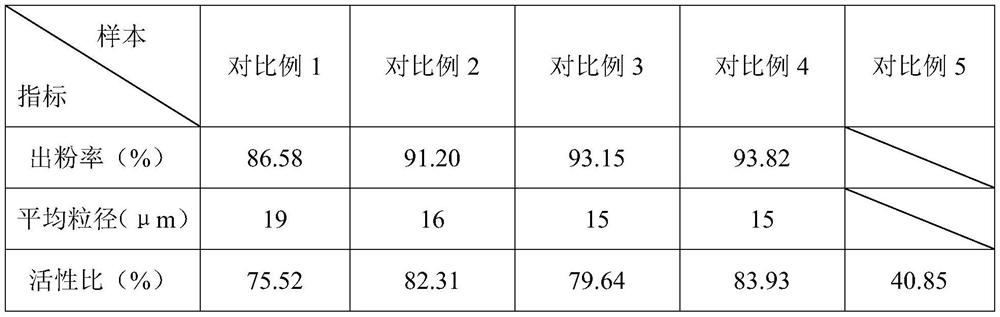

Method for processing waste glass fiber filament powder material

The invention belongs to the technical field of glass fiber recycling and in particular relates to a method for processing a waste glass fiber filament powder material. The method comprises the following steps: firstly, performing soaking treatment on waste glass fiber filaments in a mixed liquid of an alkali and supernate of cement slurry, taking out the soaked waste glass fiber filaments, and performing washing, crushing, drying and powder milling, so as to obtain the waste glass fiber filament powder material. By adopting the method, an impregnating compound on surfaces of the waste glass fiber filaments can be removed, meanwhile, micro cracks on the surface of glass fiber can be increased, the strength of the glass fiber can be degraded, the brittleness of the glass fiber can be improved, and the powder milling effect of the waste glass fiber filaments when being processed into the powder material can be improved; by adopting the method, the waste glass fiber filaments can be efficiently powdered into the powder material, the powder material is uniform and stable in component, and can be mixed with other glass raw materials into a batch which can be fed into a kiln by using a reamer, so that the time and the labor can be saved, and the waste glass fiber filaments can be efficiently repeatedly used; and by adopting the method, the recycling treatment degree of the waste glass fiber filaments of the glass fiber industry can be increased, overstock of waste materials can be avoided, the market purchase cost of cement and alkali liquids is low, and large-scale treatment iseasy.

Owner:山东硕远新材料有限公司

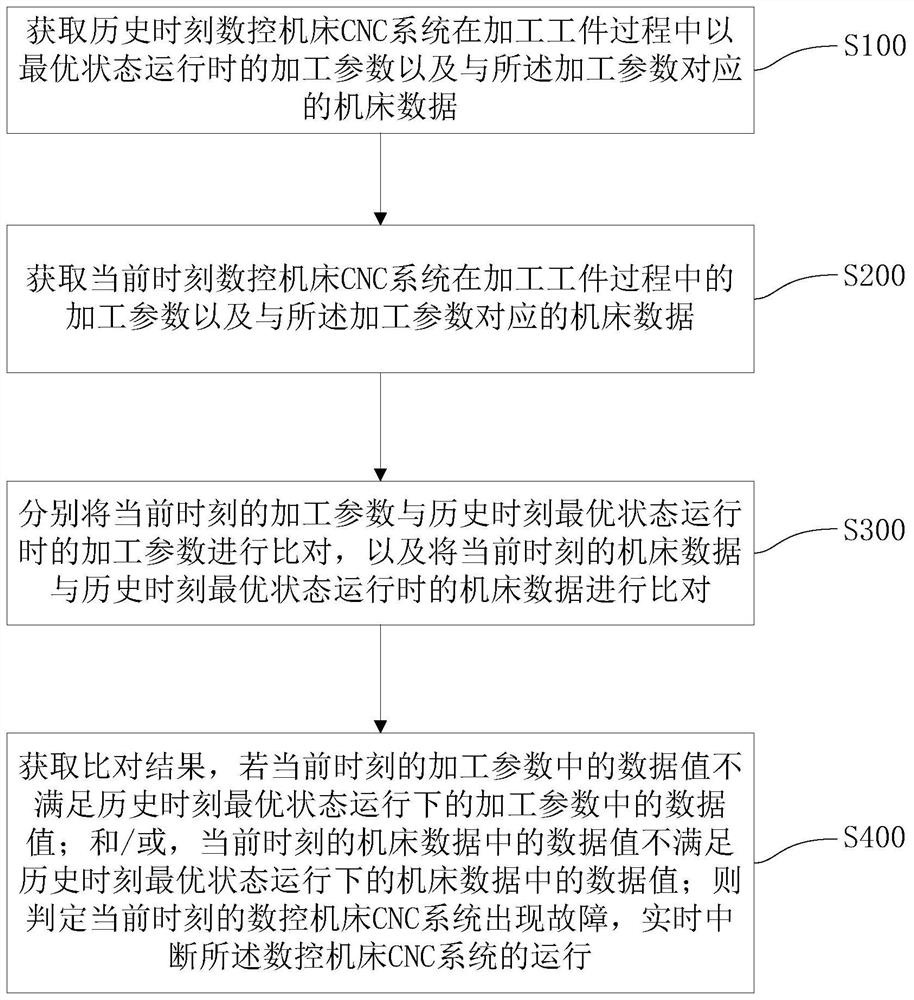

Real-time interrupt processing method for numerical control machine tool CNC system

PendingCN112068484AIncrease productionConstant qualityProgramme controlComputer controlNumerical controlProcess engineering

The invention provides a real-time interrupt processing method for a numerical control machine tool CNC system. Compared with a machine tool controlled in a traditional mechanical mode, the real-timeinterrupt processing method has higher precision in the machining process of workpieces, and the capability of producing complex workpieces can be achieved; and the speed is higher when the workpieceis machined, and meanwhile the automation degree is higher than that of the machining process. Due to the fact that the automation degree is high, the high production capacity and constant quality ofworkpiece machining can be guaranteed, and large-batch machining of enterprises is facilitated. In addition, according to the real-time interrupt method, when the workpiece machined by the machine tool CNC goes wrong, the numerical control machine tool CNC system controlling the machine tool CNC to operate is judged to break down at the first time, the corresponding fault can be modified by adjusting the corresponding machining program, the fault judging time is short, and the fault modification time is also very short.

Owner:成都广泰威达数控技术股份有限公司

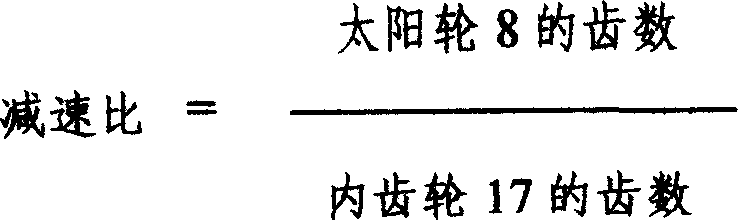

Two-way two-speed built in boost manpower vehicle stupid variable-speed shaft

InactiveCN1743225AGood dustproof performanceGood for mass processingWheel based transmissionClutchFlywheel

The invention relates to a double-direction double-speed bicycle with a built-in booster. When the bicycle is pedaled forward, it runs similar to general bicycle. When the bicycle is pedaled backward, the built-in planetary gear is driven by a reverse-engaged super-clutch to make the bicycle get a boosted drive force and run forward still. The bicycle needs no other speed-change and shifting mechanism, which can quickly and repeatedly change speed. Advantages: simple design, reliable drive and convenient using.

Owner:汤萍

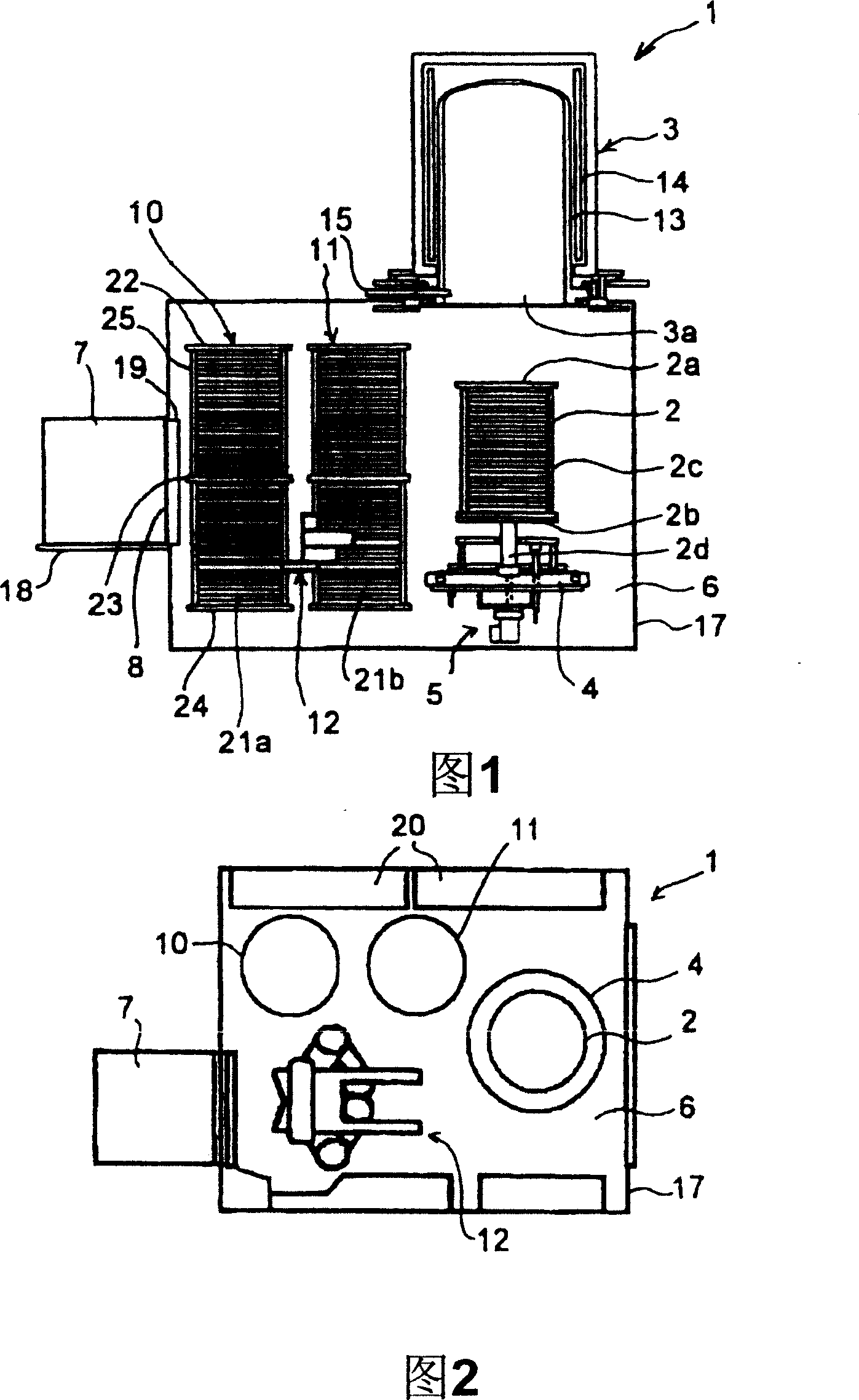

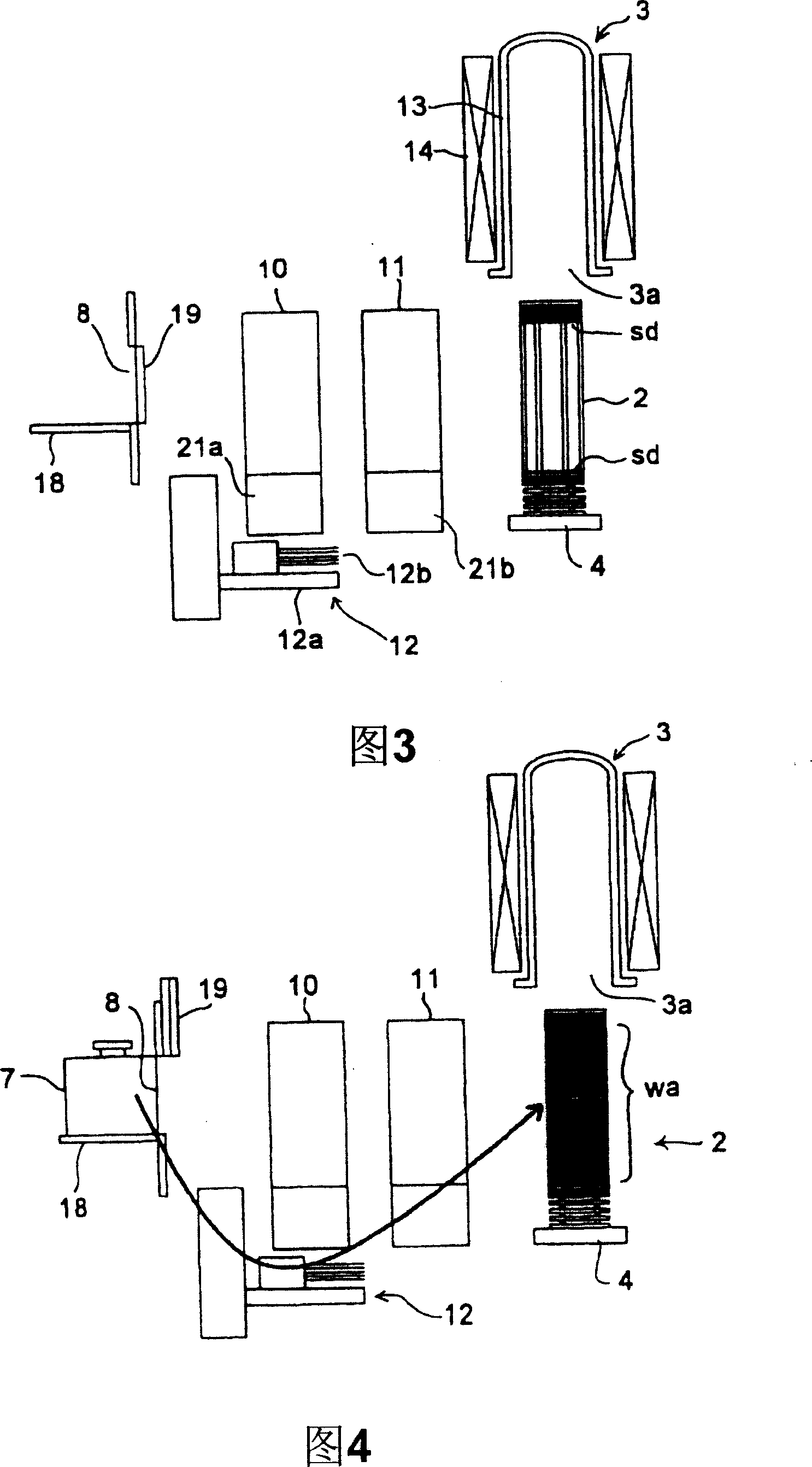

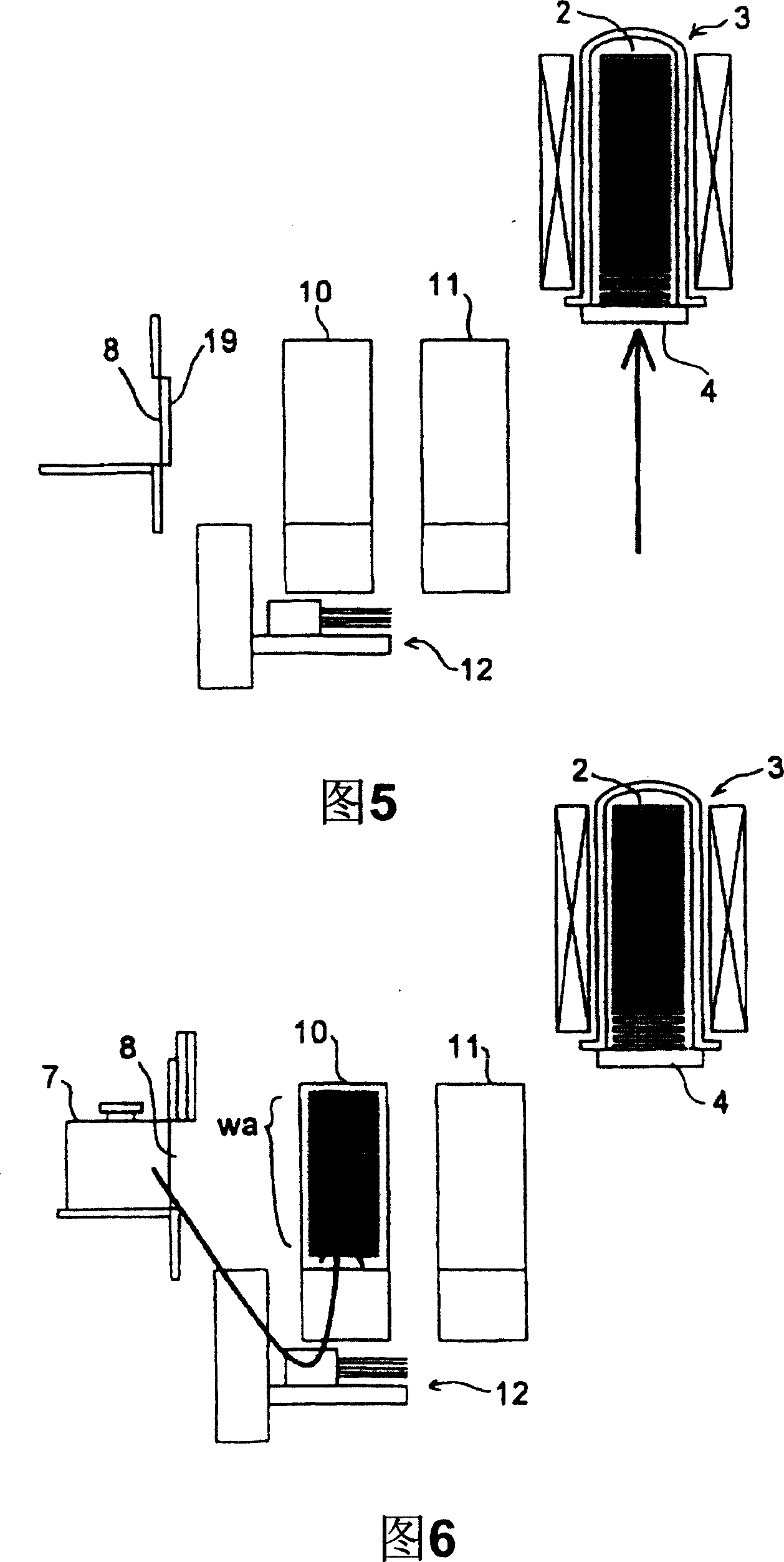

Vertical heat treatment device and method of operating the same

InactiveCN1981366AMiniaturizationLow costSemiconductor/solid-state device manufacturingThin material handlingTransfer mechanismHeat treated

A vertical type of thermal processing apparatus of the present invention includes a thermal processing furnace having a furnace opening at a lower portion thereof. A boat holding objects to be processed in a tier-like manner in a vertical direction is adapted to be contained in the thermal processing furnace through the furnace opening. A lid supporting the boat is capable of closing the furnace opening. A transferring chamber is connected to the furnace opening. An elevating mechanism provided in the transferring chamber is configured to move up and down the lid in order to load and unload the boat into and out from the thermal processing furnace. A connecting port provided at a wall of the transferring chamber is capable of being connected to an opening of a conveying container for containing the objects to be processed. A first containing portion provided in the transferring chamber is capable of temporarily containing unprocessed objects to be processed for a next thermal process. A second containing portion provided in the transferring chamber is capable of temporarily containing processed objects to be processed conveyed out from the thermal processing furnace. A transferring mechanism transfers objects to be processed between the conveying container, the first containing portion, the second containing portion and the boat.

Owner:TOKYO ELECTRON LTD

Processing method of glass fiber waste silk powder

The invention belongs to the technical field of glass fiber recycling, and in particular relates to a processing method of glass fiber waste silk powder. Firstly, the glass fiber waste silk is soaked in a mixture of alkali and cement slurry supernatant, and after soaking, it is taken out, rinsed and crushed. , drying and grinding to obtain glass fiber waste silk powder. The invention can remove the sizing agent on the surface of the glass fiber waste, increase the microcracks on the glass fiber surface, reduce the strength of the glass fiber, increase the brittleness of the glass fiber, and improve the grinding effect when the glass fiber waste is processed into powder; The invention can efficiently grind glass fiber waste into powder, and the composition of the powder is uniform and stable. When it is mixed with other glass raw materials to form a batch, it can be fed with a reamer, which saves time and effort, and makes the waste glass The reuse becomes efficient; the present invention increases the recycling treatment of glass fiber waste in the glass fiber industry, avoids the backlog of waste materials, and has low purchase costs in the cement and lye market, and is easy to process in large quantities.

Owner:山东硕远新材料有限公司

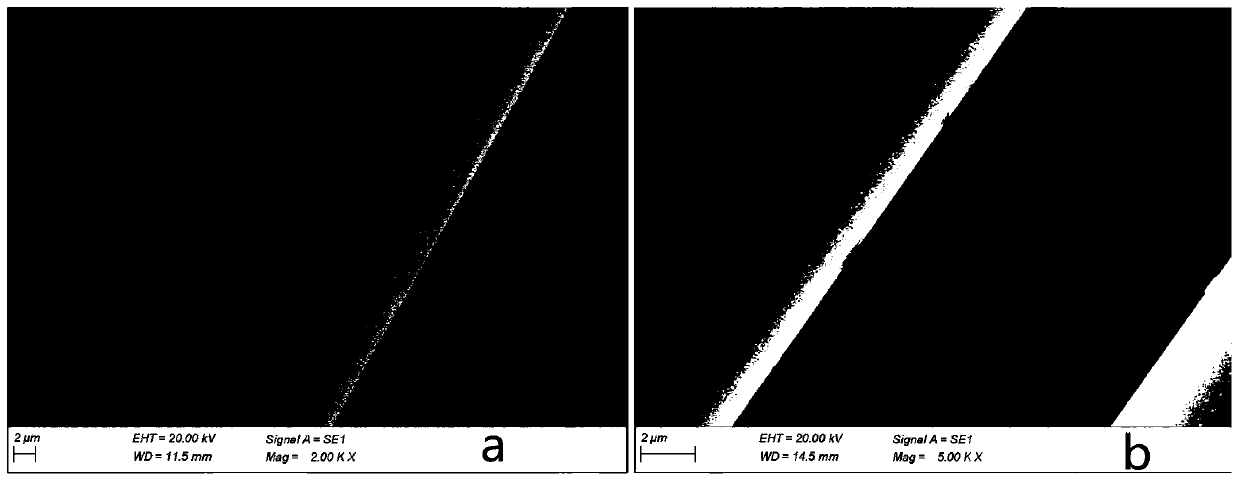

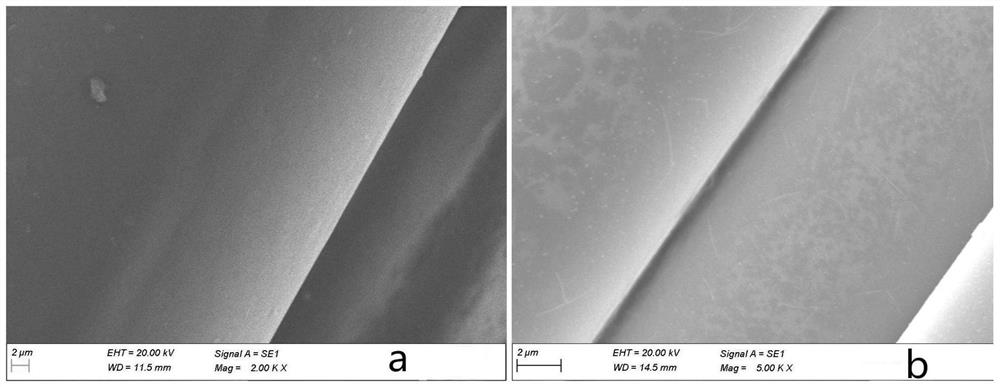

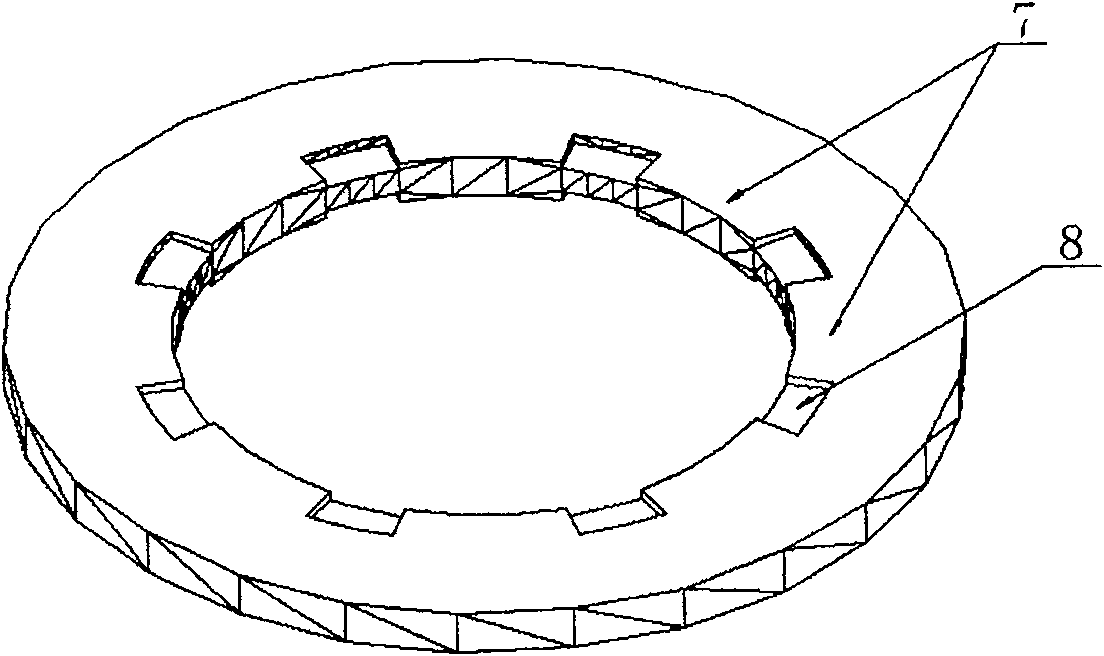

Aligned cutting tool for electroplating ultrahard material

InactiveCN101073868AHigh strengthReduce dosageMetal sawing devicesMetal sawing toolsSuperhard materialDiamond cutting

The invention is concerned with the cutting edge tool for arrangement electroplating ultra-hard material, it is: arranges the cutting edge matrix part along the moving vertical direction of the tool on the matrix, plates the ultra-hard material grain with need particle size on the all surfaces by the general composite plating method, in order to form the cutting edge tool of the arrangement electroplating ultra-hard material. Or, manufacture the cutting edge matrix and the tool matrix respectively: makes the cutting edge matrix block style including the welding transition layer, welds it on the tool matrix to get the cutting edge tool of the arrangement electroplating ultra-hard material with different shapes and use, for instance: diamond disc, band saw blade, the gang saw blade, the bit of diamond core drill, the diamond cutting bead, the block wheel etc.

Owner:于贵生

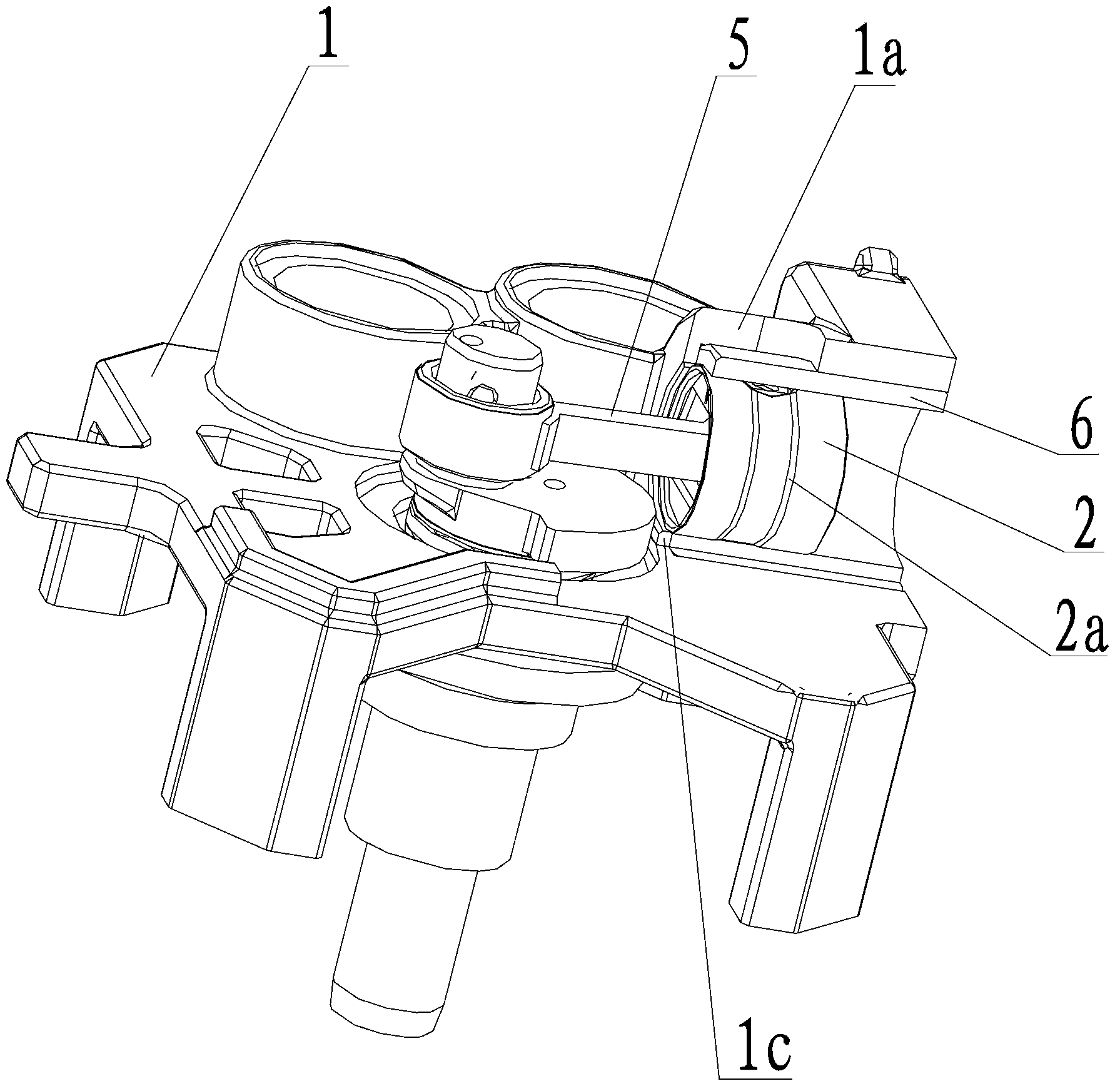

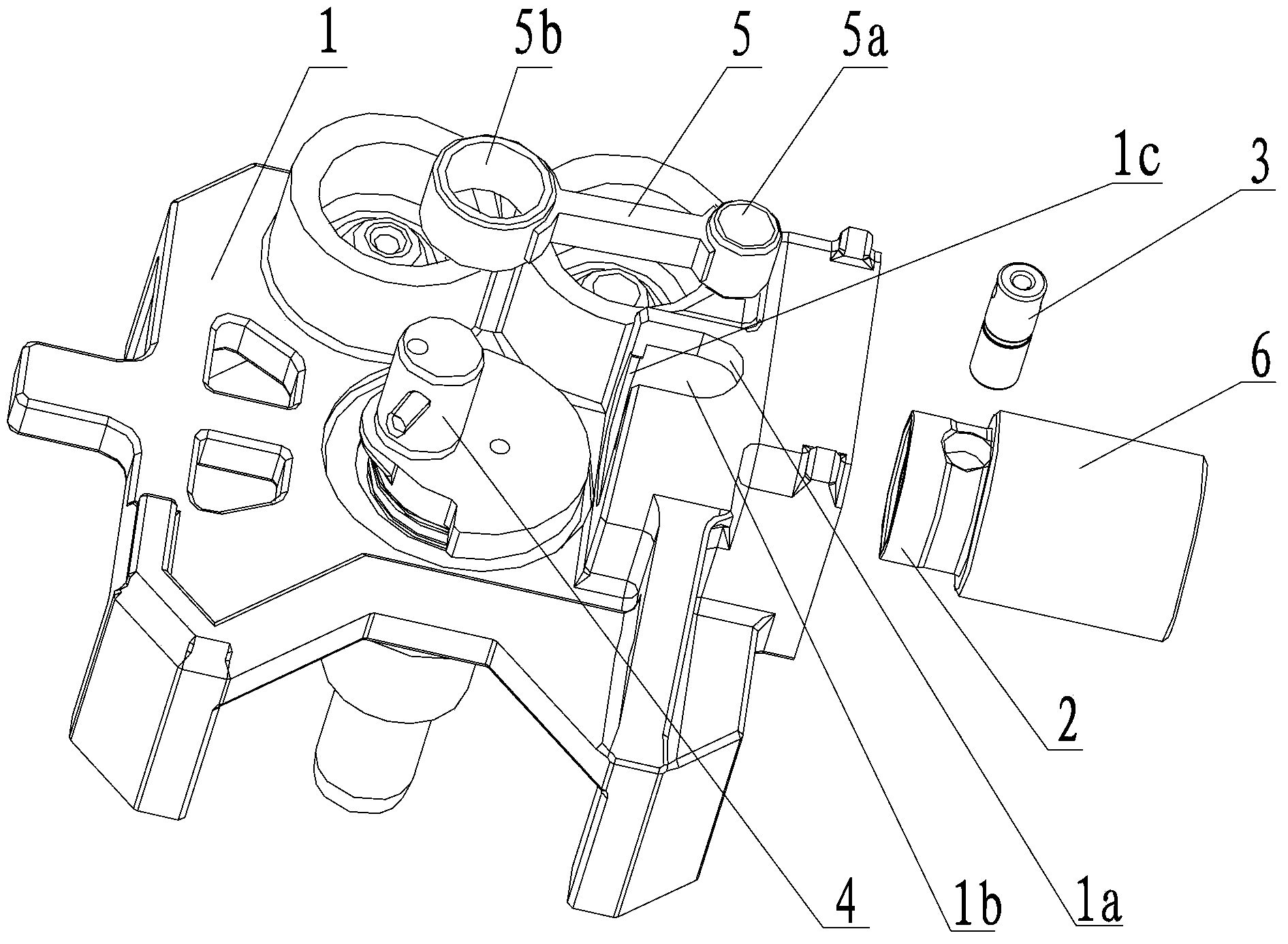

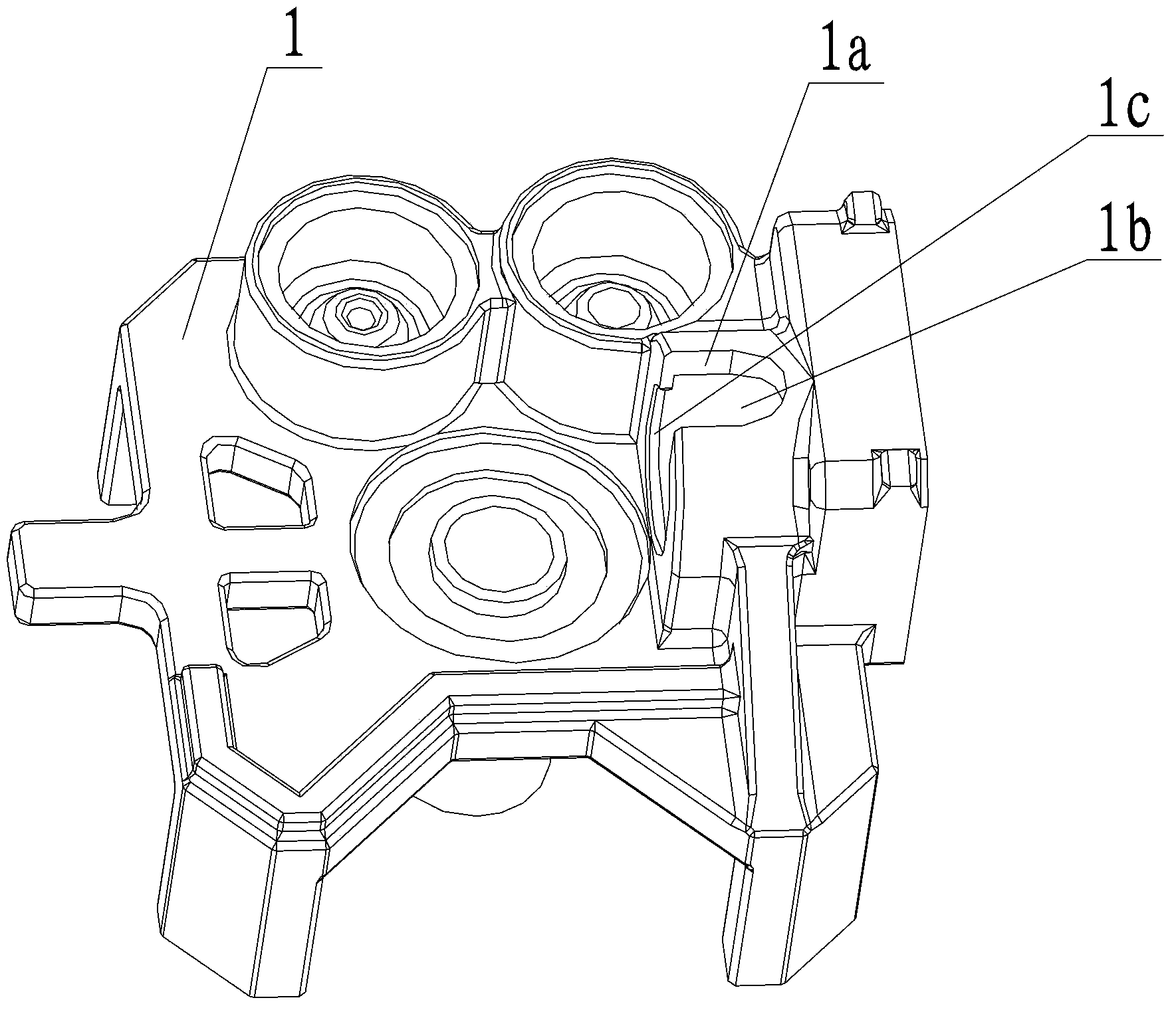

Rack assembly for compressor and assembling method of rack assembly

InactiveCN103573583AAvoid adverse effects such as deformationReduce processing deformationPositive displacement pump componentsPositive-displacement liquid enginesMachining deformationEngineering

The invention relates to a rack assembly for a compressor; the rack assembly comprises a cylinder and a rack; a cylinder insertion hole is formed in the rack; a first end part of the cylinder insertion hole is provided with a U-shaped slot; the cylinder is mounted in the cylinder insertion hole. The invention also relates to an assembling method. Unfavorable influences such as cylinder deformation caused by the fact that a U-shaped slot is formed in the cylinder are avoided, the machining deformation of the cylinder is reduced, and the cylinder precision is improved; the sealing distance on the cylinder is increased, the sealing effect is improved, the universality is strong, and model expansion is convenient; besides, the split cylinder is smaller in mass and shape, so large-batch machining is facilitated, the machining efficiency is improved, and the machining cost is reduced; a piston mounted in the cylinder can be very easily assembled onto a crankshaft by a connection rod, so the production efficiency is improved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

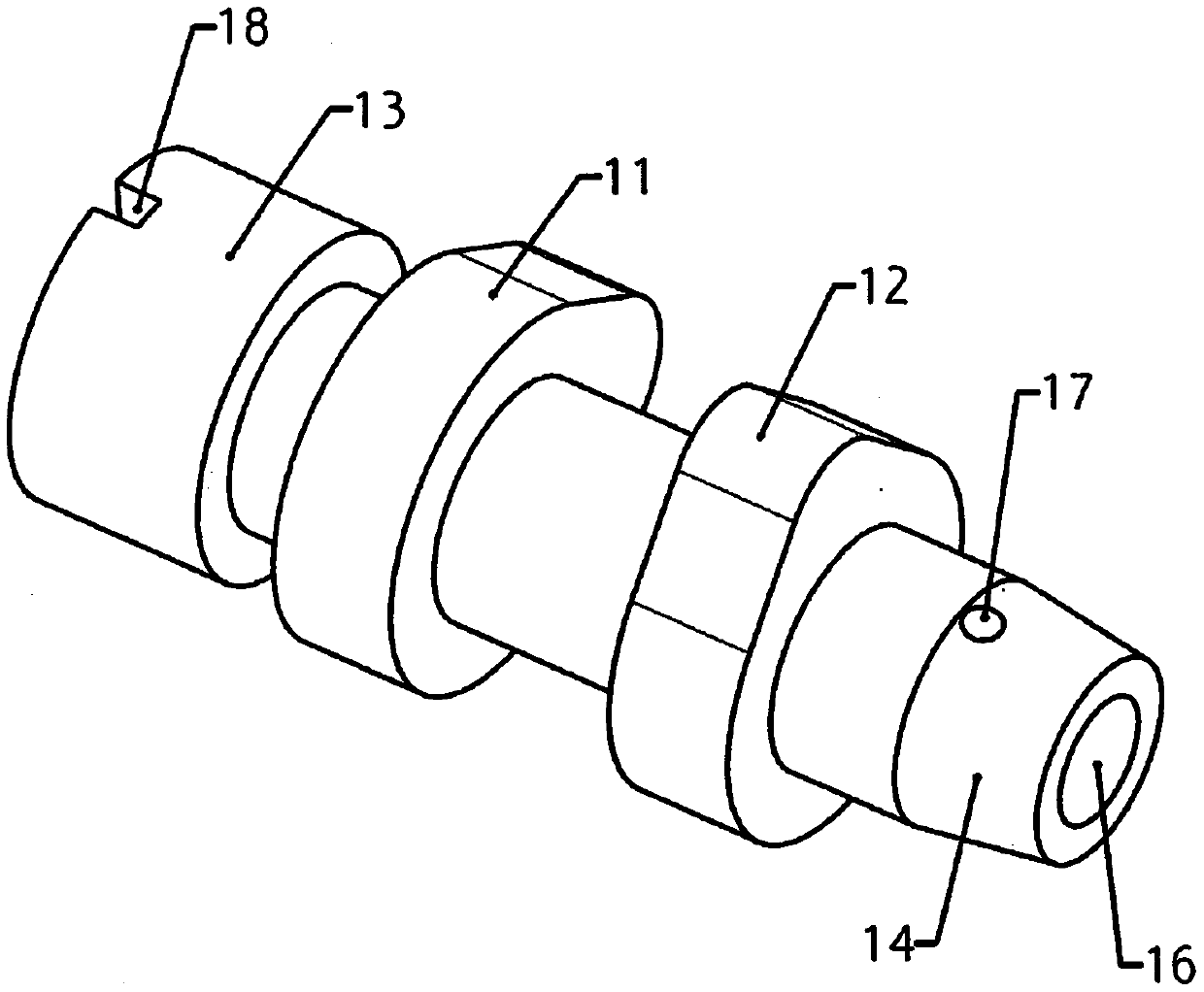

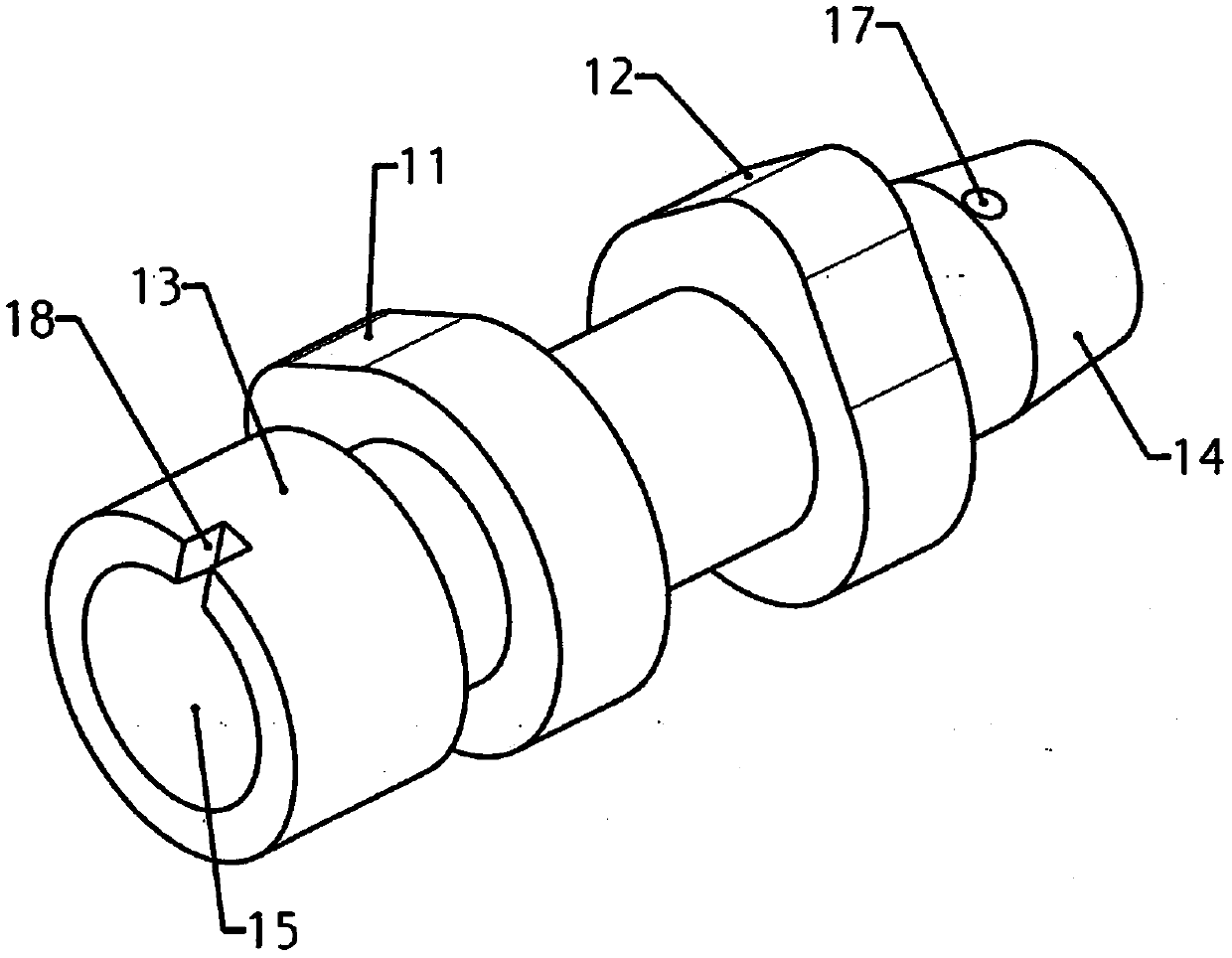

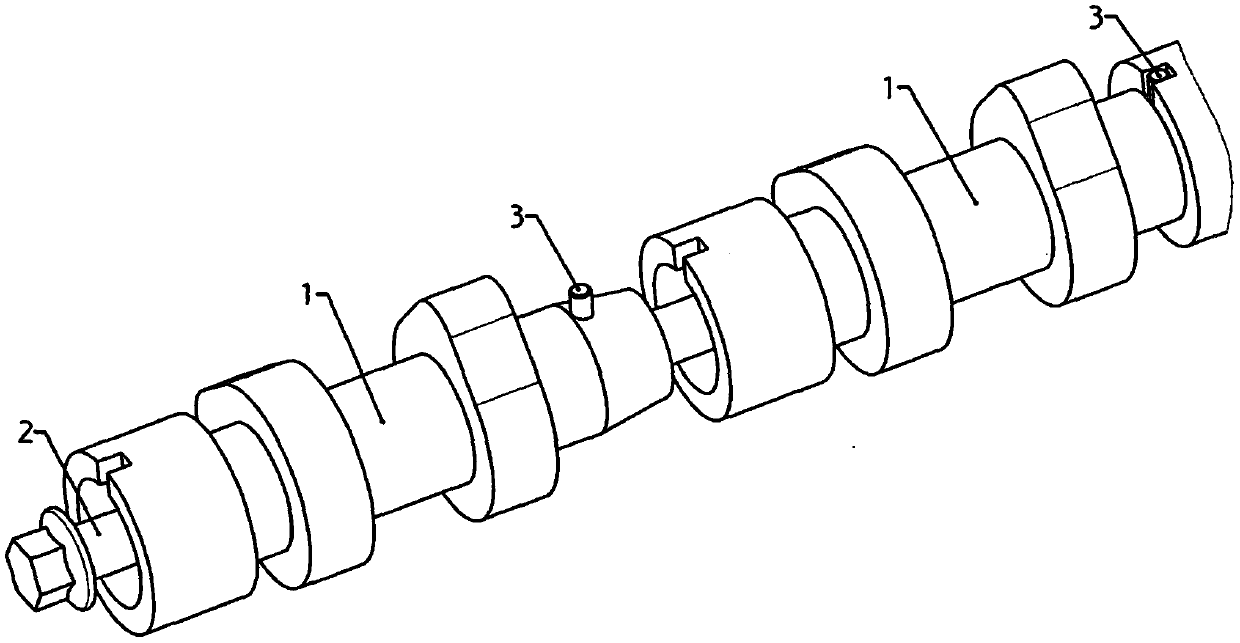

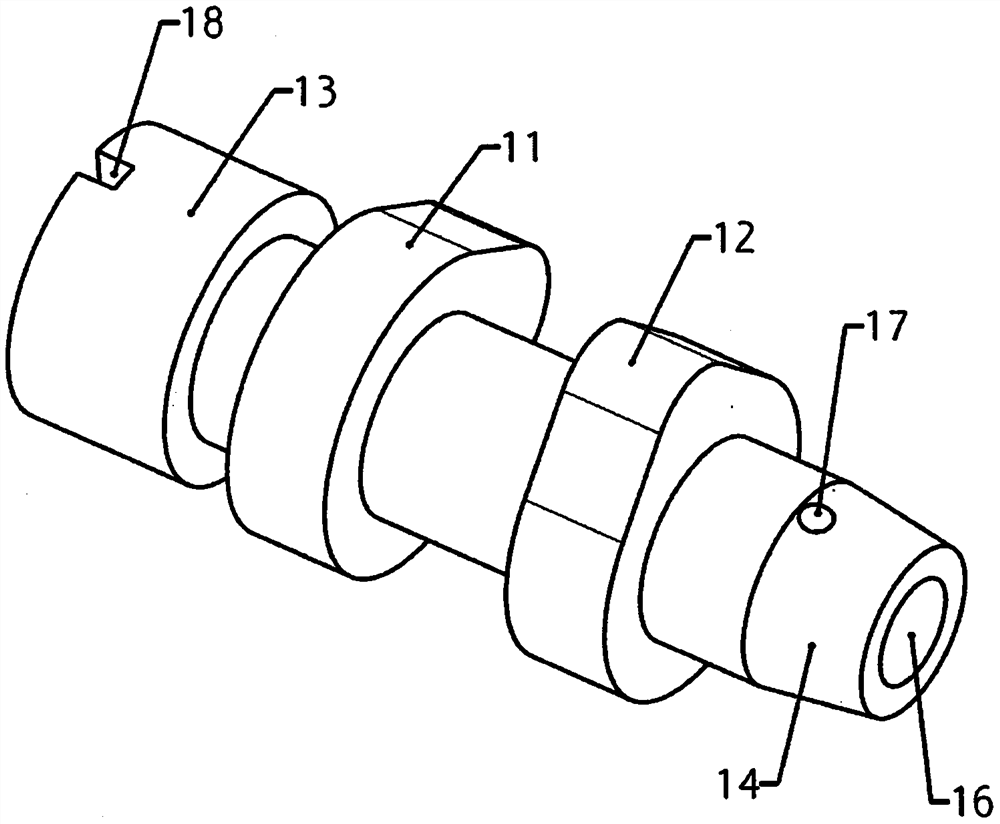

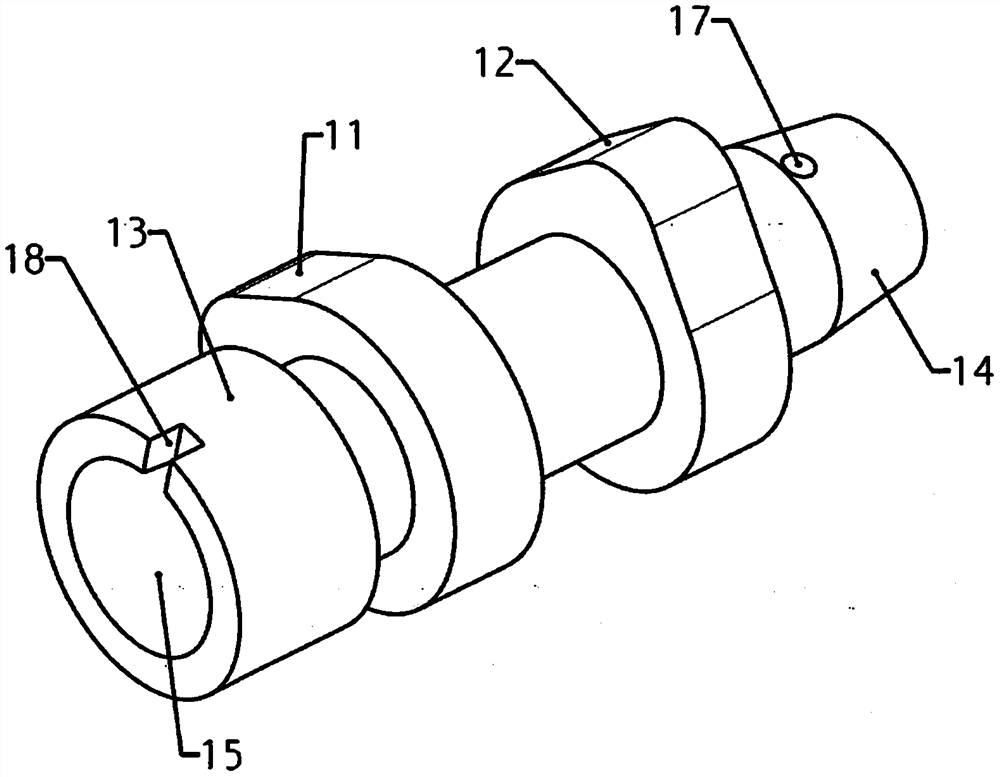

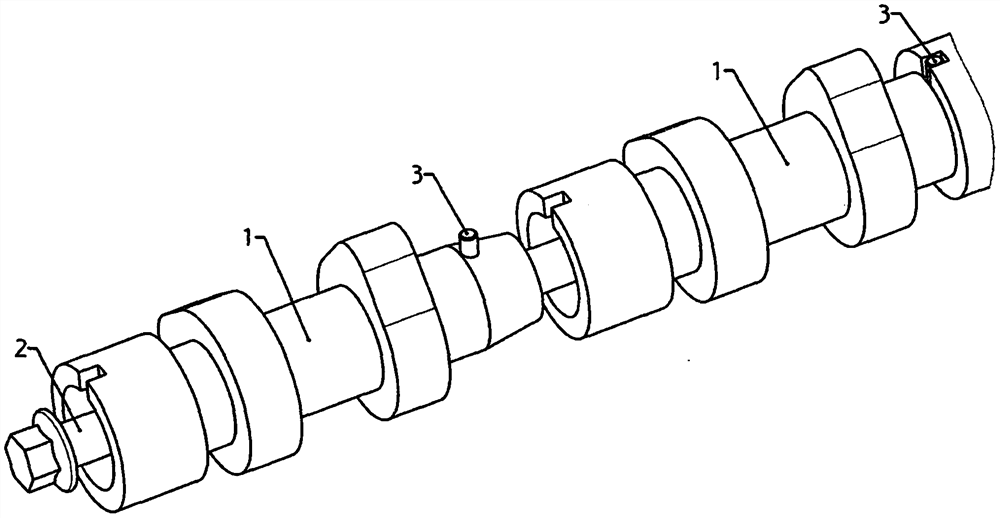

Assembled camshaft for engine

ActiveCN111502789AImprove coaxialityGuaranteed accuracyValve arrangementsMachines/enginesStructural engineeringCam

The invention provides an assembled camshaft for an engine. The assembled camshaft for the engine is of a segmented structure and is composed of two or more shaft segment units, the front ends and therear ends of the shaft segment units are provided with conical surface shafts and conical surface holes correspondingly, the front ends and the rear ends of the shaft segment units are provided withpositioning pin holes and positioning grooves correspondingly, the shaft segment units are provided with center holes, the assembled camshaft is assembled together by sequentially connecting all the shaft segment units in the front-rear direction, each shaft segment unit is coaxial with the former shaft segment unit through conical surface matching, a phase position of a cam on each shaft segmentis positioned through a corresponding positioning pin and the corresponding positioning groove, and all the shaft segment units are connected and fixed through bolts penetrating through the center holes. The assembled camshaft has the advantages that due to the self-centering effect of conical surface matching, the coaxiality of all the shaft segment units after assembly can be guaranteed, machining is more convenient through the segmented structure, all the shaft segment units have certain universality, special equipment and tool are conveniently adopted for large-batch machining to lower thecost, the camshaft is assembled without the special equipment and tool, all the shaft segment units can be replaced separately, and using and maintenance are convenient.

Owner:姬腾飞

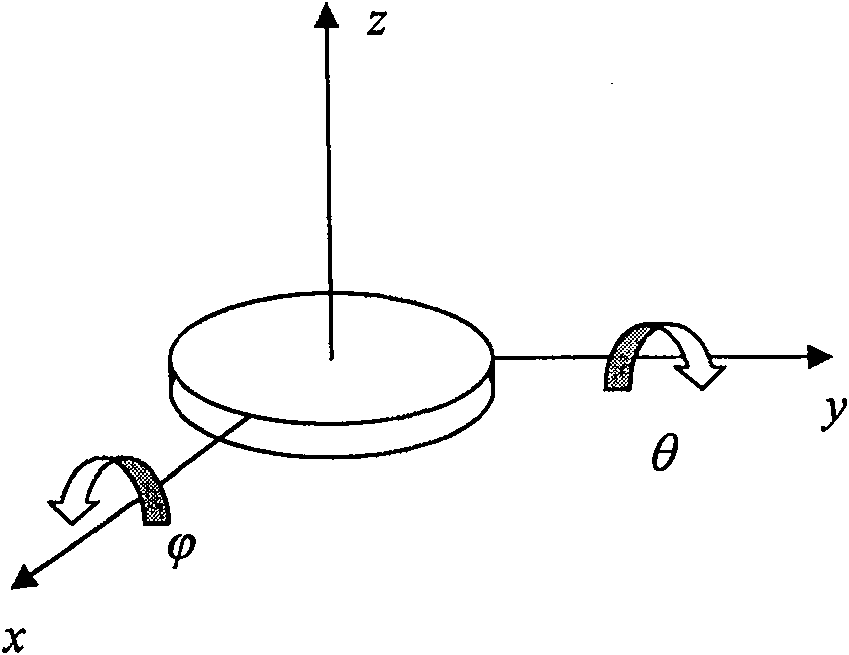

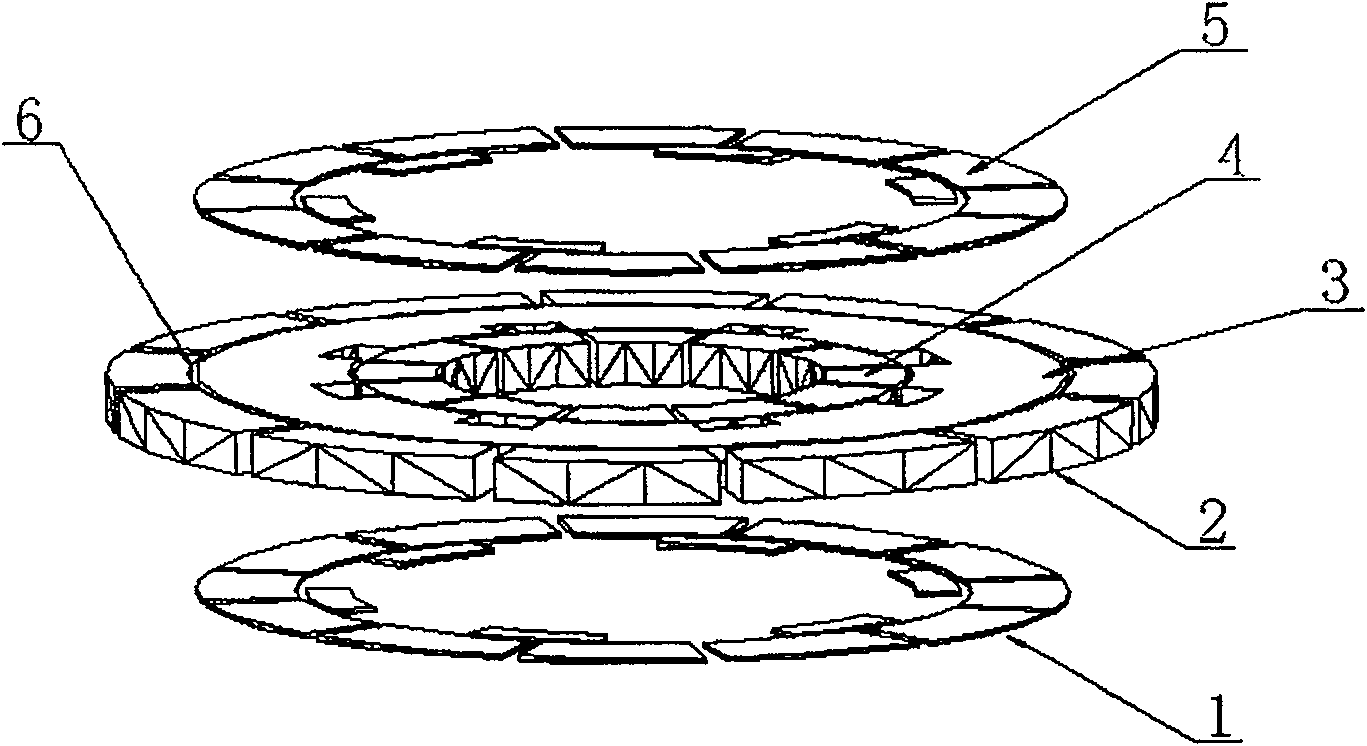

Variable capacitance micro electrostatic motor adopting five freedom degree static suspension

InactiveCN100553102CImprove radial overload capacitySolution to short lifeElectrostatic generators/motorsCapacitanceFriction torque

Owner:TSINGHUA UNIV

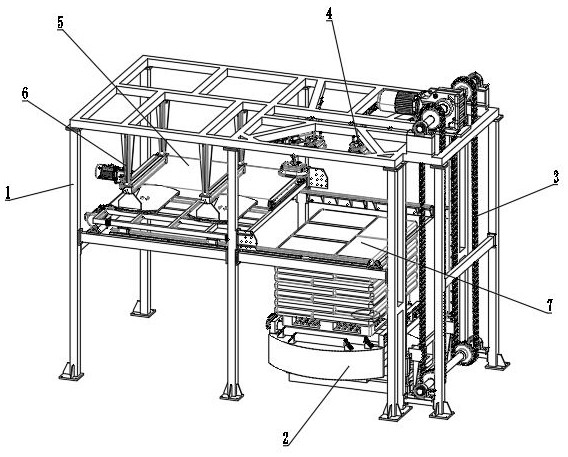

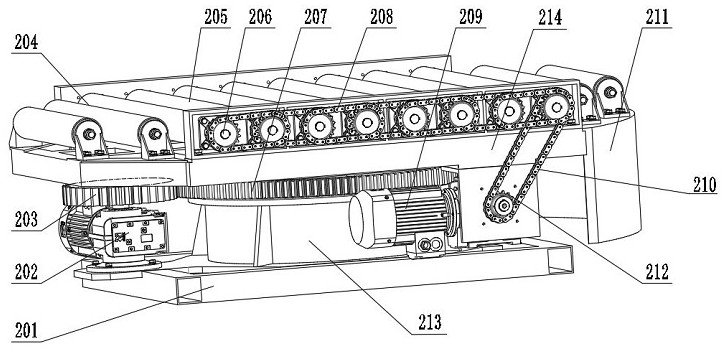

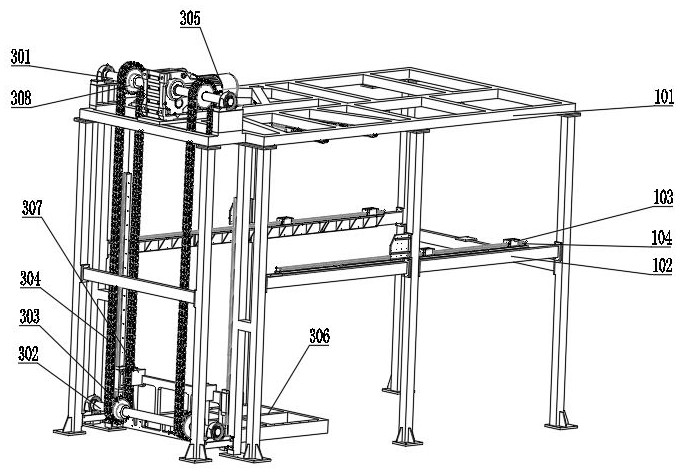

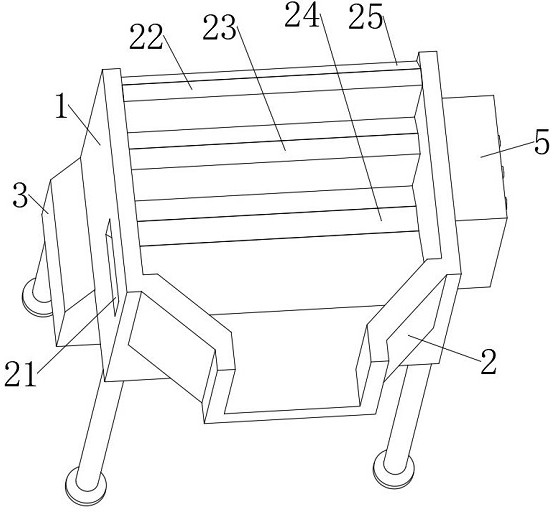

Whole-layer unstacker

ActiveCN112811195AEnsure consistent directionEasy to process in large batchesStacking articlesDe-stacking articlesStructural engineeringMachine

The invention relates to the technical field of unstacking equipment, in particular to a whole-layer unstacker. The whole-layer unstacker comprises a machine frame, the machine frame is of a double-layer structure, the upper layer is provided with a first top plate, the lower layer is provided with a transverse rod, a lifting mechanism is vertically arranged at one end of the machine frame, a rotary conveying mechanism used for bearing goods stacks is arranged on the lifting mechanism, a plurality of suction cup mechanisms fixed to the bottom of one side of the first top plate are arranged above the rotary conveying mechanism, a plurality of pushing mechanisms are arranged at the bottom of the other side of the first top plate, and a transfer mechanism is movably arranged on the transverse rod. The whole-layer unstacker solves the problems that staggered goods stacks are difficult to split, and the goods cannot be processed on a large scale due to different directions on a conveying belt.

Owner:山东朗科智能装备有限责任公司

Flexible sensor and preparation method thereof and method for simultaneously measuring rigidity and dielectric constant

InactiveCN112179383ASimple structureFew partsResistance/reactance/impedenceConverting sensor output electrically/magneticallyDielectricEngineering

The invention relates to a flexible sensor and a preparation method thereof and a method for simultaneously measuring rigidity and dielectric constant. The flexible sensor comprises a flexible substrate, a bonding layer and a conductive layer which are sequentially arranged from bottom to top, the horizontal section shapes of the bonding layer and the conducting layer are the same, and the bondinglayer and the conducting layer form two electrodes which are insulated from each other in the same plane; and the thickness of the bonding layer is smaller than that of the conductive layer, and theconductivity of the bonding layer is smaller than that of the conductive layer. The method for simultaneously measuring the rigidity and the dielectric constant comprises the following steps of: 1, respectively clinging two flexible sensors to two sides of the same to-be-measured object; 2, measuring the change of the capacitance C between the two flexible sensors when the to-be-measured object isextruded to deform, and calculating to obtain the rigidity of the to-be-measured object. The change of the capacitance C' of the electrode in the flexible sensor is measured to calculate the dielectric constant of the to-be-measured object. The flexible sensor is small in size, light in weight, bendable, capable of measuring rigidity and the dielectric constant at the same time, high in efficiency and capable of being produced in batches.

Owner:XI AN JIAOTONG UNIV

Preparation method of soft manipulator with spiral inner core

InactiveCN112873663AEasy to makeStable and reliableDomestic articlesSurgical robotsFiber Bragg gratingEngineering

The invention provides a design of a soft manipulator with a spiral inner core. The soft manipulator comprises silica gel and a fiber bragg grating (FBG). The soft manipulator is easy to manufacture and reliable in stability; the cost is low, the repeatability is high, and large-scale processing is easy.

Owner:BEIJING INFORMATION SCI & TECH UNIV

Method of assembling a frame assembly of a compressor

InactiveCN103573583BAvoid adverse effects such as deformationReduce processing deformationPositive displacement pump componentsPositive-displacement liquid enginesMachining deformationCrankshaft

The invention relates to a rack assembly for a compressor; the rack assembly comprises a cylinder and a rack; a cylinder insertion hole is formed in the rack; a first end part of the cylinder insertion hole is provided with a U-shaped slot; the cylinder is mounted in the cylinder insertion hole. The invention also relates to an assembling method. Unfavorable influences such as cylinder deformation caused by the fact that a U-shaped slot is formed in the cylinder are avoided, the machining deformation of the cylinder is reduced, and the cylinder precision is improved; the sealing distance on the cylinder is increased, the sealing effect is improved, the universality is strong, and model expansion is convenient; besides, the split cylinder is smaller in mass and shape, so large-batch machining is facilitated, the machining efficiency is improved, and the machining cost is reduced; a piston mounted in the cylinder can be very easily assembled onto a crankshaft by a connection rod, so the production efficiency is improved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Direction-adjustable sensor mounting seat and mounting method thereof

PendingCN114812647ANot affected by errorsMeet the use requirementsMeasurement apparatus componentsEngineeringMechanical engineering

Owner:NORTHWEST INST OF NUCLEAR TECH

Combined camshaft for engine

ActiveCN111502789BImprove coaxialityGuaranteed accuracyValve arrangementsMachines/enginesEngineeringStructural engineering

The combined camshaft of the engine, the combined camshaft has a segmented structure and is composed of at least two shaft section units. positioning slot, and has a central hole. The combined camshaft is assembled by all the shaft unit units sequentially connected back and forth. Locating pins and positioning slots are used to locate the phase of the cams on each shaft section, and all shaft section units are fixed by bolts passing through the center hole. The advantage of the present invention is that due to the self-centering effect of the taper surface fit, the coaxiality of each shaft section unit after assembly can be ensured, the segmented structure makes processing more convenient, and all shaft section units have certain versatility, which is convenient to adopt special Equipment and tooling are processed in large quantities to reduce costs, and the assembly of the camshaft does not require special equipment and tools, and each shaft segment unit can be replaced independently, which is convenient for use and maintenance.

Owner:姬腾飞

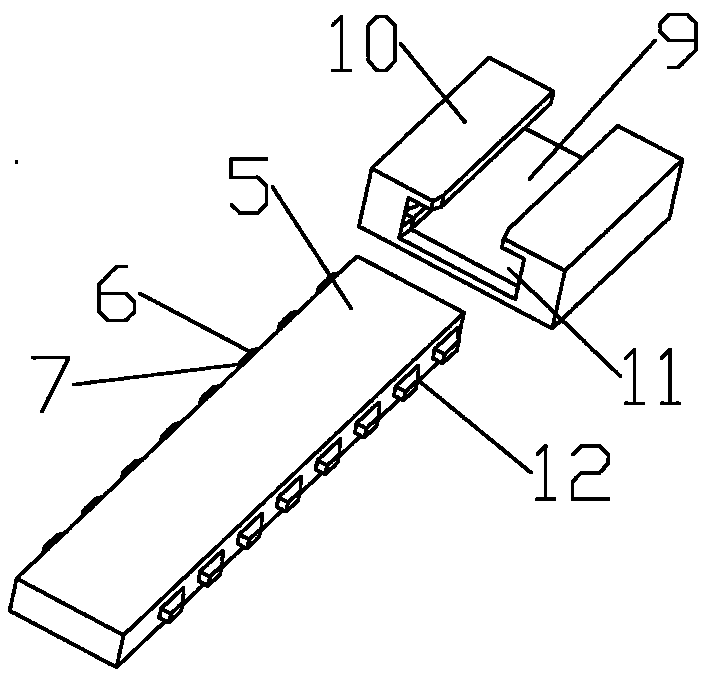

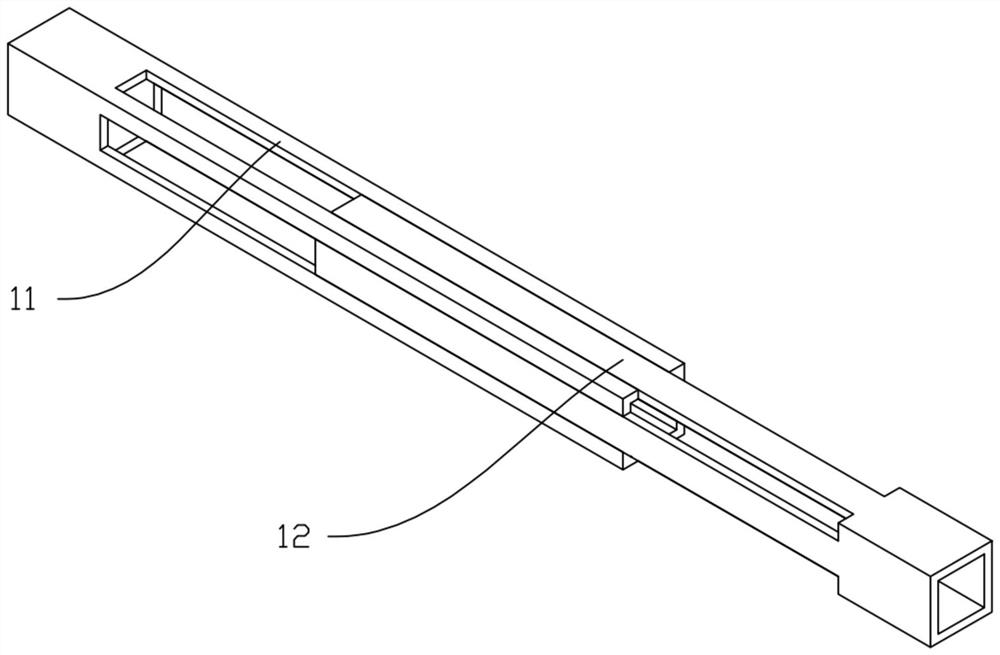

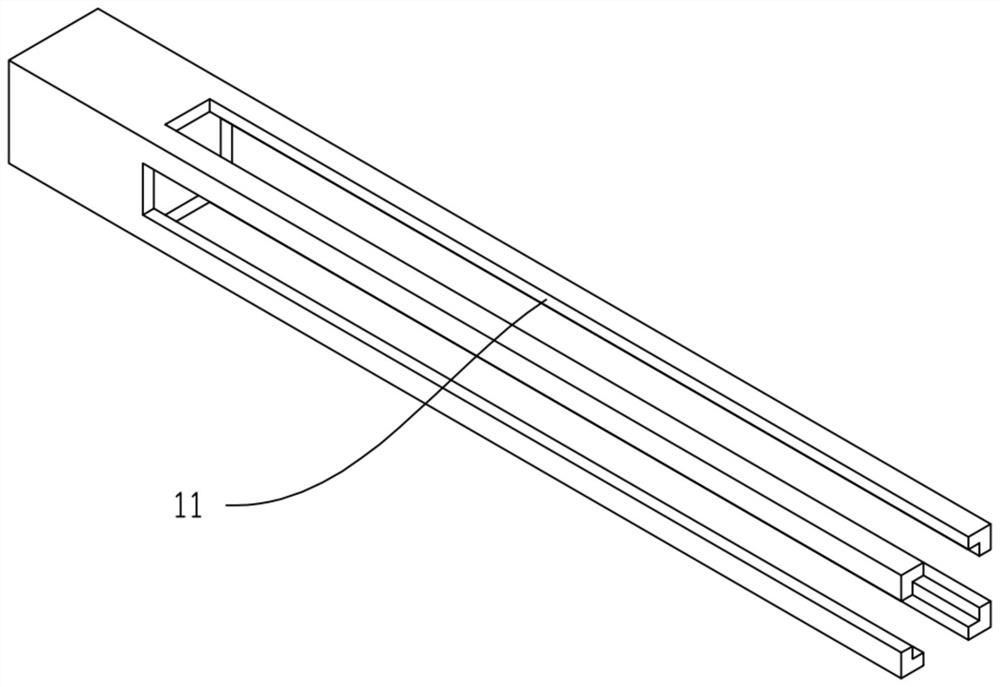

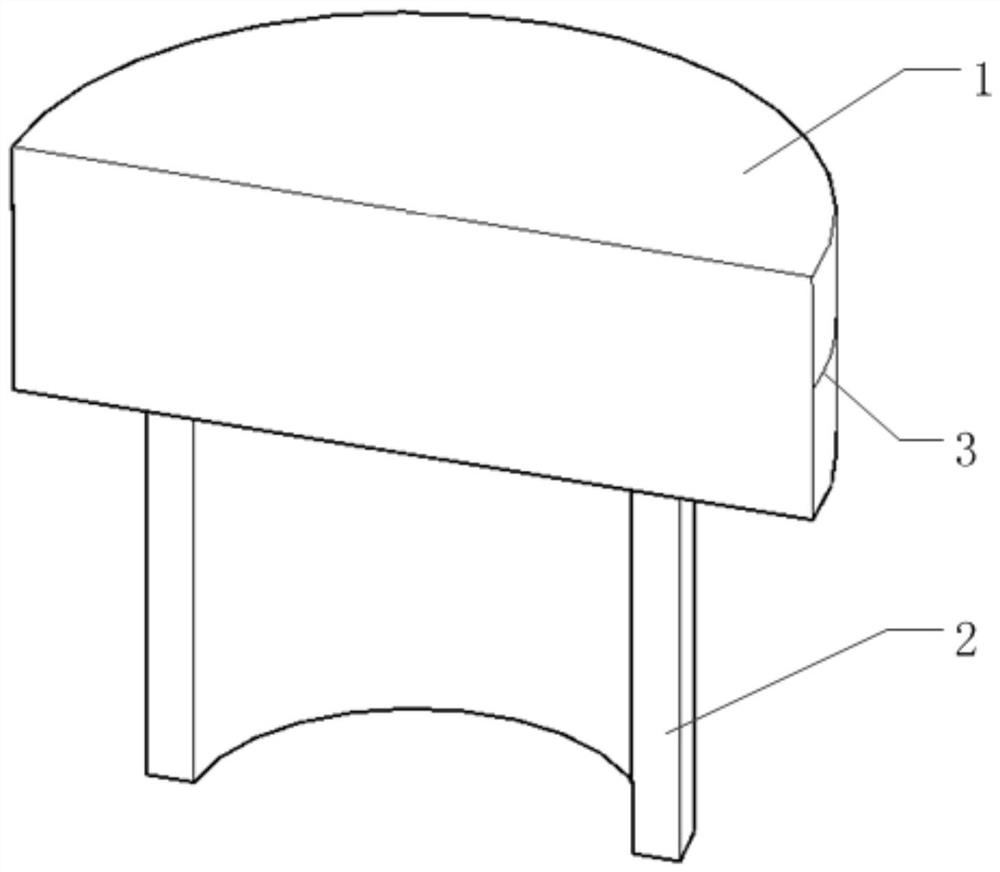

A building support template and its processing system and processing method

ActiveCN113000916BEasy to process in large batchesFeeding apparatusLarge fixed membersMilling cutterStructural engineering

The present invention relates to the processing of supporting templates, more specifically, a building supporting template and its processing system and processing method, and a processing method of building supporting templates. S1: clamp the square tube on the clamping mechanism, feed the screw Turn and drive the clamping mechanism to move towards the four milling cutters; S2: The four milling cutters process slots Ⅰ on the four sides of the opposite tube to form a support template Ⅰ; S3: Remove the support template Ⅰ, and clamp the other square tube in the On the clamping mechanism, the feeding screw rotates to drive the clamping mechanism to move to the four milling cutters; S4: The reversing mechanism changes the positions of the four milling cutters, and the four milling cutters process slots II on the four corners of the opposite tube to form a support template Ⅱ; S5: After the support formwork Ⅰ and support formwork Ⅱ are plugged together to form building support formworks of different lengths, the support formwork Ⅰ and support formwork Ⅱ are welded to each other; the building support formwork includes support formwork Ⅰ and support formwork Ⅱ, support formwork Ⅰ and support formwork Ⅱ The supporting templates II are plugged together.

Owner:广东腾仁达建设有限公司

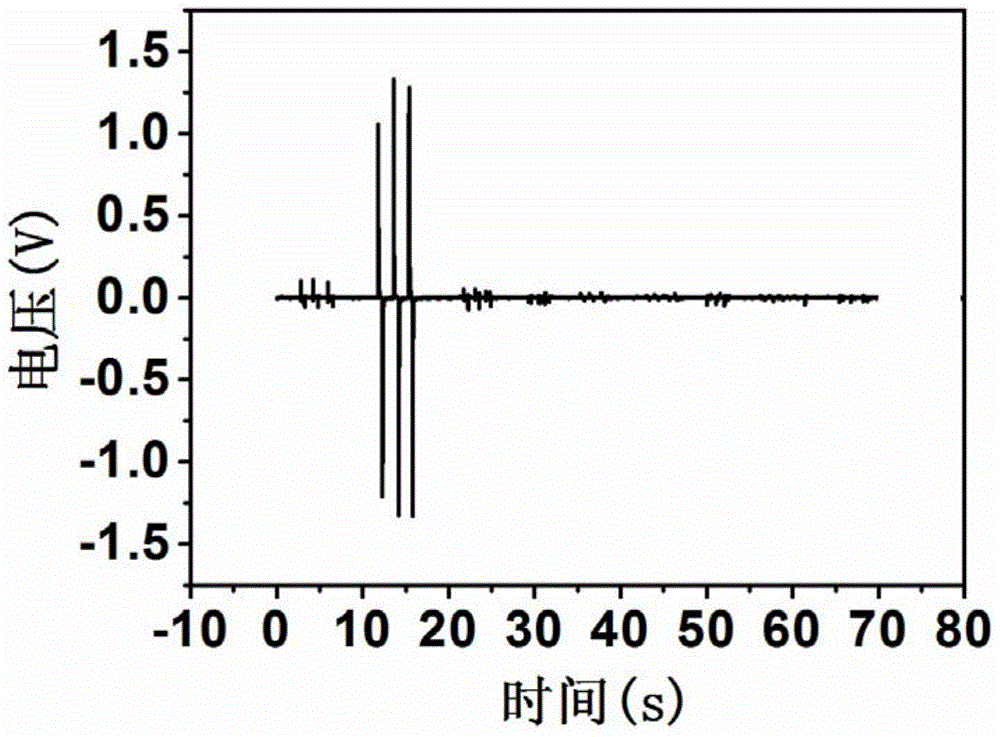

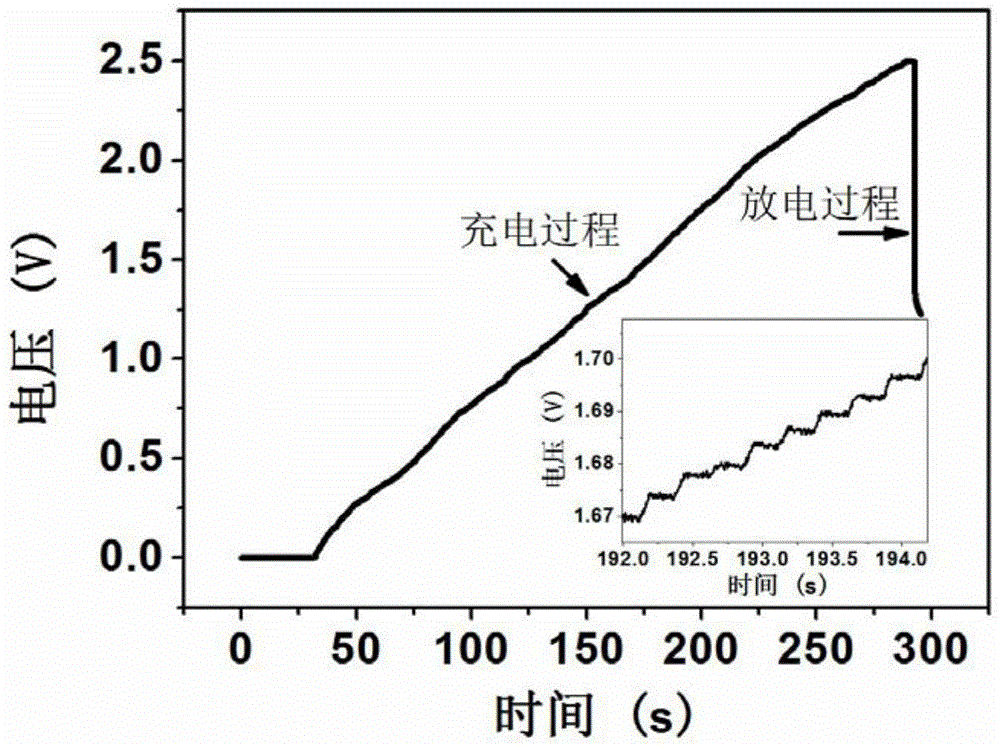

A paper-based flexible touch sensor and its manufacturing method

ActiveCN103970352BIncrease output powerHigh sensitivityInput/output processes for data processingIsolation layerPaper based

Owner:HUAZHONG UNIV OF SCI & TECH

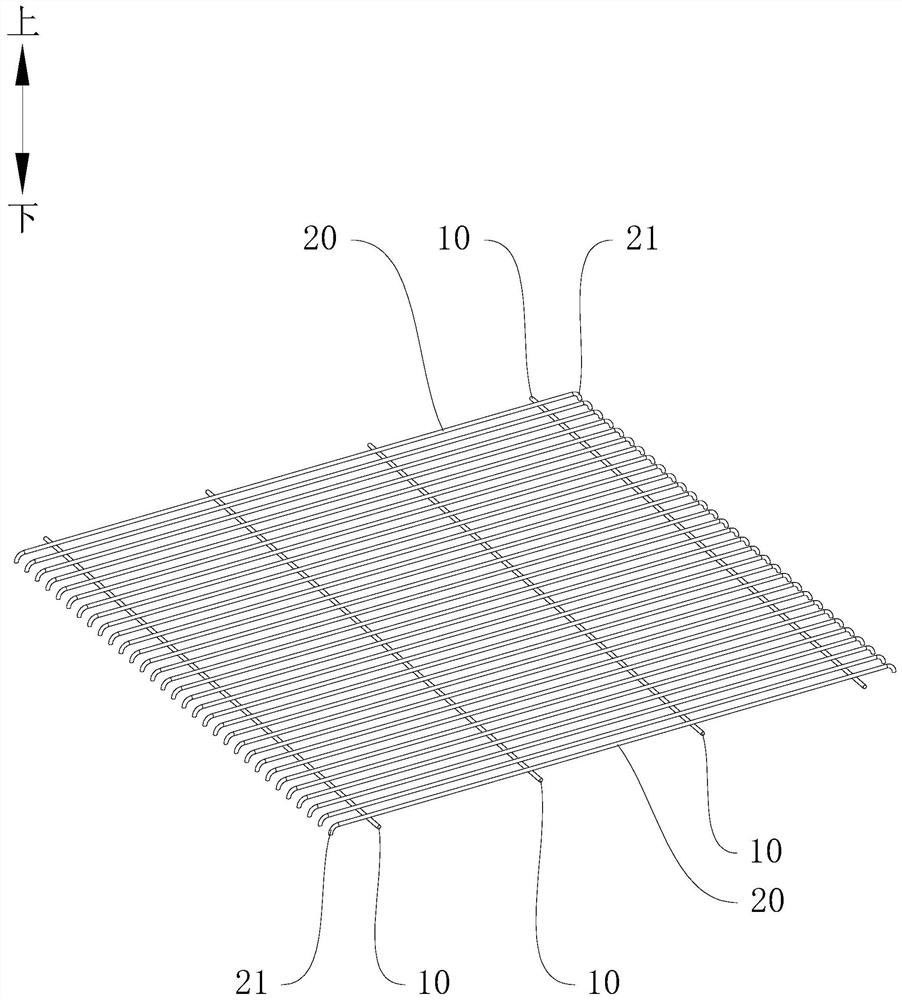

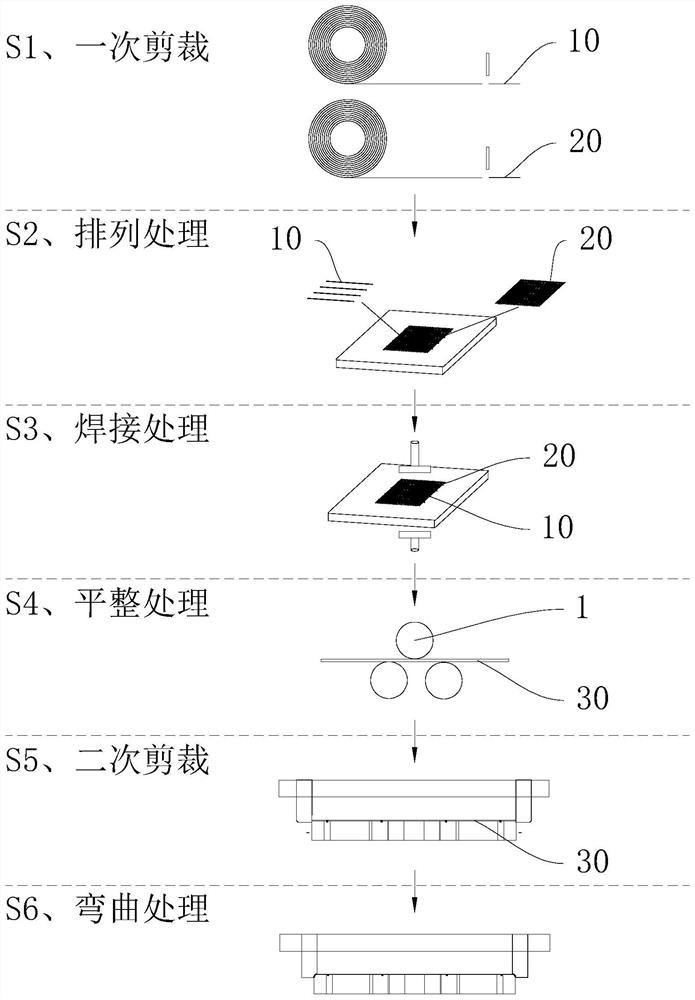

Manufacturing technology of metal net rack

InactiveCN111940648AEasy to process in large batchesImprove flatnessWire networkWire rodElectrical resistance and conductance

The invention discloses a manufacturing technology of a metal net rack. The manufacturing technology comprises the following steps that primary cutting is conducted, wherein a wire rod raw material ofa first wire rod is cut according to a required length to obtain multiple first wire rods, and a wire rod raw material of a second wire rod is cut according to a length obtained after machining allowance reserving to obtain multiple second wire rods; arranging treatment is conducted, wherein the ends of the multiple first wire rods are aligned and arranged at intervals, the ends of the multiple second wire rods are aligned and arranged at intervals, and the multiple first wire rods and the multiple second wire rods are stacked together in a staggered mode; welding treatment is conducted, wherein the contact positions between the first wire rods and the second wire rods are welded in an electric resistance welding manner, and a semi-finished product is obtained; flattening treatment is conducted, wherein rolling and flattening are conducted on the semi-finished product through a roller; secondary cutting is conducted, wherein the second wire rods on the semi-finished product are cut neatly according to the needed length; and bending treatment is conducted, wherein the end portions of the second wire rods on the semi-finished product are bent to form bent parts, so that a metal netrack finished product with good flatness is obtained.

Owner:ZHONGSHAN HENGRUN METAL PROD

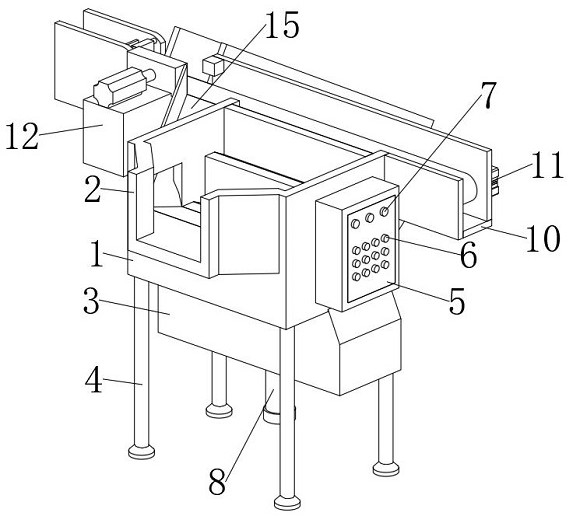

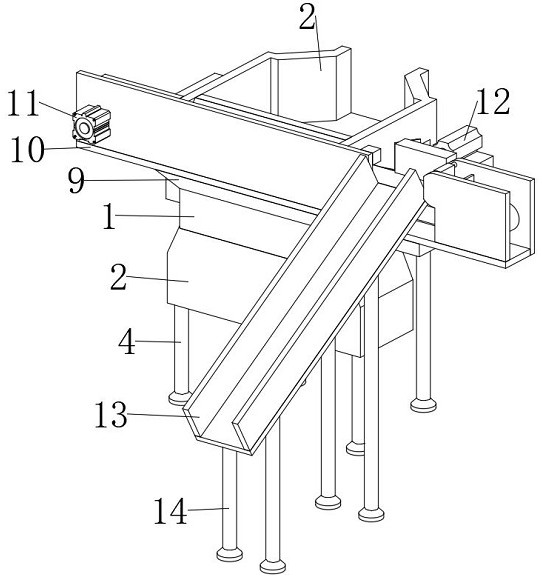

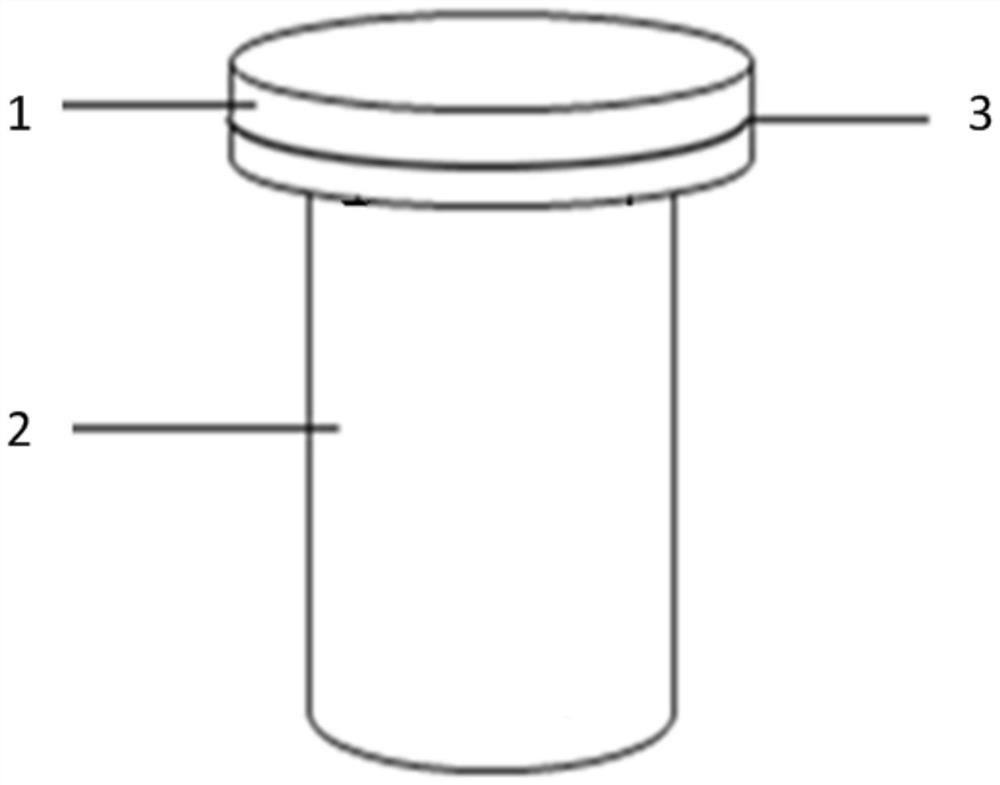

Feeding and discharging device for automatic deburring machining of minimally invasive surgery chuck parts

ActiveCN112757029ARealize automatic feeding processEasy to process in large batchesMetal working apparatusInvasive surgeryEngineering

The invention discloses a feeding and discharging device for automatic deburring machining of minimally invasive surgery chuck parts. The feeding and discharging device comprises a storage box, a feeding port is fixedly mounted at the front end of the storage box, a mounting box is fixedly mounted on the rear portion of the lower end of the storage box, a feeding mechanism is arranged at the lower end of the mounting box, and the feeding mechanism extends into the storage box. An electric control box is fixedly mounted at the right end of the storage box, a power button is arranged on the upper portion of the right end of the electric control box, a control button is arranged in the middle of the right end of the electric control box, first supporting legs are fixedly mounted at the lower ends of the storage box and the mounting box, a triangular mounting block is fixedly mounted at the rear end of the storage box, and a mounting frame assembly is arranged at the upper end of the triangular mounting block. According to the feeding and discharging device for automatic deburring machining of the minimally invasive surgery chuck parts, automatic feeding and automatic discharging of the chuck parts can be achieved, the automation degree is high, operation is easy and convenient, and the machining efficiency and quality of the chuck parts can be improved easily.

Owner:东莞市慧捷工业设计有限公司

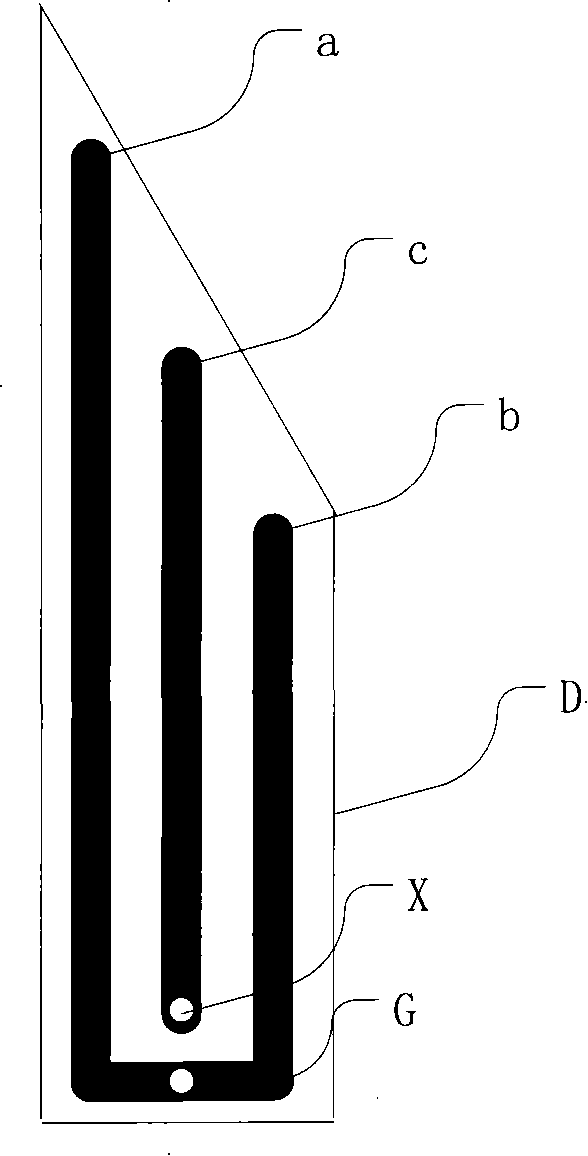

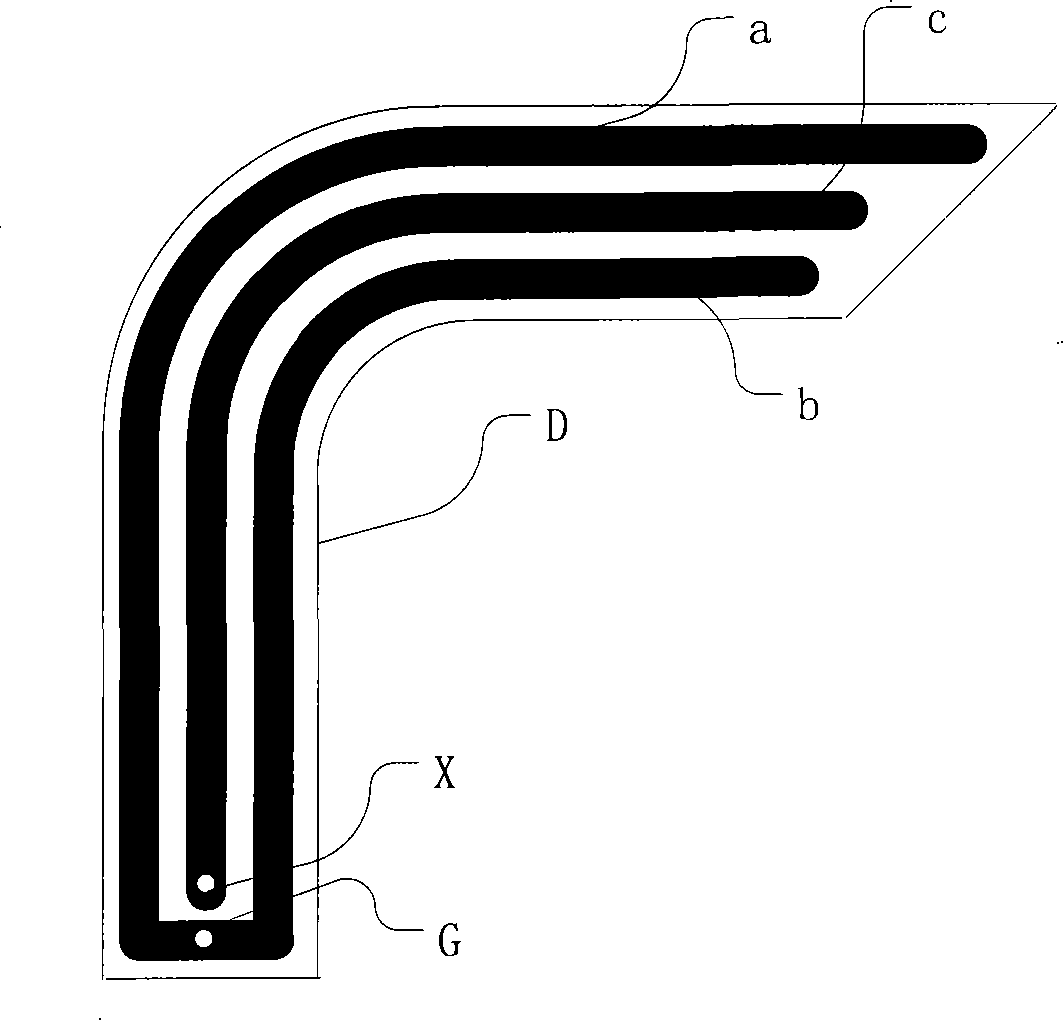

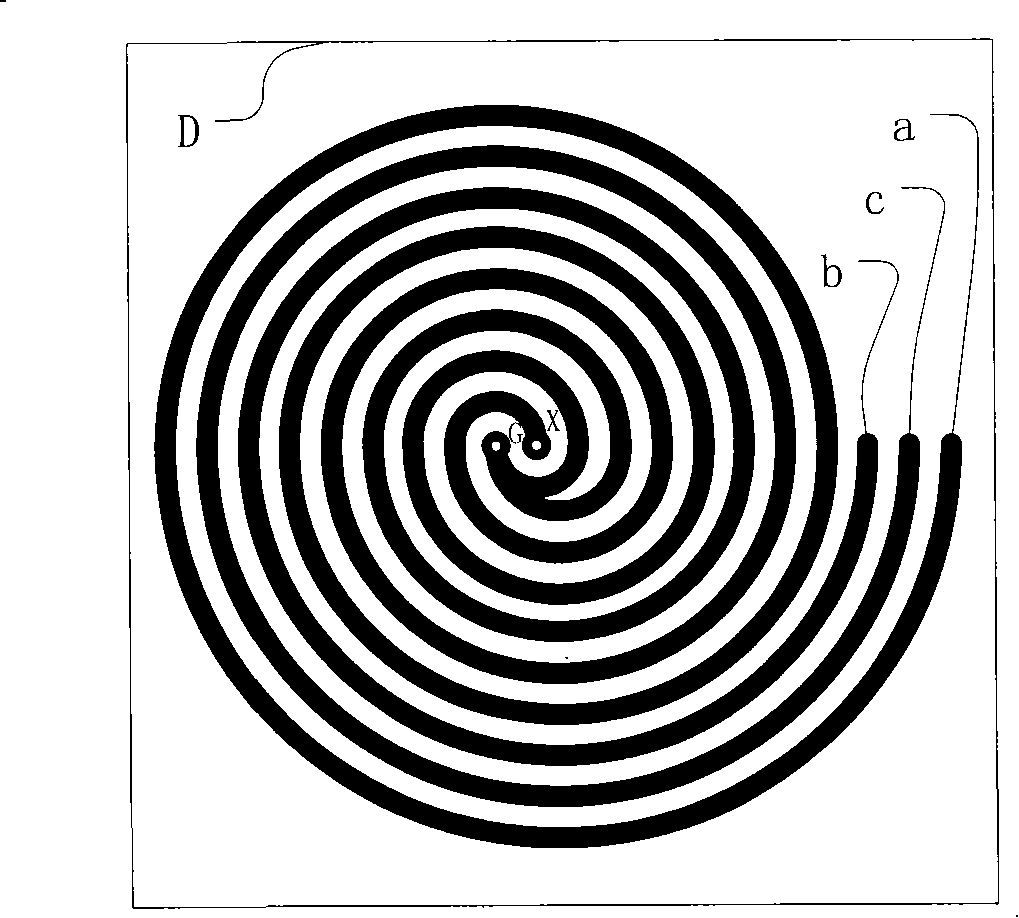

Antenna

ActiveCN101582536BSimple structureSimple processRadiating elements structural formsPolarised antenna unit combinationsElectricityElectrical conductor

The invention relates to an antenna which comprises three conductors a, b and c with certain lengths without intersection, wherein the conductor c is positioned between the conductor a and the conductor b; adjacent ends of the conductor a and the conductor b are electrically connected and then connected with a ground phase of a radio-frequency signal so as to form a connecting point (G); one end of the conductor c adjacent to the connecting point (G) is connected with a radio-frequency signal wire (X); and the length of the conductor a is larger than that of the conductor b so as to enhance the radiating capacity of an electromagnetic wave signal. To the best, the conductors a, b and c with certain lengths are manufactured on a dielectric material, and a comprehensive dielectric constant of the dielectric material between the conductor a and the conductor c is larger than or equal to a comprehensive dielectric constant of the dielectric material between the conductor b and the conductor c so as to increase the bandwidth. The conductors a, b and c are better to be circled on the dielectric material, wherein the length of the conductor a is larger than that of the conductor b, the length of the conductor a and the length of the conductor c are both larger than zero, and the length of the conductor b is larger than or equal to zero so as to reduce the volume.

Owner:YUNNAN GALAXY STAR TECH LTD

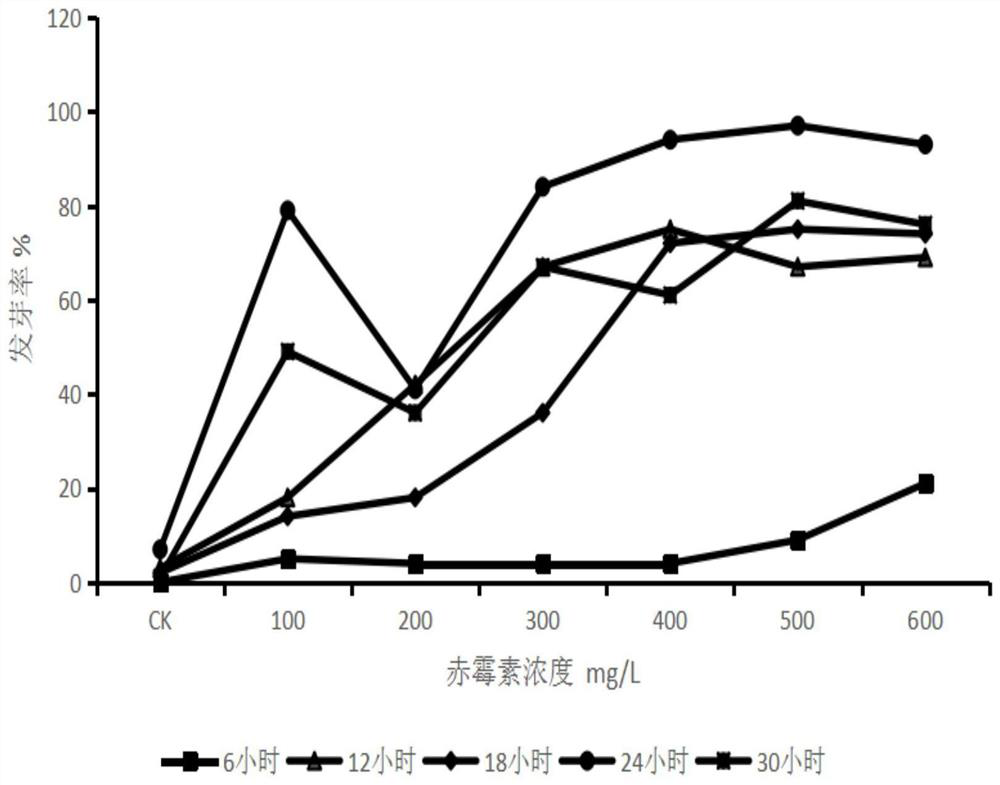

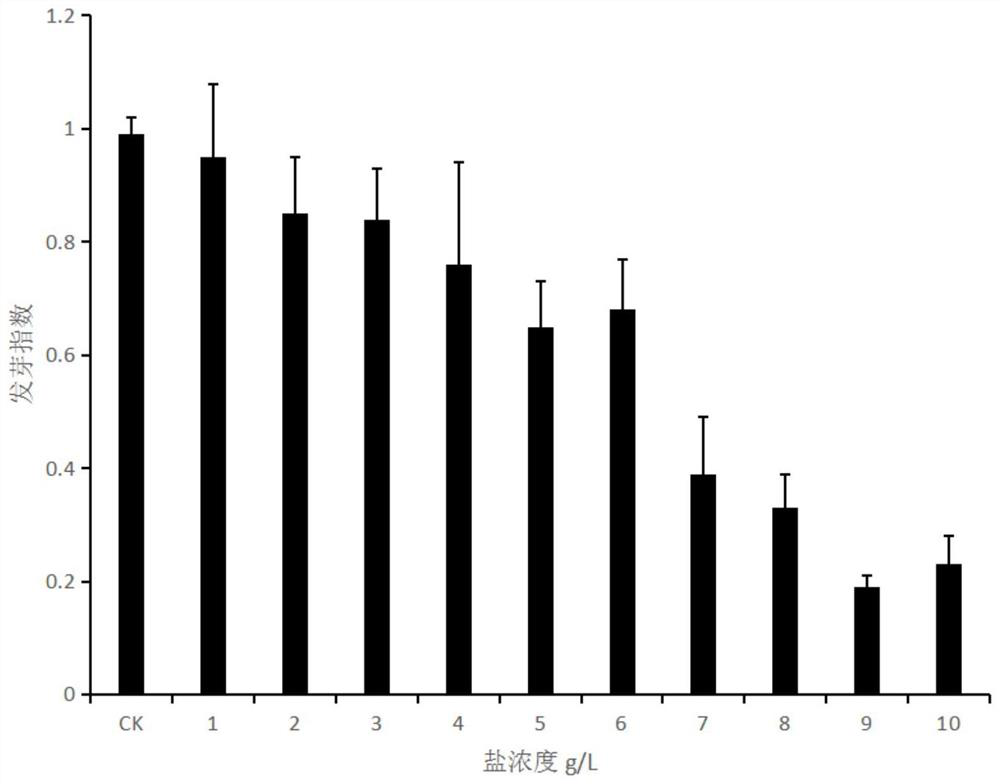

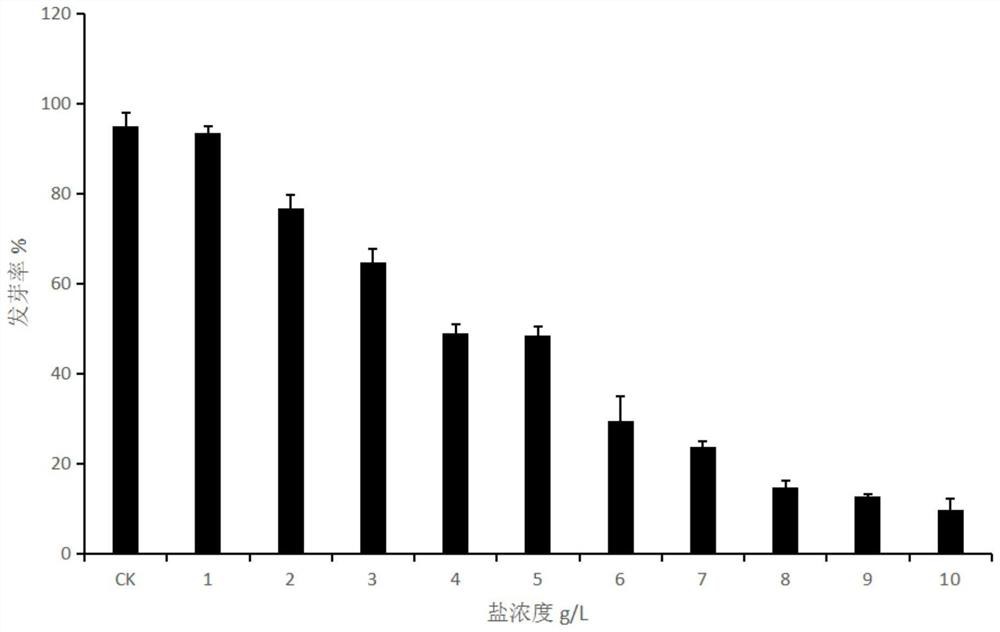

A method for promoting reed seed germination and improving salt tolerance

ActiveCN109548584BSimple process conditionsImprove germination rateSeed and root treatmentPlant cultivationGibberellinEcology

The invention discloses a method for promoting the germination of reed seeds and improving salt tolerance. The invention finds that the reed seeds are soaked in an aqueous solution of gibberellin with a concentration of 100 mg / L-600 mg / L for 12-36 hours before sowing, The germination rate of reed was greatly increased, the germination speed was accelerated, and the salt tolerance was significantly improved. Due to the wide source of reed seeds, low cost and simple gibberellin treatment conditions, it is easy to process in large quantities. Using the method of the present invention to obtain a large number of reed seeds with high germination rate and high salt tolerance is very suitable for ecological restoration projects in saline soil areas, and is also suitable for wetland ecological construction in non-saline soil areas, and the planting operation is also very simple. with broadly application foreground.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

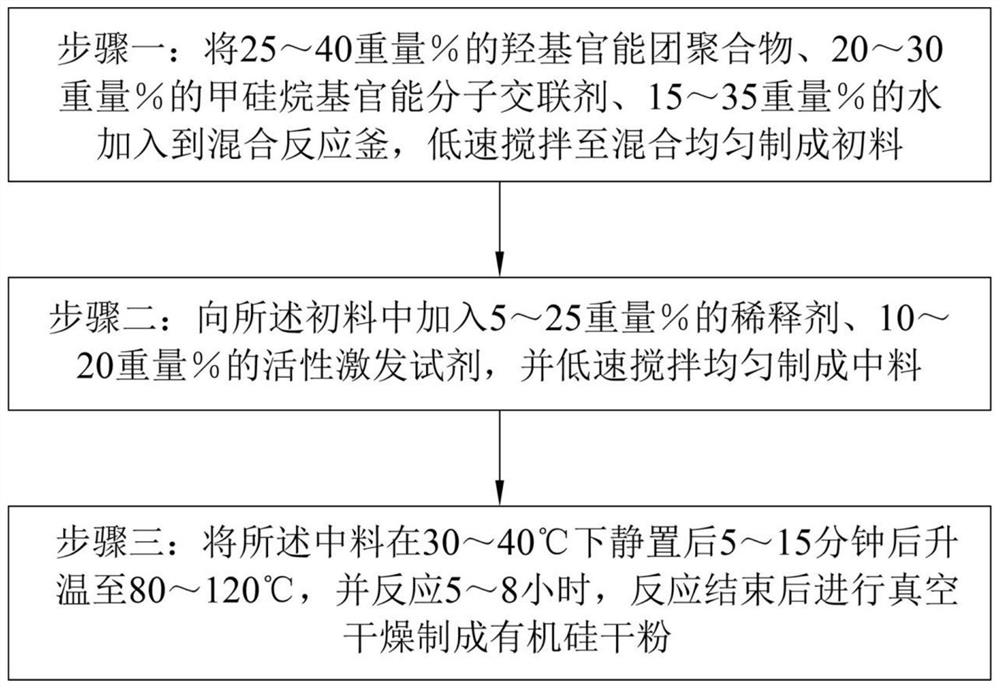

Organosilicone powder for cosmetics and preparation process thereof

PendingCN113105634AEasy to useFacilitated releaseCosmetic preparationsHair cosmeticsPolymer scienceChemical compound

The invention discloses organosilicone powder for cosmetics and a preparation process thereof. The organosilicone powder for the cosmetics comprises the components in percentage by weight: 25-40% of a hydroxyl functional group polymer, 20-30% of a silyl functional molecule cross-linking agent, 5-25% of a diluent, 10-20% of an active excitation reagent and 15-35% of water; and the active excitation reagent comprises 2-8 wt% of organosilicone oil and 8-12 wt% of a compound with a siloxy cyclic chain. The invention further discloses a preparation process of the organosilicone powder for cosmetics. According to the organosilicone powder for the cosmetics and the preparation process thereof, the process steps are simple, and the prepared organosilicone powder for the cosmetics has a promoting effect on release of active molecules in the cosmetics.

Owner:广州巴泰新材料科技有限公司

Direct connection type solar energy vacuum heat collection pipe

InactiveCN103512240AImprove heat collection effectEffective protectionSolar heat devicesSolar thermal energy generationConnection typeUltrasound attenuation

The invention discloses a direct connection type solar energy vacuum heat collection pipe which comprises a metal pipe. A solar energy absorbing coating is arranged on the outer wall of the metal pipe, the metal pipe is sleeved with a vacuum glass pipe, a sealing ring is arranged at the position, close to the two ends, between the metal pipe and the vacuum glass pipe, and an annular sealing cavity is formed. By the adoption of the structure, the heat collection effect of the heat collection pipe is effectively improved, the structure of the vacuum pipe is adopted to replace the structure of a single-layer glass pipe, the thermal preservation performance is effectively improved, due to the fact that vacuum is not required to be formed in the sealing cavity, nitrogen can be filled, the solar energy absorbing coating on the outer layer of the metal pipe is effectively protected, the coating attenuation is slowed down, batch processing of the vacuum pipe is facilitated, and compared with the prior art with the higher sealing process requirement, the direct connection type solar energy vacuum heat collection pipe has the advantage that the whole production difficulty can be reduced.

Owner:YICHANG SANXIA NEW ENERGY EQUIP

A gravity acceleration sensor

ActiveCN108152862BEasy to process in large batchesImprove consistencyGravitational wave measurementCapacitanceEngineering

The invention discloses a gravitational acceleration sensor which comprises a spring mass block structure, a displacement sensing assembly, an upper cover plate structure and a lower cover plate structure. The spring mass block structure comprises a housing frame, an examining weight and a spring structure, and under constraint of the spring structure, the examining weight moves under the effect of an external force; the displacement sensing assembly comprises a driving period array pole plate and a picking period array pole plate, the position of the driving period array pole plate is opposite to that of the picking period array pole plate in an interlaced way, and a capacitor is formed; and when a gravitational acceleration component parallel to the direction of the driving period arraypole plate or the picking period array pole plate changes, the examining weight moves so that the area of the pole plates opposite to each other of the capacitor changes, the change quantity of the capacitor is detector to determine the change quality of the gravitational acceleration component in the direction, and when the gravitational acceleration sensor works in the direction of axis-Z, sagging displacement of the examining weight includes one or more array period(s) under the effect of the gravity. Thus, three-component gravity measurement can be realized.

Owner:HUAZHONG UNIV OF SCI & TECH

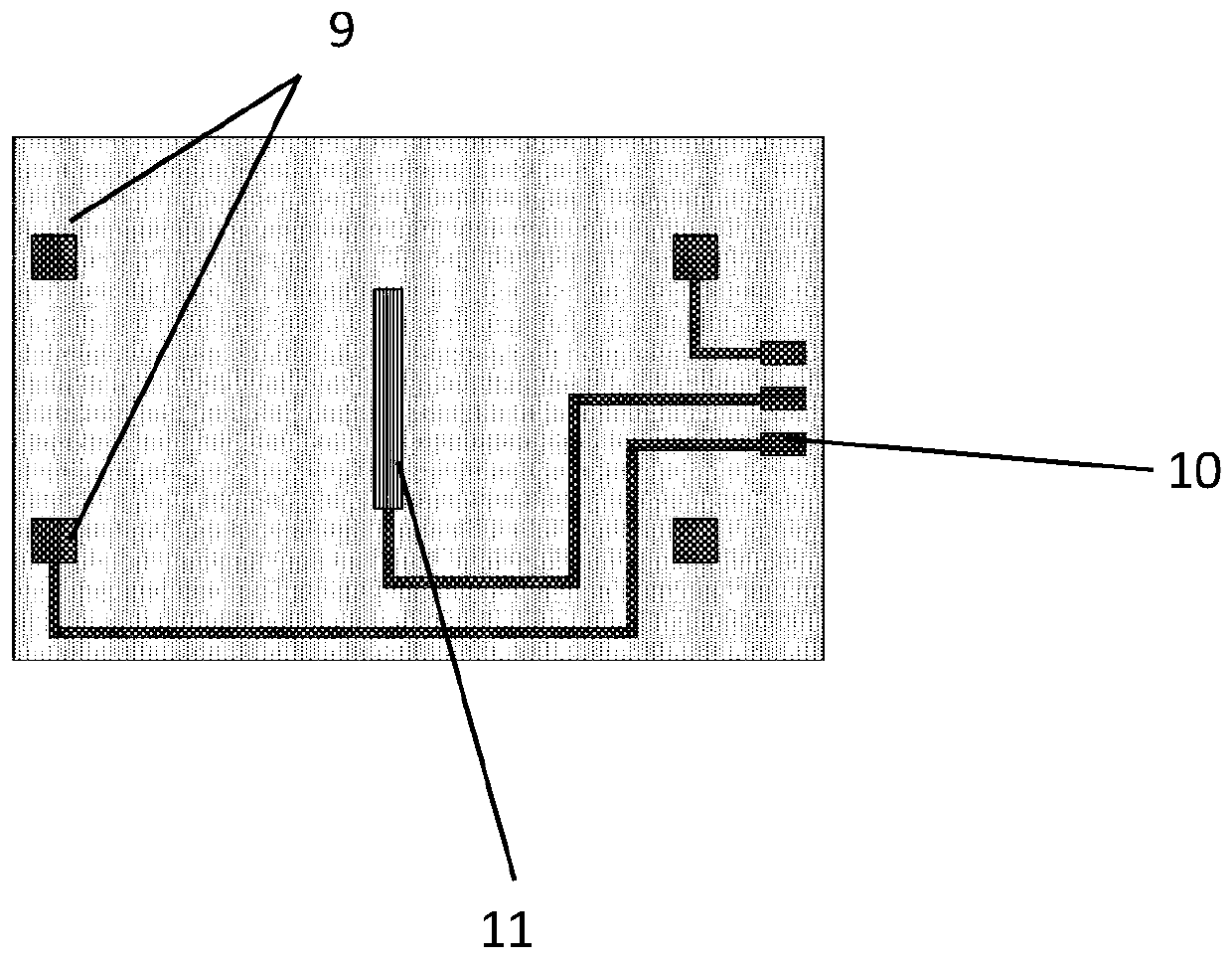

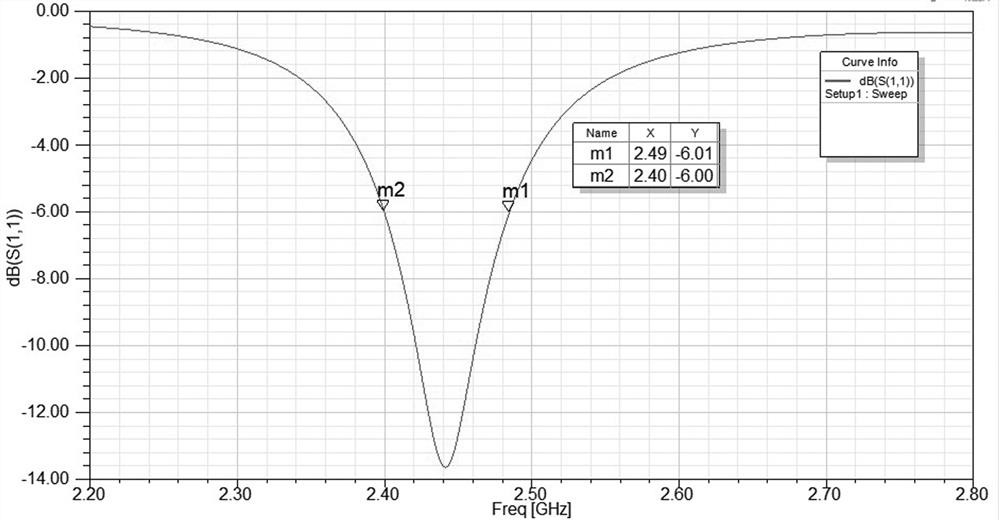

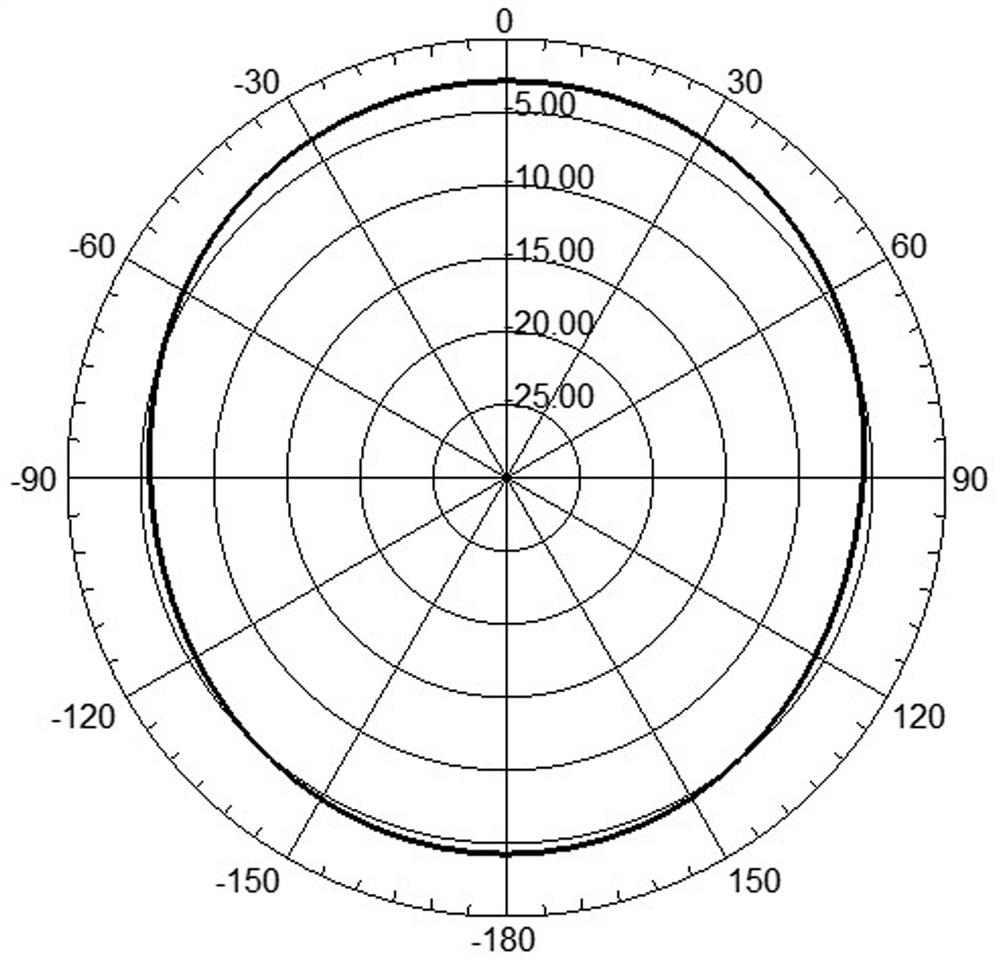

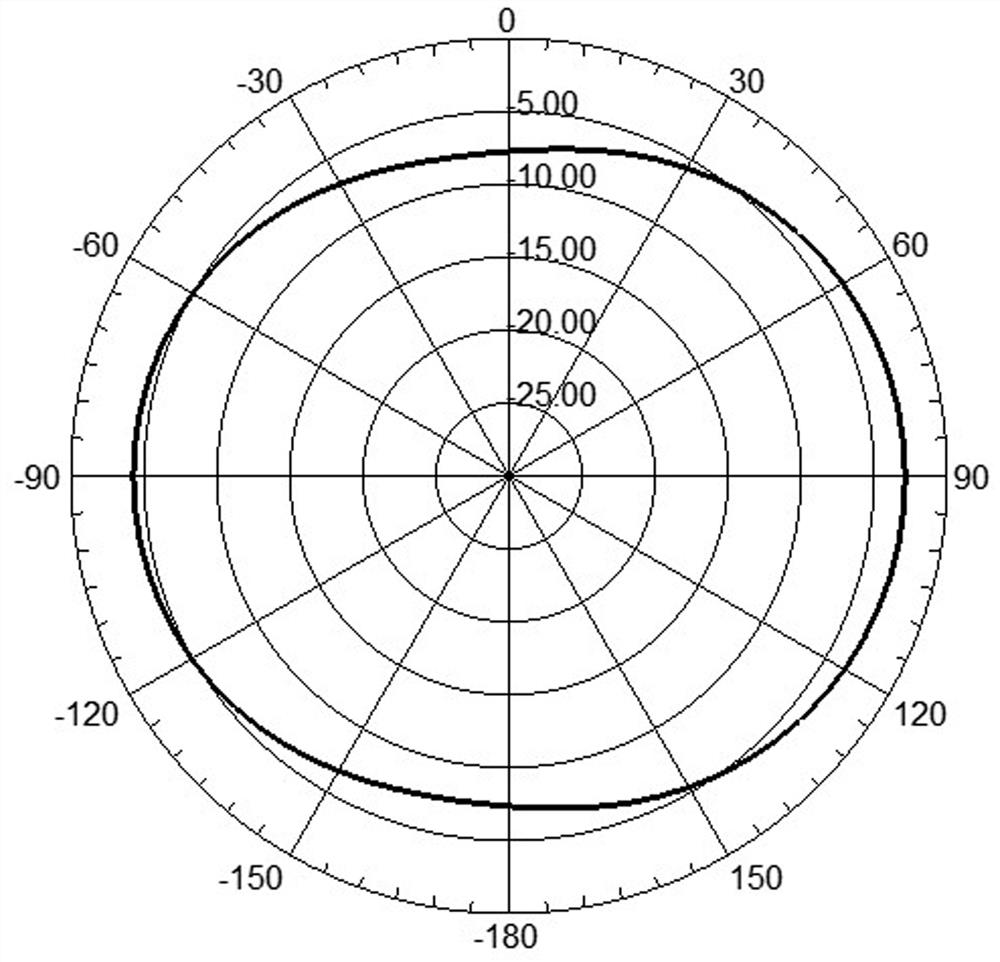

Miniature patch antenna

PendingCN111799551AImproved current distributionLower resonant frequencyRadiating elements structural formsAntenna earthingsCurrent distributionDielectric substrate

The invention discloses a miniature patch antenna which comprises the components of a broken line type radiation patch which is arranged on the front surface of a dielectric substrate, and an edge front loading unit and an edge back loading unit, wherein one end of the broken line type radiation patch is connected with a feeding part; the edge front loading unit and the edge back loading unit arecorrespondingly arranged and are respectively positioned on the front surface and the back surface of the dielectric substrate, and a spacing groove is formed between the edge front loading unit and the broken line type radiation patch. According to the invention, the broken line type radiation patch, i.e., a non-existing planar radiation patch, is adopted, and the perimeter of the broken line type radiation patch can be increased without changing the area of the patch, so that the current flowing path is increased, and the miniaturization design is realized; the edge front surface loading patches and the edge back surface loading patches on the front and back surfaces improve the current distribution in the antenna, and can reduce the resonant frequency of the antenna or reduce the size of the antenna under the same working frequency, thereby further realizing the miniaturization of the antenna, and ensuring the stable working frequency band of the miniature patch antenna at the sametime.

Owner:BEIJING INFORMATION SCI & TECH UNIV

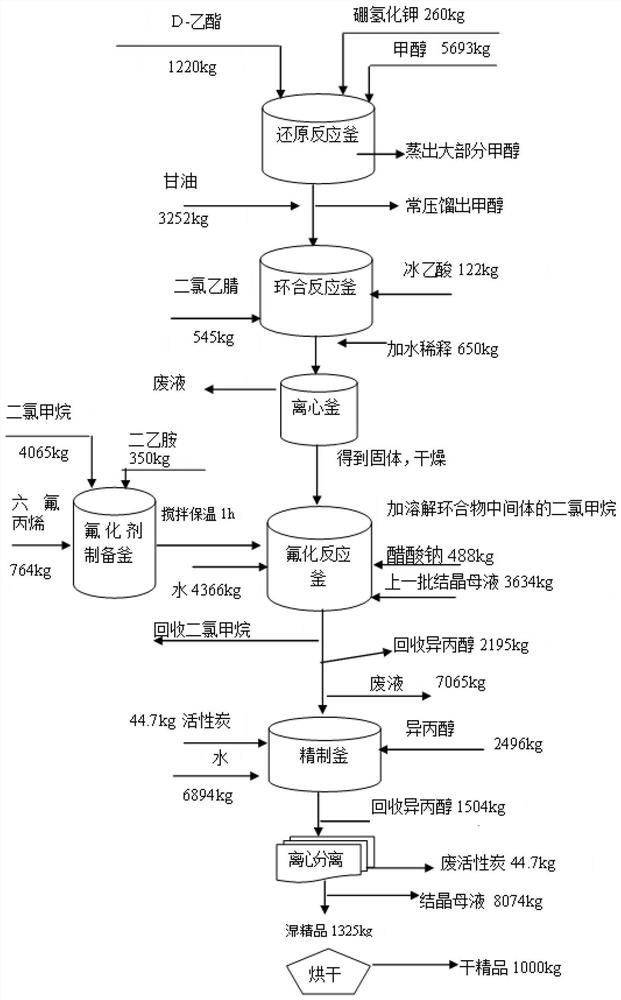

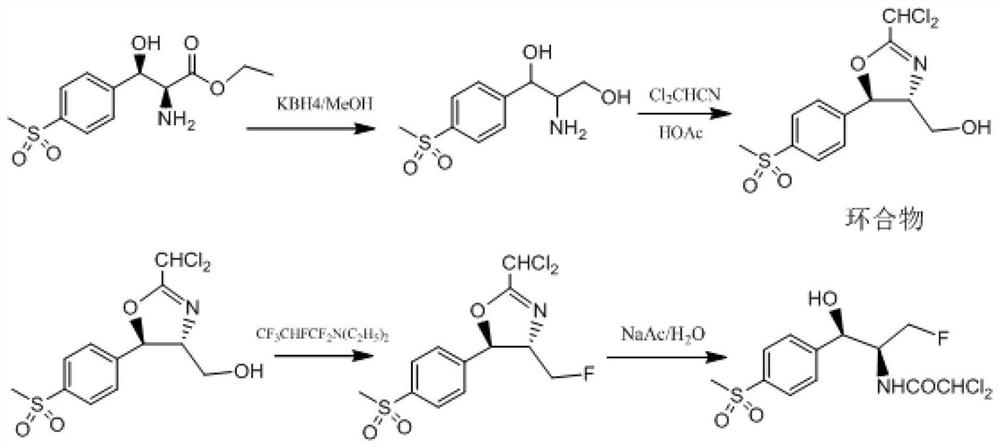

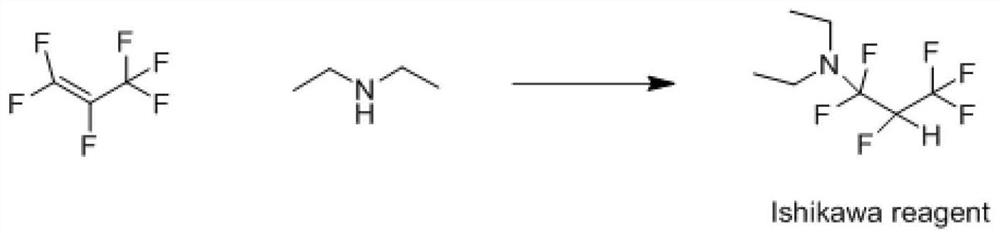

Preparation method of florfenicol

PendingCN113248412AHigh yieldEasy to operateOrganic compound preparationAmino compound preparation by condensation/addition reactionsSodium acetatePotassium borohydride

A preparation method of florfenicol comprises the following steps of: reacting D-ethyl ester with methanol and potassium borohydride to obtain a first-step product; obtaining a second-step product, namely an intermediate cyclization compound, from the first-step product under the action of dichloroacetonitrile and glacial acetic acid, preparing a third-step product, namely an Ishikawa fluorination reagent, from dichloromethane, diethylamine and hexafluoropropylene, reacting the second-step product with the third-step product by taking the dichloromethane as a solvent to obtain a fourth-step product, namely a fluorination reaction solution, and transferring the fourth-step product into a hydrolysis kettle; adding water and sodium acetate into the fourth-step product in the hydrolysis kettle, heating and distilling to evaporate dichloromethane, adding the final crystallization mother liquor of the previous batch after evaporation, heating for reaction, discharging most of isopropanol and water, cooling, and centrifugally separating to obtain crude florfenicol; and refining the crude florfenicol to obtain a pure product, and recycling crystallization mother liquor. A feeding auxiliary device is further arranged and used for effectively adding potassium borohydride in the first step and treating hydrogen in the dissolving process.

Owner:HUBEI ZHONGMU ANDA PHARMACEUTICAL CO LTD

Digital Design Method for Closing Screw Hole of Superimposed Restoration of Dental Implant with Prefabricated Inlay

The invention discloses a digital design method for closing a repair screw hole in the upper part of a tooth implant with a prefabricated inlay. It includes the steps of obtaining a working model of the oral cavity, designing the target implant restoration, and matching holes in the screw hole area. And the substrate (dental ceramics, dental metal) is pre-cut or 3D printed. The steps in clinical use include: enlarging the screw hole of the implant to the designed hole size and depth, trying-in the pre-formed inlay, filling and leveling the hole, installing the pre-formed inlay, and curing the selected adhesive And the final steps of grinding and polishing the surface of the preformed inlay. The invention is simple in design, convenient for large-scale industrial processing and manufacturing, convenient for quick installation of prefabricated inlays, does not leave too much adhesive, convenient for fast and stable sealing of screw holes, and the sealing port is beautiful, stable and has strong mechanical properties , It can also solve the problem of aesthetic closure of the labial opening of the anterior tooth screw hole, making the case of anterior tooth implant repairing the labial opening a routine indication.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com