Flexible sensor and preparation method thereof and method for simultaneously measuring rigidity and dielectric constant

A flexible sensor and dielectric constant technology, applied in the field of sensors, can solve the problems of inability to produce large bends, high requirements for sample shape, and large volume of measuring devices, and achieve the effects of simple structure, weight reduction, and accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The present invention also provides a method for preparing a flexible sensor, comprising the following steps:

[0048] Step 1, cleaning the flexible substrate 1 made of flexible polymer;

[0049] Step 2, performing photolithographic treatment on the cleaned flexible substrate 1, and transferring the photolithographic pattern to the flexible substrate 1;

[0050] Step 3, using electron beam evaporation to deposit different metals on the surface of the flexible substrate 1 to form the bonding layer 2 and the conductive layer 3 respectively;

[0051] Step 4, using a stripping process to transfer the pattern to the bonding layer 2 and the conductive layer 3 to form two mutually insulated electrodes, and finally form the flexible sensor 5 .

[0052] In step 4, the conductive layer 3 is covered with a flexible polymer to form a flexible protective layer 4 , and part of the flexible polymer is removed by photolithography and etching processes to form an opening 7 communicatin...

Embodiment 1

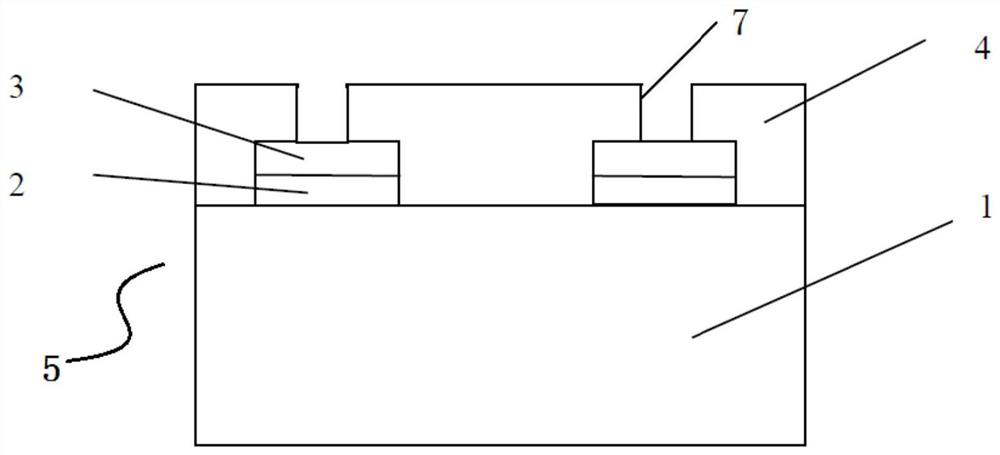

[0055] like figure 1 As shown, the present embodiment provides a flexible sensor capable of simultaneously measuring stiffness and permittivity, the flexible sensor is as follows from bottom to top: flexible substrate 1, bonding layer 2, conductive layer 3 and flexible protective layer 4; wherein, The flexible substrate 1 is polyimide with a thickness of 100 microns; the bonding layer 2 is chromium with a thickness of 20 nanometers; the conductive layer 3 is gold with a thickness of 200 nanometers;

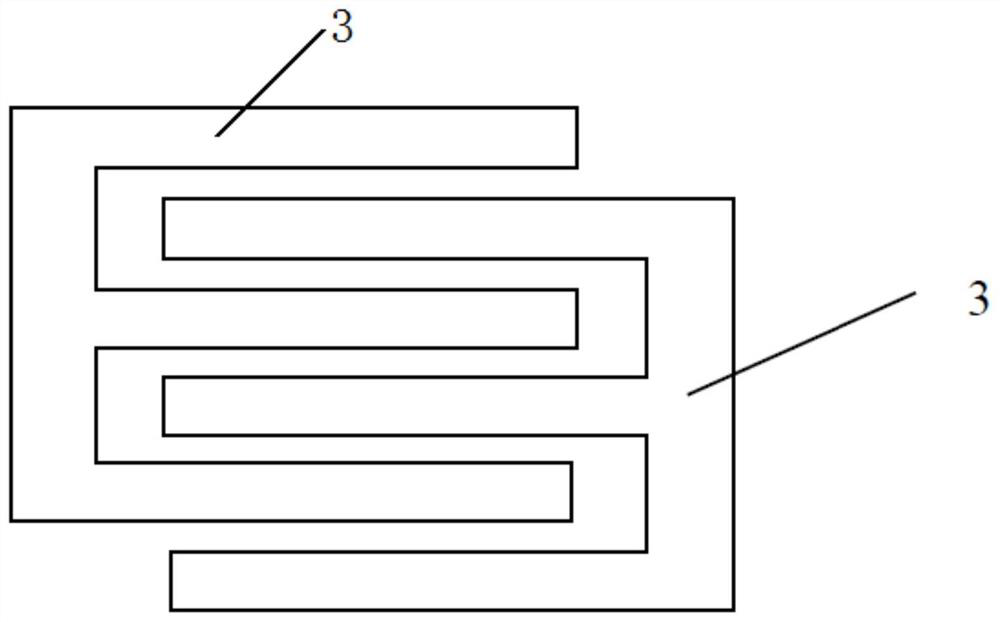

[0056] like figure 2 As shown, both the bonding layer 2 and the conductive layer 3 form interdigitated electrodes insulated from each other in the same plane.

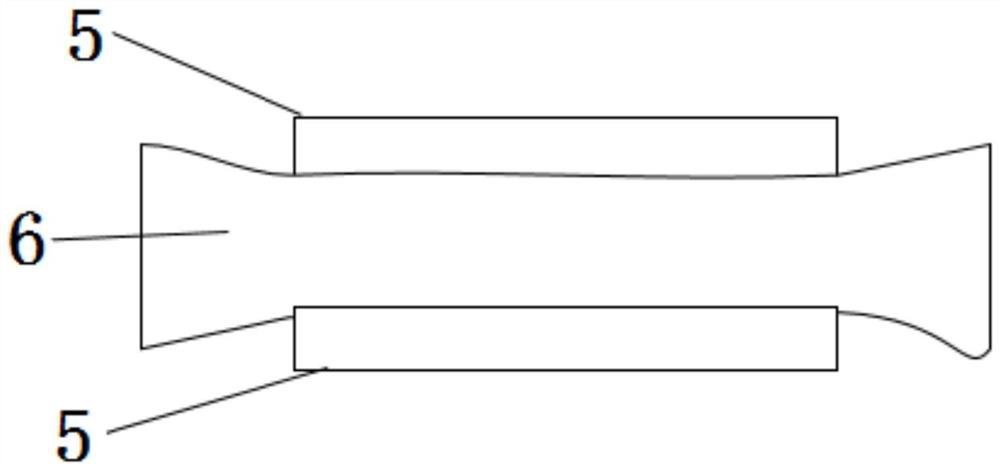

[0057] like image 3 As shown, when measuring stiffness, two flexible sensors 5 are respectively attached to both sides of the same object 6 to be measured. When the object 6 to be measured is compressed and deformed, the distance between the two flexible sensors 5 changes, and the capacitance C between the two flexibl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com