Digital Design Method for Closing Screw Hole of Superimposed Restoration of Dental Implant with Prefabricated Inlay

A design method and screw hole technology, which can be used in dental prosthetics, dental implants, dentistry, etc., can solve the problems of unsightly sealing of the labial opening of the anterior teeth, weak mechanical properties of the sealing mouth, and excessive residual adhesive, etc. It achieves the effect of convenient clinical operation, easy grinding and shaping of prosthetic shape, and excellent mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] This embodiment discloses a digital design method for prefabricated inlays to seal the upper repair screw holes of dental implants, which includes the following steps:

[0044]A. Obtain a digital oral model of the patient's oral cavity, which is generated based on oral data obtained by scanning the patient's oral cavity and implants. The patient's oral data can be obtained by scanning with a digital scanner.

[0045] B. Design of the complete restoration in the oral model. This step is a common method in oral implantology, and can be completed with the help of professional oral implant design software. The prosthesis to be replaced in the missing area is designed by referring to the adjacent teeth, homonymous teeth and antagonist teeth.

[0046] C. Steps for digital drilling of screw holes for complete restorations, including primary and secondary drilling:

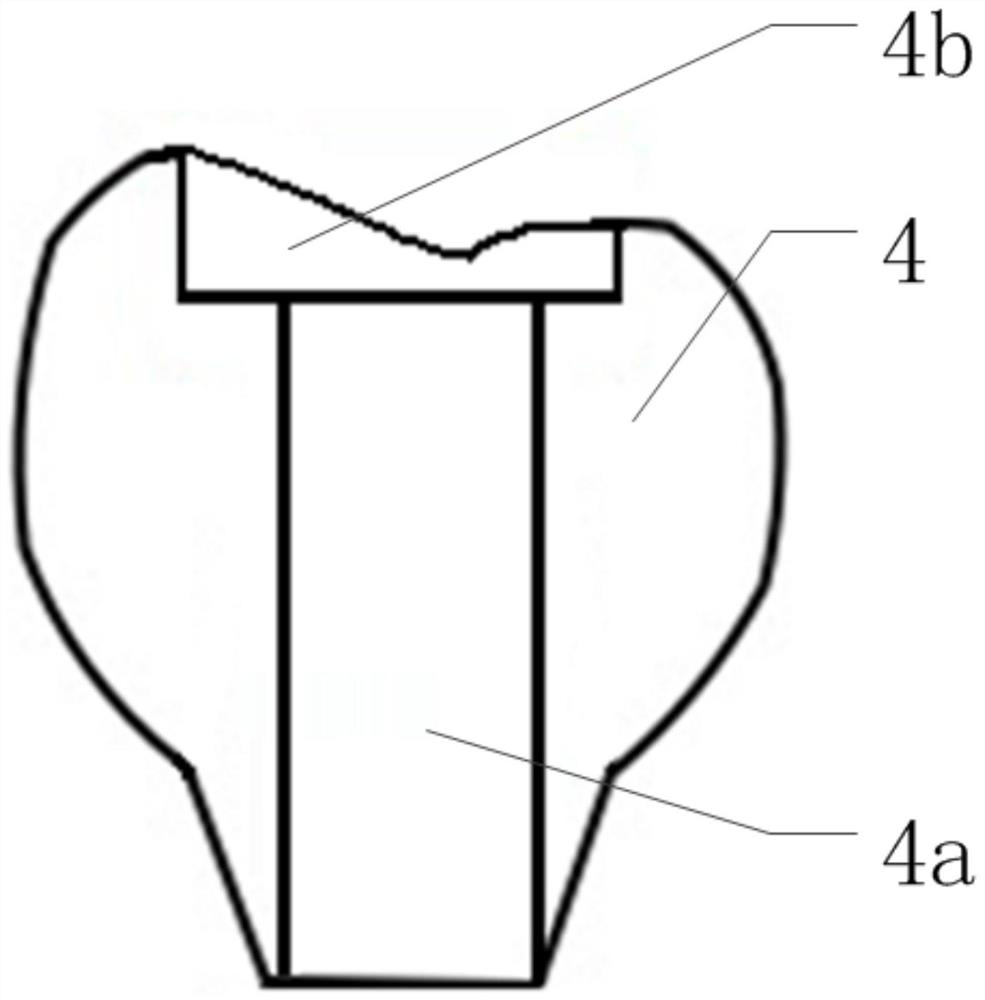

[0047] C1: Corresponding to the installation position of the upper implant, a hole is made on the complete re...

Embodiment 2

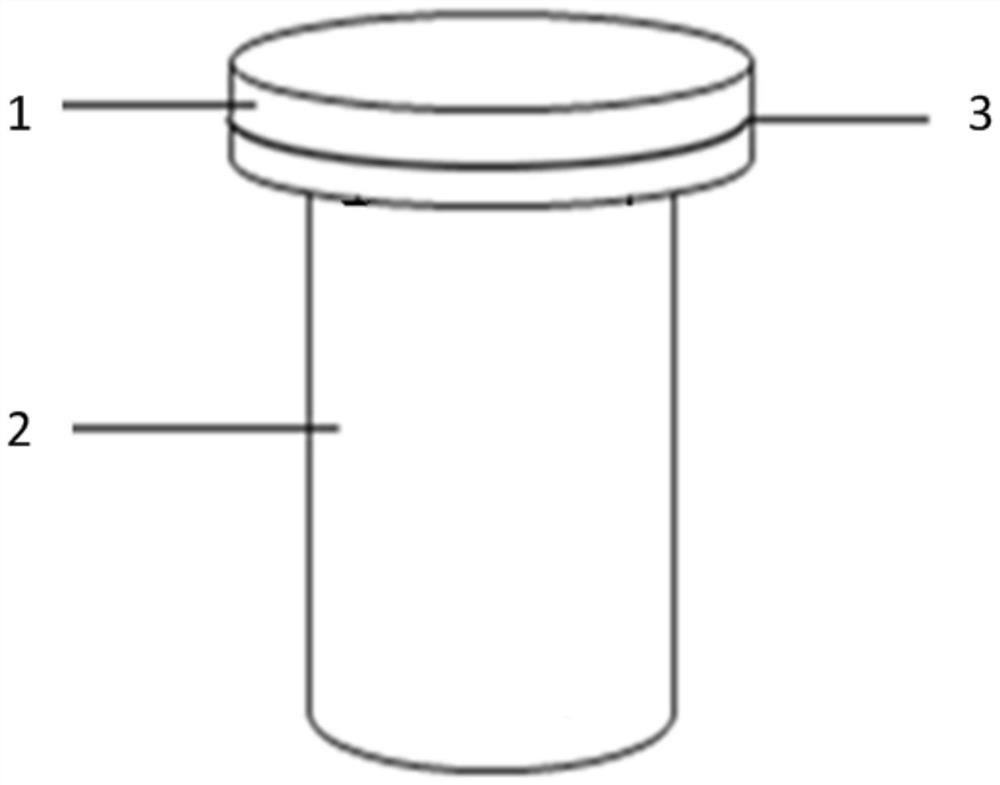

[0053] Clinically, patients need to wear dentures, and based on the digital design of implant restorations, physical implant restorations also need to be obtained. This embodiment discloses a manufacturing method of an implant restoration, the manufacturing method includes the above-mentioned design method of the implant restoration, and thereafter:

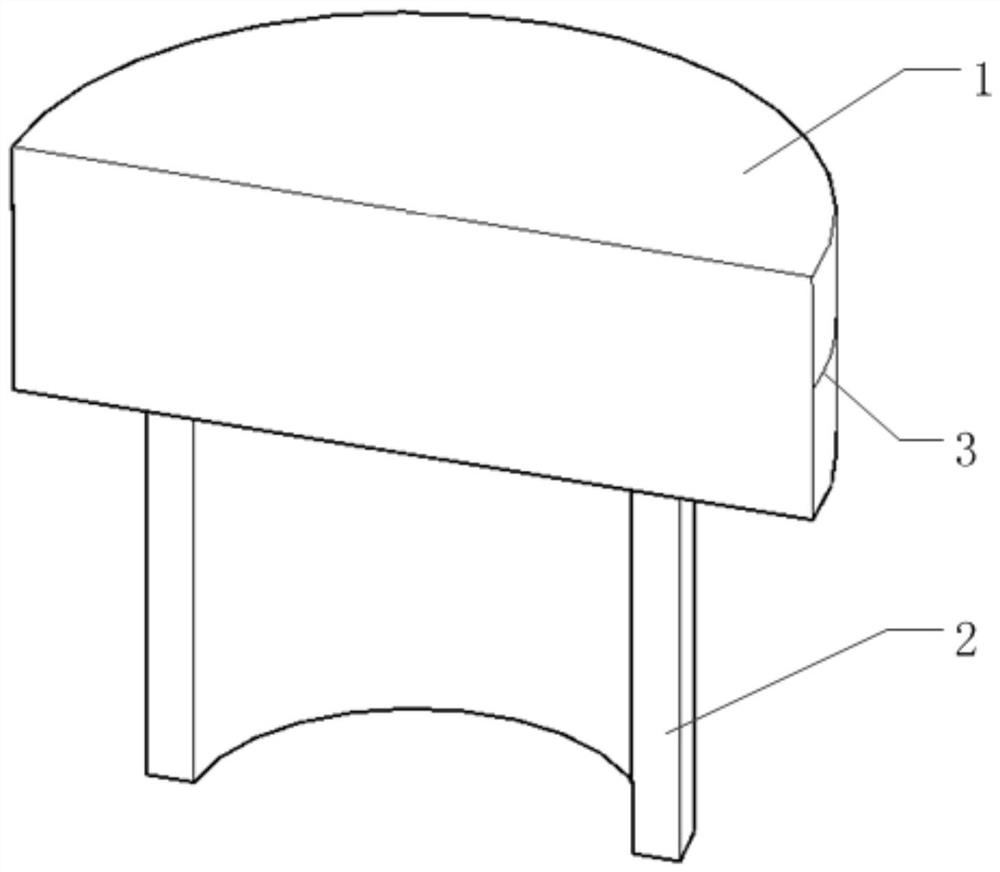

[0054] D. Import the model of the digitally perforated restoration (that is, the digital implant restoration) into the digital cutting and layout system, and use the flat needle mode to cut and shape the base material.

[0055] A solid implant restoration can be obtained through the above method.

[0056] In one embodiment, the digital implant prosthesis imported into the digital cutting and layout system is the implant prosthesis stored in the storage medium. The storage medium stores the implant restoration model designed by the design method in the first embodiment.

Embodiment 3

[0058] This embodiment discloses a method for manufacturing an implant restoration matched to a preformed inlay, comprising the following steps:

[0059] A. Acquisition of digital oral model: scan the patient's oral cavity and implants with a digital scanner to obtain data on the patient's oral cavity and implants, and use 3D modeling software to construct the patient's oral cavity model based on the oral cavity and implant data (ie, oral cavity data) , the oral cavity model includes the patient's dentition information and implant information.

[0060] B. Digital complete restoration design: Import the oral model into the professional oral implant design software, and the designer designs the target restoration of the implant position.

[0061] C. Digital preparation hole position:

[0062] C1. A hole is made on the target restoration. The first hole is a screw hole through which the retaining screw fixes the restoration to the implant. One-time opening is a routine design t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com