Patents

Literature

44 results about "Implant dentures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

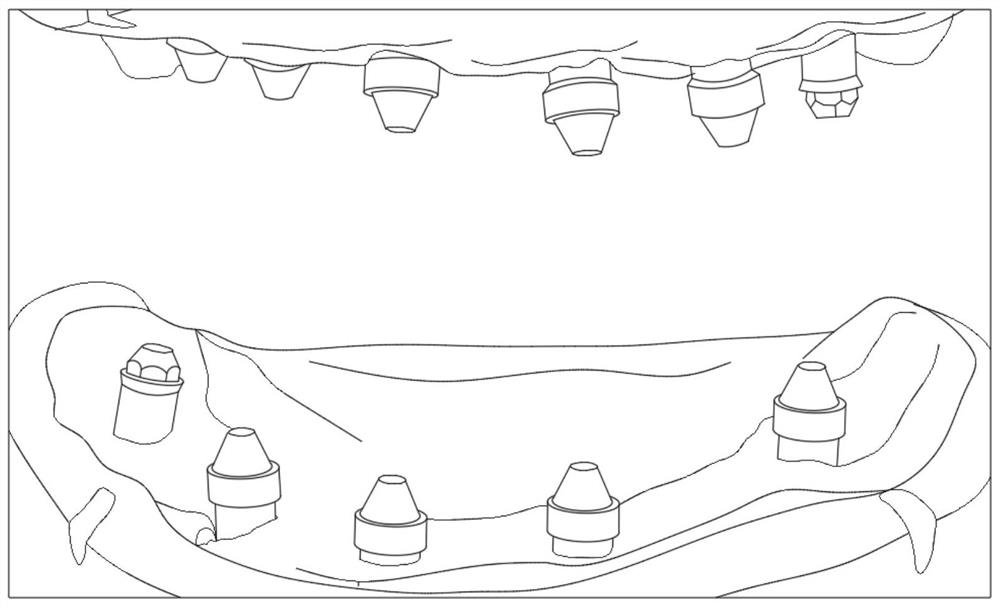

Dentures cannot be “made into implants”. Implants are metal screws placed into the jawbone to help anchor and support artificial teeth (dentures). It may be possible to have implants placed beneath existing dentures to aid in the stabilization and support for those dentures.

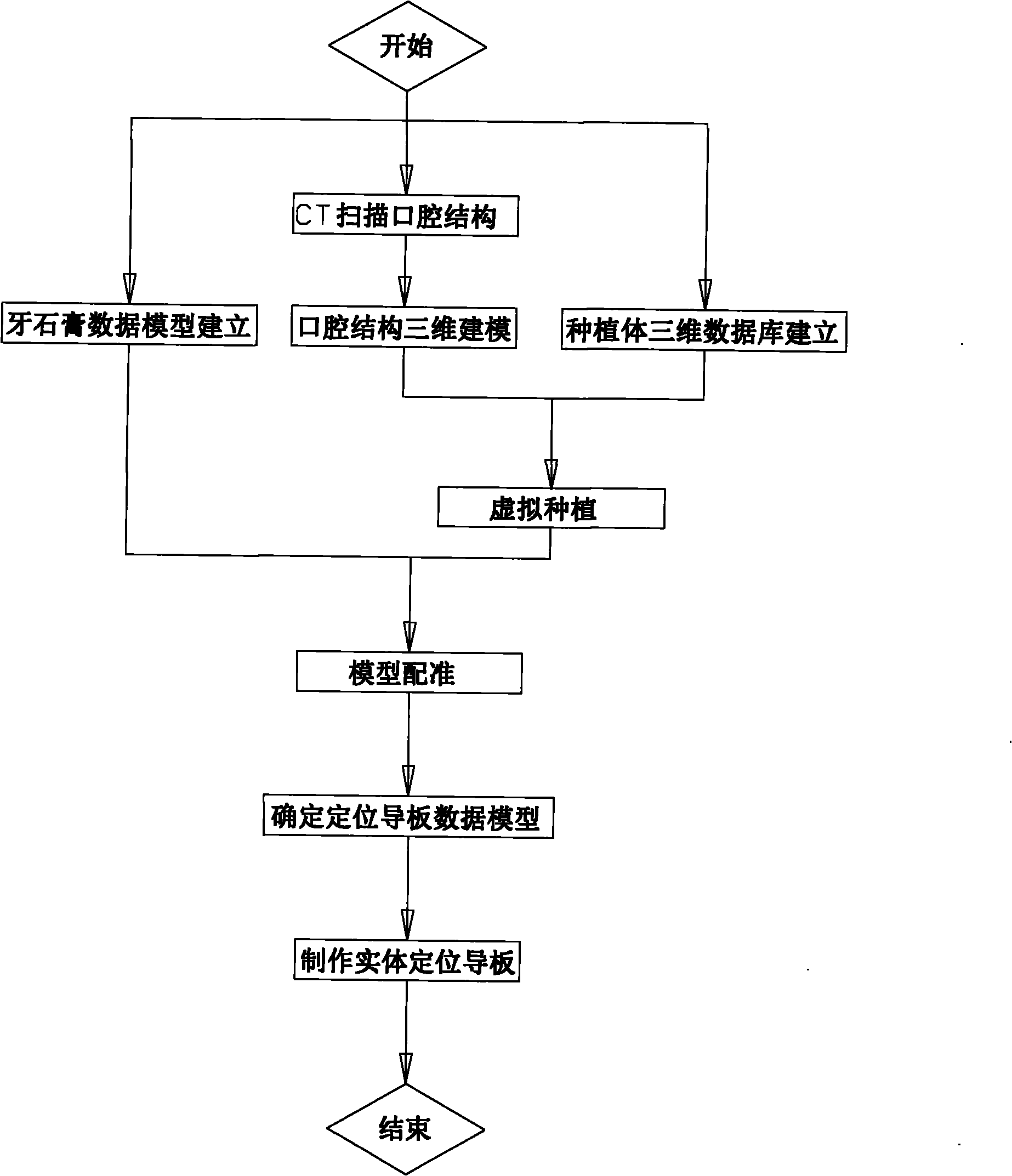

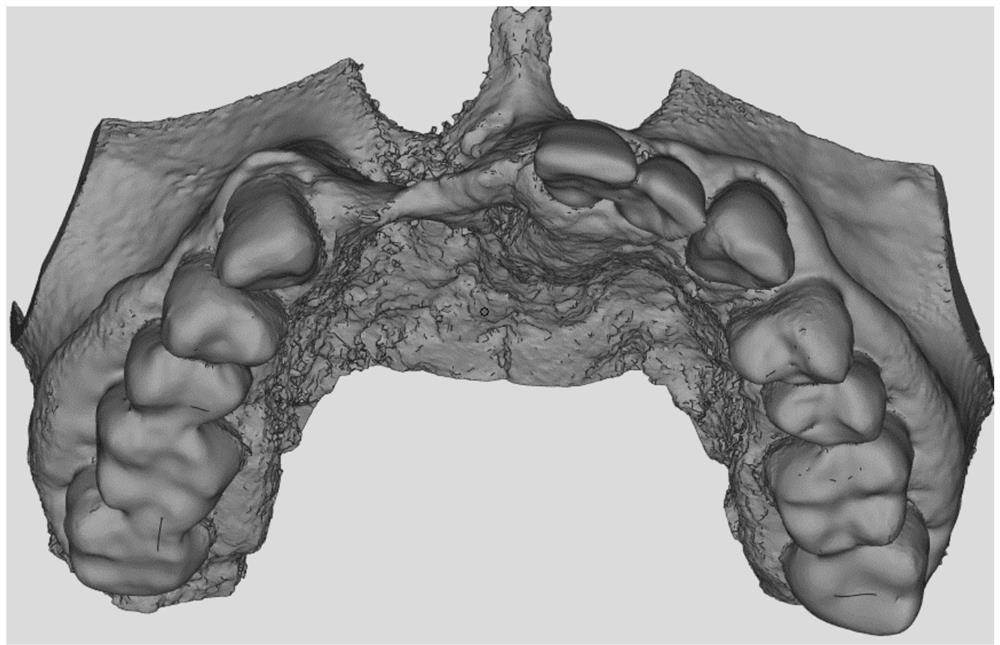

Manufacturing method of implant denture individualized positioning guide plate

InactiveCN101828974AGuaranteed manufacturing accuracyEasy to manufactureDental implantsAnatomical structuresBiomechanics

The invention relates to a manufacturing method of an implant denture individualized positioning guide plate in the technical field of tooth repair technologies, which comprises the steps of: firstly, establishing a three-dimensional model of anatomical structures of teeth, jaws, maxillary antrums, mandibular nerve conduits and the like according to oral cavity CT data of patients; secondly, carrying out virtual implanting on a solid modeled implant model, matching an implanted model with a patient oral cavity structural data model established after scanning a dental model by using an opticalscanner, determining the position of a guide hole of the positioning guide plate and the shape of a contact surface of gums, inserting a guide pipe in the guide hole; and thirdly, manufacturing a solid positioning guide plate. The solid positioning guide plate can provide optimal implanting position and direction to ensure the safety of an implanting technology and the long-term stability of an implant. The positioning guide plate can maximally utilize the bone quantity of the alveolar bone when in application. The invention can improve the efficiency and the accuracy of the implanting technology, ensure that the implanted implant accords with the biomechanical principle, and guarantee the repair aesthetic effect.

Owner:AFFILIATED STOMATOLOGICAL HOSPITAL OF NANJING MEDICAL UNIV

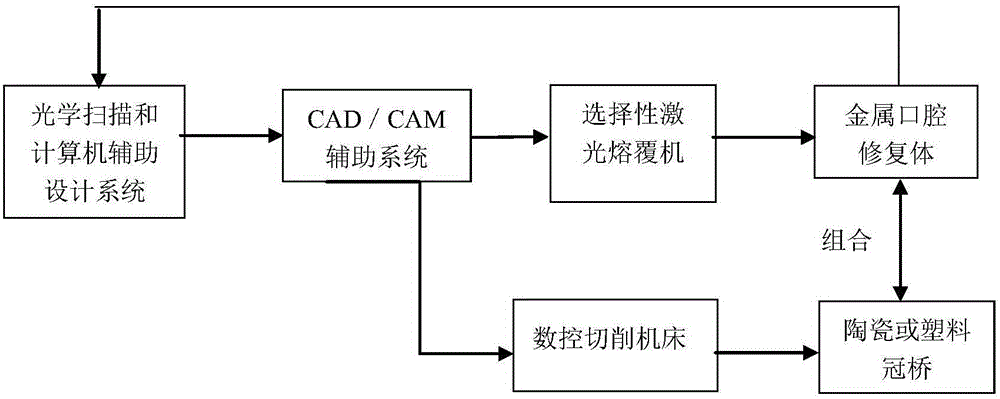

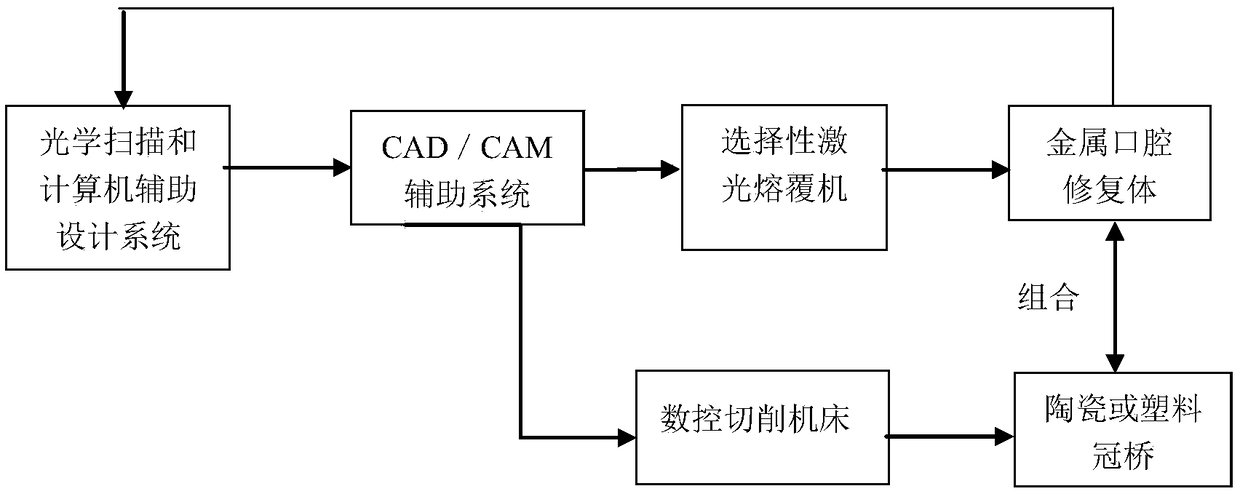

Automatic CAD/CAM/3D processing method of dental prostheses

The invention relates to an automatic CAD / CAM / 3D processing method of dental prostheses. The method comprises the step of processing dental prostheses by employing a composite system composed of an optical scanner and a computer aided design system, a CAD / CAM aided system, a selective laser cladding machine and a numerical control cutting machine tool, wherein prostheses such as removable partial dentures, fixed dentures, complete dentures and implant dentures can be rapidly manufactured. The method is characterized in that numerical control cutting (subtractive manufacturing called as subtraction) and the 3D printing technology (additive manufacturing called as addition) are organically combined and highly unified. Two aspects of the unity and opposites are merged into one uniform aspect; the automatic production efficiency of the dental prostheses, especially complex prostheses, can be greatly improved, complicated procedures of a conventional handmade dental prosthesis are eliminated, the manufacturing quality and stability of the prostheses are improved, the purposes of quickness, accuracy and individualized manufacturing are achieved, and the dental prostheses meet the urgent demands of most agomphosis patients.

Owner:维视医疗信息科技山东有限公司

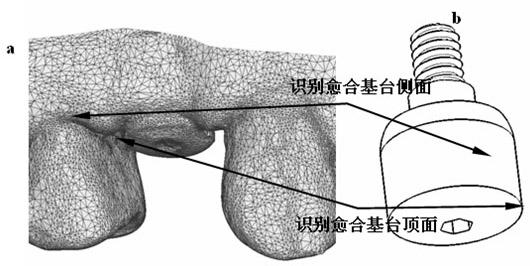

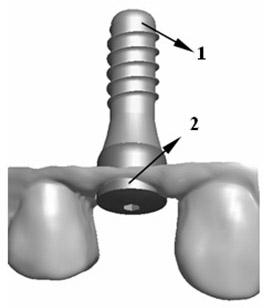

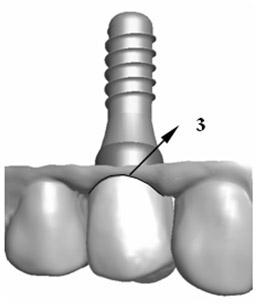

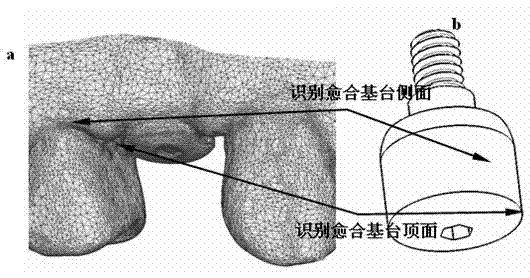

Implant denture individual abutment design method based on healing abutment dental model

InactiveCN102194030AAvoid precision lossSpecial data processing applicationsPersonalizationData acquisition

The invention discloses an implant denture individual abutment design method based on a healing abutment dental model, and belongs to the field of computer auxiliary design. The method comprises the following four steps: acquiring and preprocessing data; establishing an implant system model base; positioning a healing abutment and an implant body; and designing an individual abutment. The implant denture individual abutment design method is high in automation, not only ensures that the operation steps of manufacturing a wax pattern or casting a model, and transferring the implant body on clinic and the like can be omitted, but also can be used for improving the shape of gingival margin of the restored implant denture, greatly reducing the operation time and cost of a doctor and a skilled work, and improving the restoration efficiency and beautiful appearance; the implant denture individual abutment design method based on the healing abutment dental model has important application value in a computer auxiliary dental implant field.

Owner:AFFILIATED STOMATOLOGICAL HOSPITAL OF NANJING MEDICAL UNIV +1

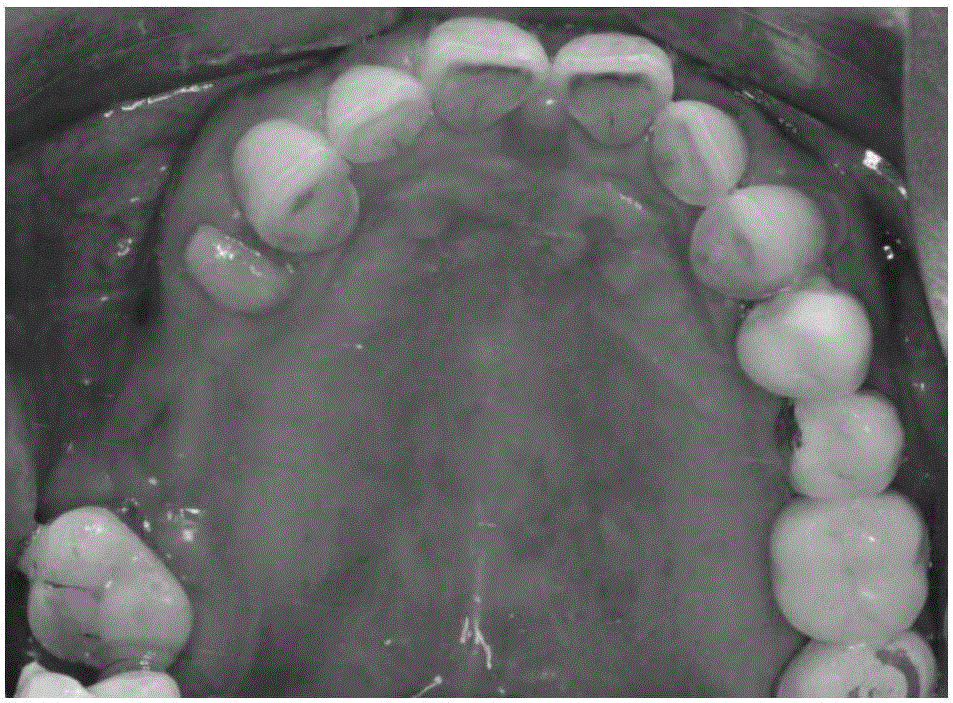

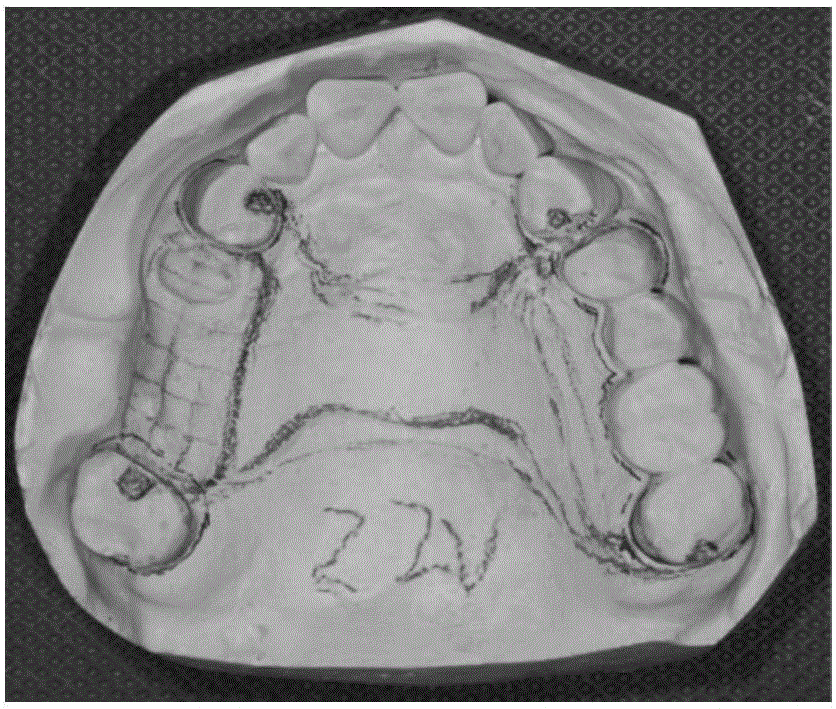

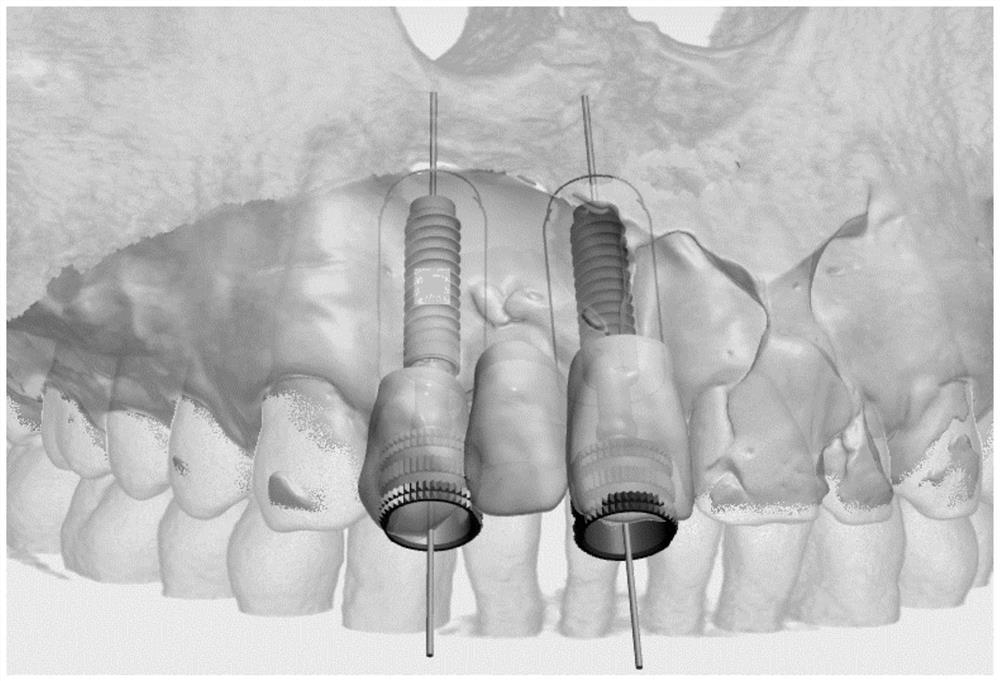

Oral cavity dental implant reconstructable guide plate and manufacturing method thereof

ActiveCN106361452AMeet the needs of individualized treatmentReduce wasteDental implantsAdditive manufacturing apparatusDentistryGreen manufacturing

The invention discloses an oral cavity dental implant reconstructable guide plate and a manufacturing method thereof. The oral cavity dental implant reconstructable guide plate consists of a movable drilling template and a personalized base plate; a designing and manufacturing method of the oral cavity dental implant reconstructable guide plate comprises the following steps: acquiring oral cavity CBCT of a patient; comprehensively evaluating the oral cavity situations of the patient; manufacturing and scanning a plaster model of an oral cavity part of the patient, matching plaster scanning data and CBCT data, and reconstructing three-dimensional models of teeth and bones; making a planting plan; analyzing the strength of an implant; designing a standard drilling template corresponding to a drilling bit of the drilling template; designing a personalized guide plate substrate; importing an implant body model into a computer to perform virtual planting; designing an implant denture; manufacturing the reconstructable guide plate. According to the oral cavity dental implant reconstructable guide plate and the manufacturing method thereof, the treatment time can be shortened by performing virtual planting by utilizing planting software; moreover, the survival rate of the dental implant is favourably improved; quick manufacturing and field reconstruction of a dental implant drilling and cutting guide plate are realized; a medical material is saved and the cost is also reduced through the use of the drilling template; the requirement of green manufacturing is met.

Owner:SHANDONG UNIV

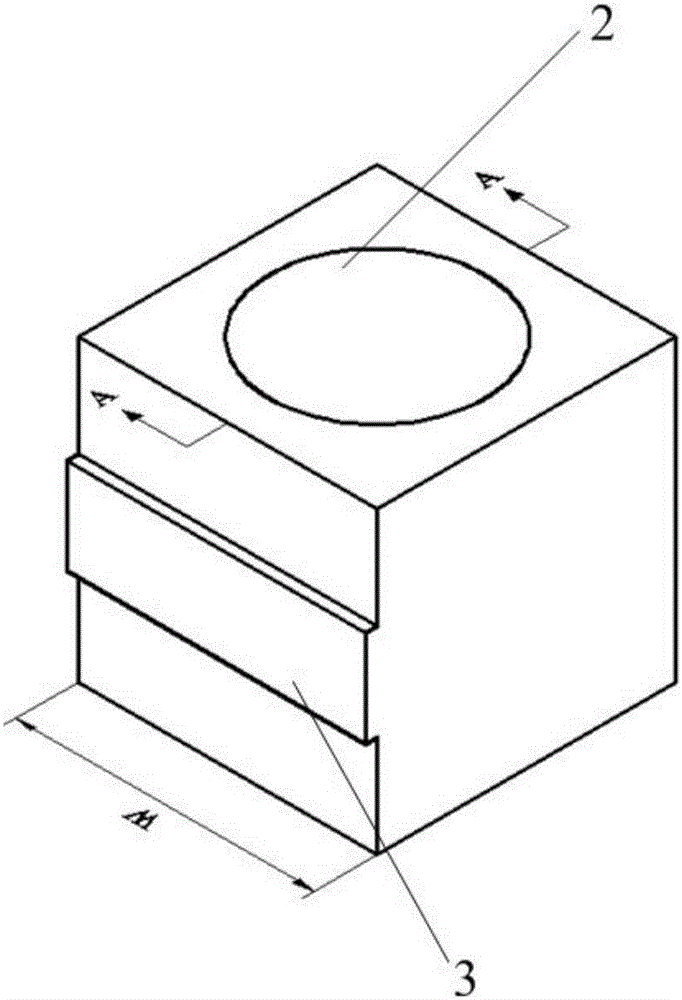

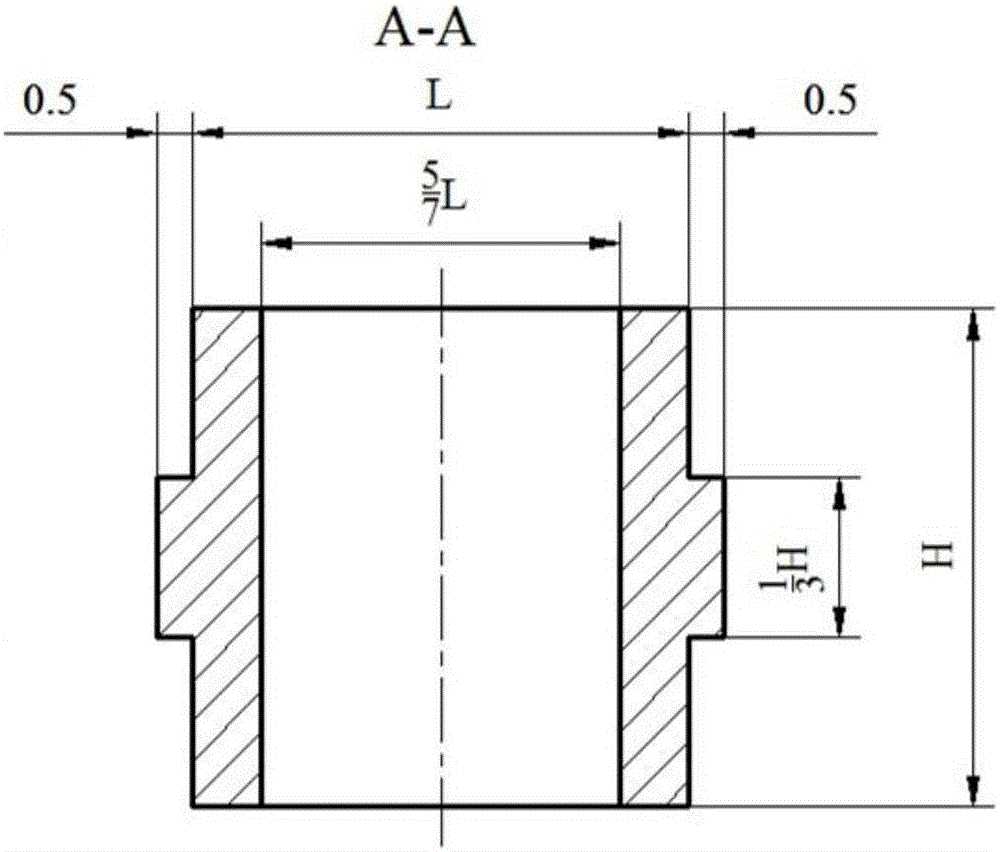

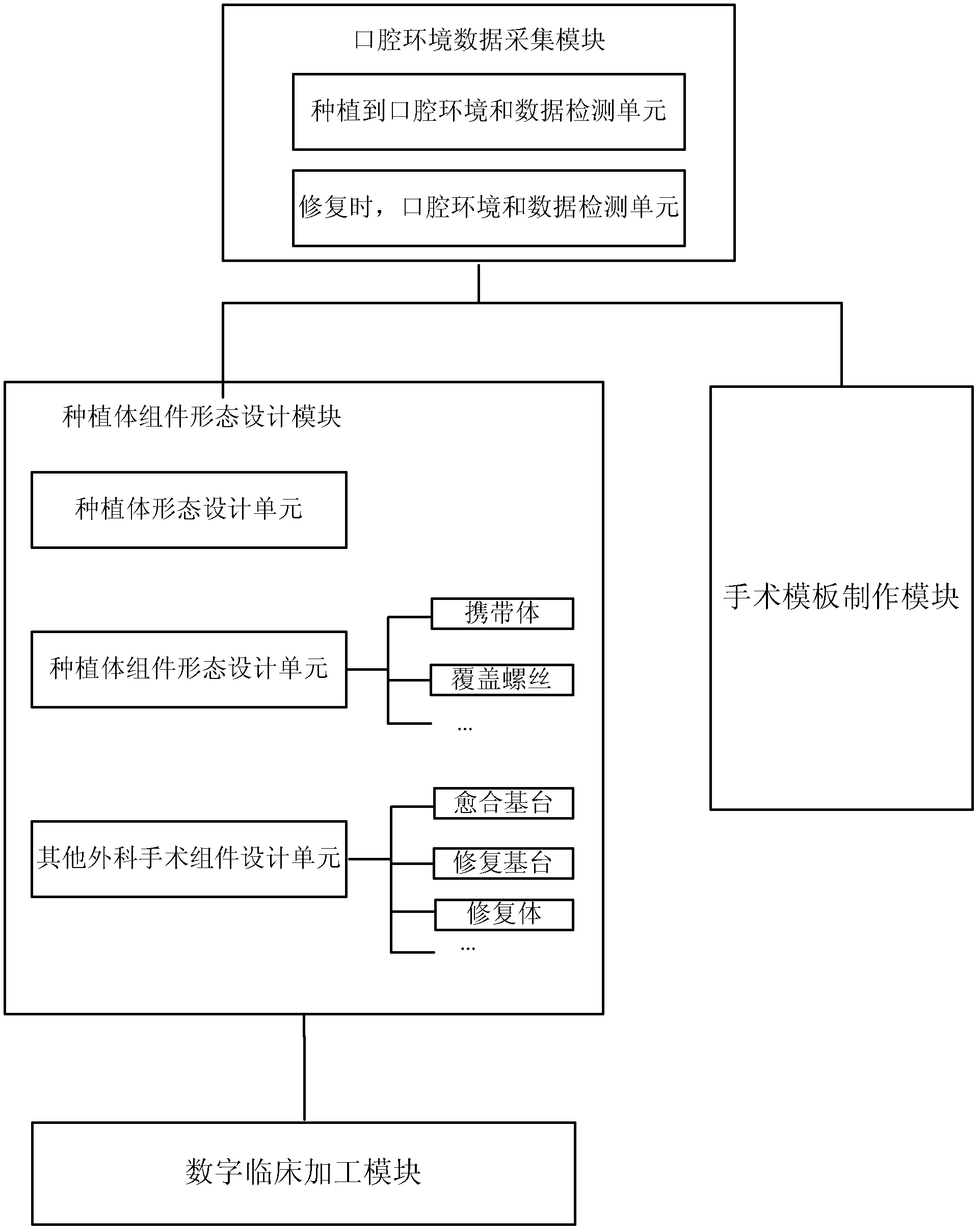

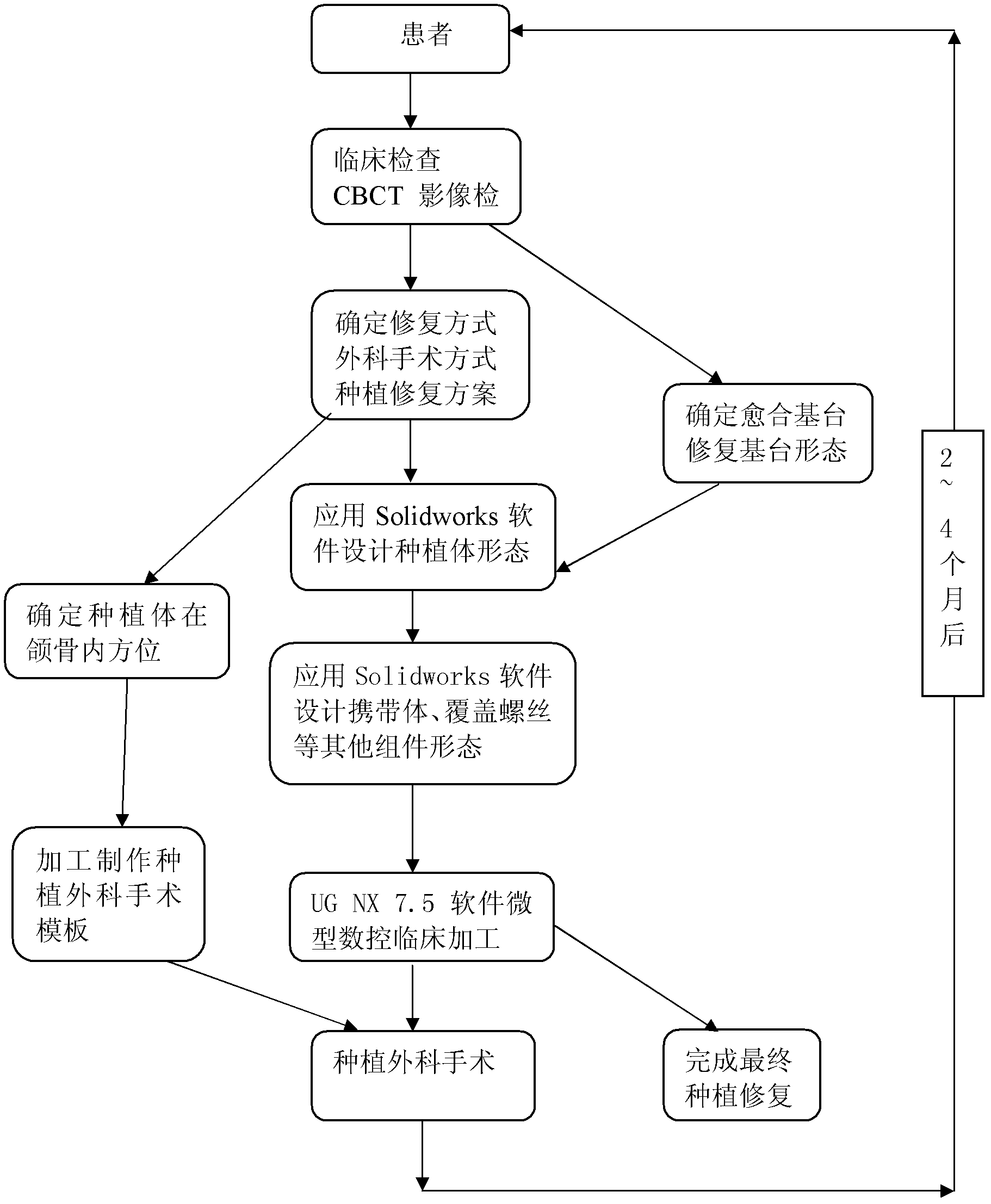

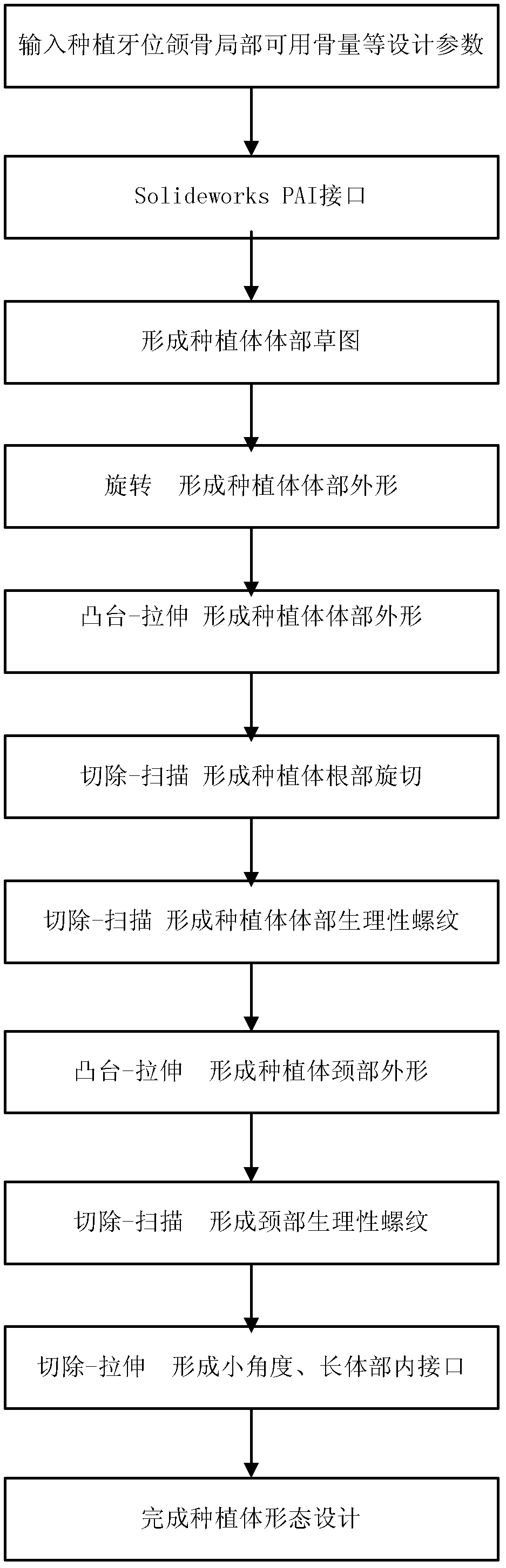

Digital processing system of personalized components in dental implantation and processing method thereof

The invention provides a digital processing system of personalized components in dental implantation and a processing method of the personalized components in dental implantation, belongs to the biomedical engineering field, and specificly relates to a personalized CAD / CAM (computer-aided design / computer-aided manufacturing) digital processing system of a dental implant, a carrier, a cover screw, a healing abutment, a restoration abutment and supporting tools. The system is characterized by comprising an oral environment data acquiring module, an implant component form design module, a digital clinical processing module and a surgical template manufacturing module. According to the digital processing system provided by the invention, the implant can be customized according to partial jaw condition of a patient so that the form of the implant can furthest meet clinical needs, compatibility of the implant to the patient as well as the success rate of the implant restoration can be improved, Meanwhile, the personalized digital processing system performs one-to-one design and processing, so that denture-implanting restoration hospitals do not need to store various implant systems and realize zero inventory, and the expenses and the waste of the product are reduced. The personalized components digital processing system provided by the invention is benefitial for popularizing and promoting denture implantation technology.

Owner:淄博昌国口腔种植技术研究院

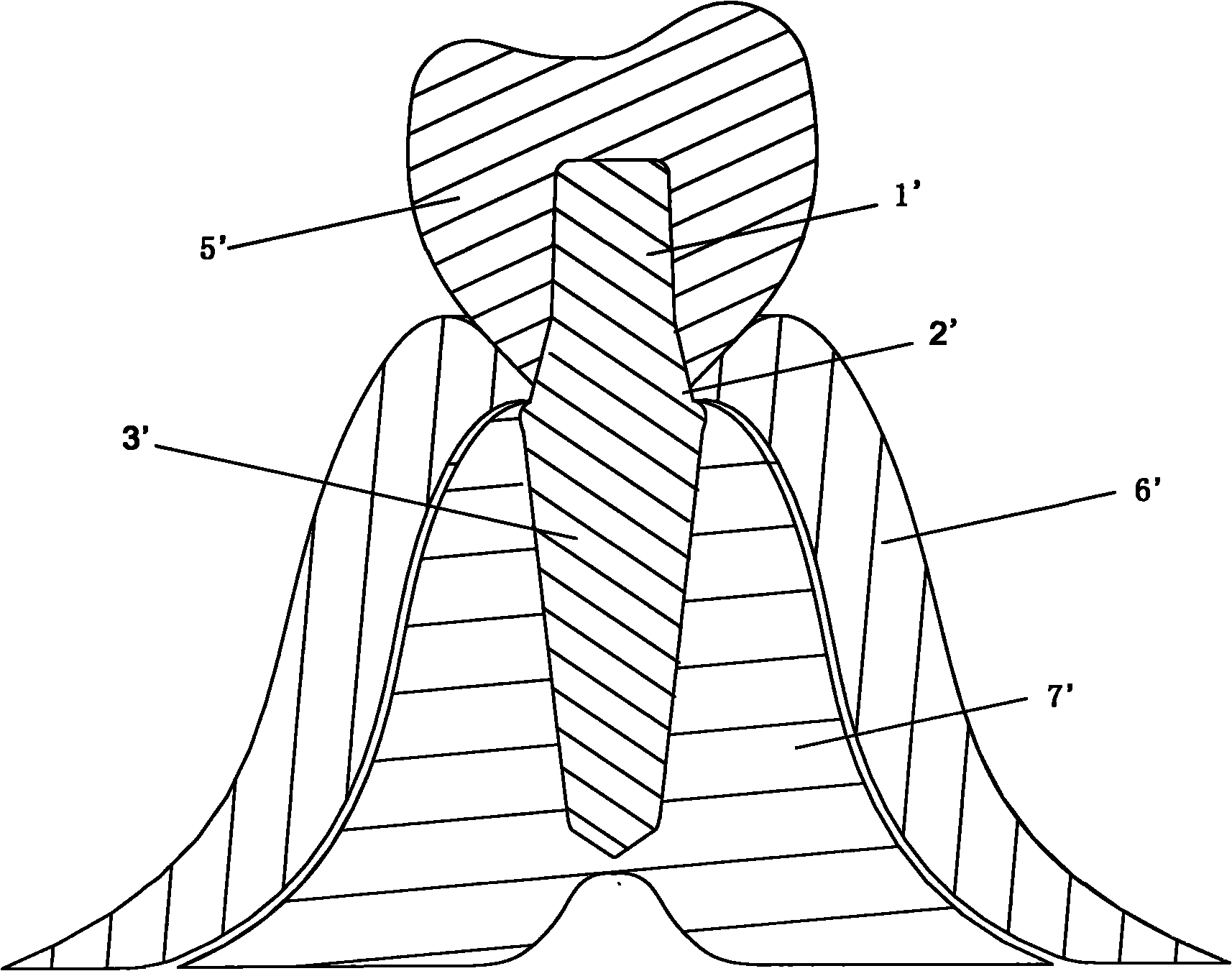

Biomimetic type preformed ceramic abutment of implanted tooth and preformed crown thereof

InactiveCN101803957AImprove aestheticsImprove missing teethDental implantsNatural toothTooth Preparations

The invention relates to a biomimetic type preformed ceramic abutment of an implanted tooth and a preformed inner crown thereof, belonging to the field of implant restoration of dentition defect or dentition deletion of an oral cavity and aiming at improving the appearance, shape and color, strengthening retention and reducing microleakage. The technical scheme of the invention is as follows: the implant denture restoration is matched with different preformed ceramic abutments according to different teeth positions, i.e., the upper parts of the implants with implanted alveolar bones are matched with preformed ceramic abutments according to different teeth positions; the preformed ceramic abutment comprises a lower part structure inserted into the implant, a middle part structure imitating the shape of the neck of a natural tooth and an upper part structure imitating the form of tooth preparation of the natural tooth; and the outer surface of the upper part structure of the preformed ceramic abutment is matched with the preformed inner crowns of initial dental crowns of different teeth positions. The invention is applicable to the implant restoration of dentition defect or dentition deletion of the oral cavity, especially the deletion restoration of anterior teeth with higher requirement for beauty.

Owner:杭州口腔医院集团有限公司

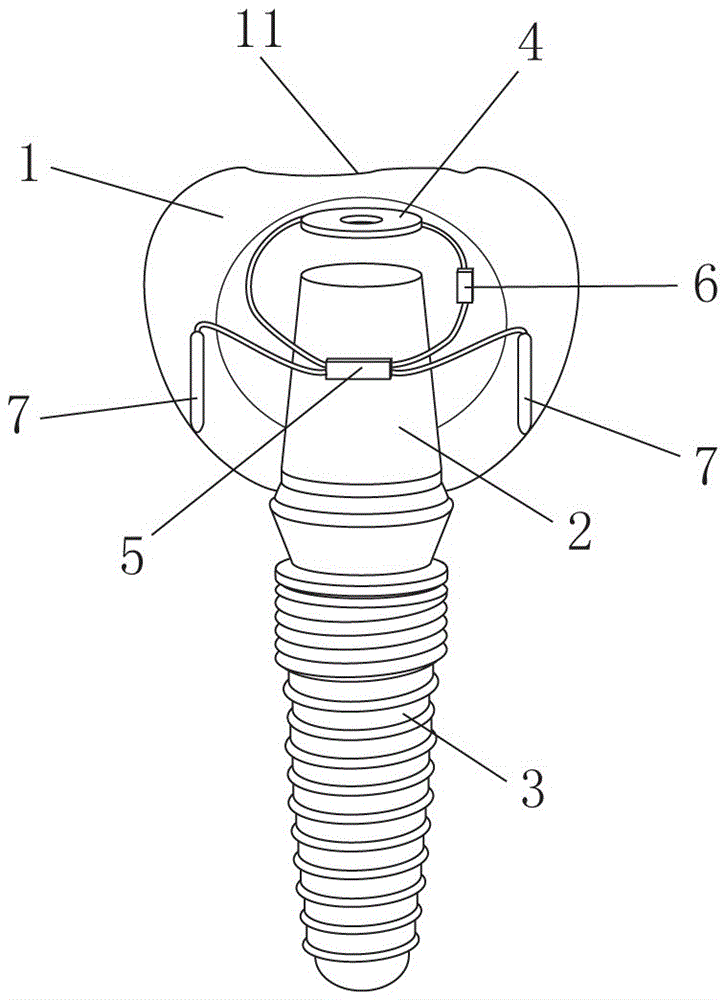

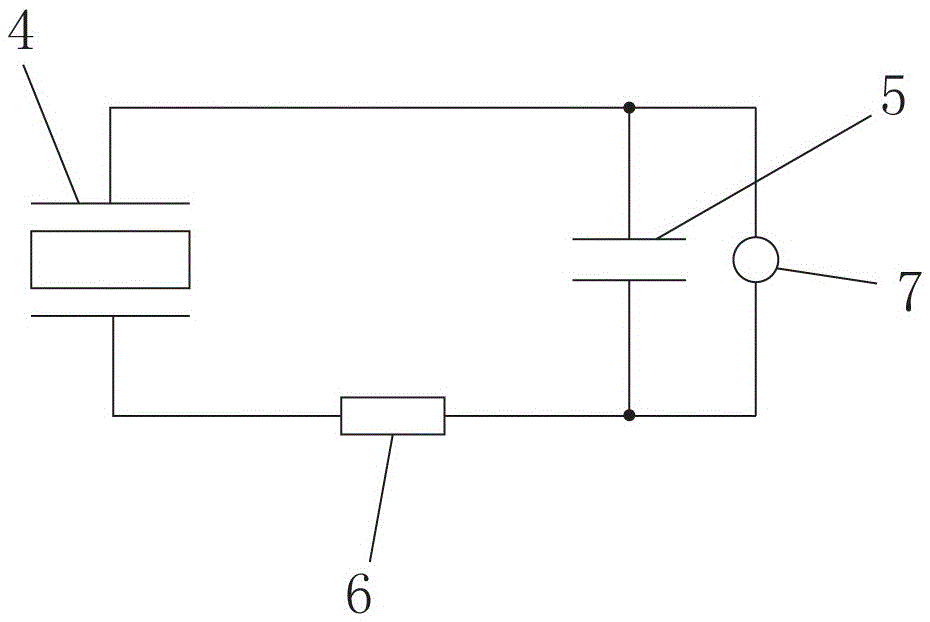

Piezoelectric inducing implant denture

The invention discloses a piezoelectric inducing implant denture, which comprises a dental crown, an abutment and an implant, wherein the top surface of the dental crown is an occlusive thrust face for interlocking force. The piezoelectric inducing implant denture is characterized in that an alveolar nerve stimulating device is arranged in the dental crown; the interlocking force on the occlusive thrust face is converted into electric energy by the alveolar nerve stimulating device; and then current is released to simulate alveolar nerves. According to the piezoelectric inducing implant denture, mechanical energy that a patient excessively utilizes the denture is converted into electric energy; a discharge electrode is released to peripheral alveolar nerves to stimulate nervous centralis of a human brain and prompt the patients to timely take protective measures, so that parodontium neurotransmission is replaced; the targets of self-detection and protection of the denture are realized; and the blank in the field is filled up.

Owner:SHANGHAI EAST HOSPITAL

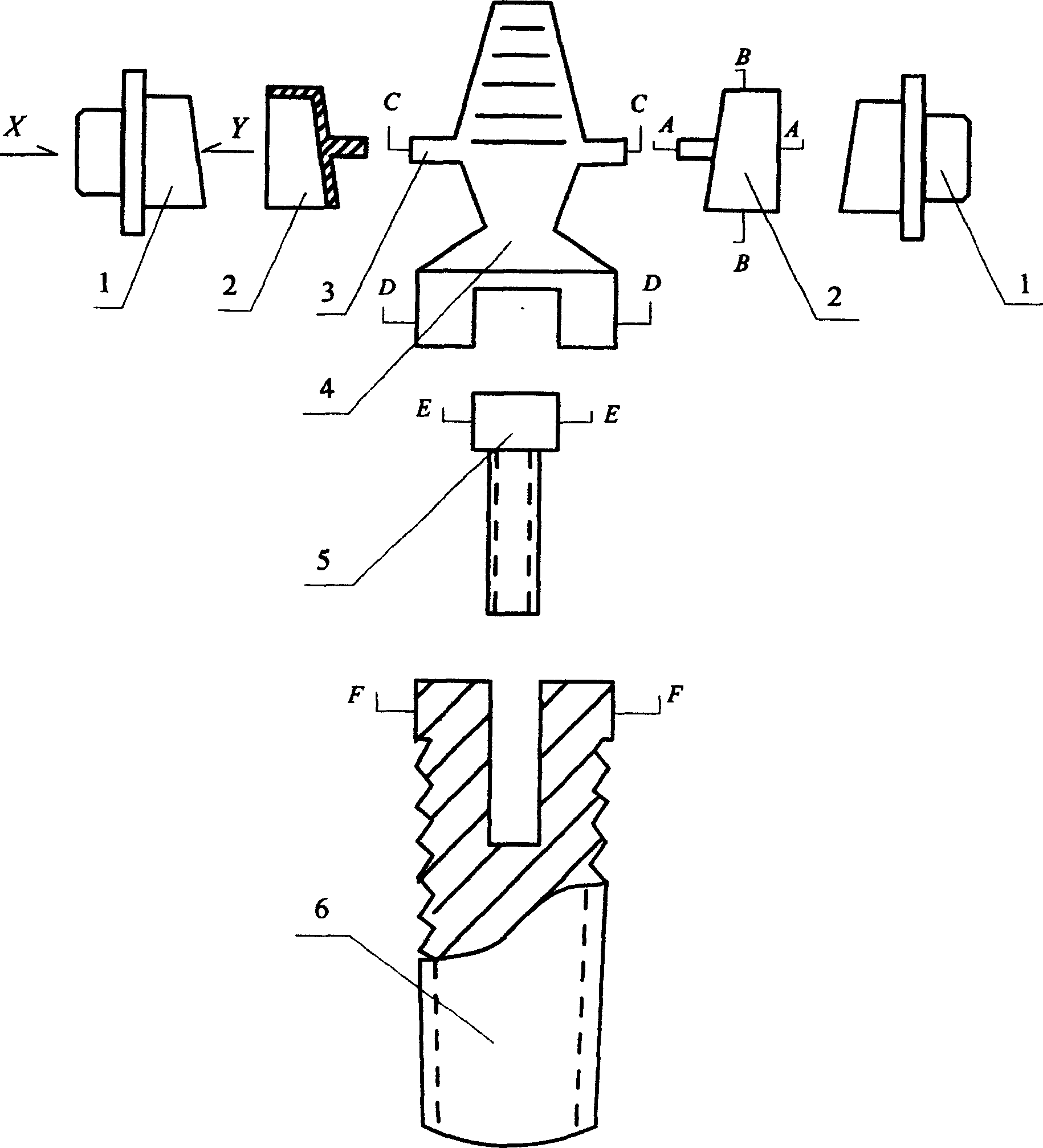

Fixed bridge type planted tooth without corona sheath and its production method

The bridge-fixed implanted tooth without crown sleeve includes one body part and one connected pile and features that the pile has two wings connected to a fixing unit via a connecting cap or to the wing in other pile. The making process of the bridge-fixed planted tooth includes making female oral cavity mold with the position of adjacent teeth; making male oral cavity mold with fixing unit connecting cap, fixing planted unit and pile connecting core; setting implant pile and welding the two wings with connecting cap; and making the upper structure of the implanted artificial tooth. The present invention makes adjacent teeth share partial pressure and reduces the pressure of the implant tooth to alveolar bone to prolong the service life of the implanted tooth. Separating the implant into two, one outer and one inside, parts facilitates the clinical operation.

Owner:THE FIRST AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIVERSITY OF PLA

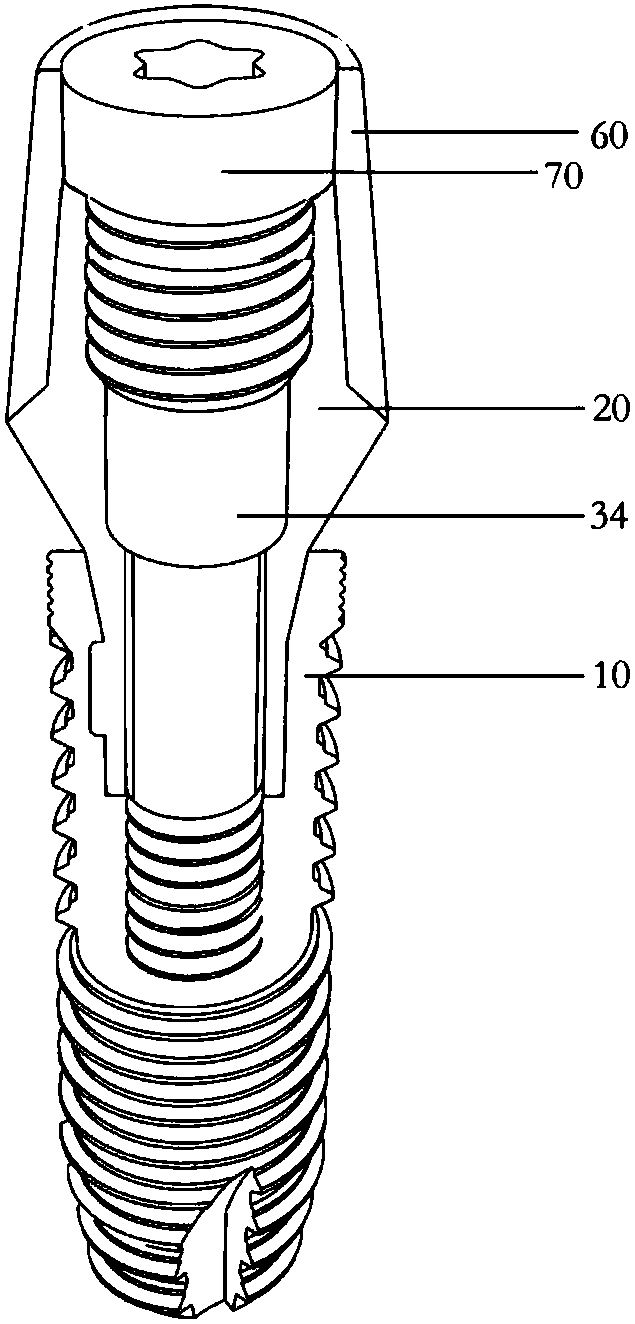

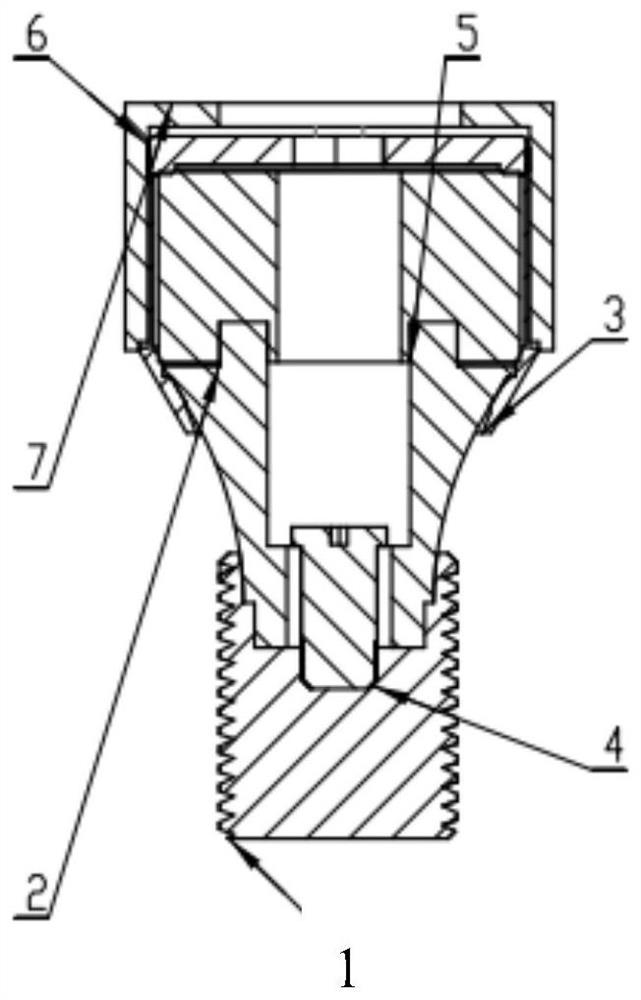

Bridge abutment component for dental implant

The invention discloses a bridge abutment component for a dental implant. An inserting section of a gingiva abutment part is mounted in an inner hole of an implant; a central through hole of the gingiva abutment part is a stepped hole; a central positioning bolt penetrates through the stepped hole and is screwed into internal threads of the implant for realizing fixing connection of the gingiva abutment part and the implant; a bridge abutment is arranged on an inverted conical frustum at the upper part of a gingiva abutment; the internal threads are arranged on the inner wall of the inverted conical frustum; a set screw is screwed into the gingiva abutment through an upper port of the bridge abutment and fastening connection of the bridge abutment and the gingiva abutment and the implant is realized; as the set screw is connected with the internal threads of the inverted conical frustum of the gingiva abutment rather than is screwed into internal threads of the central positioning bolt, the diameter of the set screw is greatly increased, further strain strength of the set screw is enhanced, and the problem that the set screw is easy to break in clinical application is solved; meanwhile, a hollow structure of the central positioning bolt is changed into a solid structure, so that the strength of the central positioning bolt is enhanced; meanwhile, the problem that the central positioning bolt is easy to break in clinical application is solved, mostly common complications of implant denture are greatly avoided and the long-term success rate of the bridge abutment component isensured.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY +1

Combined design method of bone increment and implant denture and manufacturing method of bone increment model

The invention relates to the field of oral implant same-period bone increment medicine, and discloses a combined design method of bone increment and implant denture and a manufacturing method of a bone increment model. A hard tissue model and an oral cavity model do not need to be subjected to data fusion, and only the medical image, the hard tissue model and the oral cavity model need to be subjected to registration and superposition, so that the restoration and the implant can be designed on the oral cavity model, the bone increment is designed on the hard tissue model. Not only is data operation simpler, but also compared with fused data, a prosthesis and an implant designed according to an original oral cavity model are higher in accuracy, and during design, the prosthesis, the implant and bone increment are adjusted by taking an original medical image capable of completely showing soft and hard tissues of an oral cavity and a jaw bone as a reference; the individual condition of the patient can be better adapted from the global perspective, the design suitability is ensured, and a good foundation is laid for the success of a subsequent implant repair operation.

Owner:CHENGDU DT DENTALLAB CO LTD

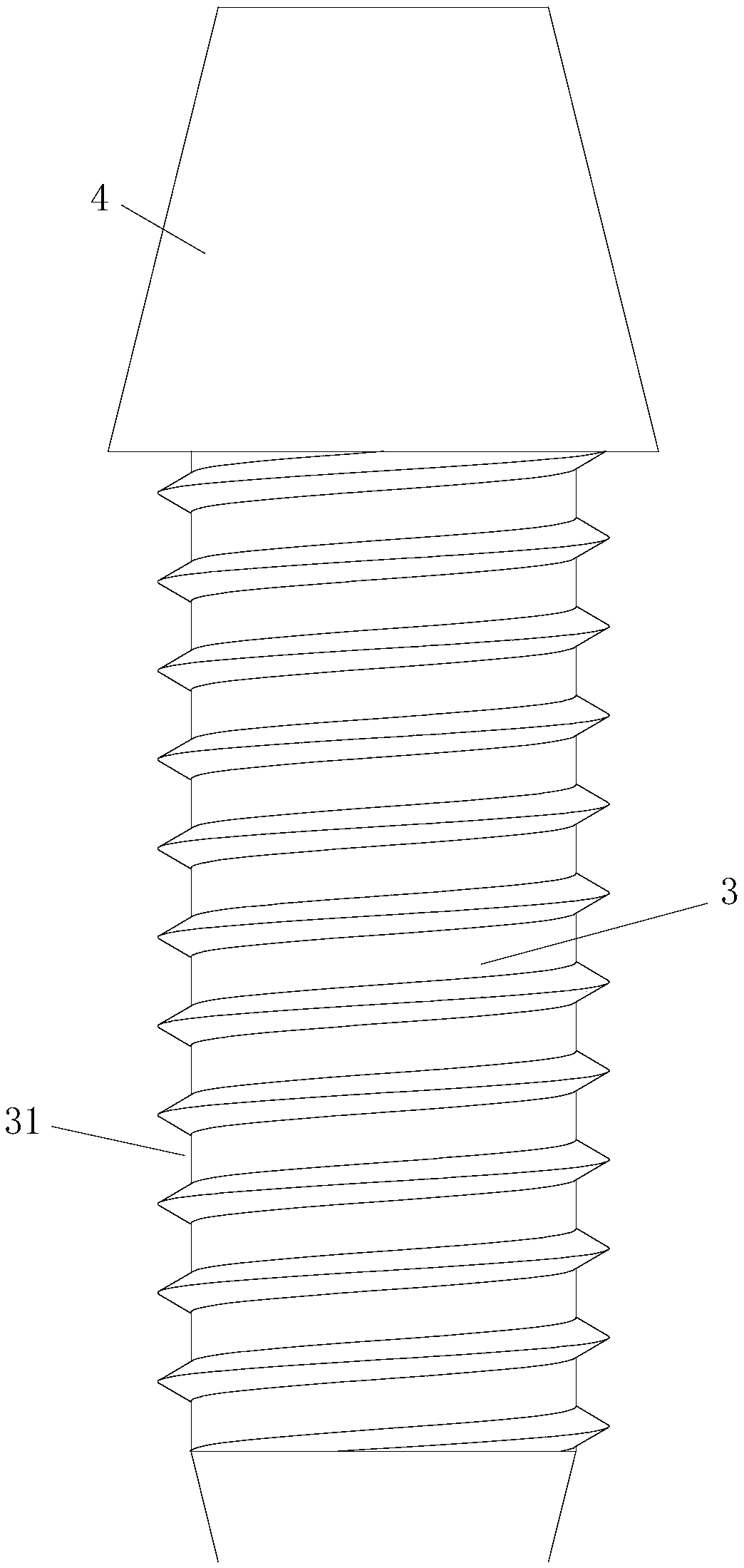

Single-tooth residual root implant

InactiveCN101933847AMinor postoperative complicationsEasy to implementDental implantsPostoperative complicationMissing tooth

The invention relates to a single-tooth residual root implant which is made into an integral multi-section type structure by adopting pure titanium and at least comprises an intraoral section, an endosteal section and an intra radicular section which are coaxially arranged in sequence, wherein the intraoral section is exposed in an oral cavity and used for installing and fixing a false tooth; the endosteal section is implanted into an alveolar bone and fixed by the alveolar bone; and the intra radicular section is implanted into a residual root of a missing tooth and fixed by the residual root. Compared with the traditional implant adopted in a false tooth implanting surgery, the invention has the advantages that: the residual root and the alveolar bone realize dual fixation on the implant of the false tooth and are more stable and firm, and the implant has high primary stability and lays a good foundation for late repair; the residual root removal of the missing tooth is not needed, the surgery is simple, and alveolar bone over-damage is prevented; postoperative complications are slight, the false tooth can immediately bear a load, and the single-tooth residual root implant is suitable for a patient with special worry, completely compatible with the surgical equipment of the traditional implant and easy for application.

Owner:深圳市宝安区石岩人民医院

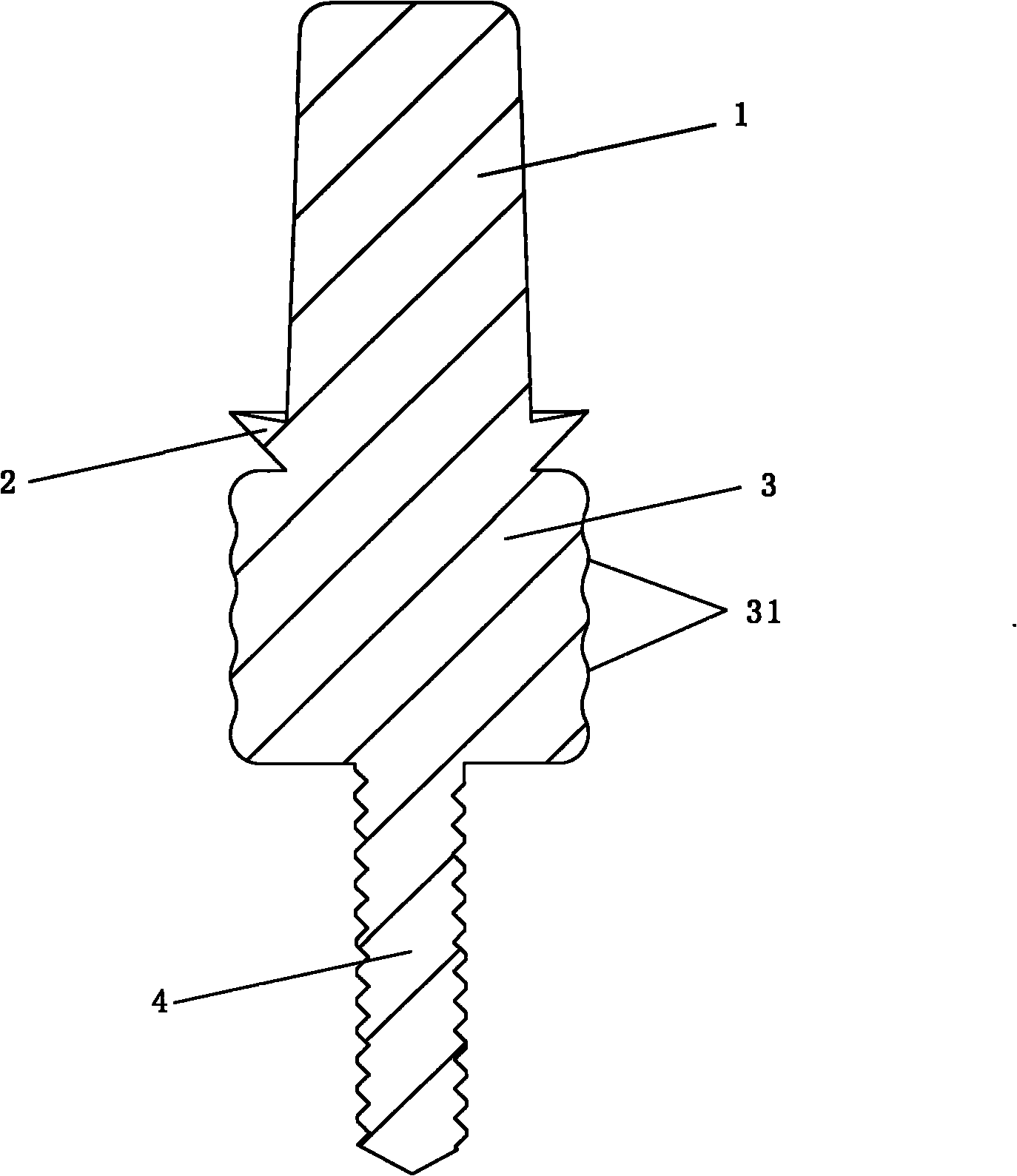

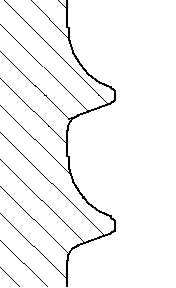

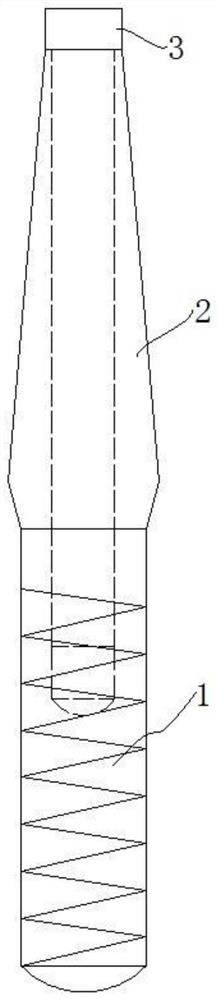

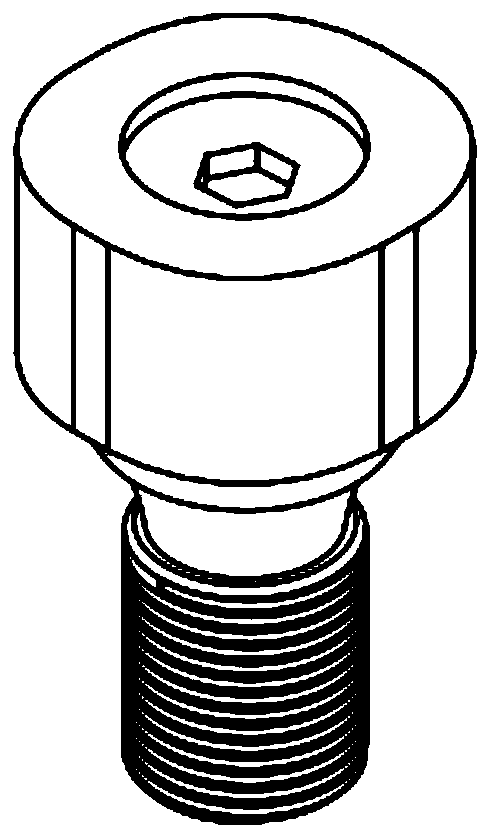

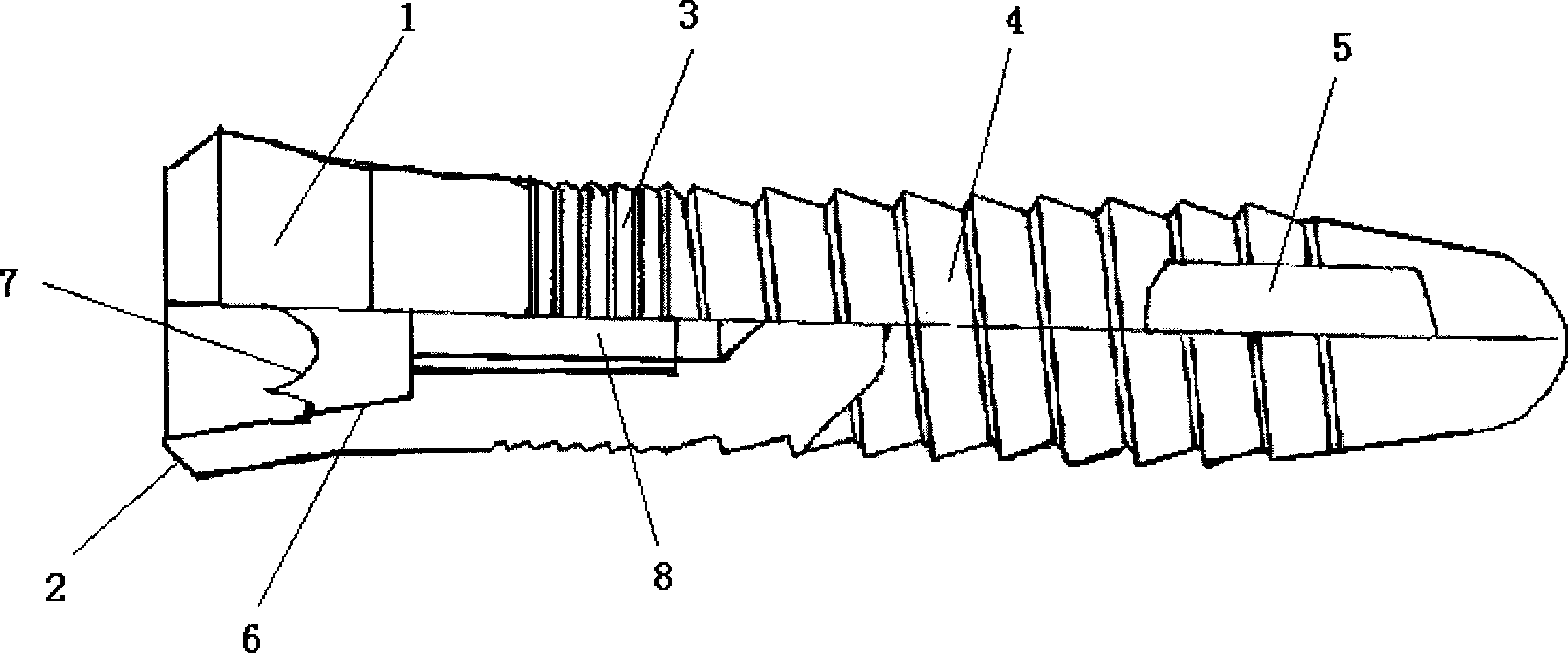

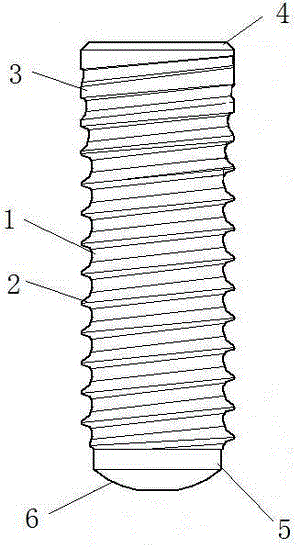

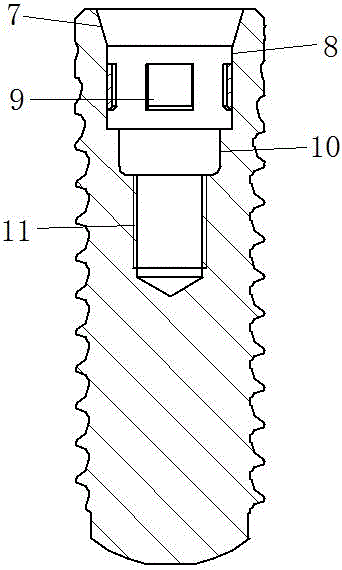

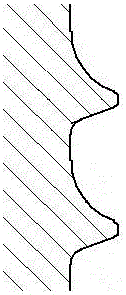

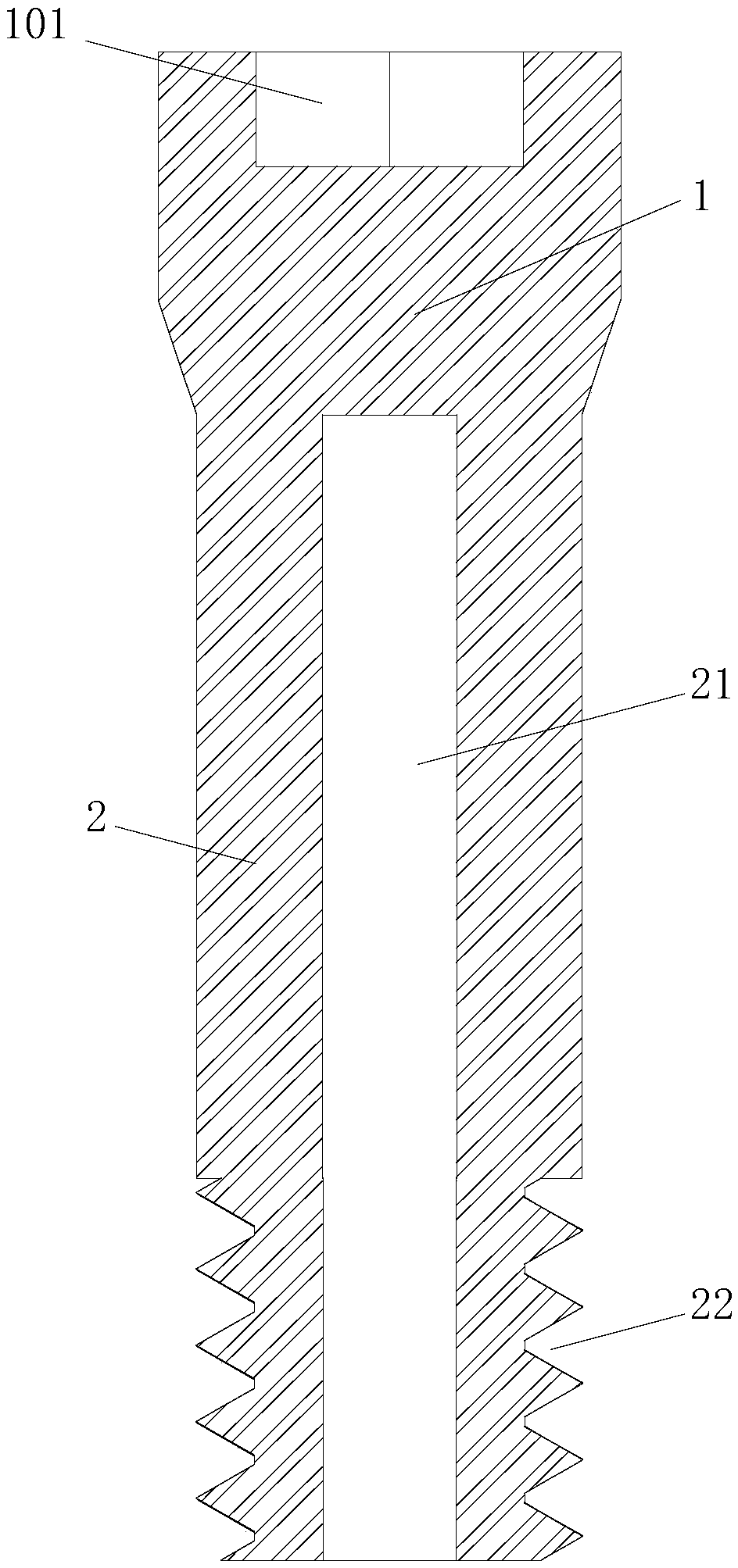

Artificial dental implant

The invention relates to an artificial dental implant which belongs to the field of dental medical instruments. The appearance of the implant is column-shaped; an asymmetry threaded appearance is adopted; the bottom of the implant is in the shape of an arced surface; the upper part of the implant is cone-shaped; a vertebral foramen structure and a cross locking structure are arranged inside the implant; a standard threaded blind hole is formed inside the implant. The artificial dental implant has the beneficial effects that the stability at the early stage is improved, the partial stress is reduced, the alveolar sorption is reduced, and the implant can be widely applied to various anodontism implant denture repairing processes.

Owner:DALIAN SANSHENG SCI & TECH DEV

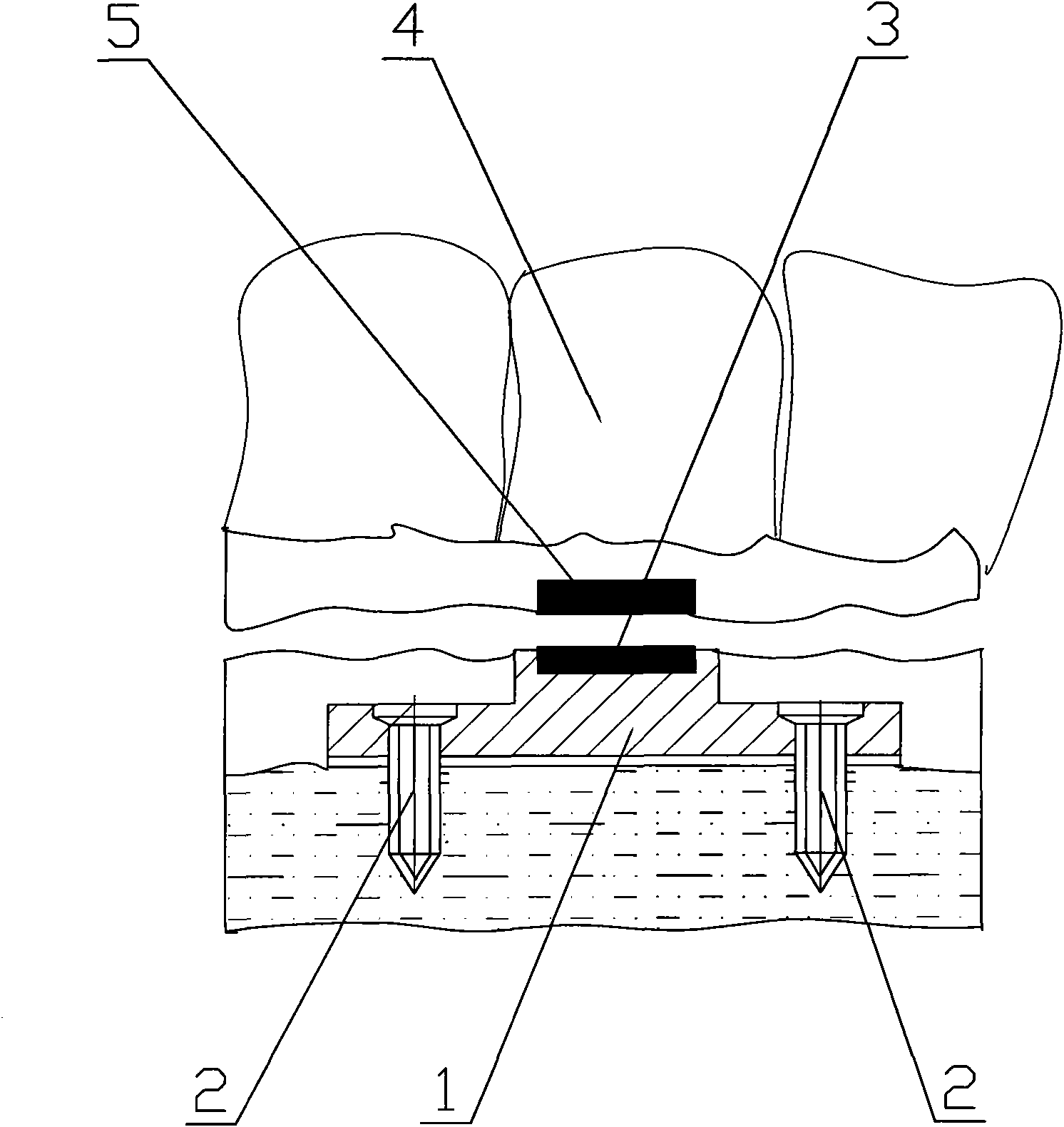

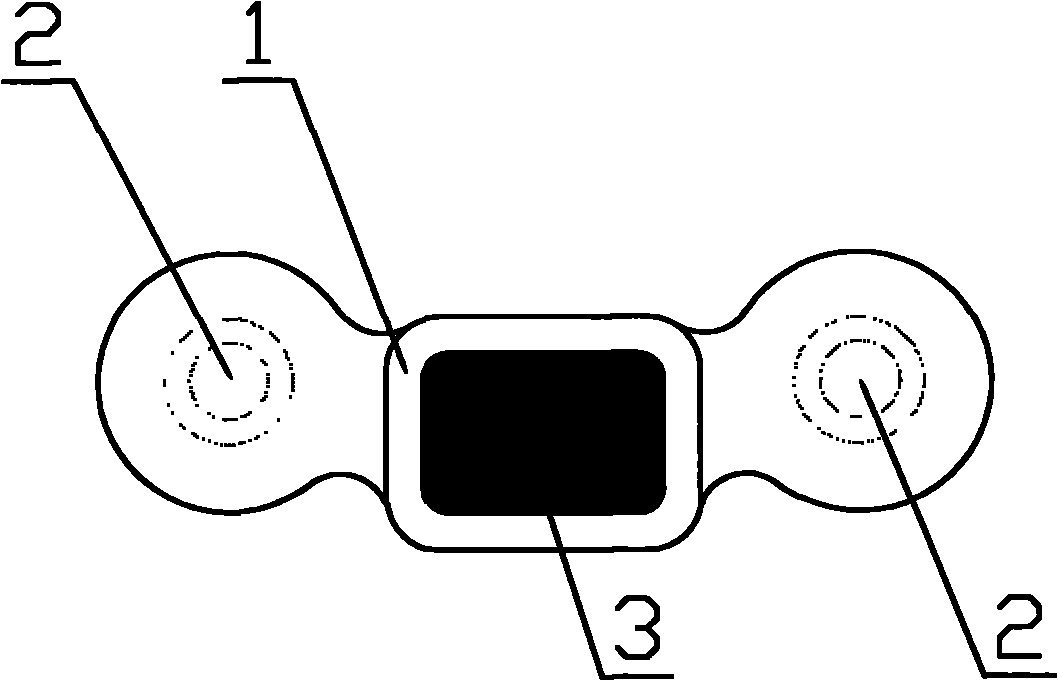

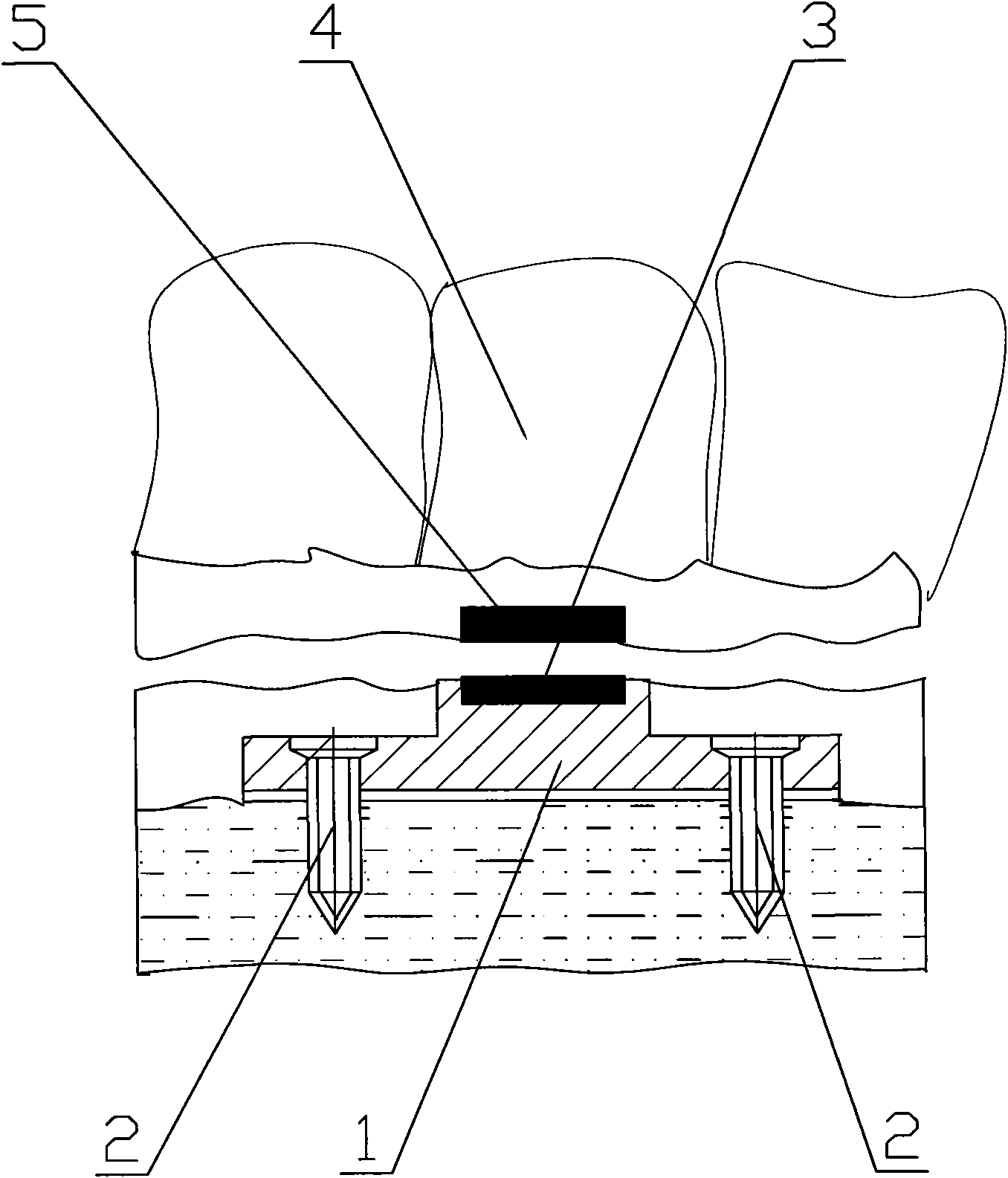

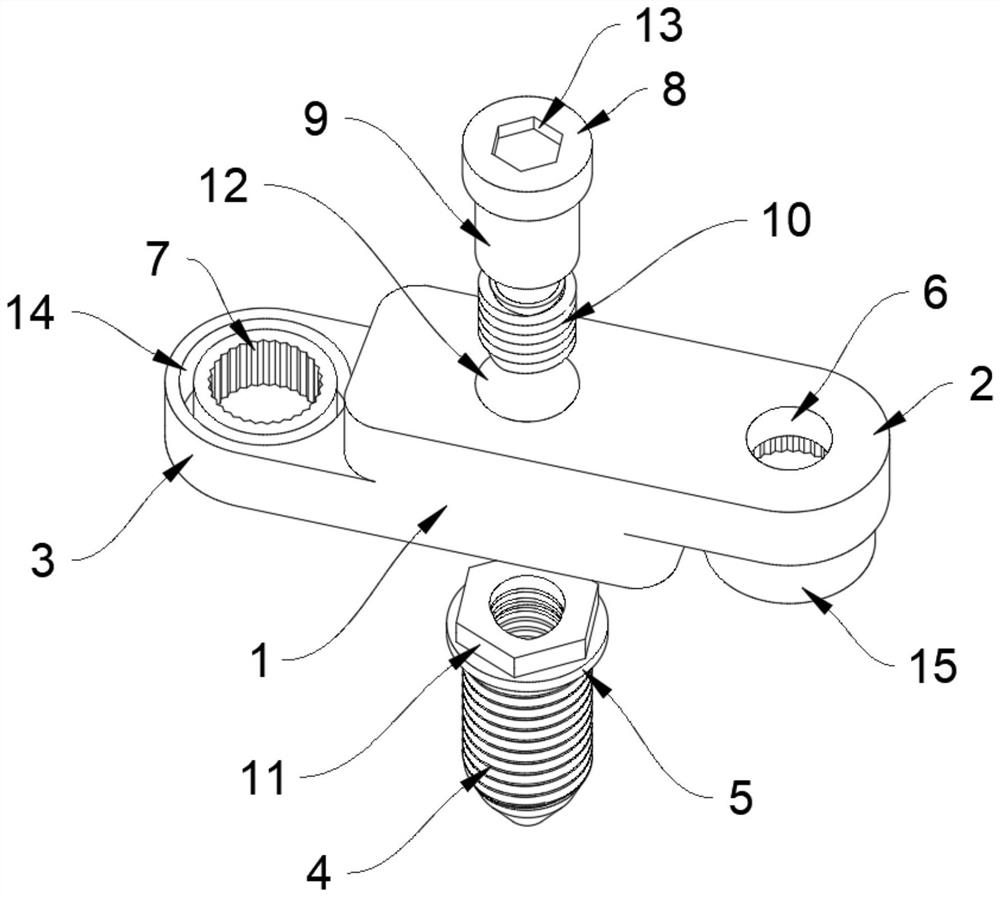

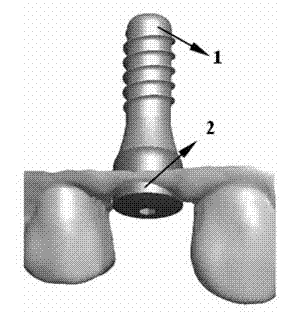

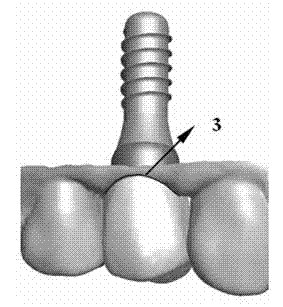

Micro titanium plate magnetic attachment

InactiveCN102058440AShorten the lengthRelieve painDental implantsFastening prosthesisDenture attachmentsTitanium

The invention discloses a micro titanium plate magnetic attachment, comprising a titanium plate (1), wherein at least two screw holes are arranged on the titanium plate (1); micro titanium bolts (2) which are 3-5mm long are matched with the screw holes; and an armature (3) is fixed on the upper surface of the titanium plate (1). Compared with the prior art, the micro titanium plate magnetic attachment has the main difference that a planar titanium plate and at least two micro titanium bolts are arranged; under the premise of ensuring the combination force between the micro titanium bolts and the alveolar bones, the lengths of the micro titanium bolts can be shortened to 3-5mm and the diameters are decreased so that the wound after the operation is small and the fixing depth is shallow; and the implantation period is greatly shortened to only about two weeks so that the pain of a patient during the implantation of the denture attachment is relieved. The micro titanium plate magnetic attachment is particularly suitable for the old that cannot wear movable dentures as the alveolar bones shrink due to bone resorption and the weight is insufficient, so that the old can eat normally, pronounce and perform social activities; and good effect is brought to the restoration of the single-jaw dentures with severe bone resorption and the fixation of the dentures in the canine tooth areas.

Owner:DALIAN SUNNY TITANIUM IND

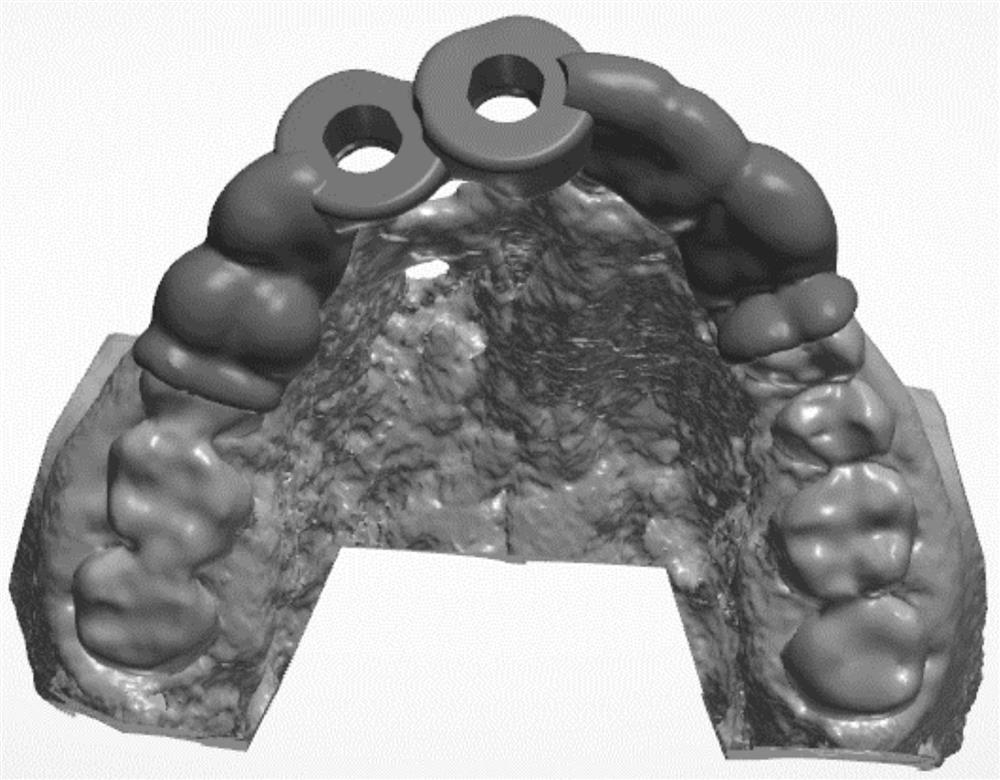

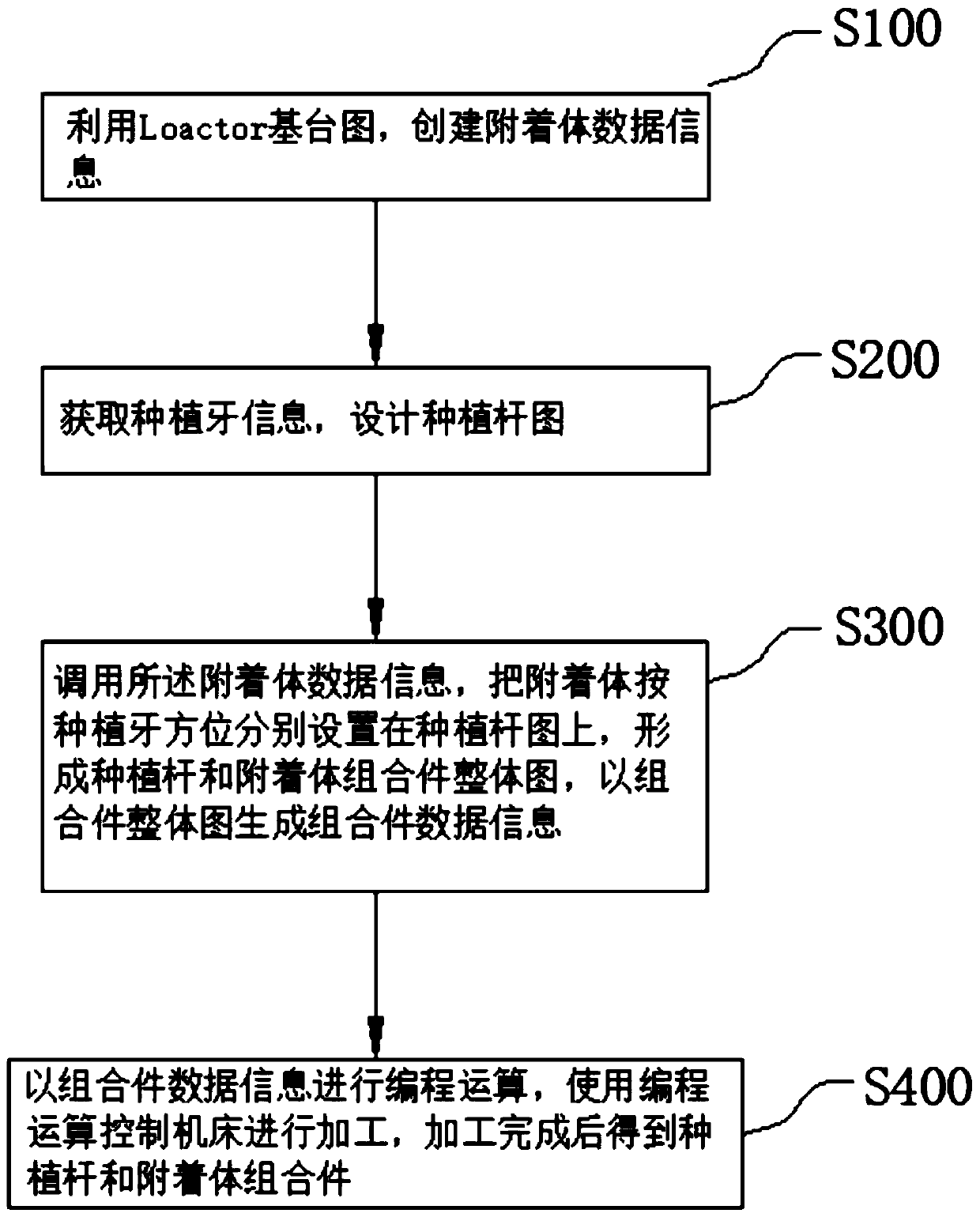

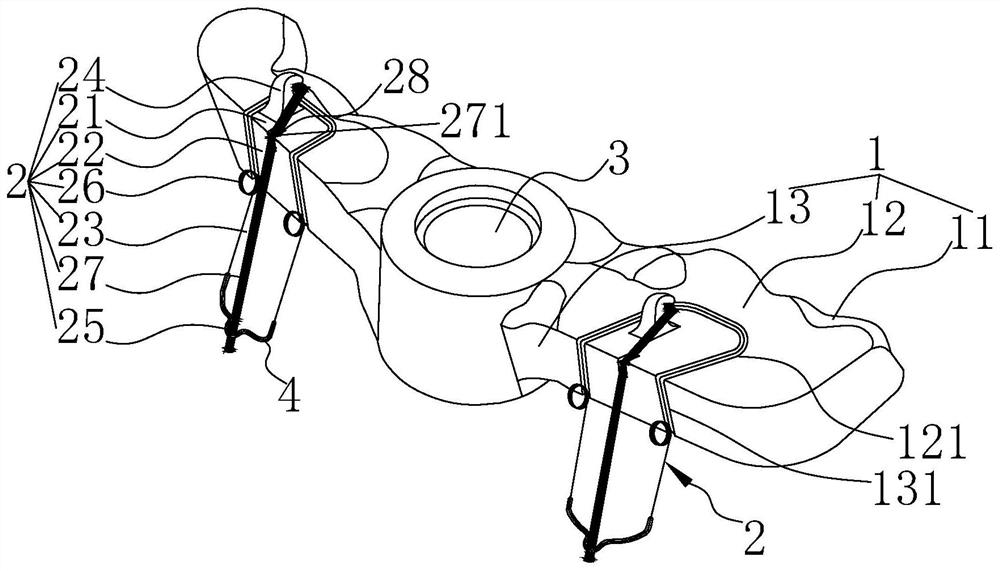

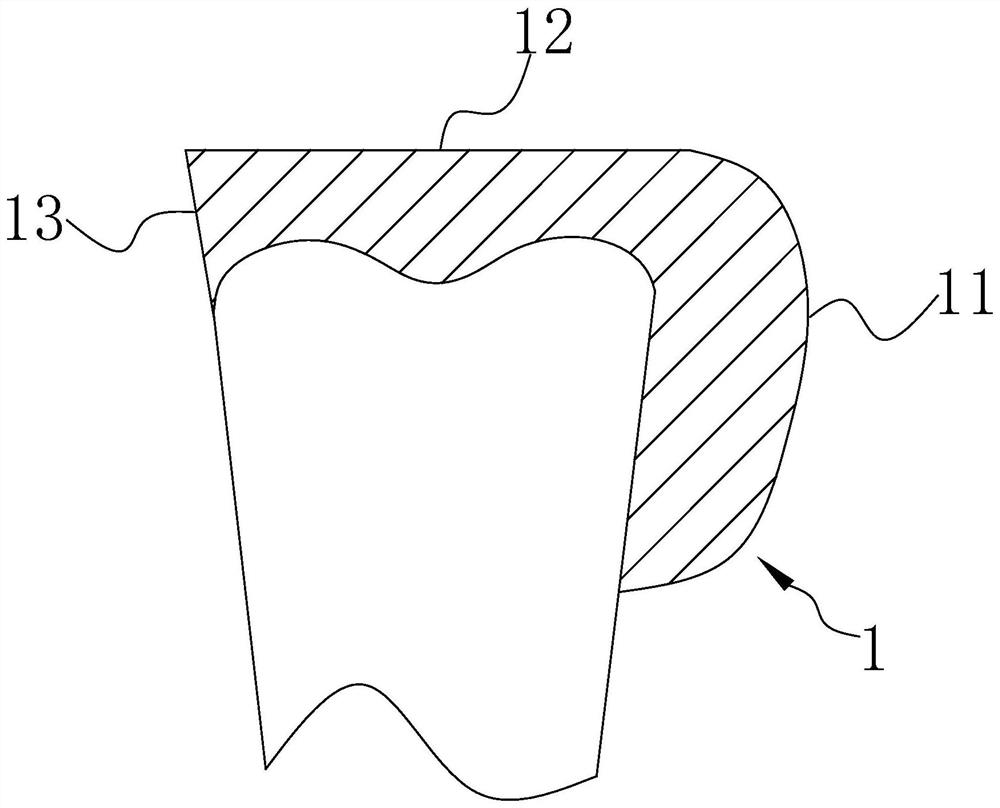

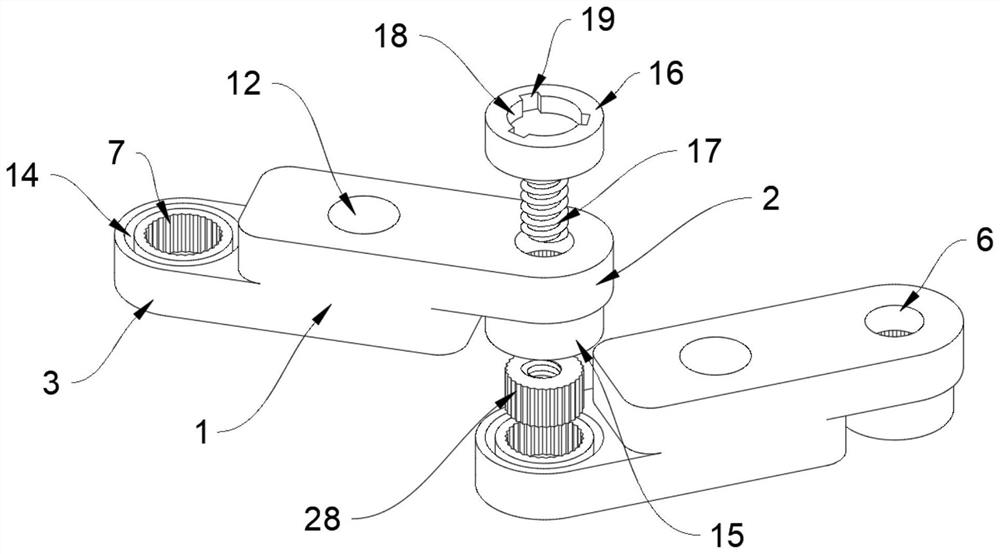

Digital design and processing method for placing Locator attachment on implanting rod

ActiveCN111529100AEasy to wearAccurate placementDental implantsArtificial teethComputer hardwareData information

The invention belongs to the technical field of artificial tooth implantation, and relates to a digital design and processing method for placing a Locator attachment on an implanting rod. The digitaldesign and processing method comprises the following steps: S100: creating attachment data information by using a Locator abutment graph; S200: acquiring dental implant information and designing an implanting rod graph; S300: calling the attachment data information, and arranging attachments on the implanting rod graph separately according to a dental implant direction to form an implanting rod and attachment assembly whole graph, and generating assembly data information from the assembly whole graph; and S400: performing programming operation with the assembly data information, and controlling a machine tool for processing with programming operation to obtain an implanting rod and attachment assembly after processing. The implanting rod and attachment assembly whole is designed and processed by a digital technology, clinical one-step wearing can be facilitated, meanwhile, mutual angles and positions of the attachments can be kept fixed, and implant dentures above the attachments can be located accurately.

Owner:北京联袂义齿技术有限公司

High-precision implantation guide plate

PendingCN112773529AImprove stabilityConvenient for clinical operationDental implantsTOOTH IMPLANTATIONSImplant dentures

The invention relates to the technical field of tooth implantation guide plates, and discloses a high-precision implantation guide plate. The high-precision implantation guide plate comprises an implantation guide plate body, a spring buckle assembly and a mounting hole part arranged on the implantation guide plate body and used for implanting a false tooth, wherein the implantation guide plate body is provided with at least two spring buckle assemblies which are used for clamping, pressing and attaching to the tooth lip side surface of a patient. According to the high-precision implantation guide plate, the at least two spring buckle assemblies are additionally arranged on the implantation guide plate body and are combined to be used for being pressed and attached to the tooth lip side face of the patient, so that accurate positioning of an implantation site and direction for implanting a false tooth in the mounting hole part is realized, the stability is good, a metal mounting ring does not need to be placed in the mounting hole part, the clinical operation is more convenient, the accuracy of planting sites and directions is improved, moreover, the high-precision implantation guide plate is simple in overall structure and convenient to mount, does not need to be fixed by a lateral nail during mounting, and causes small trauma to a patient.

Owner:GUANGZHOU RITON BIOMATERIAL

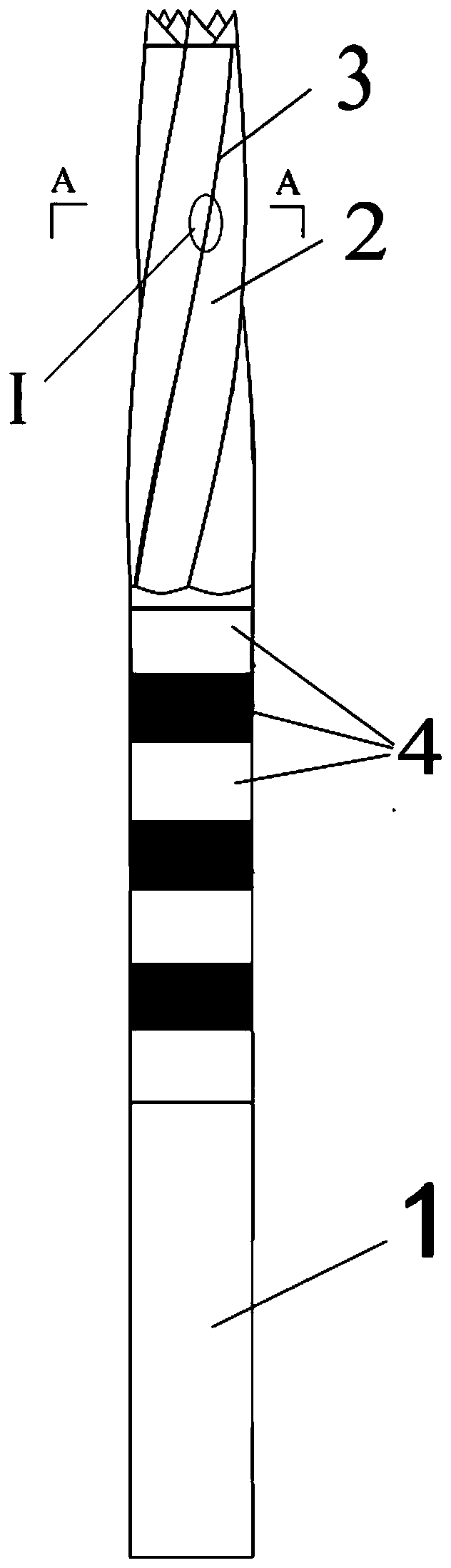

Precise tooth cutting machine needle

PendingCN111467059AAvoid breakingReduce resistance armDentist forcepsBiomedical engineeringOrthodontics

The invention discloses a precise tooth cutting machine needle. The precise tooth cutting machine needle comprises a clamping section and a cutting section, wherein the cutting section is conical, andthe clamping section and the cutting section are in smooth transition. The stress borne by the cutting section in a tooth cutting process is gradually changed, so that sudden breakage is not prone tohappening; a plurality of mark lines are arranged on the surface of the clamping section in the axial direction, each mark line surrounds the cylindrical surface of the clamping section by a circle,the mark lines are different in color, different mark lines can express different cutting depths of the machine needle, and a medical staff can be effectively reminded, so that secondary injuries caused by the fact that the machine needle touches soft tissues due to too deep cutting are avoided; and the alveolar bone can be reserved to the maximum extent, so that good conditions are created for later-period implantation, particularly immediate implantation and false tooth repair of a patient.

Owner:SHENZHEN HOSPITAL OF SOUTHERN MEDICAL UNIV

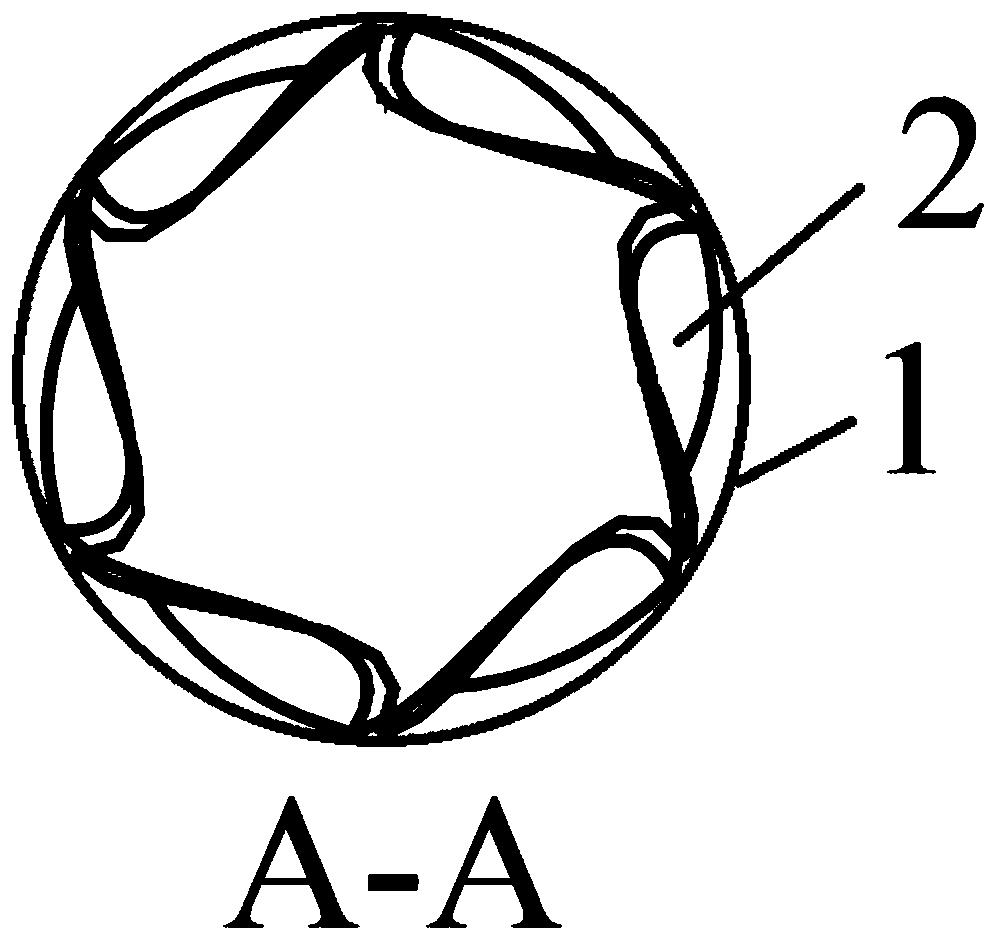

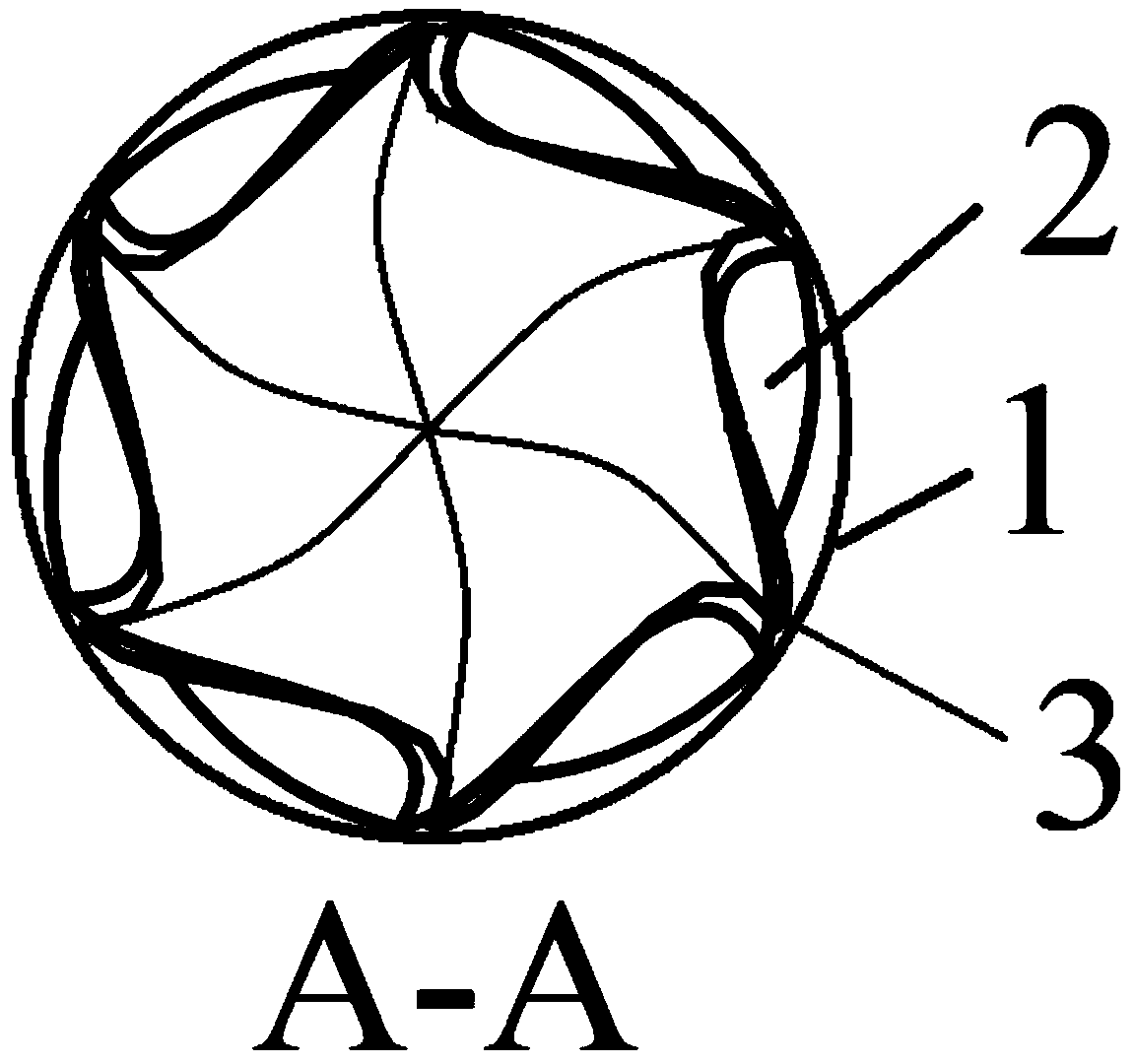

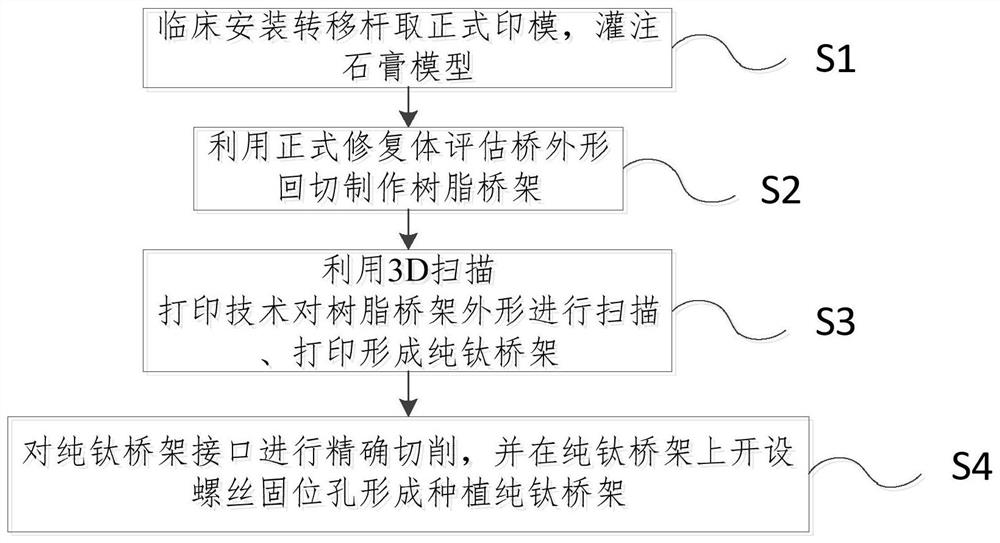

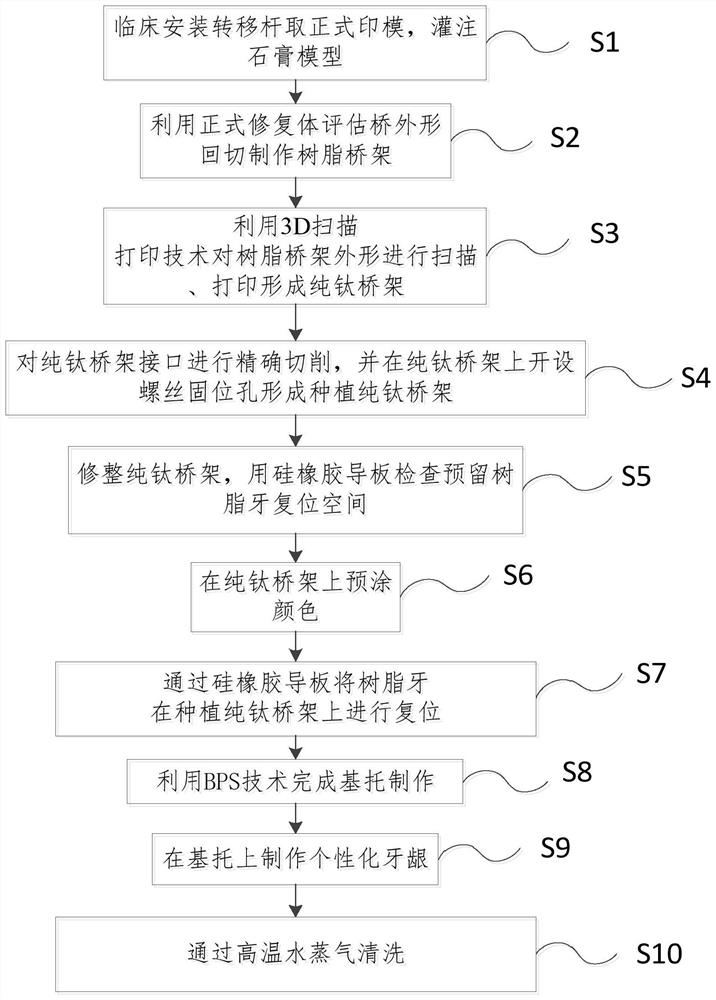

Processing technology for manufacturing implanted pure titanium bridge denture by combining additive and subtractive materials

InactiveCN111839774AAvoid lack of precisionReduce wasteAdditive manufacturing apparatusArtificial teethRough surface3d scanning

The invention relates to the field of complete implant dentures, and provides a processing technology for manufacturing an implant pure titanium bridge denture by combining additive and subtractive materials. The processing technology comprises the following steps that a transfer rod is clinically installed, a formal impression is taken, and a plaster model is poured; the shape of the bridge is evaluated by using the formal restoration, and back-cutting is carried out to manufacture a resin bridge; scanning and printing of the shape of the resin bridge are carried out by using a 3D scanning and printing technology; CAD software is used for scanning a resin bridge interface, designed data are output to CAM equipment, a pure titanium bridge interface is accurately cut, and a screw retentionhole is formed in a pure titanium bridge. According to the method, material waste is effectively reduced in a 3D scanning printing additive mode, the formed pure titanium bridge can be of a hollow structure, the weight of a finished product is effectively reduced, the material cost is reduced, meanwhile, bonding of external materials is facilitated due to the rough surface, a rough surface does not need to be manufactured on the pure titanium bridge, and then the manufacturing efficiency of the finished product is improved.

Owner:京品医学科技(北京)有限公司

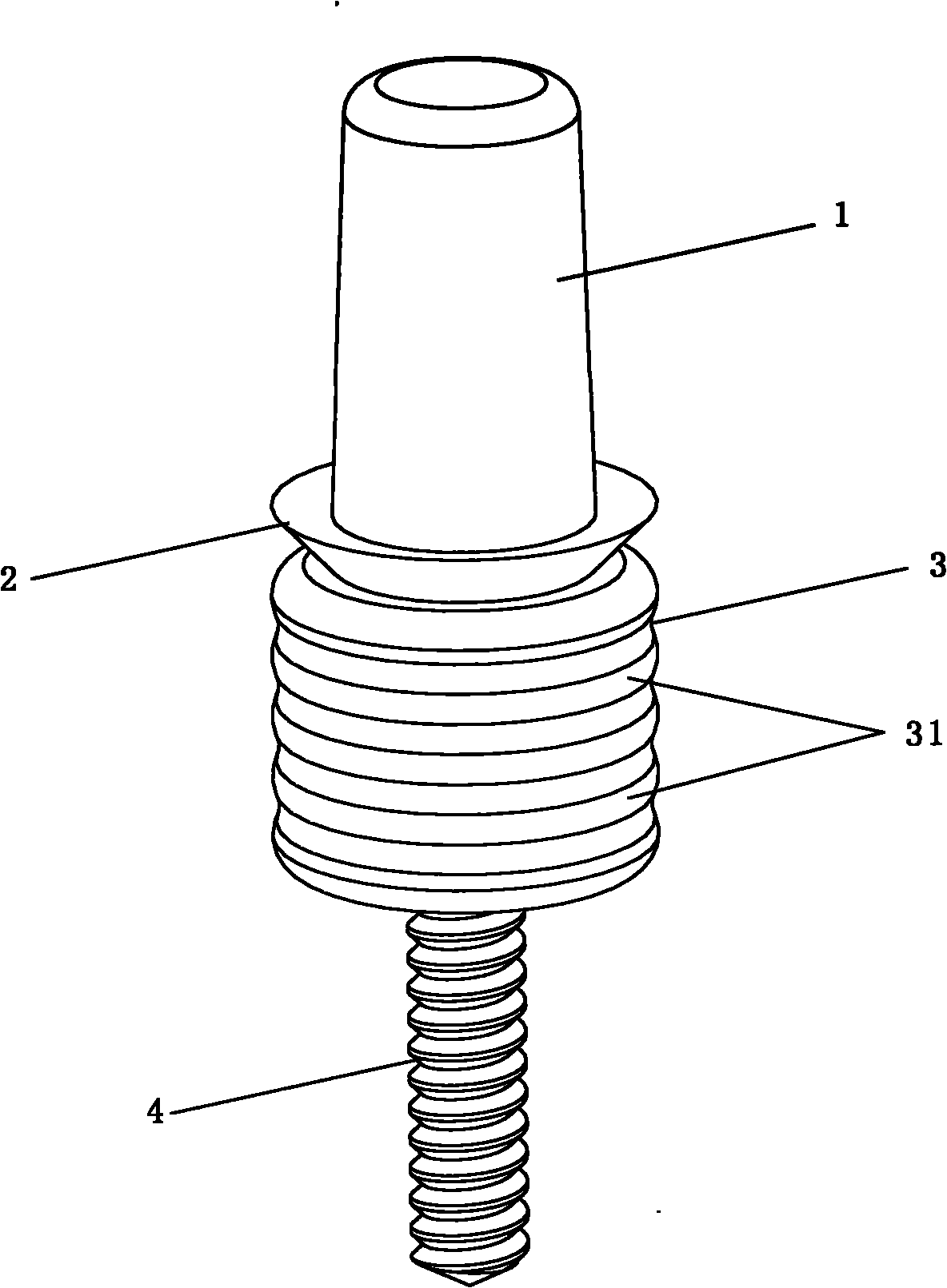

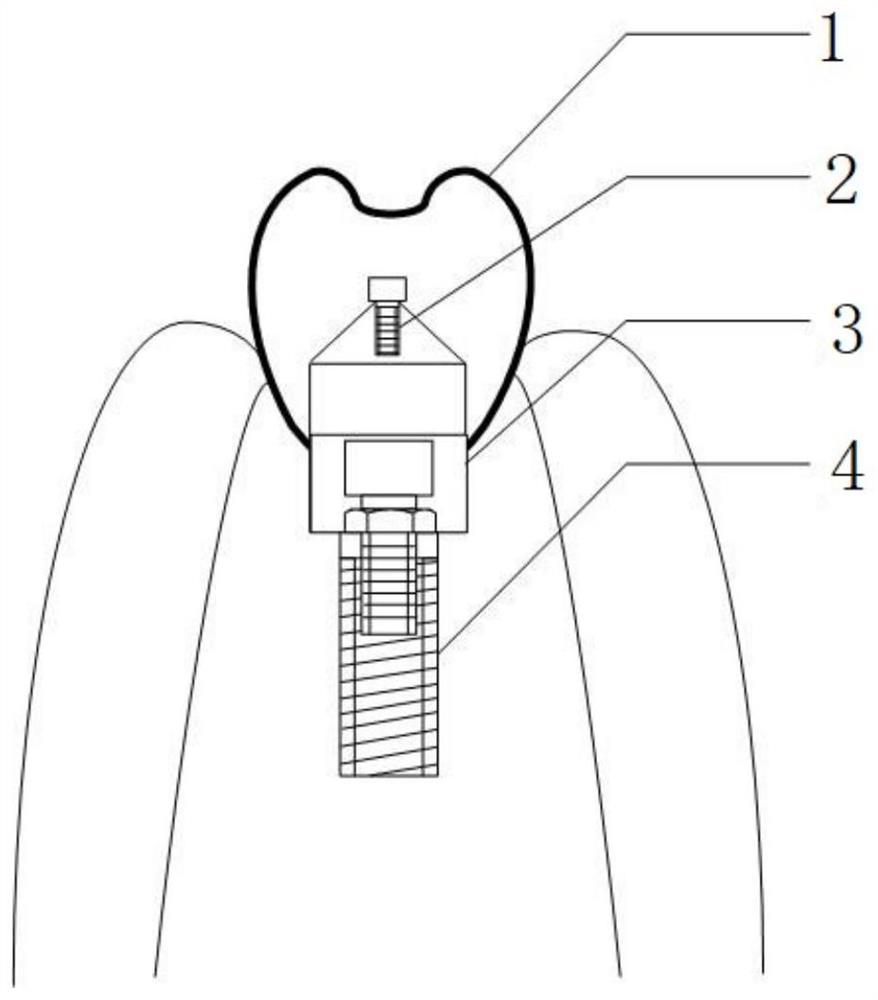

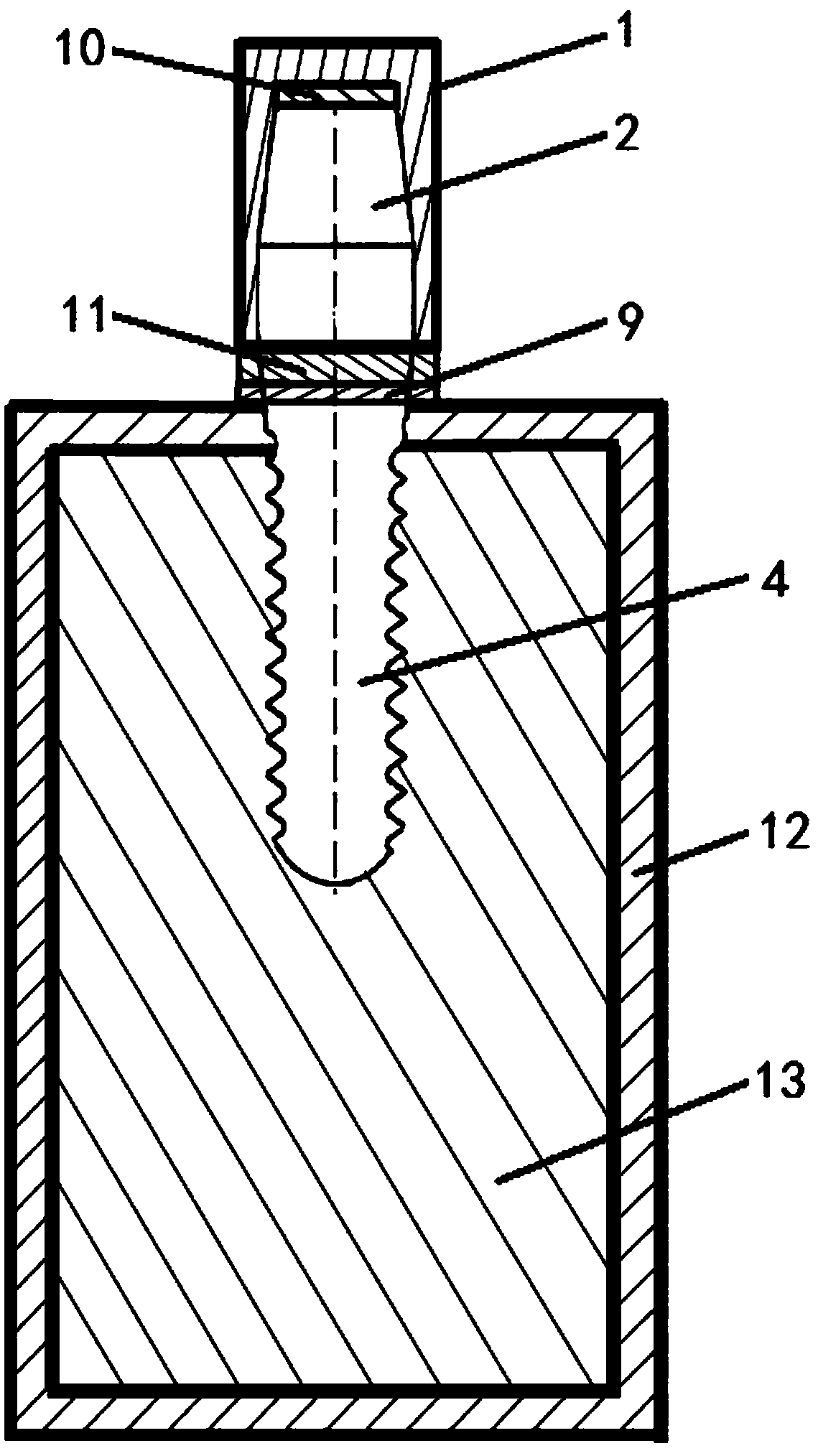

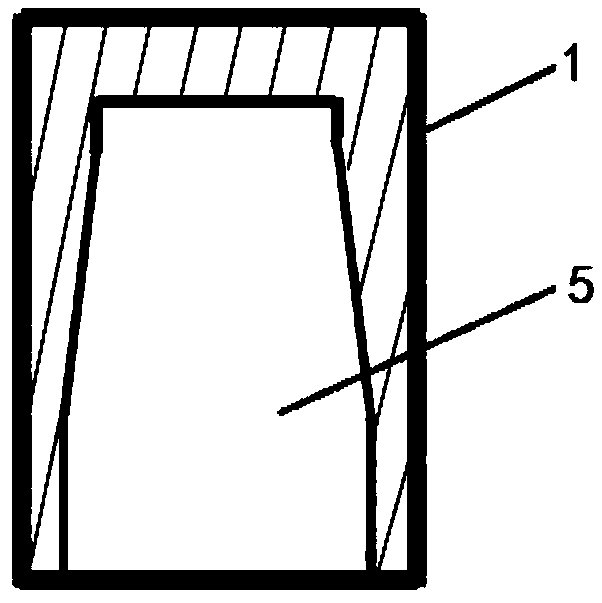

Occlusion positioner supported by implant

PendingCN114041893ASimple structureEasy to manufactureDental implantsBiomedical engineeringImplant dentures

The invention discloses an occlusion positioner supported by an implant, and the positioner comprises a silicon rubber fixing part connected on the implant and a central bolt for fixing the silicon rubber fixing part on the implant, wherein the central bolt penetrates through the silicon rubber fixing part from the middle part and is screwed on the implant. The periphery of the head of the central bolt is circular, the peripheral size of the silicone rubber fixing part is gradually increased from top to bottom, and the polymerization degree of the silicone rubber fixing part is 5-10 degrees. The occlusion positioner is simple and reasonable in structure and easy to manufacture and use, the accuracy of occlusion records is improved, the adjusting and changing procedures and time of the false tooth at the chair side end are reduced, the rework rate is reduced, the better implant false tooth repairing effect is obtained, and the satisfaction degree of a patient is higher. In addition, by using the occlusion locator, the occlusion recording process of the free end deletion implantation case can be simplified, and the waiting time beside the chair is shortened.

Owner:STOMATOLOGY AFFILIATED STOMATOLOGY HOSPITAL OF GUANGZHOU MEDICAL UNIV

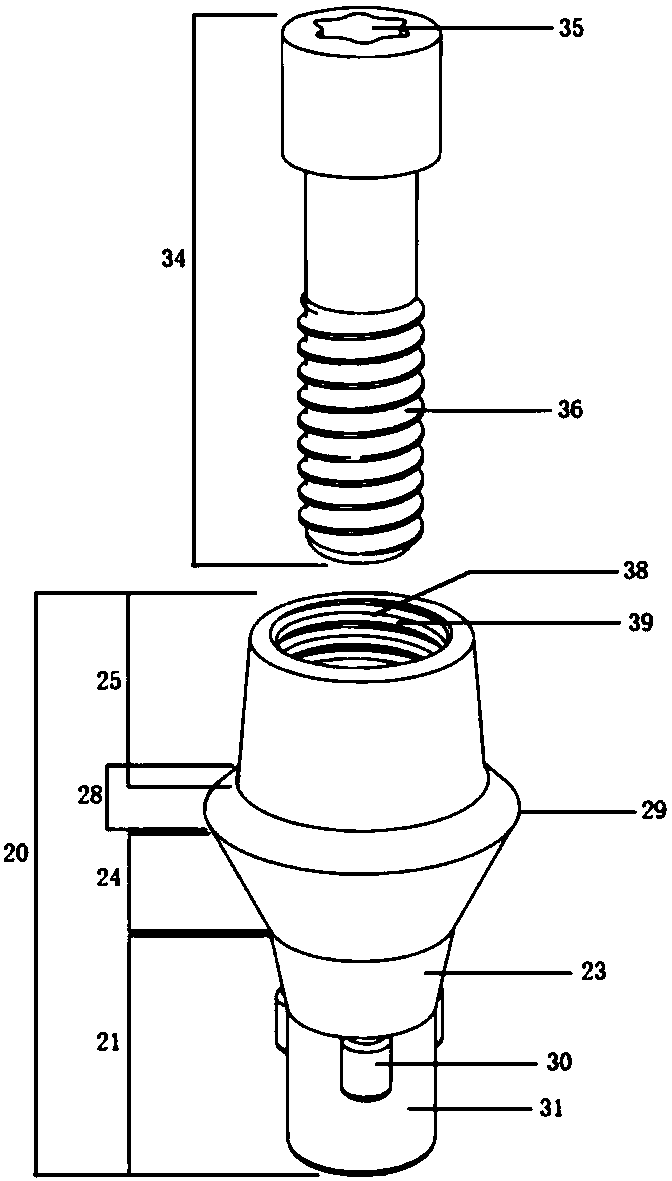

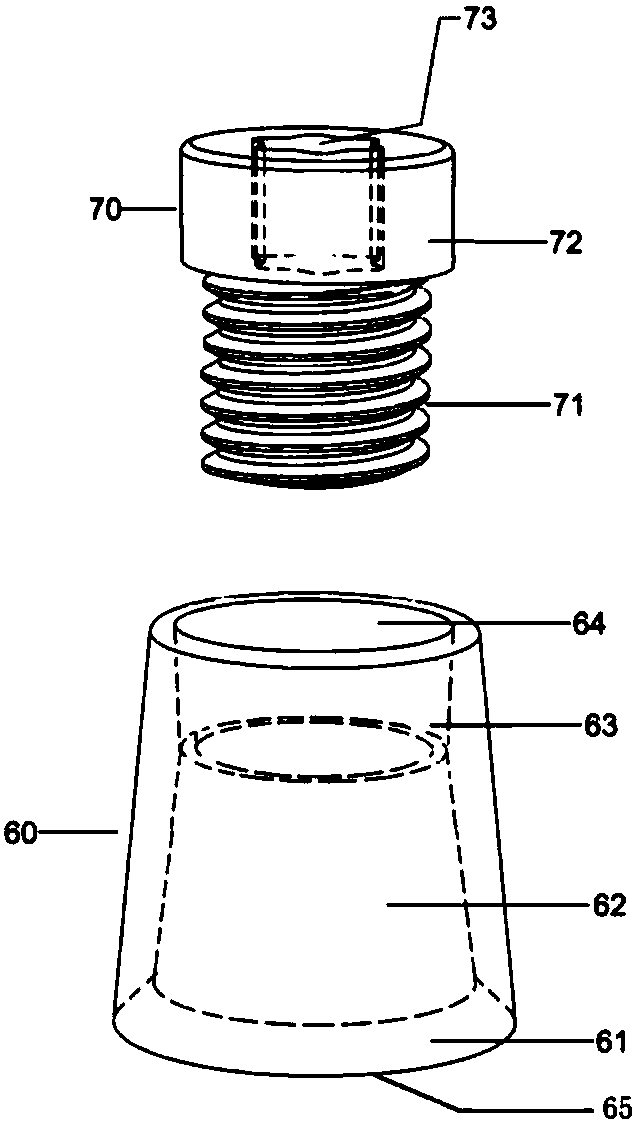

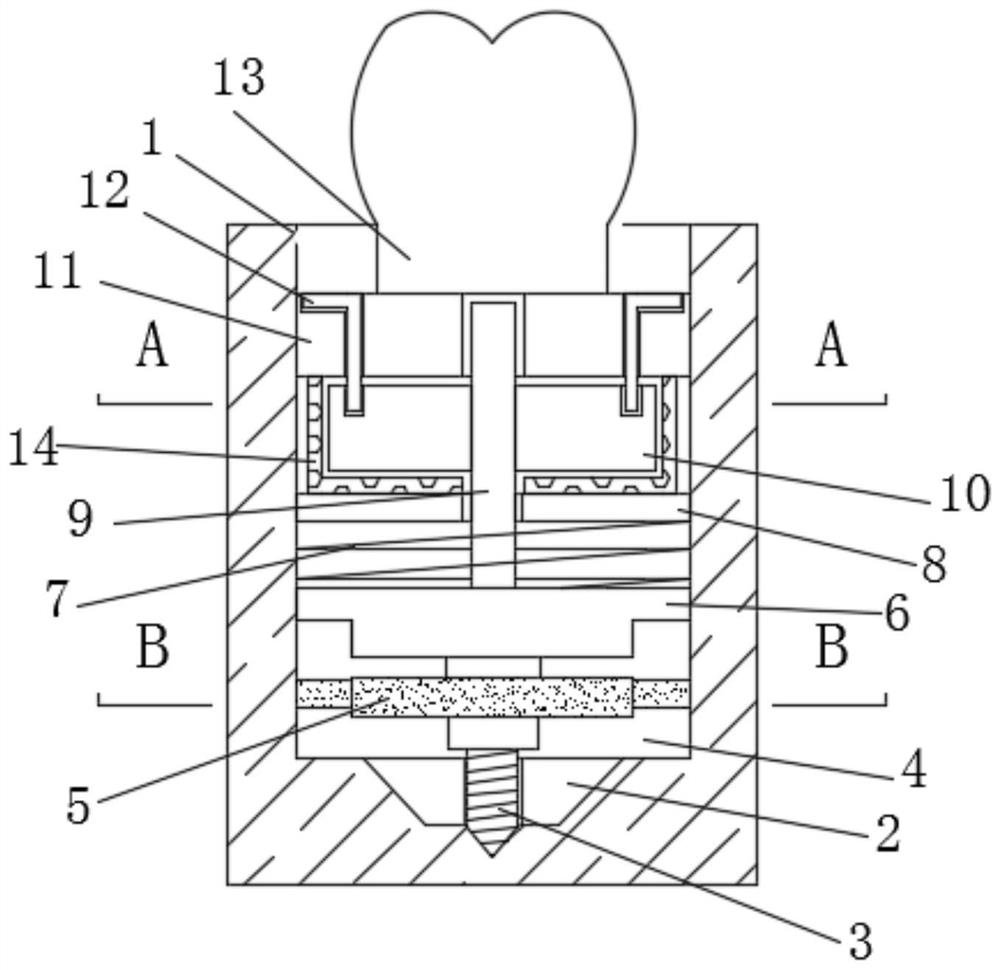

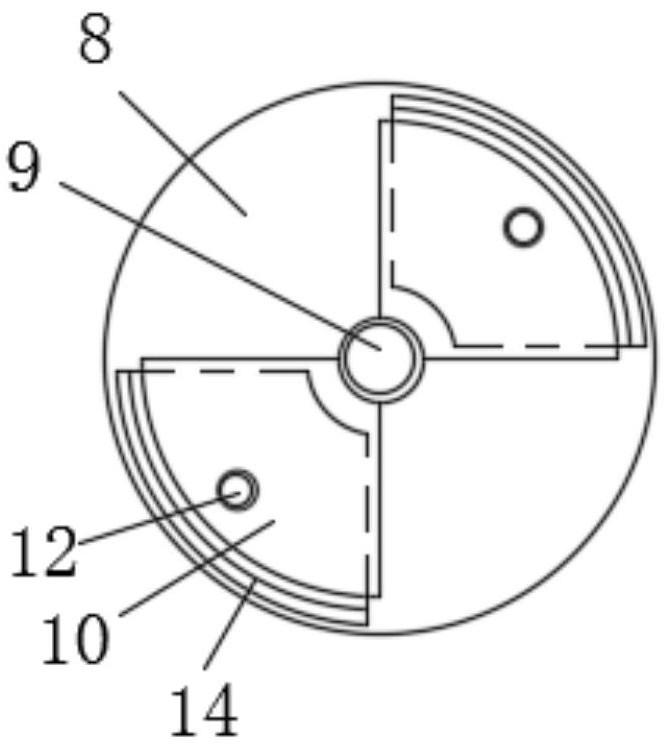

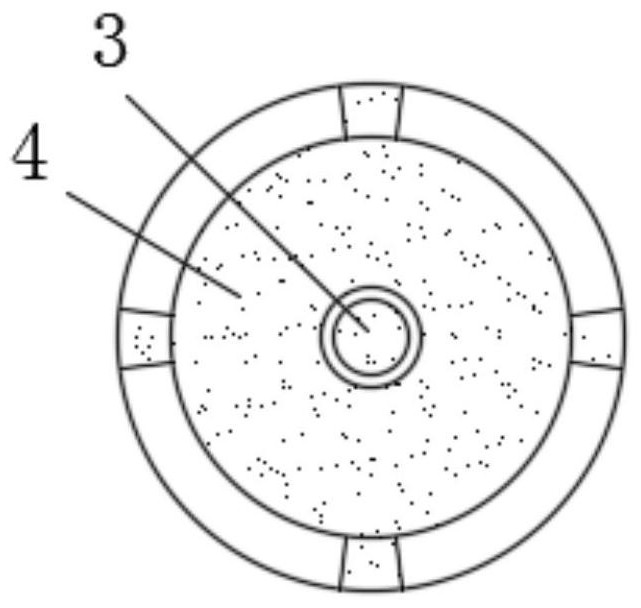

Implant false tooth with spring damper telescopic base table

The invention discloses an implant false tooth with a spring damper telescopic base table. The implant false tooth comprises an implant body, a lower telescopic base table, an upper telescopic base table, a fixing screw, a damper, a base table cover and an implant dental crown. The implant false tooth with the spring damper telescopic base table provided by the invention has the beneficial effectsthat the telescopic base table overcomes the defects of a traditional base table and plays a role in buffering occlusal force. Damping values of natural teeth and implants in the mouth of a patient can be measured clinically, a proper damper is selected, and the natural teeth are simulated to the maximum extent, so that optimal occlusion contact and occlusion force are achieved.

Owner:程国辉

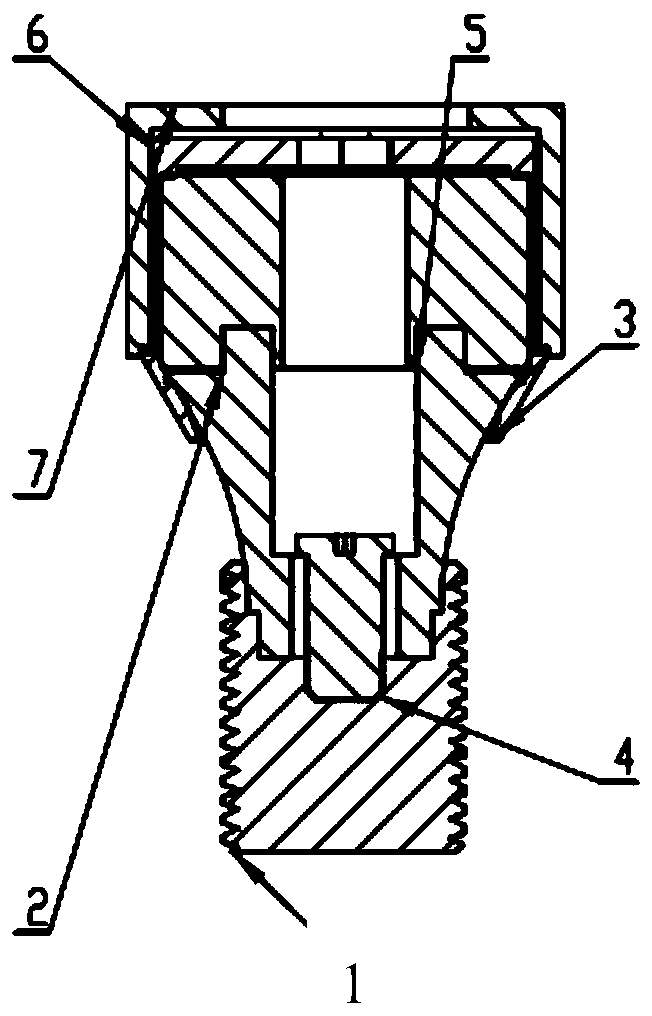

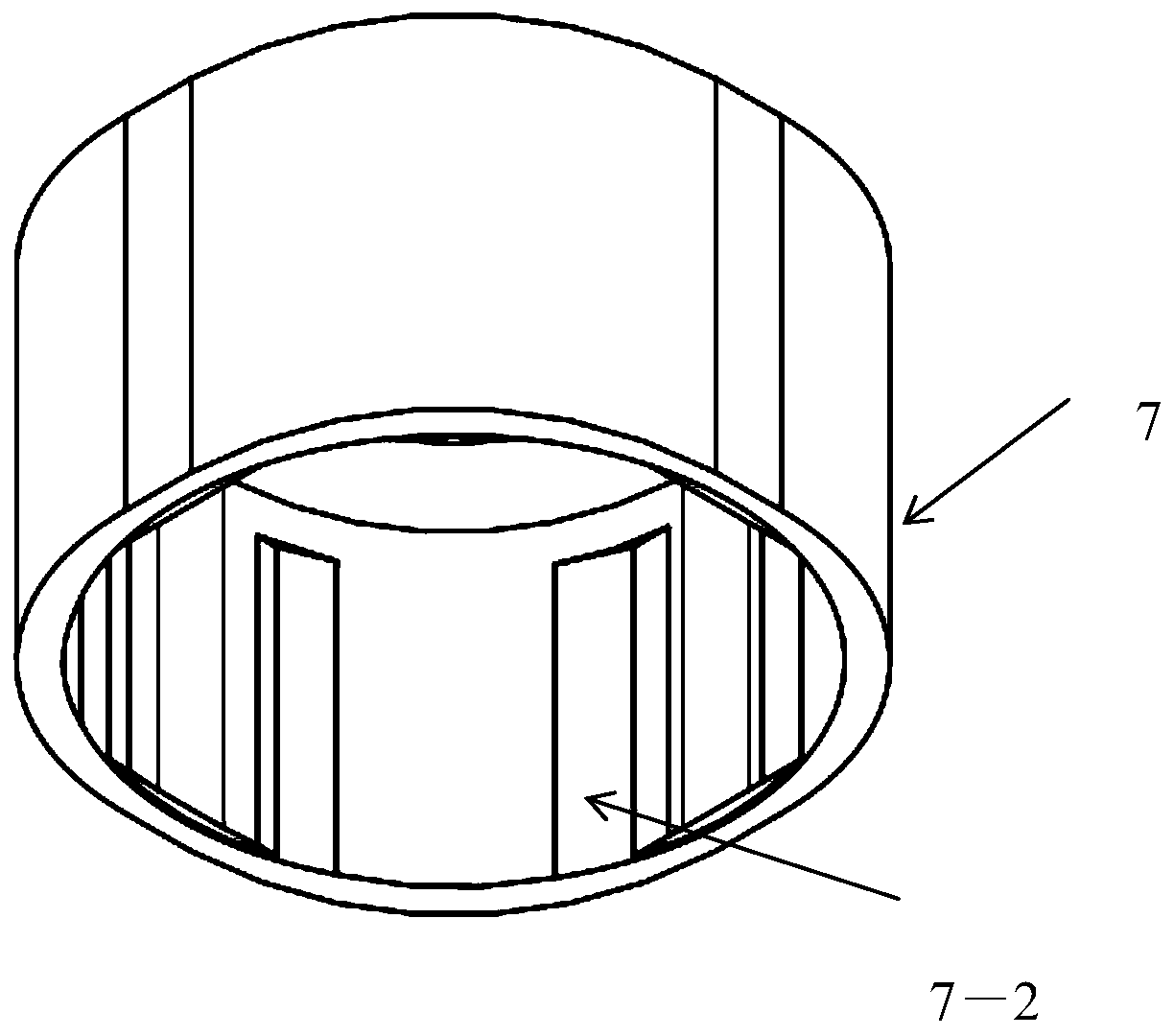

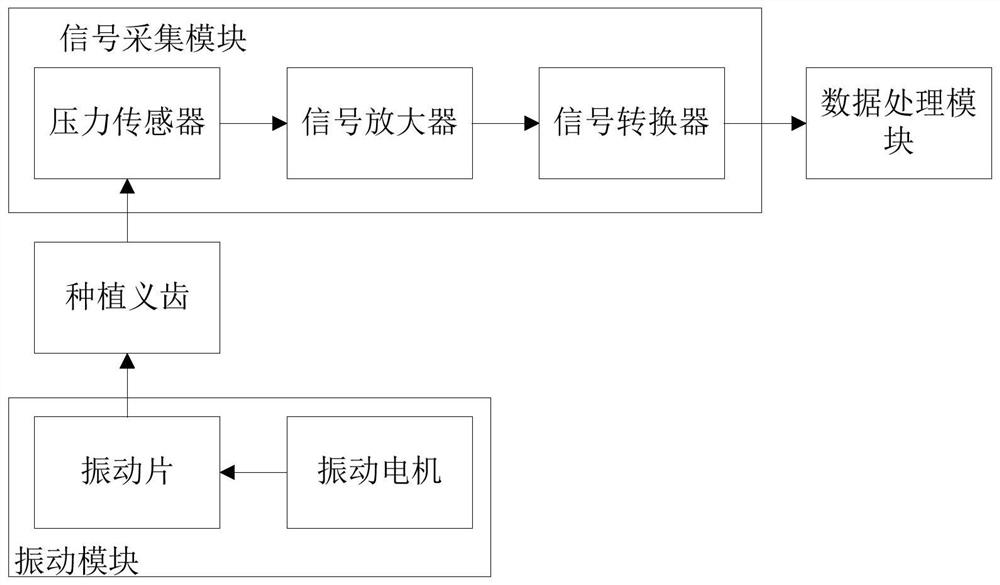

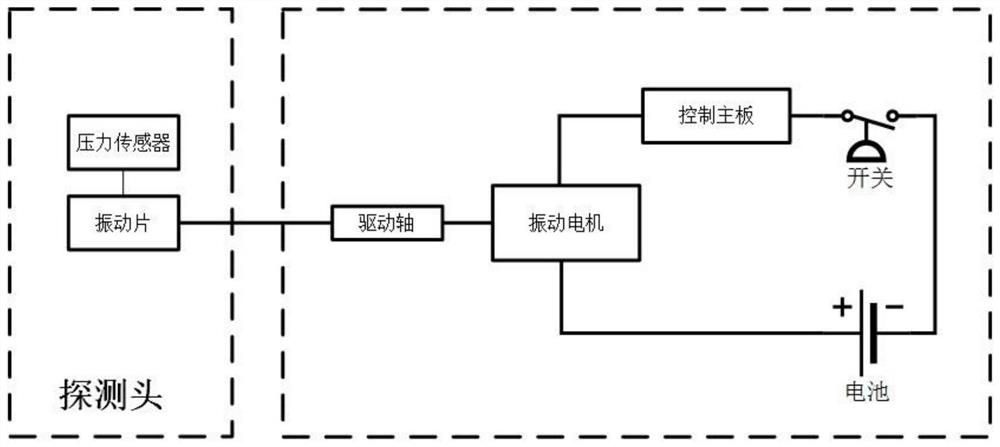

Dental implant repair screw looseness monitoring system and method

PendingCN112964460ASimple structureEasy to operateMachine part testingDental implantsDentistryDental implant

The invention discloses a dental implant repair screw looseness monitoring system and method, wherein the system comprises a vibration module which is used for providing mechanical vibration for an implant denture, a signal acquisition module which is used for acquiring a vibration signal of the implant denture, and a data processing module which is used for detecting whether the repair screw in the implant denture is loosened or not according to the collected vibration signal. According to the invention, mechanical vibration is generated to the denture, the vibration signal in the denture is collected, whether the repair screw in the denture is loosened is detected according to the vibration signal, the structure is simple, the operation is convenient, and the monitoring precision is high. The system and method can be widely applied to the technical field of implant dentures.

Owner:SOUTH CHINA UNIV OF TECH +1

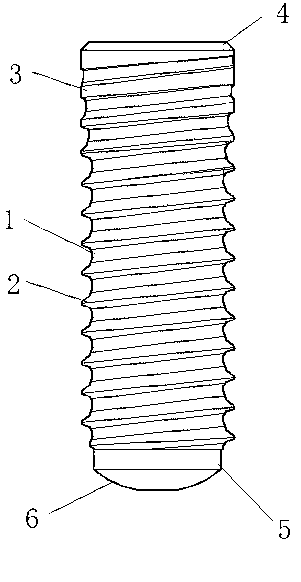

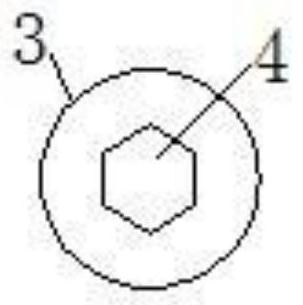

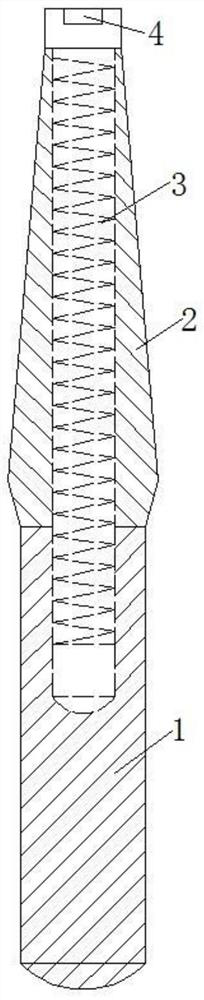

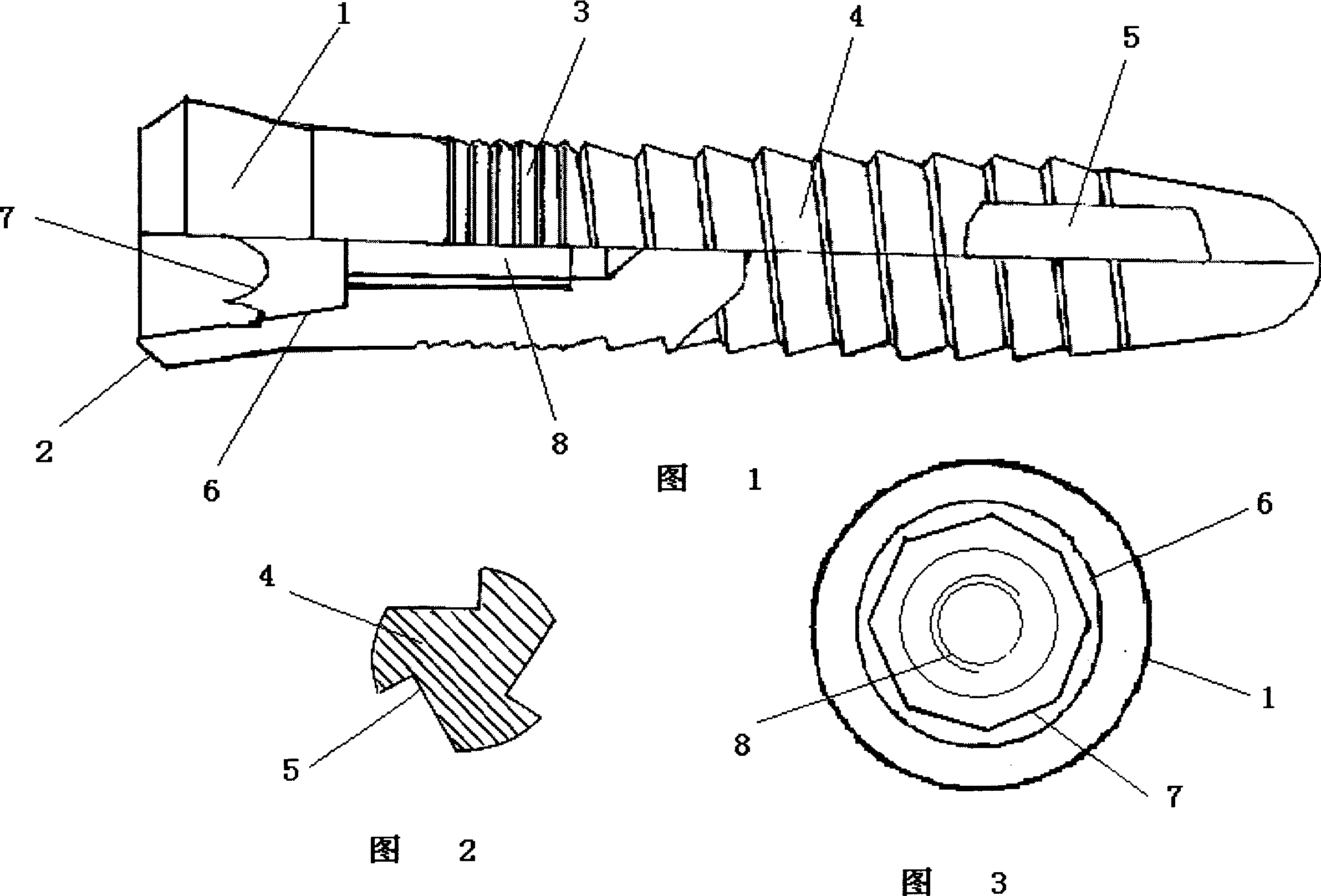

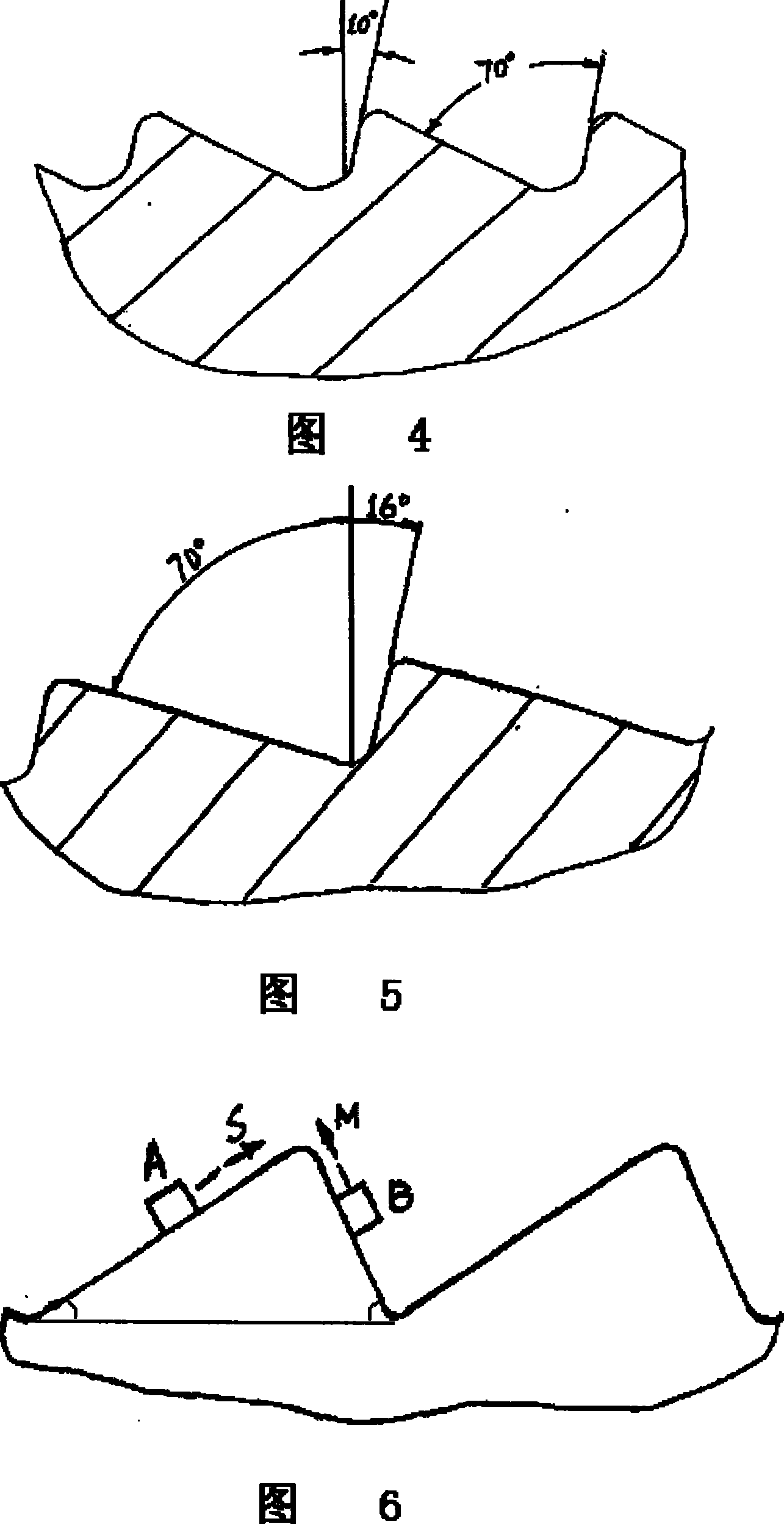

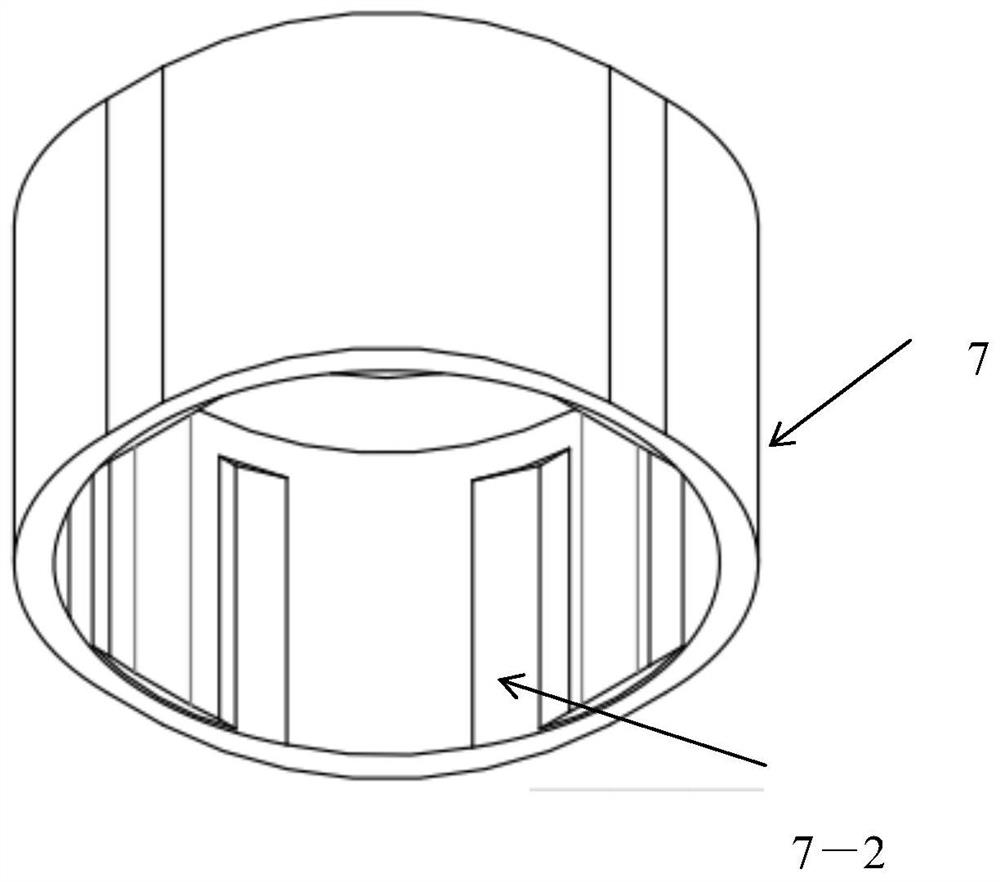

Micro thread implant

ActiveCN1931109BSolve the problem of insufficient neck strengthEasy to screw inDental implantsJaw boneSelf locking

The micro thread implant includes one conic top with larger upper part and smaller lower part, one conic hole including one octagonal middle part and one lower screw hole part and surface coating of hydroxyapatite. It features the neck with fine thread, the root part with self-tapping straight thread and the conic end, with both the fine thread and the straight thread being saw tooth threads. Thepresent invention has high neck strength, capacity of preventing microbes from invading, easy integrating with bone, easy screwing into the jaw bone and self locking, and may be used in repair dentaldefection, especially false tooth implanting operation.

Owner:BEIJING LEIDEN BIOMATERIAL

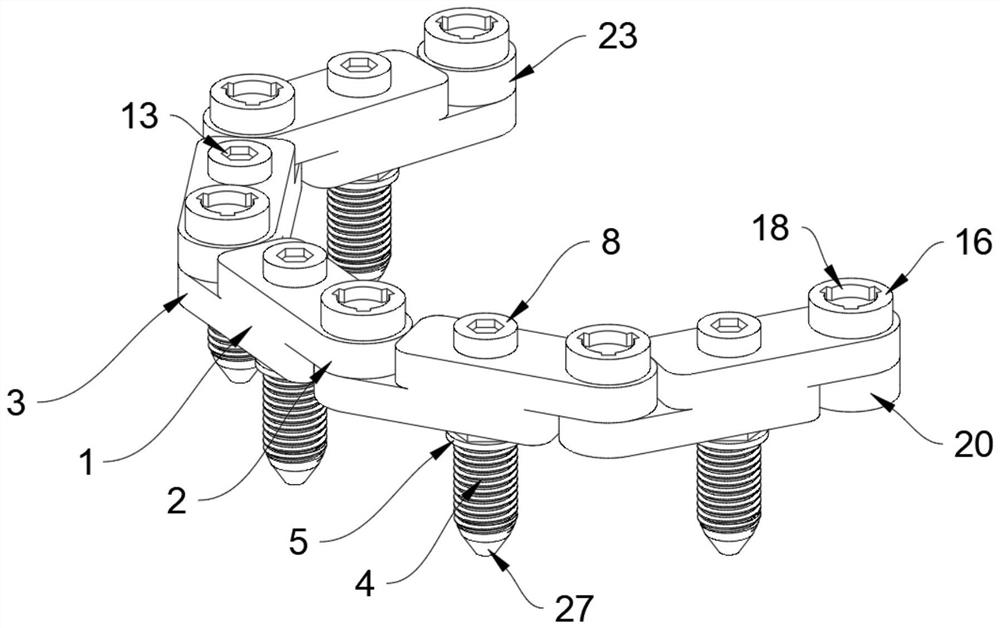

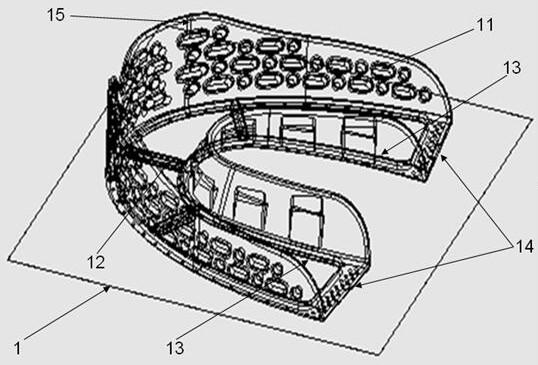

Adjustable combined type planting rod clamp

PendingCN114533315AFast installationImprove installation efficiencyDental implantsAgriculture gas emission reductionStructural engineeringMechanical engineering

The invention relates to the field of planting rod clamps, in particular to an adjustable combined type planting rod clamp. The adjustable combined type planting rod clamp comprises splicing rod clamps, upper protruding parts, lower protruding parts, implants, bearing parts, limiting grooves, adjusting heads, embedding parts, connecting columns, adjusting parts, connecting bases and threaded rods, the multiple splicing rod clamps are arranged at equal intervals and equal angles, inserting holes are formed in the tops of the splicing rod clamps, the upper protruding parts are arranged on one sides of the splicing rod clamps, and the lower protruding parts are arranged on the other sides of the splicing rod clamps. Lower protruding parts are arranged on the other sides of the splicing rod clamps correspondingly, positioning holes are formed in the tops of the upper protruding parts correspondingly, and limiting grooves are formed in the bottoms of the upper protruding parts and the tops of the lower protruding parts correspondingly. When the adjustable composite implant rod clamp provided by the invention is used, the overall length of the implant rod clamp can be spliced and adjusted according to the oral cavity, the frontal bone and the like of a user, and the radian of the implant rod clamp can be adjusted, so that the adjustable composite implant rod clamp is suitable for different crowds or is matched with implant dentures with different lengths for installation.

Owner:深圳市瑞丽牙科技术有限公司

A kind of oral implant device

The invention discloses an oral implant device, comprising alveolar bone, a screw-in body is fixedly installed in the bottom groove of the alveolar bone cavity, and a base is arranged in the alveolar bone cavity on the upper side of the screw-in body, One end of the base away from the screw-in body is provided with a threaded groove, and the inner groove wall of the threaded groove is threadedly connected with a threaded seat. In the device, the bottom end of the implant is fixed on the screw-in body screwed into the alveolar bone through a screw that penetrates deep into the alveolar bone, and hydroxyapatite is filled in the filling cavity provided with the screw at the base of the implant. The connection port is connected with the filling cavity and the alveolar bone cavity, so as to ensure the stable installation of the implant in the alveolar cavity cavity and avoid loosening; the device flexibly clamps the clamping plate on the installation seat with the denture Between the lifting plate and the clamping plate, it can flexibly install and replace the denture without moving the lower part of the implant denture, avoid secondary injury to the patient, and improve the work efficiency of medical staff.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

Implant denture individual abutment design method based on healing abutment dental model

InactiveCN102194030BAvoid precision lossSpecial data processing applicationsData acquisitionComputer-aided

The invention discloses an implant denture individual abutment design method based on a healing abutment dental model, and belongs to the field of computer auxiliary design. The method comprises the following four steps: acquiring and preprocessing data; establishing an implant system model base; positioning a healing abutment and an implant body; and designing an individual abutment. The implantdenture individual abutment design method is high in automation, not only ensures that the operation steps of manufacturing a wax pattern or casting a model, and transferring the implant body on clinic and the like can be omitted, but also can be used for improving the shape of gingival margin of the restored implant denture, greatly reducing the operation time and cost of a doctor and a skilled work, and improving the restoration efficiency and beautiful appearance; the implant denture individual abutment design method based on the healing abutment dental model has important application value in a computer auxiliary dental implant field.

Owner:AFFILIATED STOMATOLOGICAL HOSPITAL OF NANJING MEDICAL UNIV +1

A cad/cam/3d automatic processing method for dental restorations

The invention relates to an automatic CAD / CAM / 3D processing method of dental prostheses. The method comprises the step of processing dental prostheses by employing a composite system composed of an optical scanner and a computer aided design system, a CAD / CAM aided system, a selective laser cladding machine and a numerical control cutting machine tool, wherein prostheses such as removable partial dentures, fixed dentures, complete dentures and implant dentures can be rapidly manufactured. The method is characterized in that numerical control cutting (subtractive manufacturing called as subtraction) and the 3D printing technology (additive manufacturing called as addition) are organically combined and highly unified. Two aspects of the unity and opposites are merged into one uniform aspect; the automatic production efficiency of the dental prostheses, especially complex prostheses, can be greatly improved, complicated procedures of a conventional handmade dental prosthesis are eliminated, the manufacturing quality and stability of the prostheses are improved, the purposes of quickness, accuracy and individualized manufacturing are achieved, and the dental prostheses meet the urgent demands of most agomphosis patients.

Owner:维视医疗信息科技山东有限公司

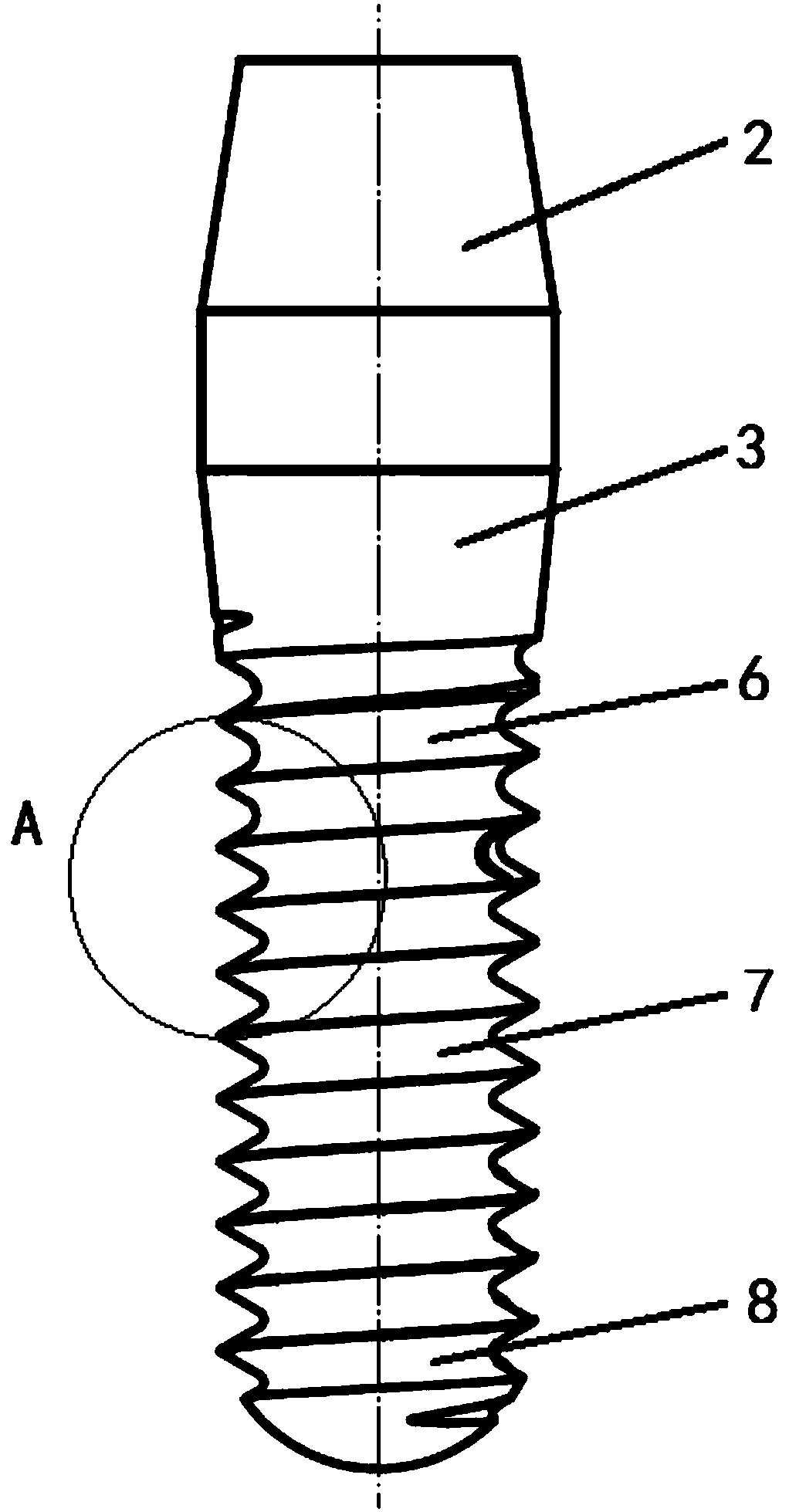

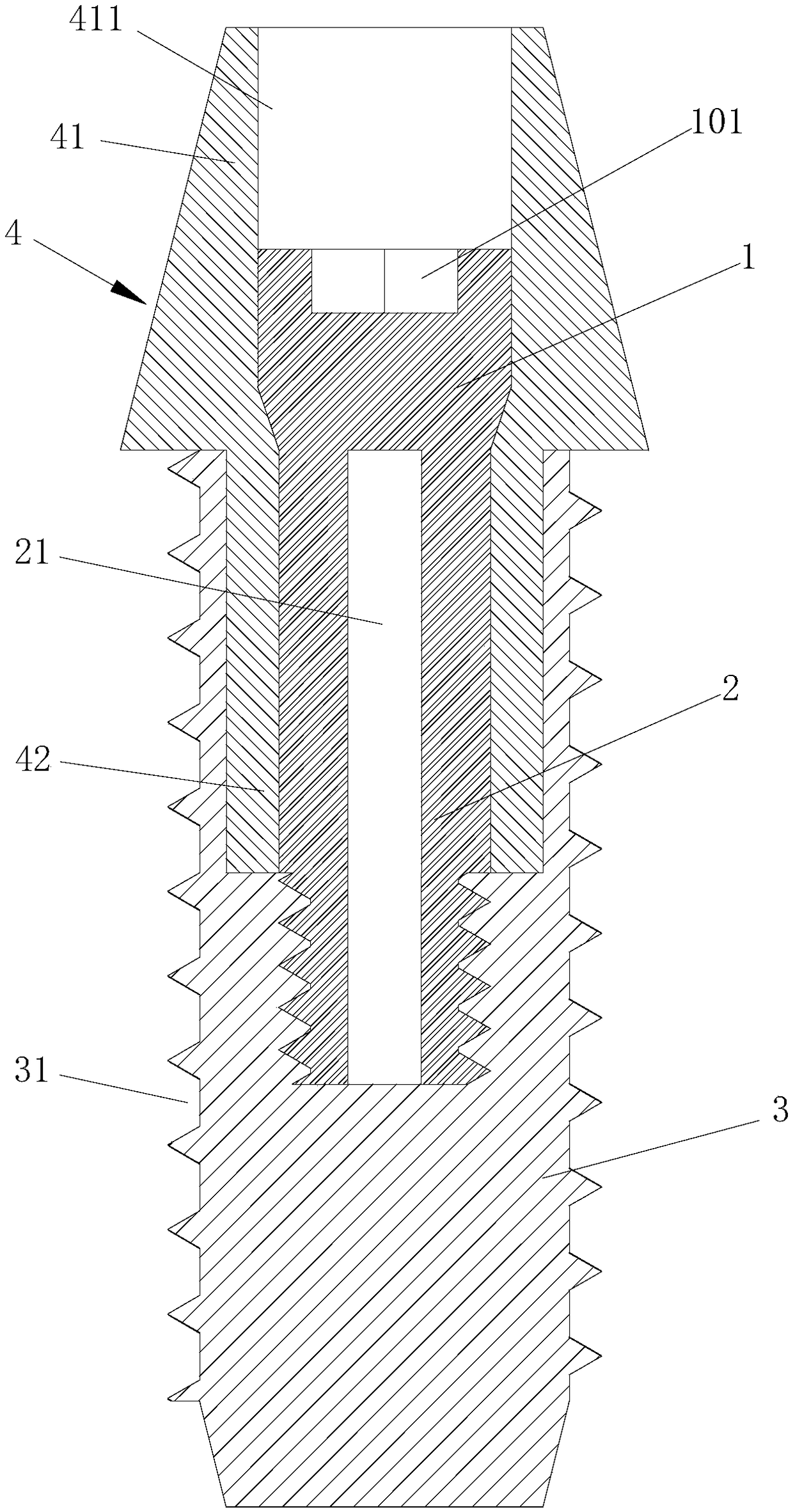

Dental implant provided with multiple sections of threads

The invention provides a dental implant provided with multiple sections of threads. The dental implant comprises a dental crown and an implant, wherein the implant consists of an implant head, an implant neck and an implant root which are arranged sequentially from top to bottom; a groove is formed in the dental crown, the implant head is embedded into the groove, and the implant head is in interference fit with the groove of the dental crown; the implant root is provided with three sections of threads which are respectively a first thread section arranged at an upper part of the implant root,a second thread section arranged at a middle part of the implant root, and a third thread section arranged at a lower part of the implant root; and a tooth form depth of the first thread section is less than that of the second thread section. The dental implant provided by the invention has improved initial stability, is firmly fixed, effectively avoids the looseness of the dental implant, and reduces the stress in an alveolar bone, thereby improving the long-term stability of the implant, inducing osteoclastogenesis, promoting bone interface fusion, reducing bone resorption around the implant root, prevents bacteria from entering and being capable of widely applied to various implant denture restoration processes for hypodontia.

Owner:无锡领缔生物科技有限公司

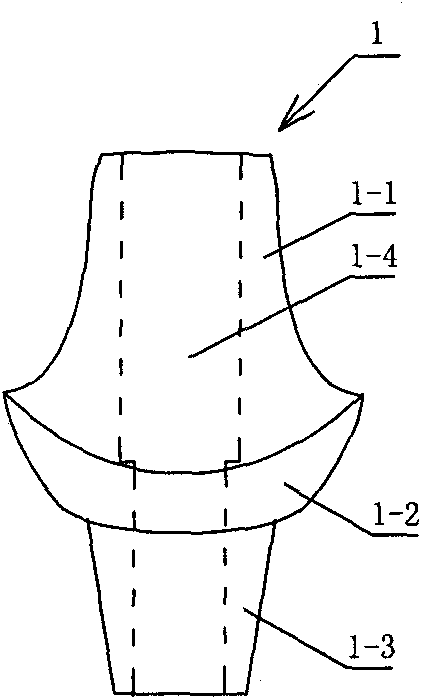

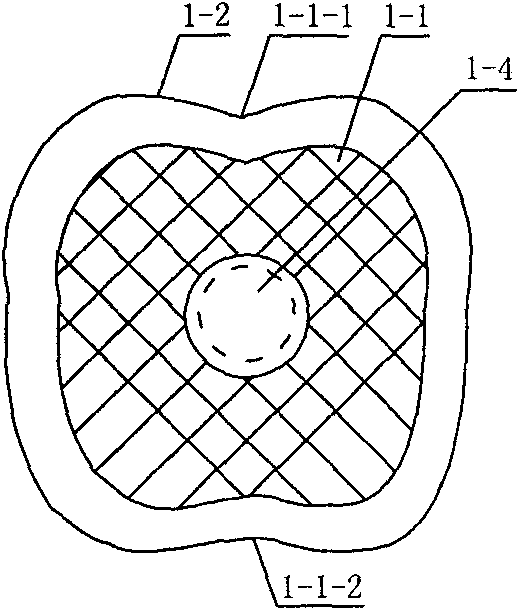

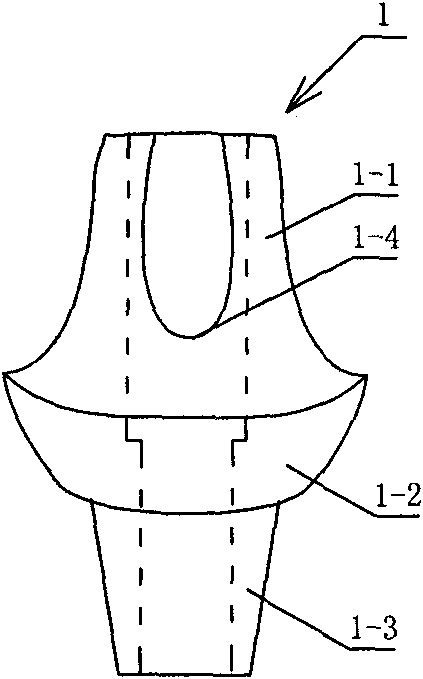

artificial dental implant

ActiveCN103284807BEffective dispersionPrevent looseningDental implantsVertebral foramenDental implant

The invention relates to an artificial dental implant which belongs to the field of dental medical instruments. The appearance of the implant is column-shaped; an asymmetry threaded appearance is adopted; the bottom of the implant is in the shape of an arced surface; the upper part of the implant is cone-shaped; a vertebral foramen structure and a cross locking structure are arranged inside the implant; a standard threaded blind hole is formed inside the implant. The artificial dental implant has the beneficial effects that the stability at the early stage is improved, the partial stress is reduced, the alveolar sorption is reduced, and the implant can be widely applied to various anodontism implant denture repairing processes.

Owner:DALIAN SANSHENG SCI & TECH DEV

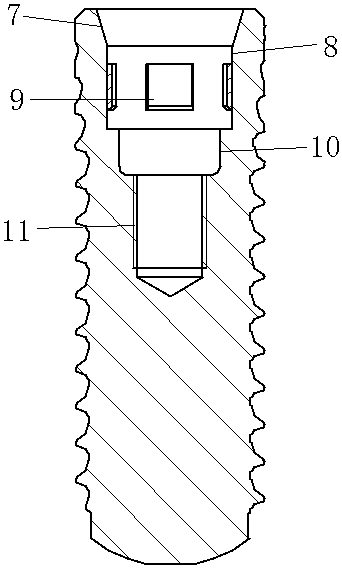

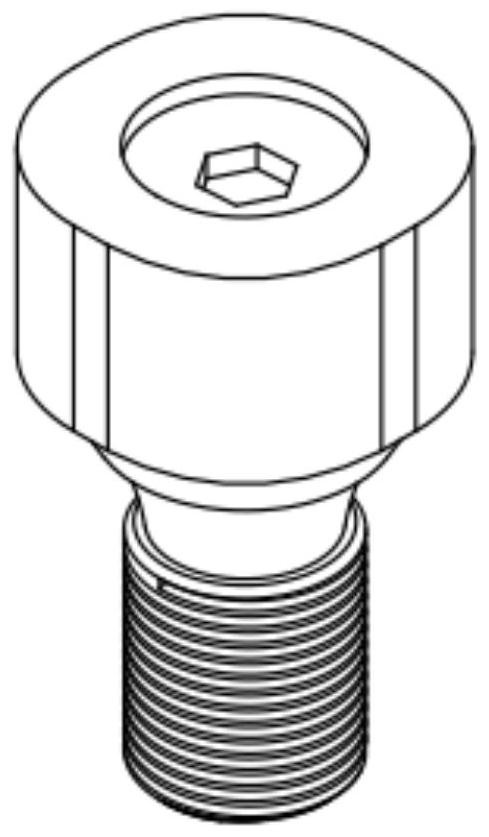

Central screw of dental implant and fracture repairing device thereof

PendingCN109350275AEasy to repair and replaceNovel structureDental implantsScrew threadDental implant

The invention discloses a central screw, which can be used for an implant denture and comprises a screw head and a screw rod, a first countersunk hole is formed in the upper end of the screw head, anda first through hole is formed in the screw rod. The screw head is composed of an upper cylinder part and a lower circle table part, and the first countersunk hole is formed in the upper cylinder part. The screw rod is round, and the outer wall of the lower part of the screw rod is provided with a first thread. The cross section of the first through hole is in a multilateral shape, elliptic shapeor special shape. The invention also discloses an implant denture and a fracture repairing device. The implant denture comprises a dental implant and a base plate, the base plate is connected to thedental implant through a central screw. The fracture repairing device comprises a handle and a rotating rod, the repairing device is used for taking out a fractured central screw, the invention also discloses a fracture repairing method of the central screw. The implant denture has a simple structure, is convenient in later maintenance and replacement, and has high creativity.

Owner:SHANDONG UNIV OF SCI & TECH

Implant Dentures with Spring Damper Telescopic Abutments

An implant denture with a spring-damper telescopic abutment. It includes an implant, a lower telescopic abutment, an upper telescopic abutment, set screws, a damper, an abutment cover and an implant crown; the implant denture with a spring damper telescopic abutment provided by the present invention has the following beneficial effects: The abutment overcomes the defects of the traditional abutment and plays a buffer role in the occlusal force. Clinically, the damping value of the natural teeth and implants in the patient's mouth can be measured, and an appropriate damper can be selected to simulate the natural teeth to the greatest extent, so as to achieve the best occlusal contact and occlusal force.

Owner:程国辉

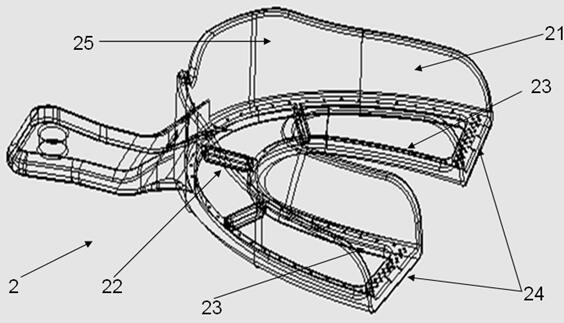

A detachable dental implant bracket and its use method

ActiveCN109907845BStrong penetrating powerResilientDental implantsImpression capsDenture WearPermlastic

The invention discloses a detachable implant denture and a utilization method thereof. The denture comprises an outer denture, an inner mesh and a film, the film sleeves the inner mesh which is provided with side wall holes, the bottom of the inner mesh is provided with reinforcing ribs, and the back face of the inner mesh is provided with convex points. An outer shell is provided with inner meshclamping fasteners, the side wall of the outer shell of the outer denture is formed by a closed structure, the bottom of the outer denture is additionally provided with concave pits peripherally, theinner wall of the outer denture is additionally provided with clamping fasteners, and the bottom of the outer denture is provided with reinforcing ribs. A method for making artificial teeth by use ofthe denture mainly includes steps: connecting the film, the inner mesh and the outer denture, coating the film with a modeling material, and allowing a patient to bite the denture, wherein in occlusion, an implant of the patient needs to penetrate the film to leave an evident mark on the inner mesh; making matched artificial teeth according to occlusion images of the inner mesh film in the denture. The implant denture is convenient to demount, an implant base is capable of penetrating the film in operation, and accuracy and cleanness in denture removal are achieved while material overflowing is avoided; high universality is realized, and repeated denture wearing times of the patient can be reduced in operation of a dentist so as to make the patient comfortable.

Owner:HUANGHUA PROMISEE DENTAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com