Bridge abutment component for dental implant

A technology for dental implants and implants, applied in dentistry, dental implants, dental prosthetics, etc., can solve the problems of increasing fixing screws, poor stress resistance, low strength, etc., so as to avoid fracture, increase strength and stress resistance. The effect of capacity, diameter increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

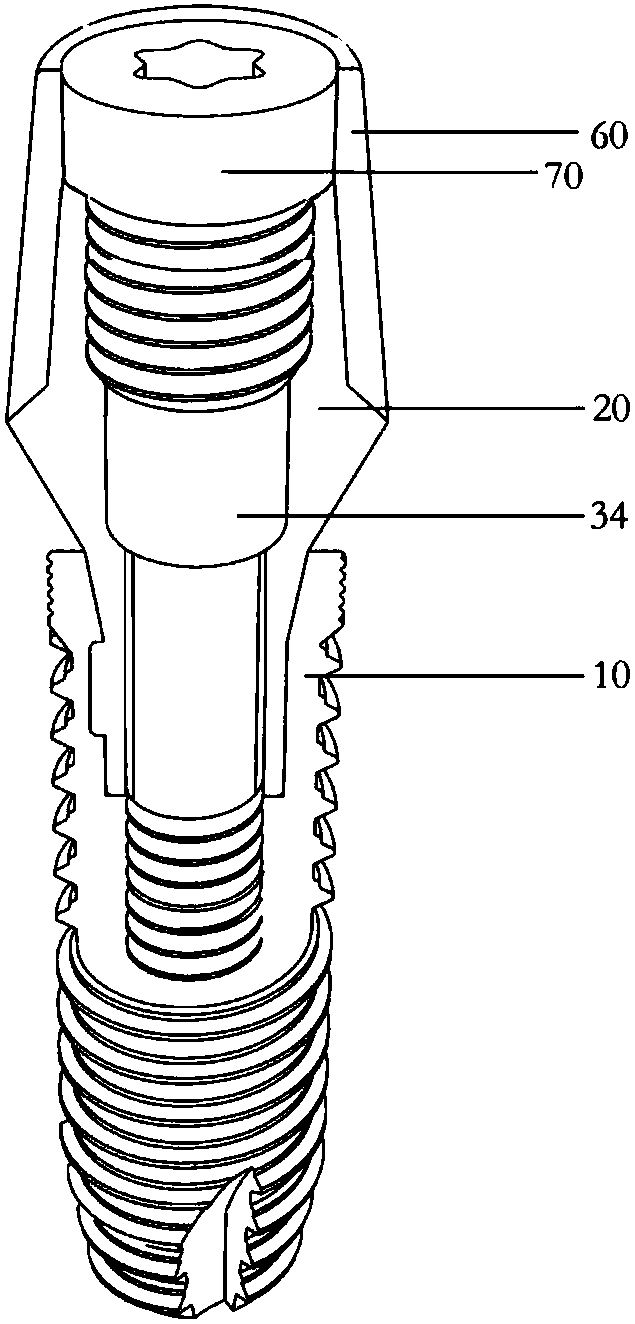

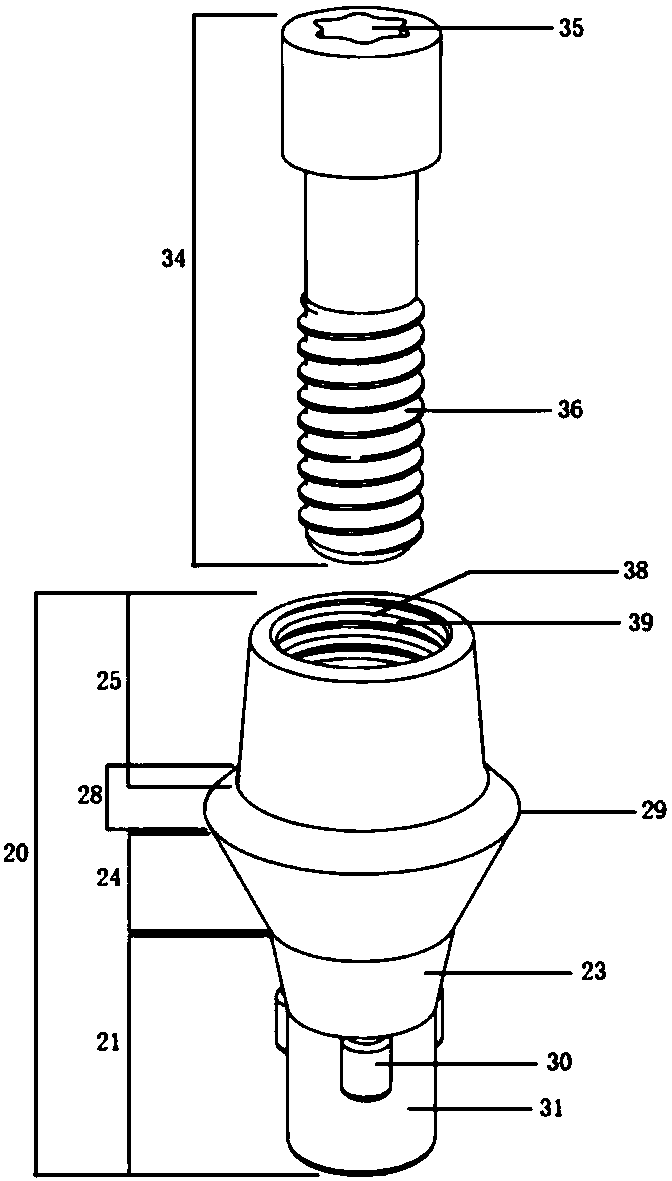

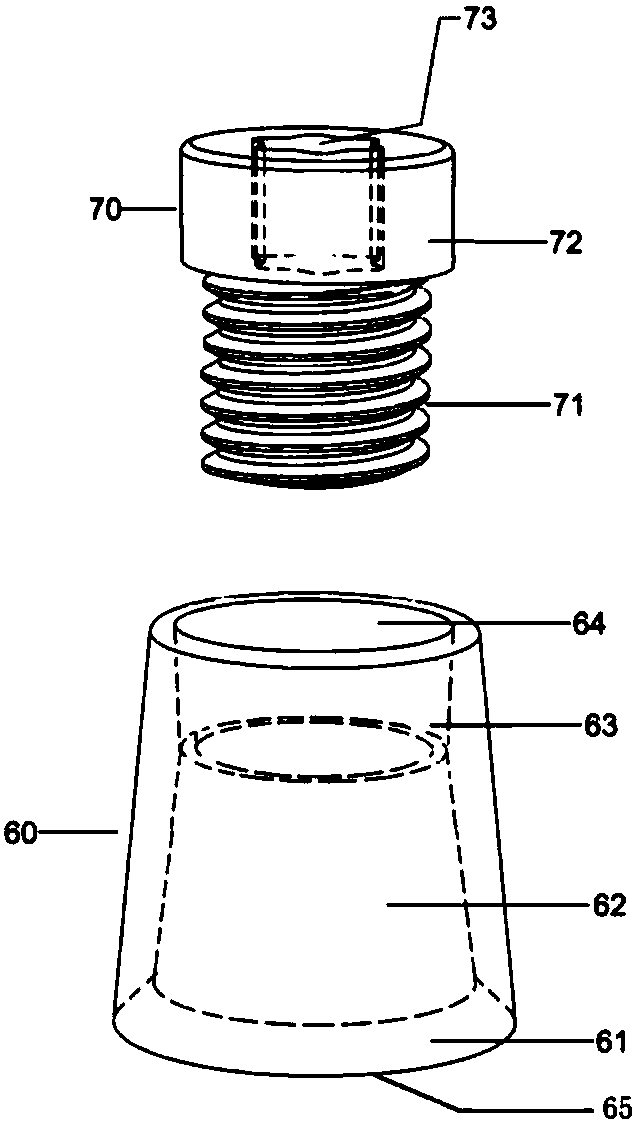

[0023] Such as figure 1 As shown, the present invention includes a gingival abutment 20, a central positioning bolt 34, a bridge abutment 60 and a fixing screw 70; the peripheral structure of the gingival abutment 20 is an inverted conical circular table 25, a groove 28, and a positive curve from top to bottom. Shaped round table 24, positive conical round table 23 and cylindrical round table 31, the cylindrical round table 31 is provided with a petal type anti-rotation structure boss 30 that is embedded with the internal structure of the implant 10 body; The lower groove 28 is covered by the bridge abutment 60 together, so that the groove 28 of the gingival abutment 20 and the groove inner cavity 61 of the bridge abutment 60 are tightly fitted, ensuring the lower edge of the dental bridge bracket or rod bracket during restoration. The fitting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com