Precise tooth cutting machine needle

A dental and precise technology, applied in dentistry, dentist pliers, dental tools, etc., can solve problems such as interruption of surgery, difficult removal of broken needles, prolongation of operation time, etc., to reduce cutting feed, prevent sudden fracture, and improve The effect of surgical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below with reference to the drawings and specific embodiments.

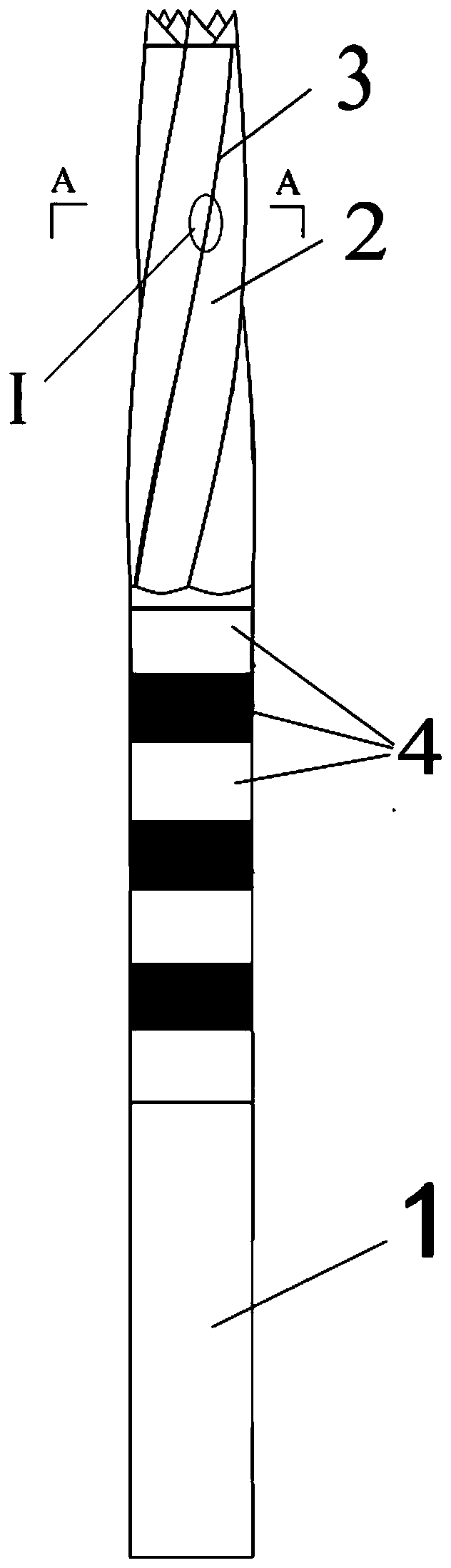

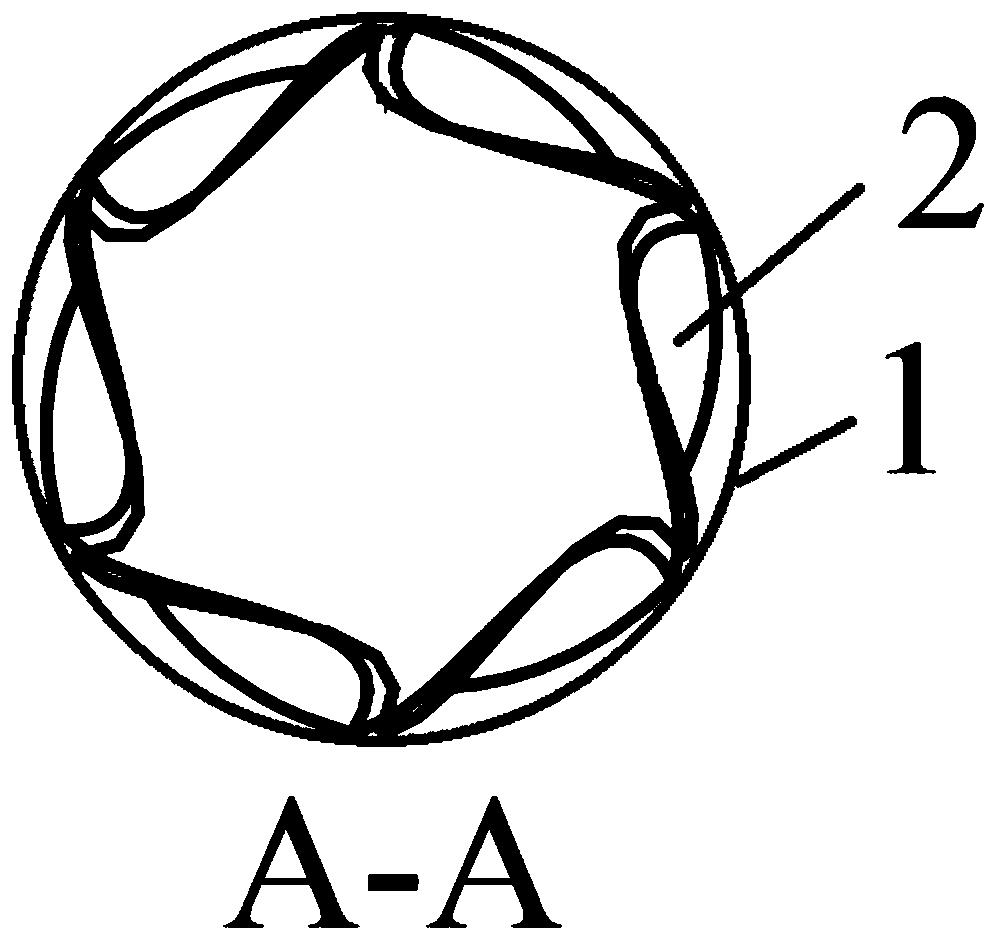

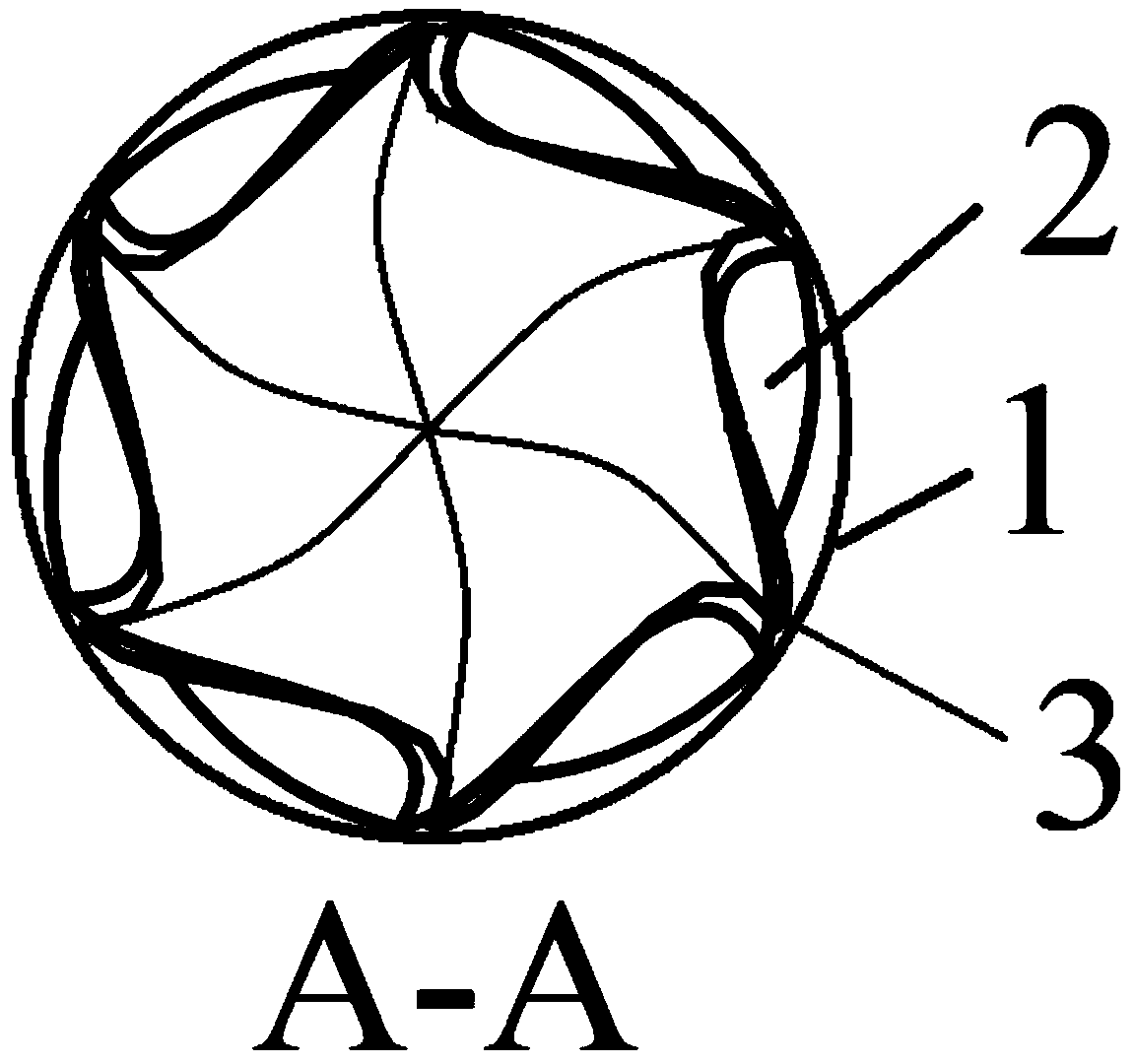

[0027] Such as figure 1 As shown, a precision tooth cutting bur includes a clamping section 1 and a cutting section 2. The cutting section 2 is tapered, and the clamping section 1 and the cutting section 2 transition smoothly; the surface of the clamping section 1 is provided with Several marking lines 4, each marking line 4 wraps around the cylindrical surface of the clamping section 1; and two adjacent marking lines 4 have different colors; the clamping section 1 and the cutting section 2 are made of the same material; marking line 4 From the junction between the clamping section 1 and the cutting section 2, the distance between two adjacent marking lines 4 is 1 mm. A cutting wing 3 is provided on the conical surface of the cutting section 2. The cutting wing 3 is helical, and the flange of the cutting wing 3 is blade-shaped, and the flange of the cutting wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com