Automatic CAD/CAM/3D processing method of dental prostheses

A dental prosthesis and CAM technology, which is applied in 3D printing, metal processing equipment, manufacturing tools, etc., can solve problems such as the need to improve the production accuracy, material waste, and inability to cut and process the prosthesis, so as to improve the production quality and stability, Get rid of cumbersome procedures and achieve the effect of personalized production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

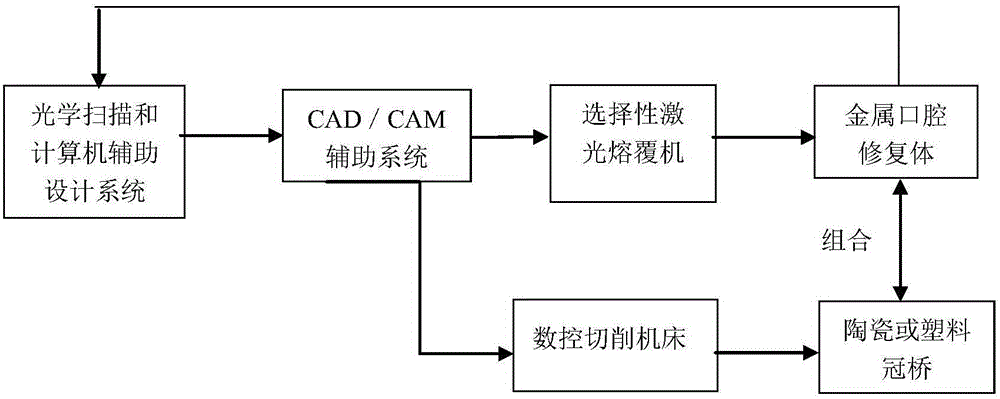

[0061] The present invention provides a brand-new CAD / CAM / 3D automatic processing method for oral restorations. The composite system organically combines the respective processing methods to maximize the efficacy.

[0062] see figure 1 , the composite system consists of three parts, the first part is optical scanning and computer-aided design system, used to complete the collection of digital models of oral restorations; the second part is the CAD / CAM auxiliary system of oral restorations and its software to complete Computer-aided design of dental restoration configurations. The third part is the miniaturized selective laser cladding machine and CNC cutting machine (CNC milling machine). Laser cladding machine for metal powder cladding accumulation molding, the types of oral restorations include metal post and core, metal crown and bridge, metal base of porcelain crown and bridge, metal bracket of removable partial denture, metal base of complete denture, implant The metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com