Patents

Literature

141 results about "Dental Prosthesis Design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The plan and delineation of dental prostheses in general or a specific dental prosthesis. It does not include DENTURE DESIGN. The framework usually consists of metal.

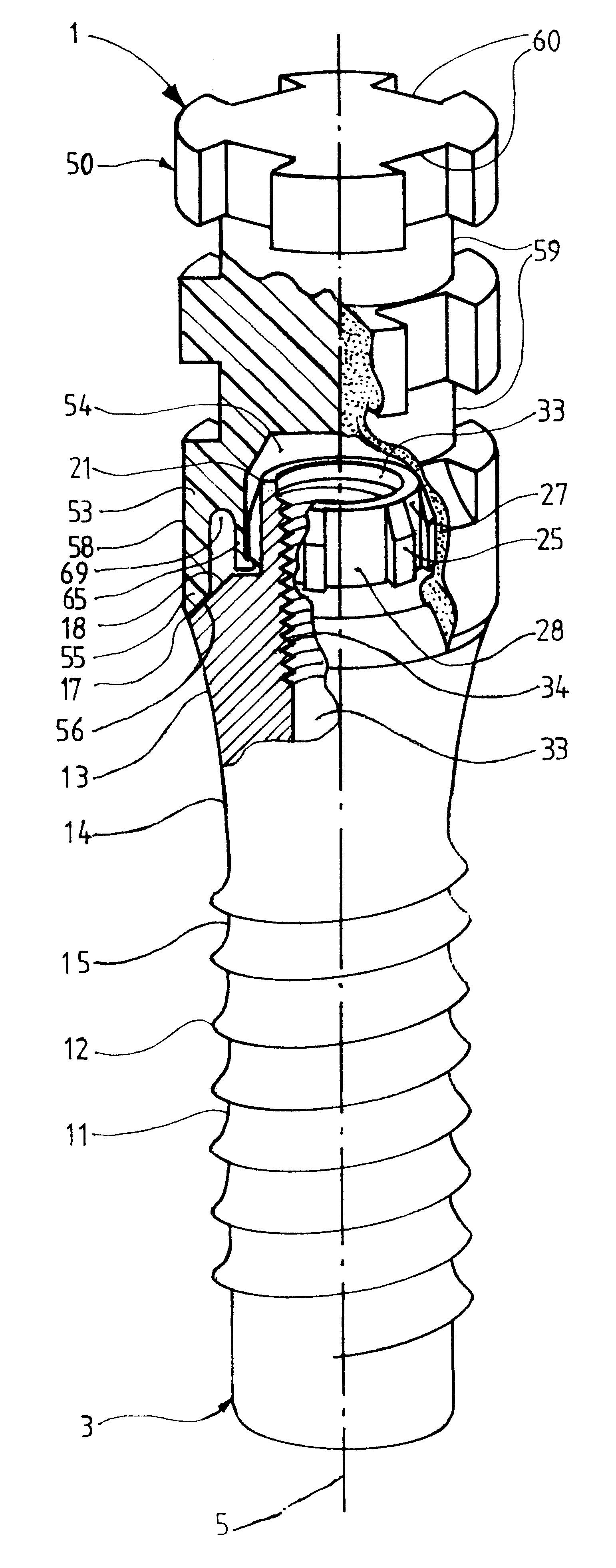

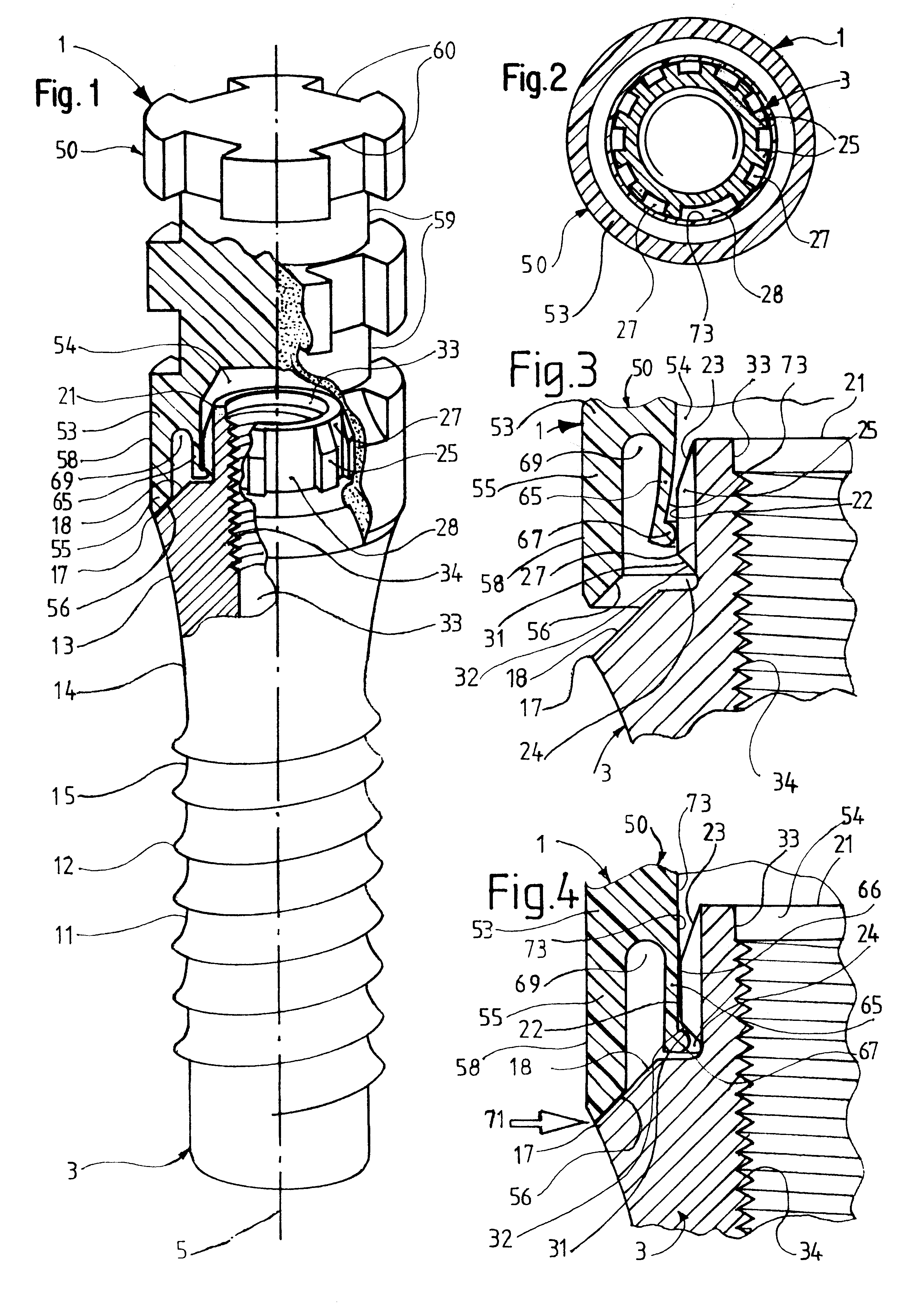

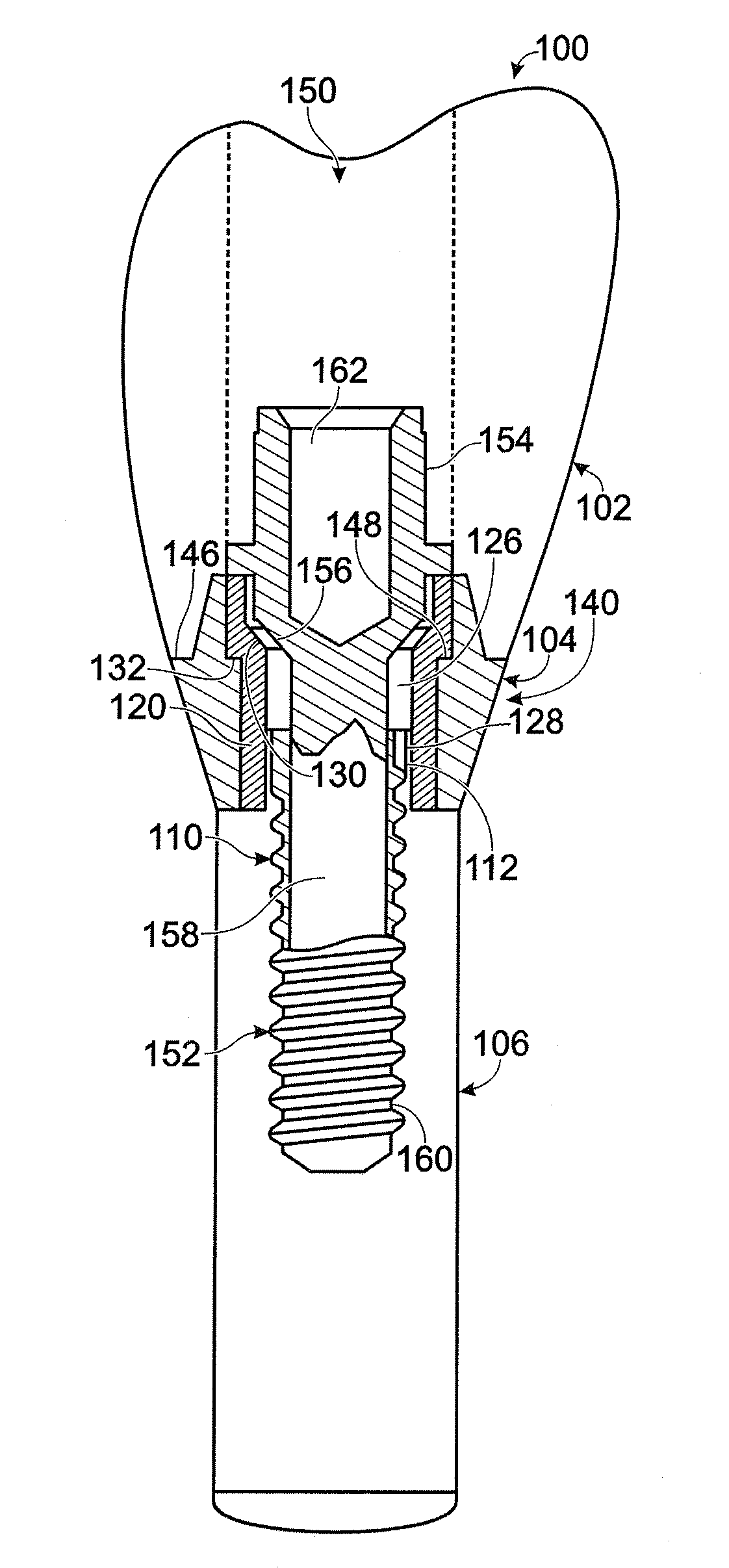

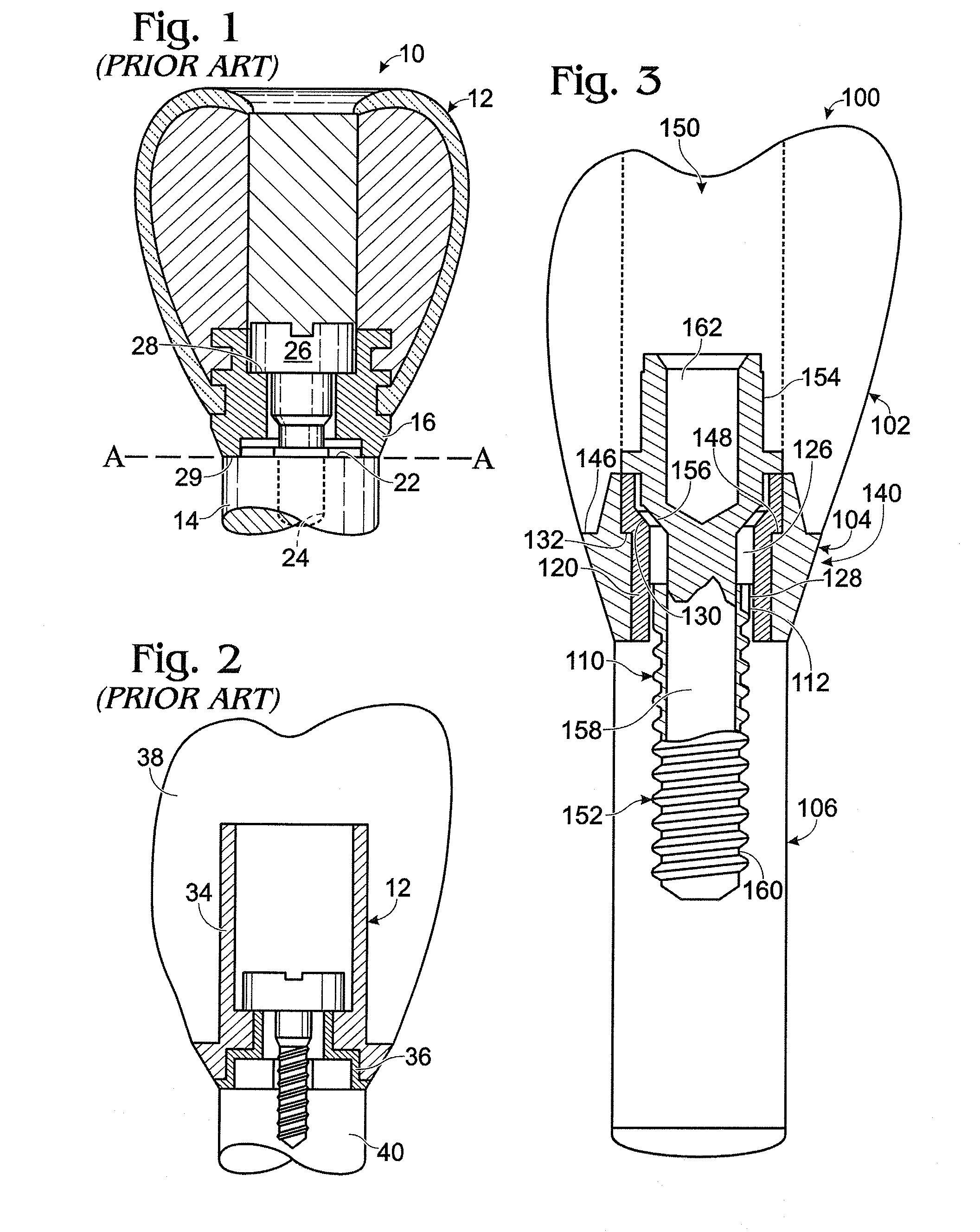

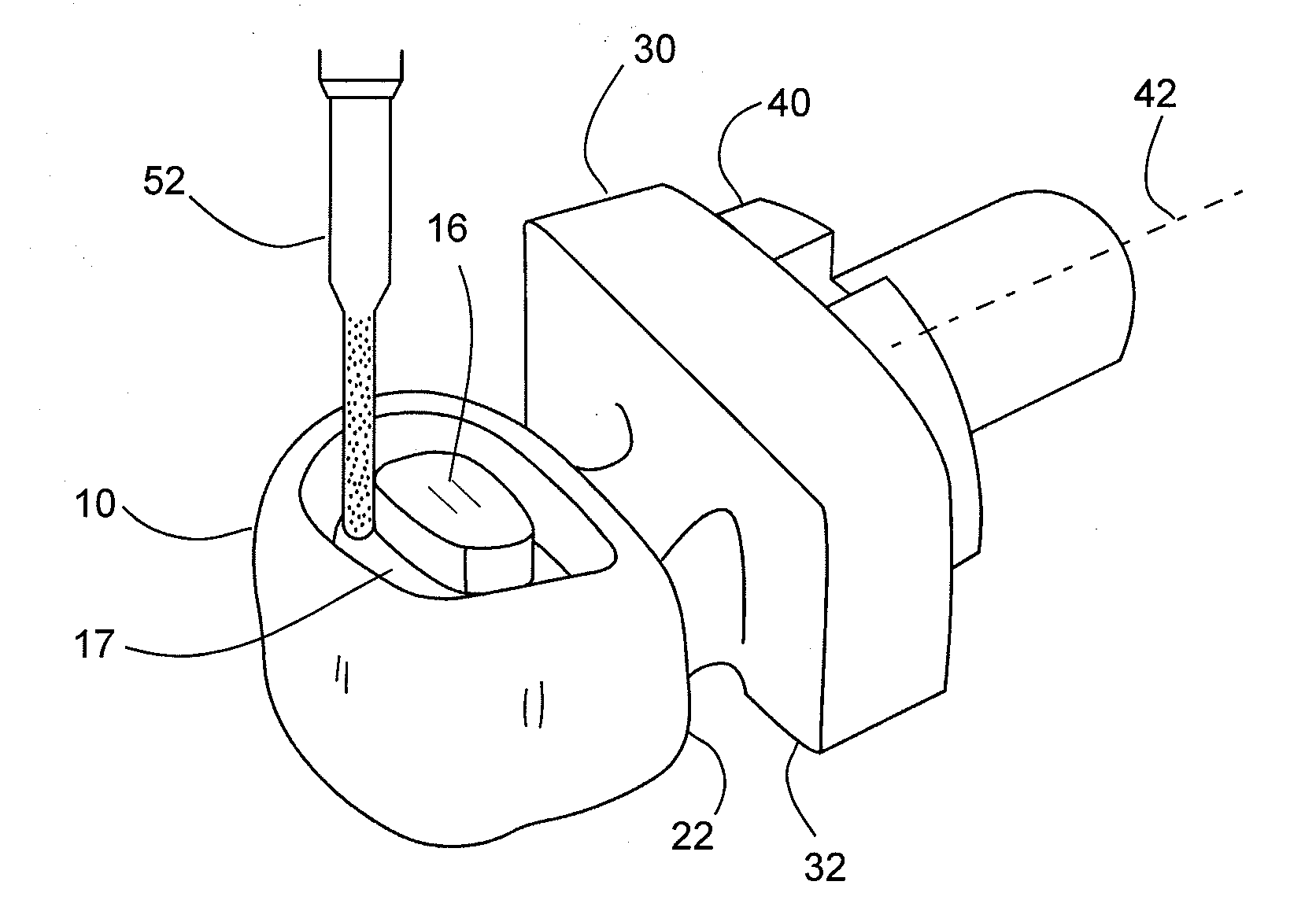

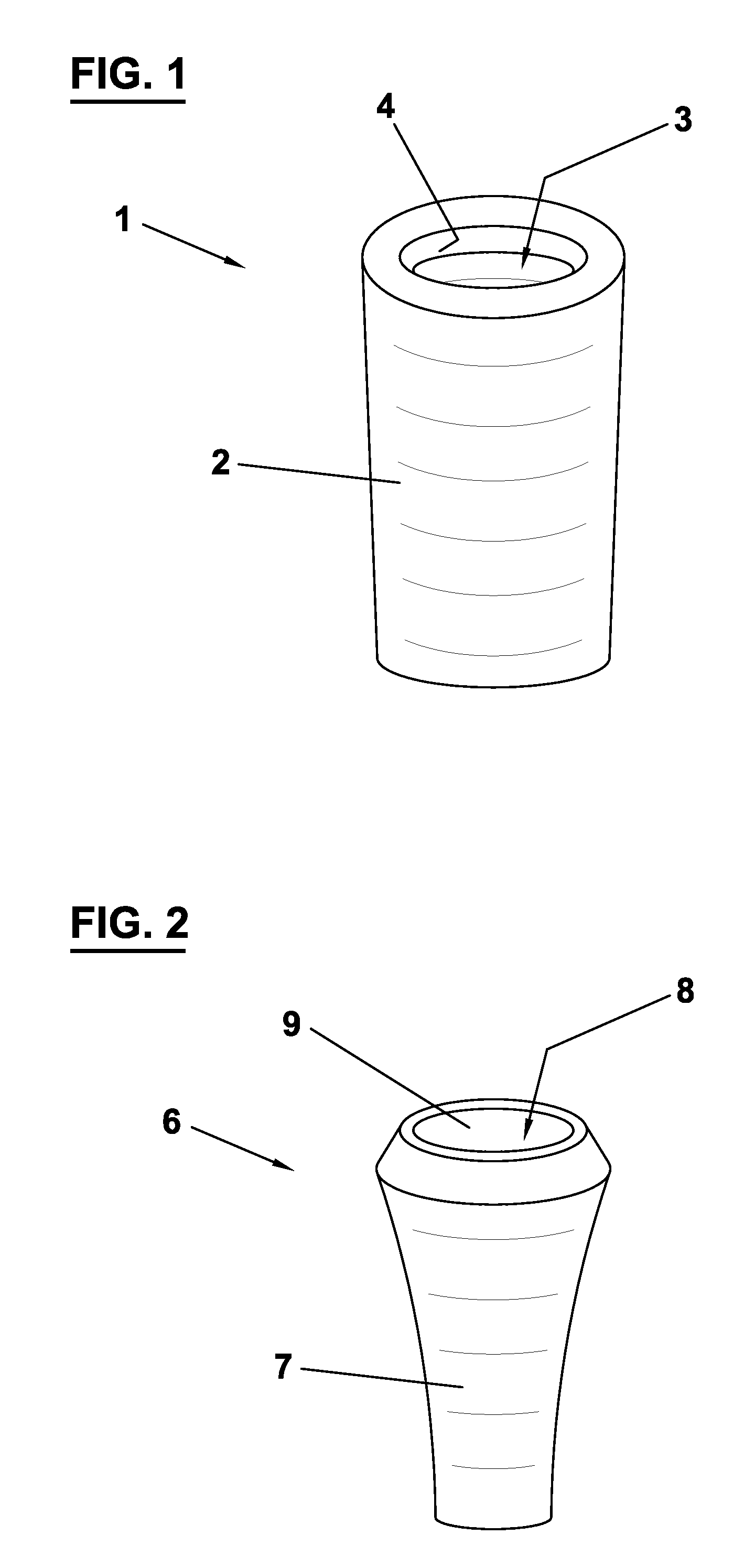

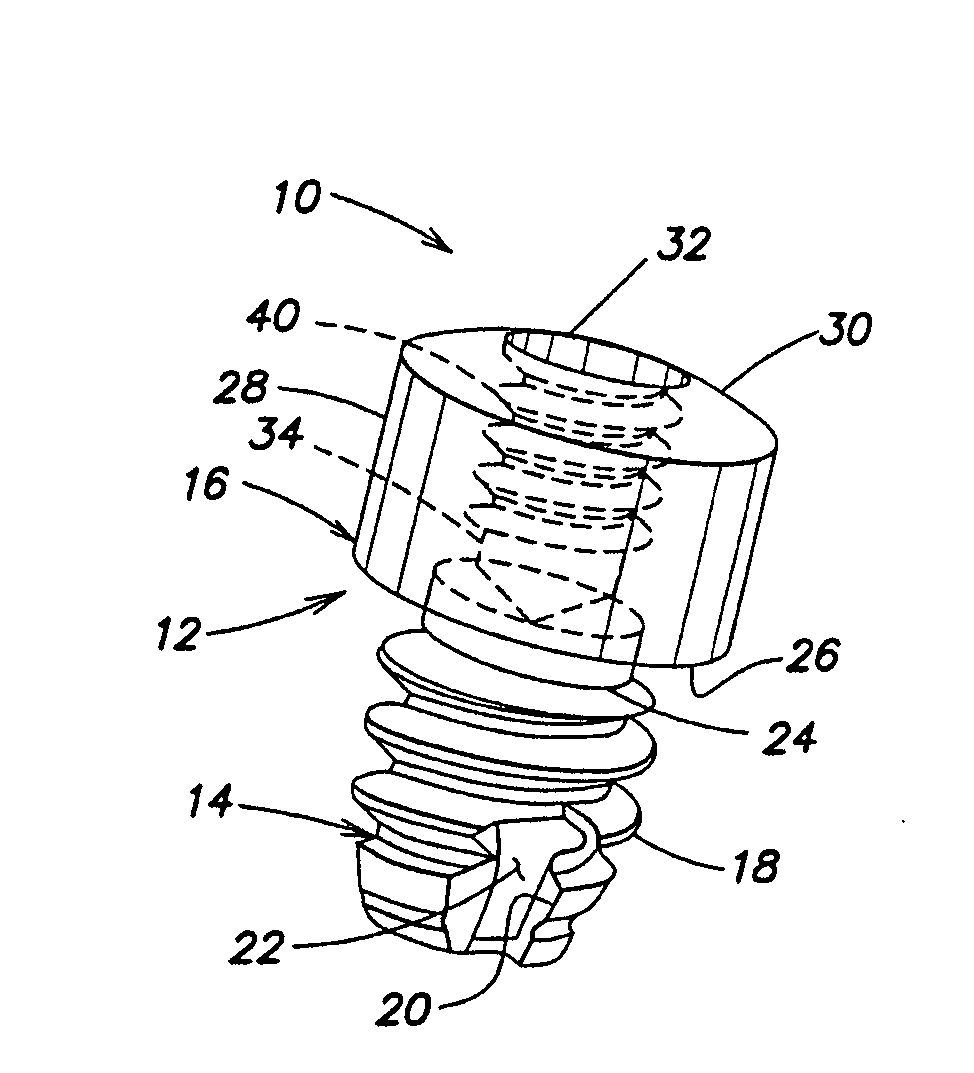

Device for forming a dental prosthesis

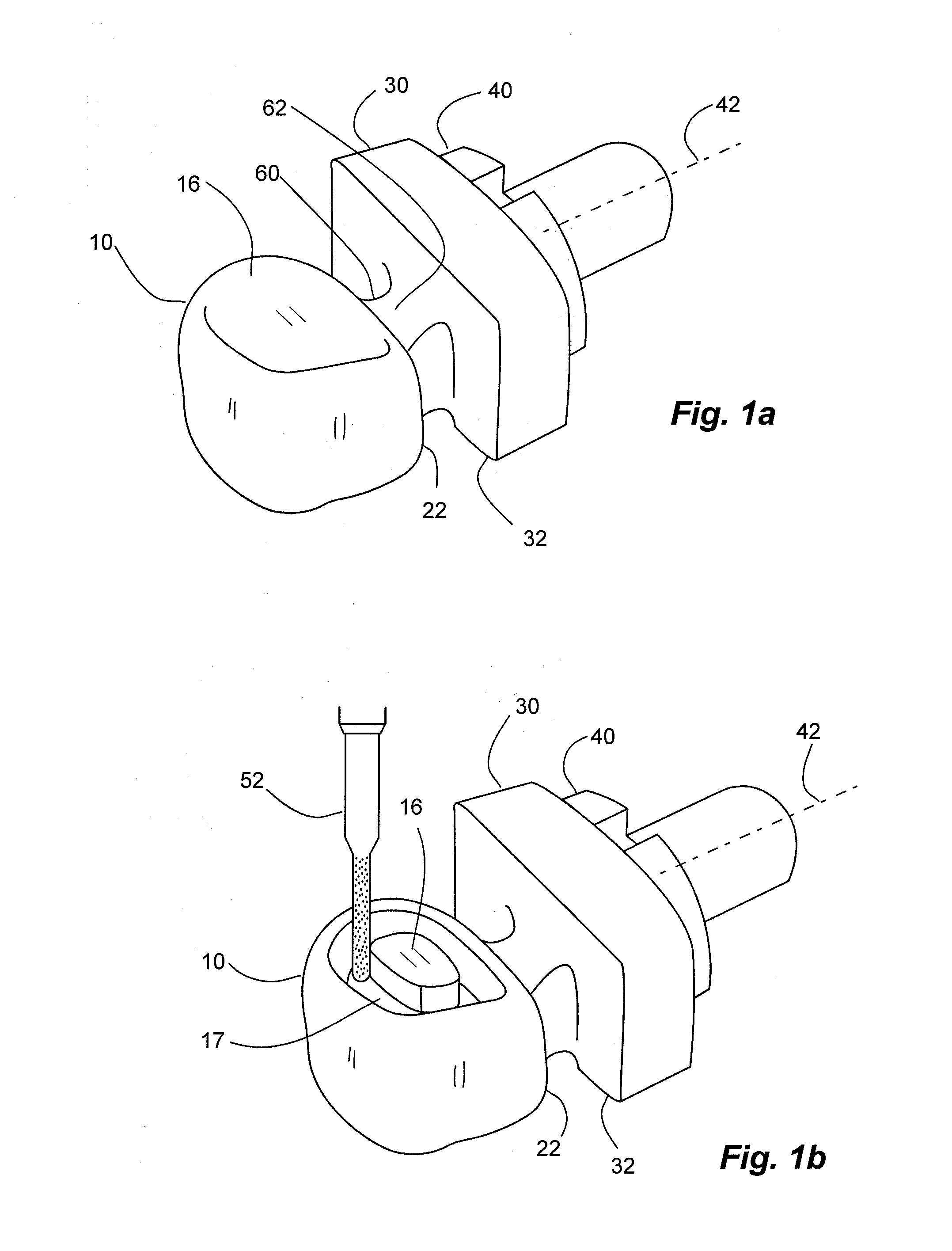

InactiveUS6332777B1Quick releaseOvercome the influence of errorDental implantsImpression capsEngineeringShoulder surface

A device for forming a dental prosthesis includes a support and an element which can be attached thereto, such as an impression element. The support has an anchoring part for anchoring in a bone or a master model, a shoulder with an annular shoulder surface, and a head. The impression element has an elastically deformable fixing agent. When the device is assembled, the fixing agent jams and / or latches with the support, either externally on the support, on the side of the shoulder facing the anchoring part, or in an axial hole of the support. The element can be quickly detachably connected to the support by placing it on top of the support, and can be quickly separated from the support by moving the support away. When the device is assembled, the support and the element can lay on top of each other with annular surfaces. The annular surfaces have fully circular outer edges which are visible from the outside in an approximately radial viewing direction.

Owner:STRAUMANN HLDG AG +1

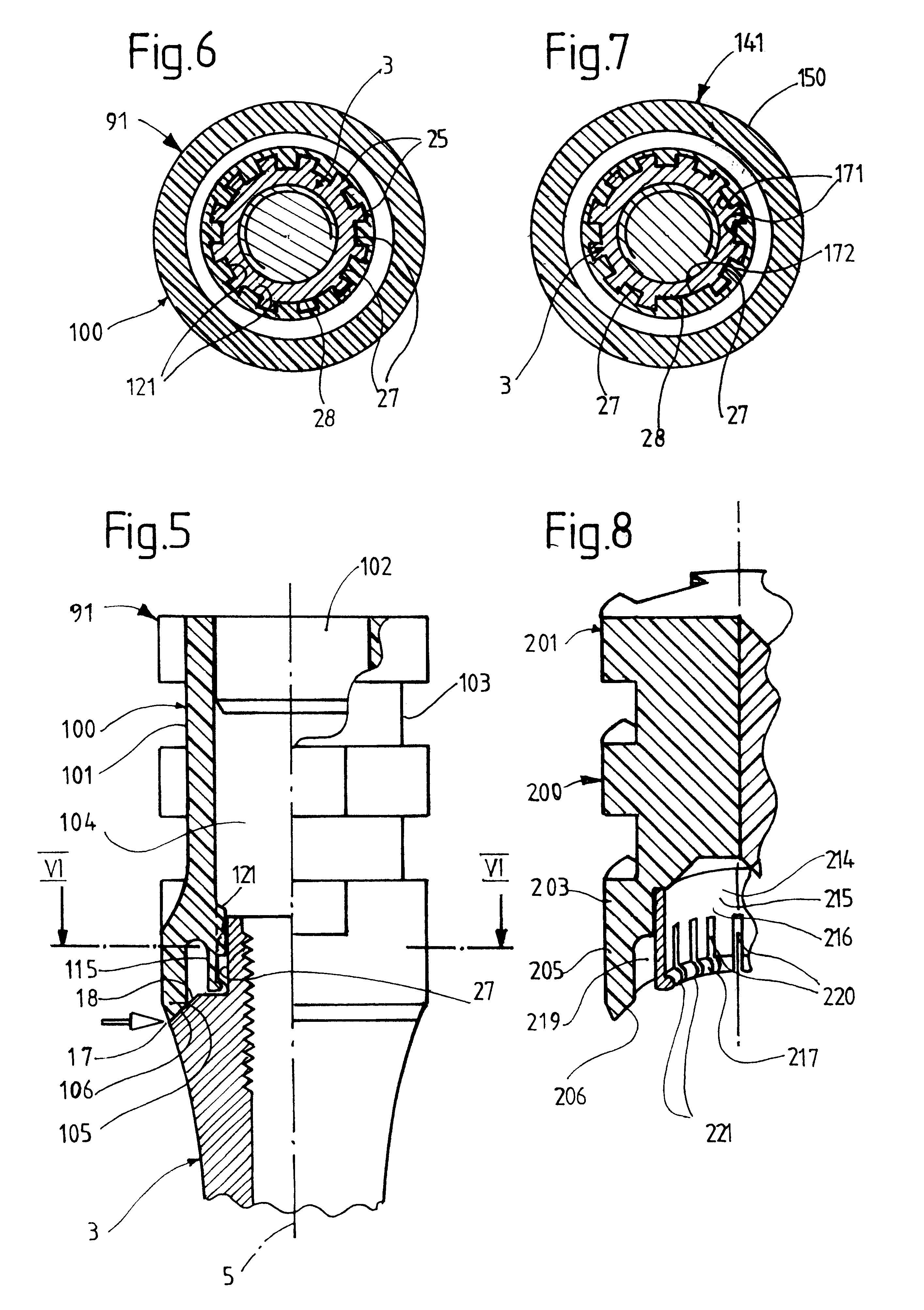

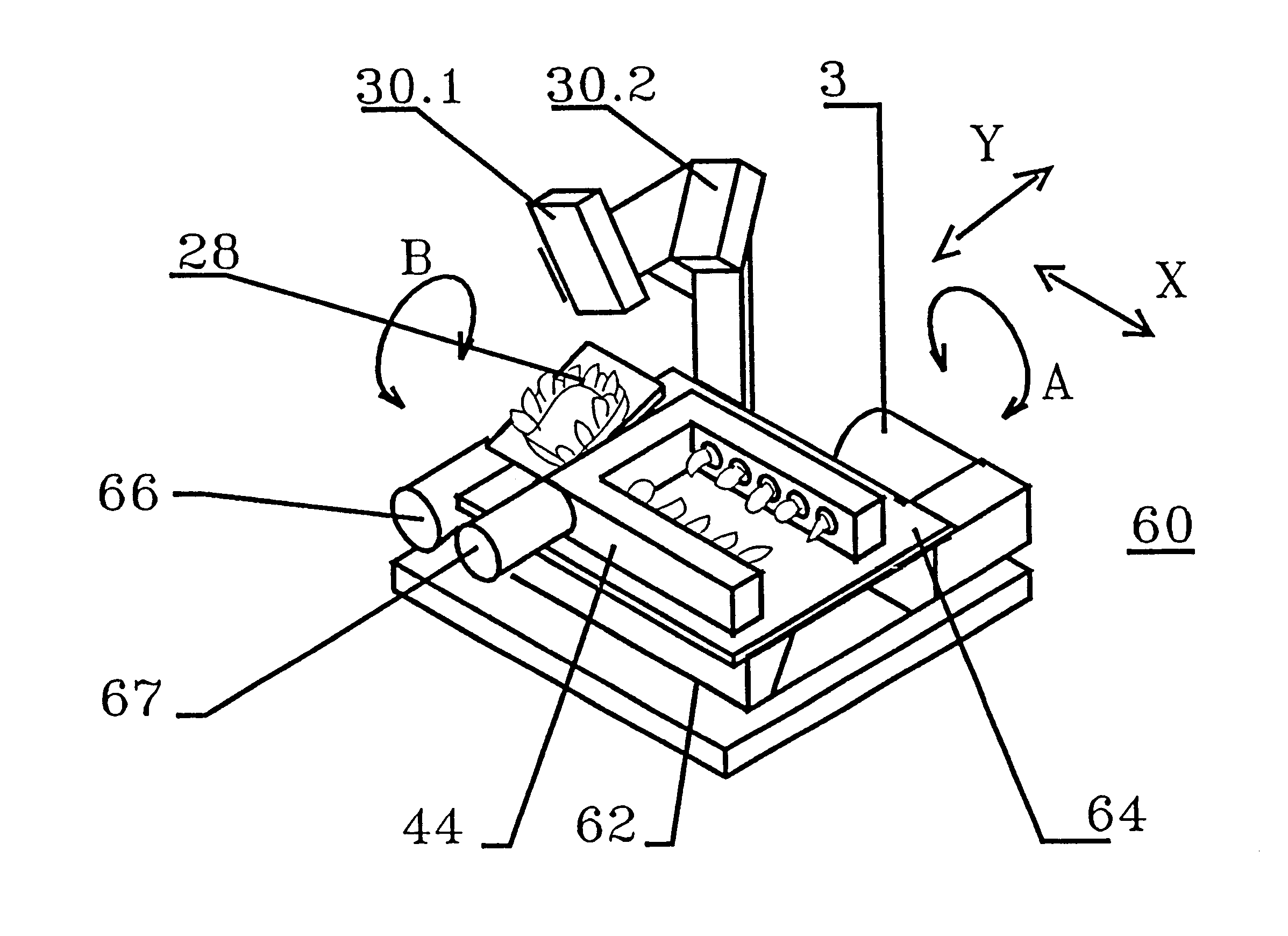

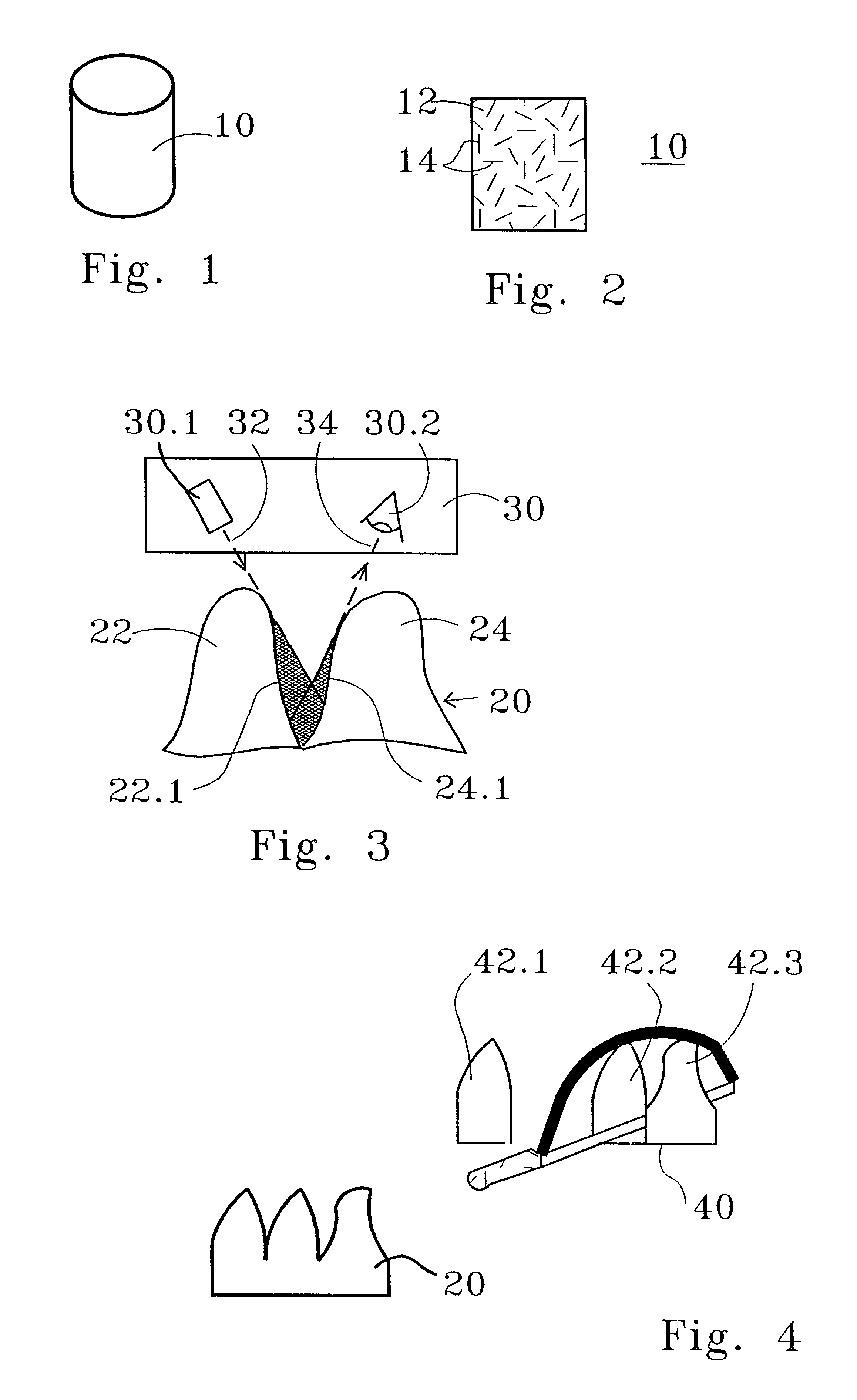

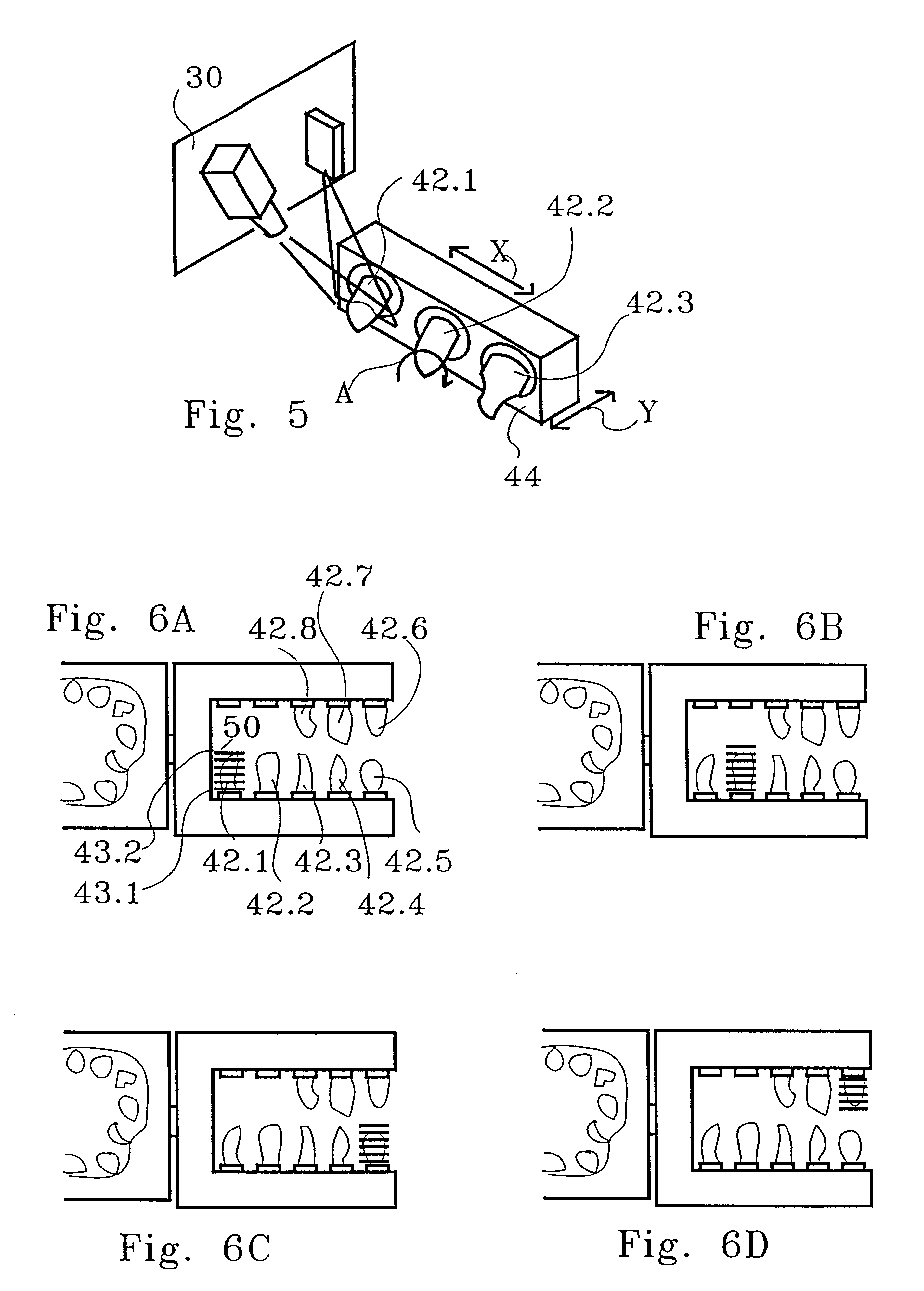

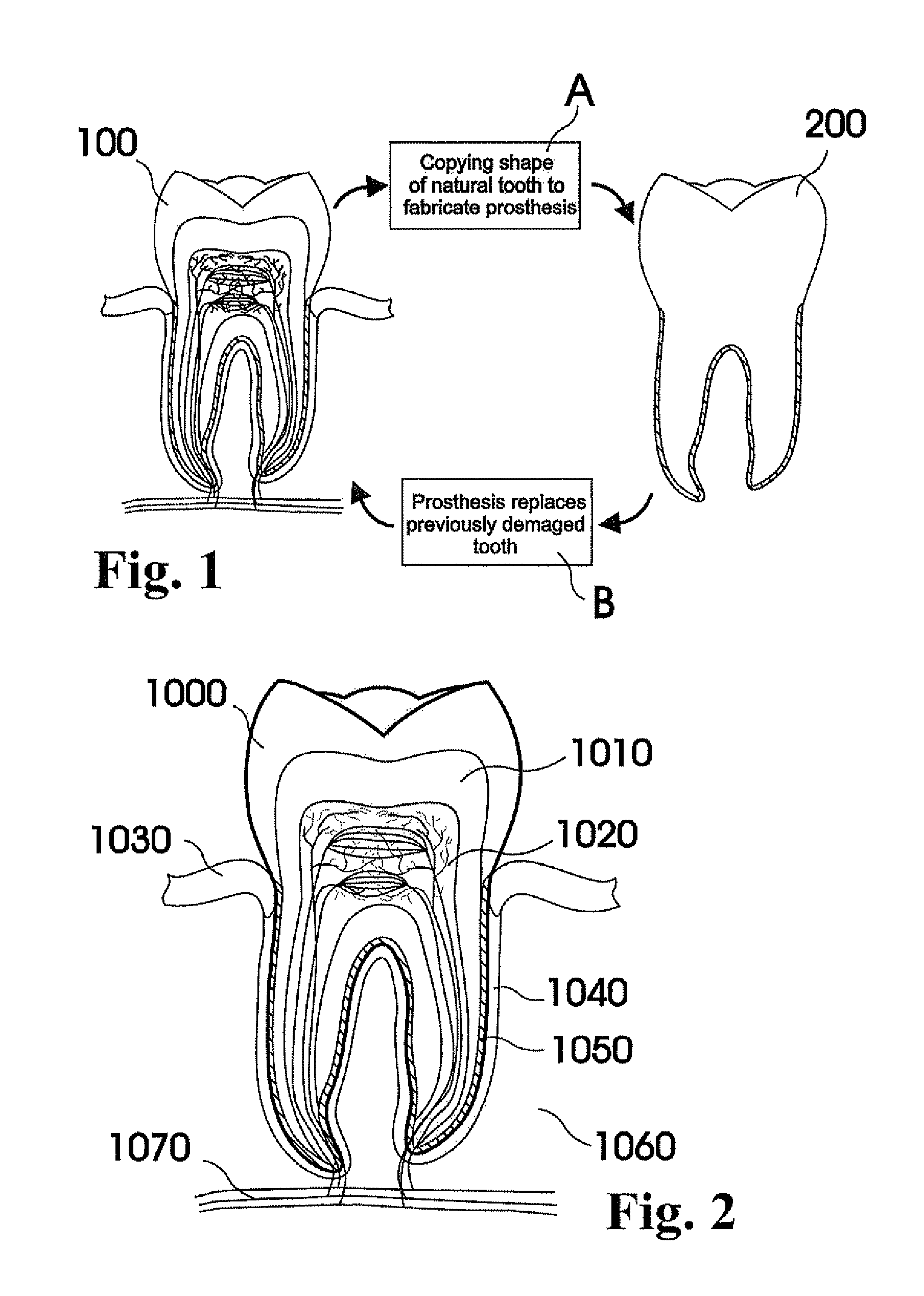

Material for a dental prosthesis, method and device for determining the shape of a remaining tooth area to be provided with a dental prosthesis, method and arrangement for producing a dental prosthesis and use of the arrangement

InactiveUS6287121B1Improve accuracySuitable for processingImpression capsTooth crownsDigital dataGlass fiber

Material for a dental prosthesis consisting of fiber glass reinforced plastic. The material is used to produce a blank by means of a special injection-molding process, which can be worked by means of a machining process. A method and a device for determining the shape of a duplicate of a remaining tooth area to be provided with a dental prosthesis. The shape of the duplicate is determined, as is the shape of duplicate sections into which the duplicate has been divided, the determined data are stored and combined. A method and arrangement for producing a dental prosthesis. The shape of a duplicate (42) of a remaining tooth area to be provided with the dental prosthesis is determined by means of a shape determination device (110), the determined data are stored in the form of digital data (DD), and the dental prosthesis (143) is produced in a production machine (114), which is controlled by means of production data (FD). The shape determination device (110) and the production machine (114) are coupled by means of an EDP installation (118), which contains a memory unit for storing the digital data (DD) and performs the calculation of the production data (FD).

Owner:STRAUMANN HLDG AG +2

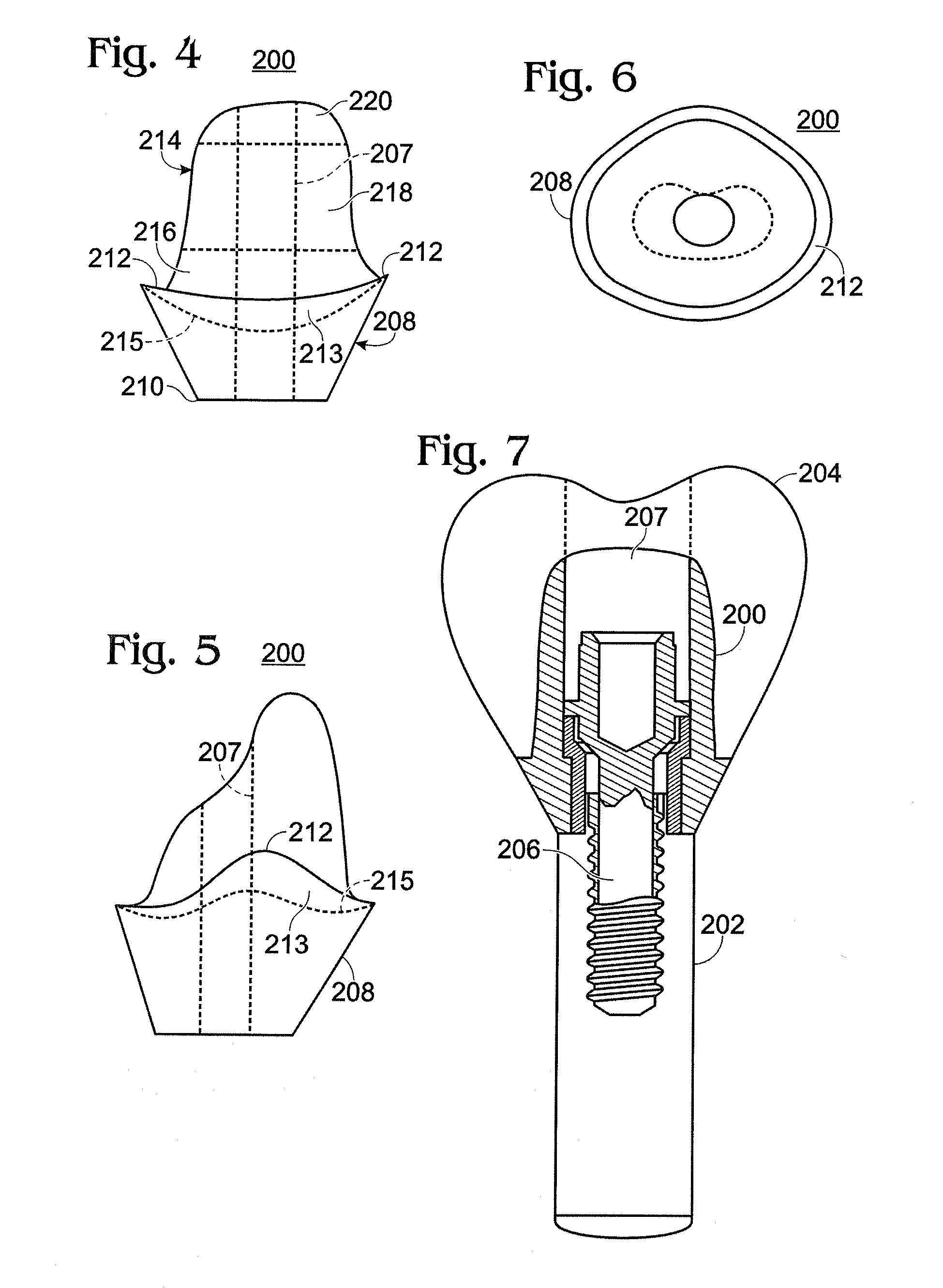

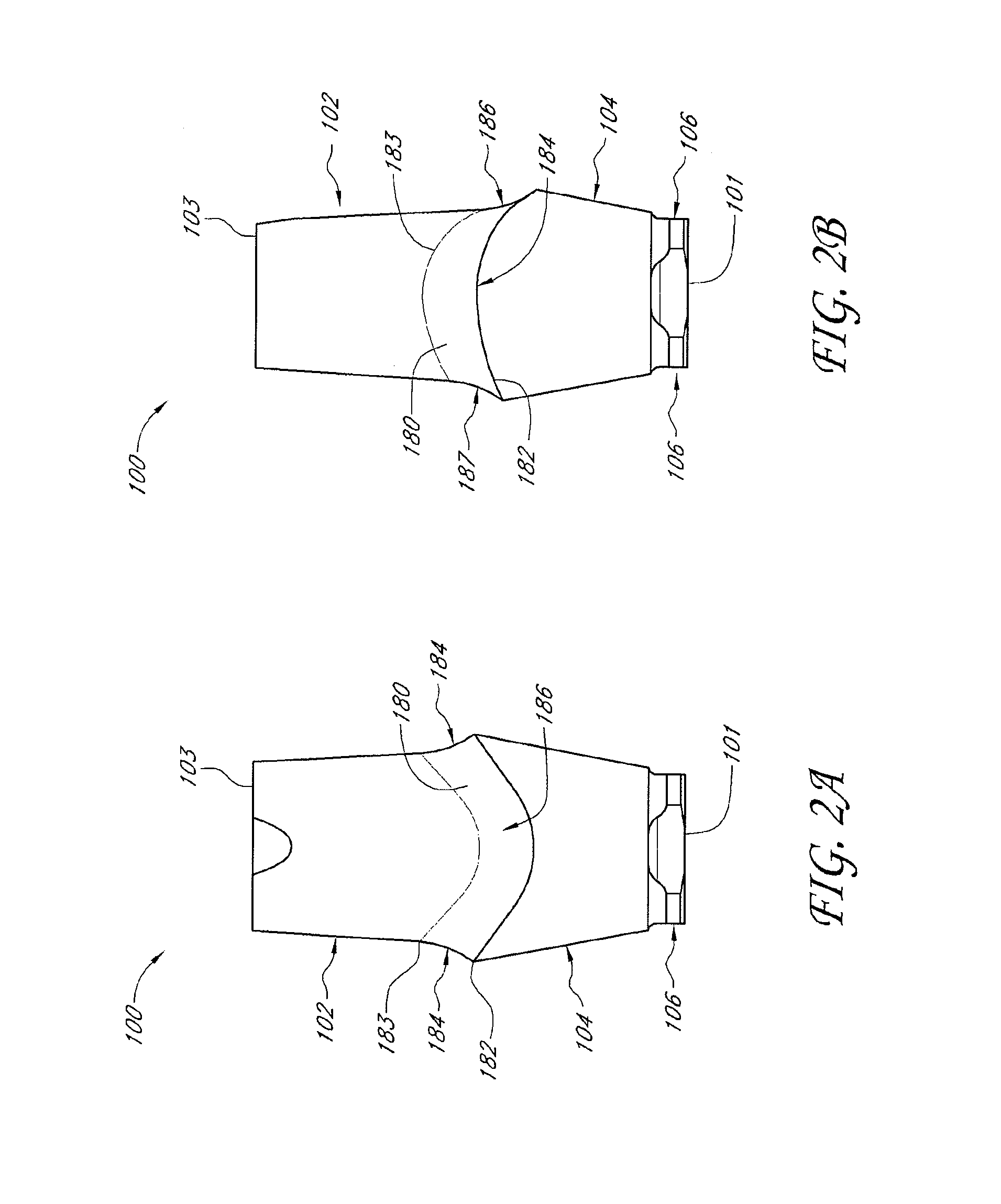

Dental Implant Abutment

A dental implant abutment for attaching a dental prosthesis within a patient's mouth. The abutment is a single unit structure fabricated of a ceramic material, multicolored throughout to match the color of the dental prosthesis, the surrounding dentition and the surrounding gingival tissue.

Owner:IVOCLAR VIVADENT AG

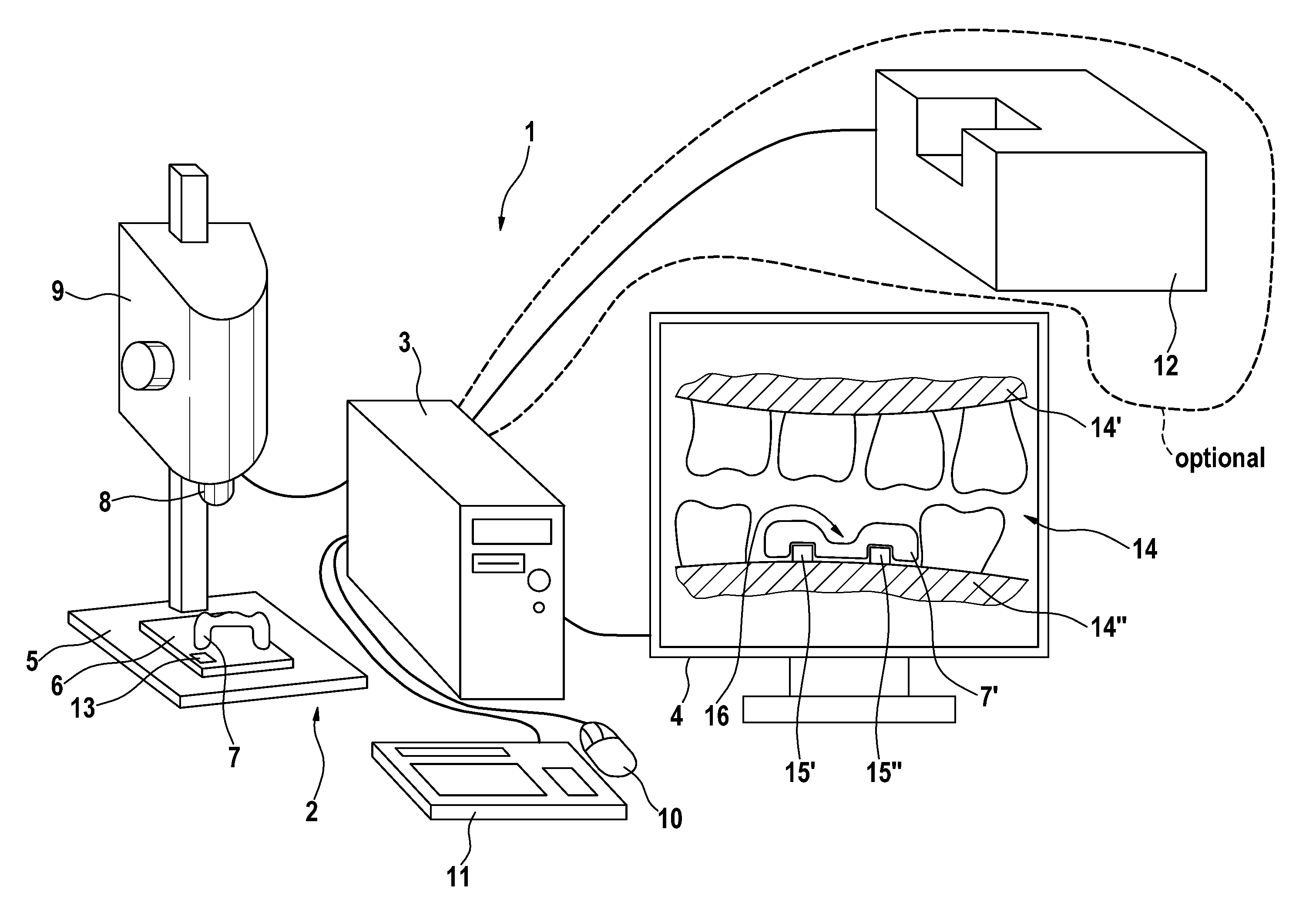

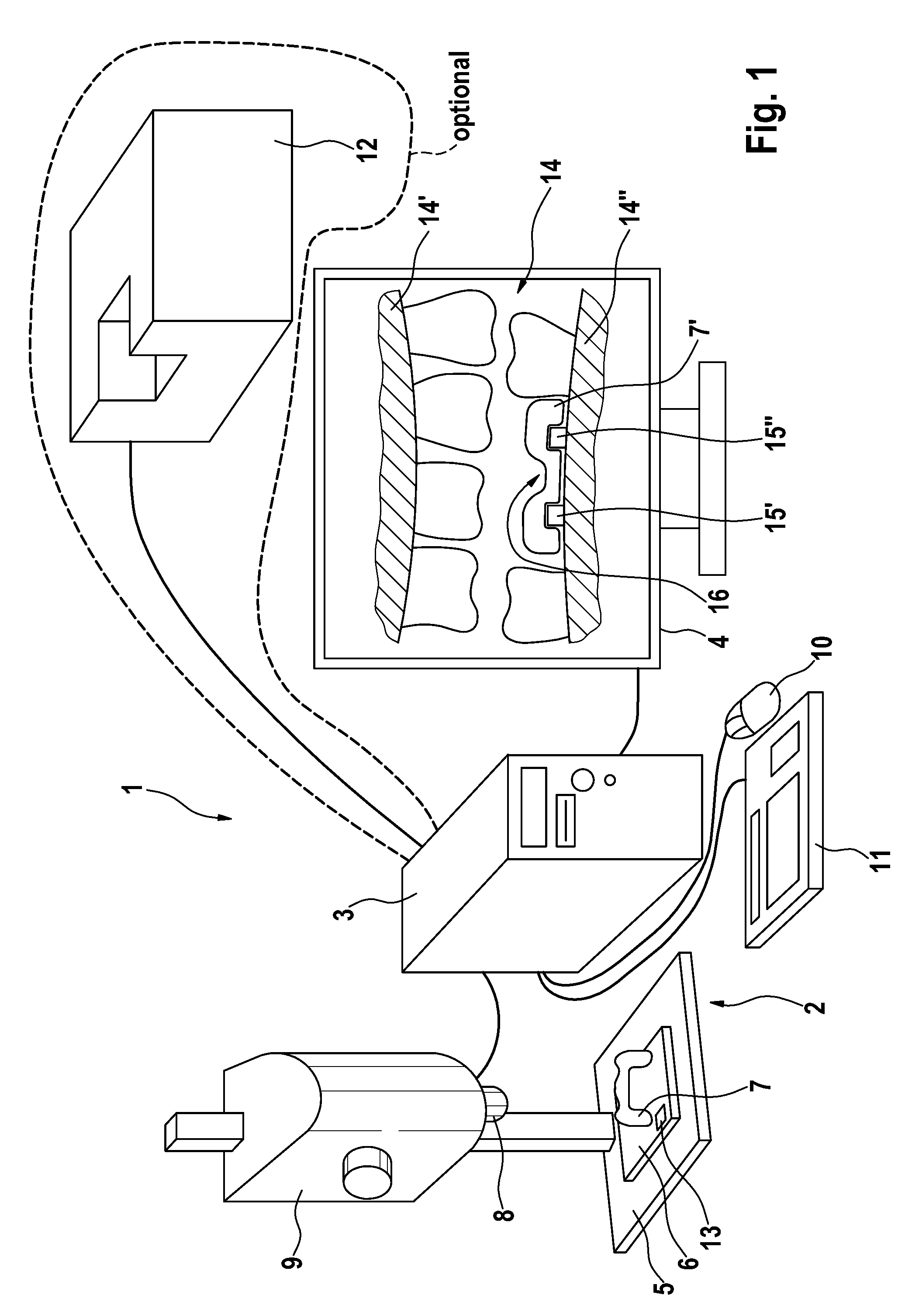

Method and device for producing dental prosthesis elements

InactiveUS7865261B2Accurate fitRetain controlDental implantsAdditive manufacturing apparatusGraphicsDentures

Owner:SIRONA DENTAL SYSTEMS

Method for forming a dental prosthesis

Owner:BIOMET 3I INC

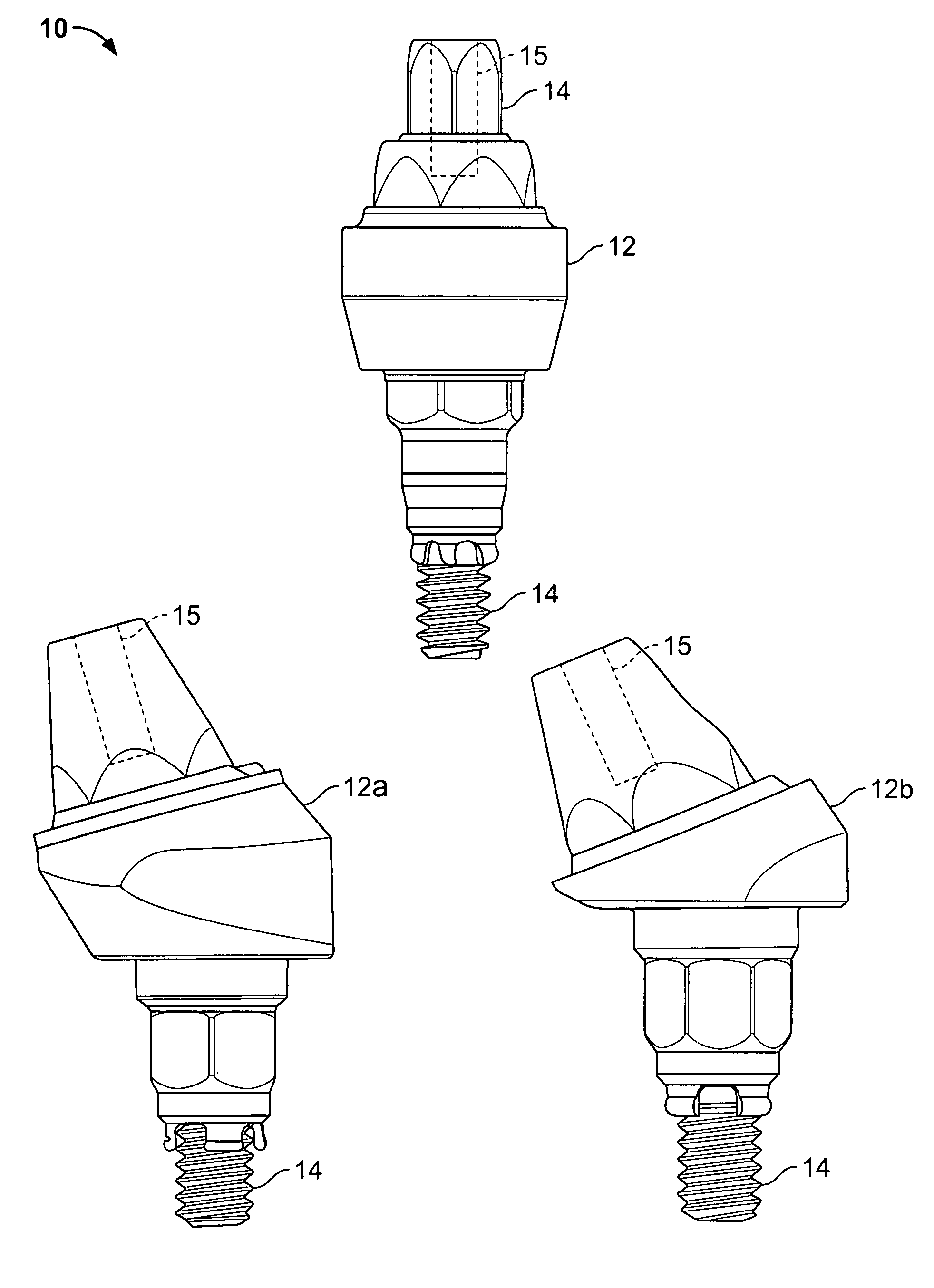

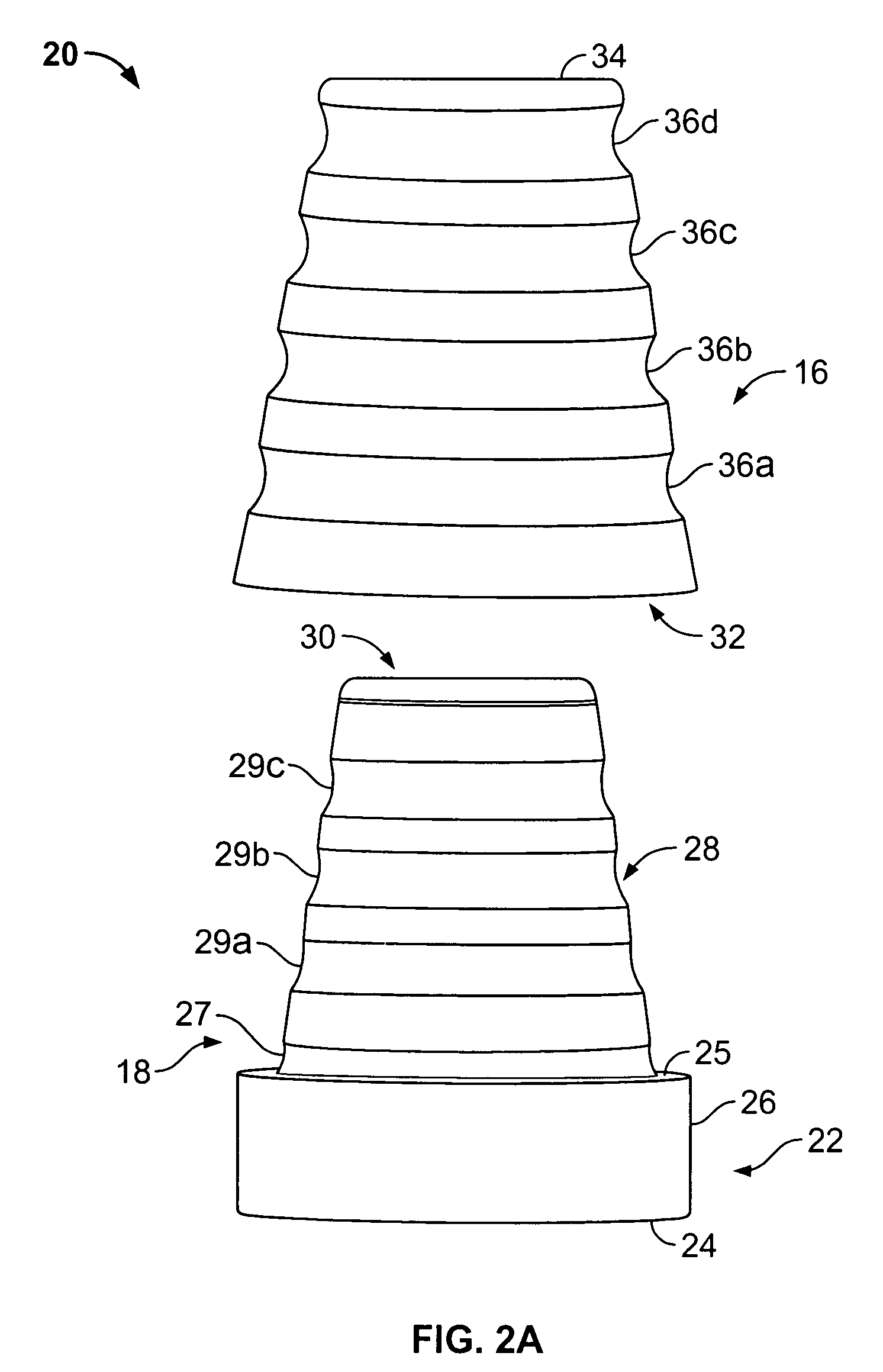

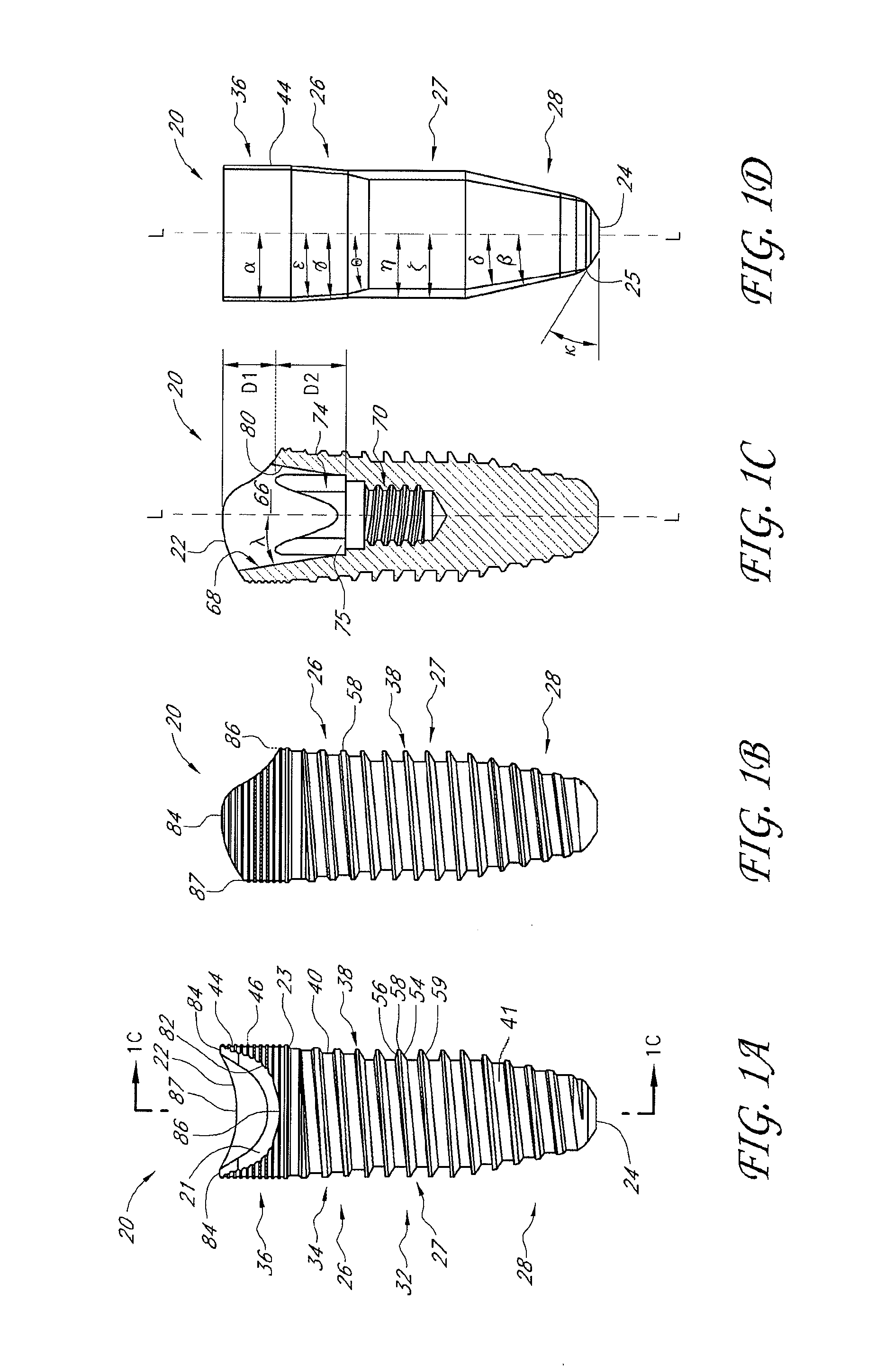

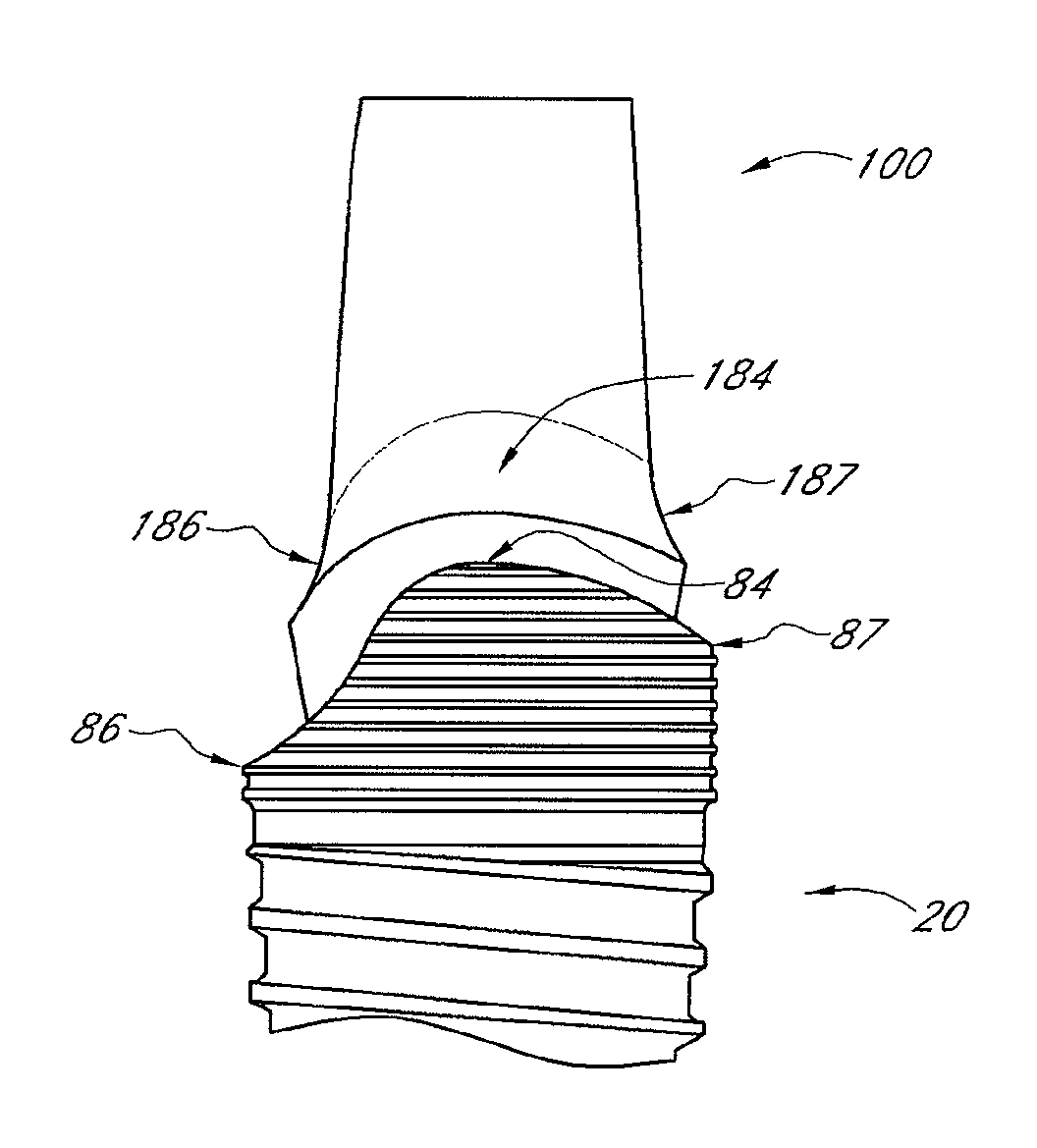

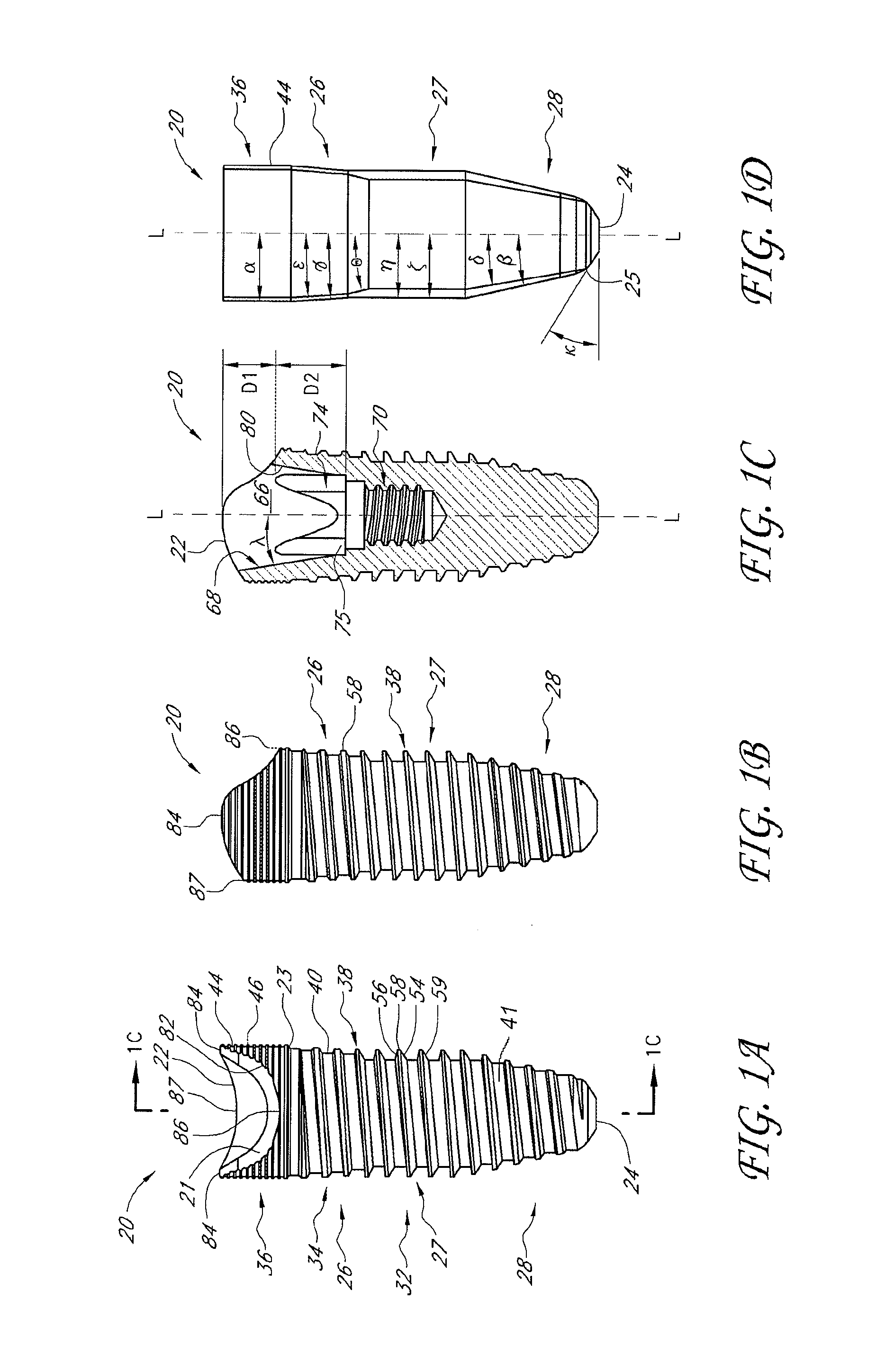

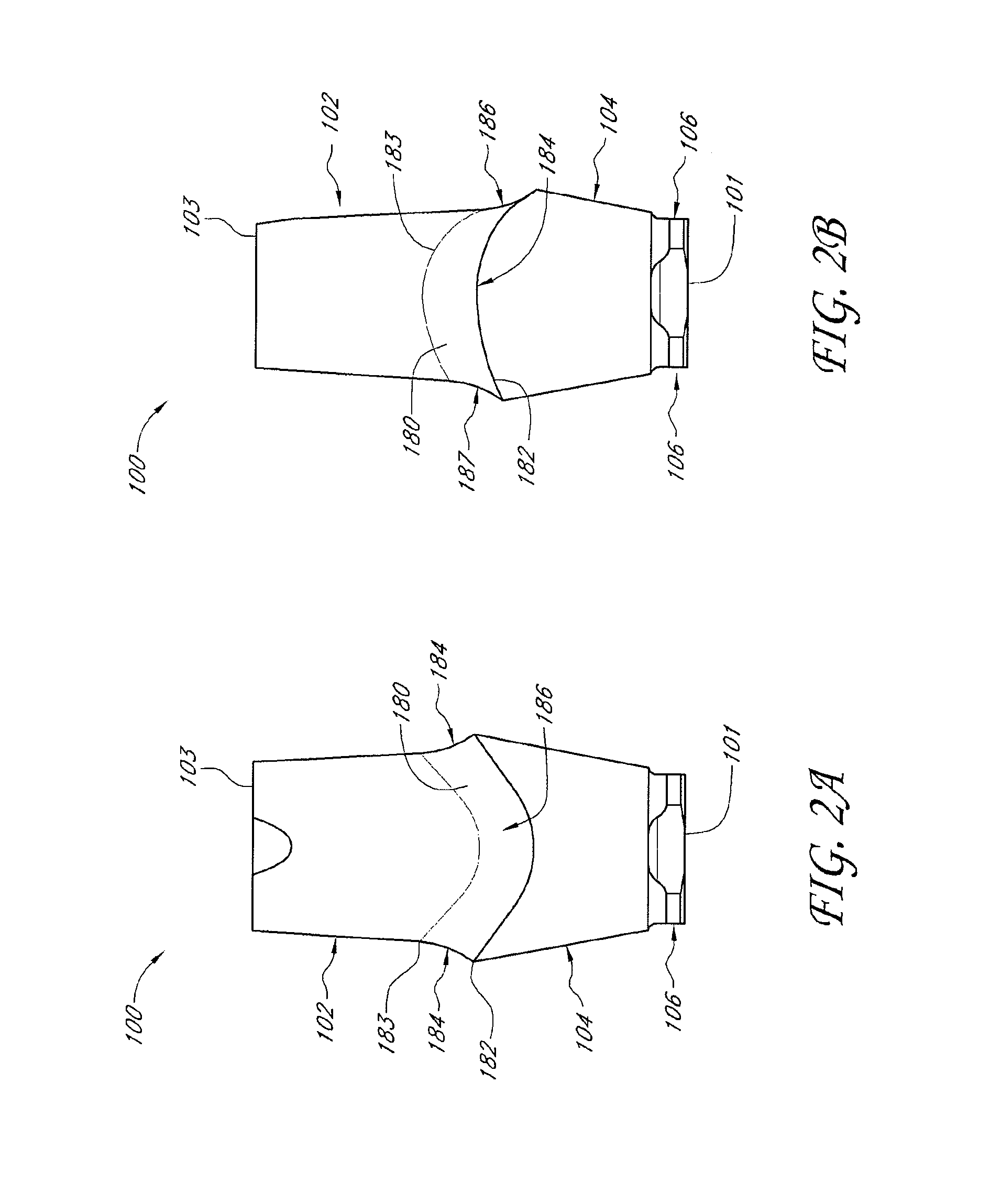

Asymmetrical dental implant

A dental implant is provided for supporting a dental prosthesis. The implant can comprise a body having an outer surface, an apical end, and a coronal portion. The dental implant can include at least one thread located on at least a portion of the outer surface of the body. The dental implant can include a collar having a top surface that defines two peaks and two valleys, where the one valley is more coronal than the second valley.

Owner:WOHRLE PETER +1

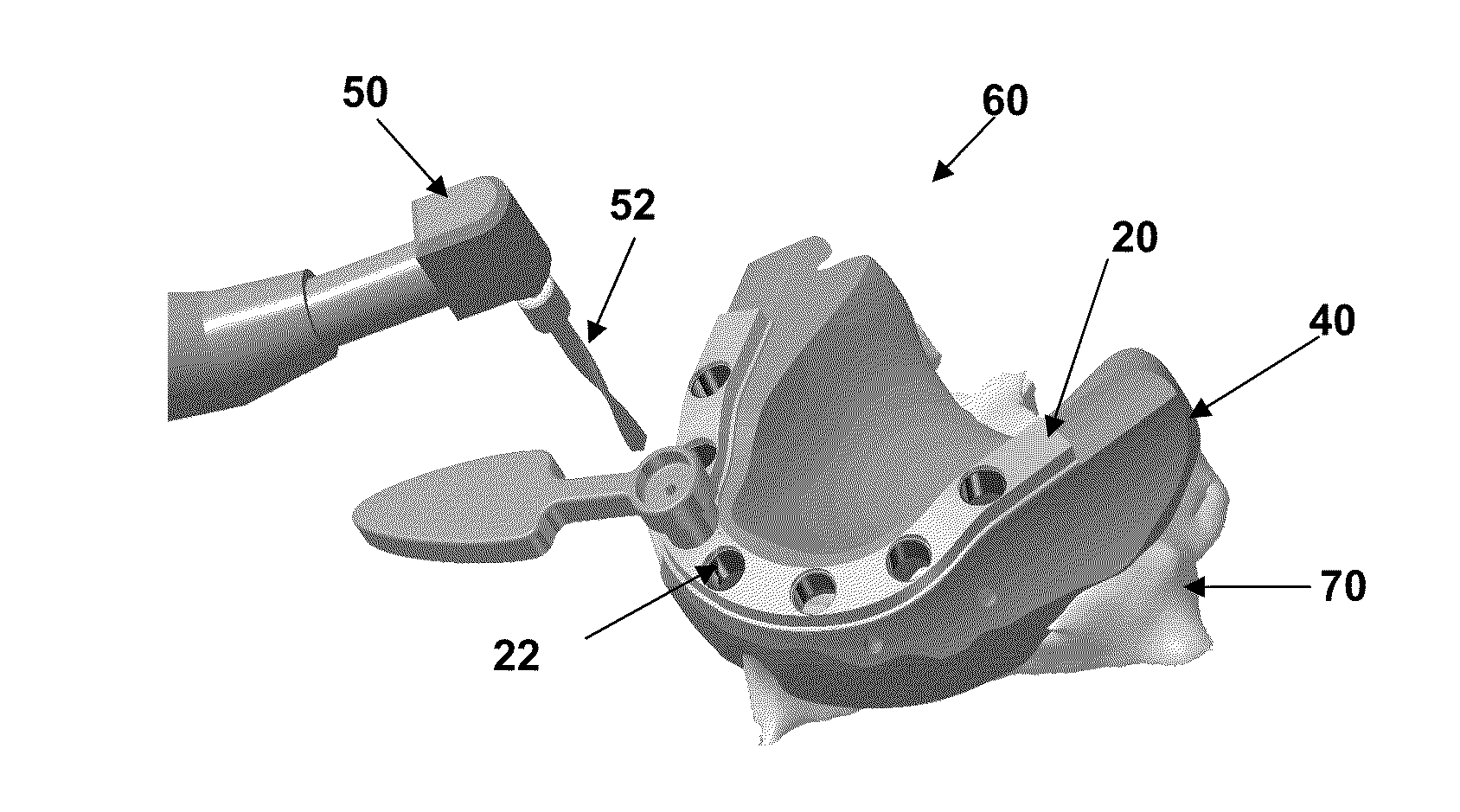

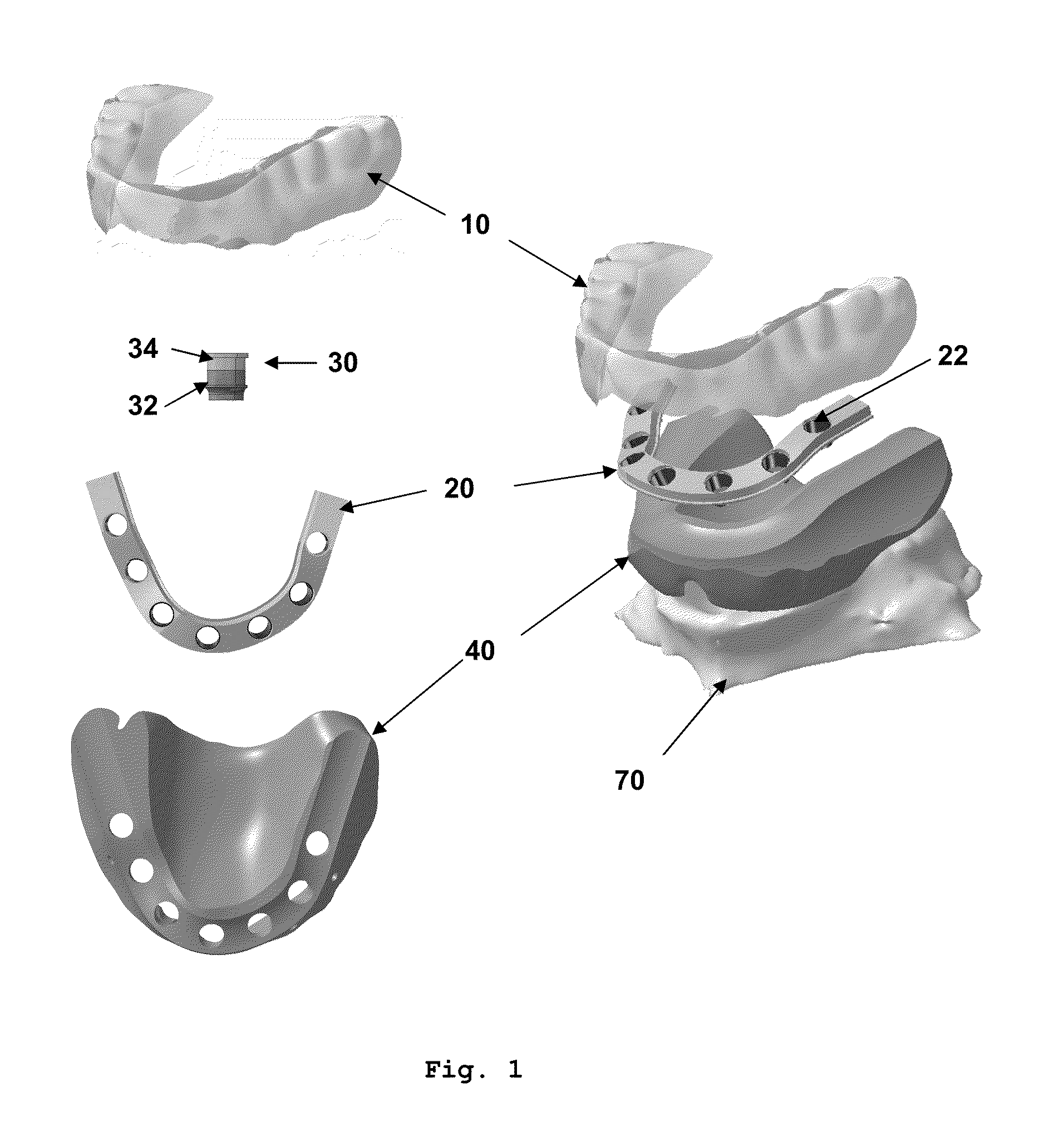

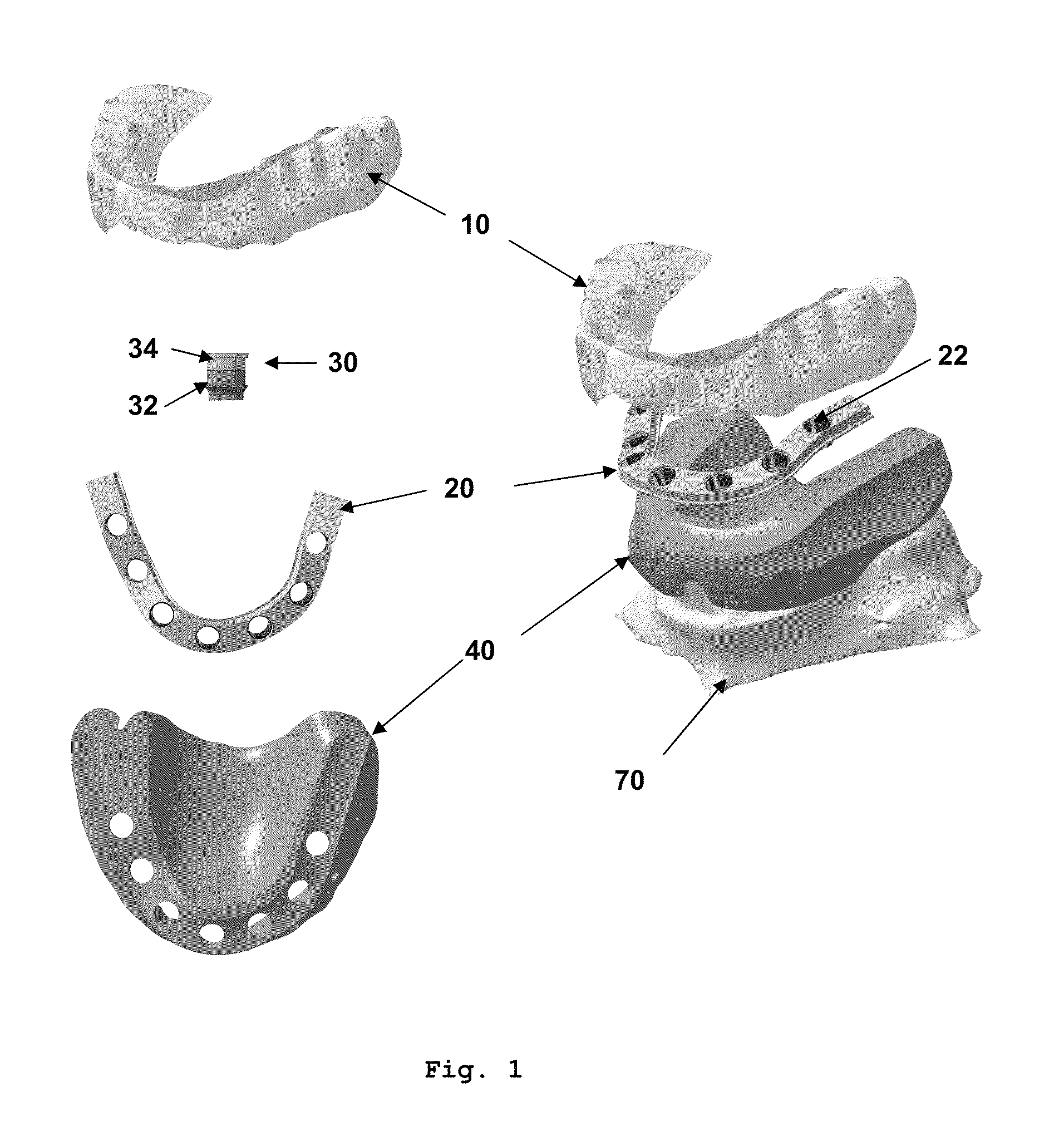

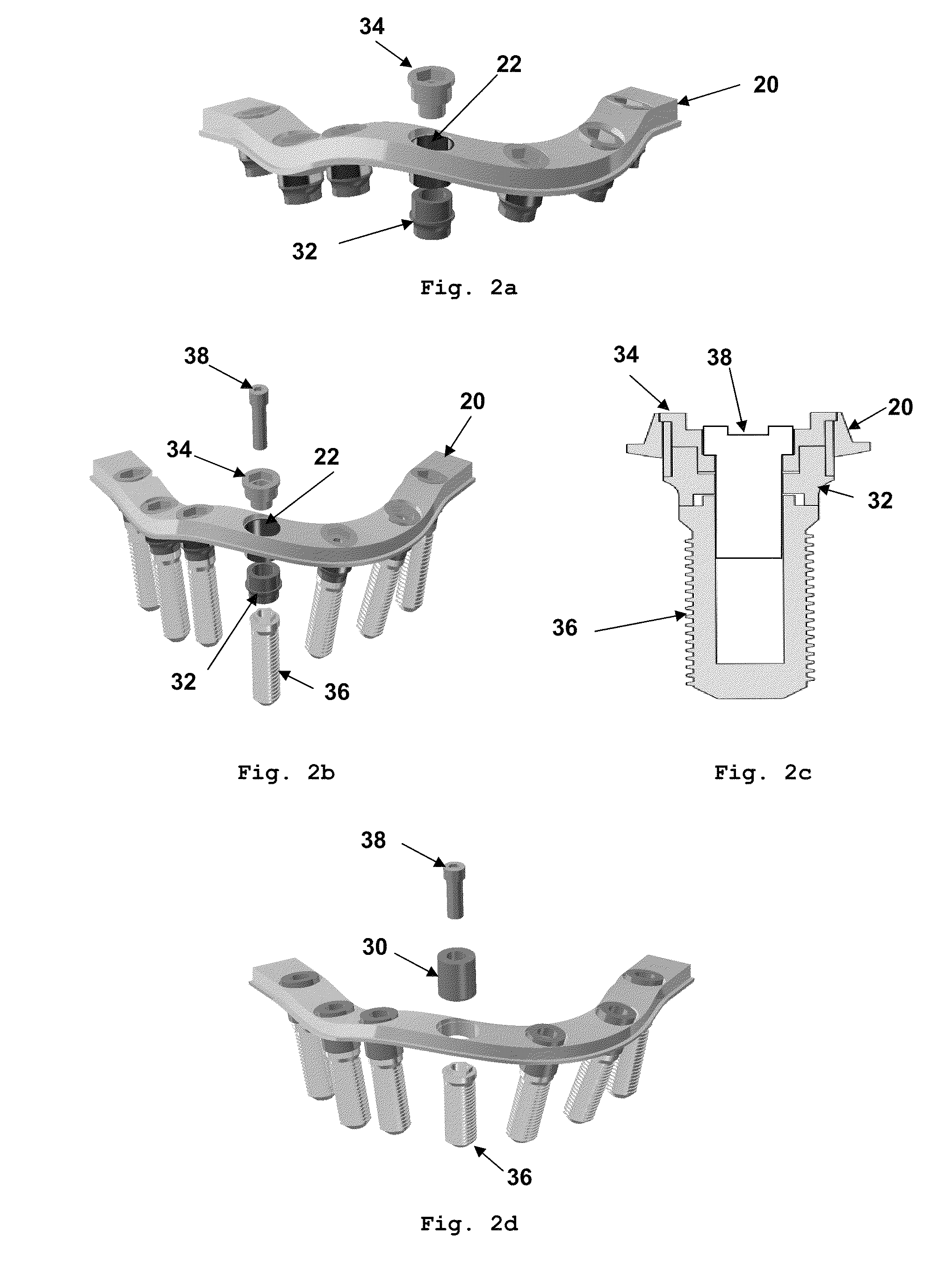

Dental prosthesis system

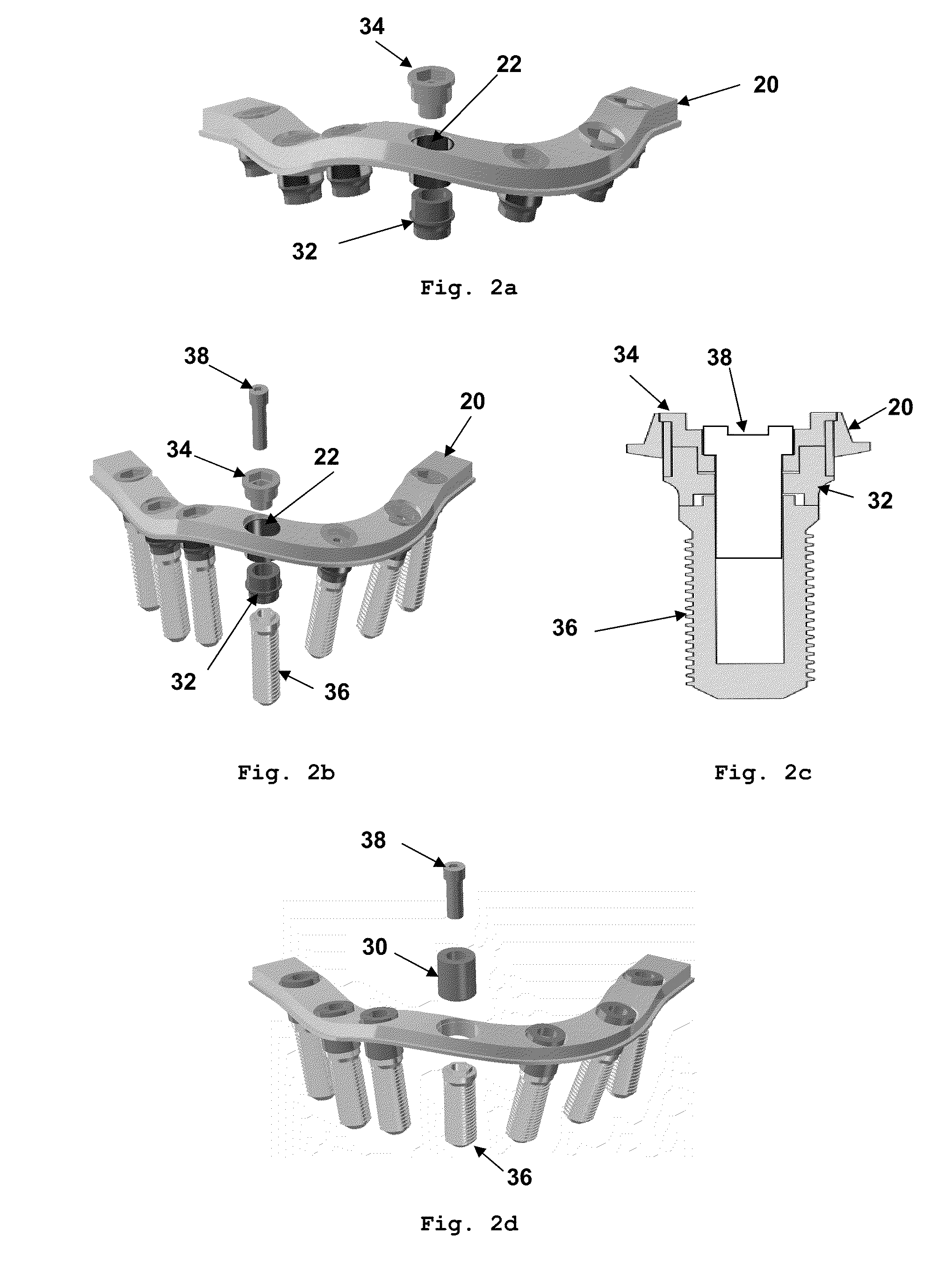

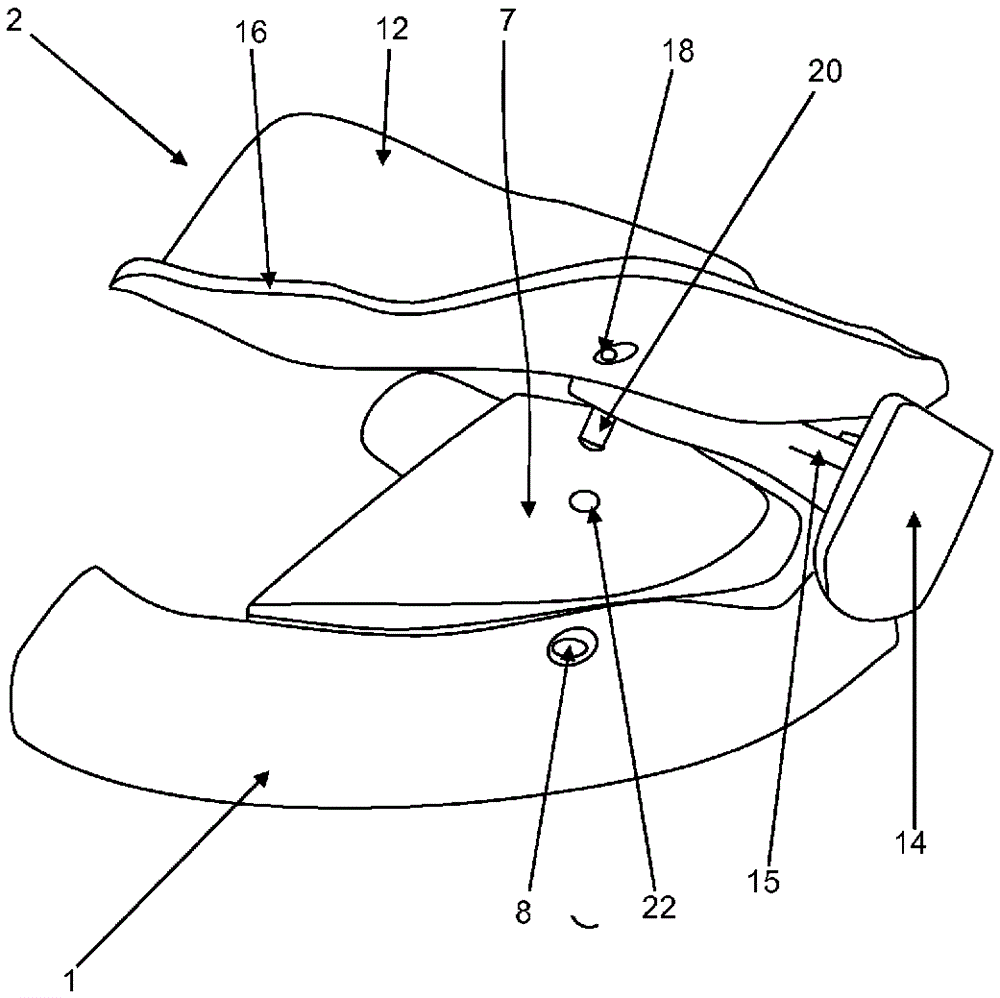

The present disclosure relates to a dental prosthesis system and a method of using same comprising a prosthesis, a primary bar, and a base-plate. The primary bar is adapted to be received on the implants and to be used as a superstructure for supporting the prosthesis, a verification jig and / or an impression matrix. The base-plate has a shape adapted to be received on the patient's gum surface, comprising at least one hole each in alignment with a corresponding one of the aperture of the primary bar when the primary bar is seated on the base-plate, each hole of the base-plate correspond to the position of each implant hole, the base-plate supporting the primary bar to form a drilling guide for guiding the drilling of implants holes in the patient's gum surface.

Owner:INSTITUT STRAUMANN AG

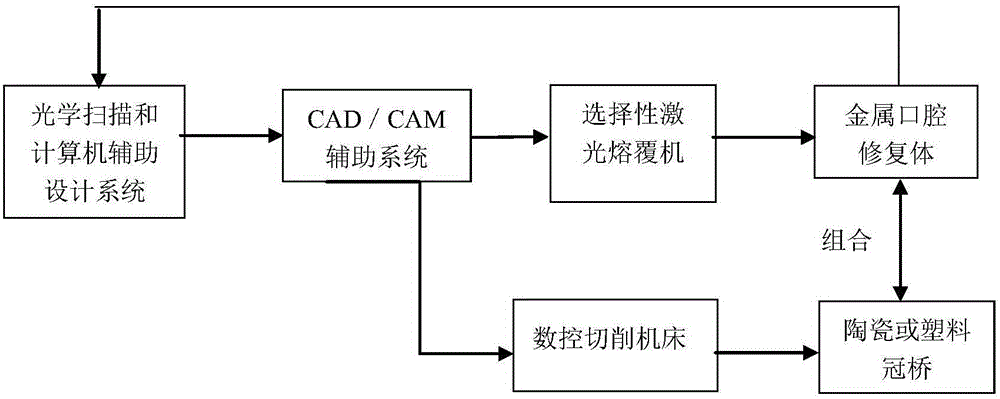

Automatic CAD/CAM/3D processing method of dental prostheses

The invention relates to an automatic CAD / CAM / 3D processing method of dental prostheses. The method comprises the step of processing dental prostheses by employing a composite system composed of an optical scanner and a computer aided design system, a CAD / CAM aided system, a selective laser cladding machine and a numerical control cutting machine tool, wherein prostheses such as removable partial dentures, fixed dentures, complete dentures and implant dentures can be rapidly manufactured. The method is characterized in that numerical control cutting (subtractive manufacturing called as subtraction) and the 3D printing technology (additive manufacturing called as addition) are organically combined and highly unified. Two aspects of the unity and opposites are merged into one uniform aspect; the automatic production efficiency of the dental prostheses, especially complex prostheses, can be greatly improved, complicated procedures of a conventional handmade dental prosthesis are eliminated, the manufacturing quality and stability of the prostheses are improved, the purposes of quickness, accuracy and individualized manufacturing are achieved, and the dental prostheses meet the urgent demands of most agomphosis patients.

Owner:维视医疗信息科技山东有限公司

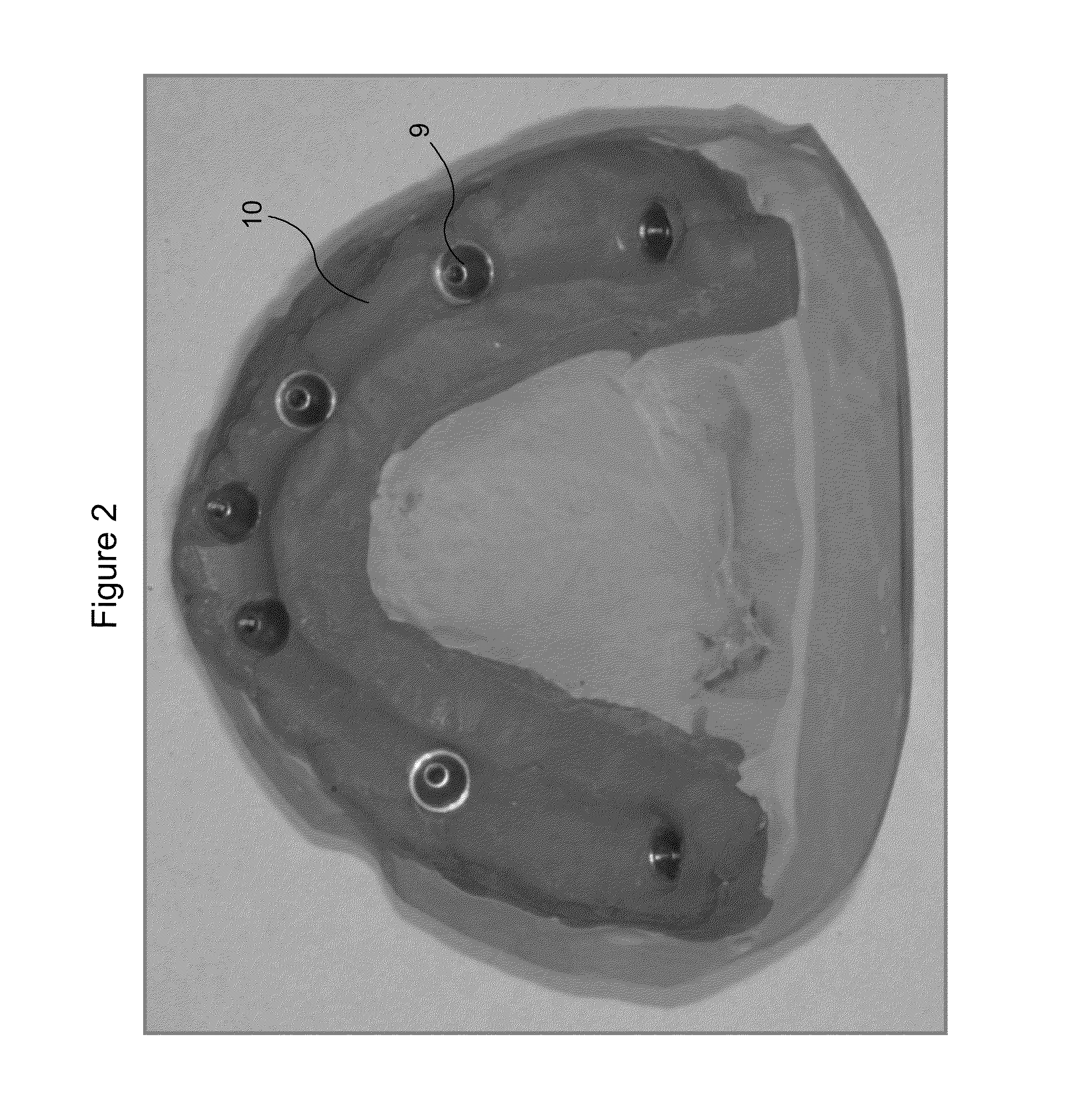

Dental prosthesis system

A dental prosthesis system and a method of using same having a prosthesis, a primary bar, and a base-plate. The primary bar is adapted to be received on the implants and to be used as a superstructure for supporting the prosthesis and / or a verification jig. The base-plate has a shape adapted to be received on the patient's gum surface, having at least one hole each in alignment with a corresponding one of the aperture of the primary bar when the primary bar is seated on the base-plate, each hole of the base-plate correspond to the position of each implant hole, the base-plate supporting the primary bar to form a drilling guide for guiding the drilling of implants holes in the patient's jawbone, an impression matrix for creating a physical model of the patient's mouth with implants, and / or a superstructure when removable cylinders are attached to the primary bar.

Owner:INSTITUT STRAUMANN AG

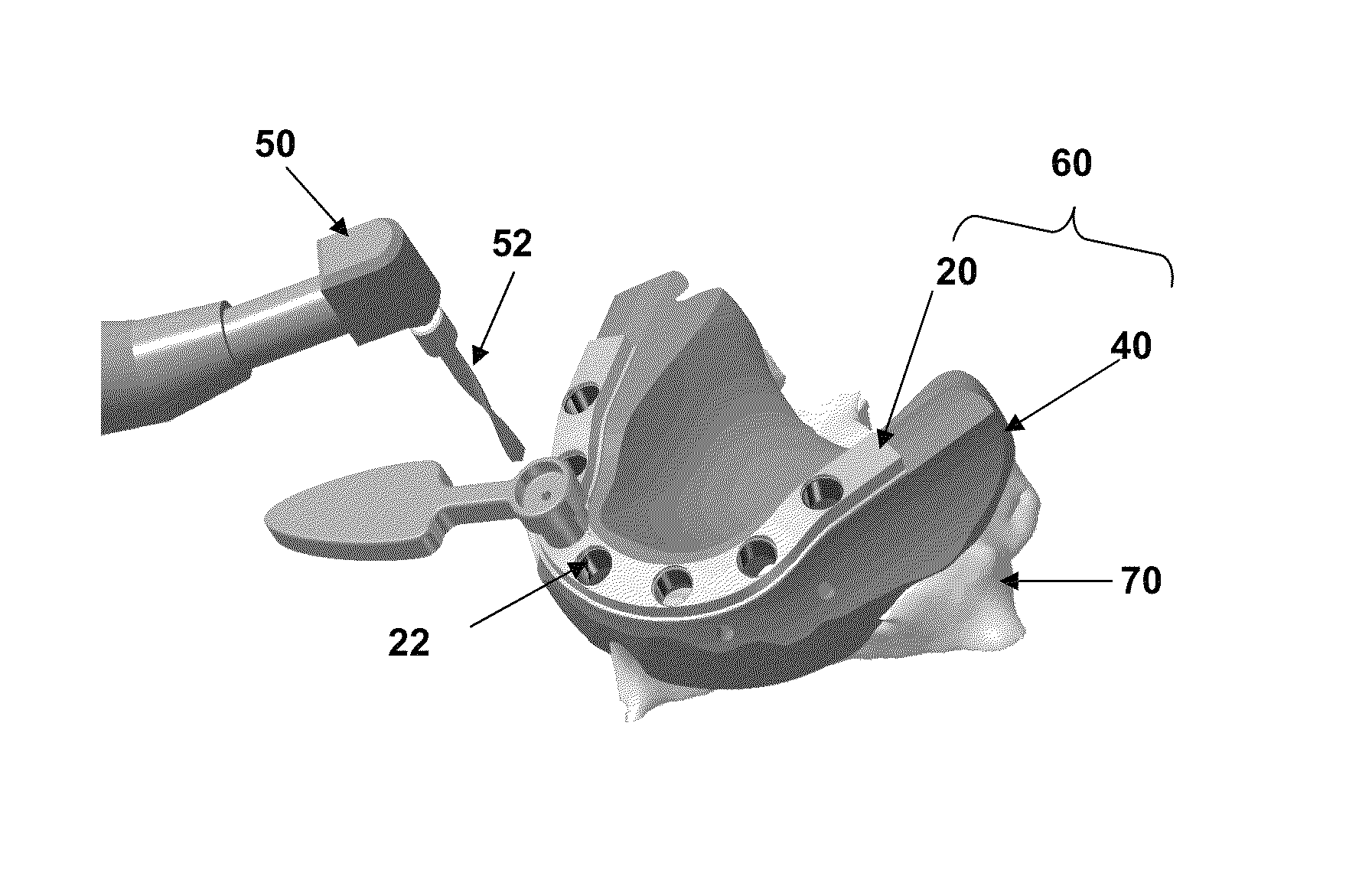

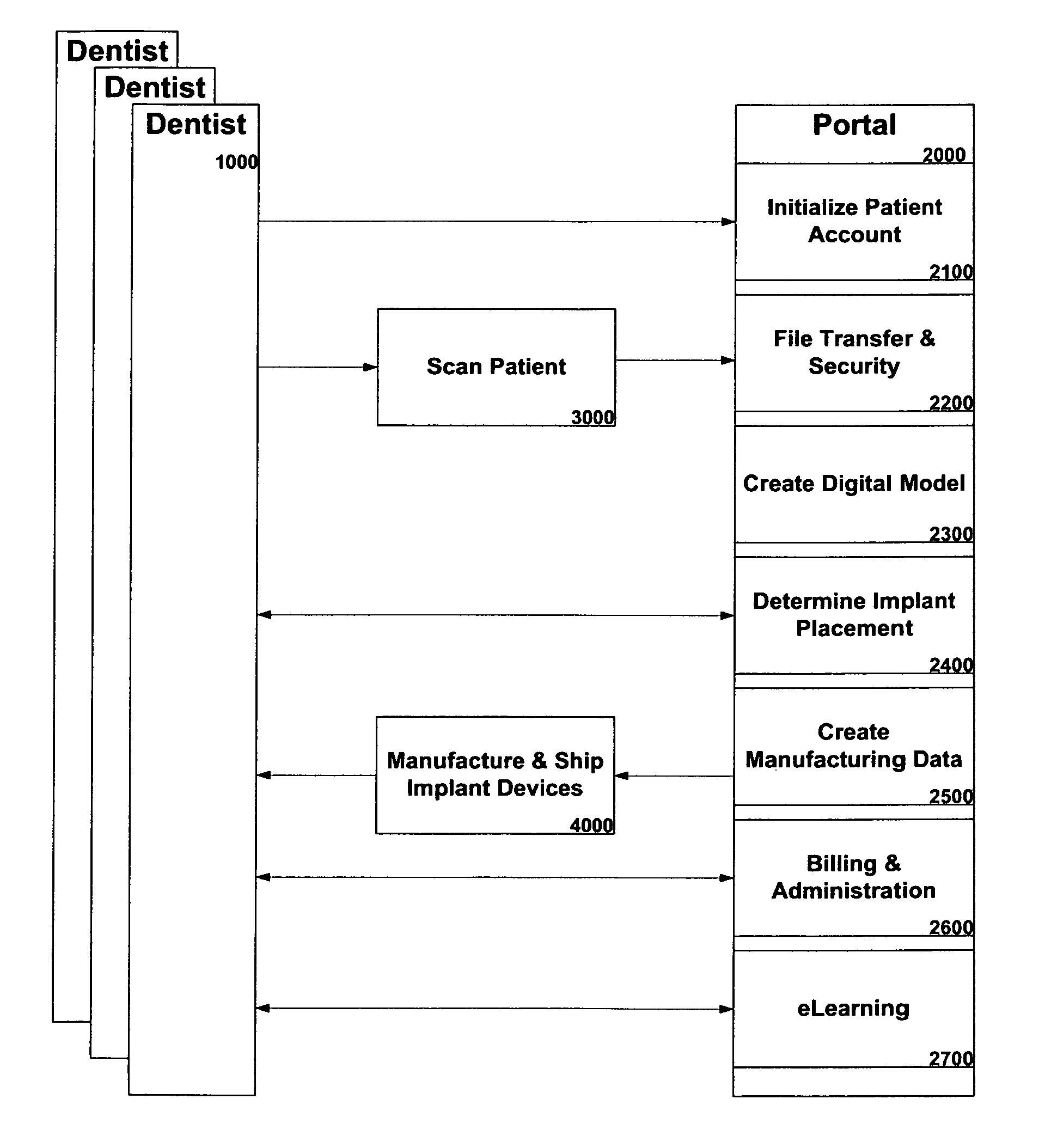

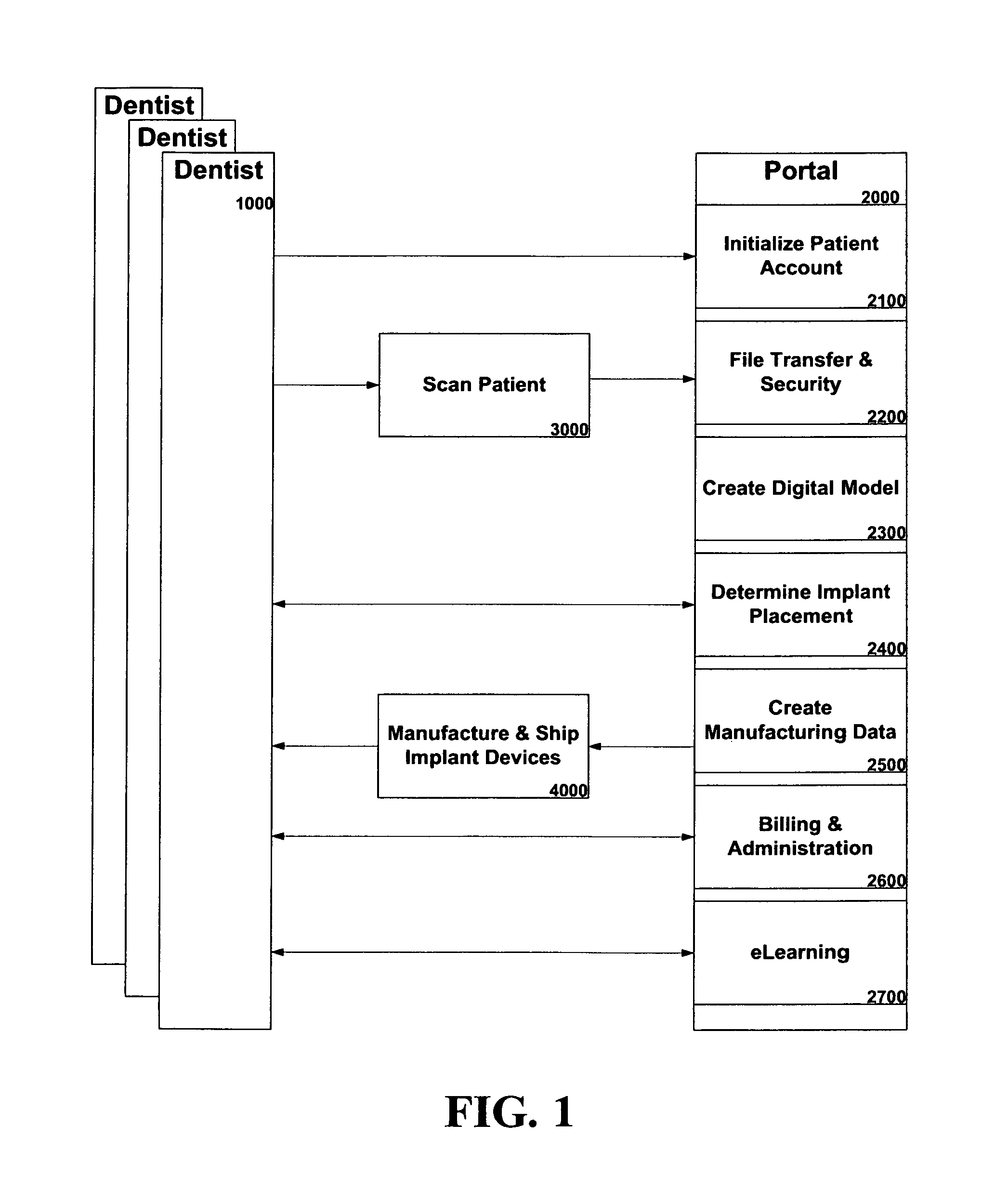

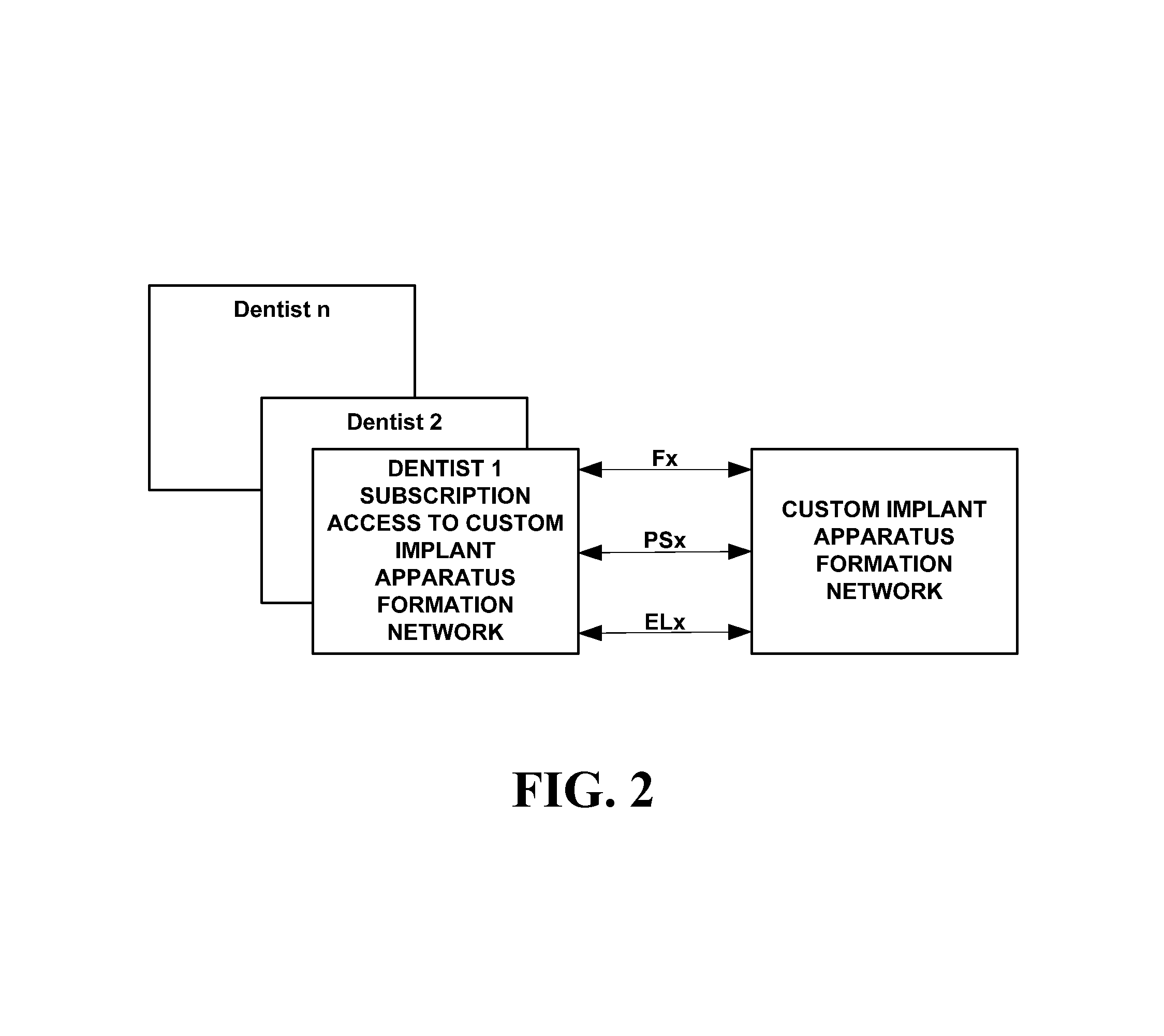

System and method for the design, creation and installation of implant-supported dental prostheses

InactiveUS9107723B2Elimination of of preciseGuaranteed to workData processing applicationsMechanical/radiation/invasive therapiesProsthesisEngineering

An improved system and method for the design, creation and installation of implant-supported dental prostheses is provided. A network accessible portal facilitates communication among a dental professional, a scanning center, a manufacturing center and others in the design and production of a dental drill guide and prosthesis, utilizing cone beam imaging, a rotatable 3-dimension representation of a patient's jaw, virtual placement of one or more implants and virtual testing prior to manufacture. Dental professionals may access the portal on a subscription or non-subscription basis.

Owner:HALL BENSON LUTHER

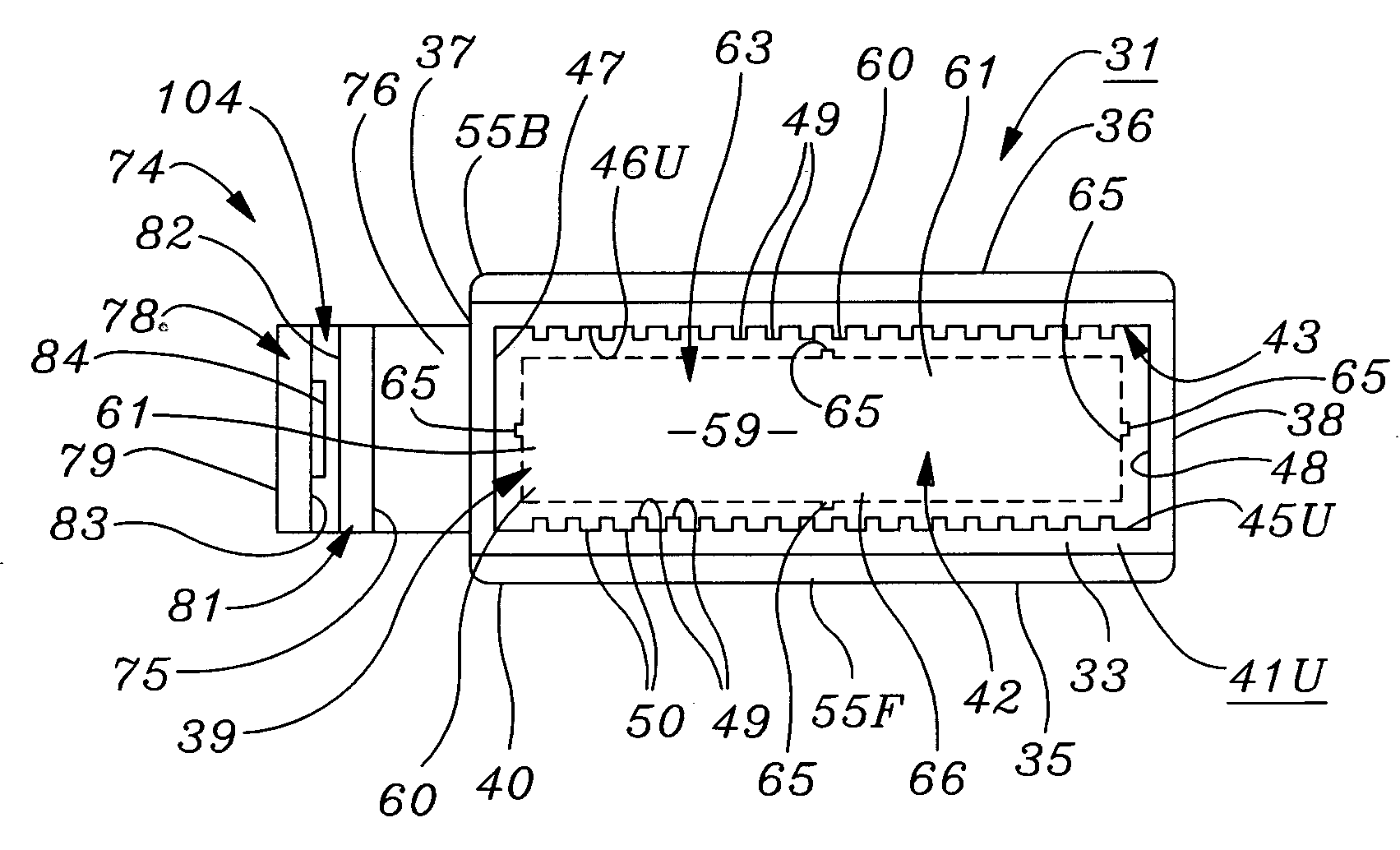

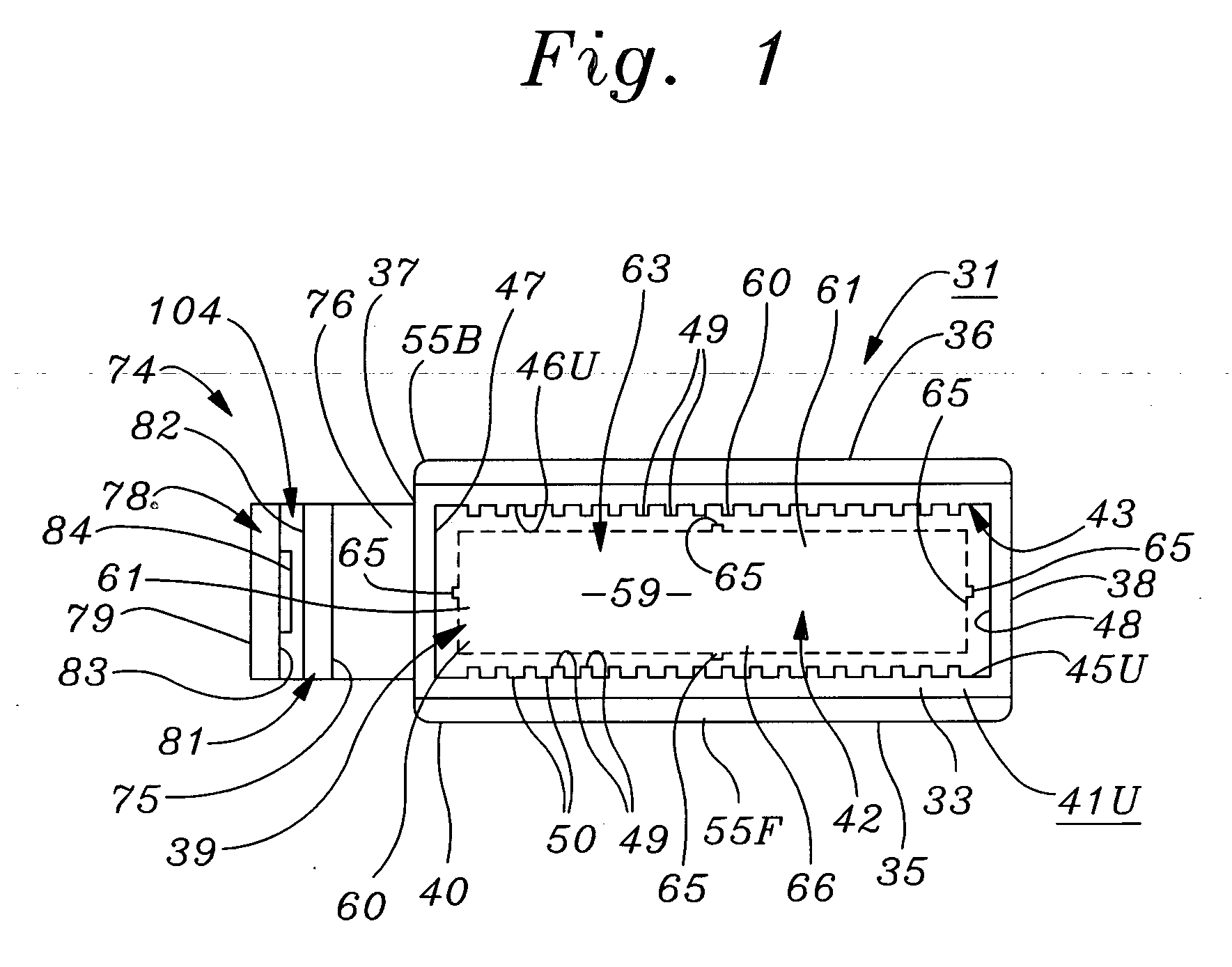

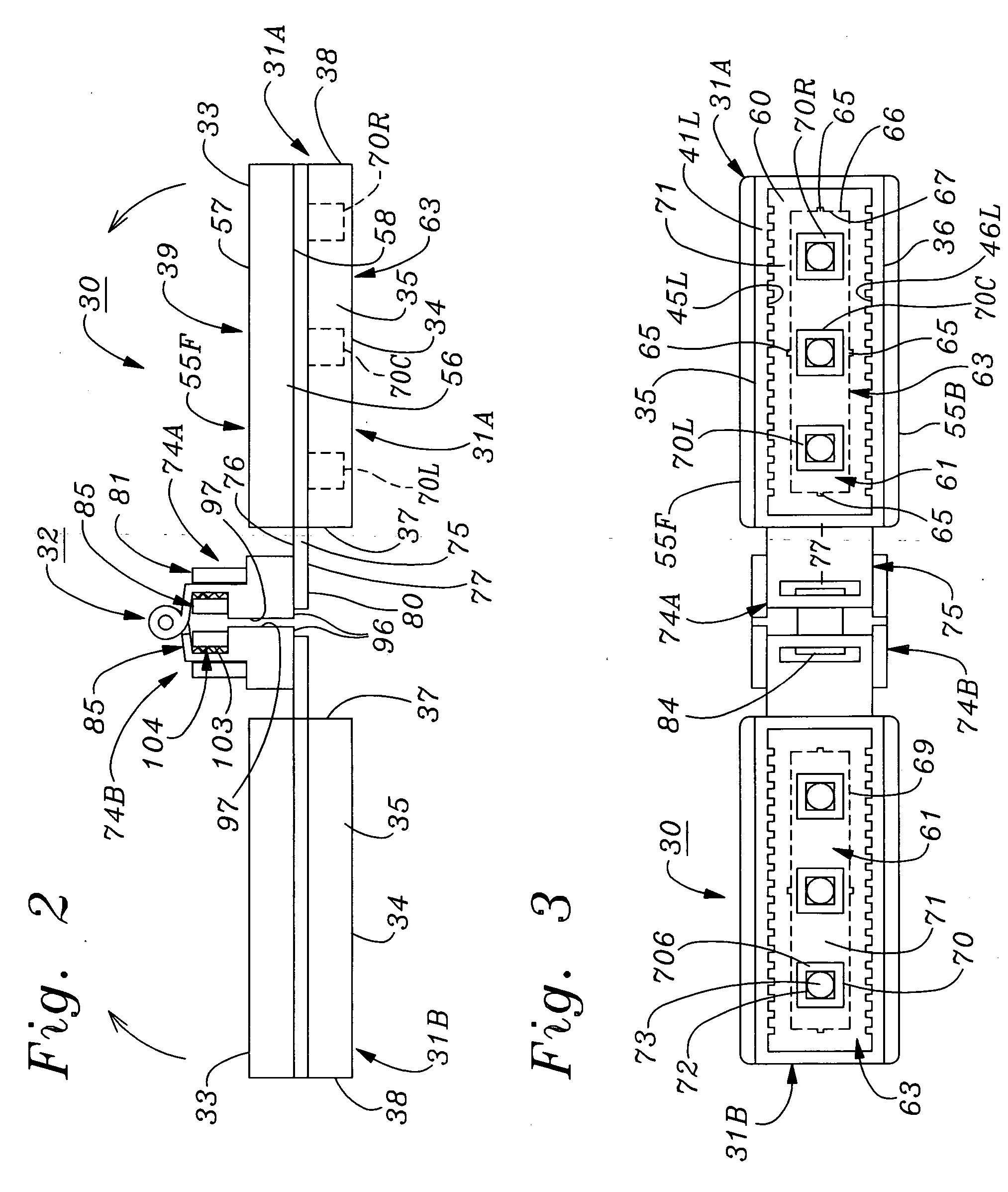

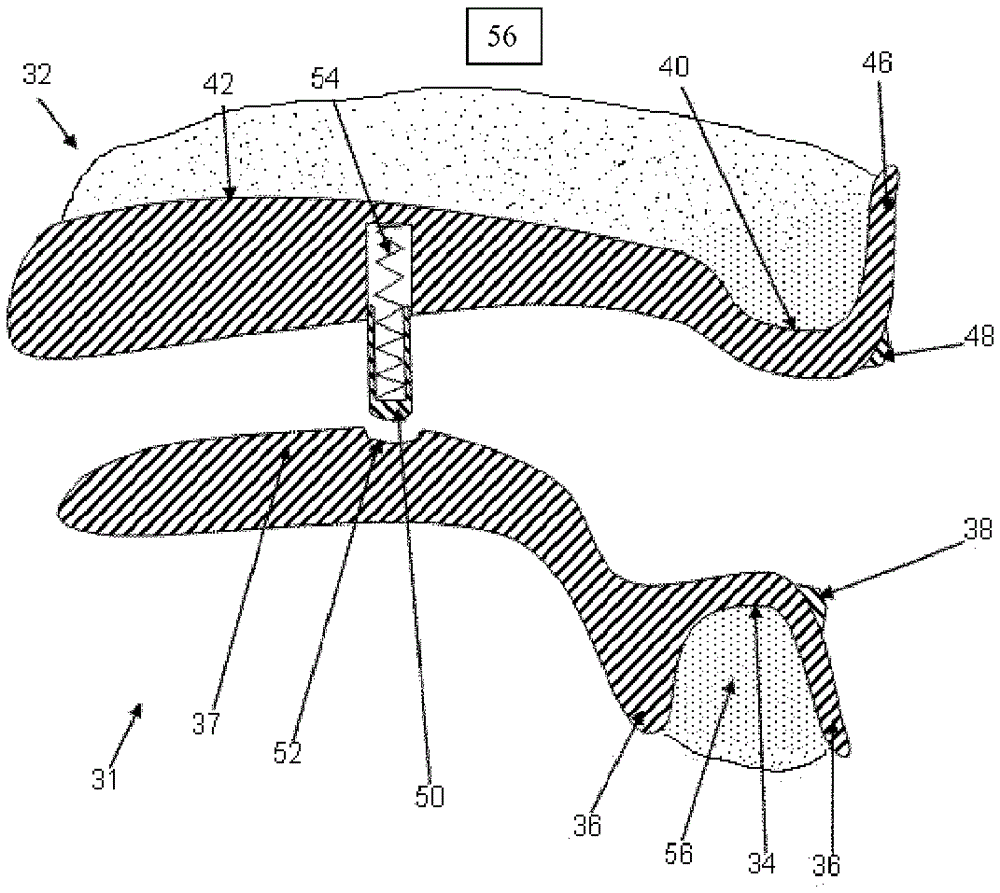

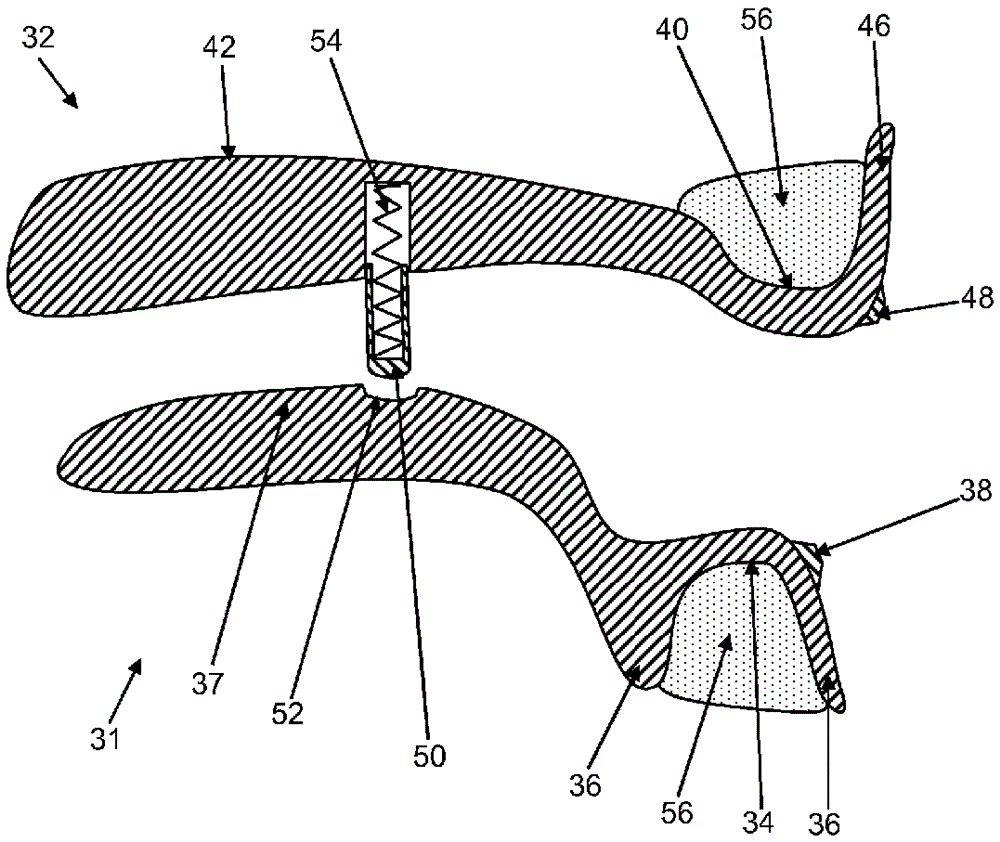

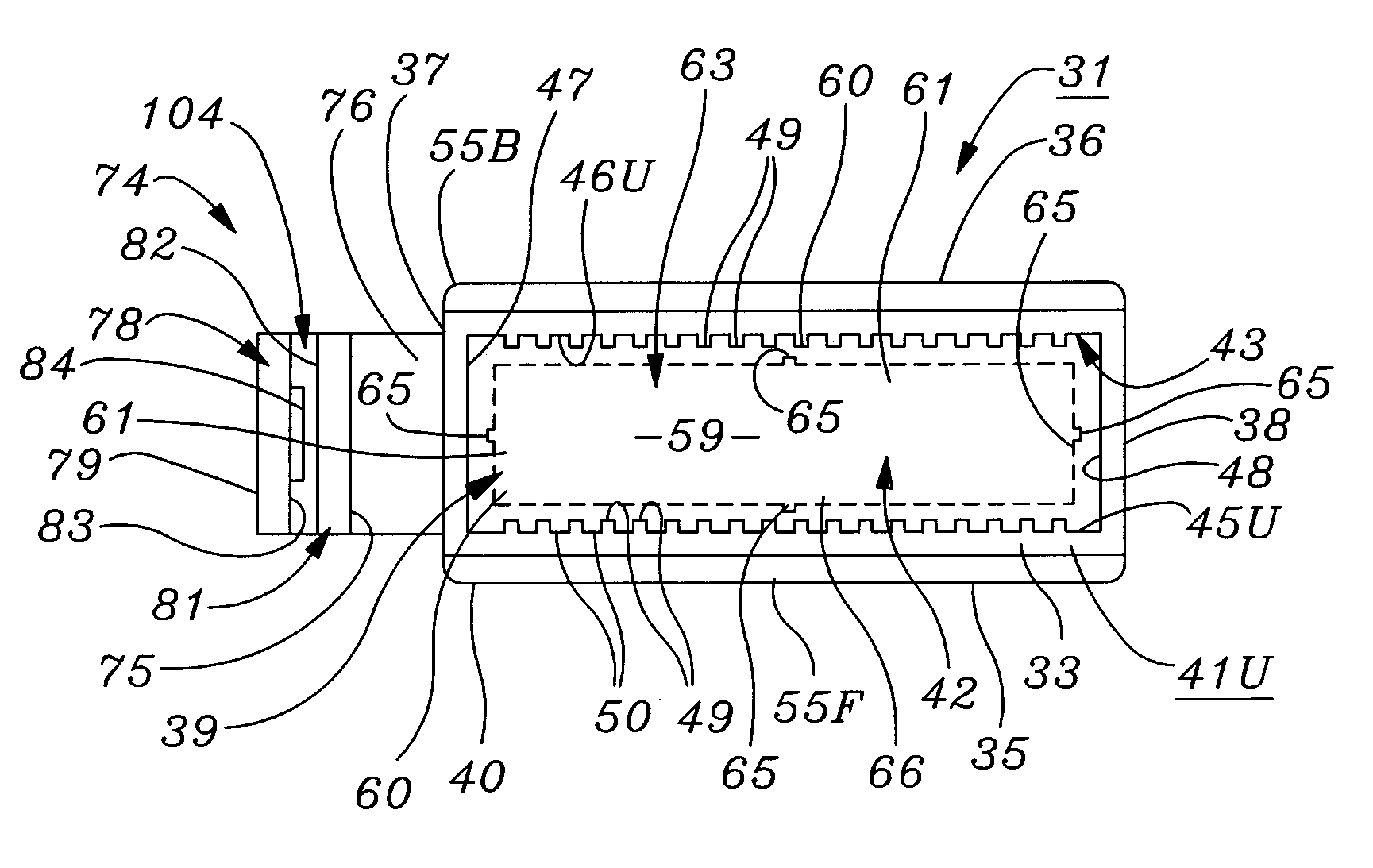

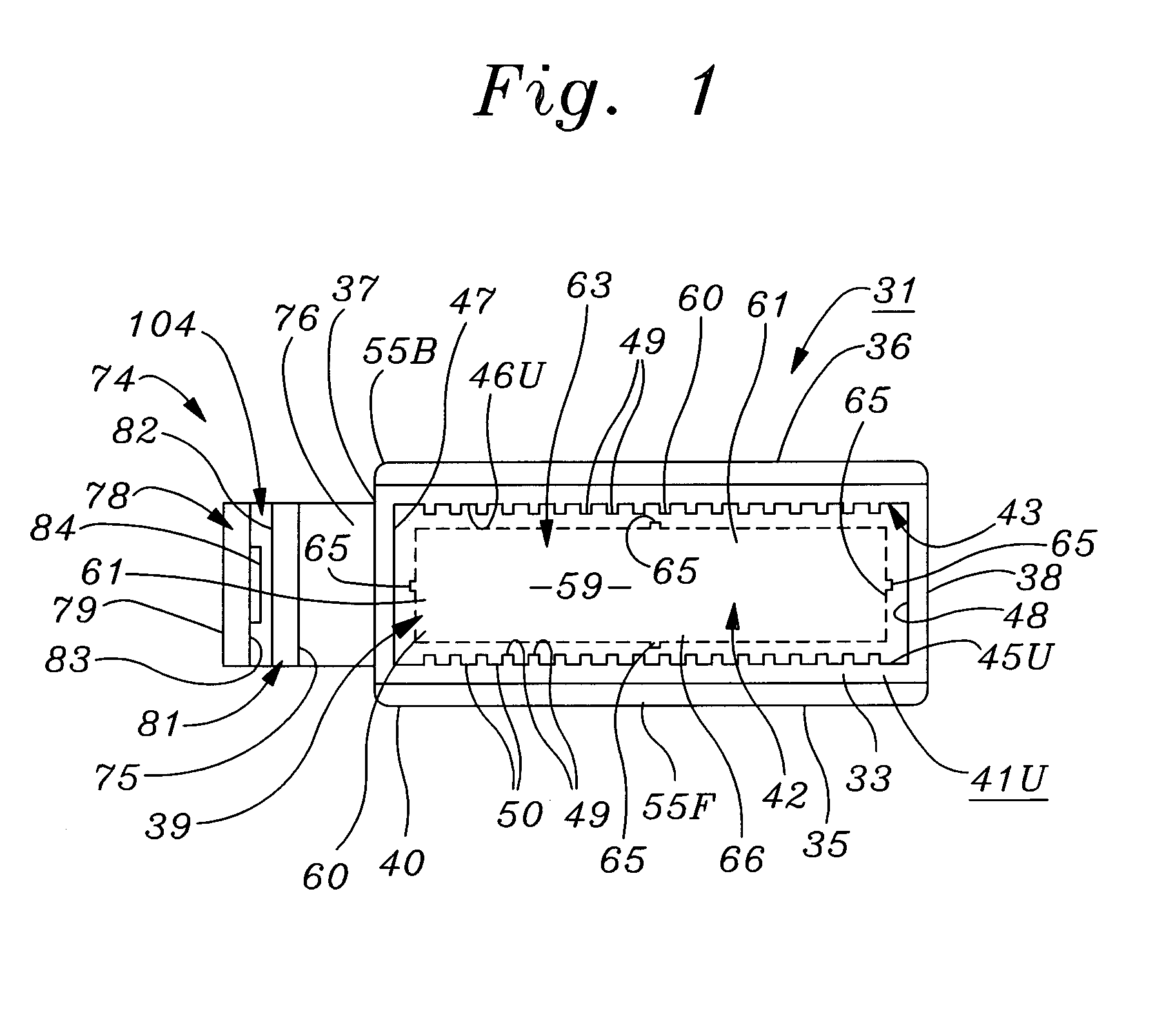

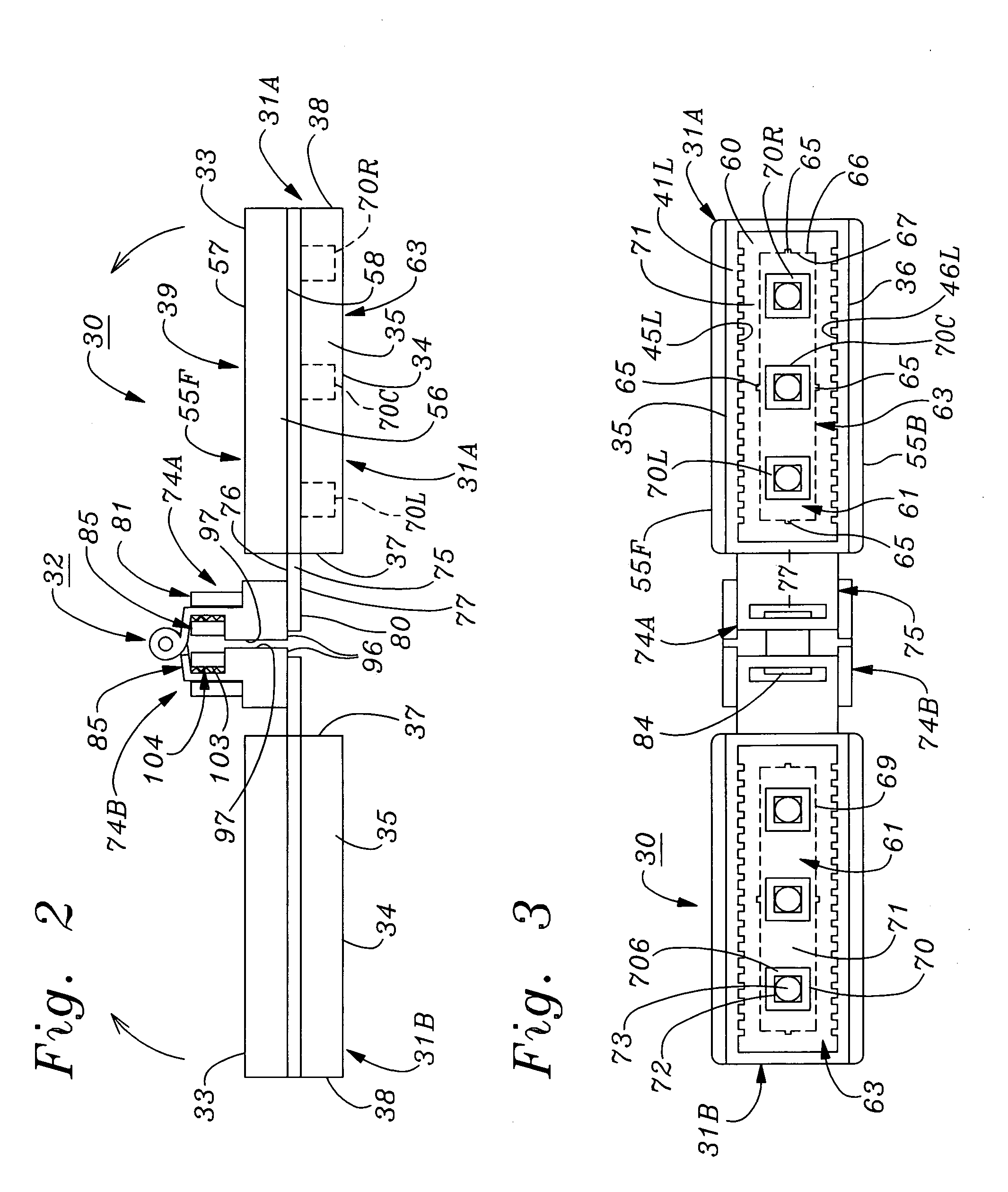

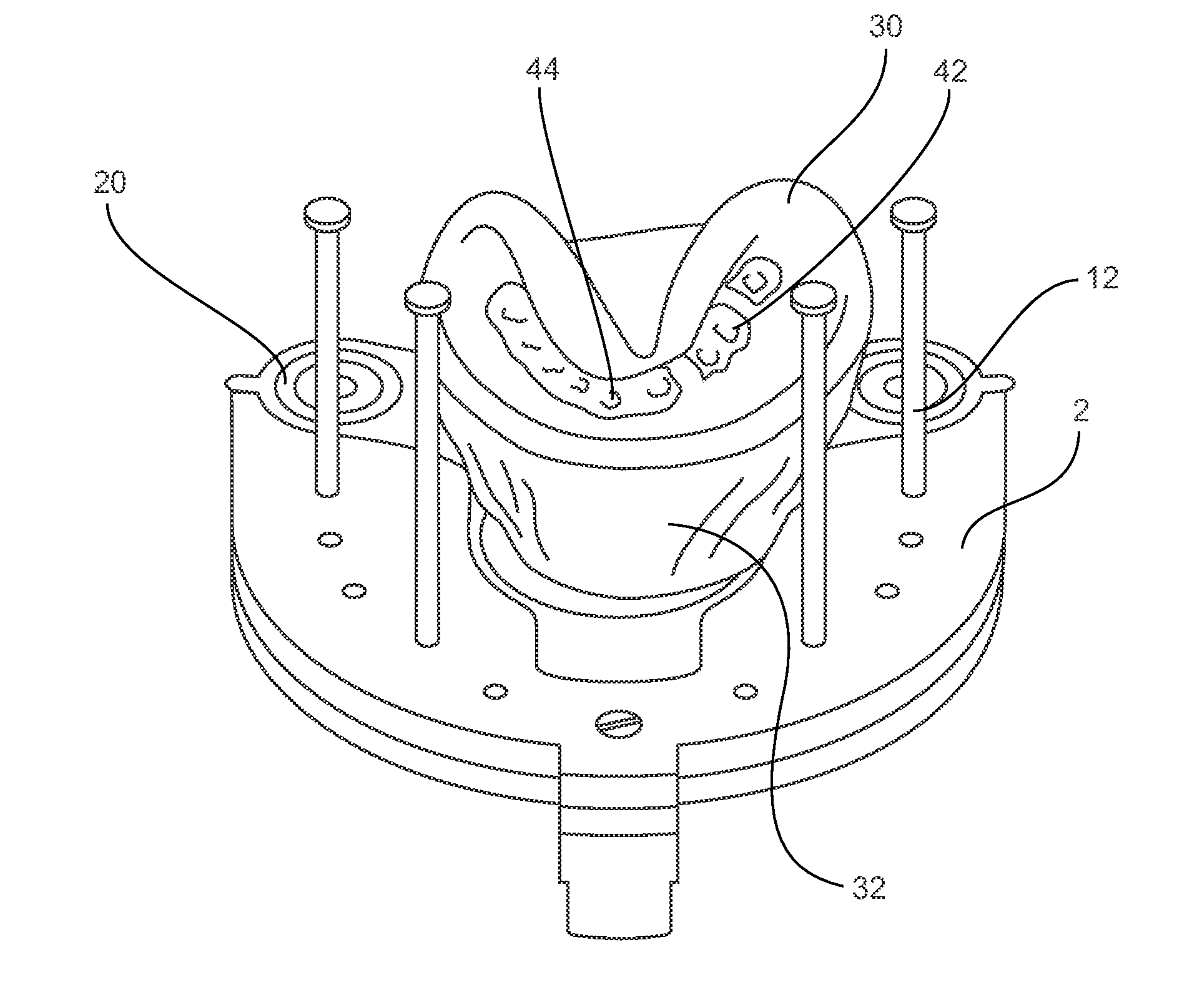

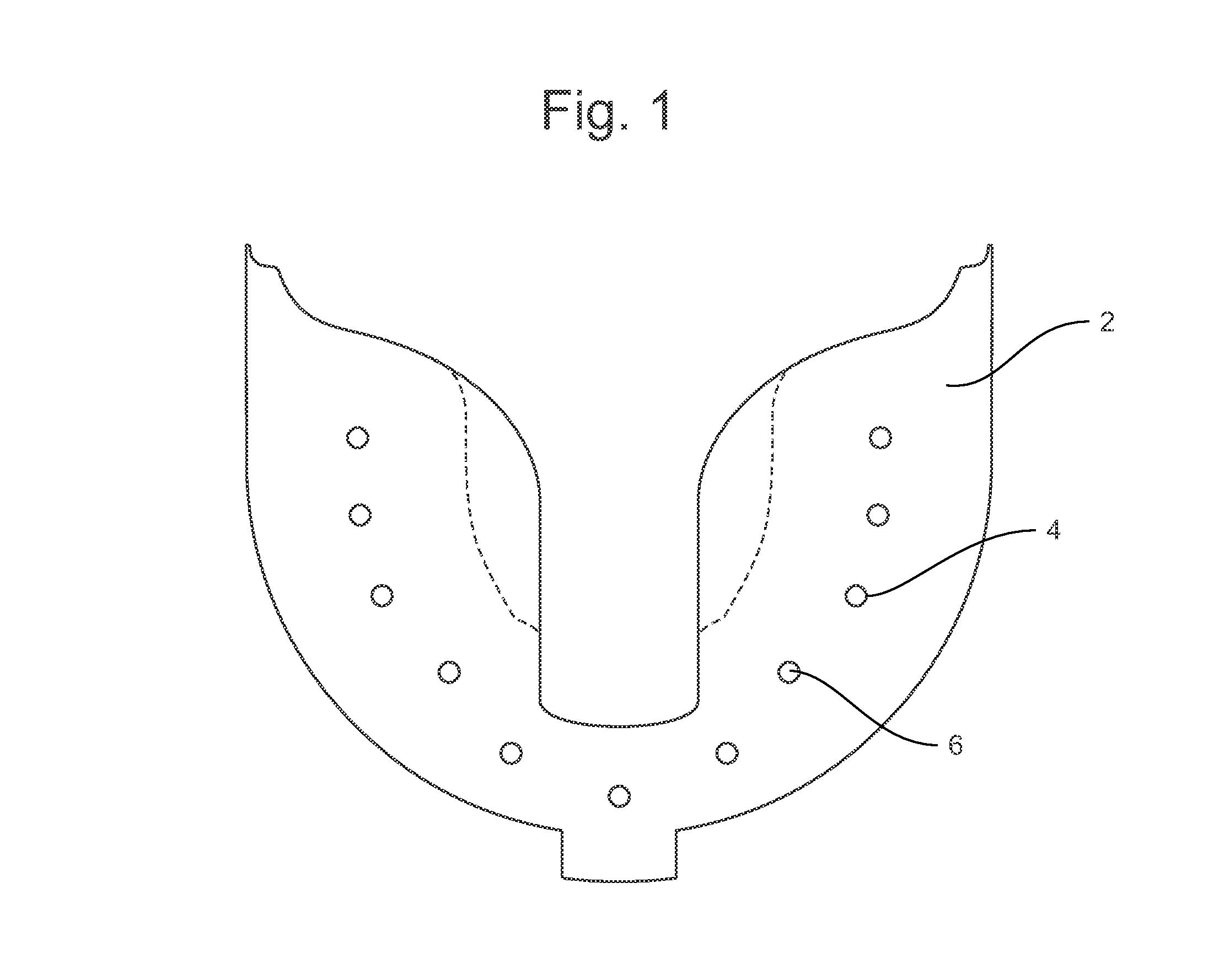

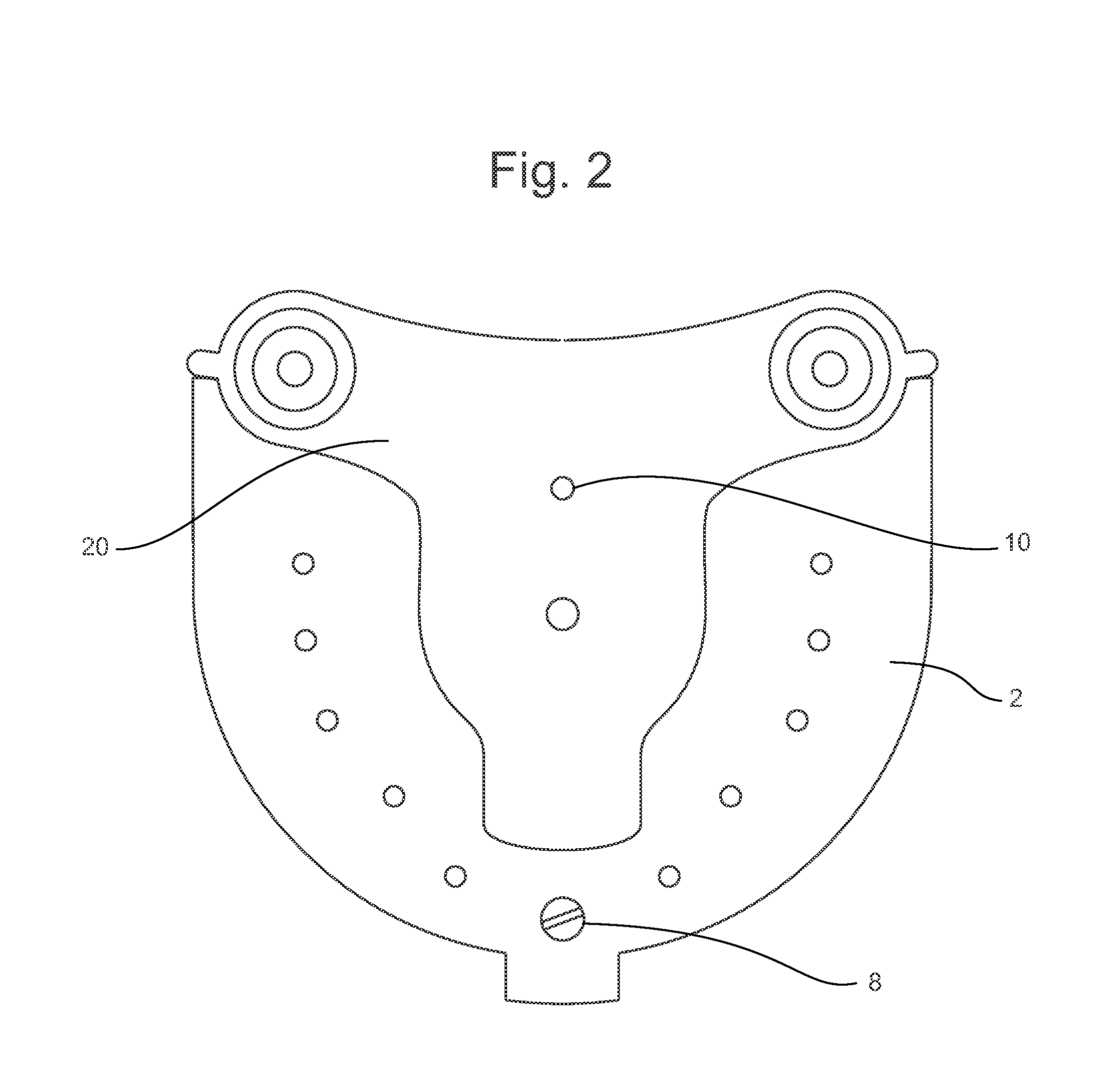

Dental prostheses modeling system with symmetric double-well trays slidably mountable to articulator

A dental prostheses modeling system includes a molding tray for molding the base of a quadrant or full-arch dental model cast which has a longitudinally disposed partition panel disposed generally between upper and lower surfaces of the tray that forms therewithin an upper well for receiving liquid die stone to mold the base of a dental impression model, and a lower well shaped symmetrically to the upper well for providing clearance for optional manipulating pins installable in the bases of selected die segments modeling individual dental prostheses severed from the hardened die stone base of the model. The partition panel includes peripheral flanges for supporting the base of the dental model, and an openable central portion for enabling a hardened dental model to be ejected from the tray, and for providing access for manipulating pins depending downwardly from die segments. A pair of slide receptacles for slidably receiving a modeling tray is removably attachable to upper and lower arms of a laboratory articulator, from which a pair of molding trays holding a pair of dental models can be slidably removed and attached to a disposable hinge mechanism to comprise a articulateable full-mouth model for a dentist and patient.

Owner:HONSTEIN JERRY P

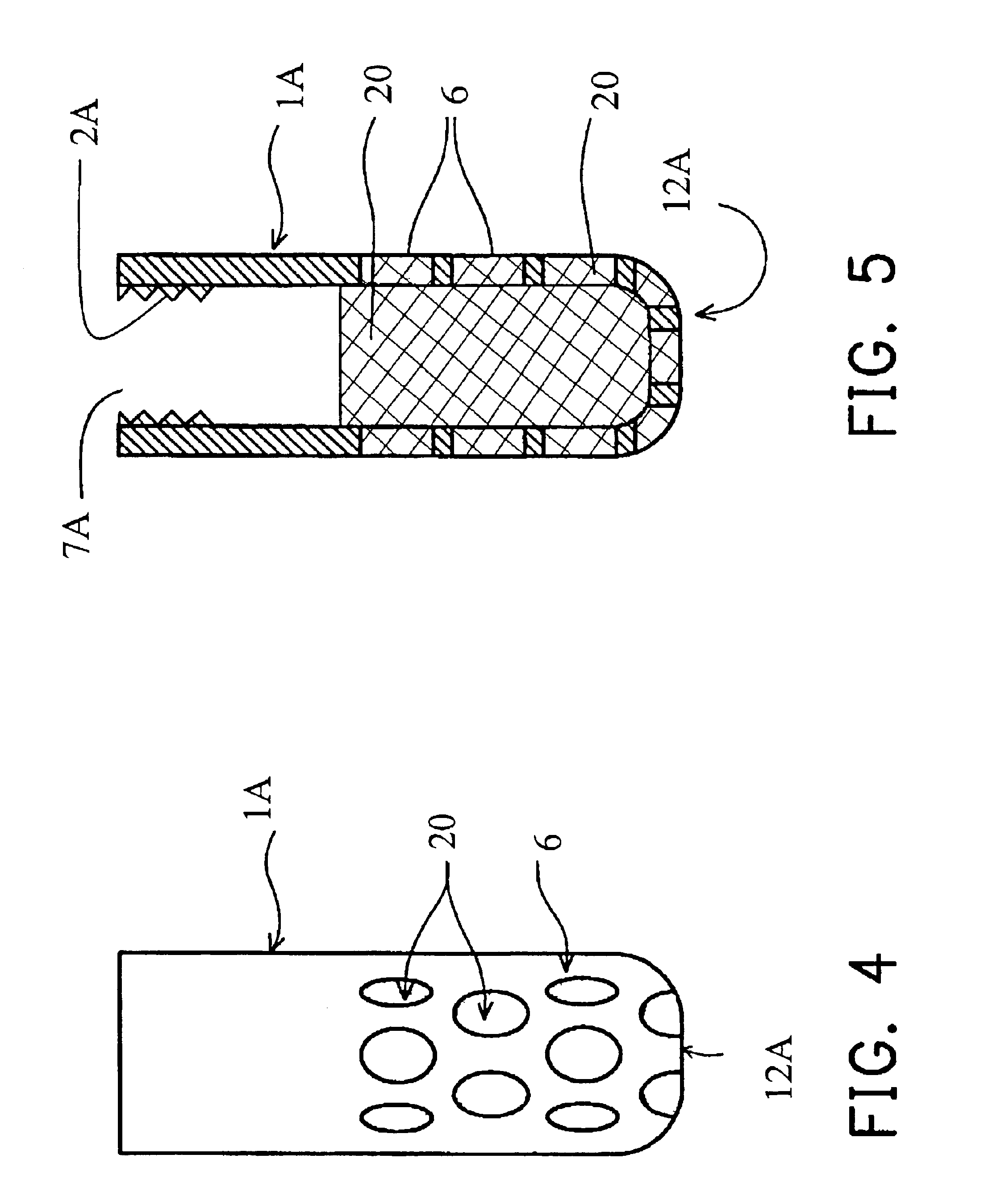

Dental implant with hardened calcium phosphate cement inside

A dental implant. The dental implant is to be installed in a predrilled bore formed in jawbone tissue for retaining a dental prosthesis. The dental implant includes a substantially cylindrical hollow base member having a wall defining a space in the hollow base member, and through-thickness holes in communication with the space and an outer surface of the wall. Hardened calcium phosphate cement is filled in the through-thickness holes and in at least a portion of the space. A receiving member is integrally formed at one end of the hollow base member for receiving a dental prosthesis.

Owner:JU CHIEN PING +1

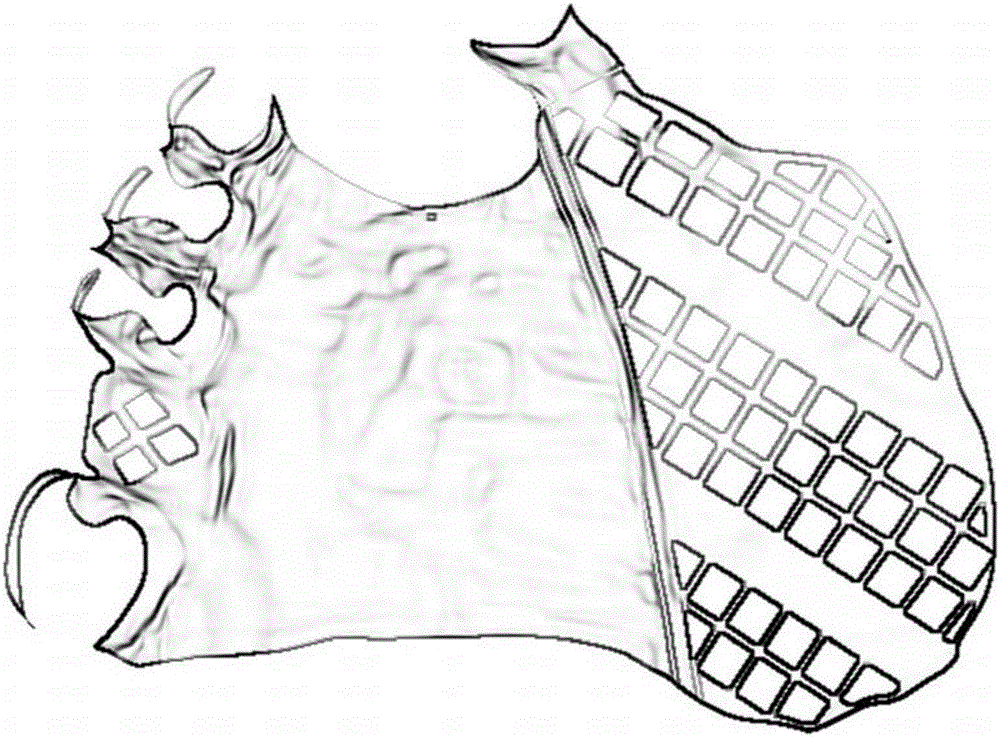

Dental prosthesis stent made of metal additives and method for manufacturing dental prosthesis stent made of metal additives

InactiveCN105213068ASave human effortReduce human errorBone implantSelective laser meltingHigh surface

The invention discloses a dental prosthesis stent made of metal additives and a method for manufacturing the dental prosthesis stent made of the metal additives. The method includes: acquiring data of a three-dimensional maxillary model of a patient, selecting a maxillofacial surface of the dental prosthesis stent on the model, reconstructing the maxillofacial surface, stretching the maxillofacial surface until formation of an initial stent model, and repairing the initial stent model to meet design requirements for forming a stent CAD (computer aided design) model available for printing and manufacturing; adopting a selective laser melting 3D (three-dimensional) printer for printing and manufacturing to obtain a stent model, and subjecting the stent model to thermal treatment and surface treatment. The dental prosthesis stent comprises a body made of a metal material, and the body comprises a nesting portion and a supporting portion with a mesh structure. The dental prosthesis stent made of the metal additives and the method for manufacturing the dental prosthesis stent made of the metal additives have the advantages that the structure meeting clinical requirements is made by means of 3D printing technology, high precision, high surface quality and short manufacturing period are realized, and the clinical requirements are met better.

Owner:ZHEJIANG UNIV OF TECH +1

Method for machining a dental prosthesis

InactiveUS20120177456A1Reduce the possibilityThread cutting toolsLayered productsDenturesEngineering

A method for machining a dental prosthesis that reduces the likelihood of forming tool failure includes machining a workpiece to form a bottom surface without machining a bottom cavity of the dental prosthesis, then machining the bottom cavity and machining the top.

Owner:JUNG YUNOH +1

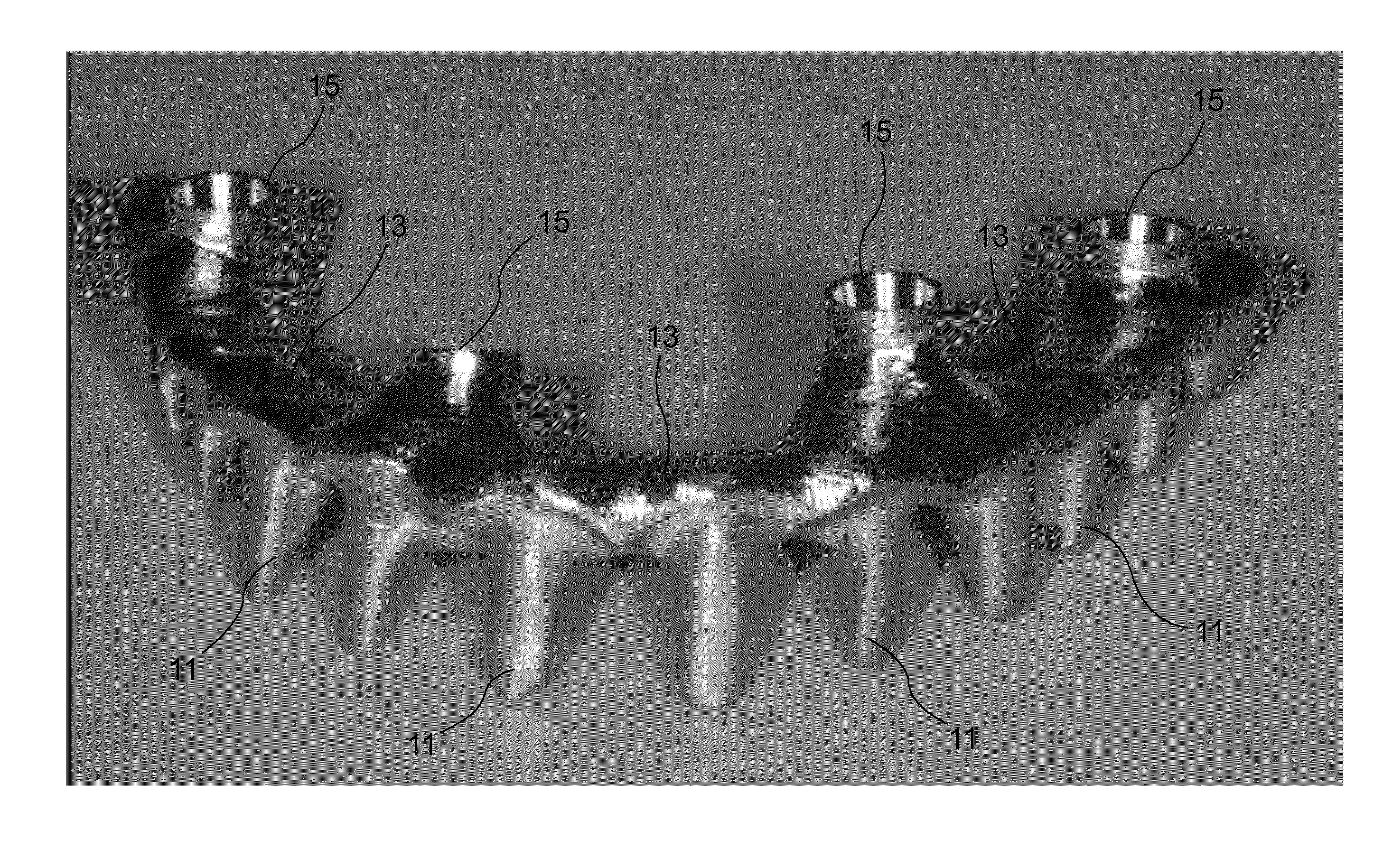

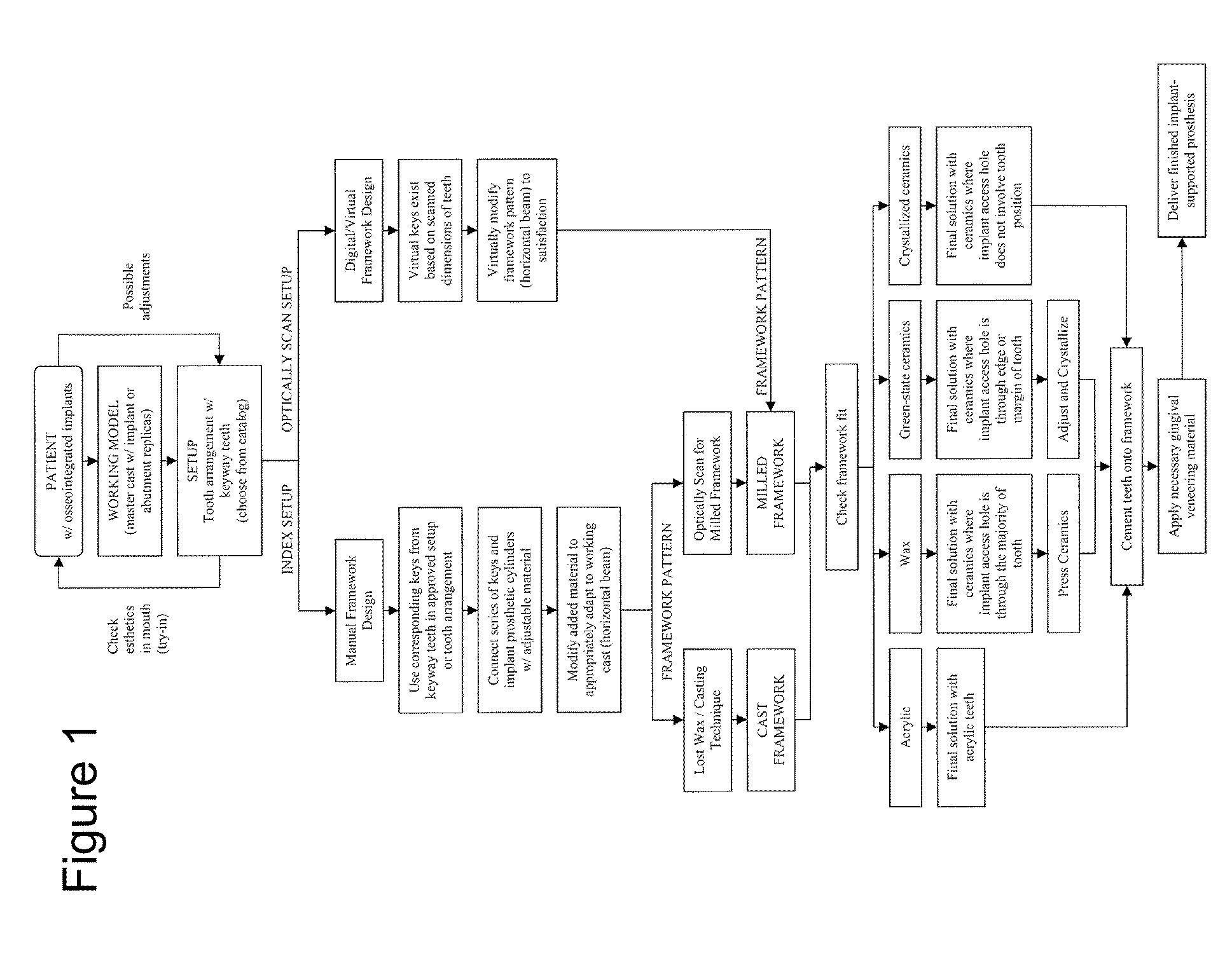

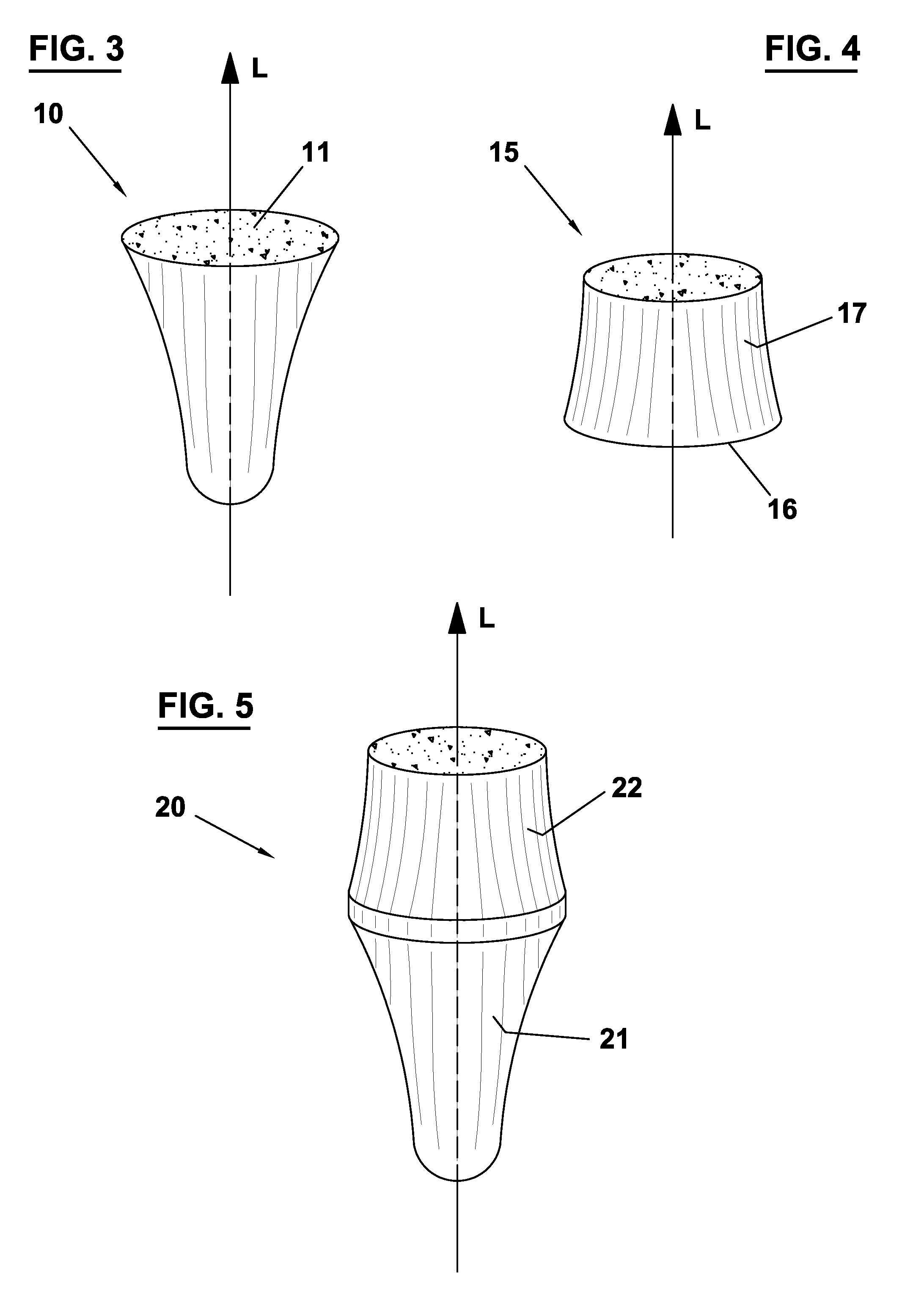

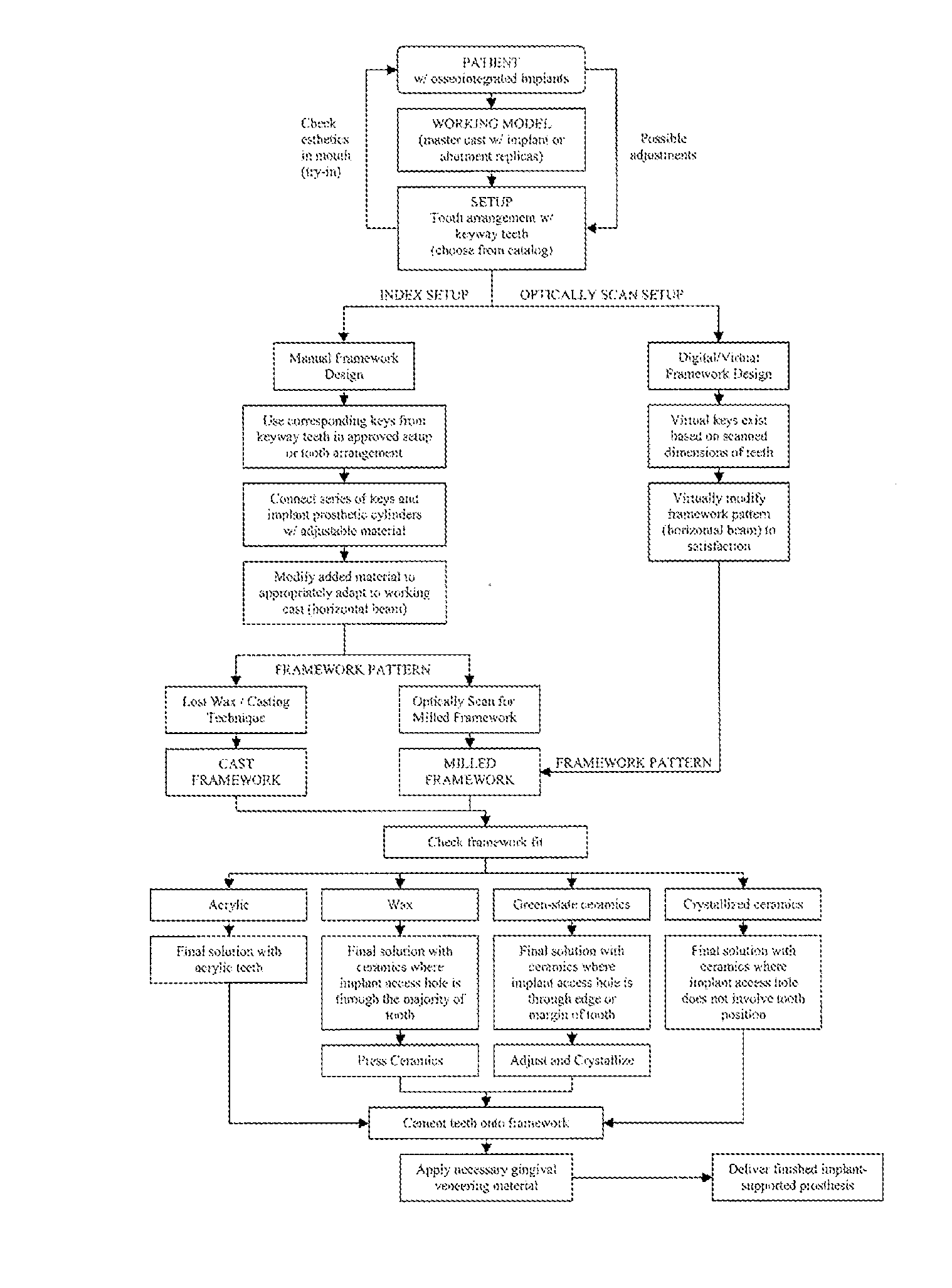

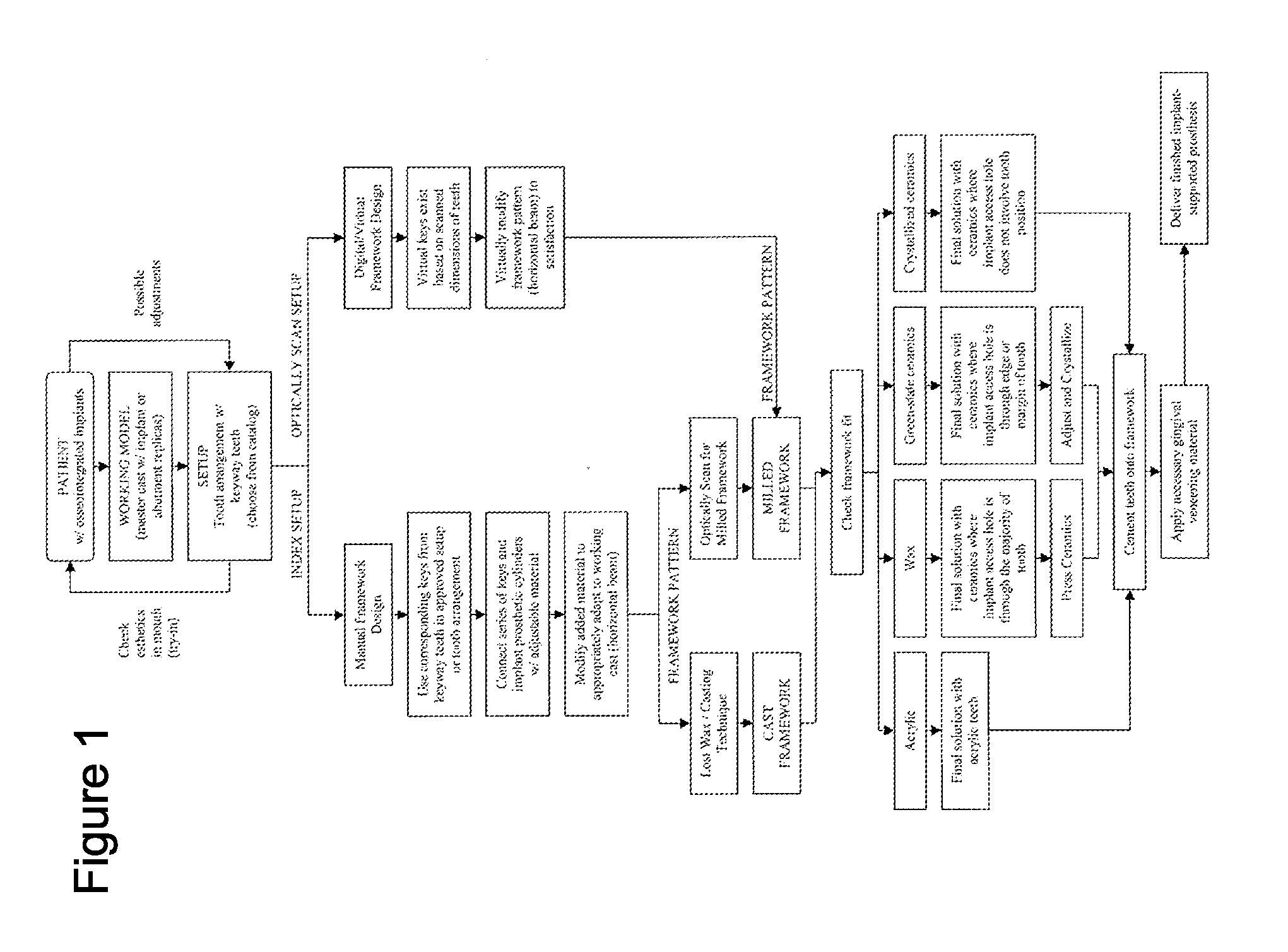

Dental prosthesis and method of its production utilizing standardized framework keys and matching premanufactured teeth

ActiveUS8875398B2Rapid and precisely accurate methodHighly repeatableDental implantsFastening prosthesisDenturesMethods of production

A system including a method and associated structures creates efficiencies in the manufacture of prosthetic tooth support frameworks. Pre-manufactured teeth with matching internal keys are used in the setup of a patient prototype. Each key includes a shaft, a cervical platform, a retention knob and preferably at least one channel for the expulsion of excess adhesive fluid. The cervical platforms are shaped to provide intimate contact with a base of their respective tooth. The same tooth / key pairs are then used to make a framework pattern from the setup positioning. The pattern can be cast or scanned for direct machining to produce the finished framework.

Owner:GLOBAL DENTAL SCI

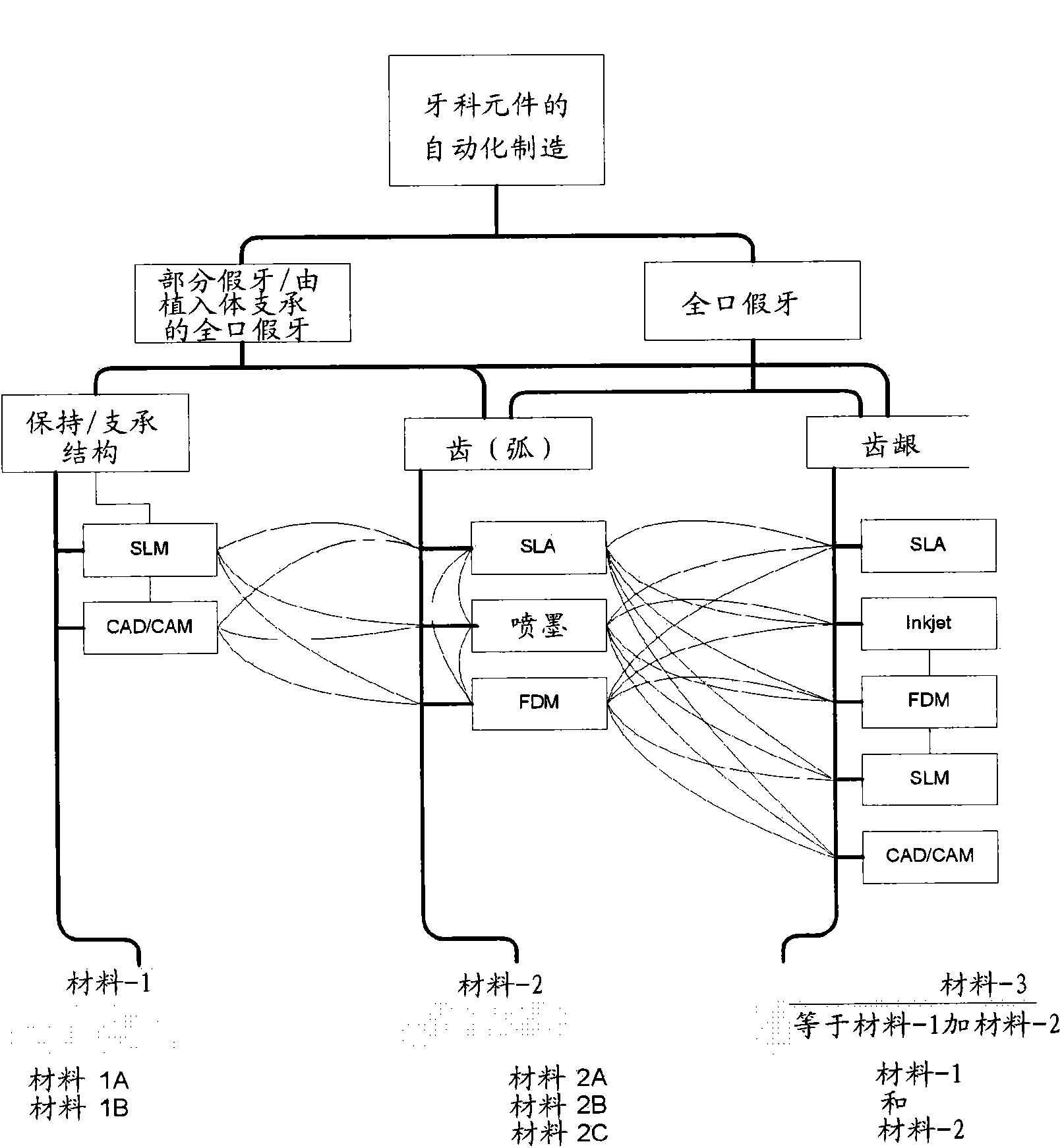

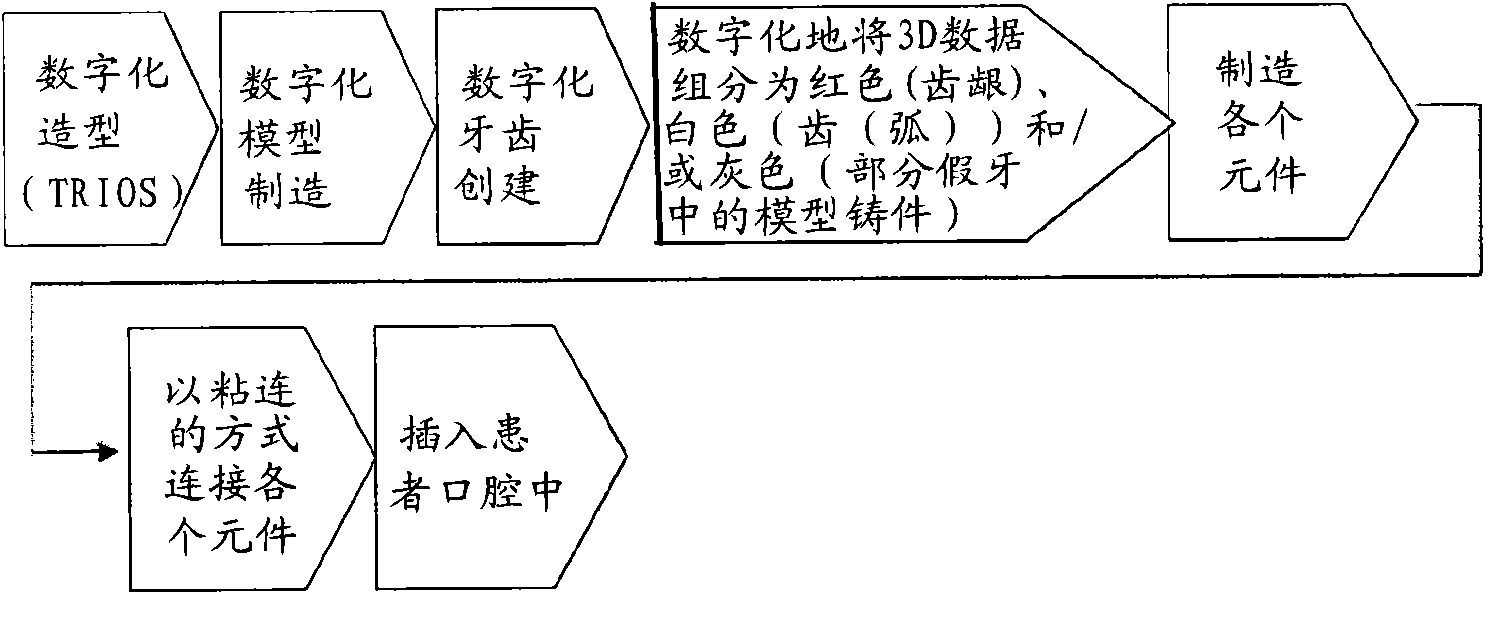

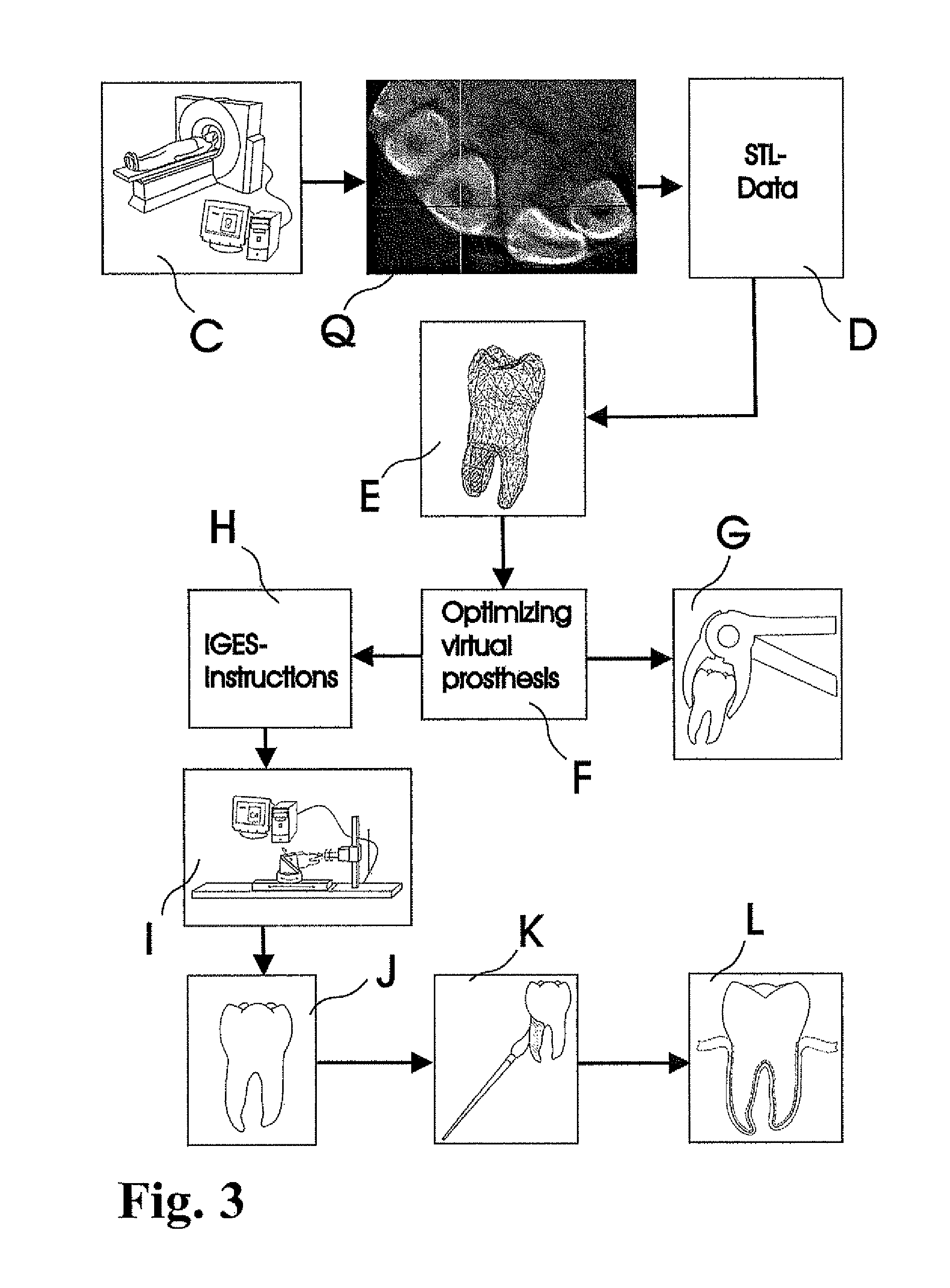

Production of dental prostheses via CAD and rapid manufacturing from digitally recorded oral data

ActiveCN103637851AHigh precisionAdditive manufacturing apparatusMechanical/radiation/invasive therapiesDenturesProsthesis

Summary Methods for the production of complete or partial prostheses involve, firstly A) provision of 3D data of the situation in the mouth in the edentulate or partly toothed state; B) digital designing of the denture base for lower and upper jaw each; C) digital positioning of virtual teeth with appropriate occlusion and a tooth shape selected according to aesthetic criteria, in the case of complete prostheses, D1) production of the dental arch using an automated method from the groups of layer-building and of material-removing methods; and D2) production of the denture base using an automated method from the groups of layer-building and of material-removing methods; and, in the case of partial prostheses; D1) production of the dental arch using an automated method from the groups of layer-building and of material-removing methods; and D2) production of the support structures or fastening elements using an automated method from the groups of layer-building and of material-removing methods.

Owner:赫罗伊斯库尔泽有限公司

Dental implant abutment

A dental implant abutment for attaching a dental prosthesis within a patient's mouth. The abutment is a single unit structure fabricated of a ceramic material, multicolored throughout to match the color of the dental prosthesis, the surrounding dentition and the surrounding gingival tissue.

Owner:IVOCLAR VIVADENT AG

Scanable tray for producing a dental prosthesis

ActiveCN105377179AReduce adverse effectsComfort removedImpression capsSurgeryComputer basedDental Prosthesis Design

The invention relates to a method for taking an impression for producing a dental prosthesis, in particular a denture, comprising the procedural steps of: A) generating an impression of at least partial regions of the upper jaw and lower jaw of a patient using an at least two-part tray in the oral cavity of the patient, whereby the tray is being inserted into the oral cavity of the patient for this purpose; B) fixing the at least two tray parts to each other or against each other in the oral cavity of the patient; C) followed by determining the position and orientation of the at least two tray parts with respect to each other in the oral cavity of the patient; and D) followed by taking the tray parts out of the oral cavity of the patient. The invention also relates to a tray for taking an impression of at least partial regions of the upper and lower jaw of a patient for implementing said method, comprising at least two tray parts, whereby at least one marking is arranged on the surface of each tray part and enables the determination of the position and orientation of the markings and tray parts with respect to each other, and to a device for intra-oral determination of the orientation and position of at least two tray parts for taking an impression of at least partial regions of the upper and lower jaw of a patient with respect to each other, whereby the device is suitable for implementing said method and the device comprises a computer and a recording facility, in particular an intra-oral scanner or an intra-oral camera, that can be used to determine the position and orientation of the tray parts with respect to each other by means of an imaging method and a computer-based analysis of the images for a known shape of the tray parts, whereby said tray preferably is a separate part of the device and the position and orientation of the tray parts with respect to each other can be determined by means of a computer-based analysis of the images of the known markings on the tray parts.

Owner:古莎有限公司

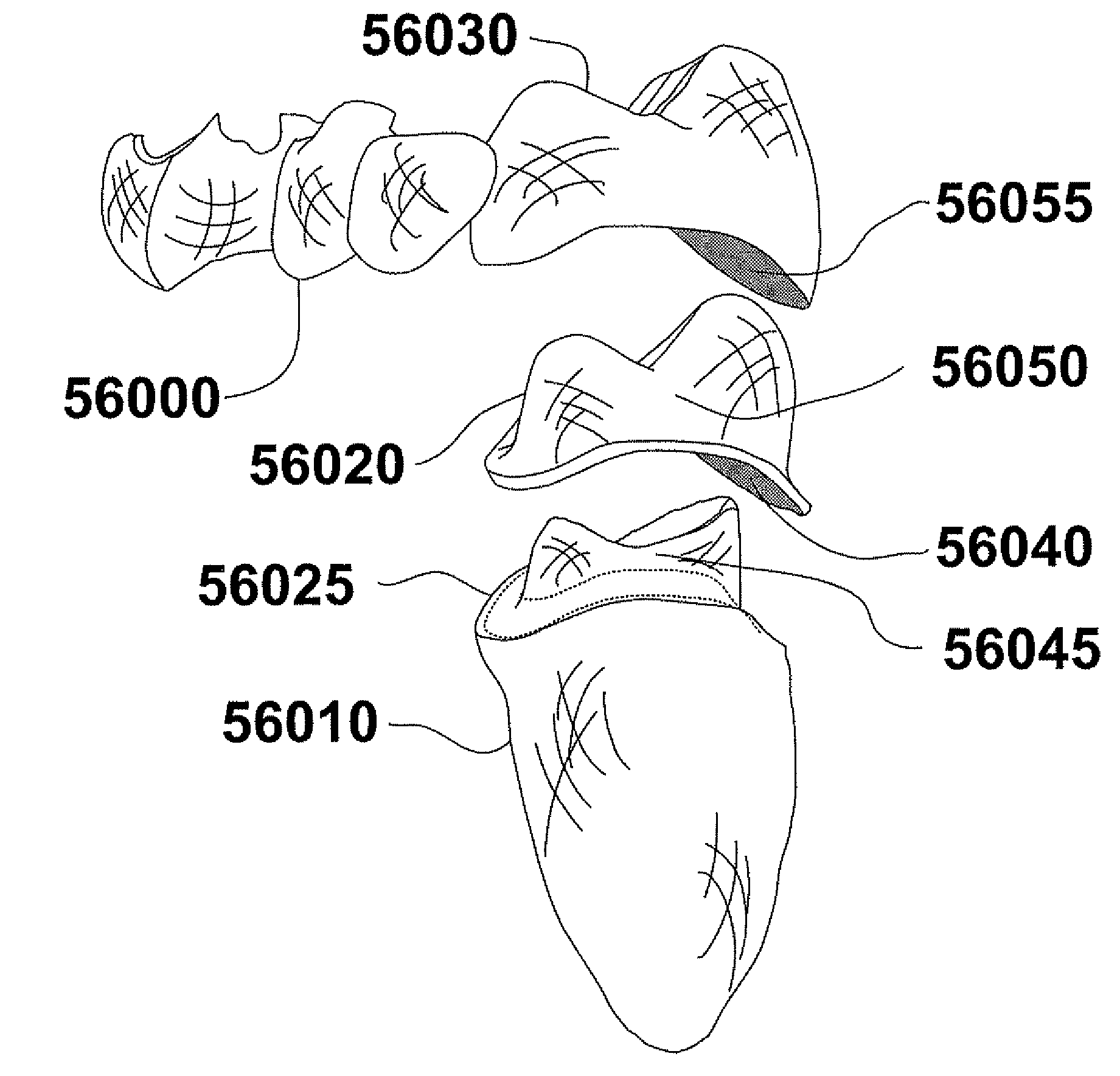

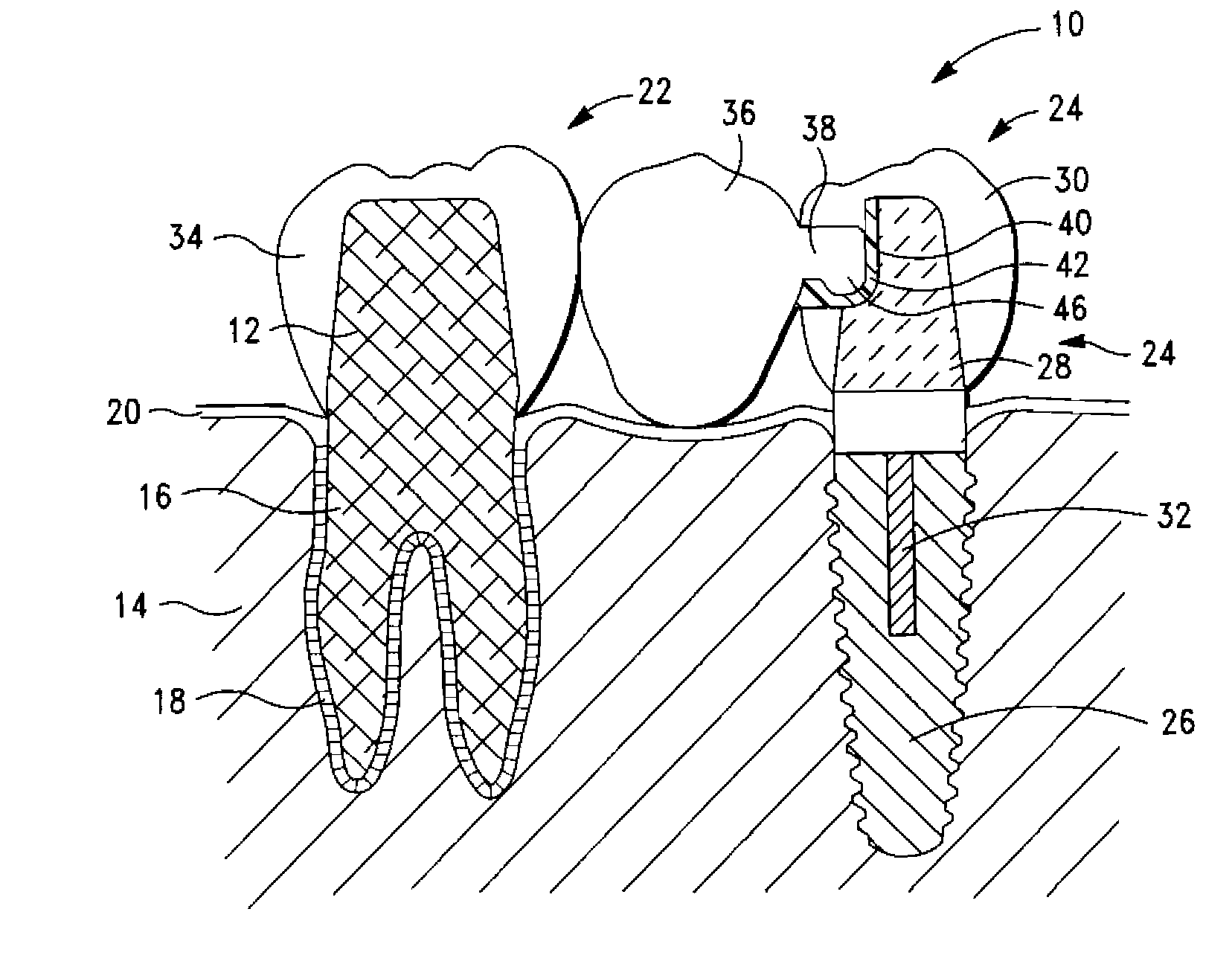

Methods of designing and manufacturing customized dental prosthesis for periodontal or osseointegration and related systems

ActiveUS9539062B2None have achieved superiorQuality improvementDental implantsImpression capsAnatomical structuresNatural tooth

Methods of manufacturing dental prosthesis / implants each to replace a non-functional natural tooth positioned in a jawbone of a specific pre-identified patient are provided. An example method includes the steps of receiving imaging data such as x-ray image data and surface scan data of a dental anatomy and / or a physical impression of the dental anatomy of a specific preidentified patient. The steps can also include forming a three-dimensional virtual model of at least portions of a non-functional natural tooth positioned in the jawbone of the specific pre-identified patient based on the imaging and surface scan data, virtually designing a dental implant based upon the virtual model, exporting the data describing the designed dental implant to a manufacturing machine, and custom manufacturing the dental implant for the specific patient.

Owner:NATURAL DENTAL IMPLANTS

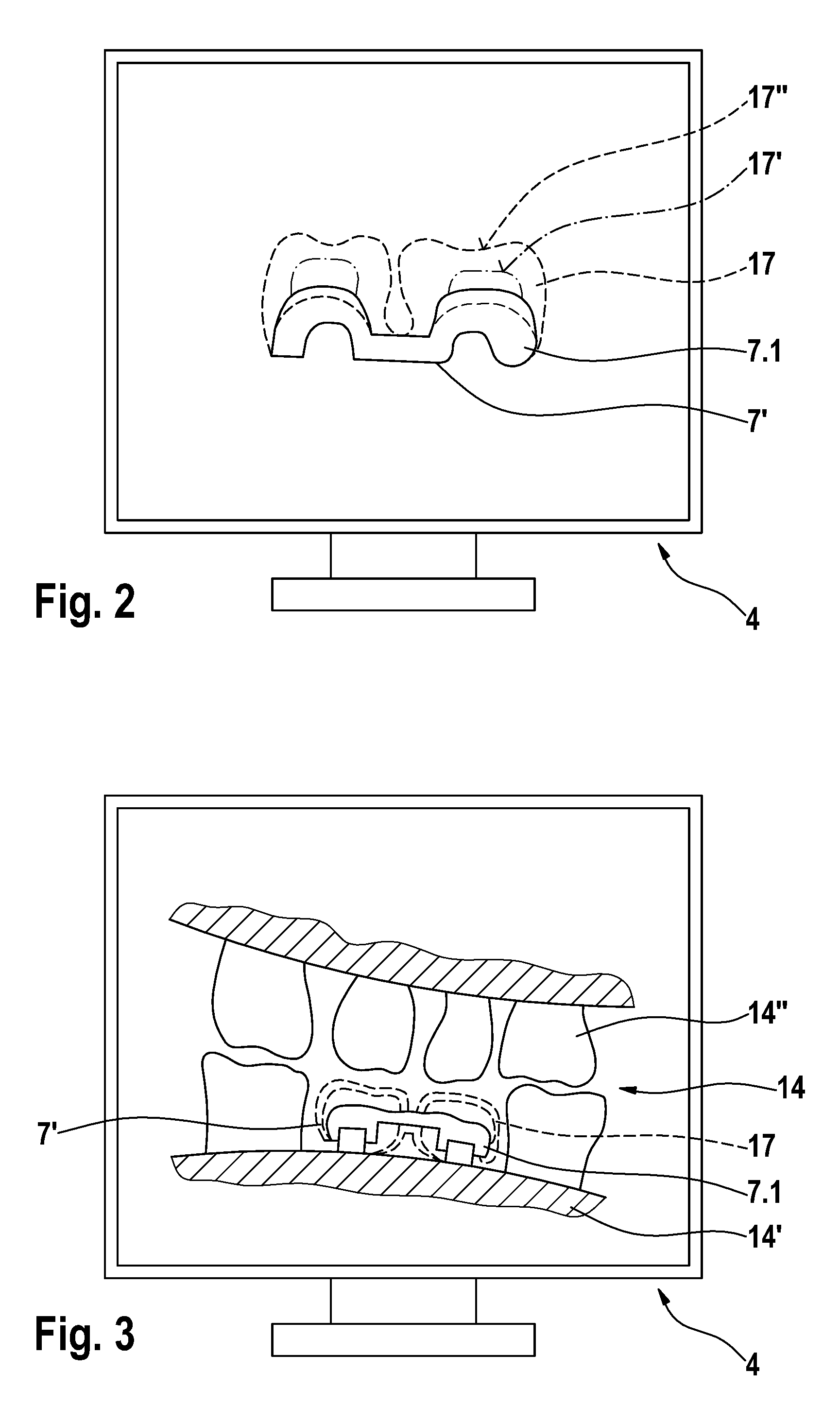

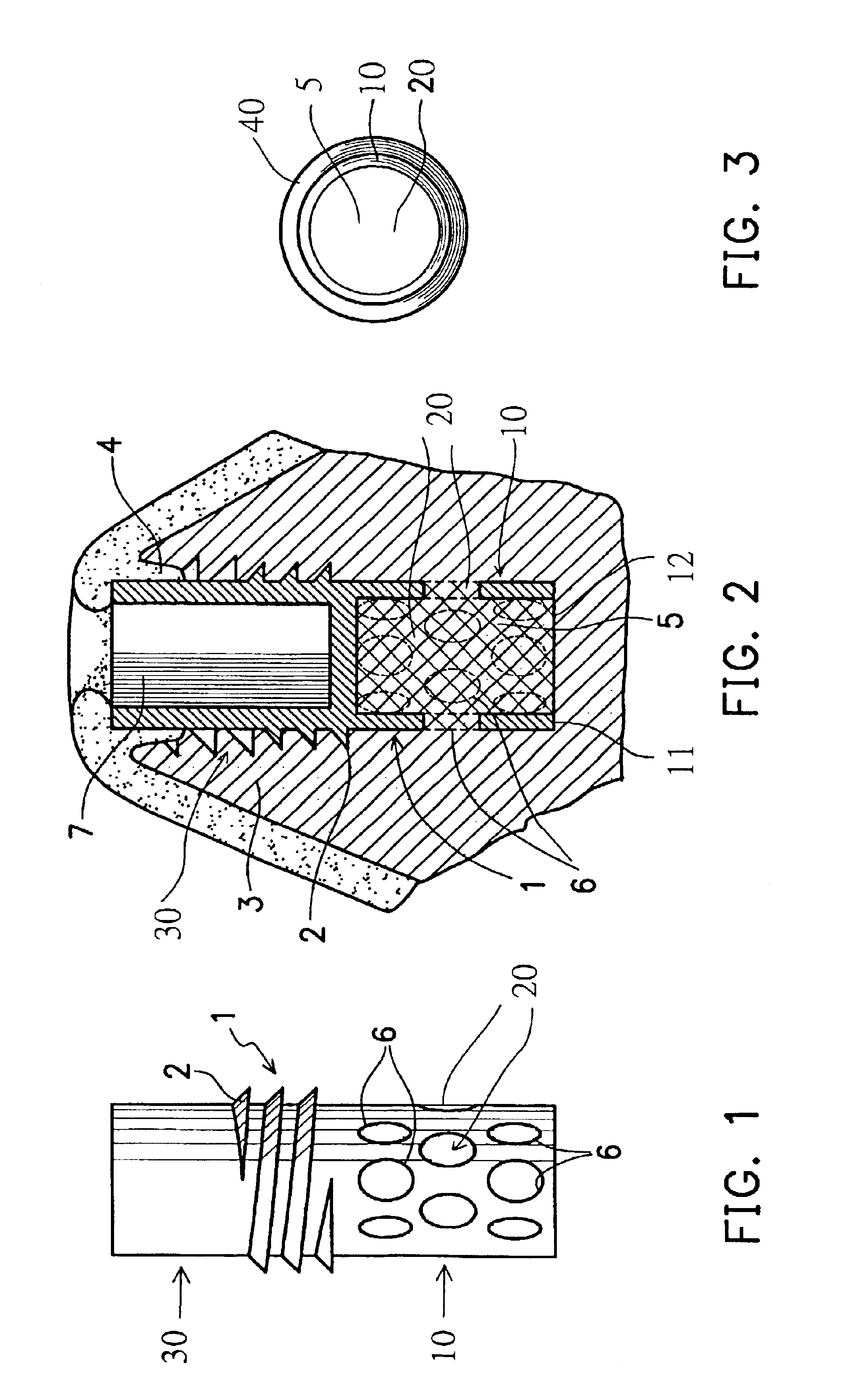

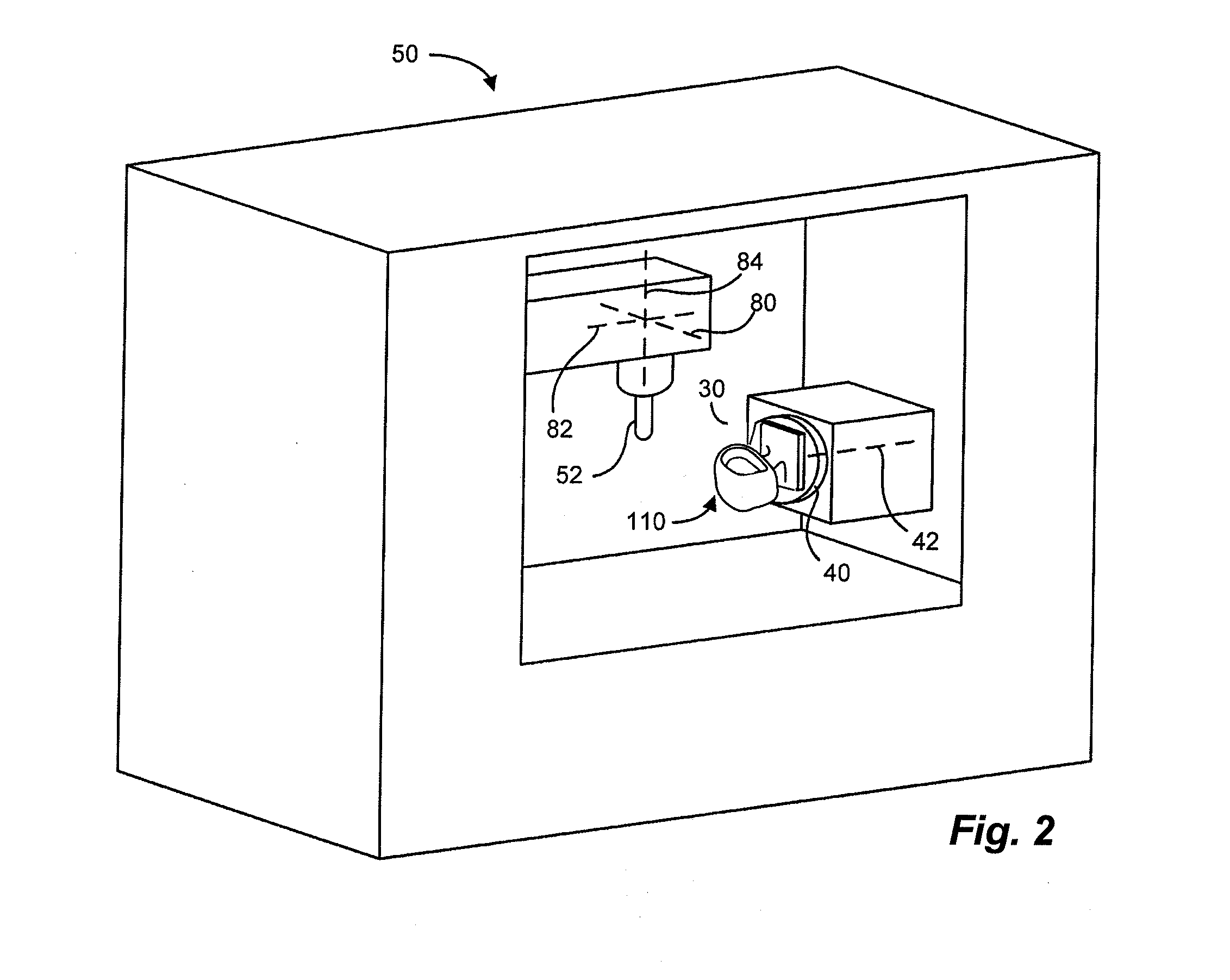

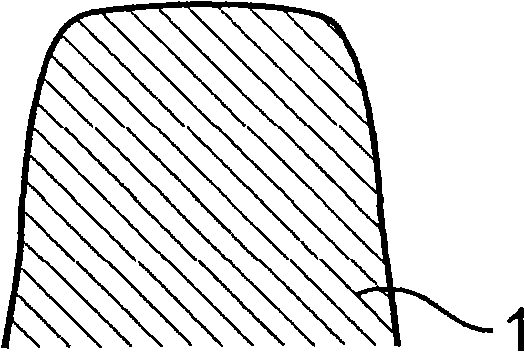

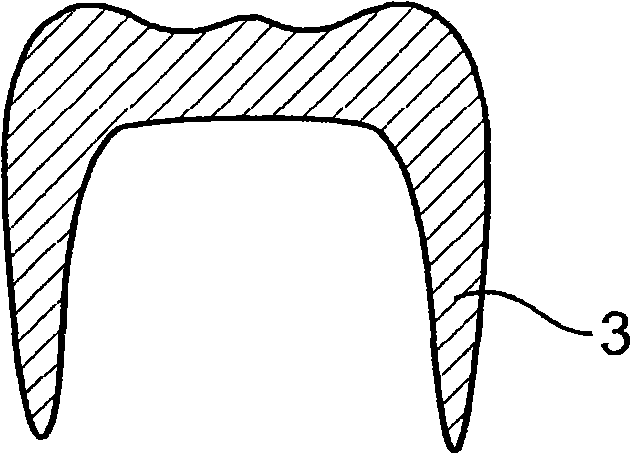

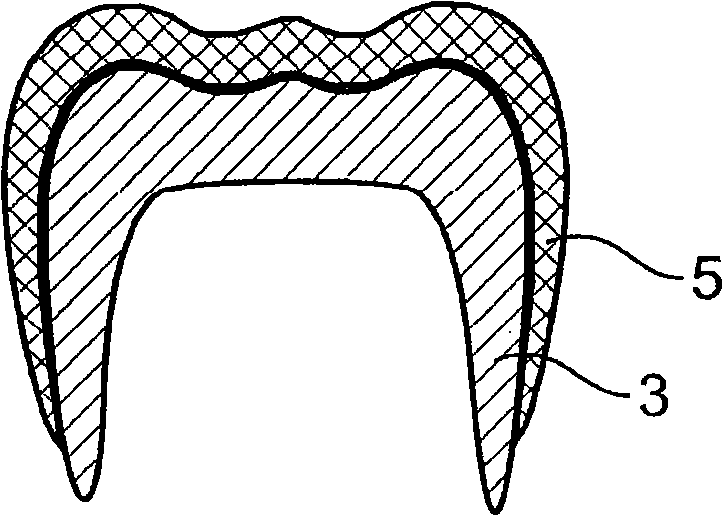

Method and system for producing a dental prosthesis

ActiveCN101360463AEasy to useImprove aestheticsTooth crownsArtificial teethDenturesUniform - quality

The invention relates to a method (100, 200, 300) for producing a dental prosthesis (17) with a framework (3) and a veneer (15), in particular for producing a crown, a bridge, an inlay or an onlay. The invention further relates to a system (40, 50) for producing a dental prosthesis (17) with a framework (3) and a veneer (15) and to a corresponding computer program. To allow the dental prosthesis (17) to be produced in a short time and in uniform quality, irrespective of the skill of the operator, the following steps are provided: definition (110, 210, 310) of three-dimensional geometrical data of the veneer (15), provision (101) or preparation (218, 318) of the framework (3), production (120, 220, 320) of a model (5, 5a, 5b, 5c, 5d) of the veneer (15) on the basis of the three-dimensional geometrical data of the veneer (15), on the framework (3) or separately, formation (124, 224, 324) of a female impression (11) of the veneer (15) by inclusion (126, 226, 326) of the model (5, 5a, 5b, 5c, 5d) between the framework (3) and a shaping material (9), and then removal (128, 228, 328) of the model (5, 5a, 5b, 5c, 5d), and filling (130, 230, 330) of the female impression (11) with veneer material for producing the veneered dental prosthesis (17).

Owner:BEGO BREMER GOLDSCHLAGEREI WILH HERBST

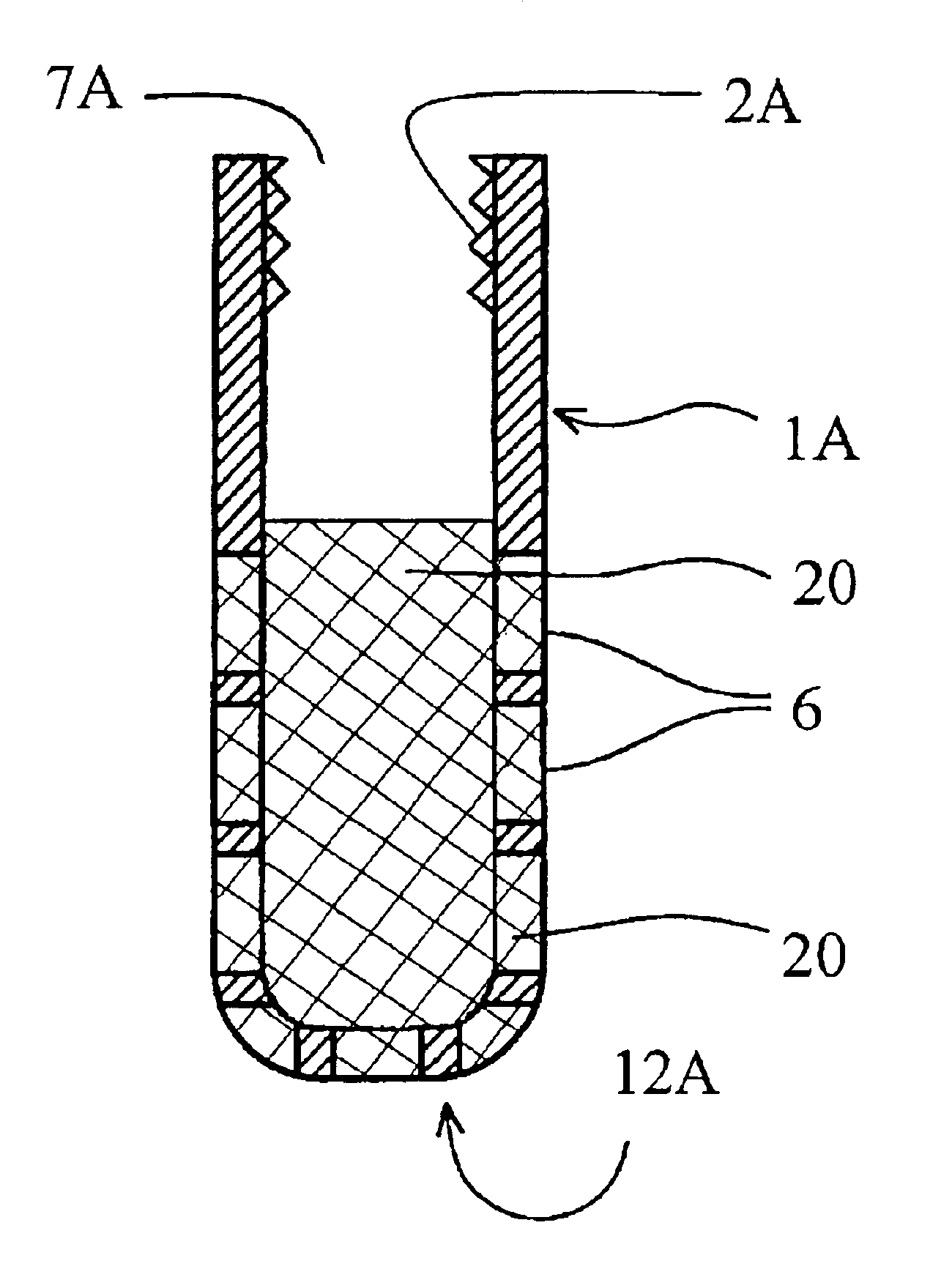

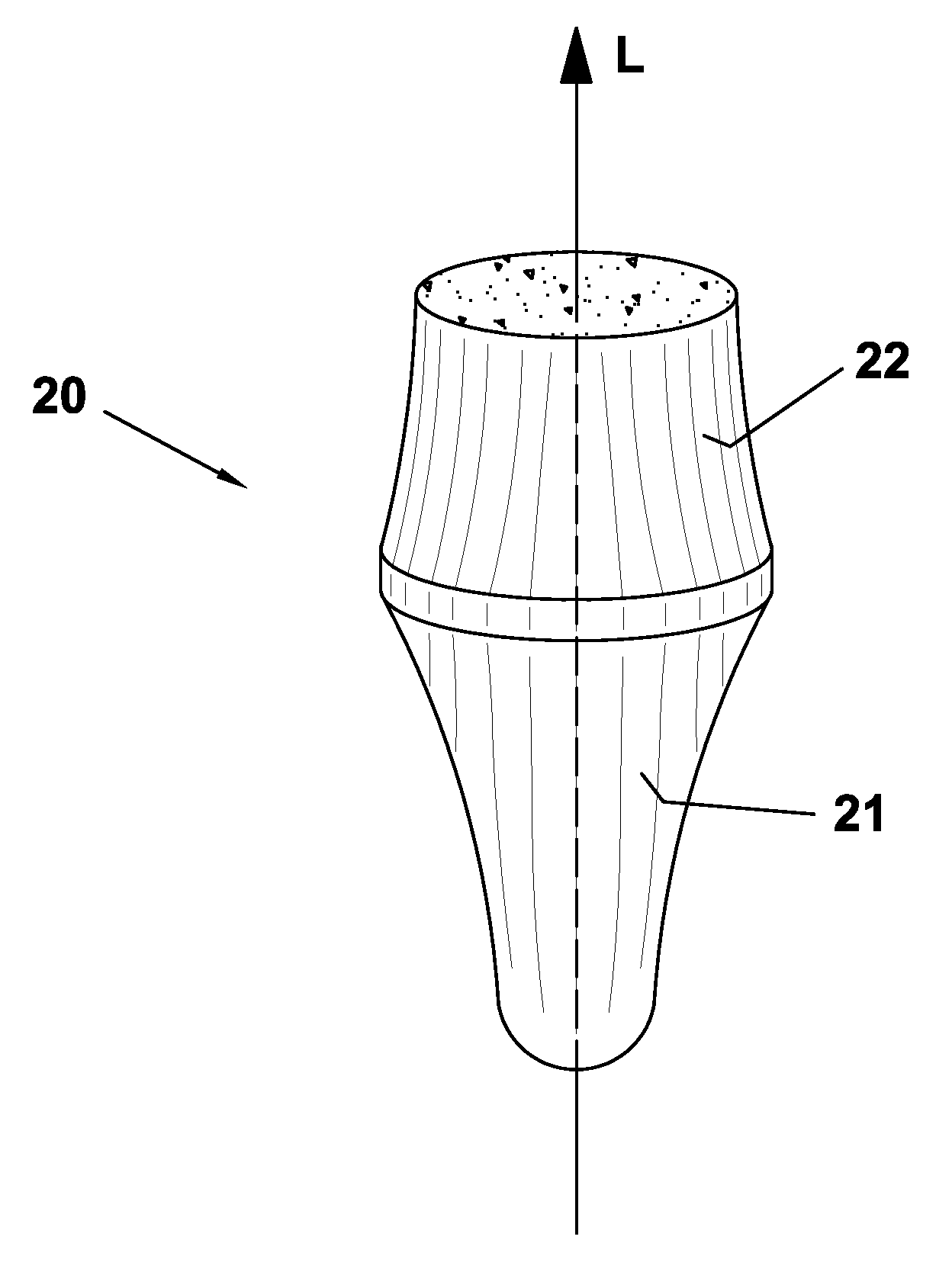

Dental implant

The invention relates to a dental implant configured to be anchored in a jawbone for supporting a dental prosthesis.In order to allow an adjustment of the tooth restoration structure to properties of a natural tooth the dental implant comprises a jacket member consisting at least in part of an osseo-integratable material and enclosing a cavity in an apical direction, and a filling member consisting of fiber reinforced material and being shaped so as to substantially fill out said cavity.

Owner:NORDIN PETER +1

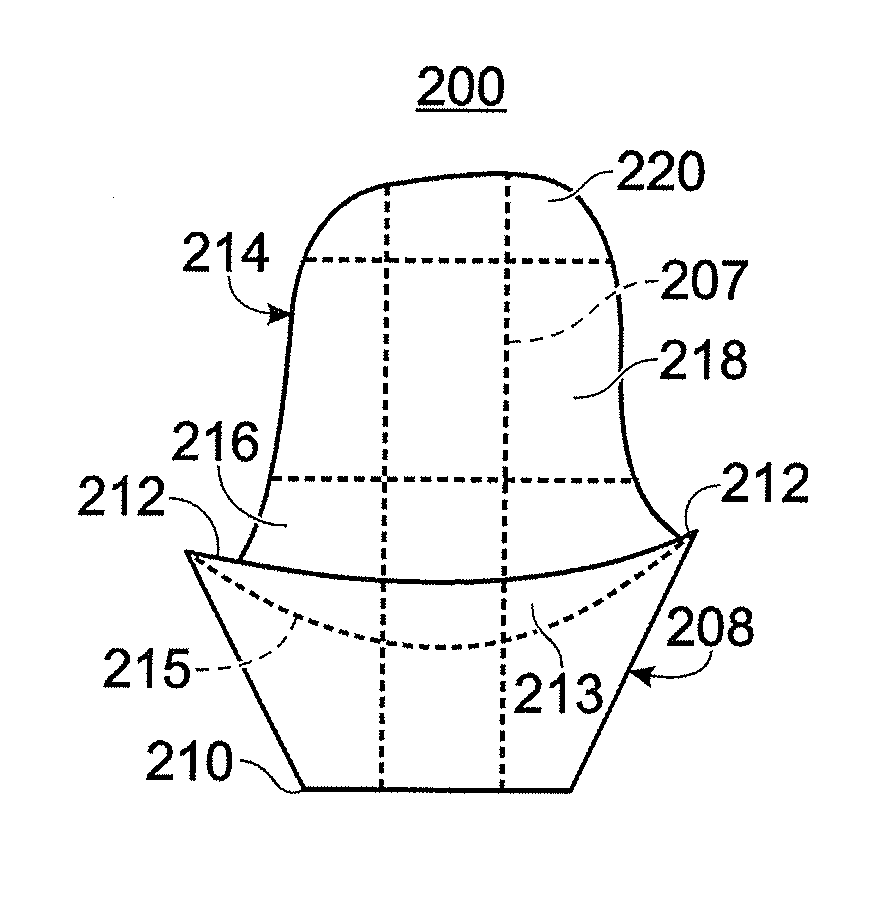

Dental prosthesis and method of its production utilizing standardized framework keys and matching premanufactured teeth

ActiveUS20130167380A1Rapid and precisely accurate methodHighly repeatableDental implantsFastening prosthesisDenturesMethods of production

A system including a method and associated structures creates efficiencies in the manufacture of prosthetic tooth support frameworks. Pre-manufactured teeth with matching internal keys are used in the setup of a patient prototype. Each key includes a shaft, a cervical platform, a retention knob and preferably at least one channel for the expulsion of excess adhesive fluid. The cervical platforms are shaped to provide intimate contact with a base of their respective tooth. The same tooth / key pairs are then used to make a framework pattern from the setup positioning. The pattern can be cast or scanned for direct machining to produce the finished framework.

Owner:GLOBAL DENTAL SCI

Dental prostheses modeling system with symmetric double-well trays slidably mountable to articulator

A dental prostheses modeling system includes a molding tray for molding the base of a quadrant or full-arch dental model cast which has a longitudinally disposed partition panel disposed generally between upper and lower surfaces of the tray that forms therewithin an upper well for receiving liquid die stone to mold the base of a dental impression model, and a lower well shaped symmetrically to the upper well for providing clearance for optional manipulating pins installable in the bases of selected die segments modeling individual dental prostheses severed from the hardened die stone base of the model. The partition panel includes peripheral flanges for supporting the base of the dental model, and an openable central portion for enabling a hardened dental model to be ejected from the tray, and for providing access for manipulating pins depending downwardly from die segments. A pair of slide receptacles for slidably receiving a modeling tray is removably attachable to upper and lower arms of a laboratory articulator, from which a pair of molding trays holding a pair of dental models can be slidably removed and attached to a disposable hinge mechanism to comprise a articulateable full-mouth model for a dentist and patient.

Owner:HONSTEIN JERRY P

Asymmetrical dental implant

Owner:WOHRLE PETER +1

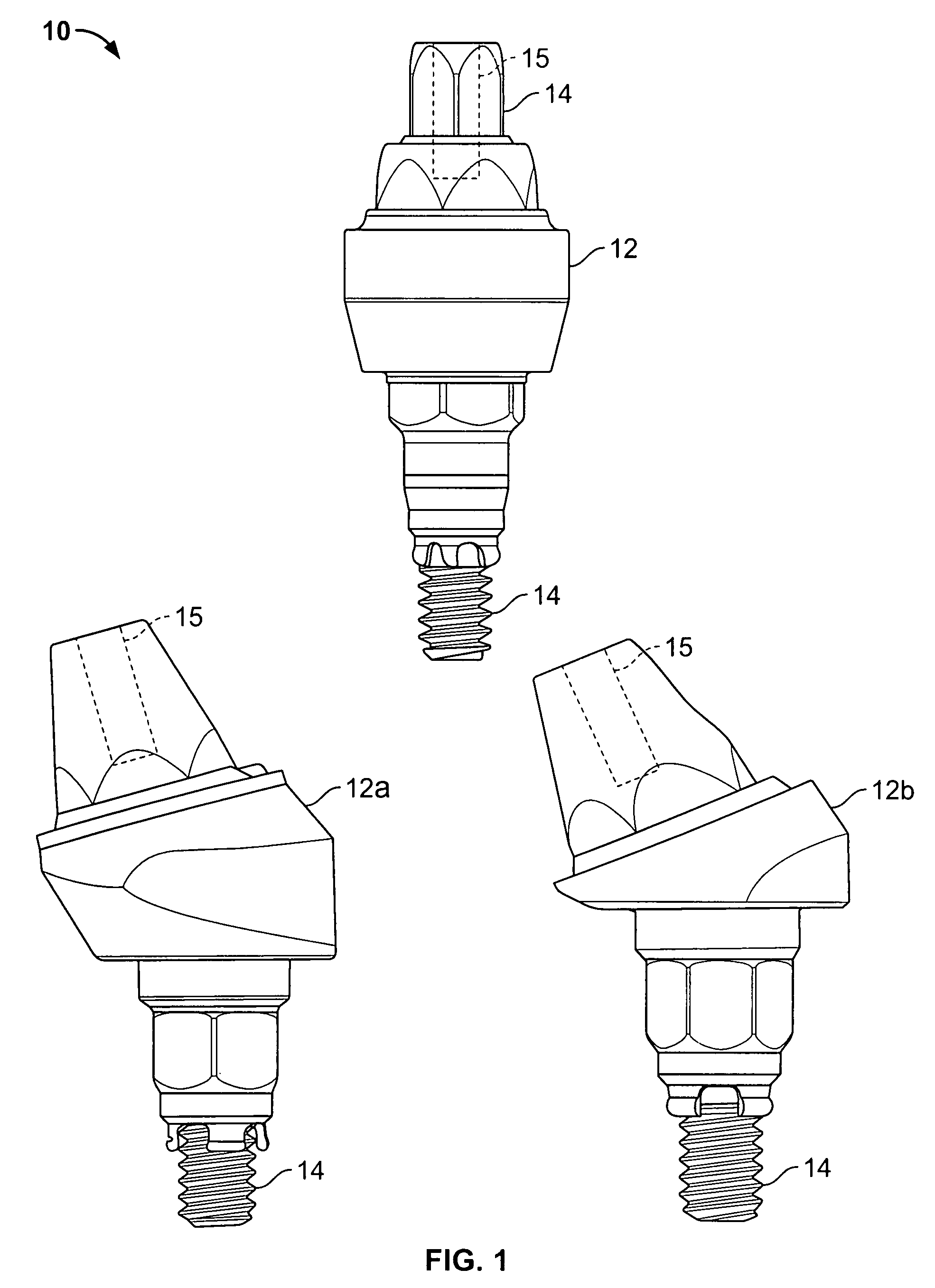

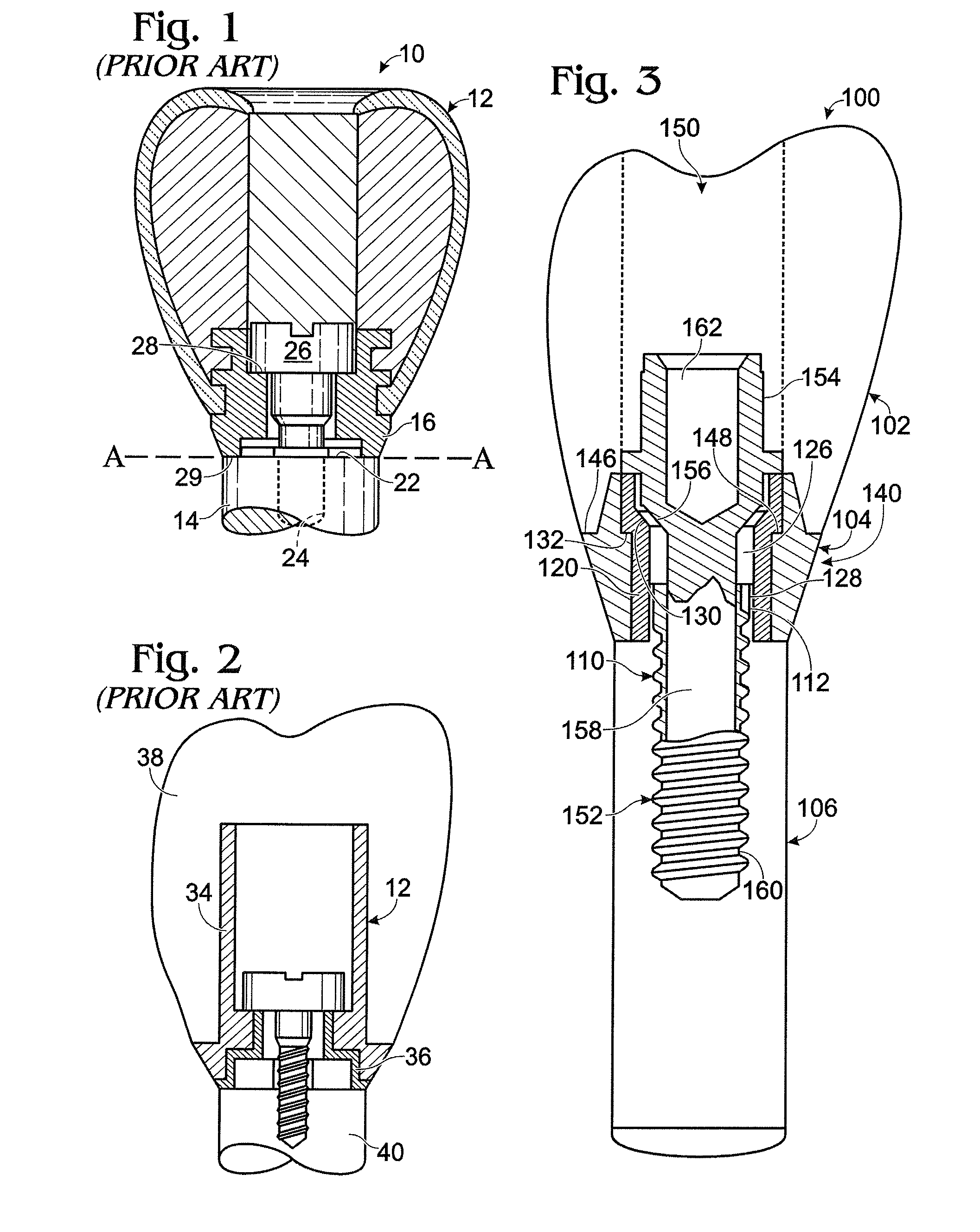

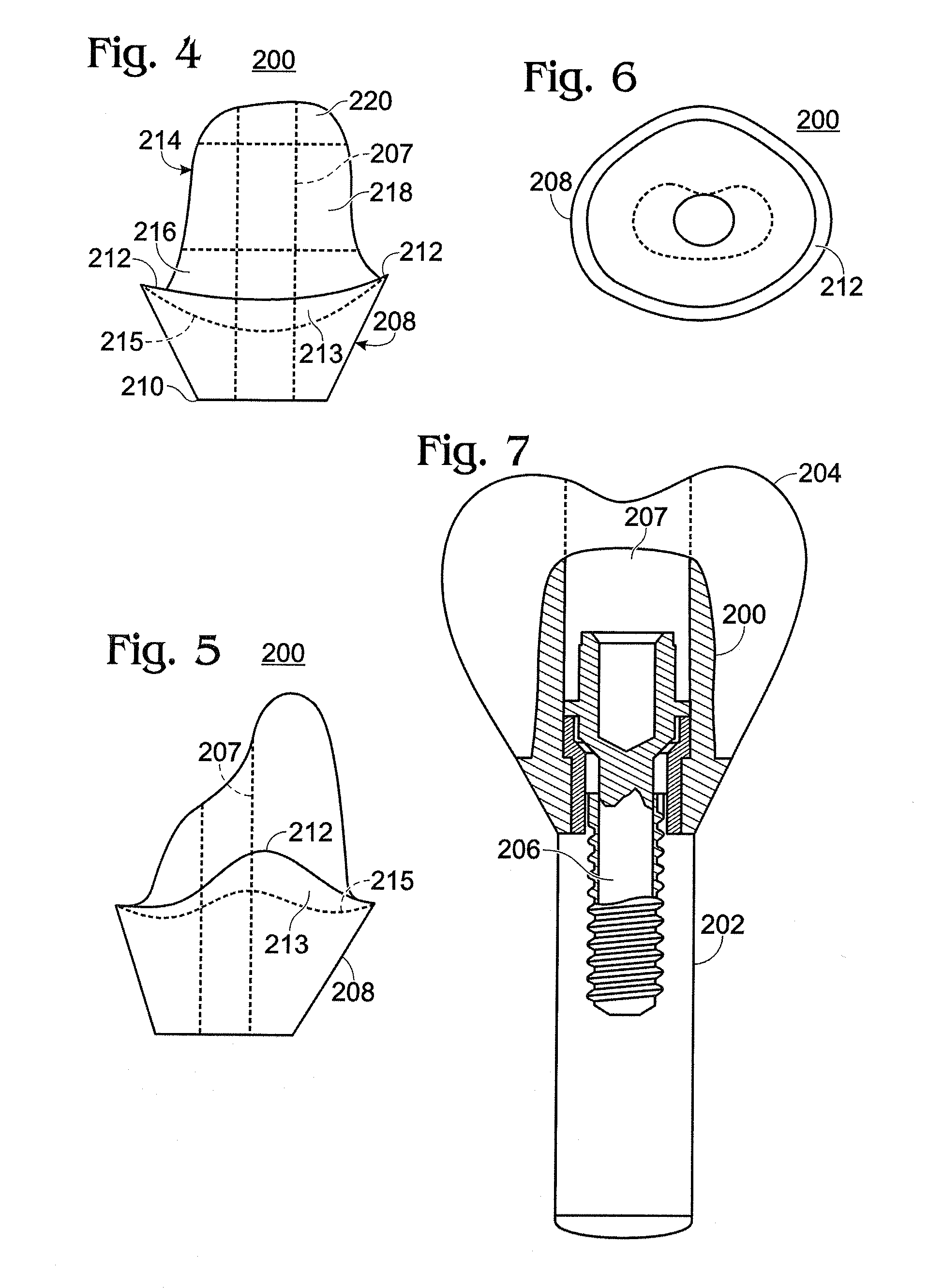

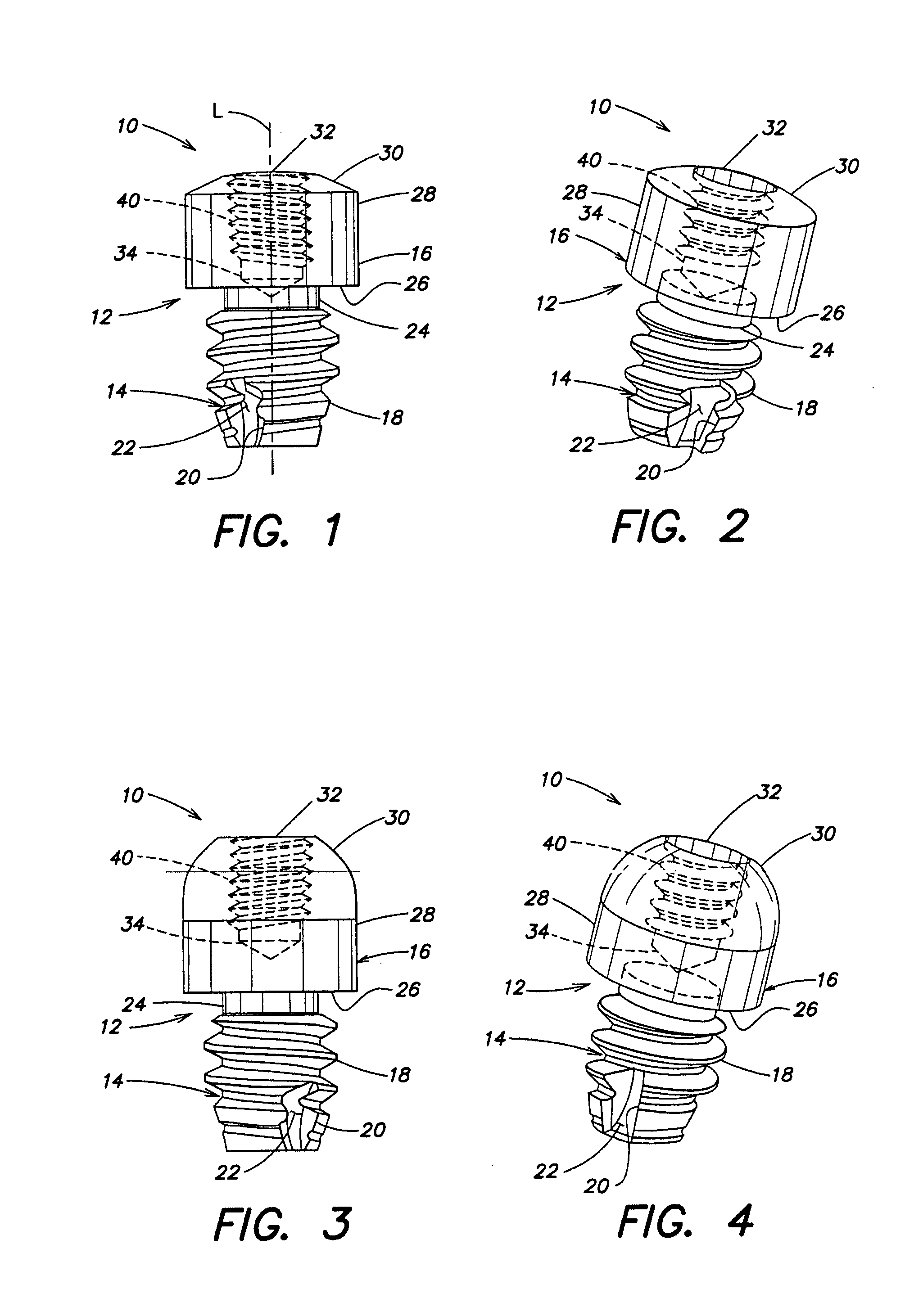

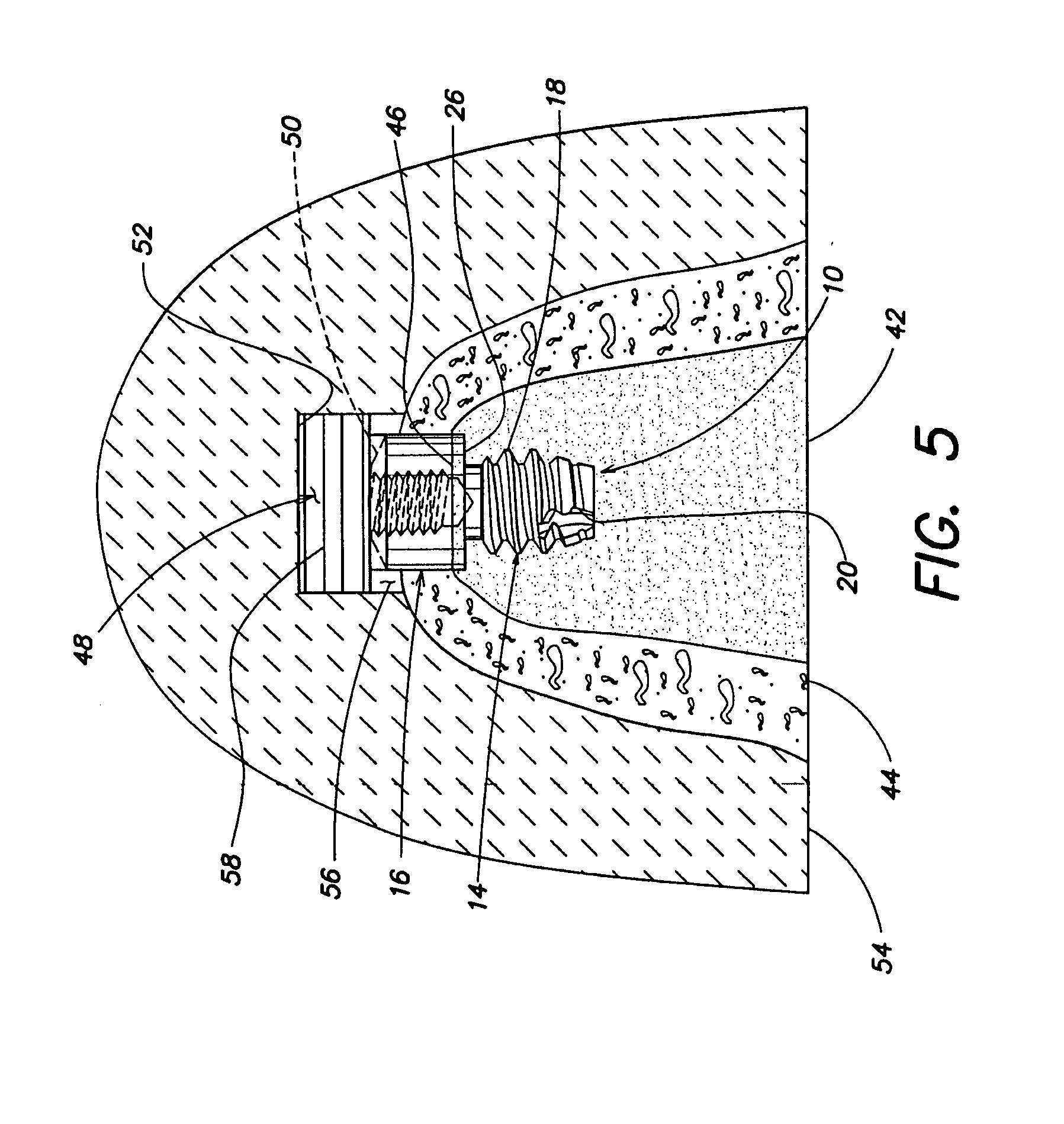

Dental implant for supporting a dental prosthesis

Dental implant (10) for supporting a dental prosthesis on a jaw bone, is equipped with a main body (12), which comprises a securing portion (14) intended to be anchored in the bone tissue and, lying opposite it, a head portion (16). The head portion (16) protrudes radially beyond the securing portion (14) with respect to the longitudinal axis of the main body (12) to form a support face (26), in such a way that, in the state of insertion in the jaw bone, the pressure of the dental implant (10) on the jaw bone is reduced, and a sinking movement of the dental implant (10) into the jaw bone is effectively avoided, even over quite long periods of time.

Owner:STRAUMANN HLDG AG

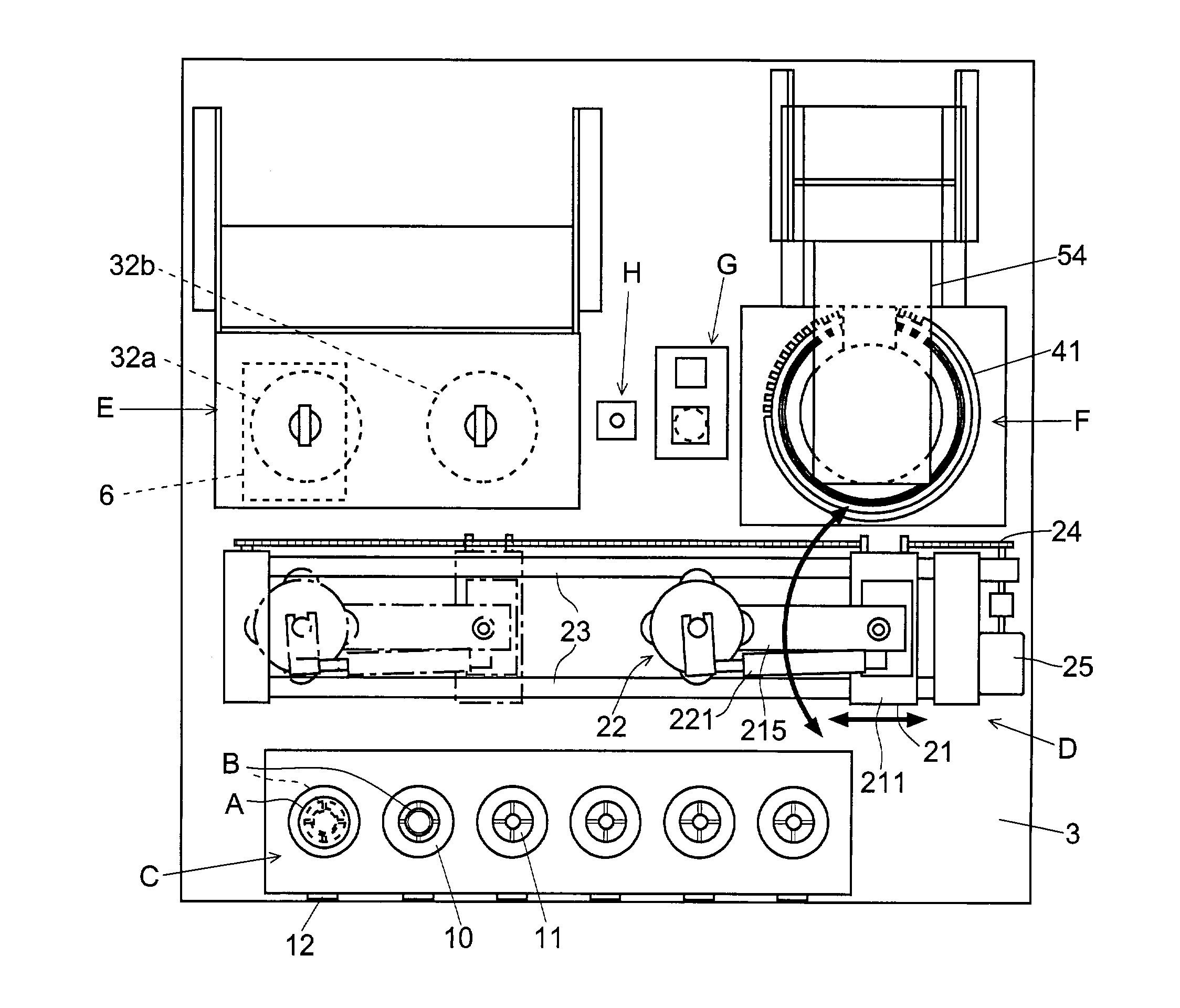

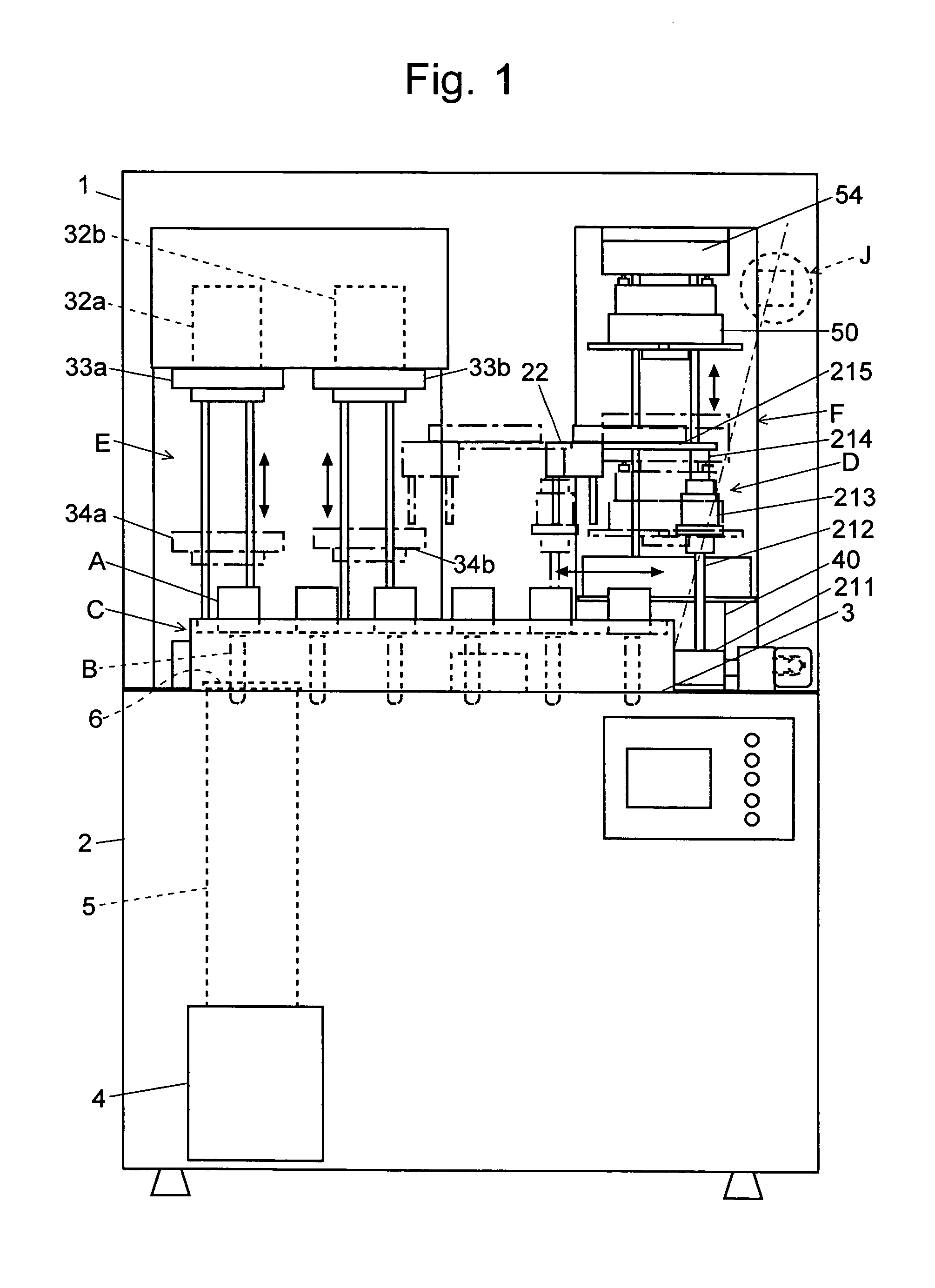

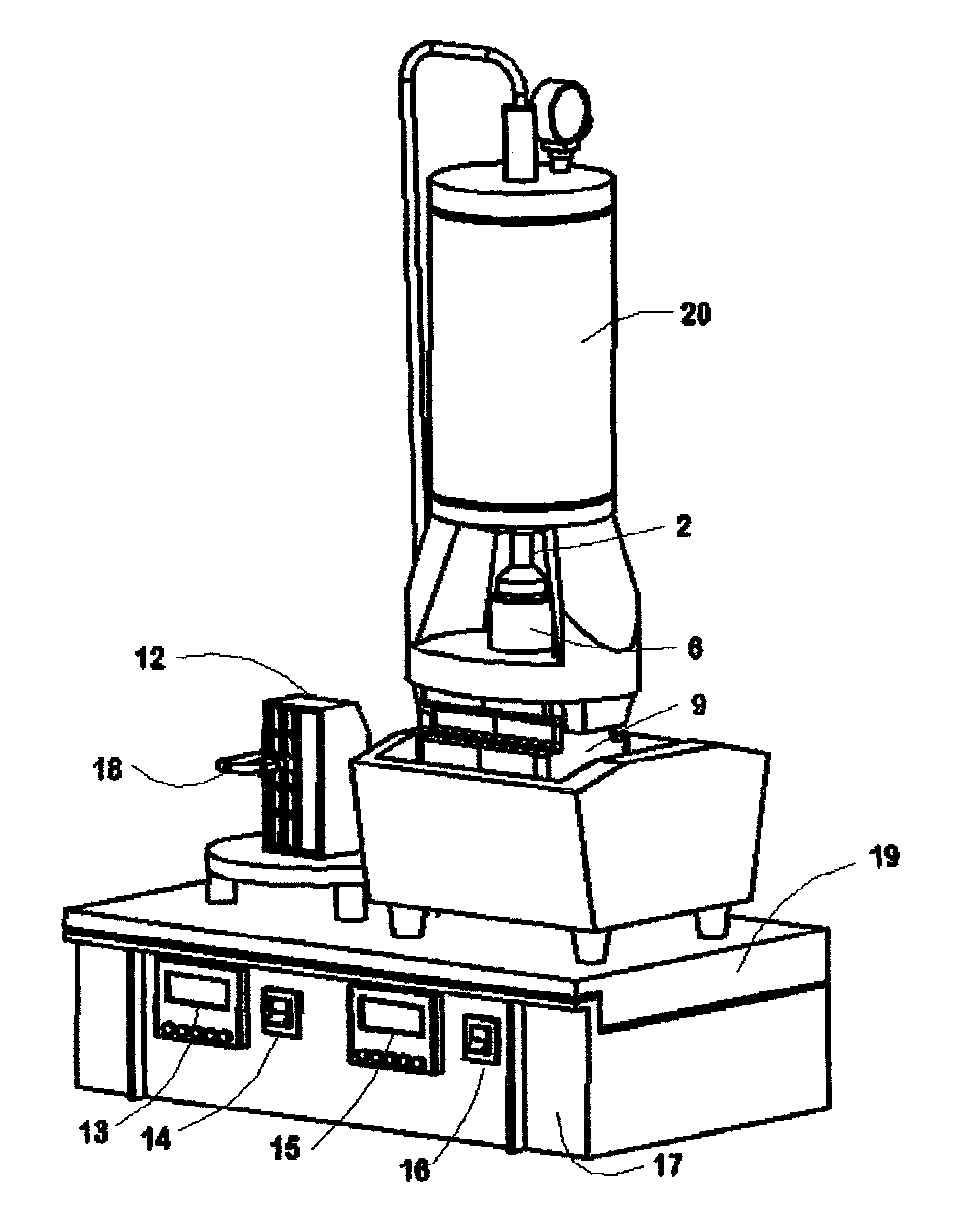

Apparatus for casting dental prosthesis

InactiveUS7048031B2Easy to checkEnhance the imageMelt-holding vesselsPig casting plantsBurn unitsDentures

A new apparatus for casting dental prosthesis has been proposed, comprising a ring-placing section onto which plural rings are to be placed, a crucible holder for holding plural cylindrical crucibles, a burning unit with a furnace, a casting unit and a conveyer for conveying the ring or the crucible. The lifting state of the burning unit includes a base capable of rotating around a substantially horizontal axis, an orientation-maintaining mechanism for maintaining the base substantially horizontal and an orientation-changing mechanism for exerting an external force onto the base. The conveyer performs a position-correcting motion for correcting the position of the ring by lowering the gripper. The apparatus provides a management code to each crucible for preventing troubles or delay of work caused by the breaking of crucibles due to the aging.

Owner:DENKEN

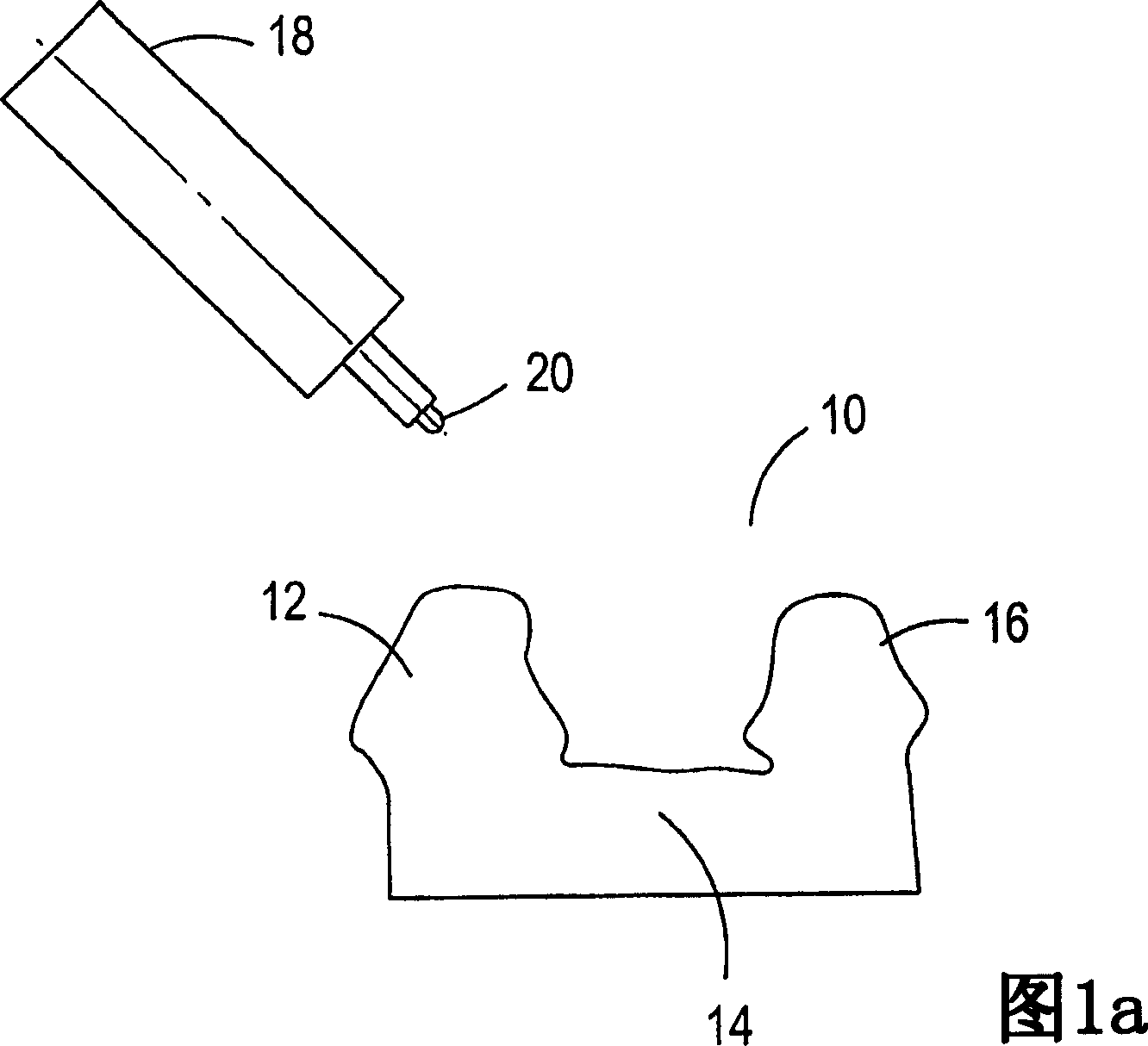

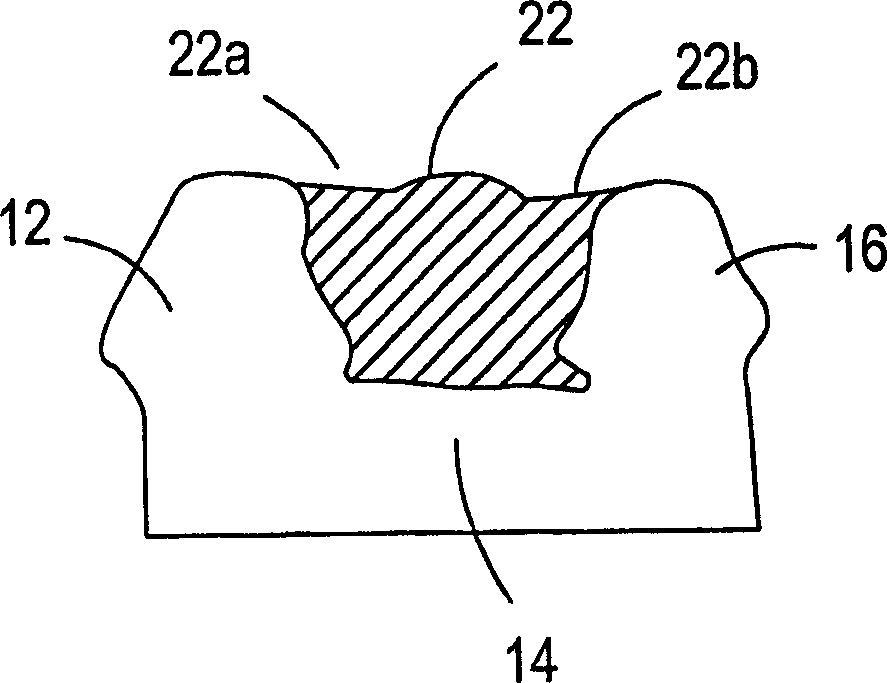

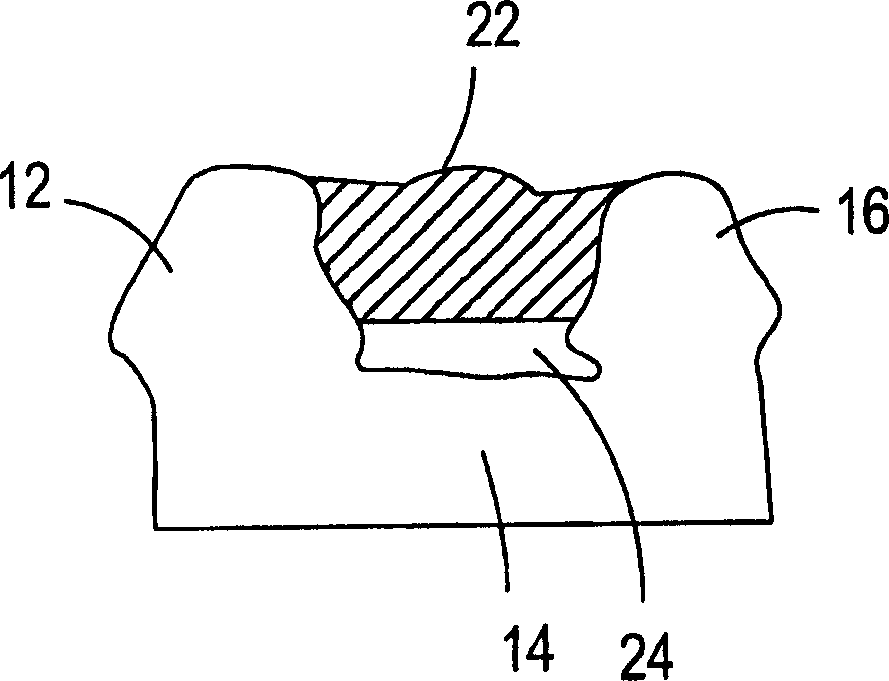

Manufacture of dental prostheses

A method of determining the shape of a dental prosthesis is disclosed comprising, scanning at least a connecting portion (14) of a preparation (10), wherein the preparation (10) comprises a first anchor (12) and a connecting portion (14) connected thereto, forming a physical model on the connecting portion (14) to produce a pontic (22), and scanning at least the pontic (22) whereby the surface of the first anchor (12) is also scanned during a scanning step whereby the scanning steps can be carried out in either order. The preparation (10) may be scanned to provide data concerning relative locations of the first anchor (12) and connecting portion (14), which may be used to align data obtained during the scanning steps. Also disclosed is a method of producing a model of a dental prosthesis and a method of manufacturing a dental prosthesis.

Owner:RENISHAW PLC

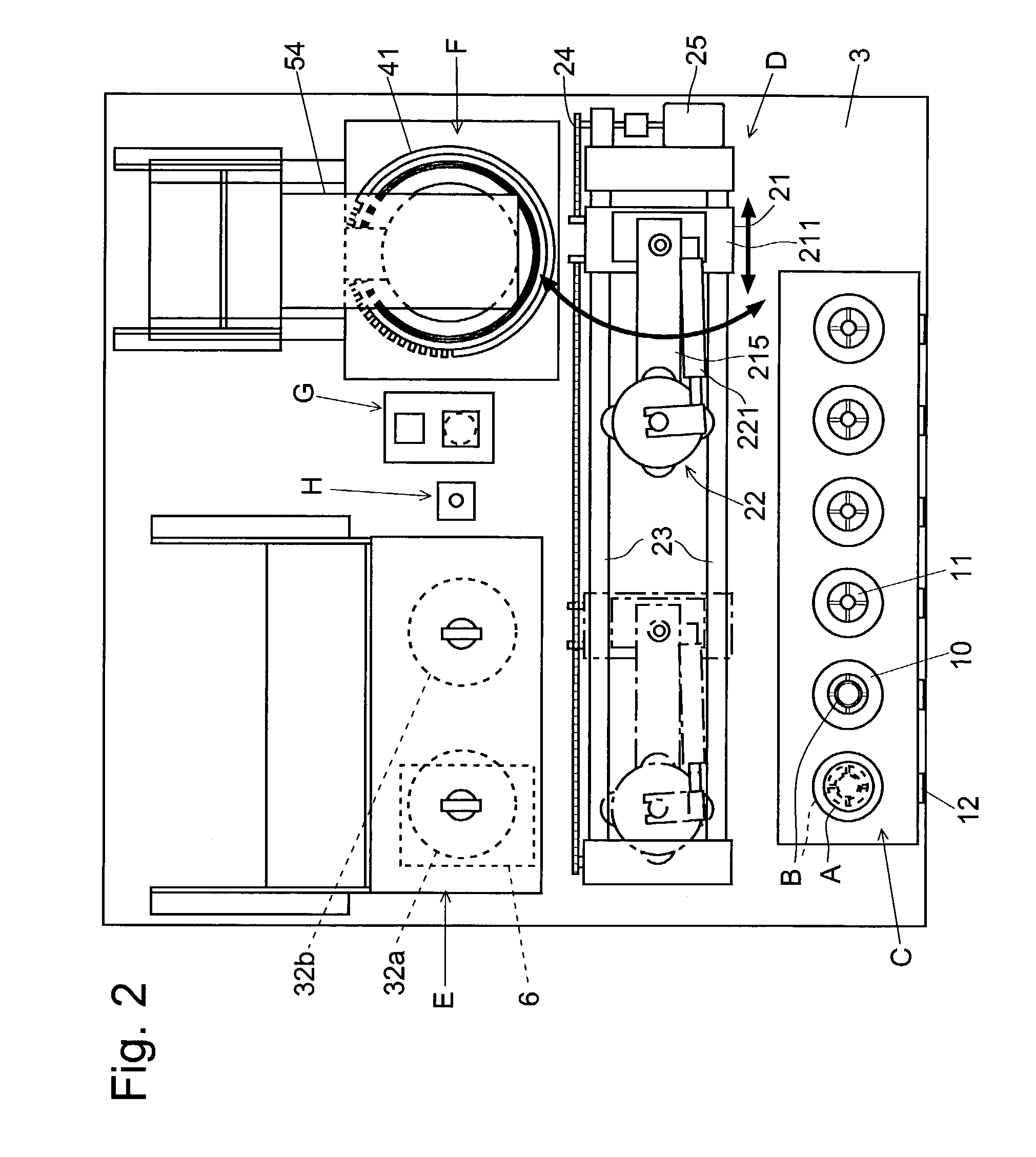

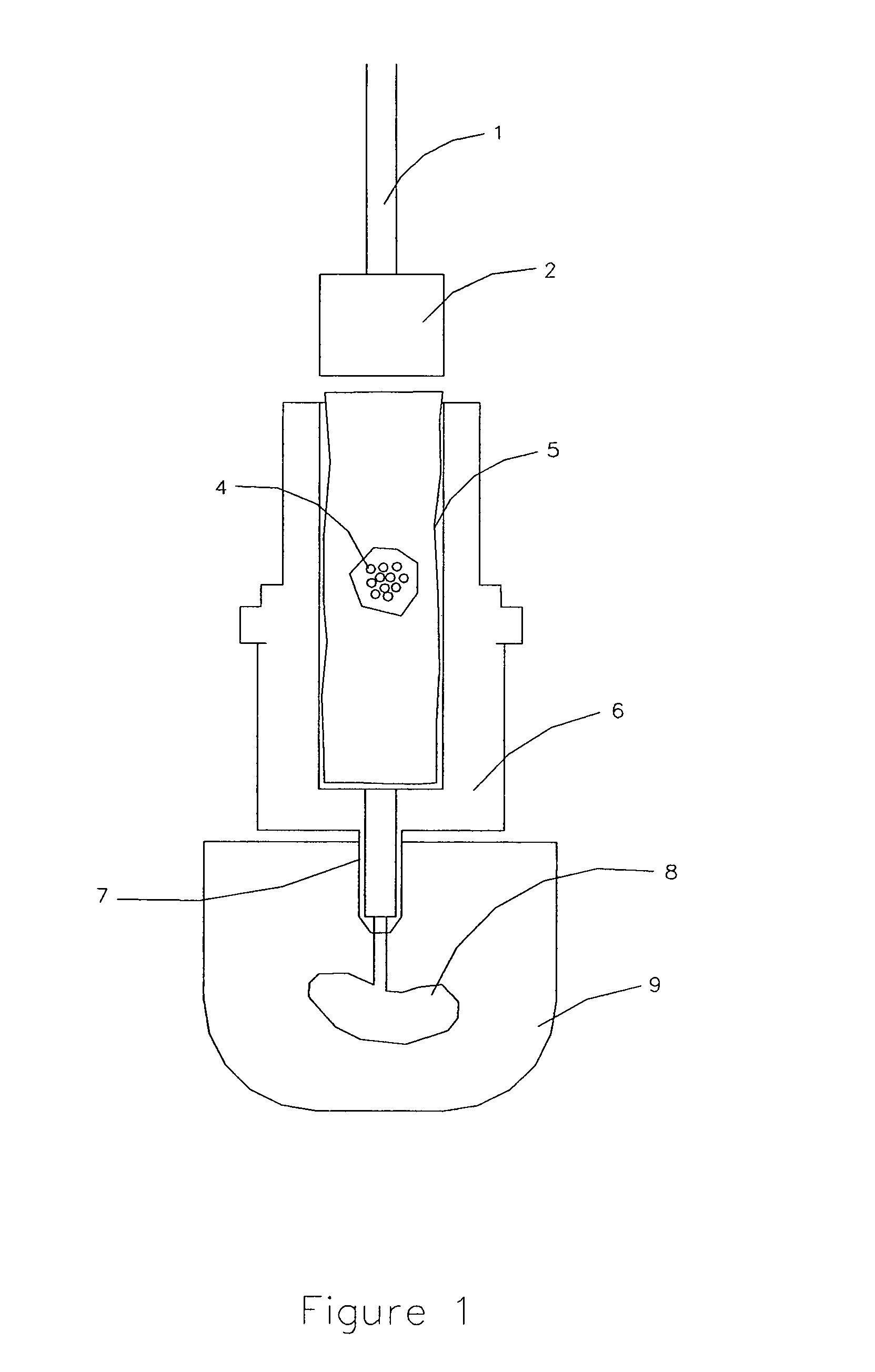

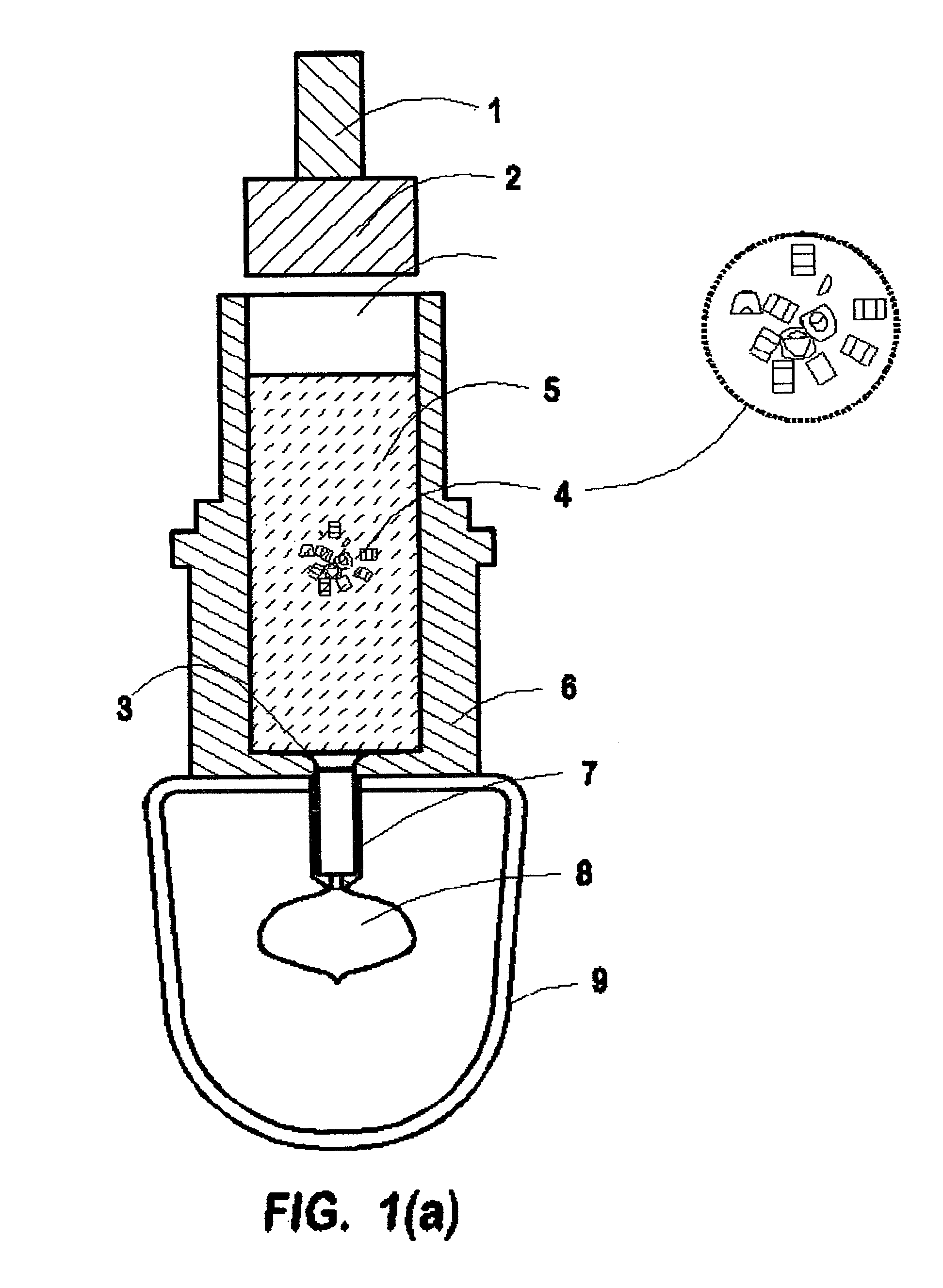

Apparatus for producing dental prostheses

Disclosed are an apparatus, materials, devices and methods for the use of a variety of thermoplastic resins in fabricating dental prostheses without the use of expensive hot-press equipment unavailable to most dental laboratories. The prostheses made by the process and materials disclosed herein provide more attractive and longer lasting prostheses with significant savings in both costs and materials. Among the aims of the technology disclosed is to save time and money for the dental industry (dentists, dental labs) and the dental consumer / patient.

Owner:CDM DENTAL LLC

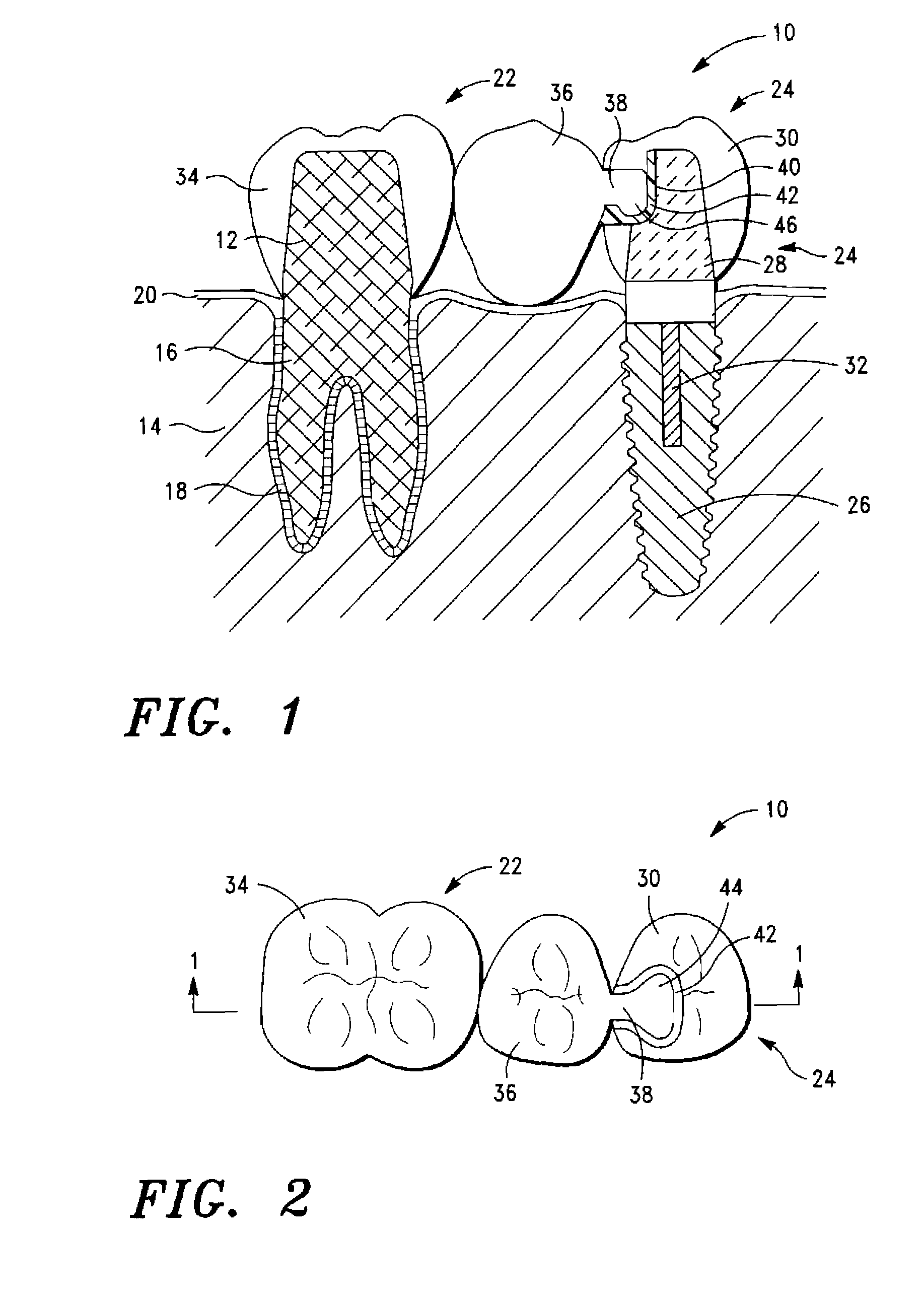

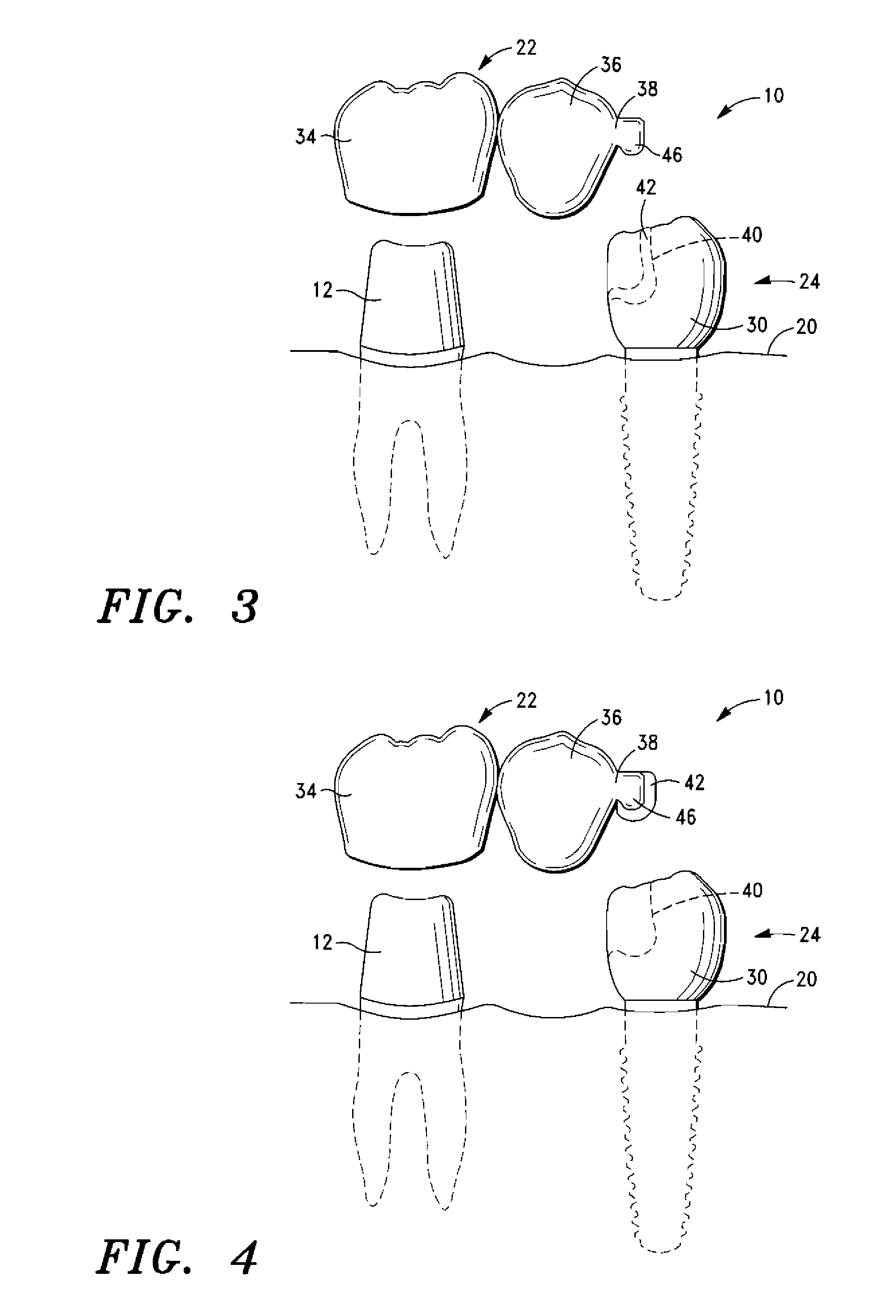

Dental Bridge

A system for attaching a natural tooth to a dental implant. The system comprises a dental prosthesis and an elastomeric cushion. The dental prosthesis has a first end and a second end. The first end is fixed to a natural tooth and the second end is engaged with a dental implant. The elastomeric cushion is positioned in contact, either directly or indirectly, with at least a portion of the dental implant and at least a portion of the dental prosthesis such that the elastomeric cushion permits movement of the second end relative to the dental implant in response to movement of the natural tooth transferred through the dental prosthesis to the second end.

Owner:RANDALL JAMES MICHAEL

Positioning jig and improved methods to design and manufacture dental implants

This invention is directed to a positioning jig for preparing a two or more of adjacent teeth for a dental prosthesis comprising a member with (i) three or more parallel bores in the member and (ii) one or more means to attach the member to a dental articulator. The invention is also directed to methods of use of the position jig such as to prepare a series of aligned holes in teeth or aligned holes mockup of a dental bridge for a prosthesis.

Owner:LERNER TODD H

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com