Positioning jig and improved methods to design and manufacture dental implants

a technology of dental implants and jigs, which is applied in the field of positioning jigs, can solve the problems of high mechanical complications of hybrid prostheses, inability to design and manufacture dental implants with individualized metal supports, and attachment to underlying teeth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]5.1. Positioning Jigs

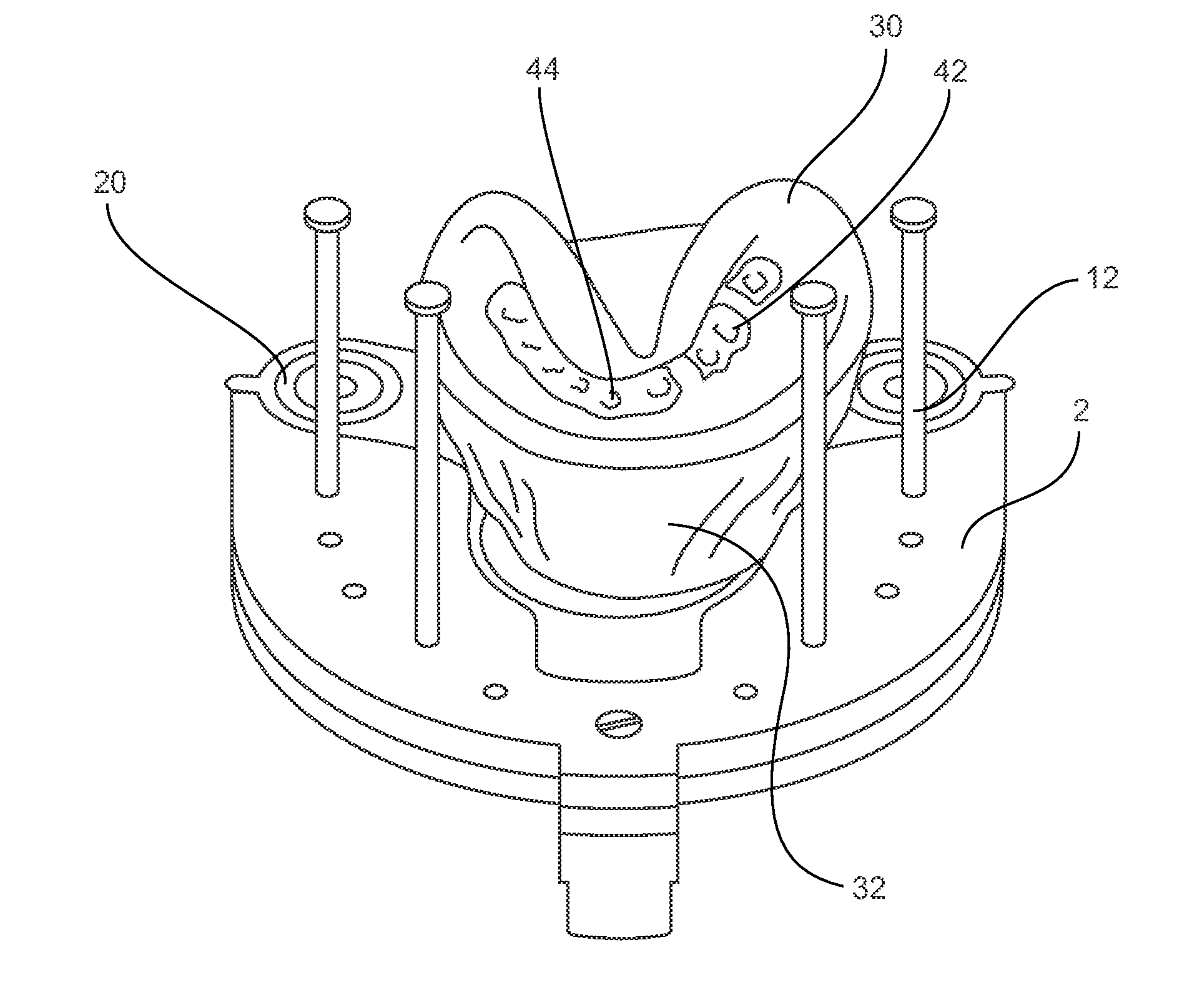

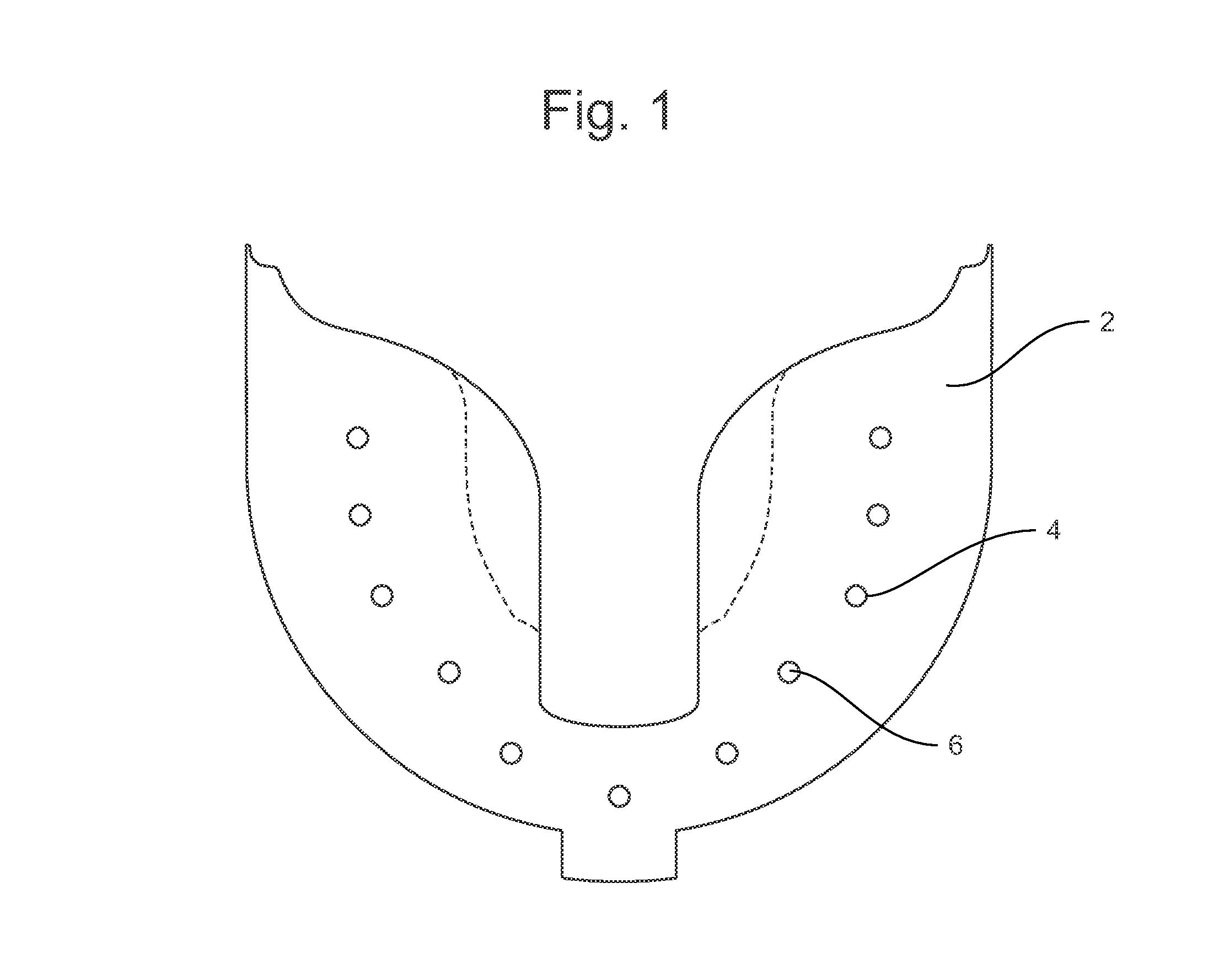

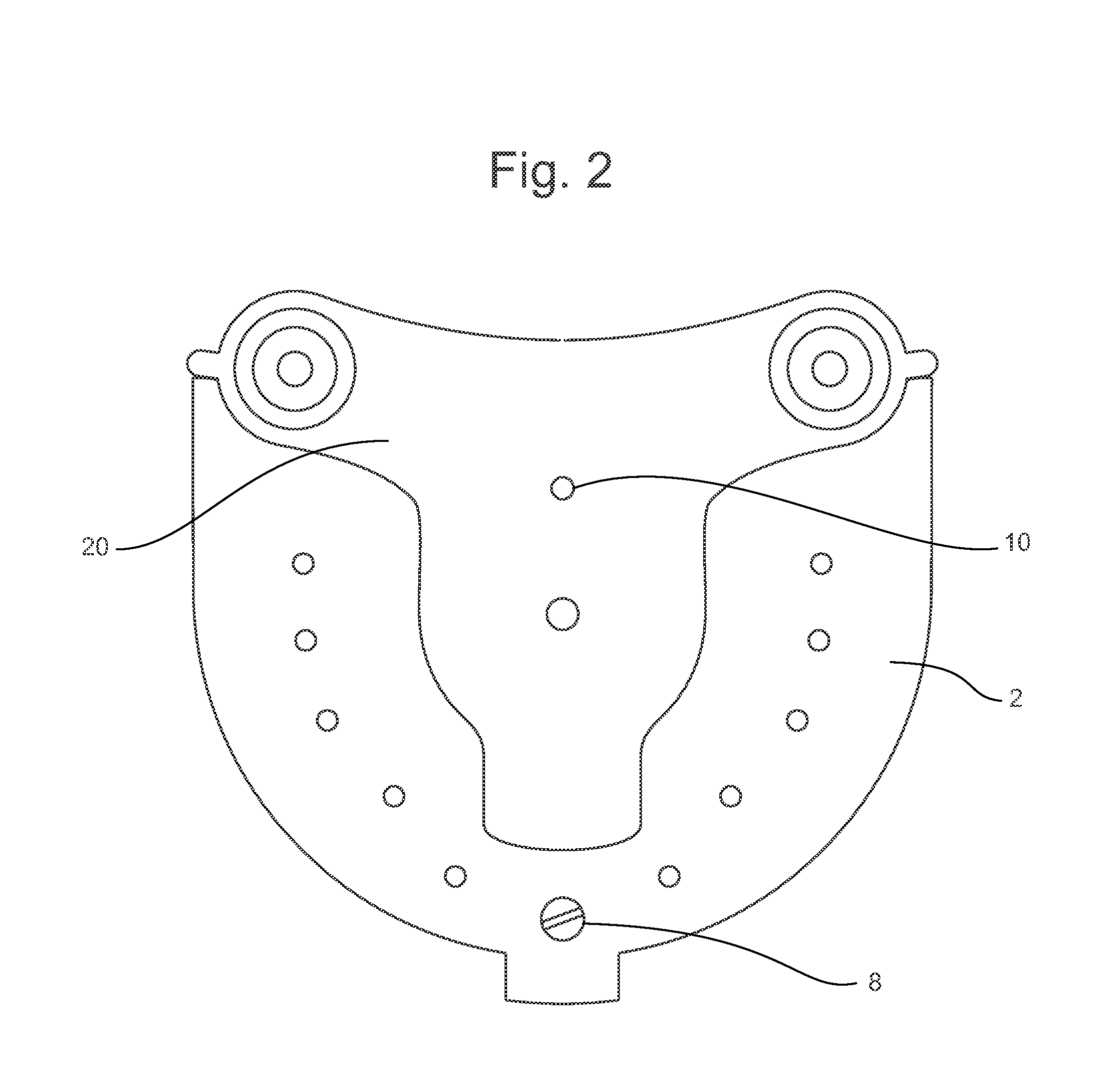

[0036]The invention provides a positioning jig for preparing two or more adjacent teeth for a dental prosthesis comprising: a member with (i) three or more parallel bores in the member; and (ii) one or more means for attaching the member to a dental articulator. In one embodiment, the member has four or more parallel bores. In another embodiment, the member has six or more parallel bores. In a preferred embodiment, the parallel bores are perpendicular to the plane of the member. In one non-limiting embodiment of the positioning jig, at least three of the parallel bores are of a first diameter and at least three of the parallel bores are of a second diameter. In a non- limiting preferred embodiment, the parallel bores in the member are distributed evenly on either side of the means for attaching to the dental articulator.

[0037]The positioning jig may have a means for attaching the member to the dental articulator which may be a screw; a pin and a screw; a p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| composition | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com