Scanable tray for producing a dental prosthesis

A technology for trays and dentures, applied in the directions of additive manufacturing, manufacturing tools, applications, etc., which can solve the problems of large oral cavity, uncomfortable removal of patients, and deterioration of dentures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

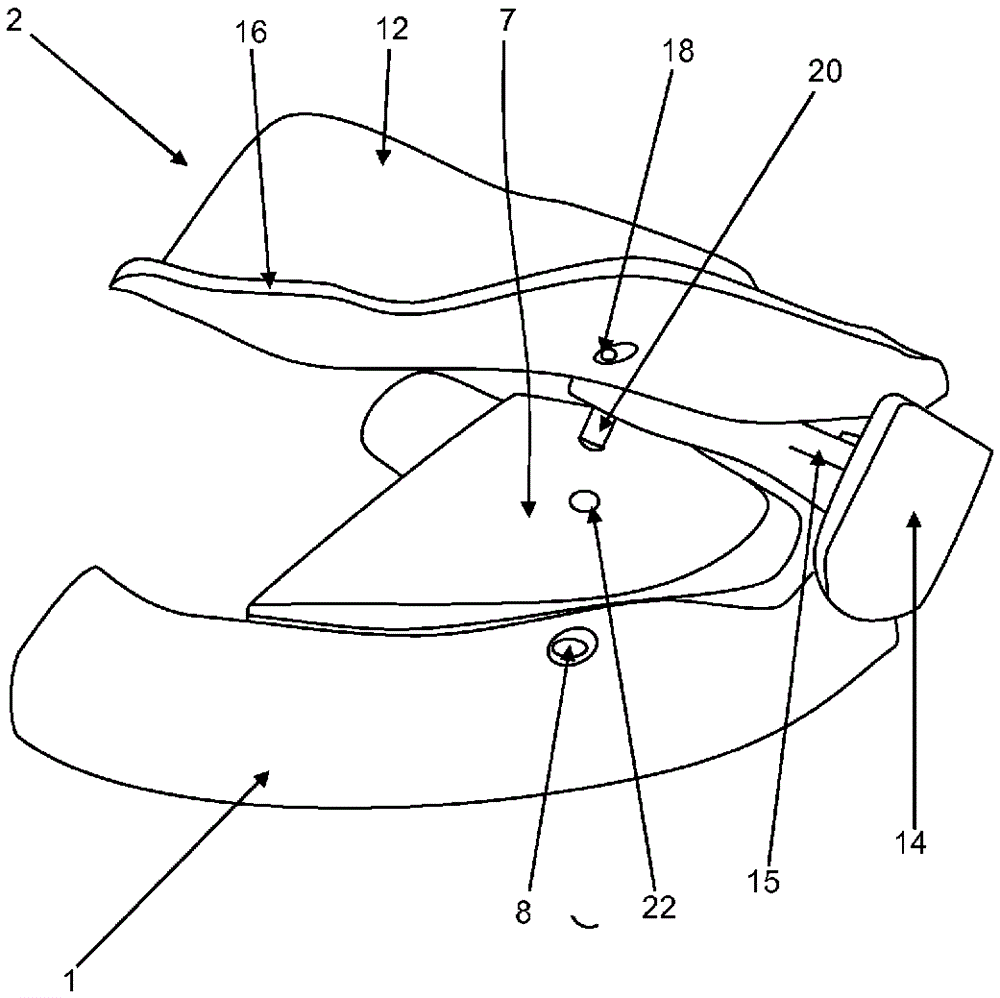

[0052] figure 1 A schematic perspective view of a tray according to the invention for dental impressions is shown. The tray is divided into two tray sections1,2. The first tray part 1 is intended for the lower jaw and the second tray part 2 is intended for the upper jaw. The tray parts 1 , 2 are intended to have impression material (not shown) filled into them, which is then pressed against the patient's alveolar ridge, causing a negative image of the patient's oral condition to be present in the impression material. Such methods are known and can be found in the prior art.

[0053] For this purpose, the tray part 1 for the lower jaw comprises a bed 4 for containing impression material, which is shaped like a dental arch and is designed to be large enough to enclose mandibular dental arches of various shapes. The bed 4 is delimited at both sides by walls 6 extending out of the figure 1 The image plane in , and extends towards the viewer. The bed 4 thus forms a U-shaped pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com