Manufacture of dental prostheses

A technology of dentures and data, applied in the field of the shape of dental bridges, can solve problems that require labor and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

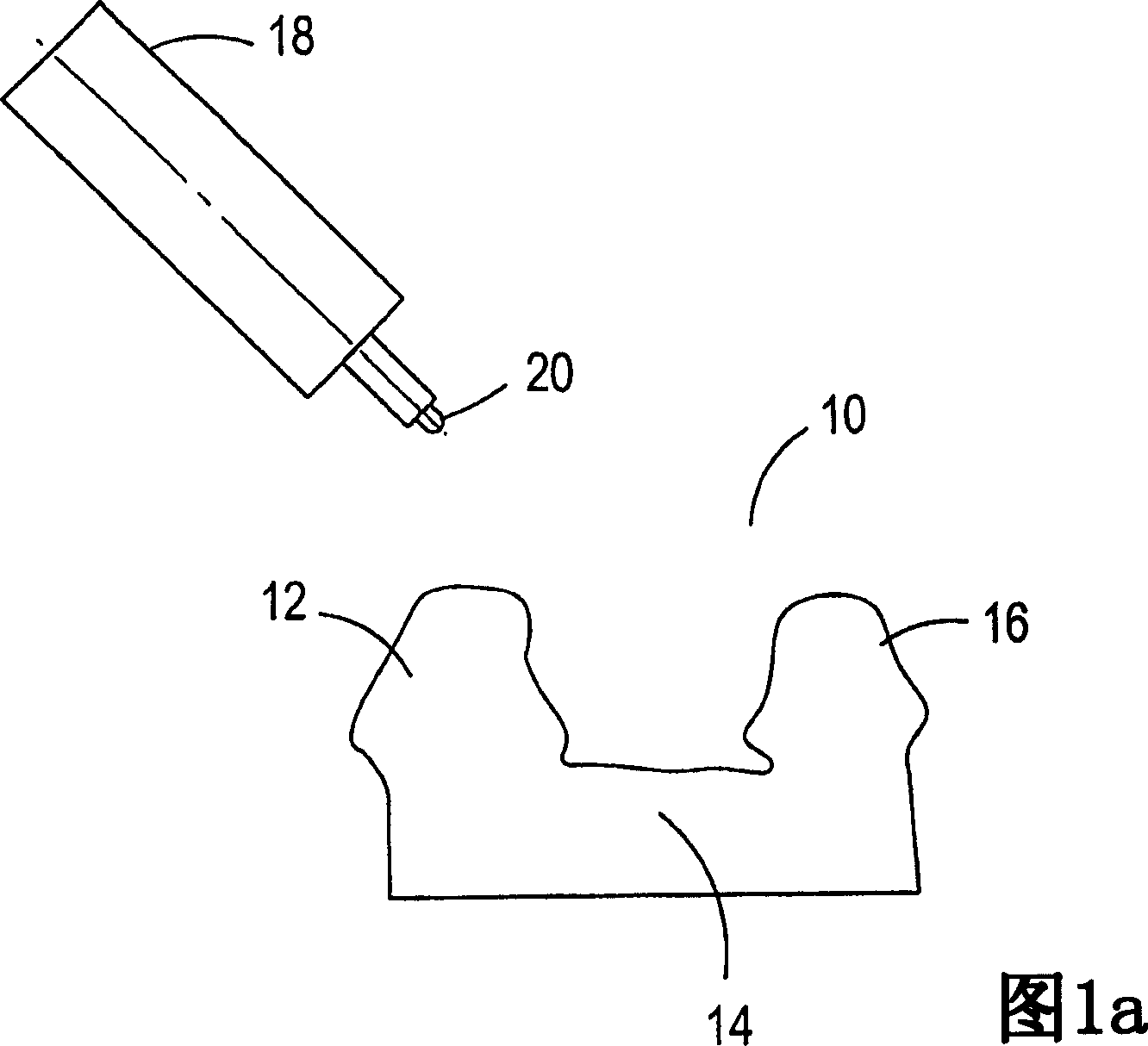

[0021] FIG. 1 a shows a tooth blank 10 , which in this example comprises a first fixing body 12 , a connecting portion 14 and a second fixing body 16 . The first and second fixing bodies are positioned on opposite sides of the connecting portion 14 . The connecting portion 14 is the location of the missing tooth to be replaced by the bridge artificial tooth or pontic.

[0022] The surfaces of the first and second fixed bodies 12 , 16 and the connection part 14 are scanned using a probe 18 with a scanning tip 20 . This can be done as a single module, for example by CT (Computed Axial Tomography) or MRI (Magnetic Resonance Imaging) scan or using a non-contact scanning device as described in US Patent No. 6,217,334. The data from the scan represent the inner surface of the crown that will be fabricated to cover the first and second fixtures.

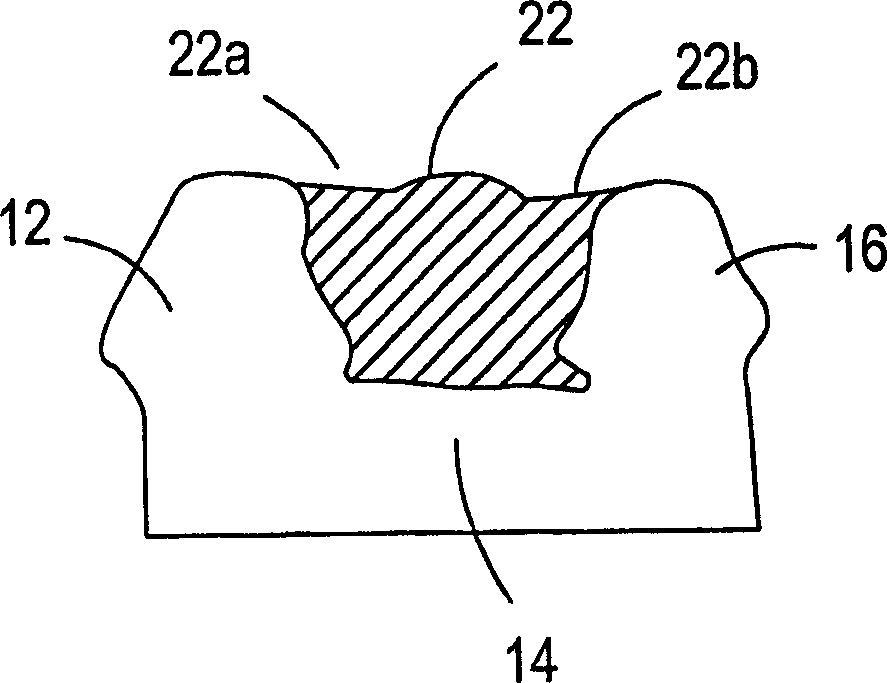

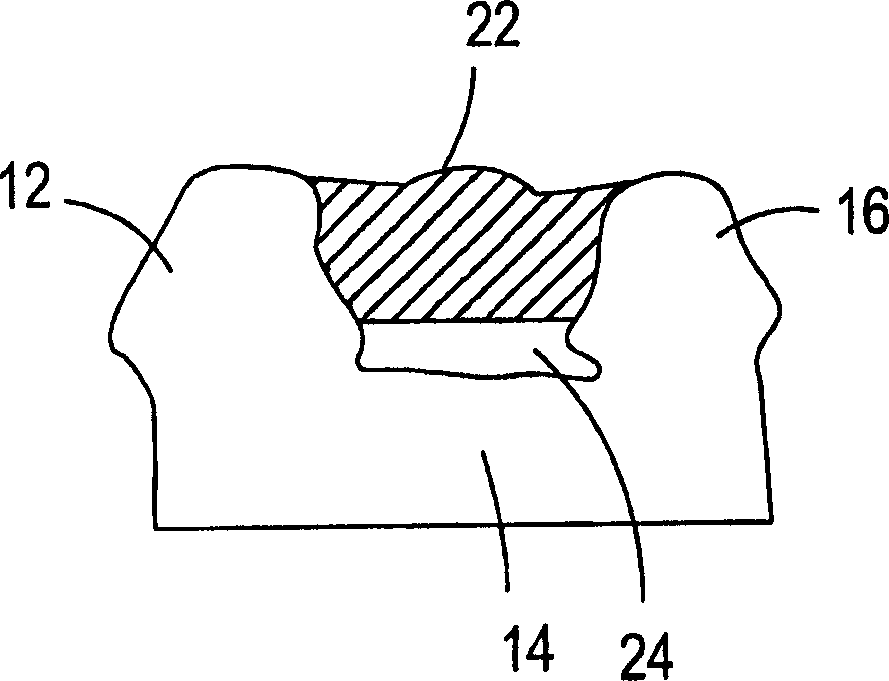

[0023] Optionally, the different features of the model are segmented to allow a thorough scan of each feature to be formed. An initial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com