Two-way two-speed built in boost manpower vehicle stupid variable-speed shaft

A technology for rickshaws and shifting shafts, applied in vehicle gearboxes, vehicle components, wheeled transmissions, etc., can solve the problems of redundant parts assembly, difficult processing of inner sleeve teeth, energy consumption, etc., achieve good dustproof performance, and is conducive to The effect of mass processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

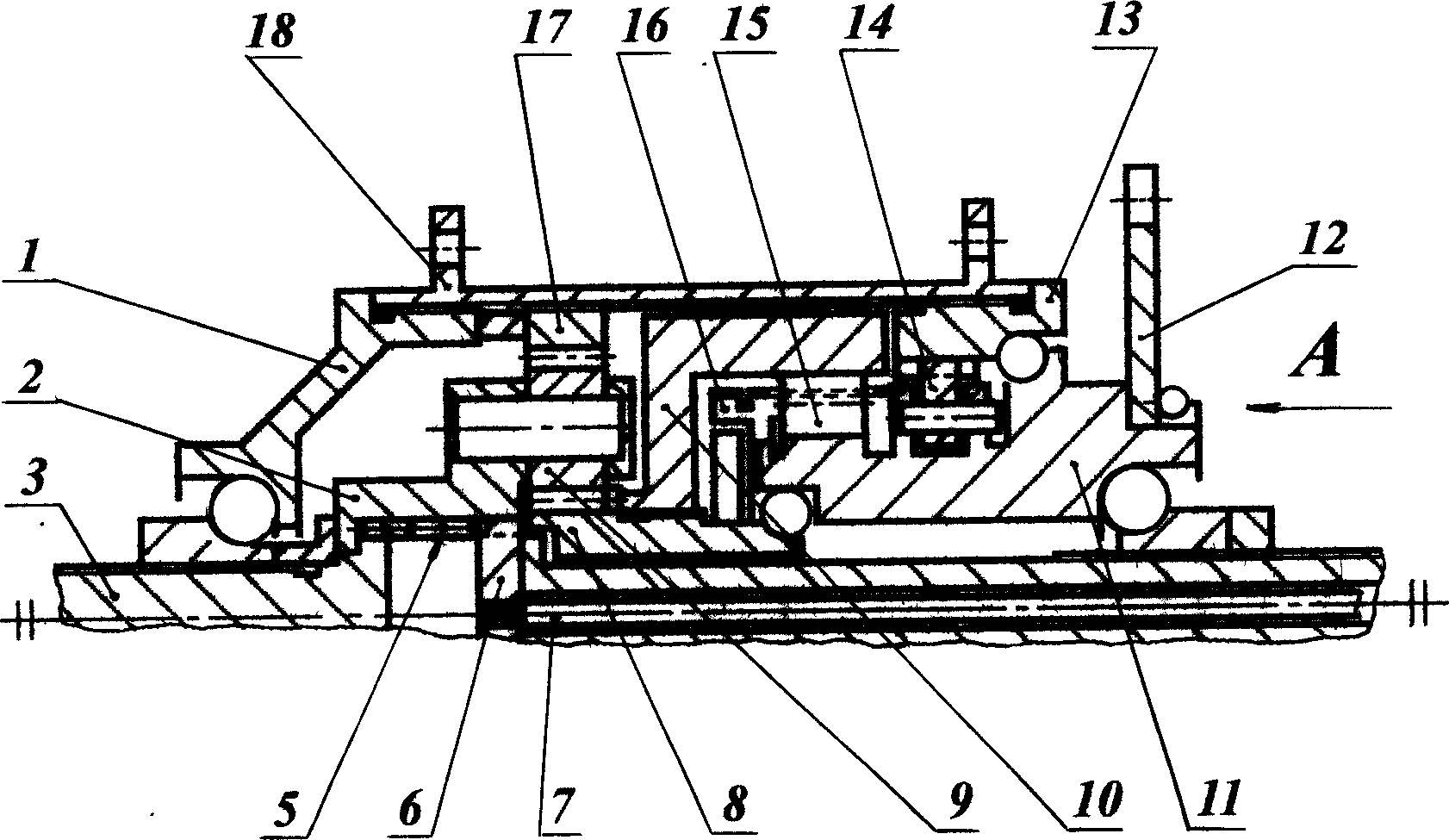

[0022] The structure and operation process of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

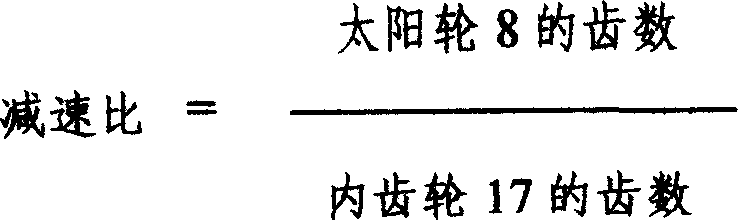

[0023] Accompanying drawing is an embodiment that the present invention is used as bicycle rear axle, and this embodiment comprises left end cap 1, planetary wheel frame 2, mandrel 3, spring 5, positioning key 6, reversing bar 7, sun wheel 8, planetary wheel 9 , Reverse torsion overrunning clutch driven casing 10, transmission shaft 11, sprocket 12, right end cover 13, pawl 14, reverse torsion overrunning clutch torsion member 15, cage 16, internal gear 17 and housing 18 . The planetary gear 9 meshes with the sun gear 8 . The outer edge of the right end cover 13 has threads to be screwed with the housing 18, the inner edge has a ball raceway, and the inner ratchet is engaged with the ratchet 14. There is a ratchet groove on the transmission shaft 11, and the ratchet 14 is positioned in the ratchet groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com