Aligned cutting tool for electroplating ultrahard material

A super-hard material and permutation technology, which is applied in the direction of manufacturing tools, abrasives, metal sawing equipment, etc., can solve problems such as poor self-sharpening, complicated process, and high technical operation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to achieve the above purpose, this patent adopts two technical solutions of directly manufacturing the cutting edge base on the tool base and separately manufacturing the cutting edge base block. Below in conjunction with the accompanying drawings, the specific implementations of various arrayed electroplated superhard material cutting edge tools will be further described.

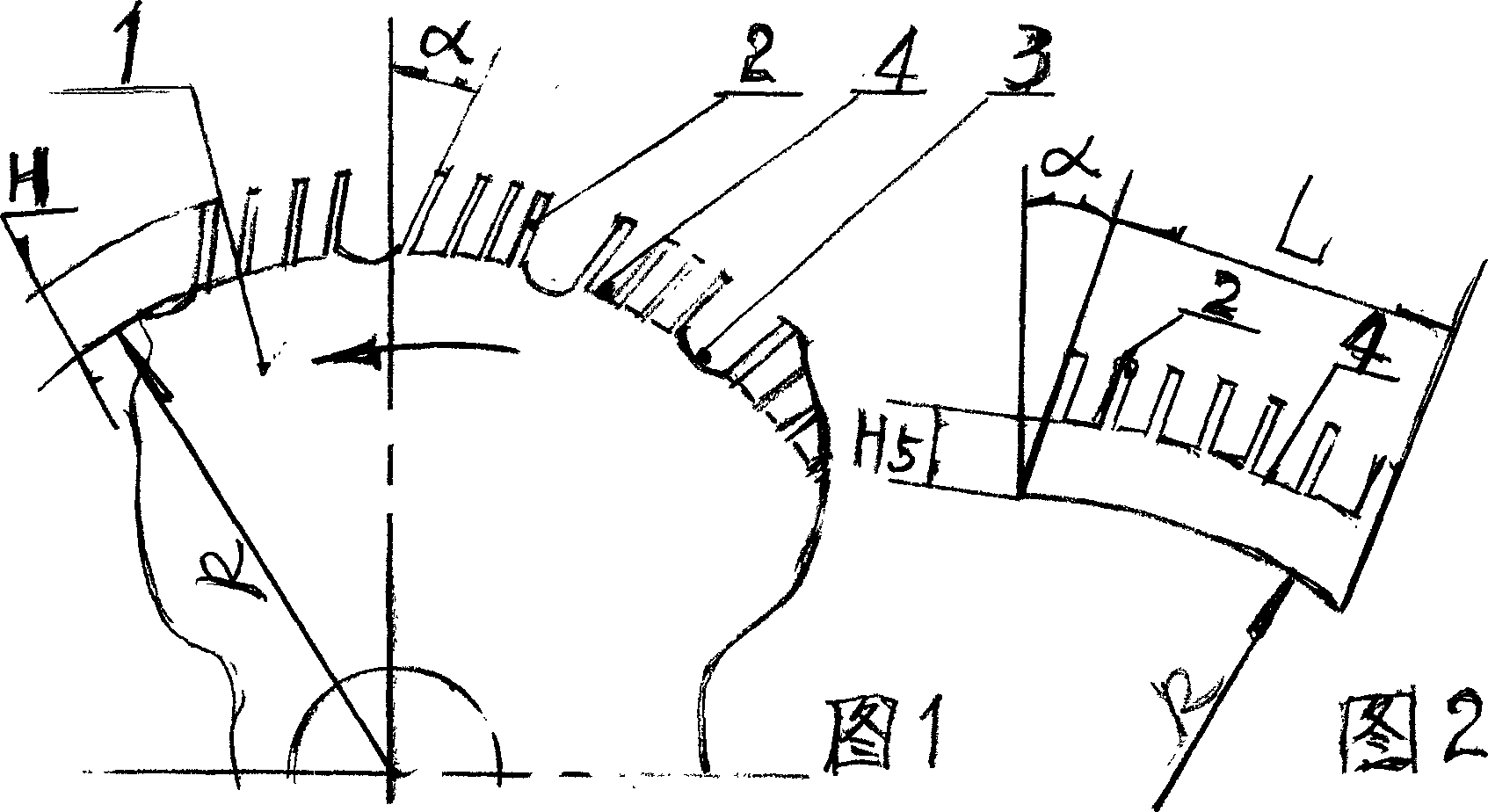

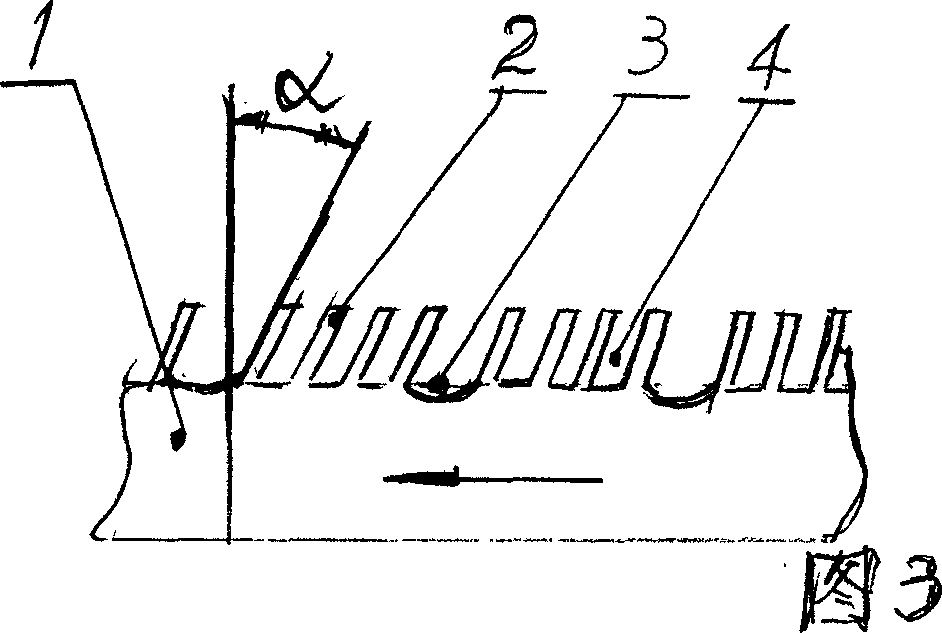

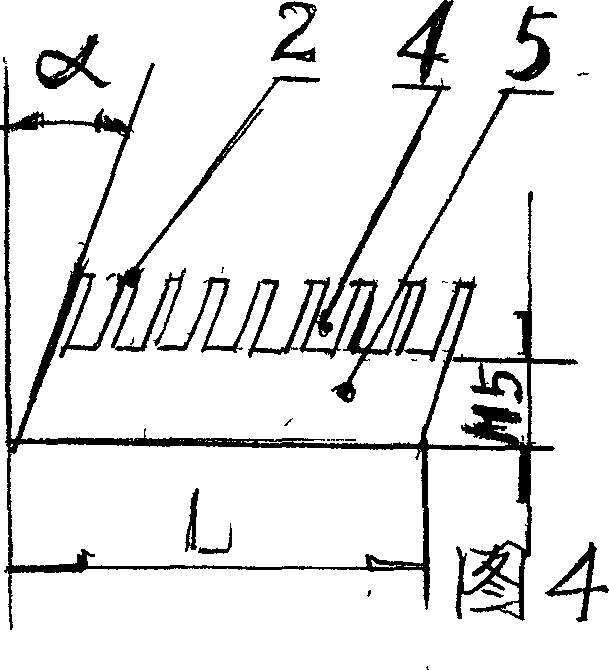

[0023] As shown in Figure 1, it is a diamond circular saw blade, one of the cutting edge tools of arrayed electroplated superhard materials. On the tool base 1, a thin rectangular cutting edge base 2 with an angle α inclined backward to the running direction shown in the figure is directly produced. Generally, the α angle is preferably 20-30 degrees. This inclination and the cooling of the chip flute 3 and the inter-teeth 4 can make the cutting force stable, reduce vibration and noise, and improve the service life of the tool. A layer of diamond particles of superhard material is coated (as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com