Direct connection type solar energy vacuum heat collection pipe

A technology of vacuum heat collecting tubes and solar energy, applied in the direction of solar thermal power generation, solar thermal devices, heating devices, etc., can solve the problems of not being suitable for large-scale popularization and application, high production cost, low vacuum degree, etc., so as to facilitate mass processing, Reduce the difficulty of production and delay the effect of coating attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

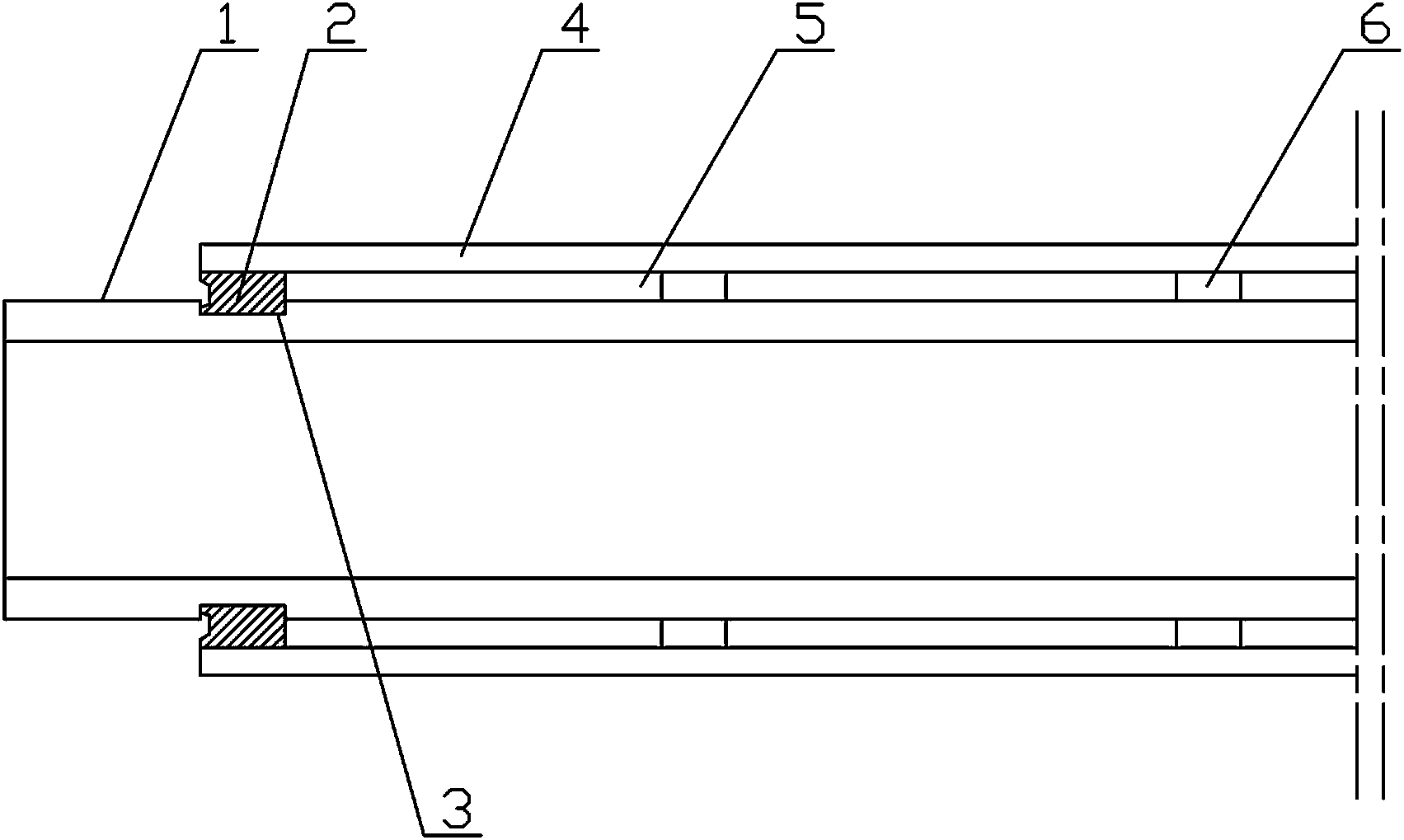

[0012] Such as figure 1 Among them, a straight-through solar vacuum heat collection tube includes a metal tube 1, the metal tube 1 in this example is made of aluminum, the inner wall of the metal tube 1 has been oxidized or coated, and the outer wall of the metal tube 1 is provided with a solar absorbing coating. The coating used in this example is "aluminum-nitrogen / aluminum solar selective absorption coating", which uses aluminum metal tubes with good thermal conductivity; absorbent coating". Aluminum is rich in resources, easy to process, and relatively low in cost and cost. Aluminum metal tubes have high recycling value and can be reused. Of course, in some occasions, such as occasions with higher pressure bearing requirements, stainless steel can also be used.

[0013] The metal tube 1 is covered with a vacuum glass tube 4, and a sealing ring 2 is provided between the metal tube 1 and the vacuum glass tube 4 near both ends. As shown in the figure, an annular groove 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com