Automatic leakage-stopping apparatus of full glass solar vacuum tube breakage

A vacuum tube, all-glass technology, applied in the field of automatic leak-stopping devices for all-glass solar vacuum tube breakage, can solve the problems of water heater or hot water system paralysis, spring connecting rod and piston can not enter practical, single vacuum tube breakage, etc., to avoid alternating Damage caused by impact and cracking, increase the effective daylighting length, and improve the effect of heat collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

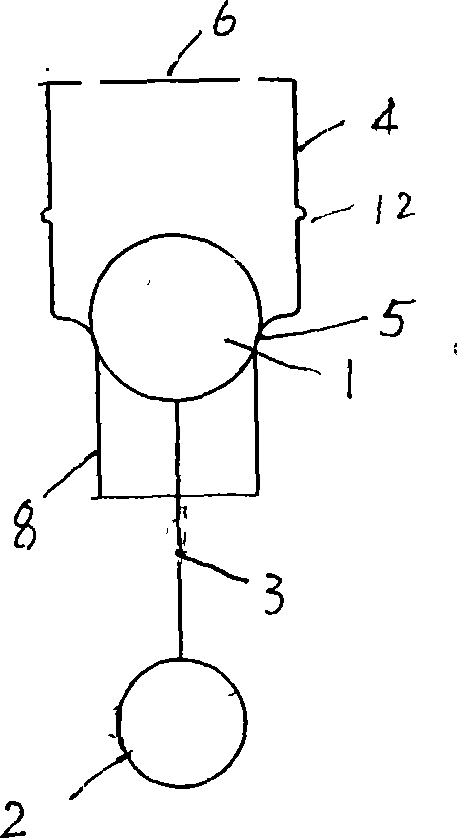

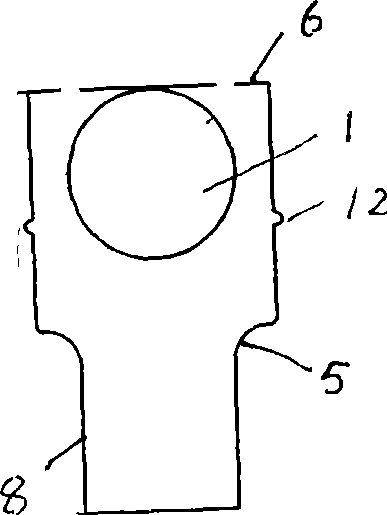

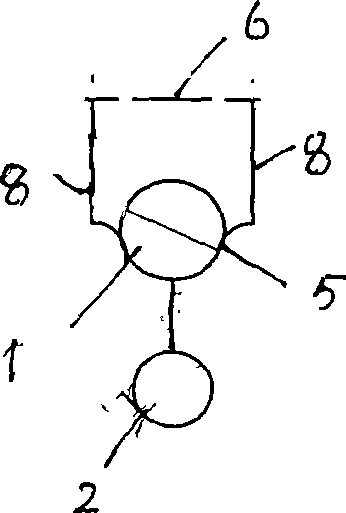

[0020] In the figure, the floating ball 1 adopts high temperature and pressure resistant material (metal or plastic) balls, plastic balls, leather balls, metal shell balls, solid wood balls, foam, considering that the temperature of the hot water of the water heater may reach nearly 100 degrees, so the material of the ball To be able to withstand the temperature, especially the inner gas of the hollow ball is capable of bearing pressure at high temperature, the diameter of the ball is slightly larger than the inner diameter of the neck in the sleeve 4. In the embodiment of the present invention, also can adopt the structure that float 1 is a weight 2,

[0021] The nozzle of the solar vacuum tube is provided with a floating ball slightly larger than the pipe diameter, and a height limiter is arranged above the floating ball to prevent the floating ball from passing through. This embodiment can be this structure: install the height limiter on the installation position of the noz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com