High temperature heat conduction castable

A castable and high-temperature technology, applied in the field of refractory materials, can solve the problems of scale shedding, endangering safety production, increasing costs, etc., and achieve the effect of not easy to fall off and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

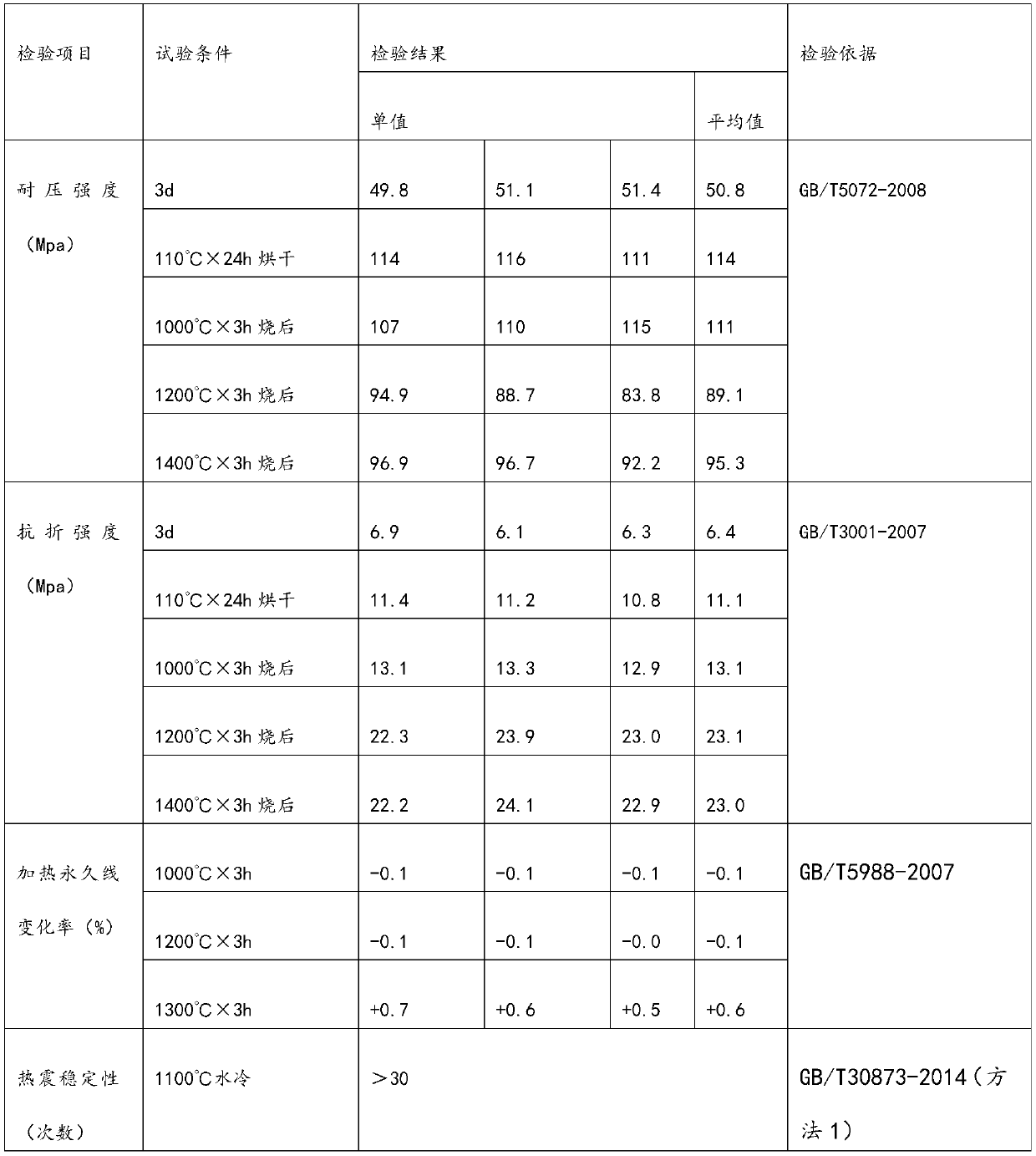

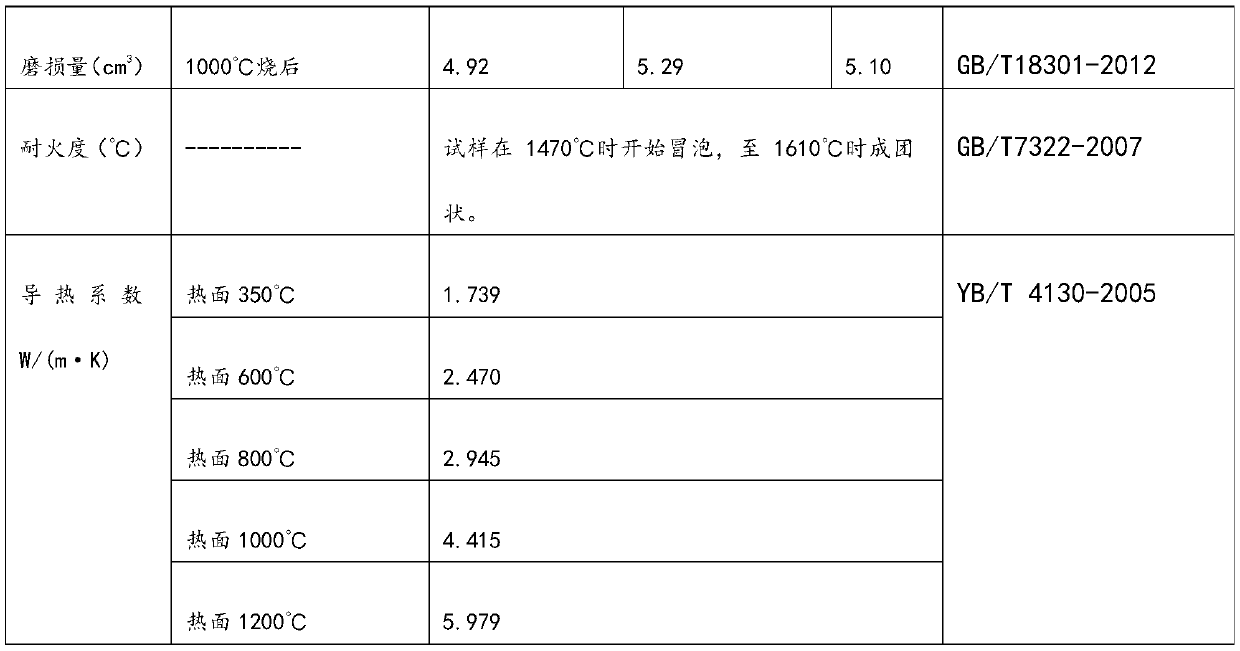

Image

Examples

Embodiment Construction

[0016] The high-temperature heat-conducting castable of this embodiment is composed of the following components: black silicon carbide aggregate, silicon carbide fine powder, alumina fine powder, metal aluminum powder, silica fume, aluminate cement, explosion-proof fiber, and BASF F10.

[0017] The mass fraction of silicon carbide in the black silicon carbide aggregate is 98%; Silicon carbide aggregate, black silicon carbide aggregate with a particle size greater than 3 mm and less than or equal to 5 mm, and black silicon carbide aggregate with a particle size greater than 5 mm and less than or equal to 8 mm.

[0018] 11kg of black silicon carbide aggregate with particle size greater than 0mm and less than or equal to 1mm, 20kg of black silicon carbide aggregate with particle size greater than 1mm and less than or equal to 3mm, 25kg of black silicon carbide aggregate with particle size greater than 3mm and less than or equal to 5mm 24kg of black silicon carbide aggregate with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com