Whole flow passage magnetization showering heat recovery plate

A technology of heat recovery and recovery plate, applied in the direction of heat exchanger type, indirect heat exchanger, fixed plate conduit assembly, etc., can solve the problems of heat exchange rate drop, large thickness and volume, unfavorable cleaning, etc., to improve thermal efficiency, Reasonable and practical structure, easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

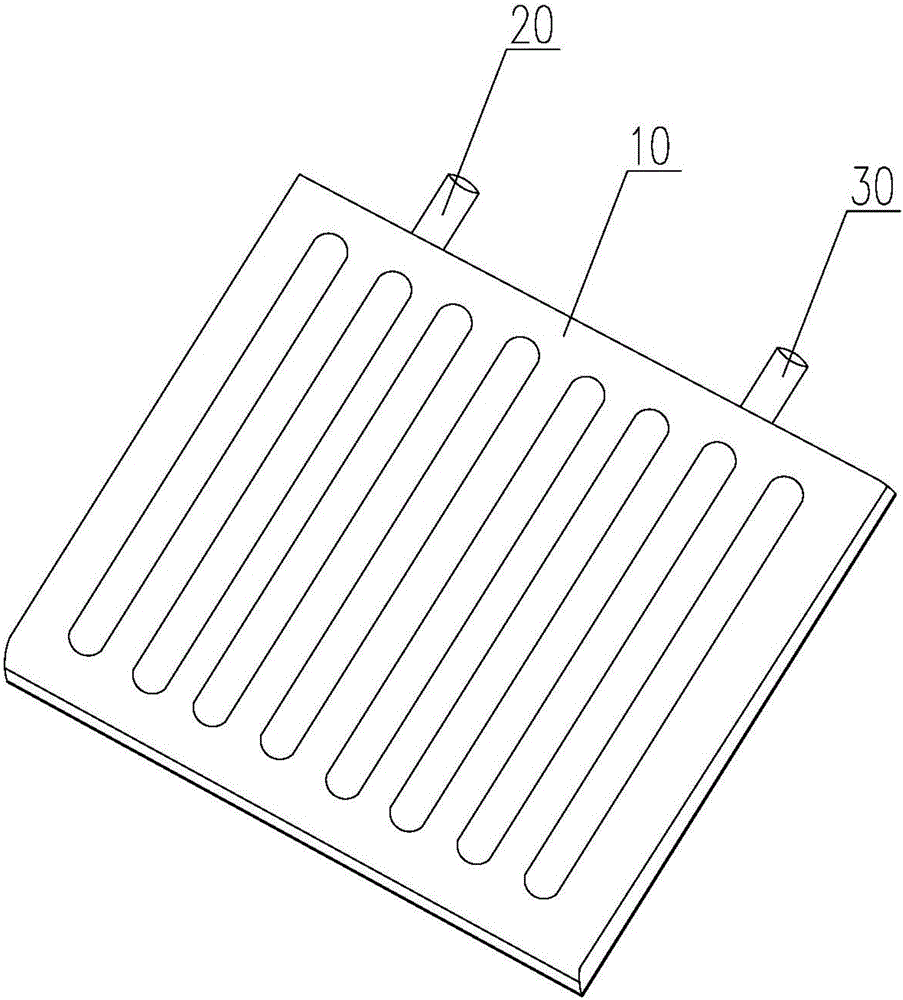

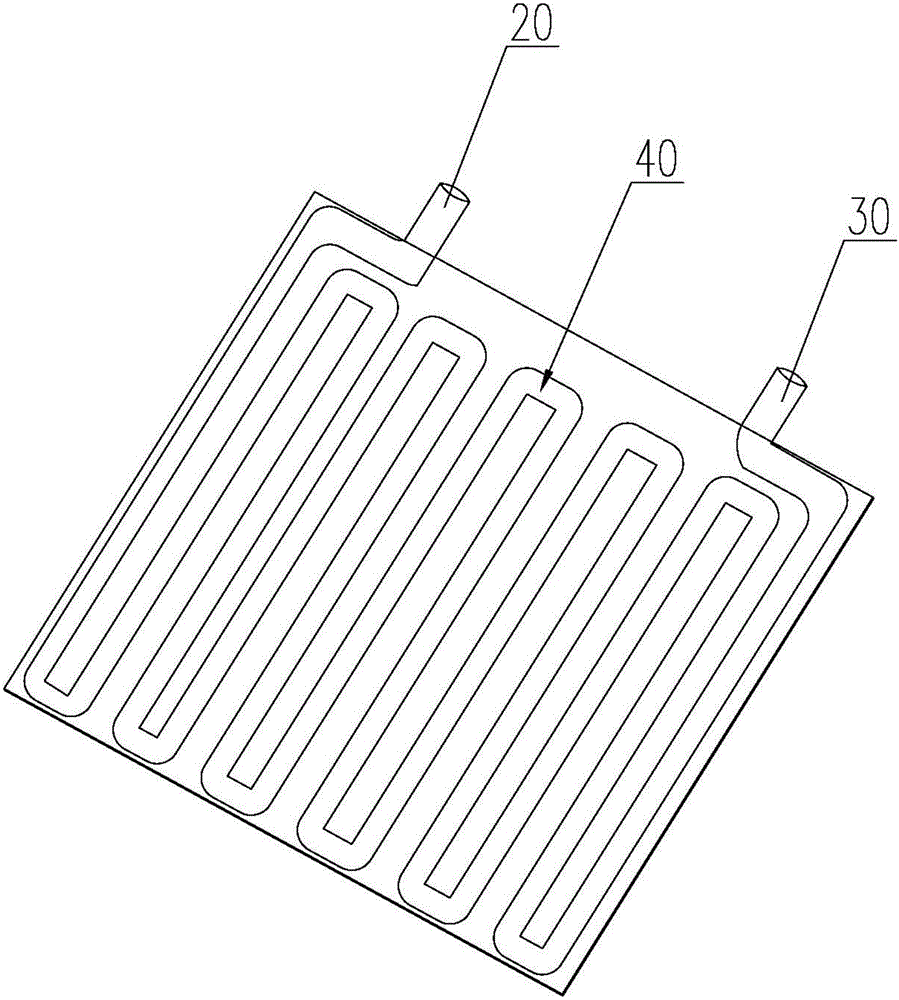

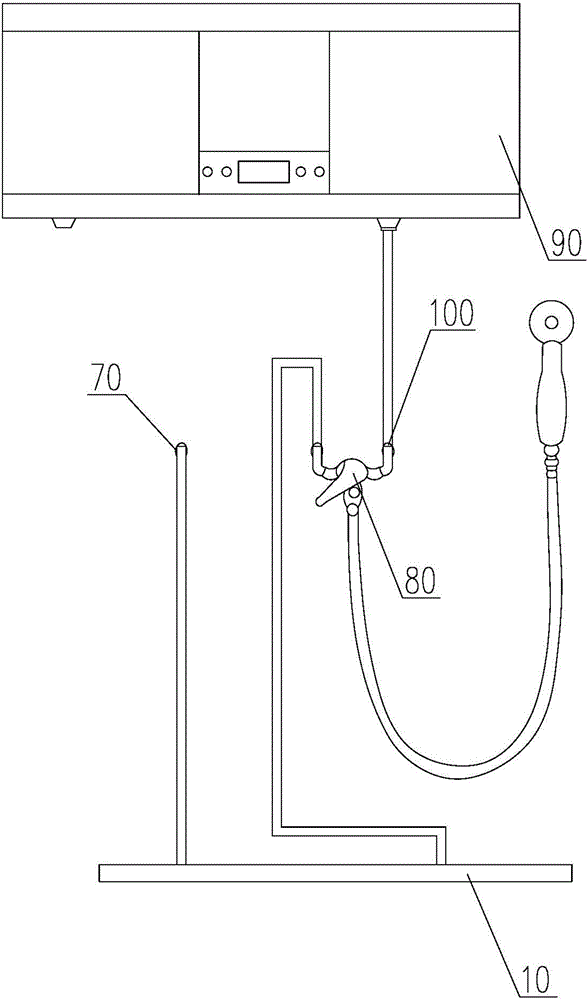

[0021] A full channel shower heat recovery system such as figure 1 , 2 , 3 and 4, including recovery plate 10, and water inlet joint 20 and water outlet joint 30 located at the side of recovery plate 10, described water inlet joint 20 is connected with tap water outlet valve 70, and described water outlet joint 30 is connected with mixed water The cold water inlet of the valve 80 is connected; the recovery plate 10 is a sealing body formed by combining the upper plate and the lower plate and the lower plate and forms a cavity between the upper plate and the lower plate, and the surroundings of the upper plate and the lower plate are tightly sealed. The water inlet joint 20 and the water outlet joint 30 extend to the interior of the recovery plate 10 to communicate with the inner cavity of the recovery plate 10; in the cavity, there is a connection between the end of the water inlet joint 20 and the end of the water outlet joint 30. The water flow channel 40; in this embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com