A continuous casting mold

A crystallizer and water outlet technology, which is used in the fields of special-shaped billets, slabs, ultra-thin slabs, continuous casting molds, round billets, continuous casting molds, square billets, and molds, and can solve cracks and uncontrollable flow rates. , uneven heat conduction and other problems, to achieve the effect of good heat conduction, elimination of defects, and convenient manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

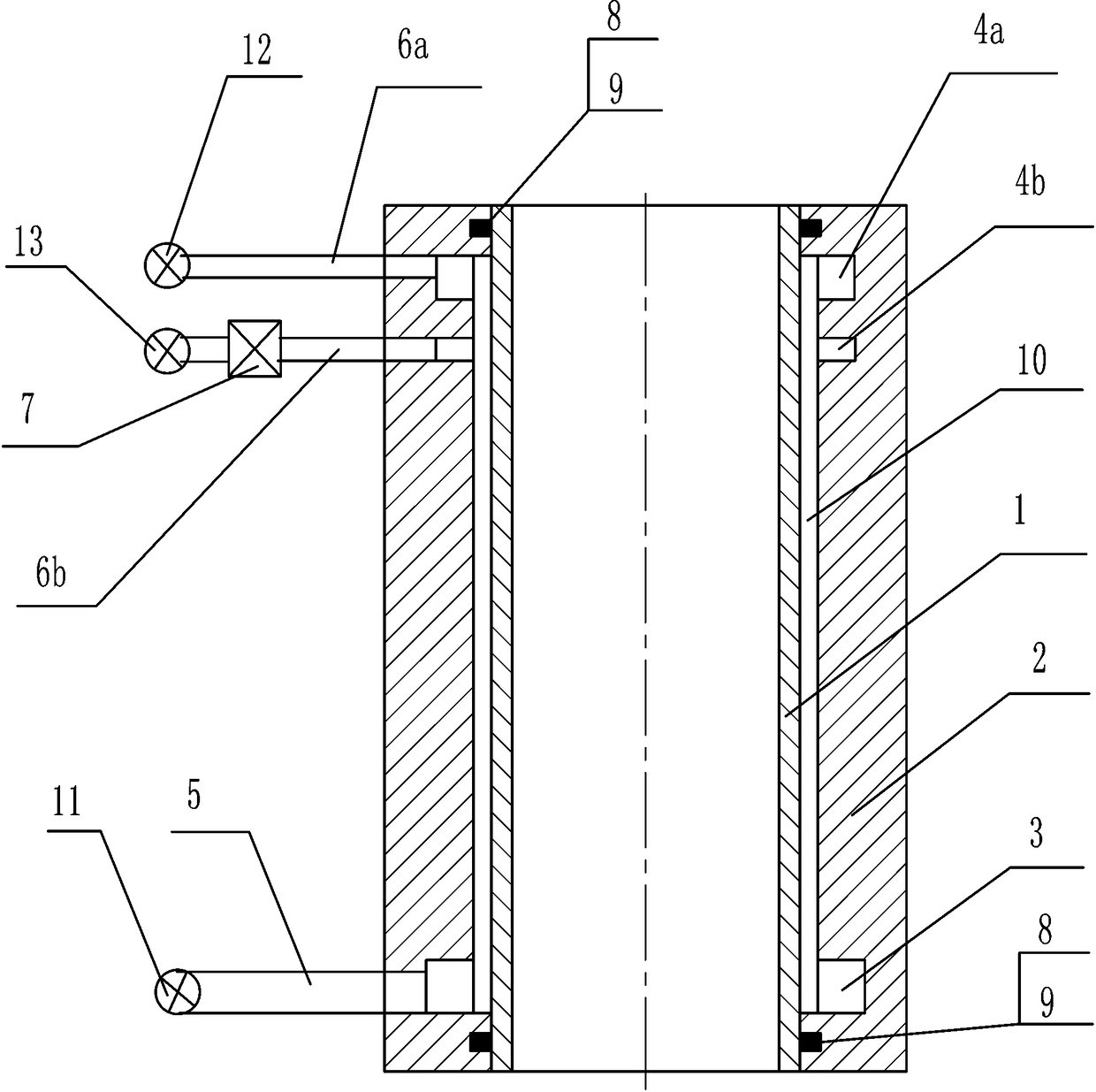

[0037] Embodiment one: as figure 1 As shown, a continuous casting mold includes a mold copper tube 1 and a mold water tank 2 that supports the mold copper tube and cools the water. The mold water tank is provided with a water inlet chamber 3 and two The outlet chambers are respectively outlet chamber one 4a and outlet chamber two 4b, the water inlet chamber 3 communicates with the water inlet pipe 5, the outlet chamber one 4a communicates with the outlet pipe one 6a, and the outlet chamber two 4b communicates with the outlet pipe two 6b communicates, and a valve 7 is set on the outlet pipe two 6b, and the outlet pipe two 6b communicates with the valve 7, and the crystallizer water tank 2 is provided with a central depression, a peripheral protrusion with a sealing groove 8 and a sealing ring 9, The contact surface with the crystallizer copper tube 1 forms a peripheral seal, and there is a gap in the middle of the water-cooled heat exchange channel 10. The first water outlet ch...

Embodiment 2

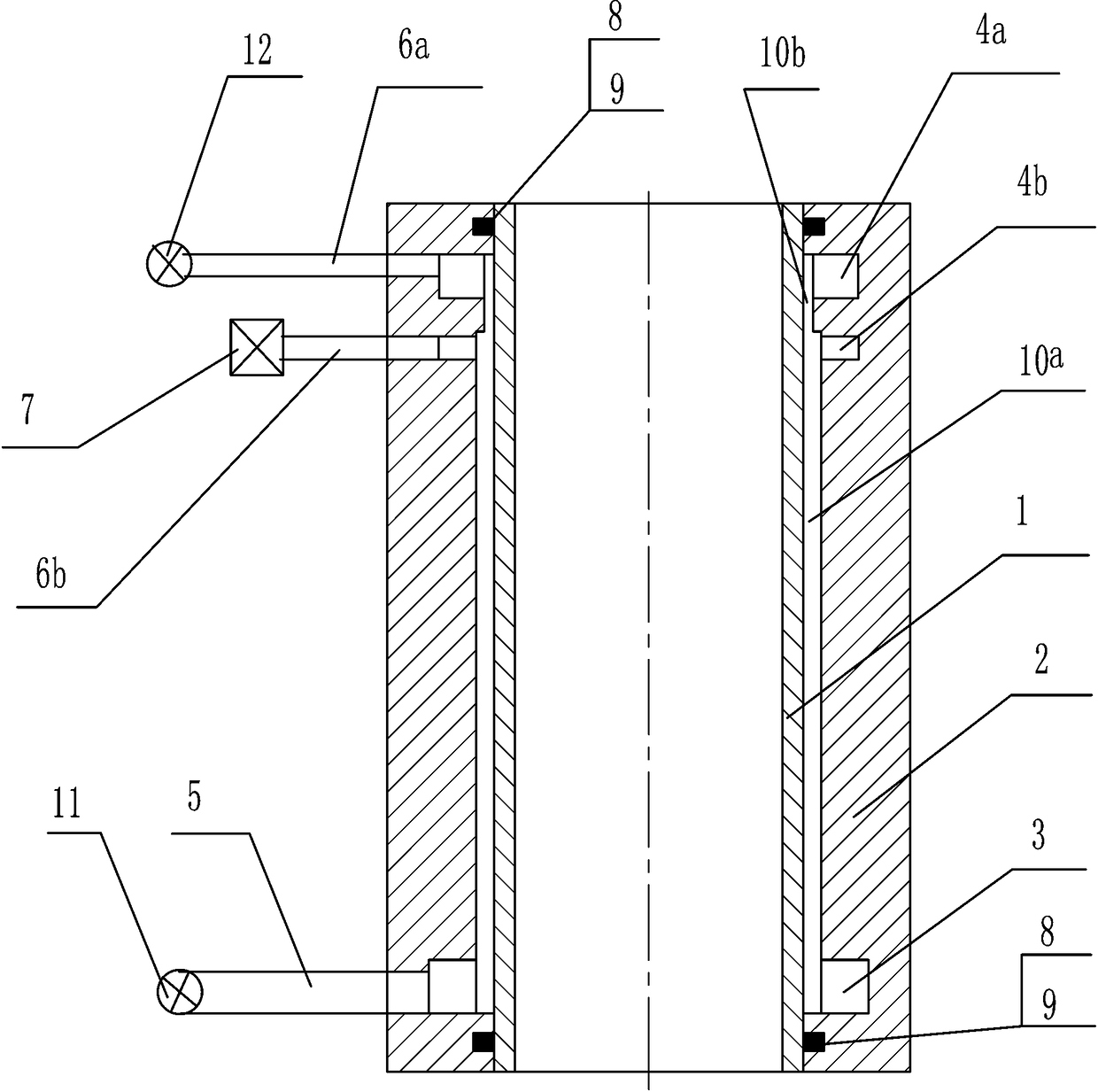

[0038] Embodiment two: if figure 2As shown, a continuous casting crystallizer includes a mold copper tube 1 and a crystallizer water tank 2 that supports the mold copper tube and cools the water through it. The crystallizer water tank 2 is provided with a depression with a step in the middle, The peripheral protrusion has a sealing groove 8 and a sealing ring 9, forming a peripheral seal with the contact surface of the mold copper tube 1, and a water-cooled heat exchange channel with a step gap in the middle, and the depression with a step in the middle corresponds to the meniscus area The depression corresponding to the meniscus is relatively shallow, the depression below the meniscus is relatively deep, the water-cooling heat exchange channel 10b corresponding to the meniscus area is relatively small, and the water-cooling heat exchange channel 10a corresponding to the meniscus area is relatively large , the crystallizer water tank is provided with a water inlet chamber 3 a...

Embodiment 3

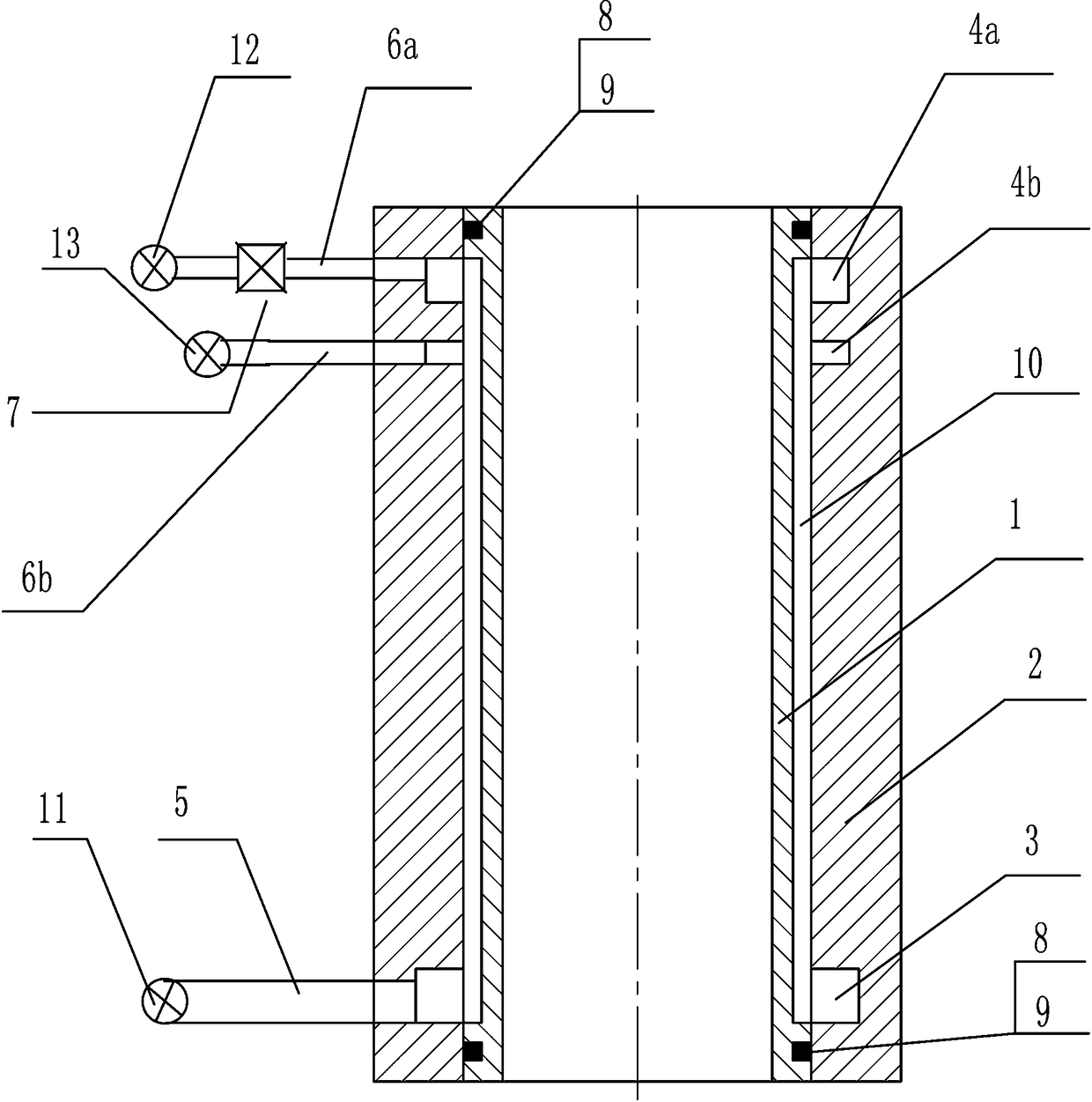

[0039] Embodiment three: as image 3 As shown, a continuous casting crystallizer includes a crystallizer copper plate 1 and a mold water tank that supports the mold copper plate and cools water through it. The water tank back plate 2b that can be quickly replaced is added between them. The water tank back plate 2b is provided with a water inlet chamber 3 and two water outlet chambers, namely the water outlet chamber one 4a and the water outlet chamber two 4b, that is, the crystallizer water tank inlet The water chamber and the water outlet chamber of the crystallizer water tank are transferred to the corresponding position of the water tank back plate, the water inlet chamber 3 is communicated with the water tank 2a and the water inlet pipe 5, and the water outlet chamber-4a is communicated with the water tank 2a and the water outlet pipe-6a, so The second water outlet chamber 4b is communicated with the water tank 2a and the second water outlet pipe 6b, the second water outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com