A building support template and its processing system and processing method

A processing system and template technology, applied in the direction of metal processing equipment, metal processing machinery parts, supports, etc., can solve the problems of inability to process support structures, etc., and achieve the effect of convenient mass processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings.

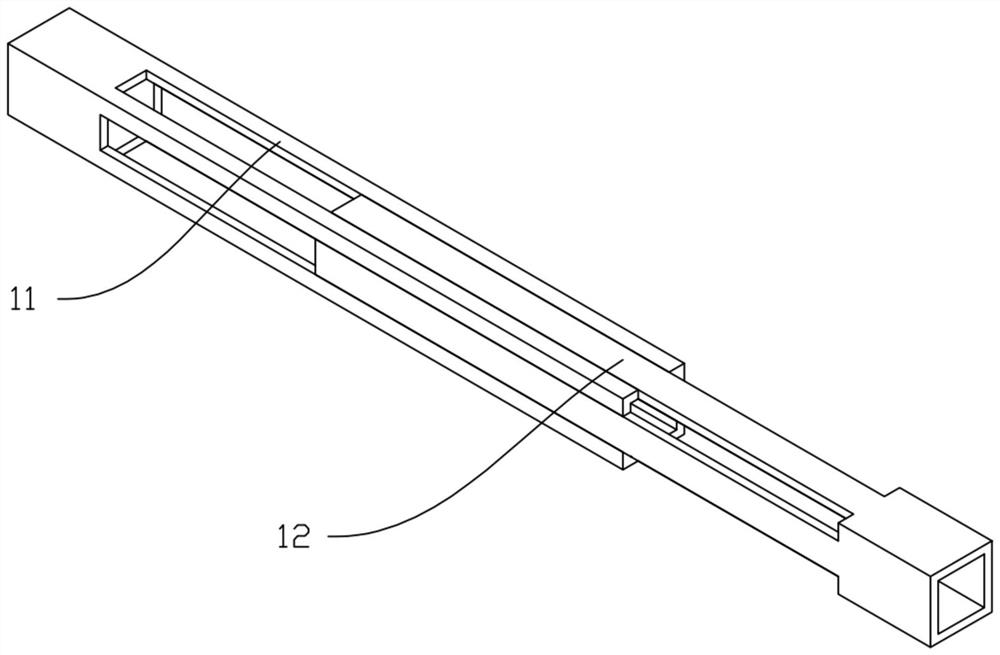

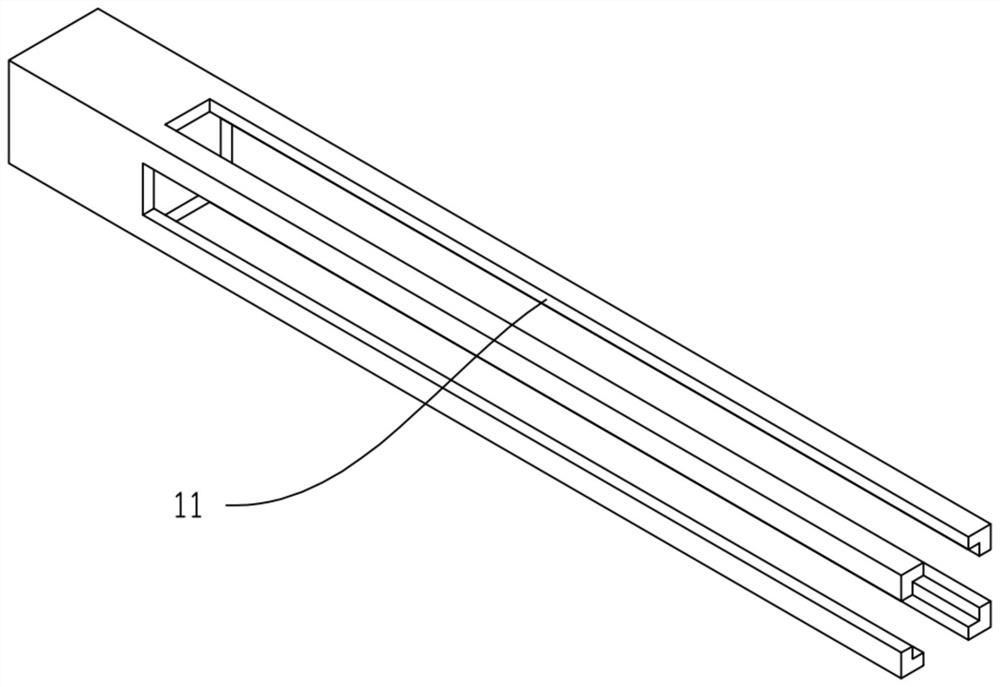

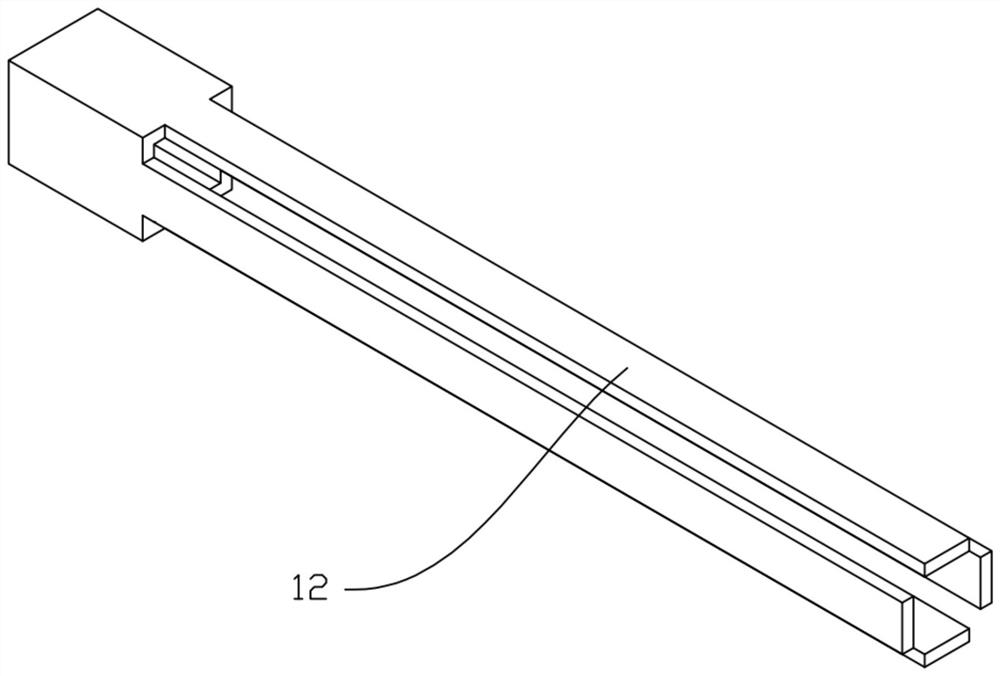

[0035] Combine below Figures 1 to 14 Illustrating this embodiment, a building support formwork processing system includes a cutting mechanism, a reversing mechanism, a feeding support 40, a clamping mechanism 50 and a sliding support 60. The cutting mechanism includes a limit support I21, a tool support I22, a thread Block 23, adjusting slideway 24, tool support II25, machining motor 26, milling cutter 27 and threaded disc I28, two limit brackets I21 are provided, and four tool supports I22 are slidably connected between the two limit brackets I21. The outer sides of the four tool holders I22 are fixedly connected with threaded blocks 23, the inner sides of the four tool holders I22 are fixedly connected with adjustment slideways 24, and the four adjustment slideways 24 are slidably connected with tool holders II25, four tool holders A machining motor 26 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com