End mill with special groove and micro edge structure based on bionics

An end mill and bionic technology, applied in milling cutters, milling machine equipment, manufacturing tools, etc., can solve the problem that milling cutters are difficult to take into account tool rigidity, chip removal and heat dissipation, and reduce the risk of chipping or broken tools. Possibility, reduction of plastic strain, effect of increasing tool life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

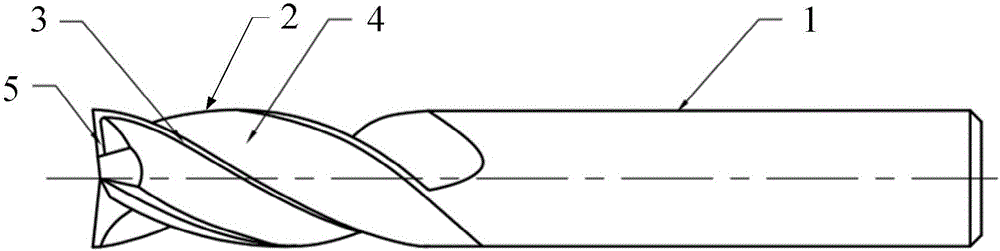

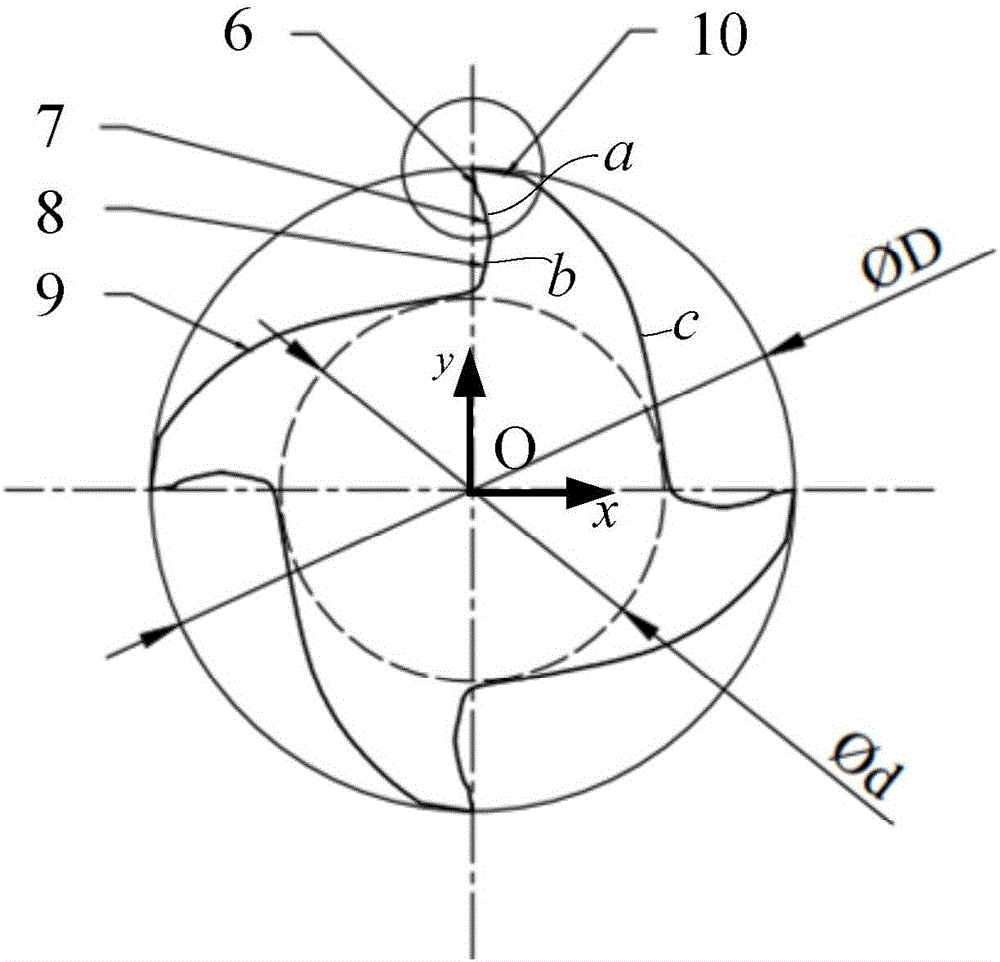

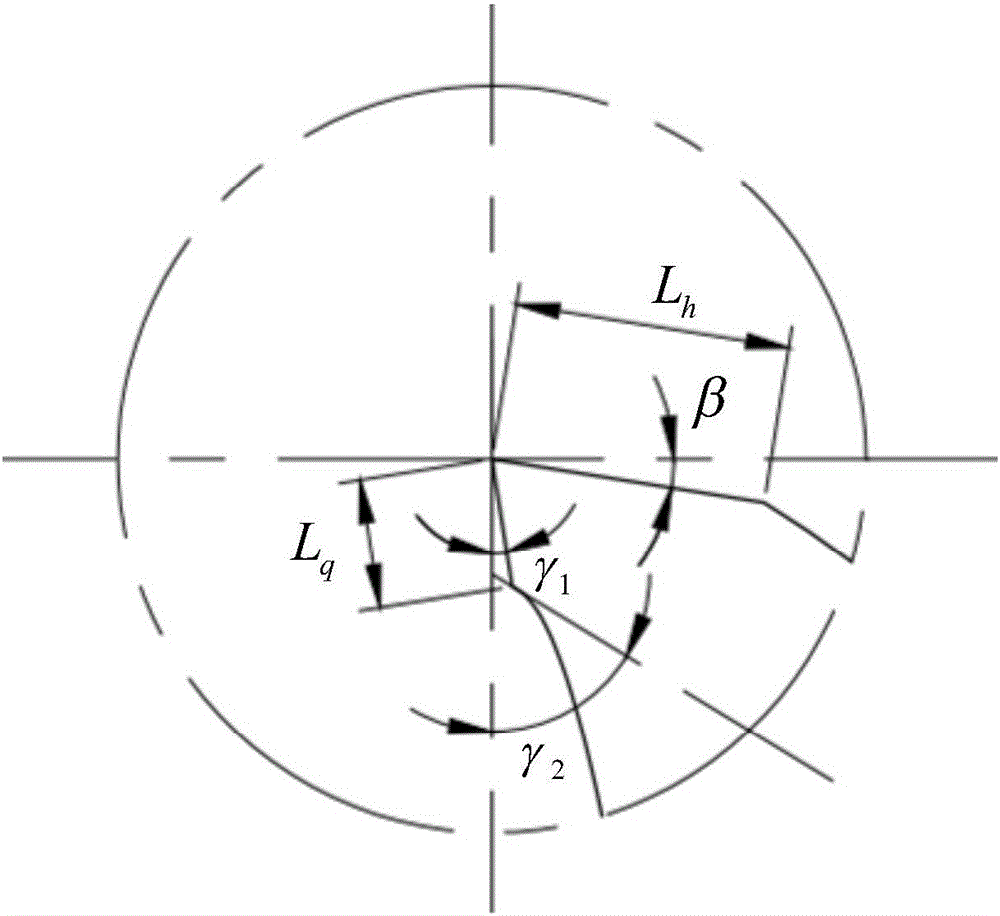

[0027] The bionic-based end mill with special groove shape and micro-blade structure of the present invention is especially suitable for processing titanium alloys, and is a solid carbide end mill. Its structure figure 1 , figure 2 and image 3 shown. The end mill includes a shank part 1 and a cutting part 2 , and the front part of the shank part 1 is the cutting part 2 . The cutting portion 2 includes peripheral cutting teeth 3 and chip flutes 4 . The number of teeth of the outer peripheral cutting teeth 3 is 4, the inter-tooth angle is 90°, and the helix angle of the outer peripheral cutting teeth 3 is 38° to 40°. The origin, with the line connecting the rotation center and the tool nose as the y-axis, the peripheral cutting tooth 3 has a unique micro-edge structure, such as figure 2 (D in the figure is the edge diameter of the end mill, d is the core thickness, the value range of the edge diameter D of the end mill is 5mm-20mm, and the core thickness d is 0.6D-0.75D),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com