Patents

Literature

38results about How to "Increase the force contact area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

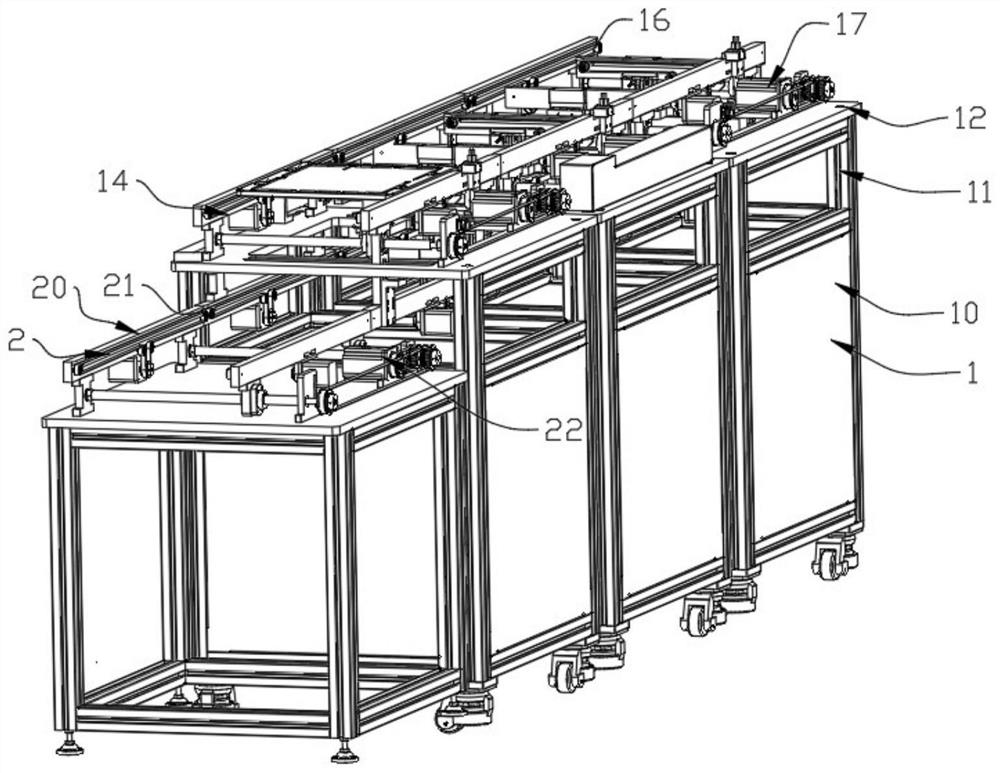

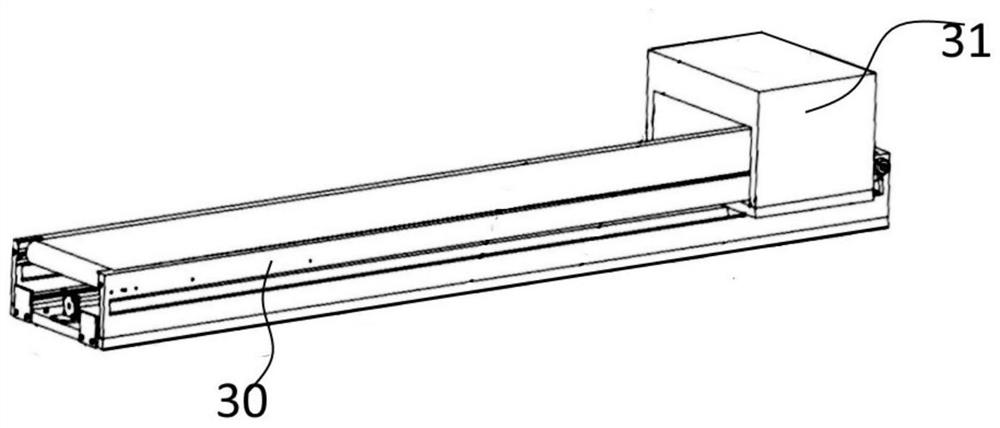

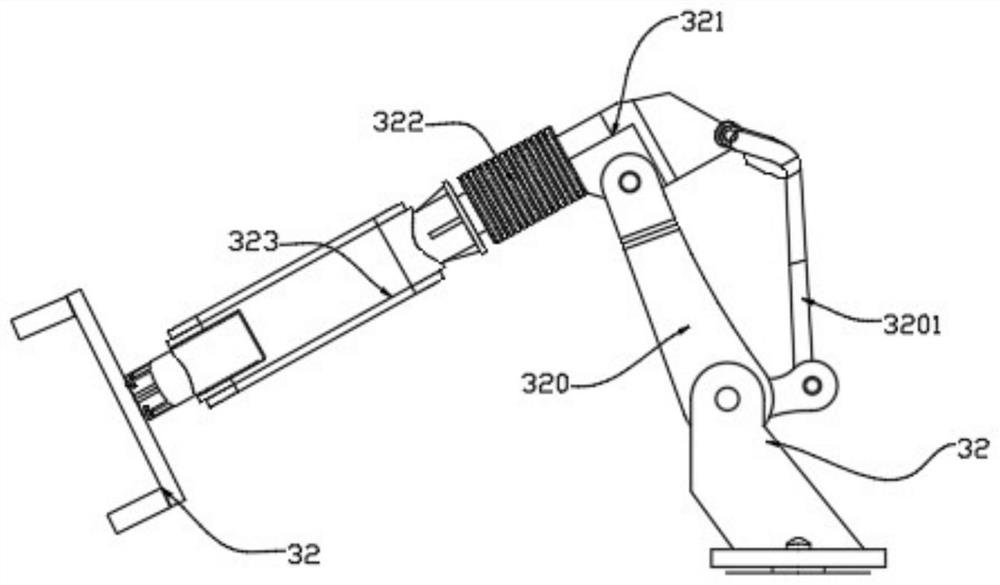

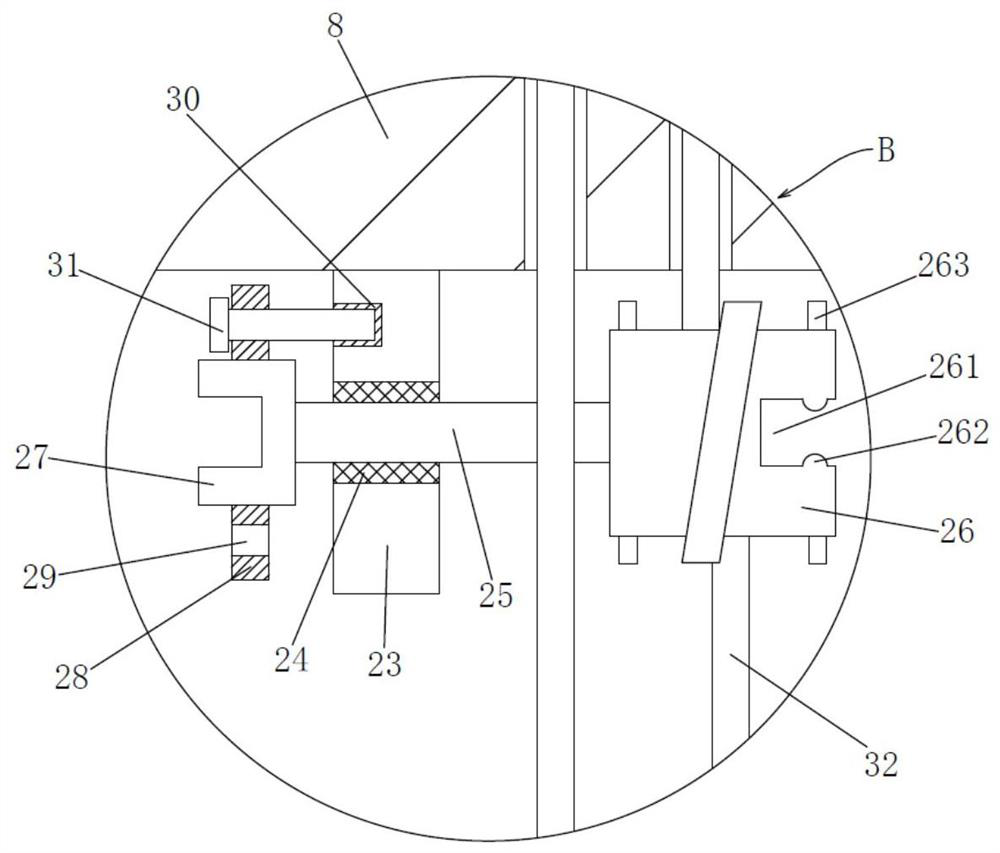

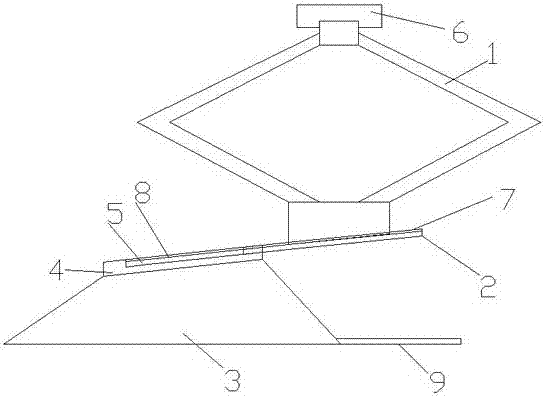

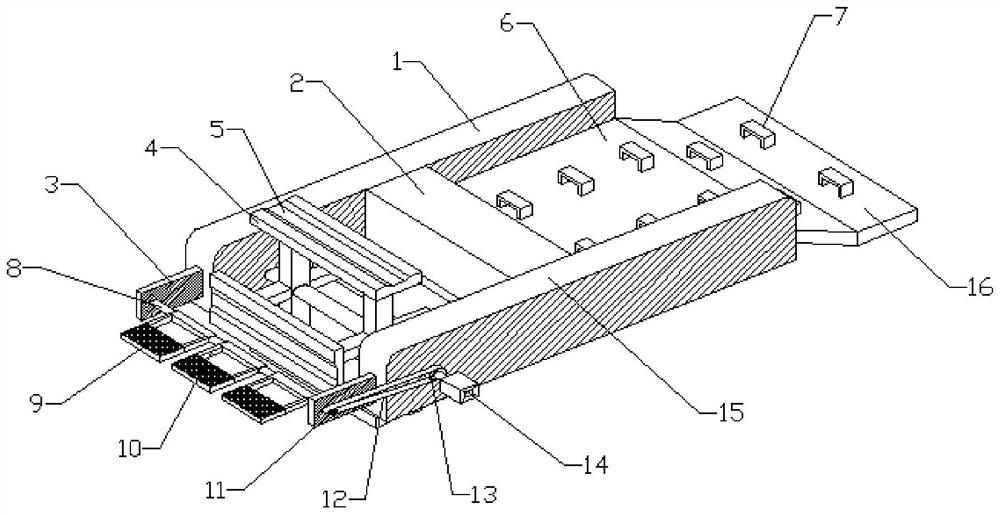

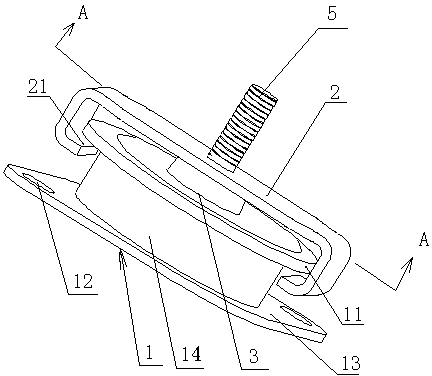

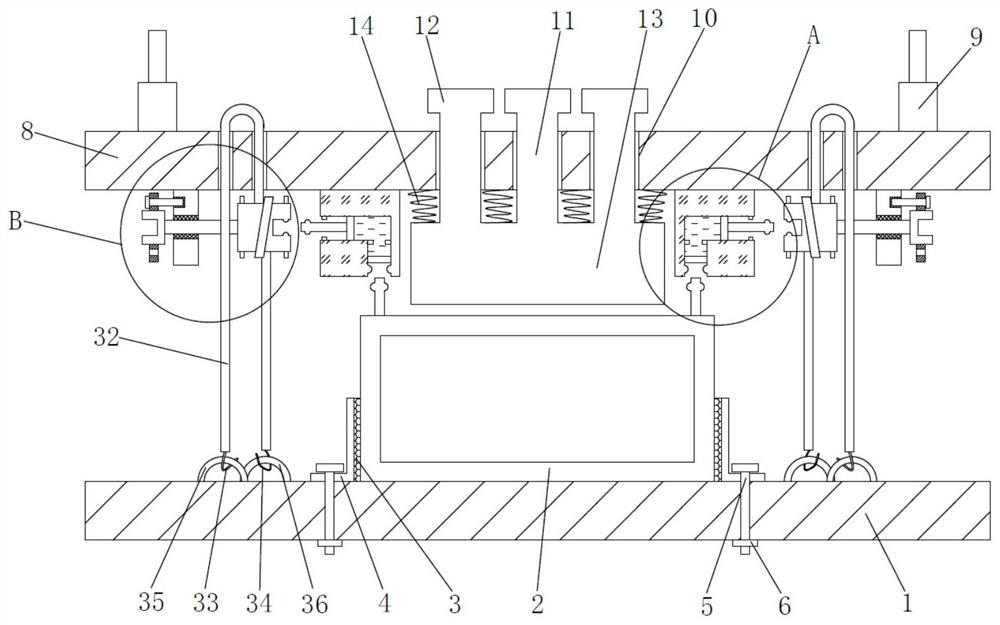

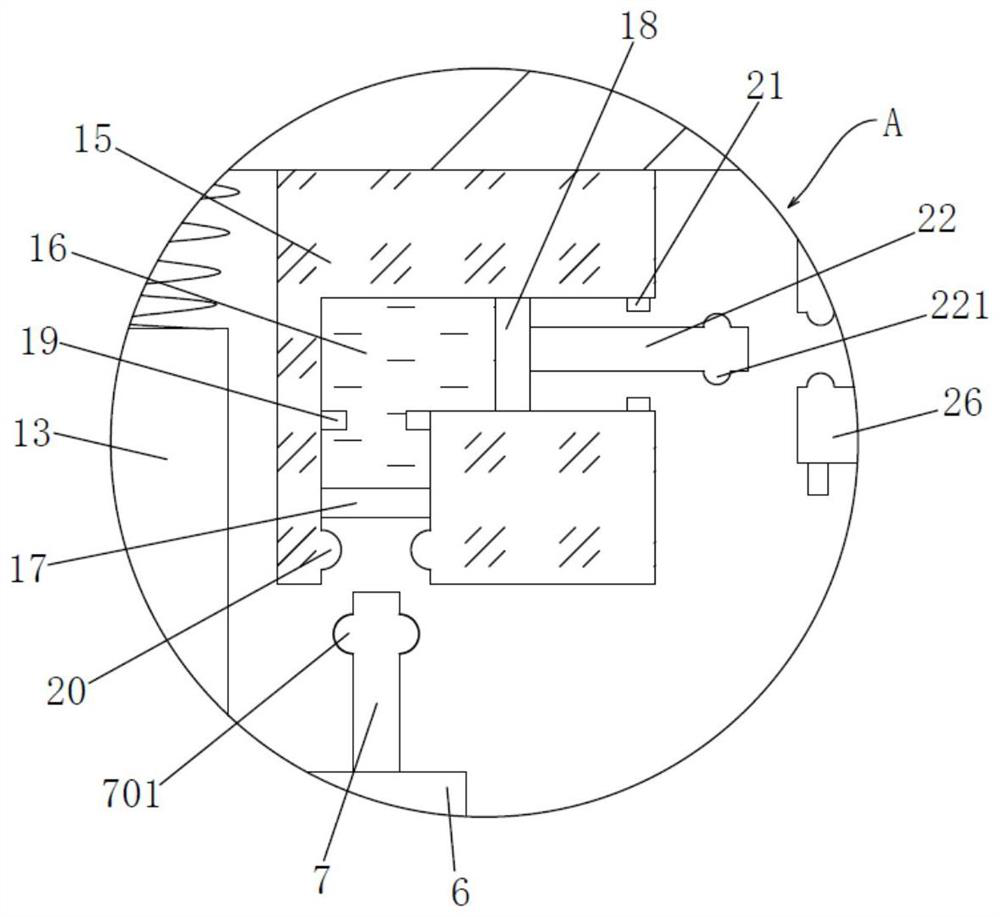

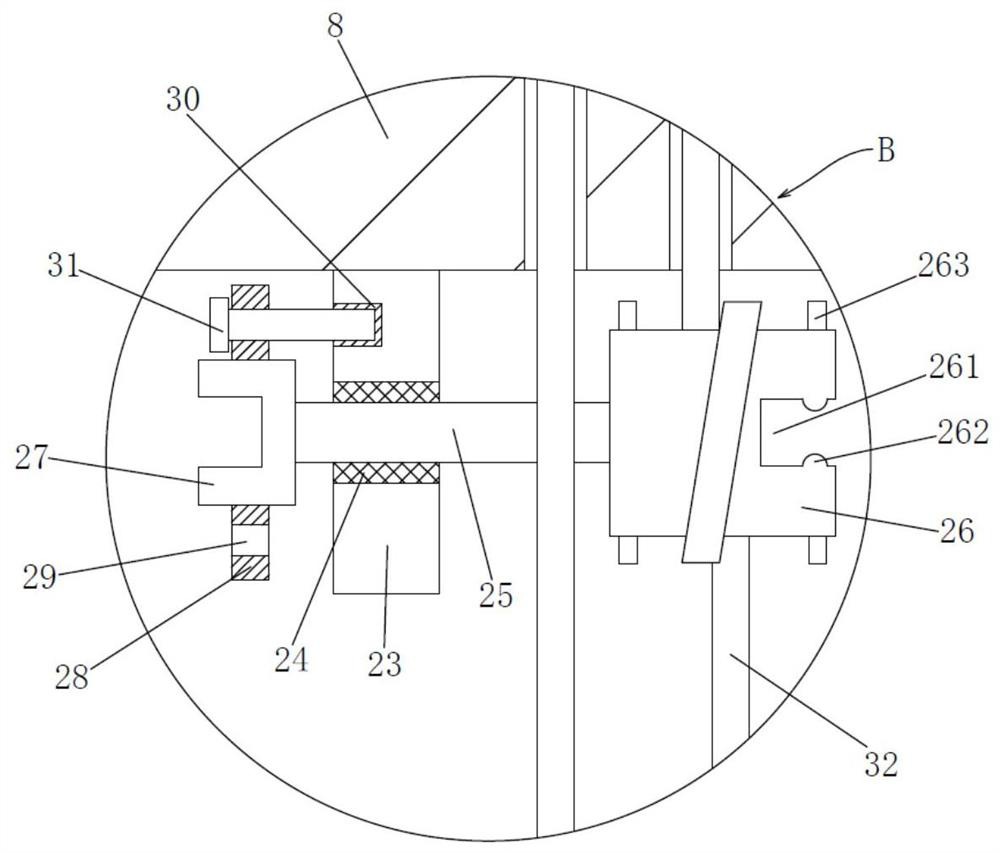

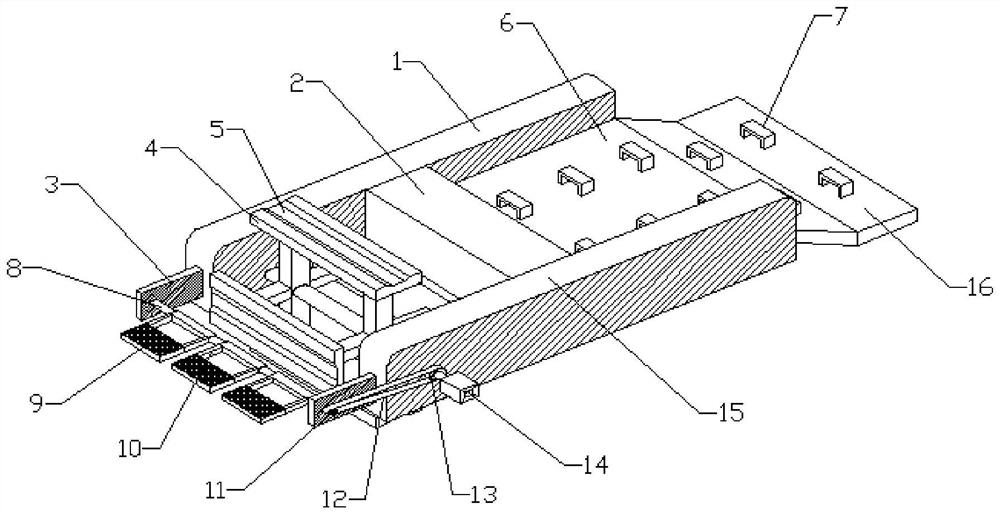

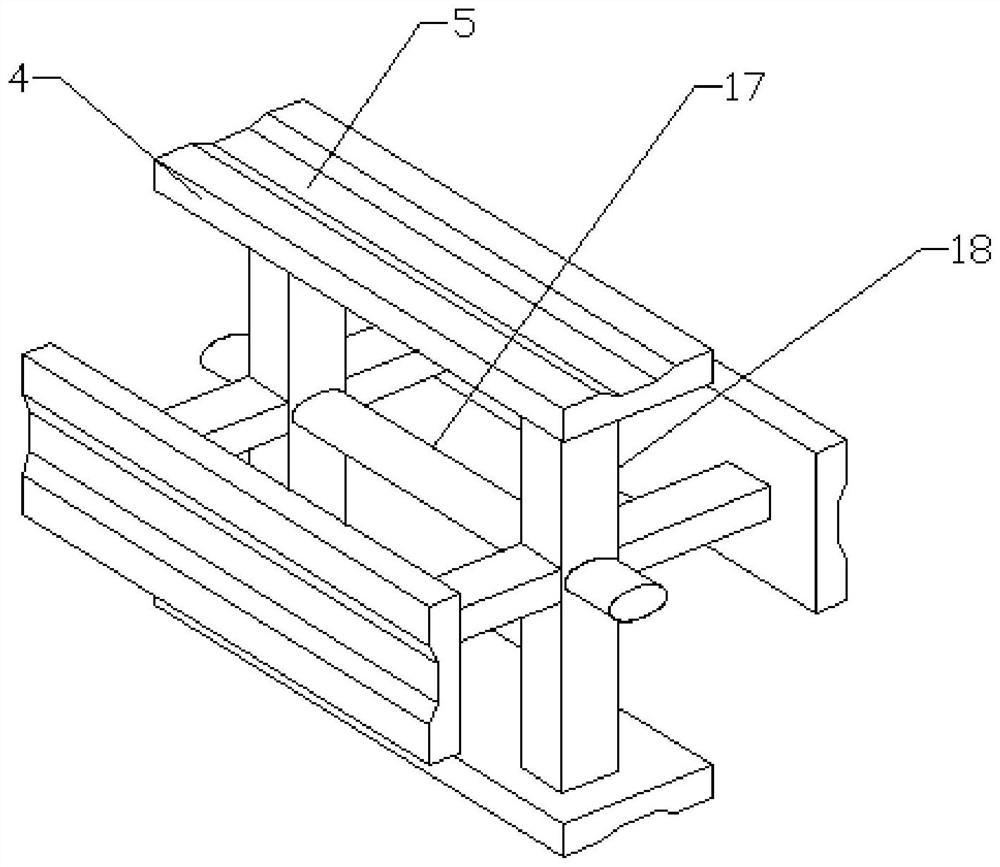

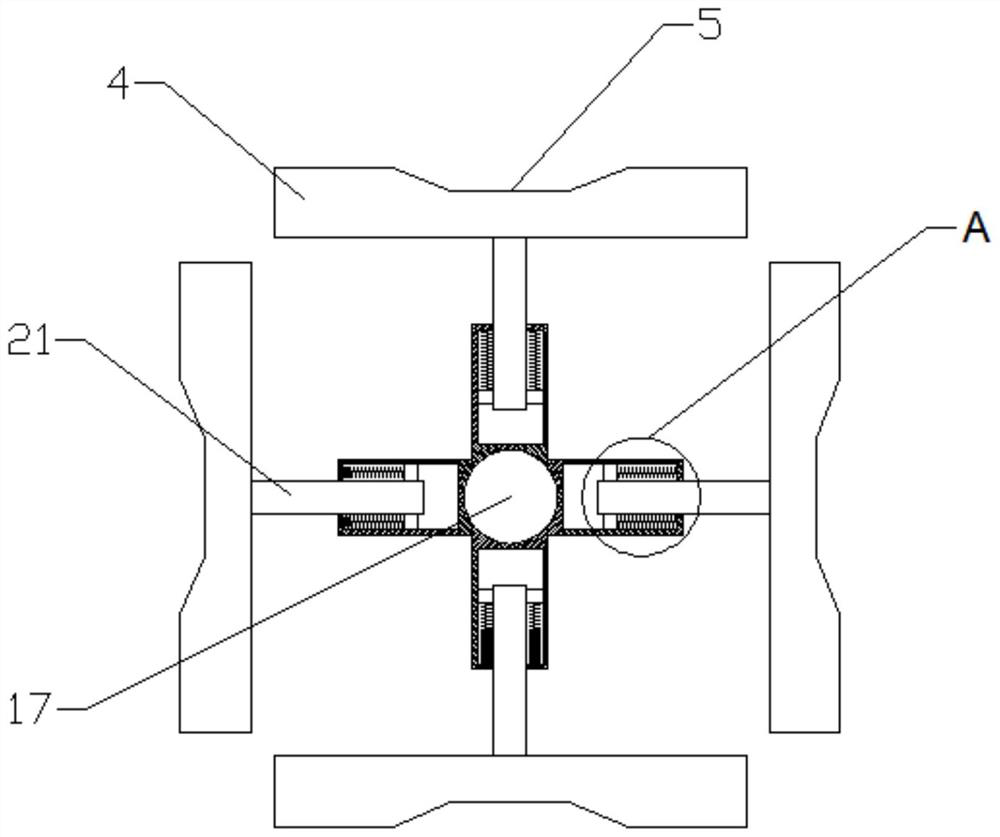

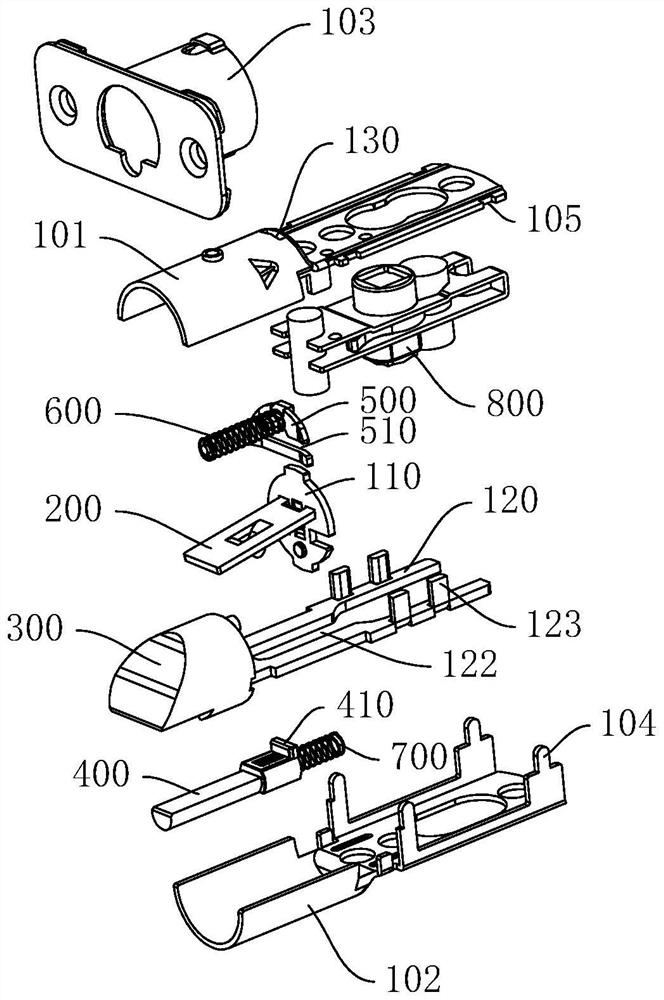

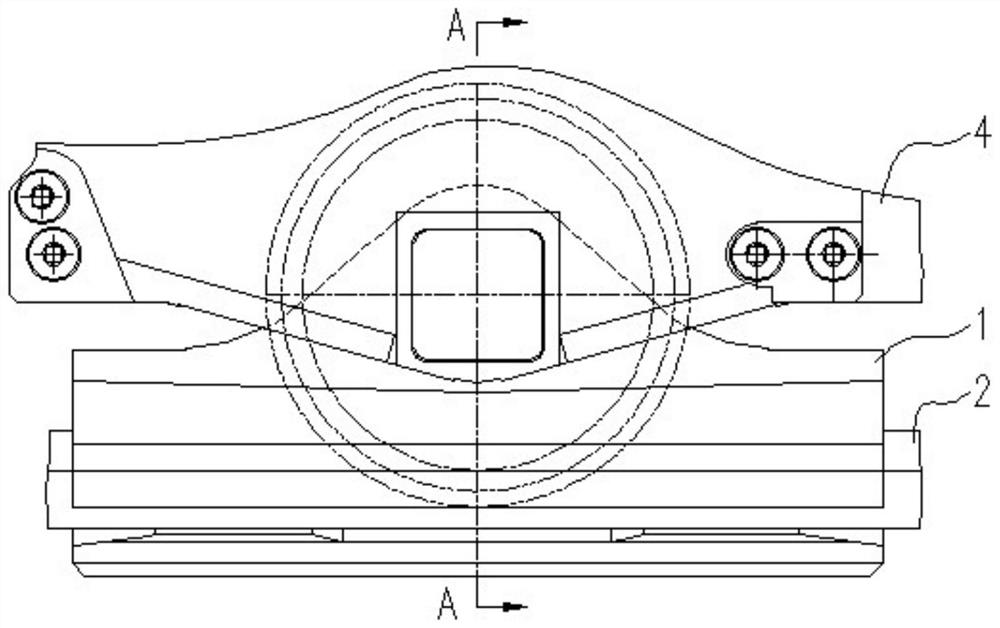

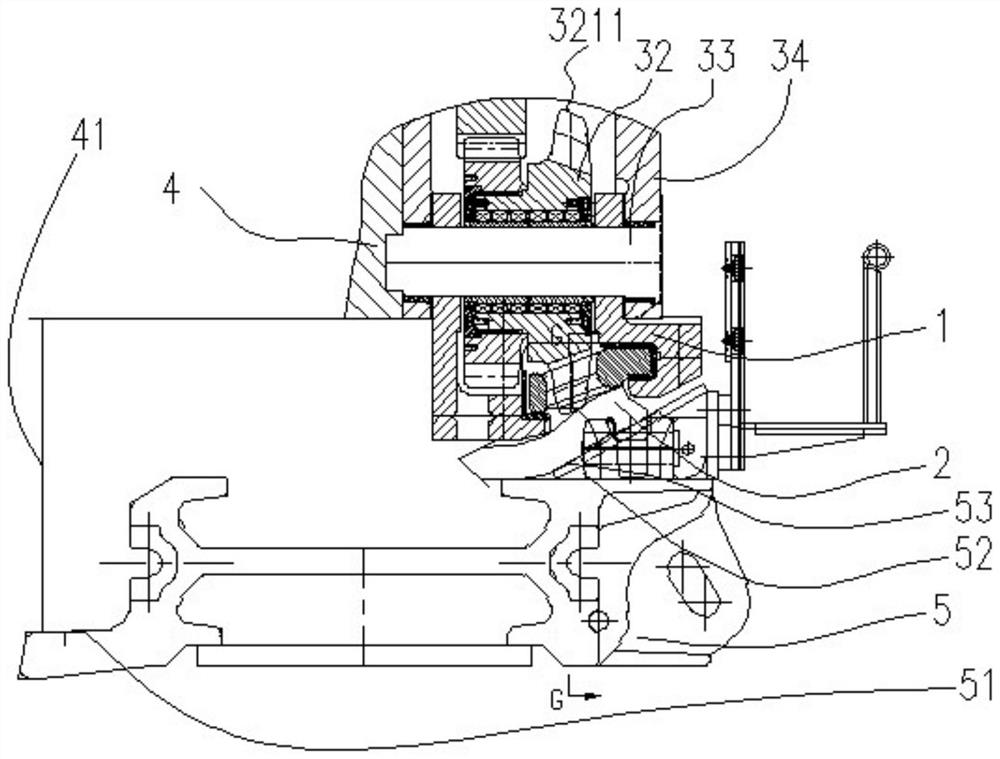

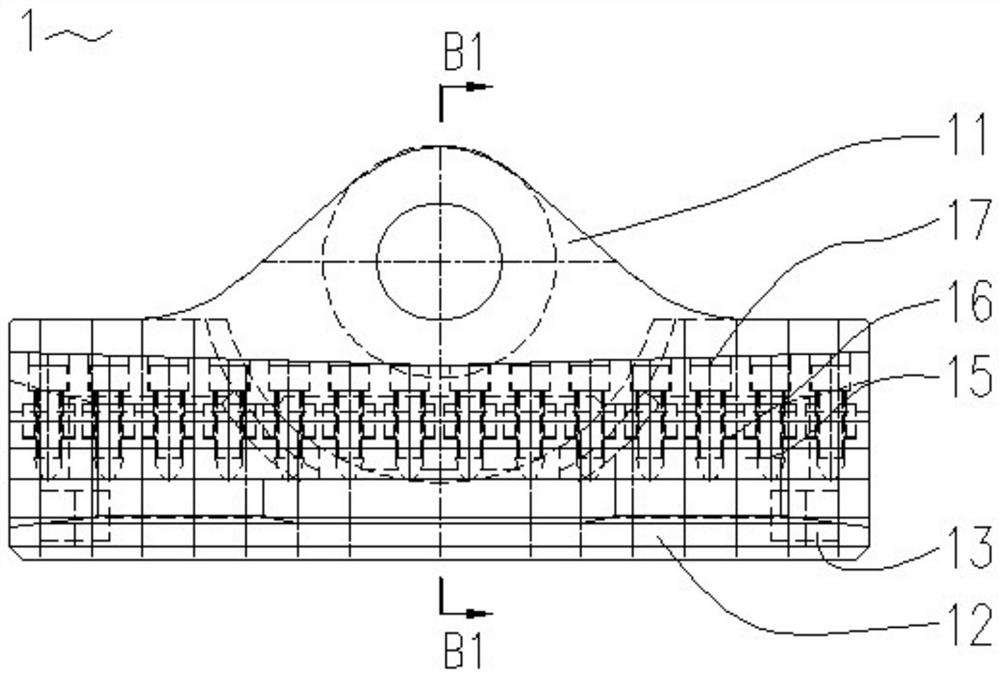

Defective battery discharging device on battery production line and working method thereof

InactiveCN112058714AIncrease the force contact areaStable water levelSortingConveyor partsElectrical batteryControl system

The invention discloses a defective battery discharging device on a battery production line and a working method thereof. The defective battery discharging device on the battery production line is arranged on a battery conveying production line, is used for discharging defective batteries which do not pass an electrical test, and comprises a linear guide rail assembly arranged on one side of a battery conveying machine body, a mechanical arm installed on the linear guide rail assembly in a transmission mode, and a special clamp is fixedly installed on the mechanical arm; and a linear driving device and a positioning mechanism are arranged on one side of the linear guide rail set, and the linear driving device is in communication with a control system. A lithium battery production line anda fire-fighting conveying line are synchronously arranged, the fire-fighting path and waiting time are shortened for solving the fire problem of the production line, and the distance between clampingjaws can be adjusted by arranging the lead screw assemblies on the connecting parts on the special clamps, so that the clamping jaws adapt to trays of various sizes; and meanwhile, the front and rearclamping parts are synchronously taken and placed to increase the stress contact area of the tray, stabilize the gravity center of the battery in the tray and prevent the battery from falling out of the tray.

Owner:NANJING LINGQUE INTELLIGENT MFG CO LTD

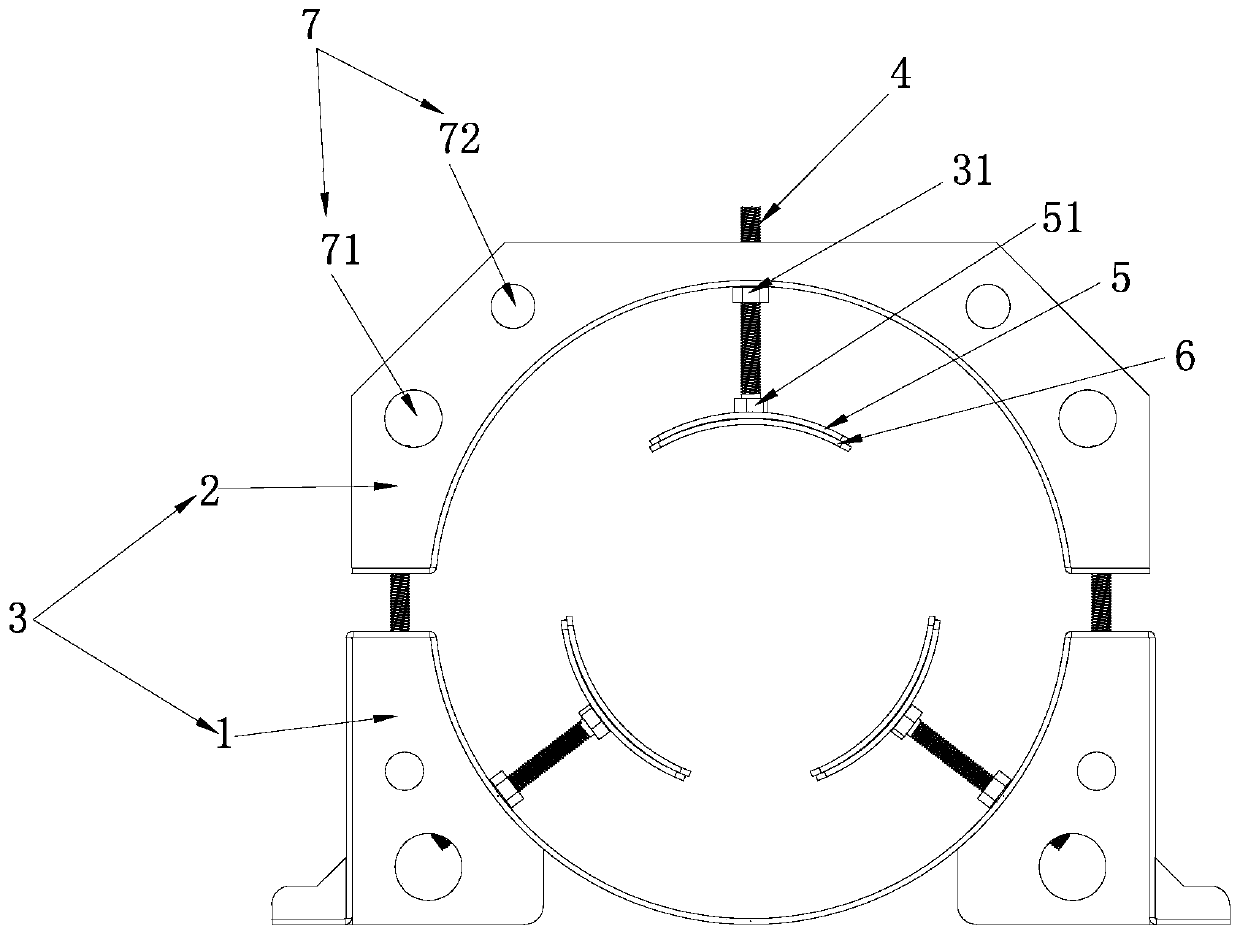

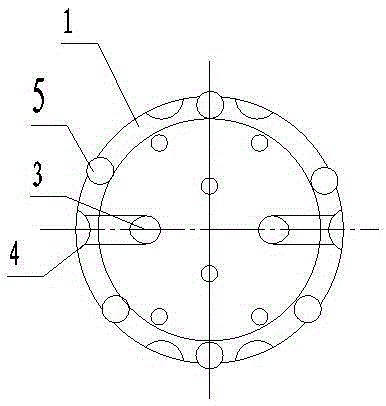

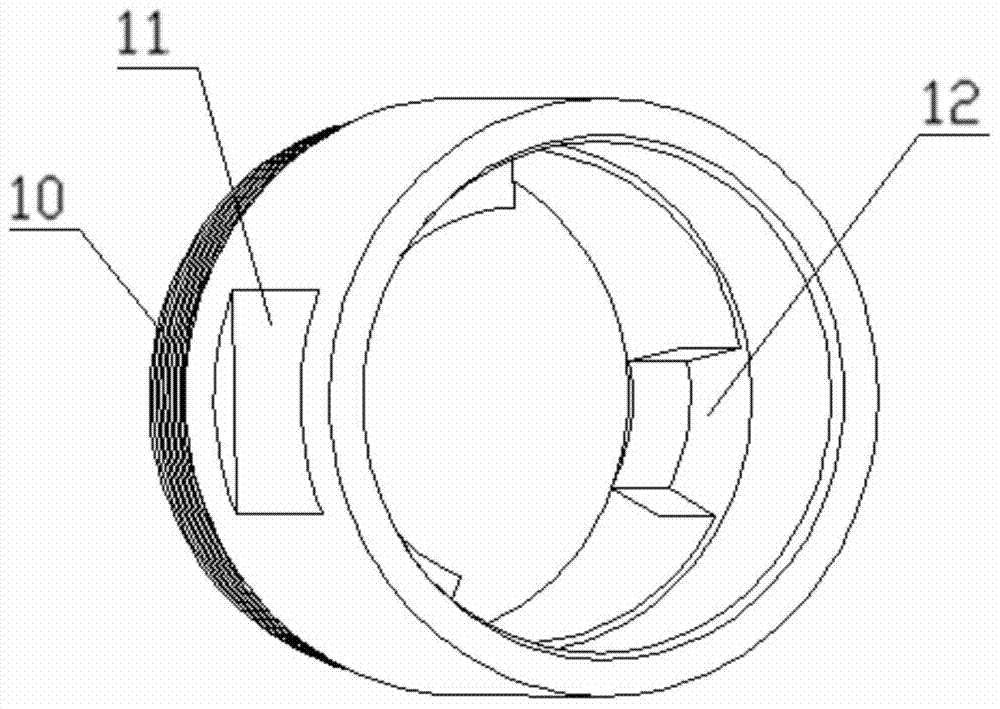

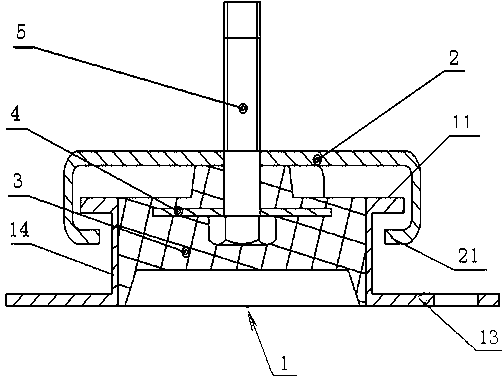

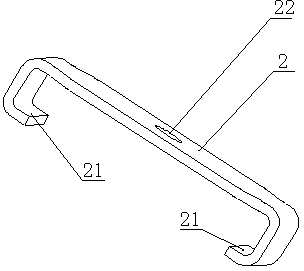

Holt hoop iron and electric meter box

PendingCN110376410AUniform forceEasy to holdFriction grip releasable fasteningsTime integral measurementMechanical engineeringEngineering

The invention discloses holt hoop iron and an electric meter box applied to the technical field of electrical components. The holt hoop iron comprises a first semi-annular holt hoop iron part and a second semi-annular holt hoop iron part connected via a connecting device and forming an annular holt hoop iron body after being connected; the holt hoop iron body is connected with the electric meter box, and provided with at least three adjusting bolts, the adjusting bolts are uniformly distributed along the annular arm of the holt hoop iron body, each adjusting bolt can be stretched and contracted along the annular radius direction of the holt hoop iron body, one end of each adjusting bolt is provided with an arc clamping plate, all the arc clamping plates are positioned in the ring of the holt hoop iron body, the inner cambered surface of each arc clamping plate is arranged towards the annular center of the holt hoop iron body, and the outer cambered surface of each arc clamping plate isconnected with the corresponding adjusting bolt. When holding electric poles of different diameters, the holt hoop iron can be adjusted, the holding force is high, and large load as of the electric meter box can be born.

Owner:威胜能源技术股份有限公司

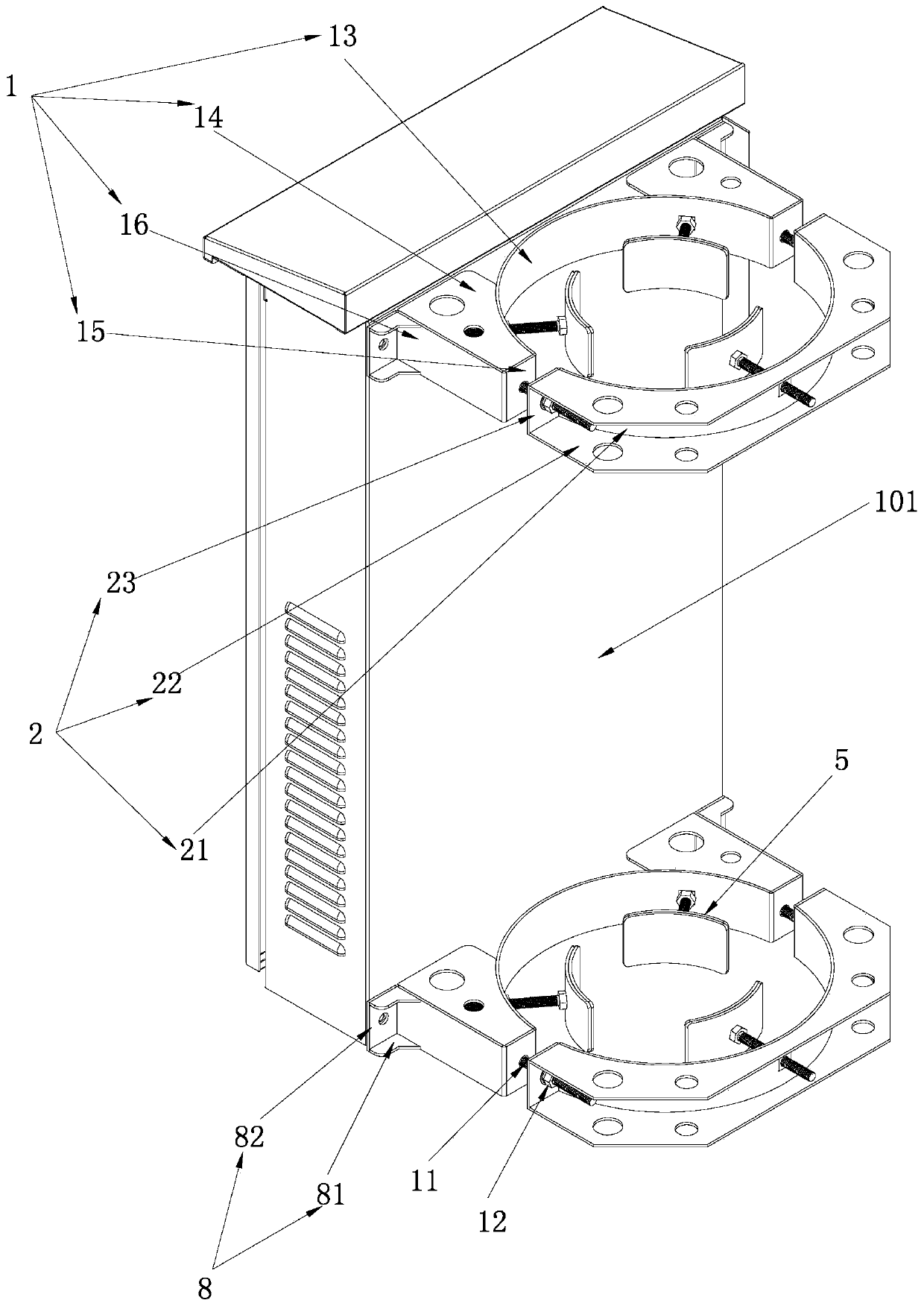

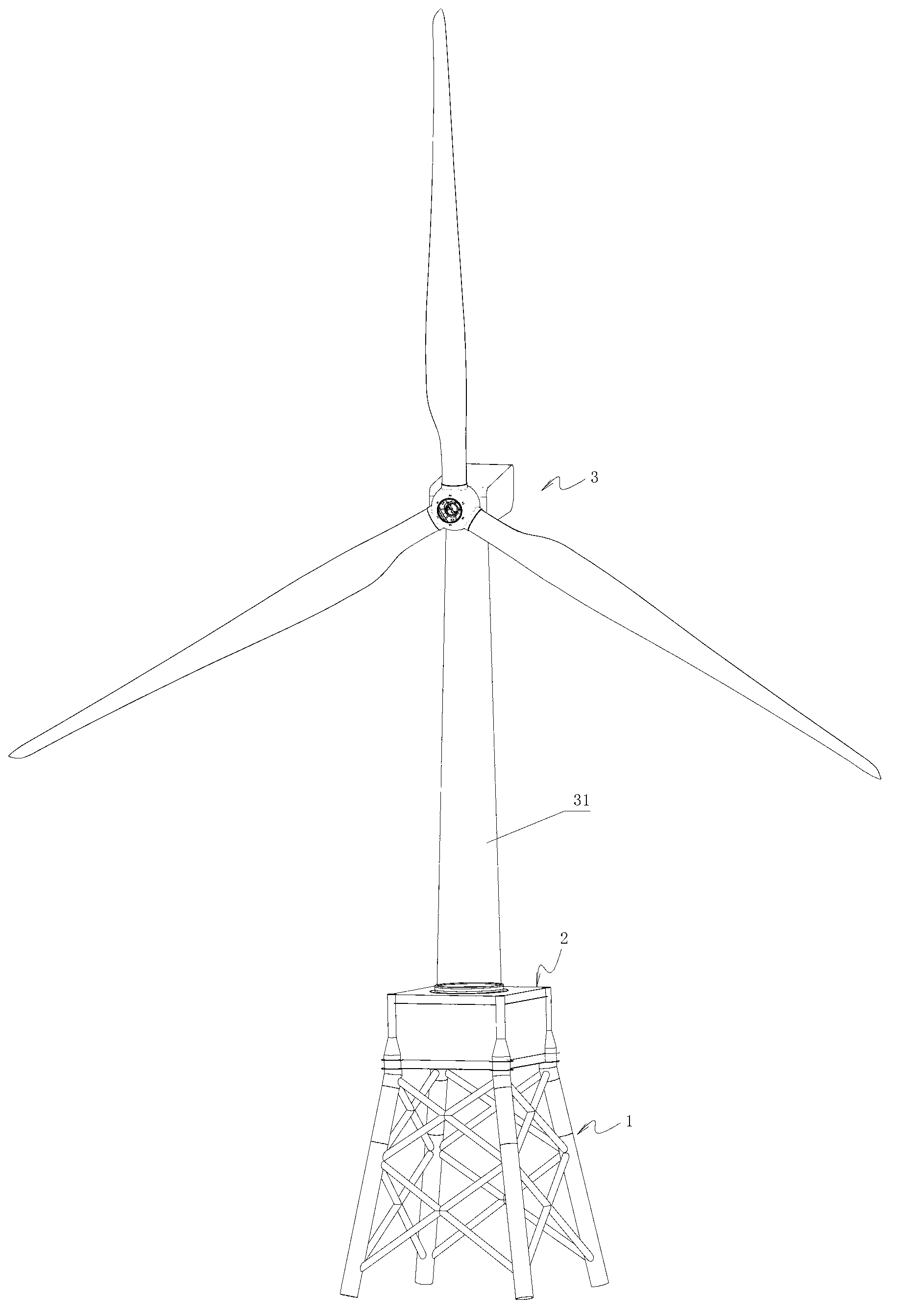

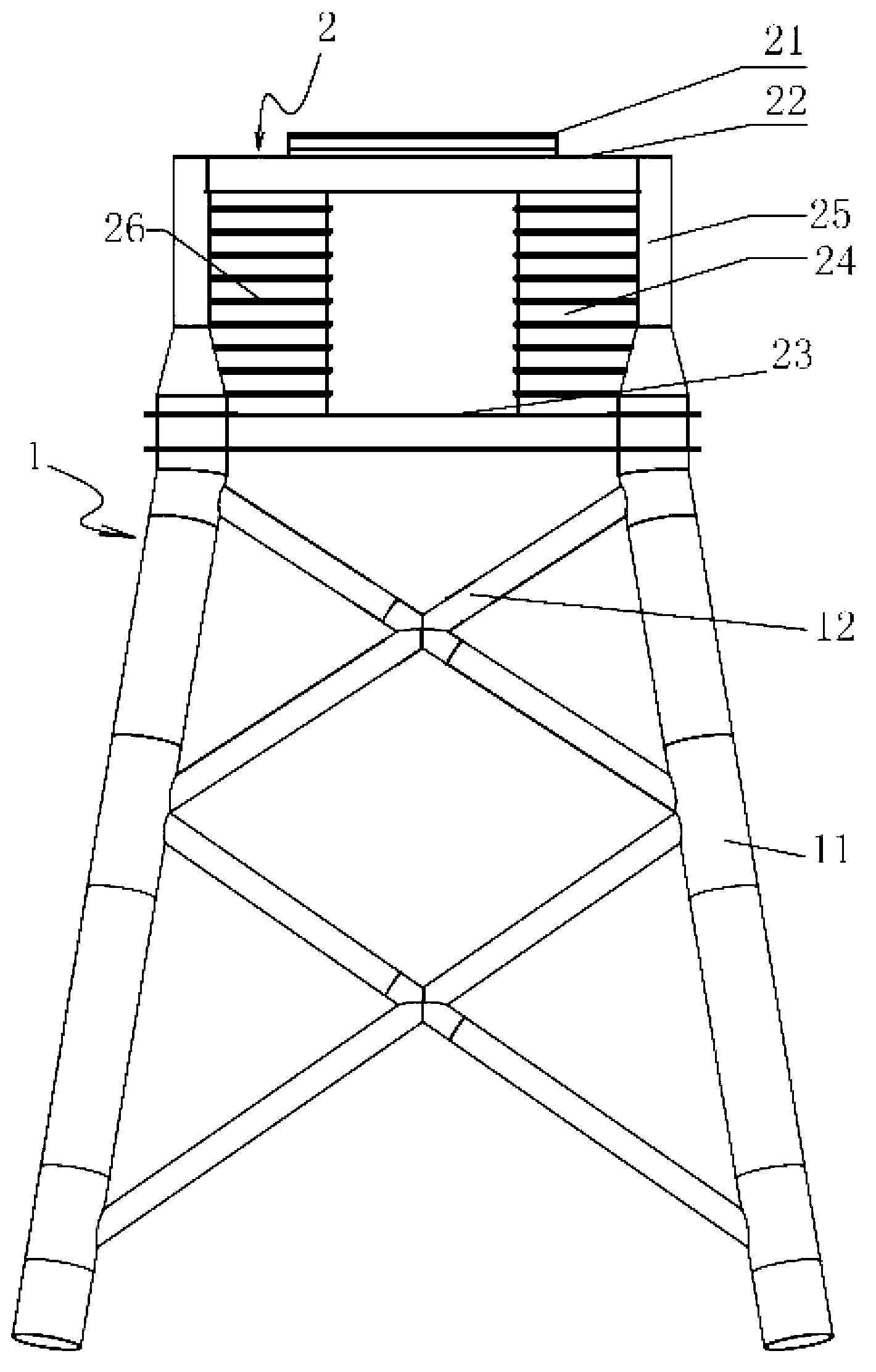

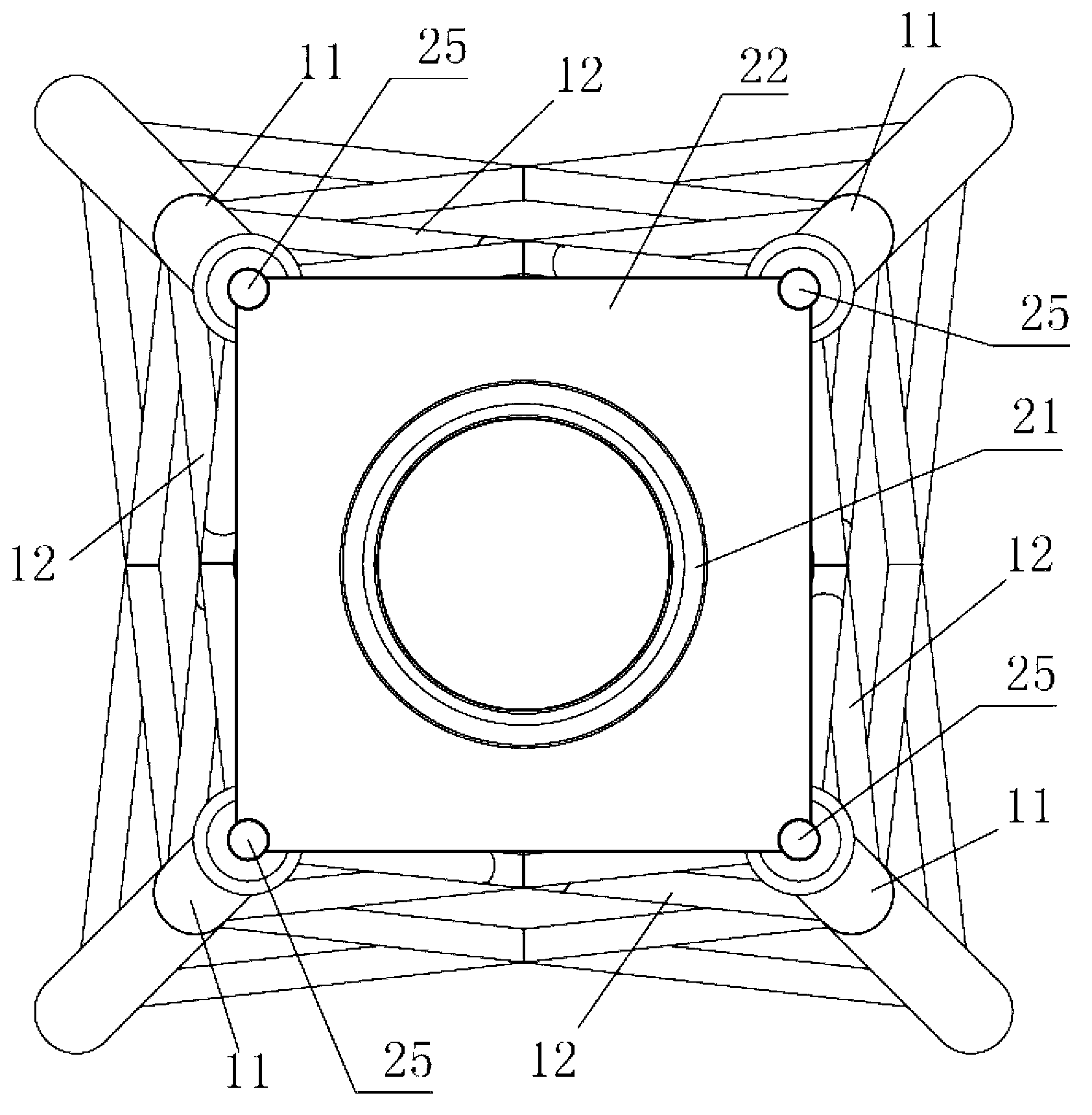

Double-deck supporting connection structure of tower drum of wind driven generator and jacket foundation

InactiveCN102797647AReduce wall thicknessAvoid deformationWind energy generationWind motor componentsStress concentrationHorizontal force

The invention discloses a double-deck supporting connection structure of a tower drum of a wind driven generator and a jacket foundation. The middle of the double-deck supporting connection structure is provided with a vertical upright post, the top and the bottom of the vertical upright post are both provided with decks containing reinforcing ribs, the vertical upright post is welded on the two decks, and the two decks are used for resisting horizontal shearing force and a bending moment which are generated during the operation of an air blower to prevent the tower drum or the vertical upright post from being deformed because of the operation of the vertical upright post; a vertical plate containing the reinforcing ribs is arranged between the two decks, the vertical plate enlarges the stress contact area of the two decks so as to reduce stress concentration, and the vertical plate can also bear a torsional moment and horizontal force which are generated during the operation of the air blower so as to generate a resisting bending moment. The double-deck supporting connection structure of the tower drum of the wind driven generator and the jacket foundation adopts the vertical plate and a horizontal plate to be respectively connected with the vertical upright post; with the structural mode, the stress concentration of the connecting position of the tower drum of the wind driven generator and the jacket foundation is reduced, and the steel using amount is reduced.

Owner:GUANGDONG MINGYANG WIND POWER IND GRP CO LTD

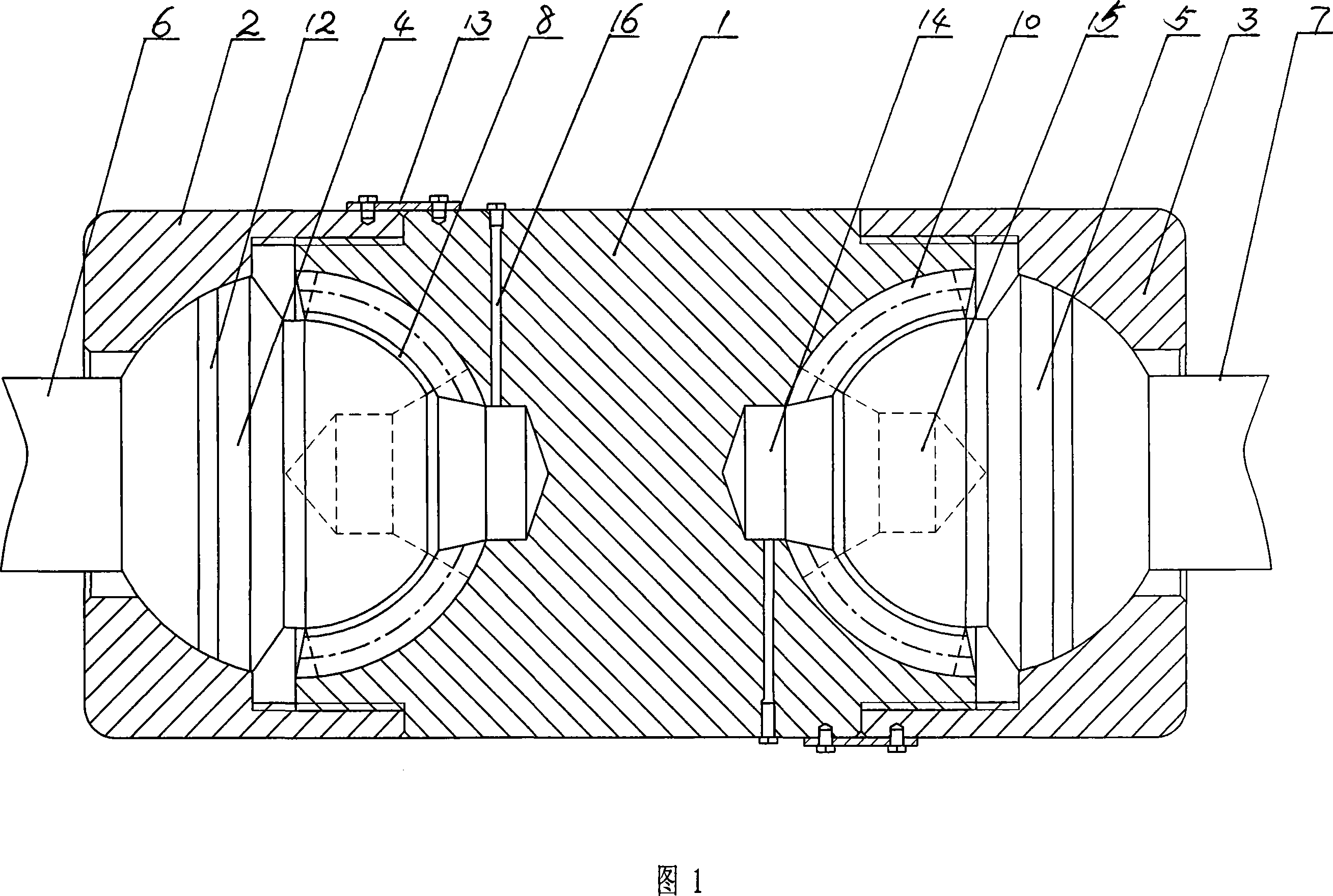

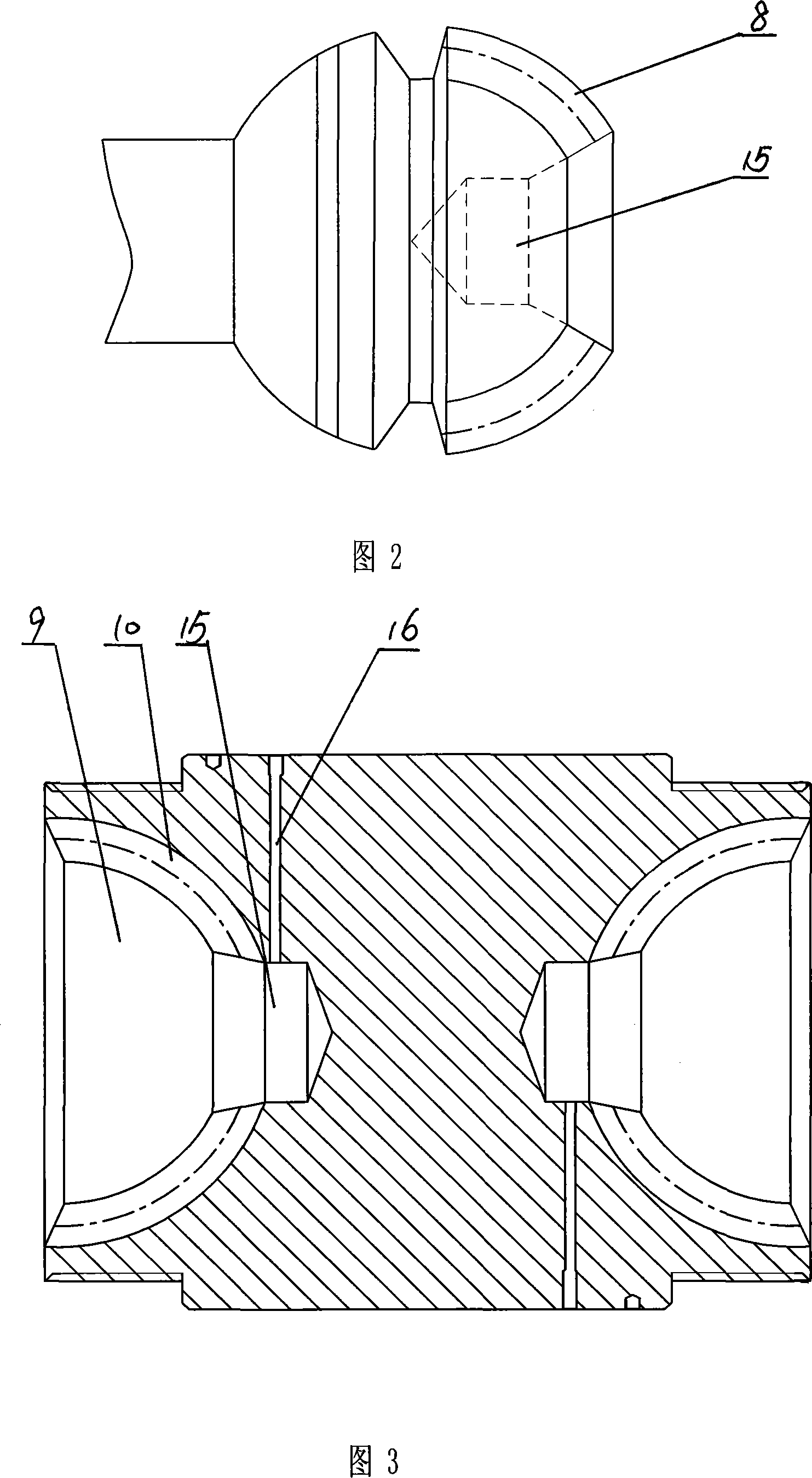

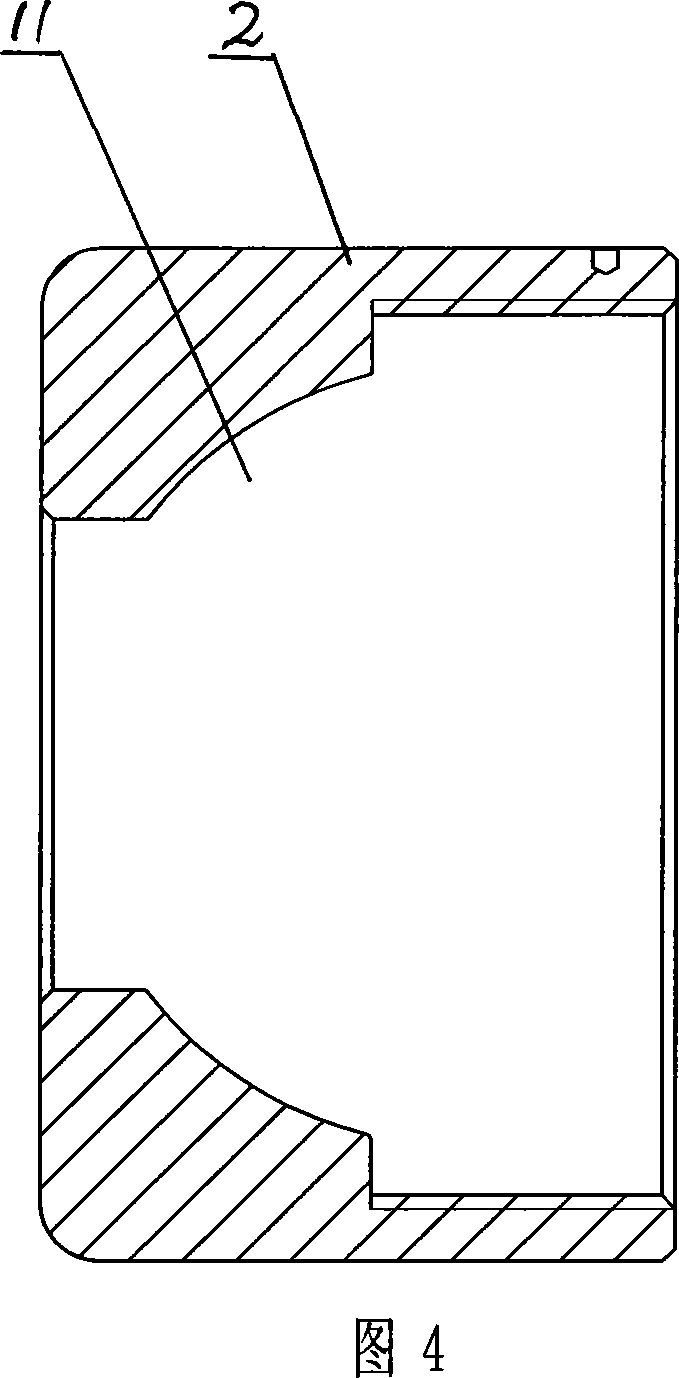

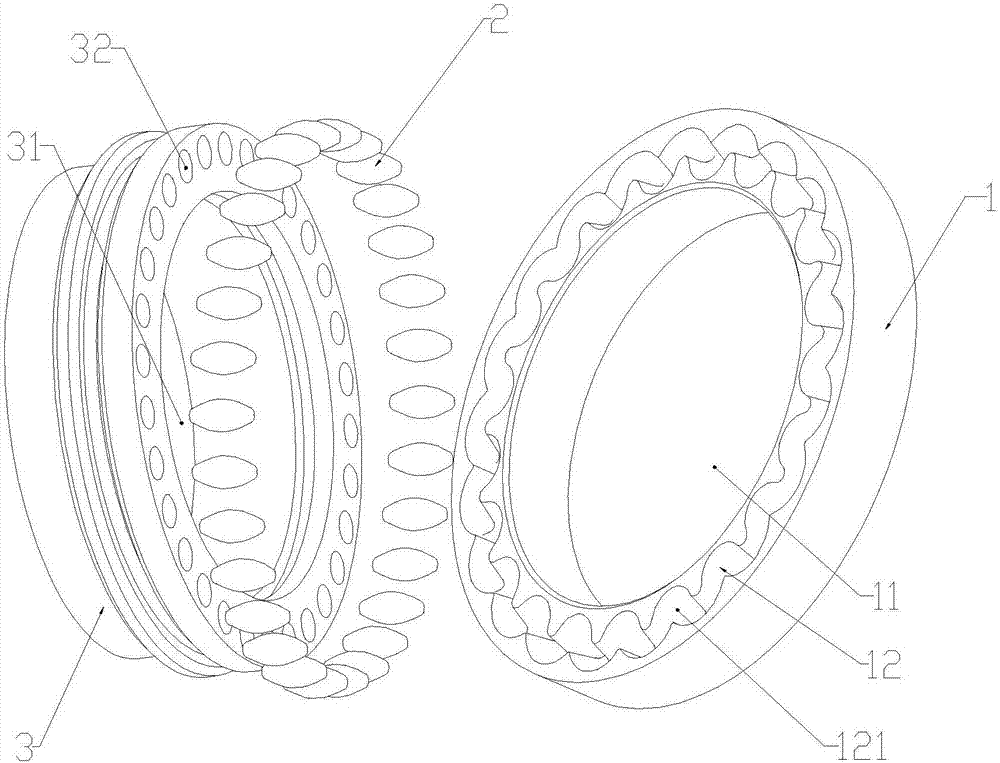

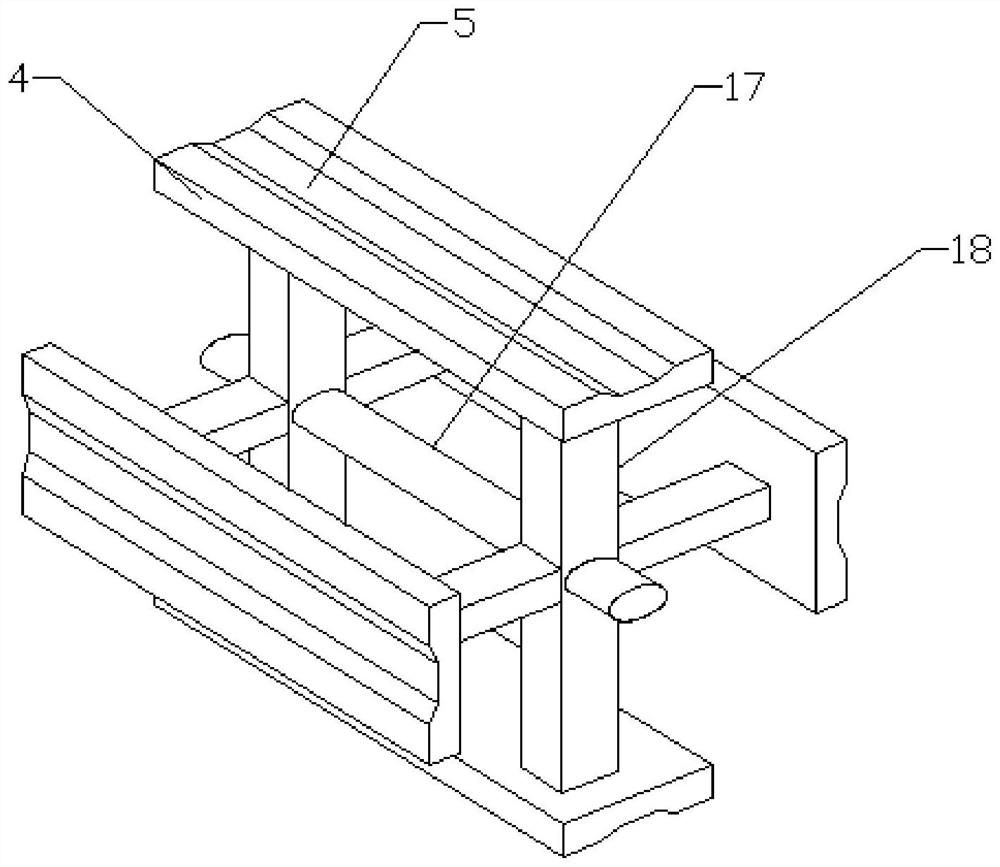

Spherical tooth type universal coupling

InactiveCN101135346AReduce contact stressEasy to assemble and disassembleYielding couplingCouplingEngineering

The ball-tooth universal coupler comprises a left-right symmetric intermediate joint axle and two half-couplers mounted on the two ends of the intermediate joint axle through end caps. The said half coupler is a ball-shape ball joint connected respectively with the power input end and the power output end. At the front half sphere of the ball joint are provided with several bars of externally convex arc teeth, and in the sphere recess at the two ends of the intermediate joint there is provided with internal concave arc teeth. The internal cavity of the end cap is a spherical recess corresponding to the rear sphere of the ball joint, and the ball joint is mounted movably in the ball-shape cavity formed by the end cap and the intermediate joint. Advantages: reduced contact stress to stress surface, high transfer torque, stable operation, good sealing and lubricating effect, long service life, compact structure and convenient maintenance.

Owner:郭太利

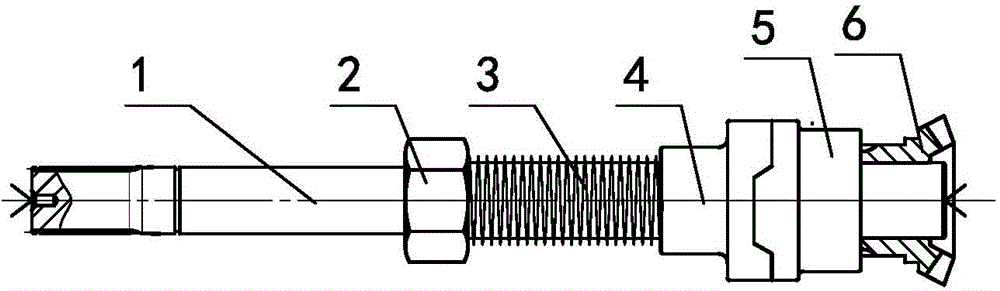

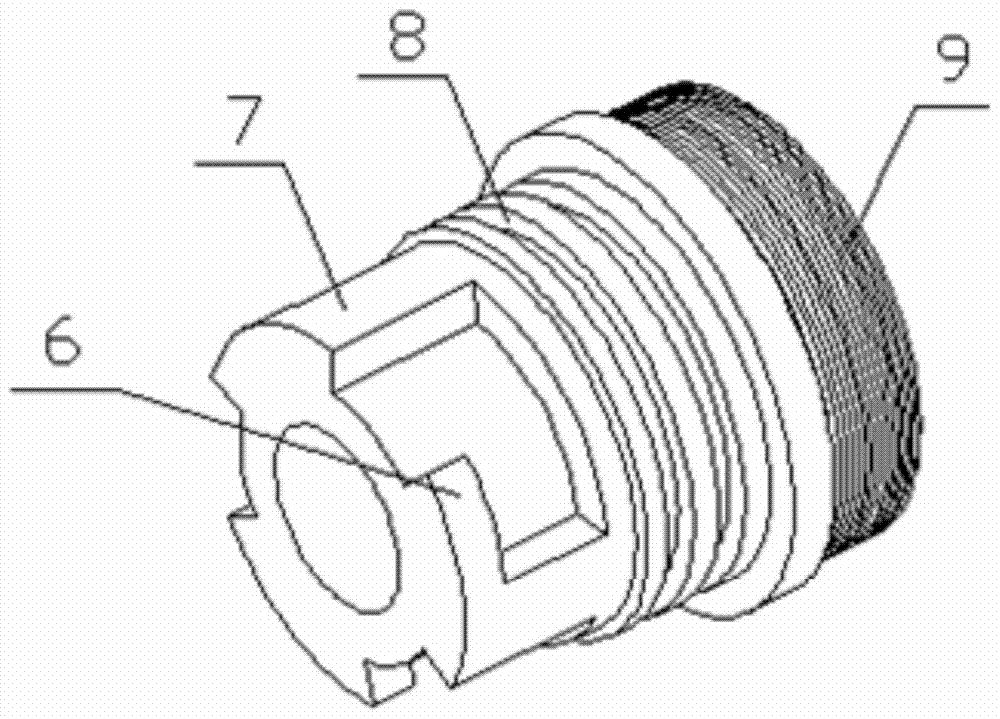

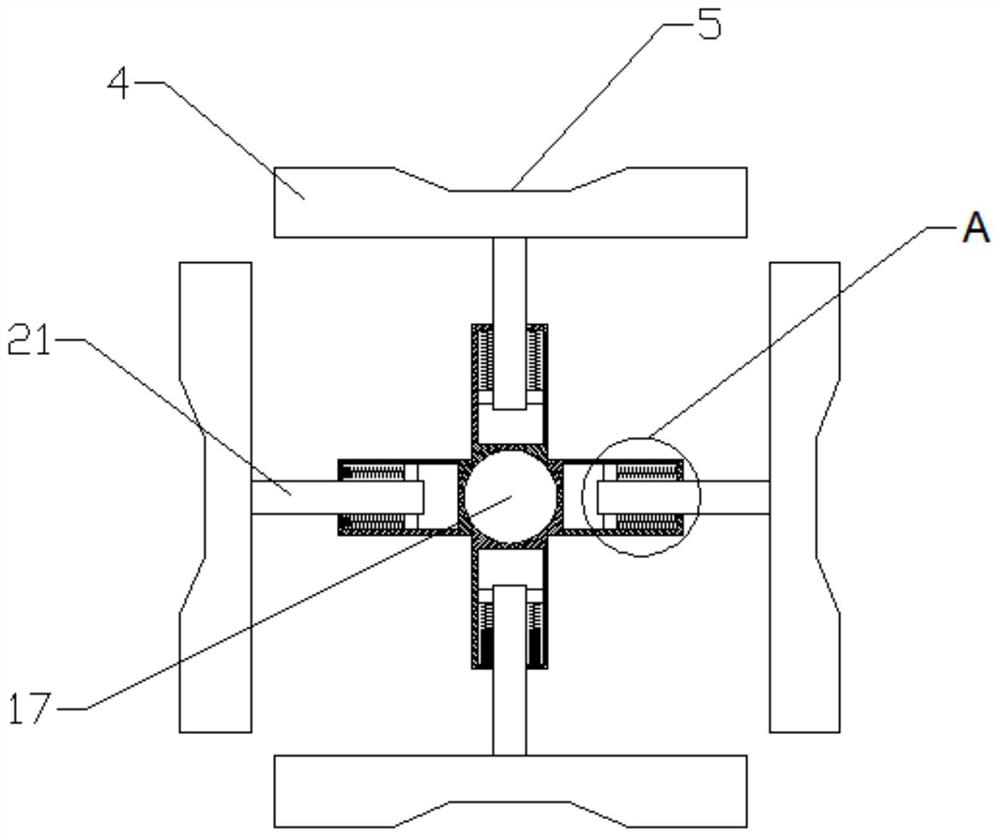

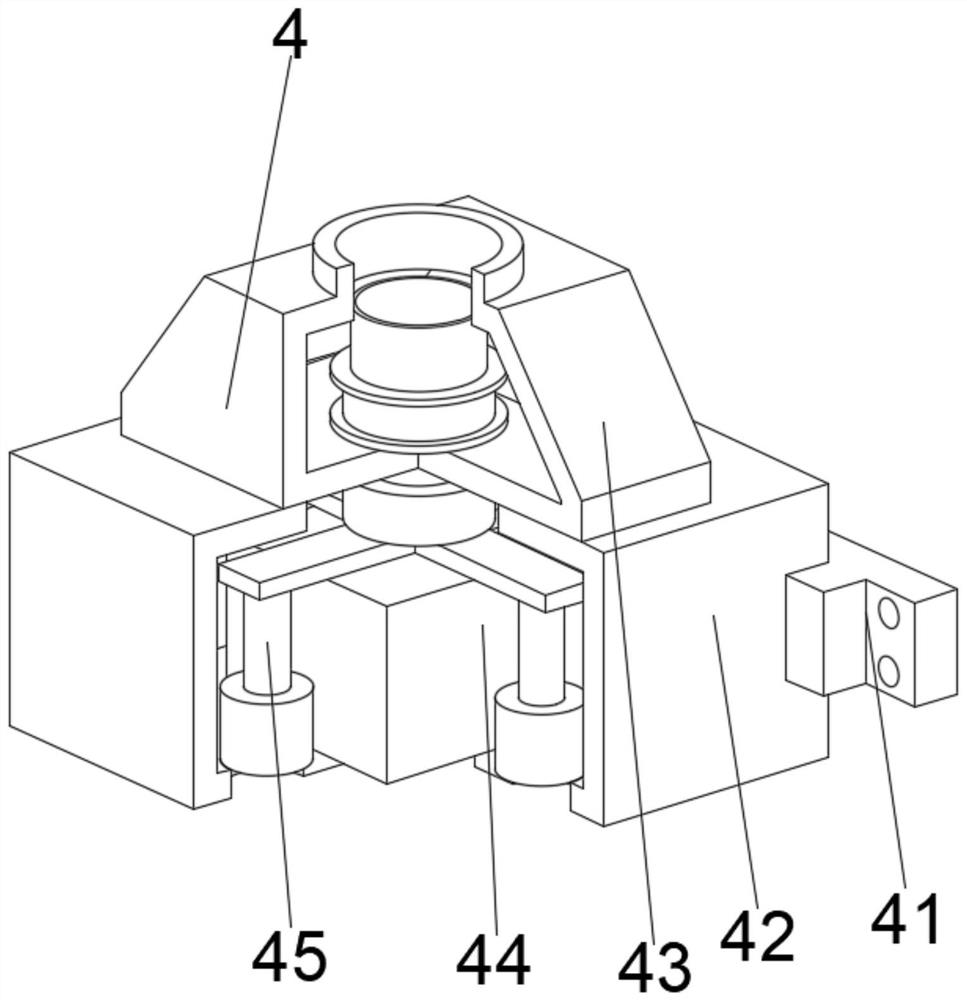

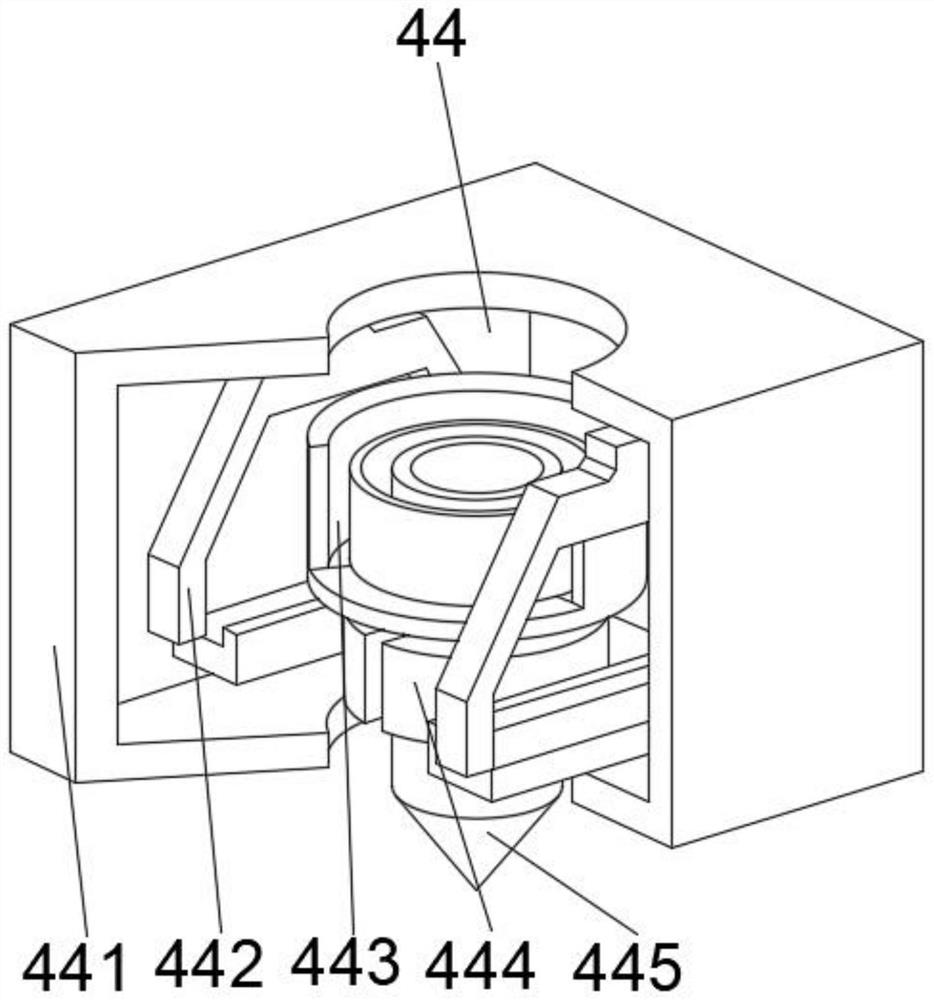

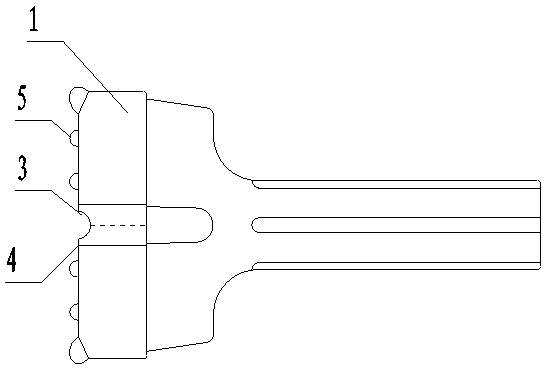

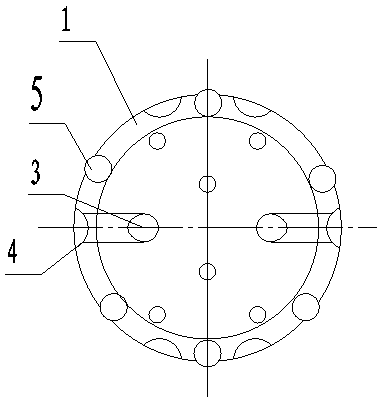

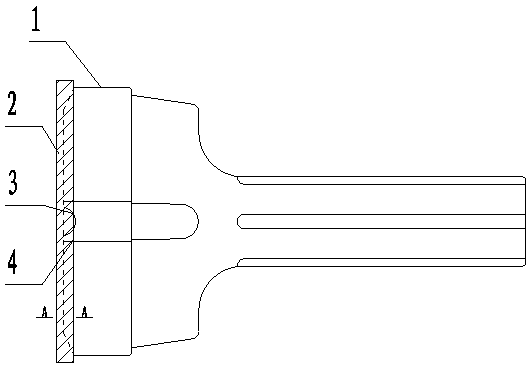

Overload protection clutch used for shaft connection

InactiveCN105351382ASimple structureIncrease the force contact areaSlip couplingAutomatic clutchesEngineeringConical teeth

The invention relates to an overload protection clutch used for shaft connection, and belongs to the technical field of connectors. The overload protection clutch used for shaft connection comprises a horizontal shaft and conical teeth arranged on the shaft in a penetrating mode, and the shaft and the conical teeth are independent; the shaft is sleeved with a nut in a threaded connection mode; a first clutch body used for axial power transmission is installed on the part, on the right side of the nut, of the shaft, the part, between the first clutch body and the nut, of the shaft is sleeved with a spring, the left end of the spring abuts against the nut, and the right end of the spring abuts against the first clutch body; a second clutch body capable of freely rotating around the shaft is installed on the part, on the right side of the first clutch body, of the shaft and connected with the first clutch body in a matched mode through a clutch claw; the second clutch body and the shaft are transversely positioned through built-in balls, and the left ends of the conical teeth are connected with the second clutch body through a spline. The overload protection clutch used for shaft connection is simple in structure and large in stress contact area, the tangential force is reduced, transmission is more stable, and overload protection is achieved.

Owner:CHONGQING HANYUAN MACHINERY

Large-range fishing spear and fishing method thereof

PendingCN107435526AWide range of salvageExpand the scope of salvageBorehole/well accessoriesEngineeringStructural engineering

The invention discloses a large-range fishing spear and a fishing method thereof. The large-range fishing spear comprises a mandrel, an upper sliding sleeve and a lower sliding sleeve, wherein the mandrel is sleeved with the upper sliding sleeve and the lower sliding sleeve. The mandrel comprises a spear rod, an upper connector and an adjusting sleeve, wherein the upper connector and the adjusting sleeve are connected to the upper end and the lower end of the spear rod correspondingly. Four split type slips are connected between the upper sliding sleeve and the lower sliding sleeve. T-shaped heads are arranged at the two ends of each split type slip correspondingly. T-shaped grooves are formed in the lower end of the upper sliding sleeve and the upper end of the lower sliding sleeve correspondingly. The T-shaped heads are clamped into the T-shaped grooves to connect the upper sliding sleeve and the lower sliding sleeve together. The split type slips can move radially on the spear rod so that fishing of downhole drilling tools of different diameters can be adapted, the fishing range is larger, and the large-range fishing spear further can be used when the diameters of the downhole drilling tools cannot be precisely determined; and meanwhile, mutually-matched double conic surfaces are arranged on each split type slip and the mandrel, so that the force-bearing contact area is increased, and fishing force is improved.

Owner:GUIZHOU GAOFENG GASOLINEEUM MACHINERY

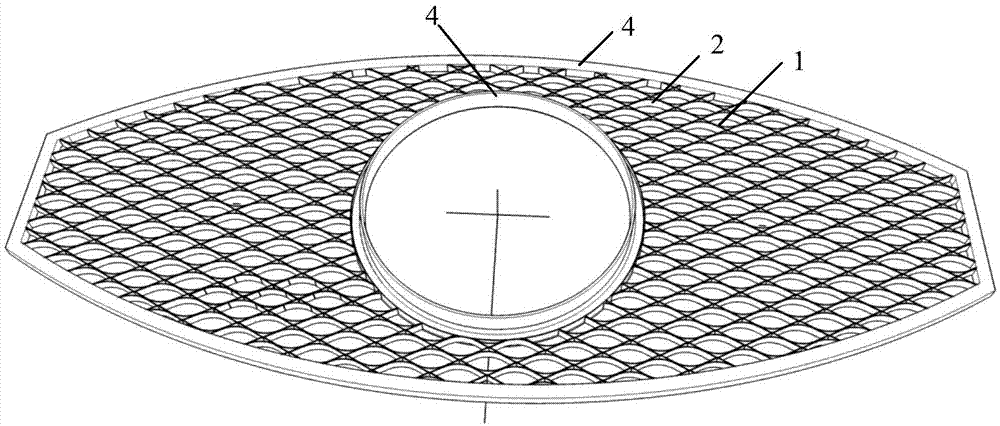

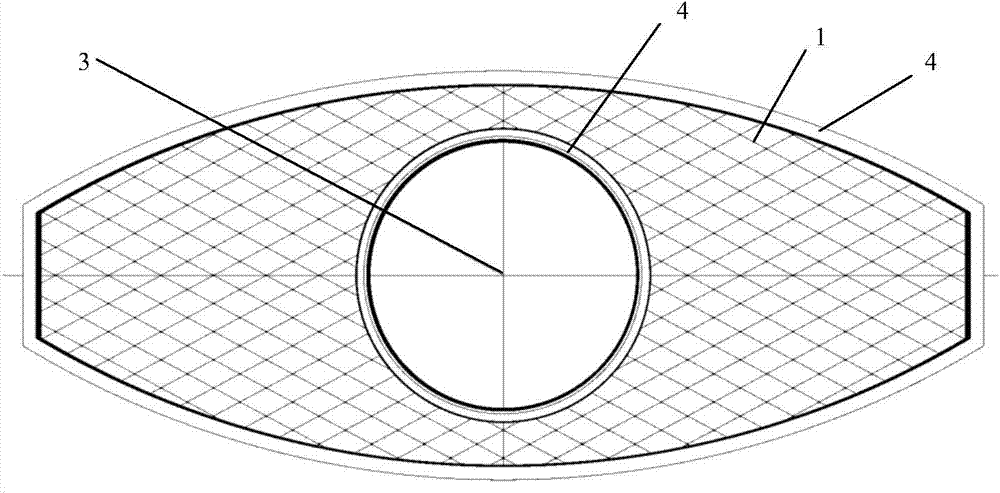

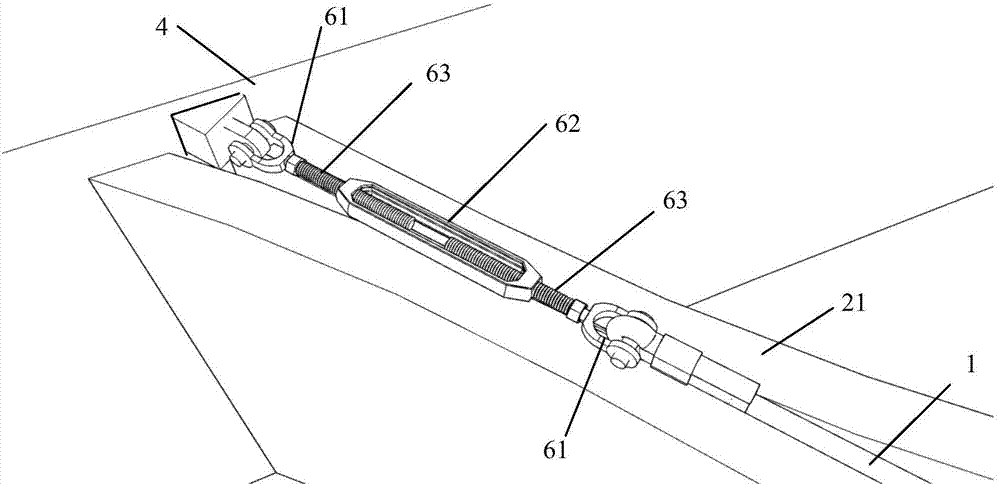

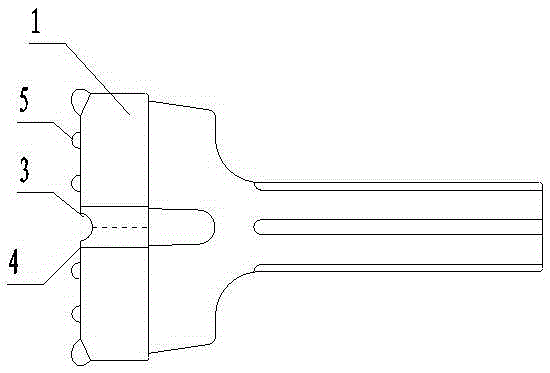

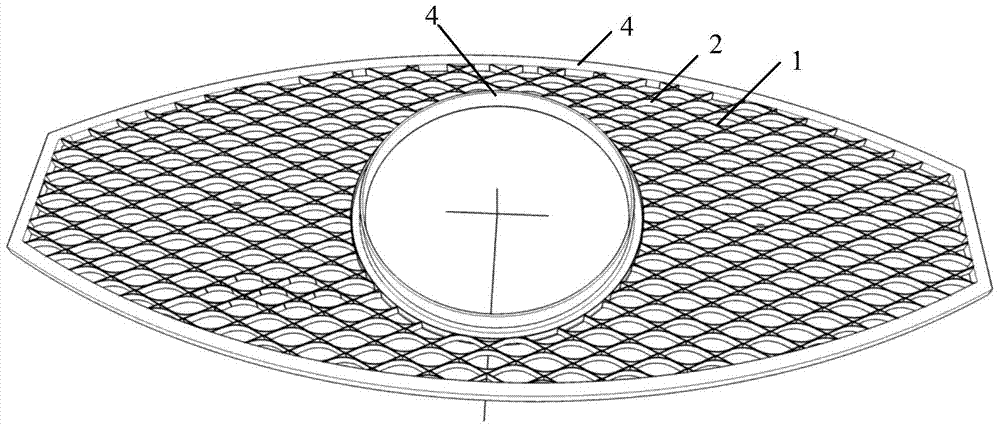

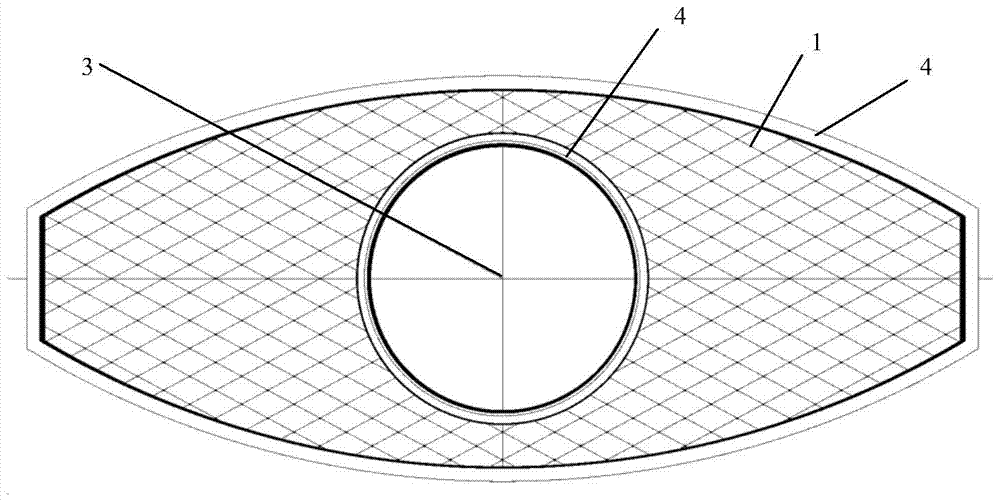

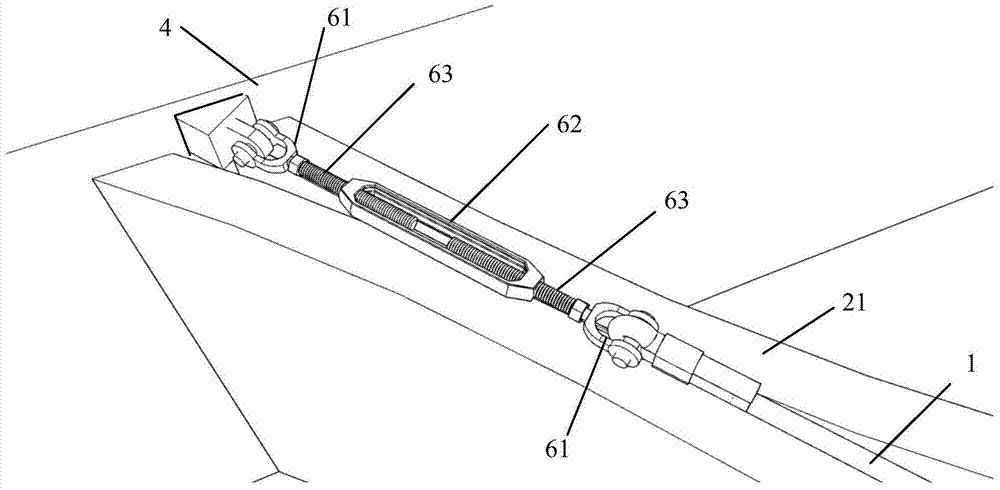

Steel cable supporting net for large-span net shaped ceiling system

ActiveCN104763088AAvoid direct forceThe force structure system is clearCeilingsSupporting systemEngineering

The invention provides a steel cable supporting net for a large-span net shaped ceiling system, and aims at solving the problems that the exposed house frame and supporting system of the open type light roof in the existing public building influence the artistic effect of the large space, and the added decorative ceiling is limited by the stressing of the lifting rods supporting the house frame. The steel cable supporting net comprises a plurality of steel cables and a plurality of adjustable length mechanisms, wherein the steel cables are knitted into a net shape; the end parts of the steel cables are arranged between structure ring beams through the adjustable length mechanisms. According to the steel cable supporting net, the gravity of a net shaped ceiling is transferred to the structural ring beams, thus the form of transferring the gravity of the net shaped ceiling to the house frame structure through a ceiling and a conversion layer in the prior art can be replaced, and the house frame is free of stressing; a plurality of clamp connecting parts for suspending the net-shaped ceiling are arranged on the steel cables; the knitting direction of the steel cables are corresponding to the style direction of the net-shaped ceiling, and therefore, the steel cable supporting net can be hidden above the net-shaped ceiling, and the problem that the lifting rods cannot be hidden in the traditional scheme can be solved.

Owner:SHANGHAI BUILDING DECORATION ENG GRP

Drill bit used for high air-pressure down-the-hole drill hammer with capability of penetrating reinforced concrete

Provided is a drill bit used for a high air-pressure down-the-hole drill hammer with the capability of penetrating reinforced concrete. The drill bit comprises a drill bit body, air exhaust holes and slag removing holes. The key point of the structure is characterized in that elongated tooth heads are inlaid on a panel of a head of the drill bit body. The drill bit used for the high air-pressure down-the-hole drill hammer with the capability of penetrating reinforced concrete has following advantages: by changing the distribution of the tooth heads of the drill bit body, the point distribution structure of the tooth heads is changed to be elongated distribution structure for alloy tooth heads; tooth roots are used to be small-diameter blind holes and are changed to be elongated tooth grooves; elongated alloy tooth heads are embedded into the drill bit body so that heat treatment technology becomes easy; welding-on reliability is greatly improved; due to the elongated structure of the alloy tooth heads of the drill bit body, the contact area for acting force is increased; force is applied by lines instead of points; and under effect of high frequency impact, panels of the alloy tooth heads of the drill bit body can operate in the knife-cutting mode in order to generate plastic deformation by force. The drill bit used for the high air-pressure down-the-hole drill hammer with the capability of penetrating reinforced concrete has following beneficial effects: the speed for penetrating reinforced steel bar is 20 times as high as original speed; and the drill bit has 10 or 20-fold service lifetime as compared with an ordinary drill bit.

Owner:SINOHYDRO BUREAU 16 CO LTD

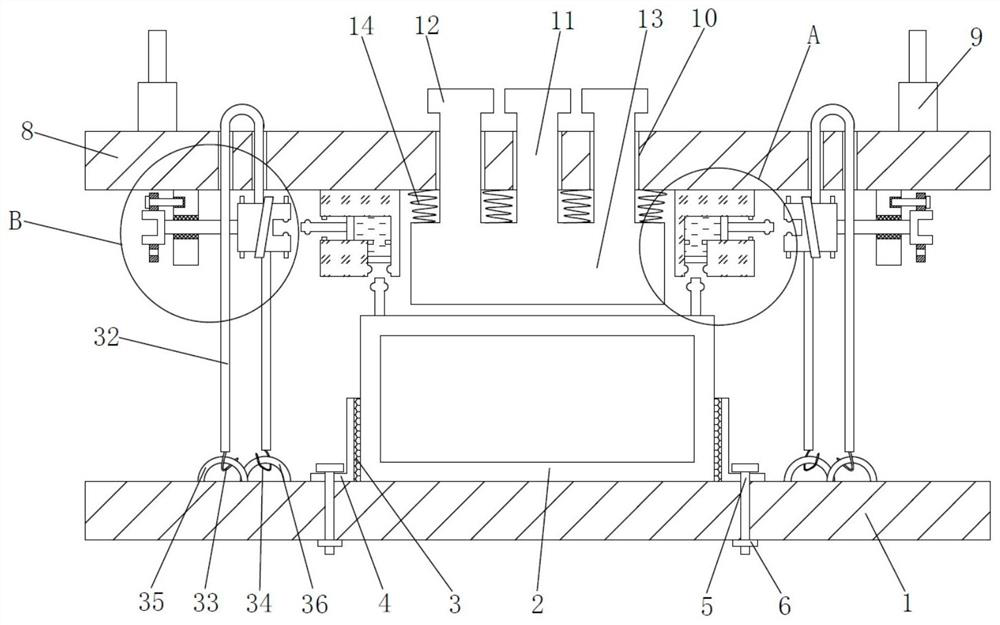

Anti-earthquake support system provided with steel wire ropes and used for rectangular air pipe

ActiveCN111853363AIncrease the force contact areaStable supportPipe supportsPipe elementsClassical mechanicsEngineering

The invention discloses an anti-earthquake support system provided with steel wire ropes and used for a rectangular air pipe. The anti-earthquake support system provided with the steel wire ropes andused for the rectangular air pipe comprises a lower support, wherein the rectangular air pipe is placed on the lower support, and L-shaped limit plates are arranged at the two sides of the rectangularair pipe; a rubber push plate is arranged below a rubber rod, and a earthquake absorption spring is arranged between the rubber push plate and an upper support in a connection manner; the upper support is symmetrically provided with fixing blocks at the two sides of the rubber push plate, an L-shaped piston cavity is formed in each fixing block, and a second clamping rod is fixedly arranged at one side away from the corresponding L-shaped piston cavity, of a second piston plate; an annular plate is fixedly arranged at the outer side of a connection element, and a plurality of thread holes areformed in the annular plate; and the steel wire ropes are symmetrically arranged on the upper support in a penetrating manner. The invention provides an anti-earthquake support system provided with steel wire ropes and used for a rectangular air pipe. The anti-earthquake support system provided with the steel wire ropes and used for the rectangular air pipe is more stable in support, and capableof uniformly limiting an allowable swing amplitude, an elastic extrusion state and the like of the rectangular air pipe; and therefore, a plurality of anti-earthquake supports are capable of uniformlydispersing an action force during an earthquake, and the anti-earthquake support system is worthy of popularization.

Owner:HEFEI YUANKANG ENVIRONMENT SCI & TECH

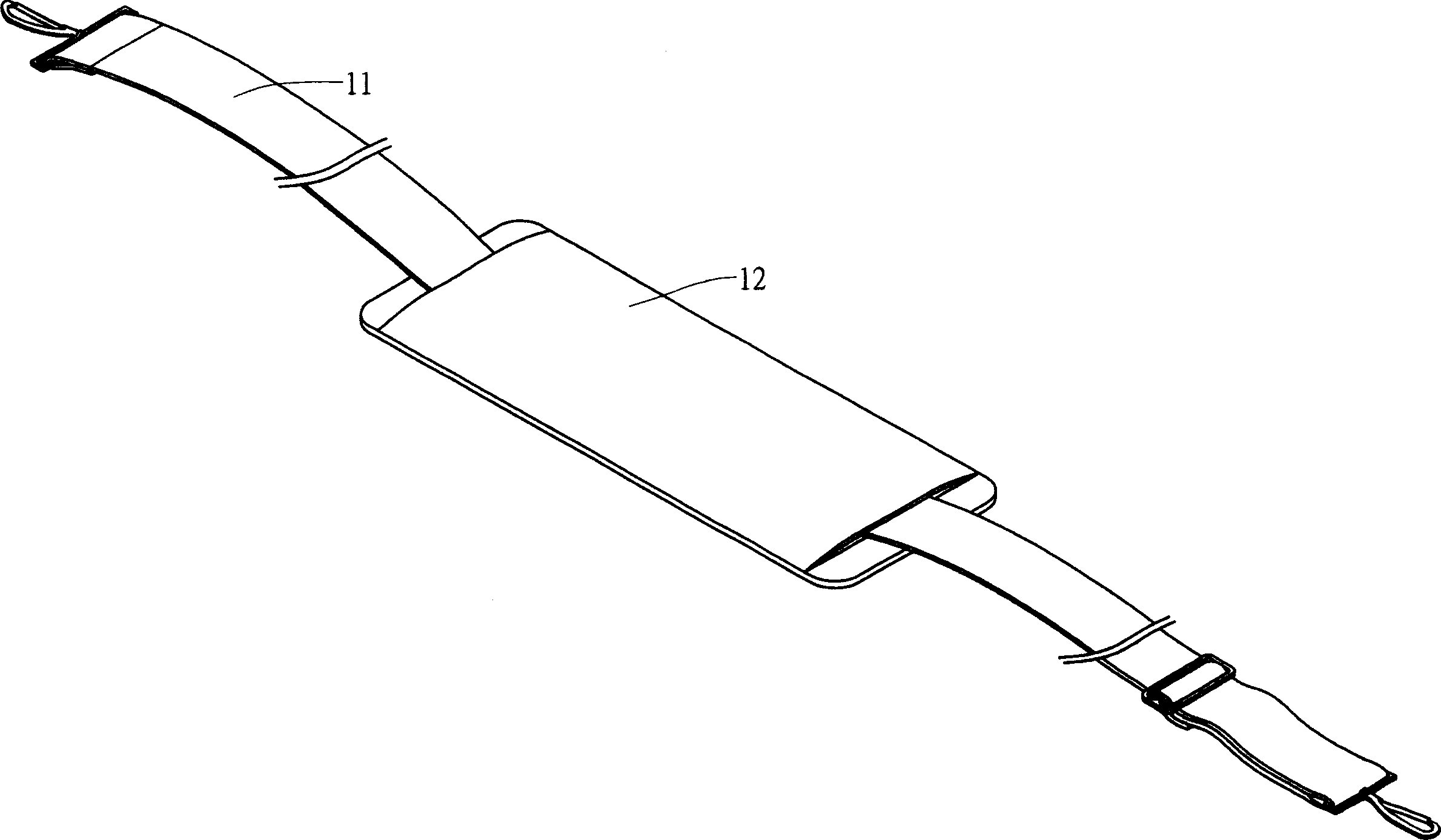

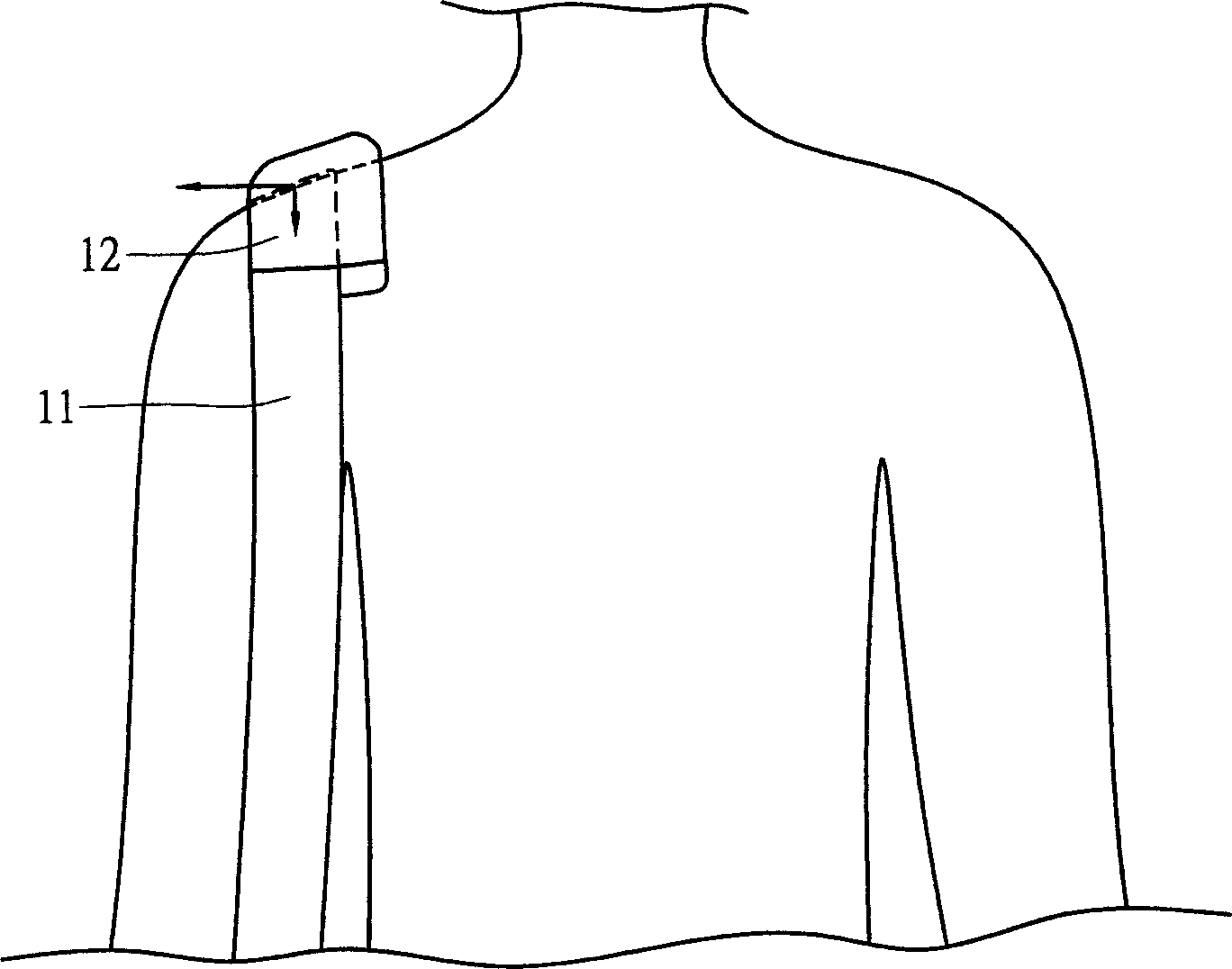

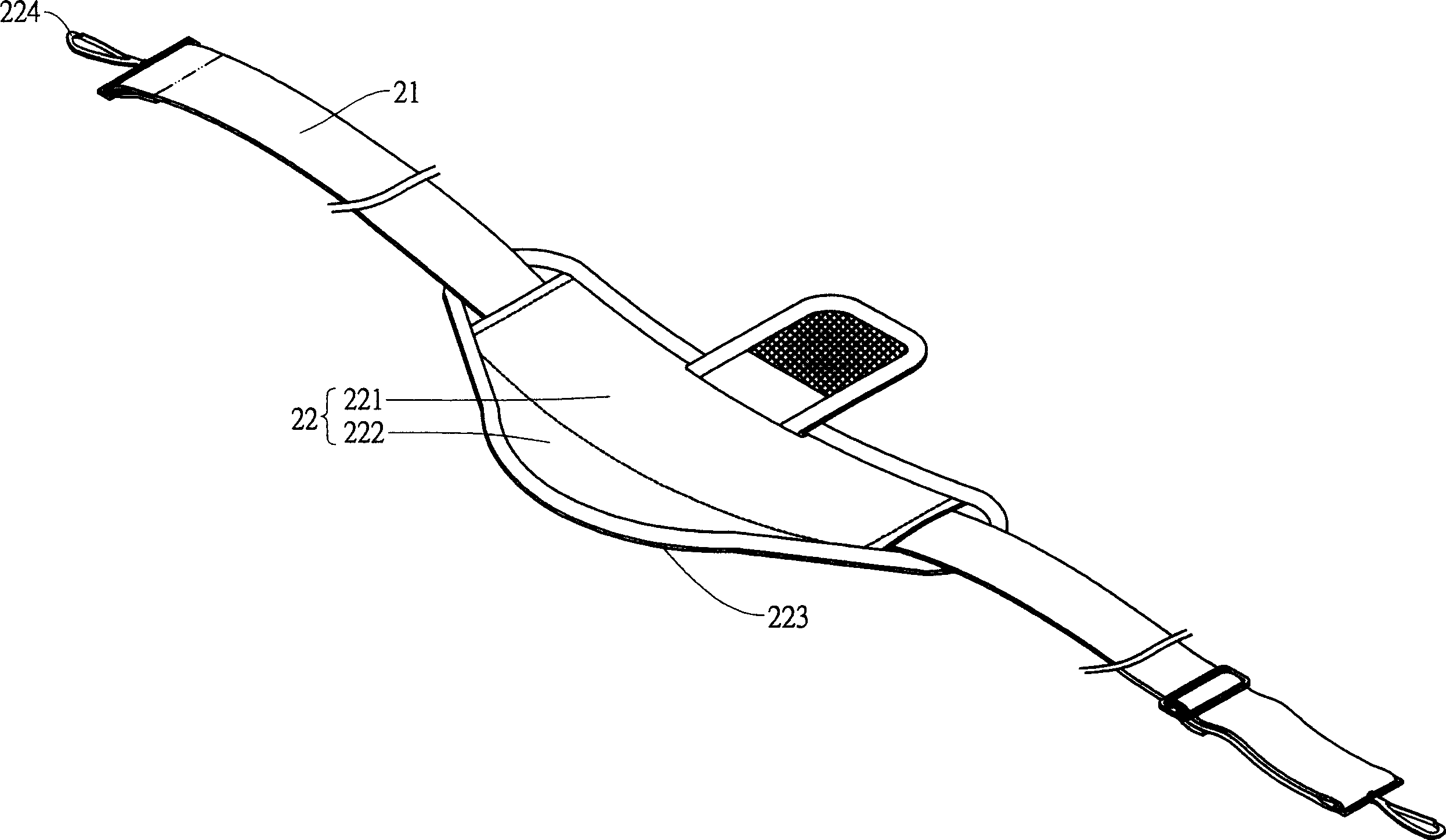

Straps

InactiveCN1891103AIncrease the force contact areaIncrease frictionTravelling sacksOther accessoriesFlange

The present invention relates to a kind of shoulder strap. It includes a slip-stopping unit, said slip-stopping unit contains a receiving portion and a flange portion, on said receiving portion of said slip-stopping unit a bearing unit is cover-connected. When it is used by user, the flange portion of said slip-stopping unit can be used for increasing bearing area so as to produce the effect of stopping slip.

Owner:康群国际有限公司

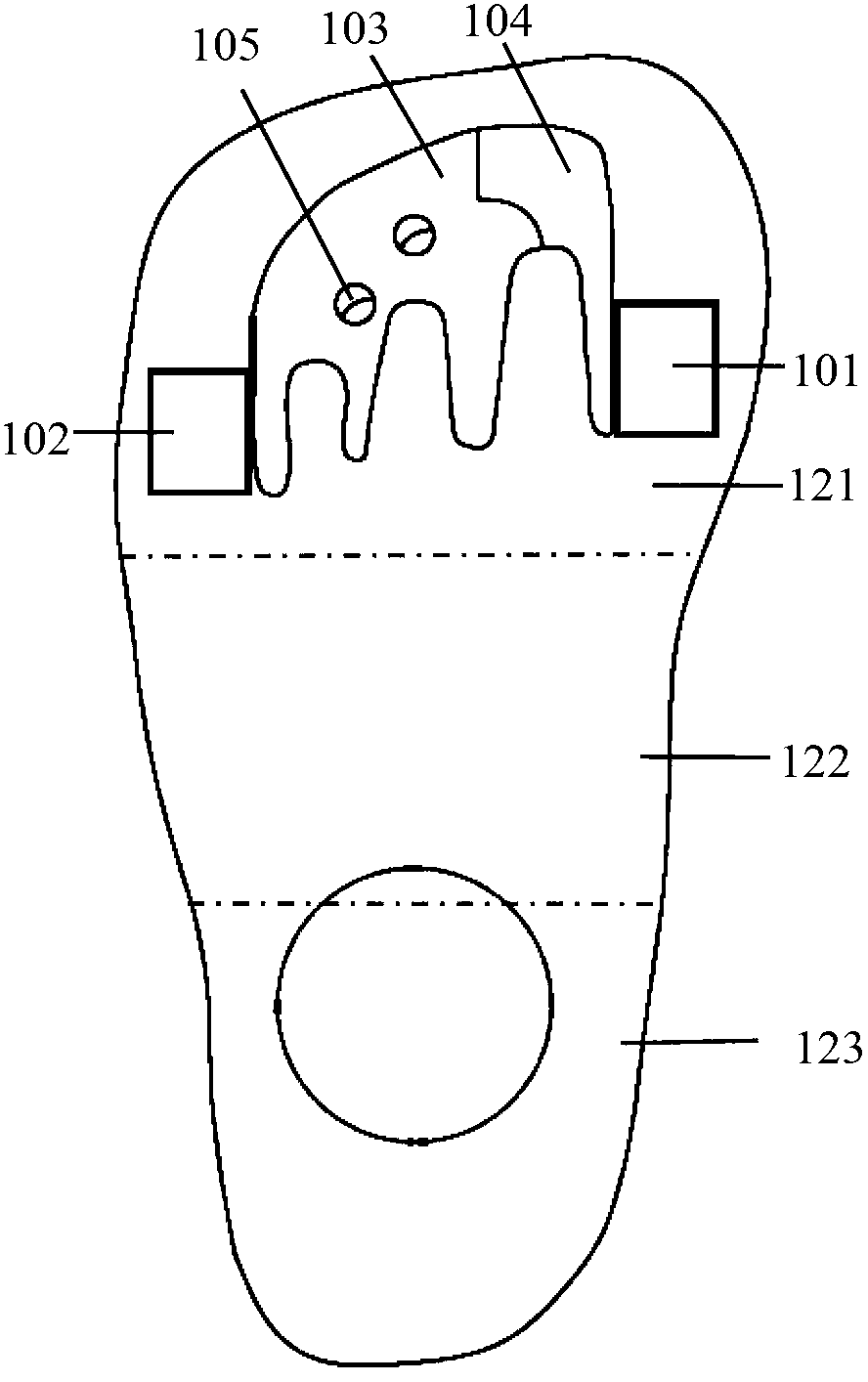

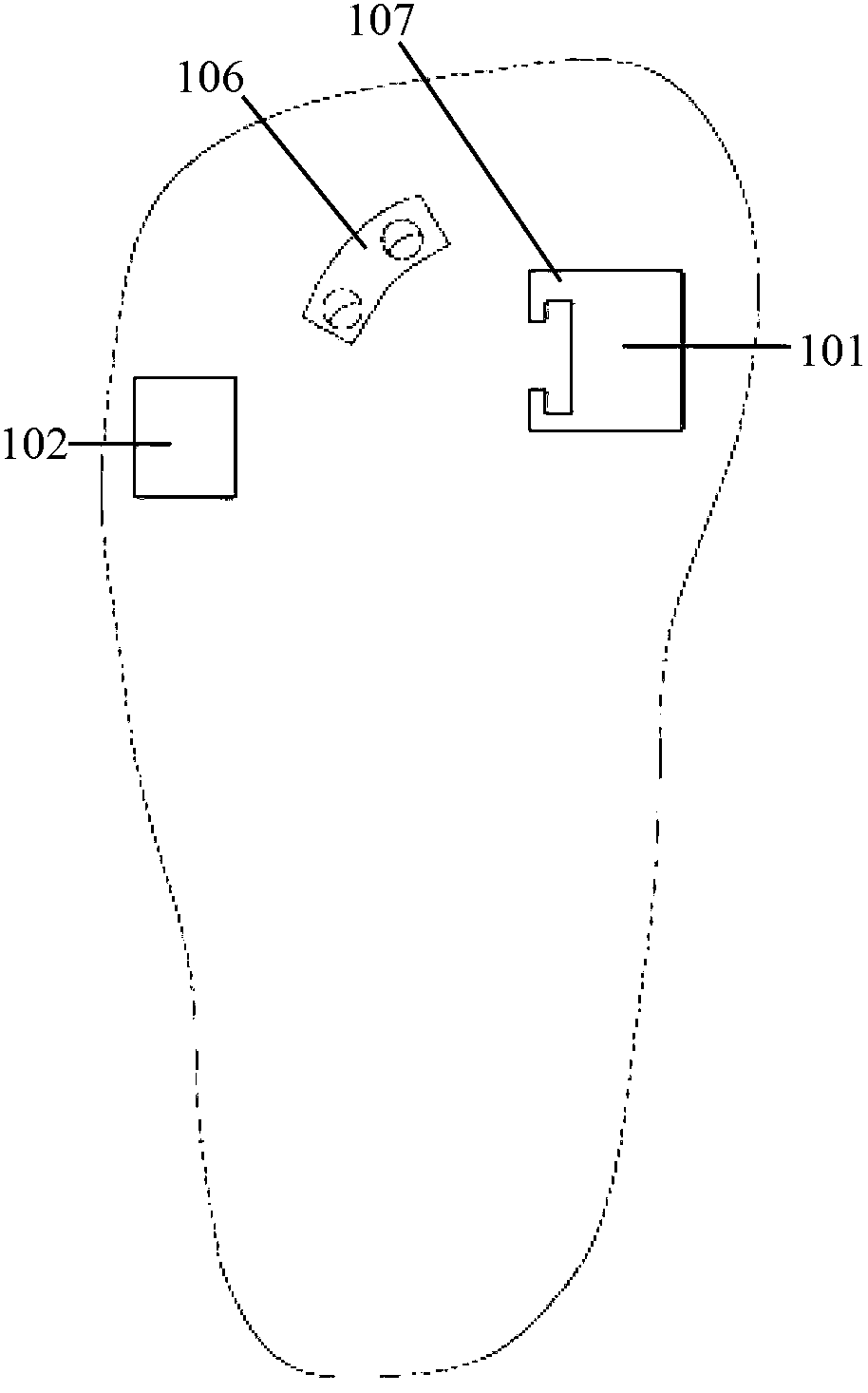

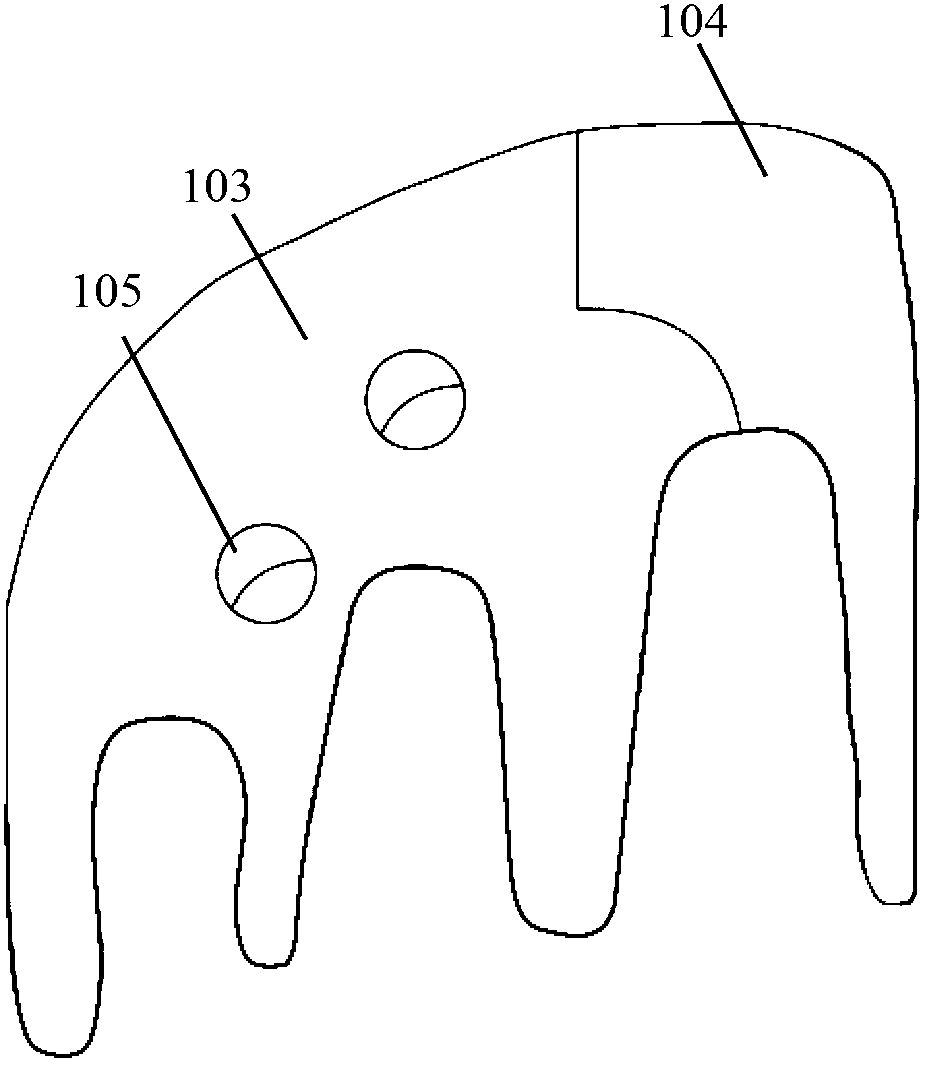

Healthcare shoes and use method of healthcare shoes

InactiveCN103005779APrevent eversionIncrease the force contact areaSolesUpperBody balanceEngineering

The invention provides a pair of healthcare shoes and a use method of the healthcare shoes. Grooves corresponding to big toe and little toe and a toe sleeve accommodating three central toes are arranged on each sole, wherein the toe sleeve is provided with partitions for separating the toes; by respectively positioning the little toe, the big toe and the three central toes, the contact areas of the forefoot is forced to be increased, so that supporting force and friction of the forefeet are improved, the leg force is increased, and a large role for improving leg frictions and body balance is played.

Owner:陶美土

Convenient-to-use high-stability jack

The invention discloses an easy-to-use high-stability jack, which includes a jack body, a deck is arranged at the bottom of the jack body, the deck is arranged in an inclined flat plate structure, and a bottom is arranged under the deck The bottom bracket includes a fitting panel below and a fixed support arranged on the top of the fitting panel. The top of the fixed support is also arranged on an inclined slope, and an inclined surface is also provided on the inclined surface of the fixed support. The insertion groove, the inlet end of the insertion groove is arranged on the top side of the inclined slope, and a supporting plate is arranged on the top of the jack body. The invention has the advantages of simple structure and convenient use, which can increase the force-bearing contact area with the automobile and the bottom surface, and increase the stability.

Owner:SUZHOU YOUNUOTE ELEVATORING MACHINERY CO LTD

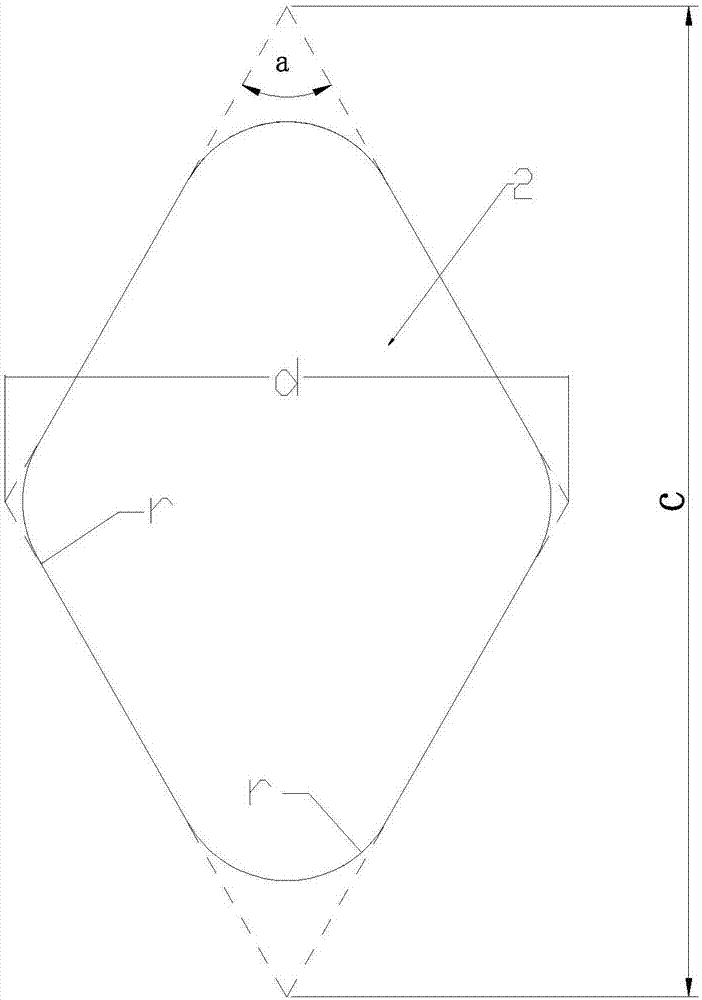

Cycloidal transmission mechanism of speed reducer based on rolling cone pieces

ActiveCN107165986AIncrease contact areaIncrease the force contact areaToothed gearingsPhotovoltaic energy generationDiagonalEngineering

The invention discloses a cycloidal transmission mechanism of a speed reducer based on rolling cone pieces. The mechanism comprises a cycloidal disc, transmission pieces and an output disc; the transmission pieces are the rolling cone pieces; each rolling cone piece is a rotating body obtaining by performing the round angle guidance on four corners of a rhombus or a quadrangle according to a radius r and rotating by one lap along a longitudinal diagonal line; rolling cone piece fixed holes are uniformly distributed in the periphery of one side disc surface of the output disc; the number of the rolling cone pieces is consistent with the number of the rolling cone piece fixed holes; the profile shapes and sizes of one ends of the longitudinal diagonal directions of the rolling cone piece fixed holes and the rolling cone pieces are matched; a cycloidal trajectory groove is formed in the disc surface, corresponding to one side of the output disc, of the cycloidal disc; one sides, in the long-axis direction, of the rolling cone pieces are fixedly embedded in the rolling cone piece fixed holes; and the other sides, in the long-axis direction, of the rolling cone pieces are slidingly and movably connected with the cycloidal trajectory groove of the cycloidal disc. The mechanism has the advantages of high transmission power and low wear of the cycloidal groove.

Owner:HSOAR GRP

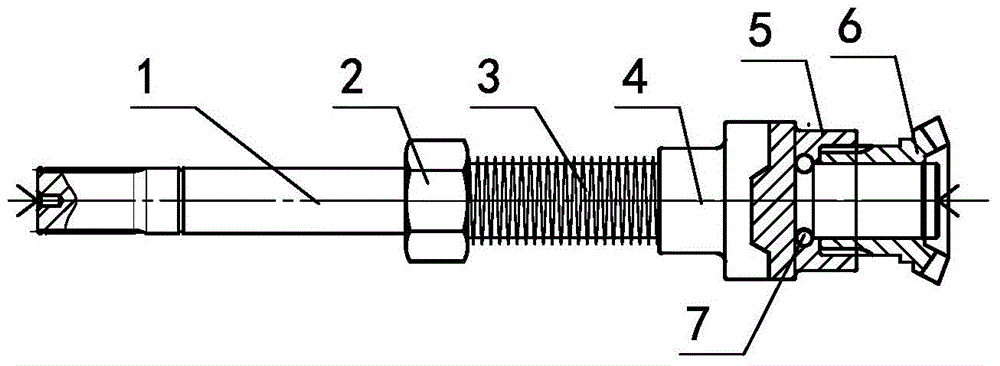

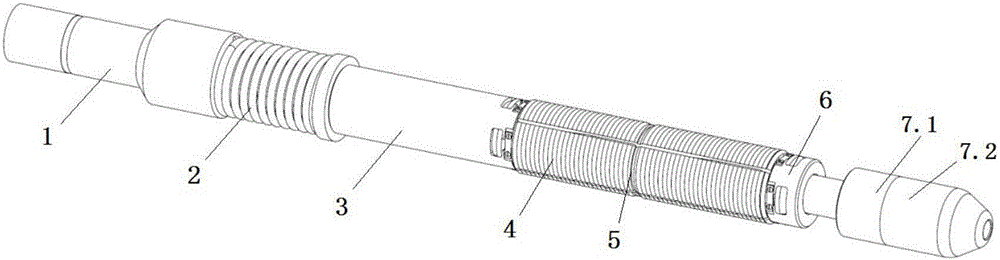

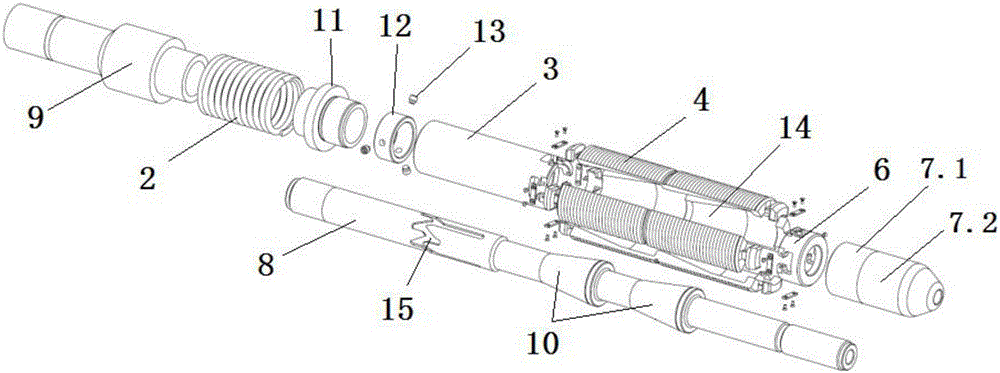

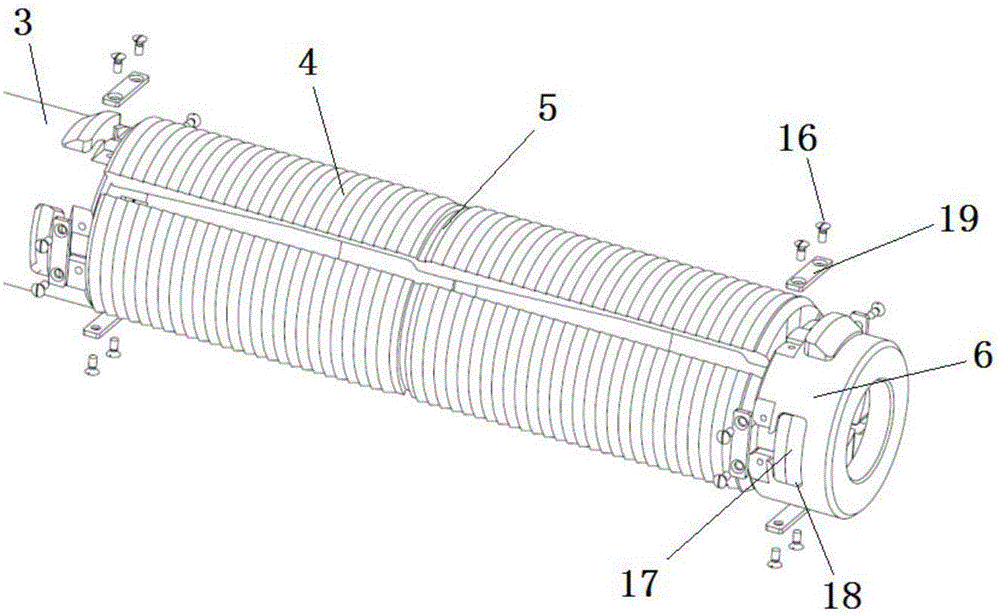

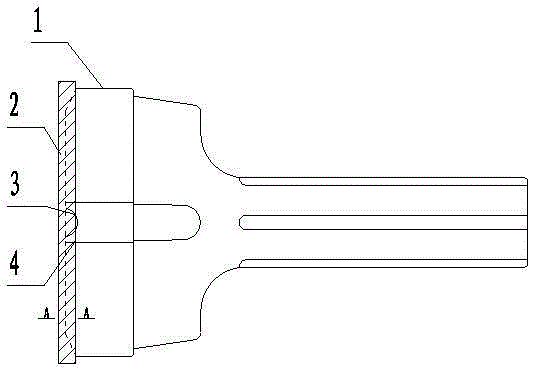

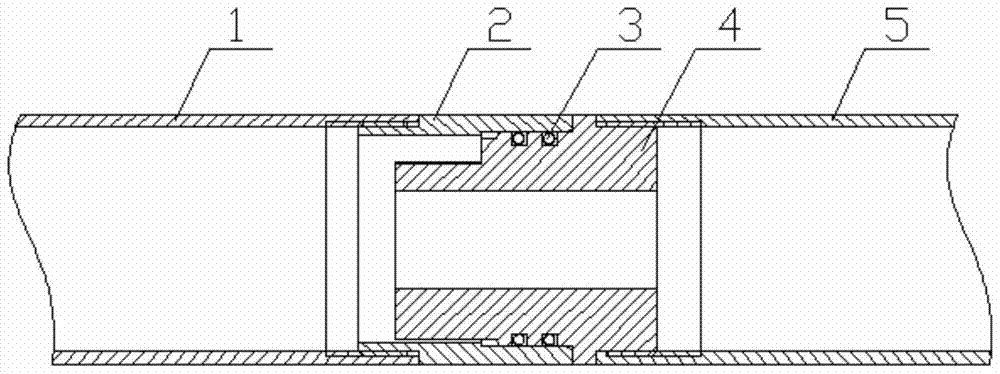

Quick connect joint for drill pipe

InactiveCN105298408BImprove sealingGuaranteed tightnessDrilling rodsDrilling casingsOuter CannulaGeological exploration

The invention relates to a quick connection joint of a drill pipe, which is composed of an outer casing, an O-ring and an inner casing, and the inner and outer casings are sealed by an O-ring; The outer casing thread and flat groove are provided on the pipe wall, the inner casing thread, the inner casing sealing groove and the inner casing stopper with an axial stopper at the lower end are provided on the inner casing, and the inner casing thread and the outer casing thread are respectively used for Connecting the upper and lower drill pipes; the order in which the joint of the present invention is connected to the drill pipes is the lower drill pipe, the outer casing, the inner casing and the upper drill pipe. When the inner and outer casings are connected, the side contact of the inner and outer casing stoppers is formed to bear the transmission torque; the axial stopper is in contact with the end face of the outer casing stopper, so that the inner and outer casings cannot be axially pulled apart, and is used to withstand the lifting of the drill when the axial tension. The joint of the invention has the advantages of compact structure, good sealing performance, long service life, convenient and fast installation and disassembly, and is especially suitable for use on small-sized and portable geological exploration sampling drilling rigs.

Owner:武汉众恒六合工业技术有限公司

Rescue device for marshland

ActiveCN112642072AStable supportImprove work efficiencyBreathing protectionStructural engineeringRescue agent

The invention relates to the technical field of rescue devices, in particular to a rescue device for marshland. The rescue device comprises a first mounting plate, a partition plate, a supporting plate, a gas cushion main body and a second mounting plate, wherein the partition plate is fixedly mounted between the first mounting plate and the second mounting plate; the left end surface of the first mounting plate and the left end surface of the second mounting plate are fixedly equipped with supporting plates; the gas cushion main body positioned at the right side of the partition plate is fixedly mounted between the first mounting plate and the second mounting plate; and a rotary rod is fixedly mounted between the two supporting plates. The rescue device for marshland disclosed by the invention is simple in structure, is convenient in use, greatly improves rescue efficiency, avoids the risk that a rescuer is mired down in mud, does not cause harm to the rescuer, saves time and labor, and saves resources.

Owner:杨梦琳

Detection method for constructional engineering

InactiveCN113882439AImprove stabilityUniform pressureFoundation testingEngineeringStructural engineering

The invention discloses a detection method for constructional engineering. A storage box is included, a standby electric box is fixedly connected to the middle position of the top of the outer wall of one side of the storage box, a detection device is arranged at the bottom of an inner cavity of the storage box, and an ascending and descending frame is fixedly connected to the two sides of the top of the detection device, a driving piece is arranged in the middle of the top of the ascending and descending frame, and a fastening frame is fixedly connected to two sides of the top of the driving piece. The detection method for constructional engineering belongs to the technical field of constructional engineering. Through the standby electric box, the device is more convenient and safer to use, the stability of an abutting box can be improved through the connecting plate, the contact position of the device cannot deviate due to shaking, during detection by a detection mechanism, a foundation pile is fixed at first through a fixing mechanism, and the device is effectively enabled to be in contact with the foundation pile and receive uniform and consistent pressure during detection, so that the detection accuracy of the device is improved, the detection effect of the device is improved, and the contingency of the device during detection is avoided.

Owner:陈令文

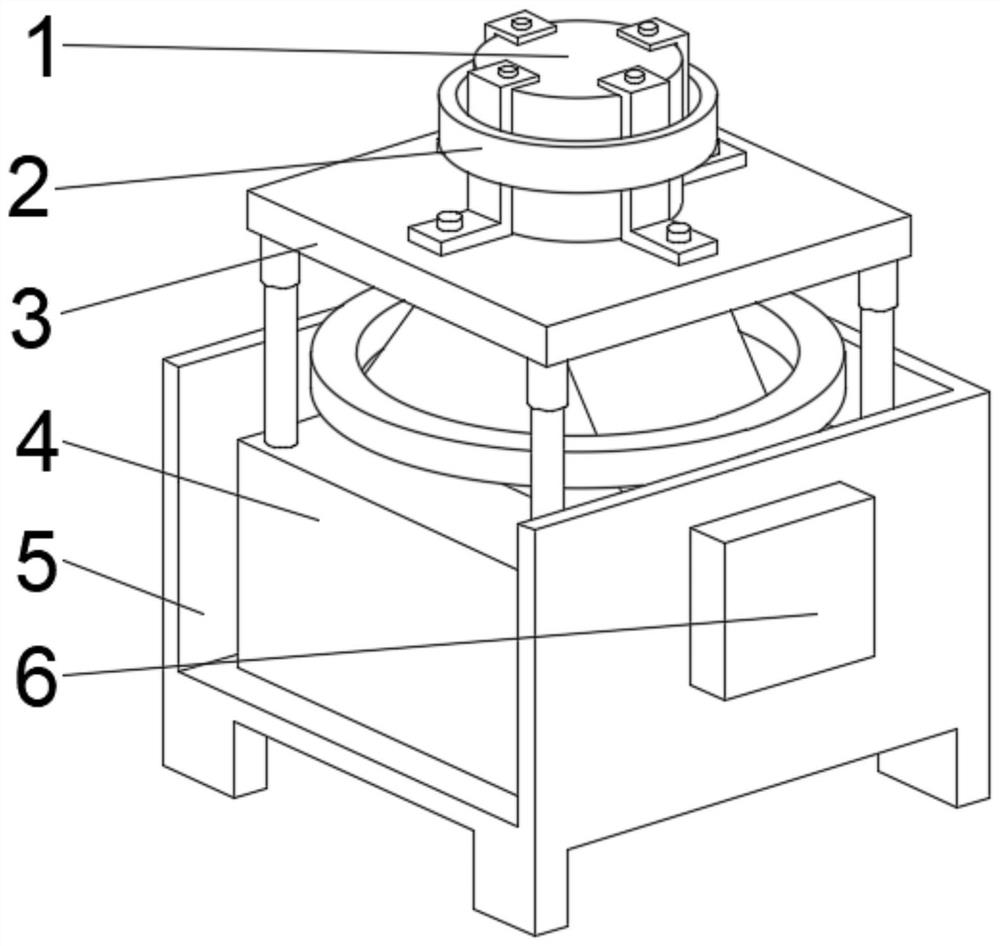

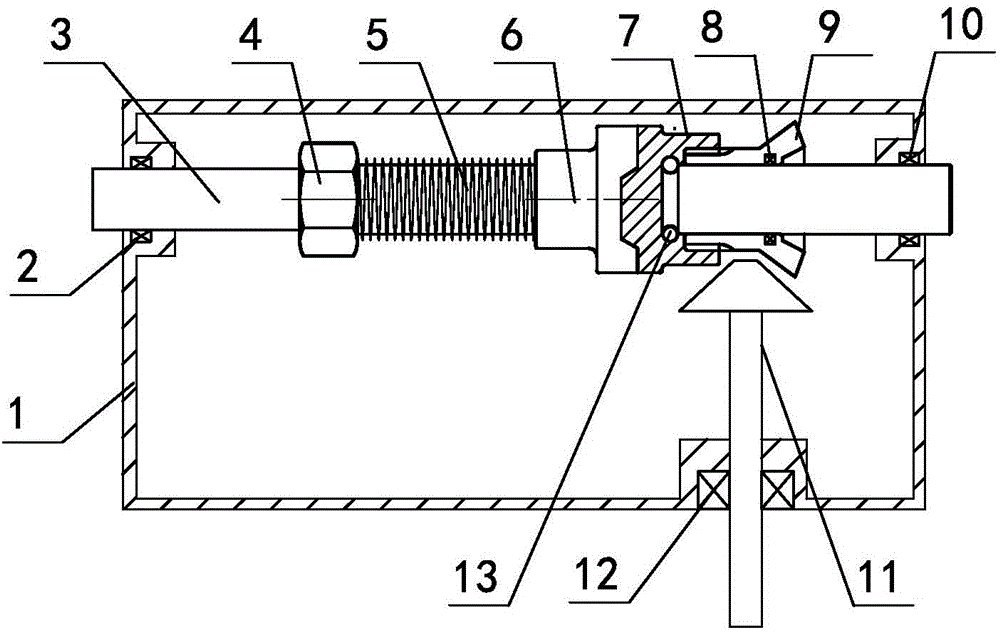

Overload protection diverter used for power transmission of harvester

InactiveCN105333081ASimple structureIncrease the force contact areaHarvestersGearingClutchElectric power transmission

The invention relates to an overload protection diverter used for power transmission of a harvester and belongs to the technical field of converters. The overload protection diverter comprises a box body. A shaft is transversely installed in the box body. The shaft is provided with a conical tooth through a third bearing. A bevel gear shaft engaged with the conical tooth is longitudinally installed in the box body. The part, on the left side of the conical tooth, of the shaft is sleeved with a nut in threaded connection, and a first clutch used for power transmission of the shaft is installed on the part, on the right side of the nut, of the shaft. The part, between the first clutch and the nut, of the shaft is sleeved with a spring. The left end of the spring abuts against the nut, and the right end of the spring abuts against the first clutch. The part, on the right side of the first clutch, of the shaft is provided with a second clutch which can rotate freely around the shaft. The second clutch is connected with the first clutch through a clutch jaw in a matched manner. The second clutch and the shaft are transversely positioned through internally-contained balls. The left end of the conical tooth is connected to the second clutch through a spline. The overload protection diverter is simple in structure, the stress contact area is large, transmission is more stable, and overload protection is achieved.

Owner:CHONGQING HANYUAN MACHINERY

Limiting shock attenuation device connecting forklift truck cab with frame

ActiveCN103661644AImprove assembly efficiencyPlay a shock absorbing roleLoading-carrying vehicle superstructuresUltrasound attenuationVehicle frame

The invention provides a limiting shock attenuation device connecting a forklift truck cab with a frame. The limiting shock attenuation device connecting the forklift truck cab with the frame comprises a base. A shock attenuation block is arranged in the base, and a fastener is buried into the shock attenuation block. The upper end of the fastener penetrates out of a limiting block on the top end face of the shock attenuation block and is fixedly connected with the limiting block. According to the integrated structure integrating the shock attenuation block and a fastener connection bolt, the assembling efficiency is improved; a damping gasket and the bottom end of the connection bolt are connected and buried into the shock attenuation block, and the shock attenuation effect is improved; due to the fact that folded edges of the two ends of a limiting board are matched with flangings of a box body of the base, the oscillation range of the cab is limited, and therefore driving safety and driving stability are improved.

Owner:ANHUI HELI CO LTD

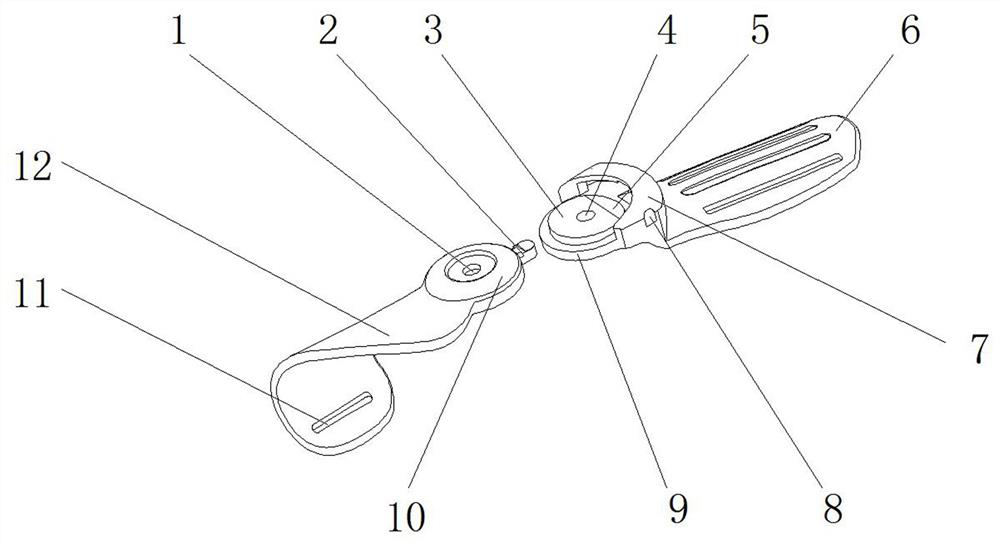

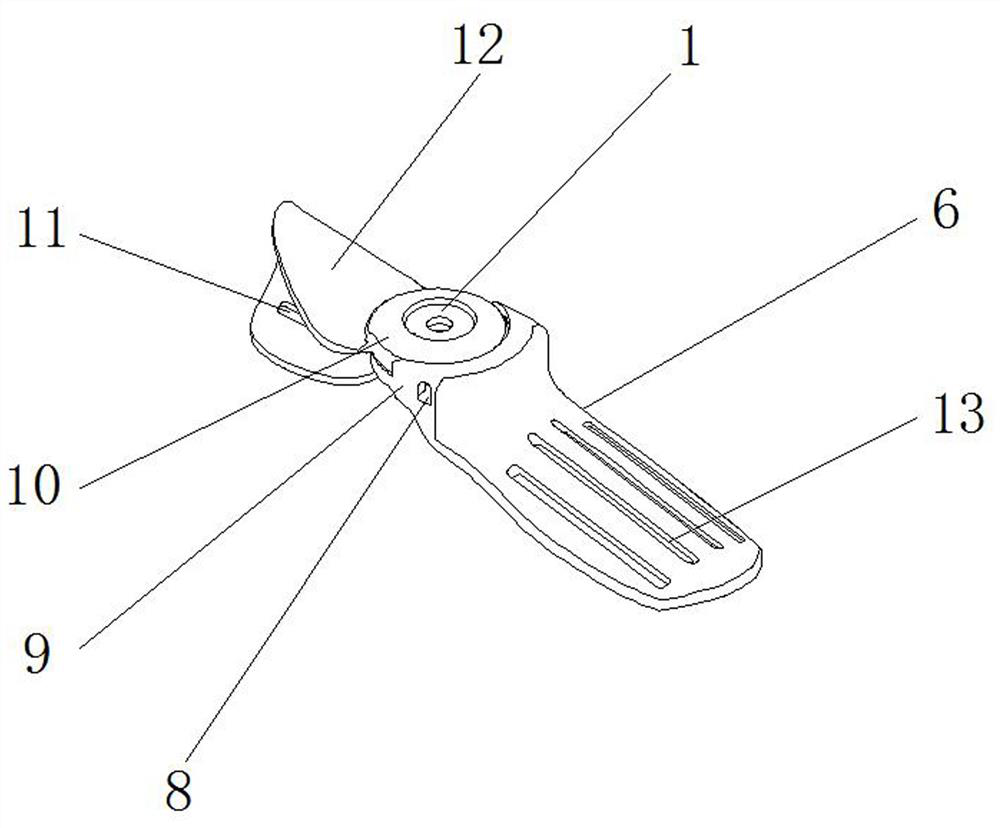

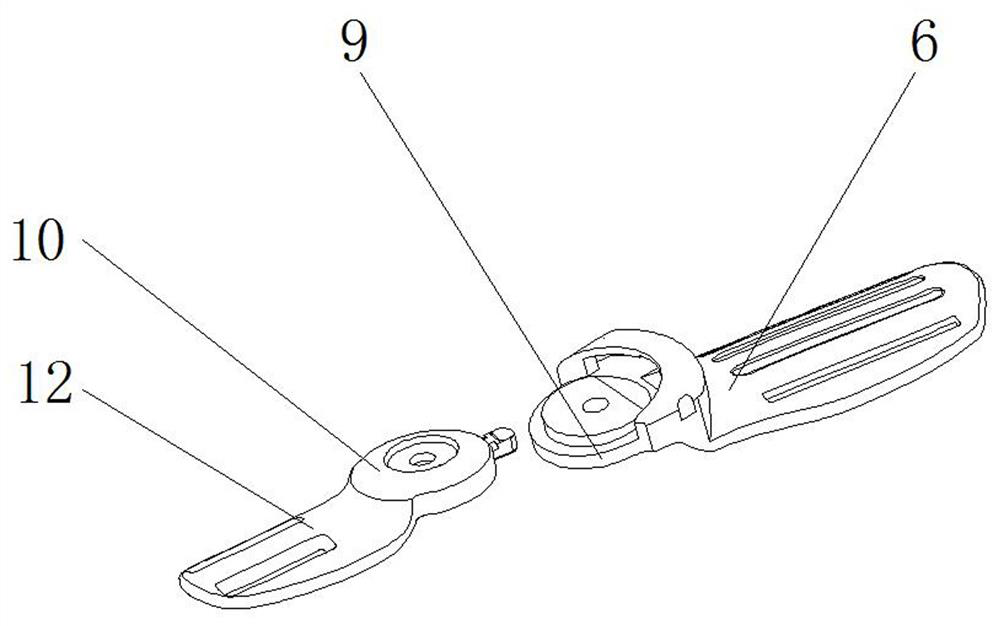

Hallux valgus correction regulator capable of being freely bent and adjusted for use

PendingCN114272003AStrong feeling of incompatibilityImprove the correction effectMedical scienceHuman bodyEngineering

The hallux valgus correction adjuster comprises a metatarsal bone fixing piece and a thumb fixing piece hinged to the metatarsal bone fixing piece, and the thumb fixing piece and the metatarsal bone fixing piece are provided with a first wearing hole and a second wearing hole respectively, and the first wearing hole and the second wearing hole are used for being worn by the thumb and the metatarsal bone of the human body. The metatarsal bone fixing piece is provided with a hinge seat used for installing the thumb fixing piece, and the thumb fixing piece is provided with a hinge head used for being connected with the hinge seat. The device is easy to wear and use, when the thumb fixing piece is spiral, the spiral thumb fixing piece can directly sleeve and wrap the thumb part for positioning, the installation part needing to be worn and used can be determined and fixed through the thumb of the human body, and therefore a user can conveniently, rapidly and accurately wear and use the device when frequently using the device; and the spiral thumb fixing sheet can generate more uniform traction correction force, so that a better correction use effect is achieved.

Owner:马庆利 +1

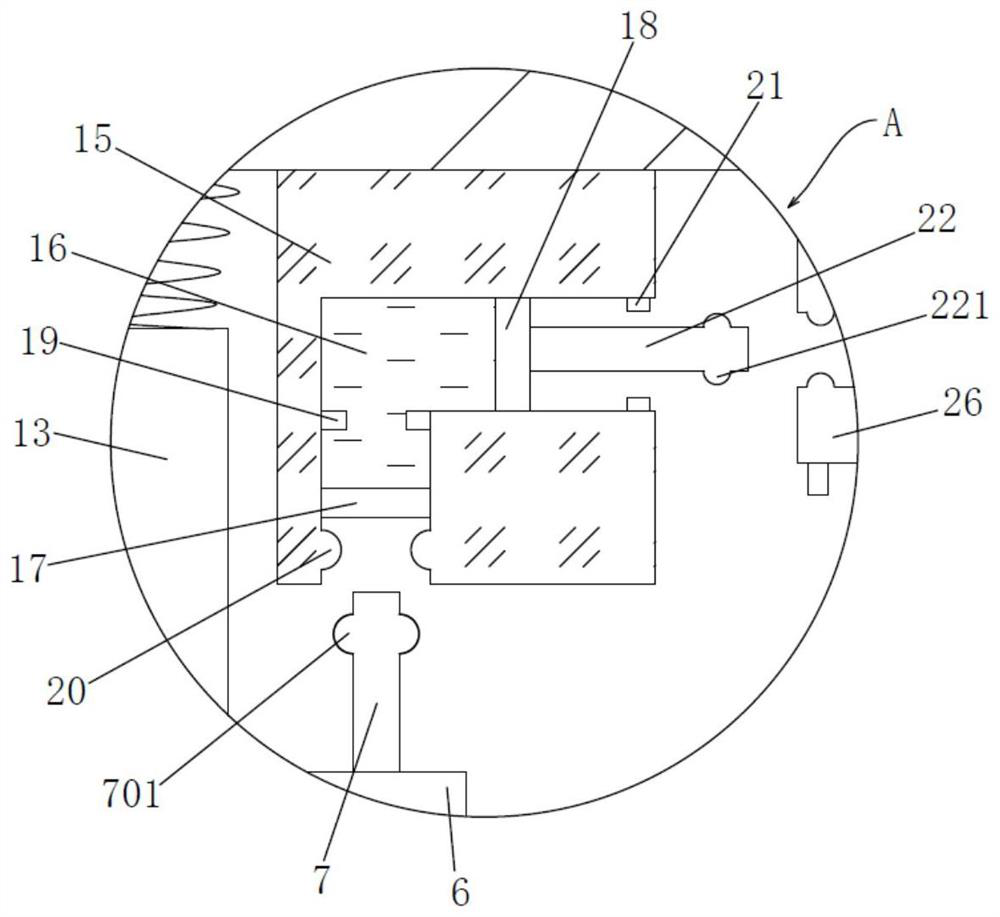

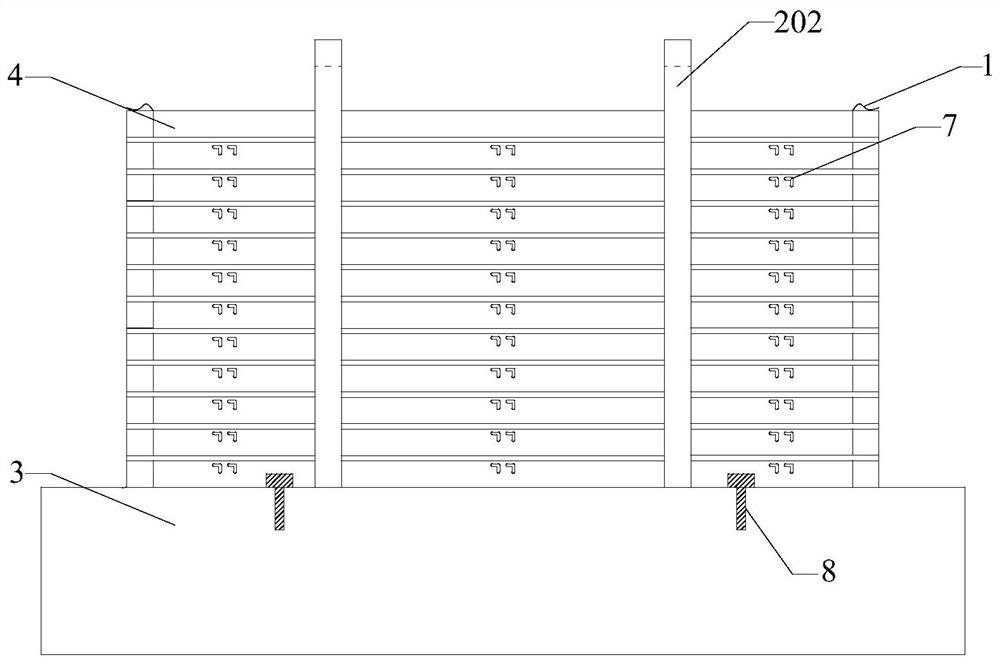

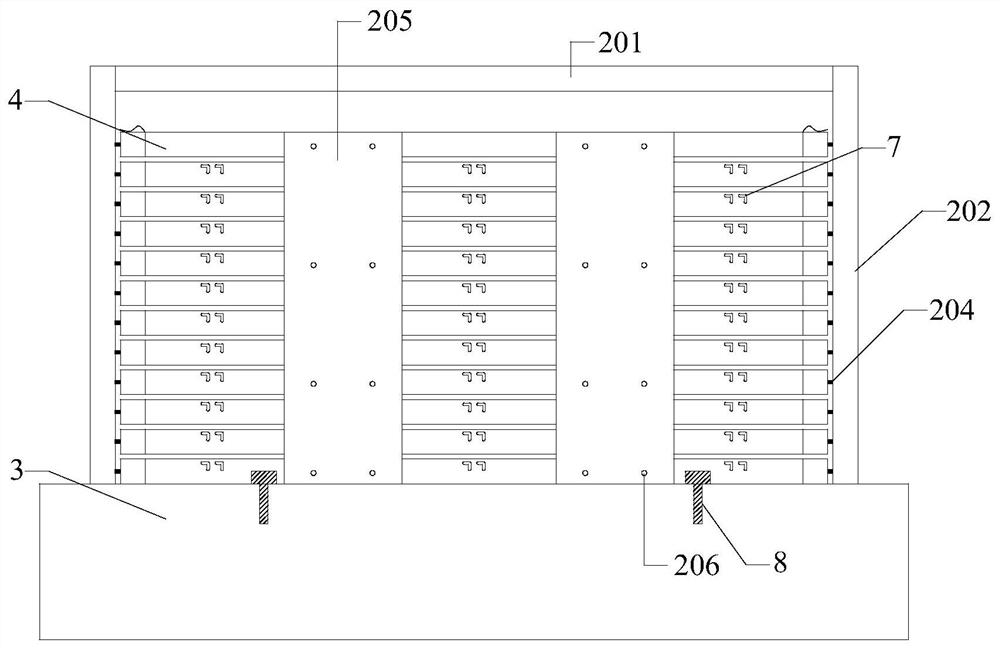

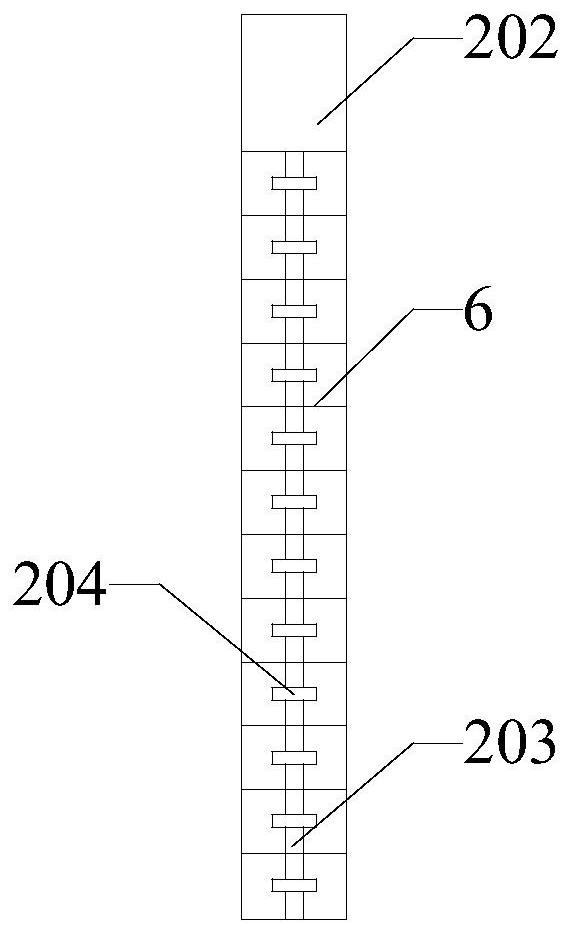

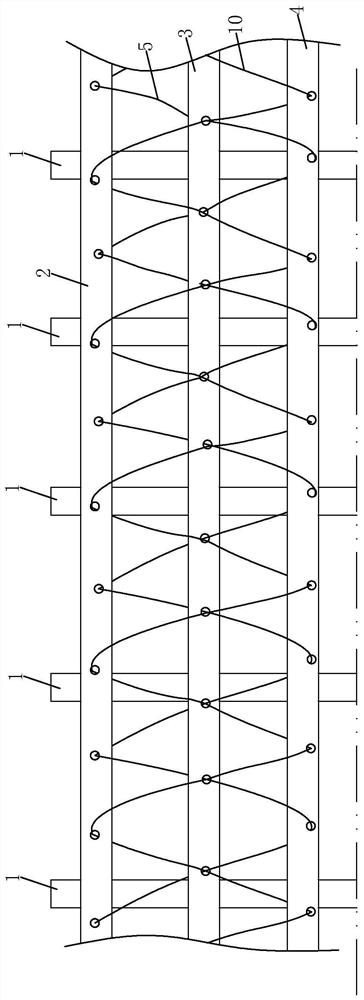

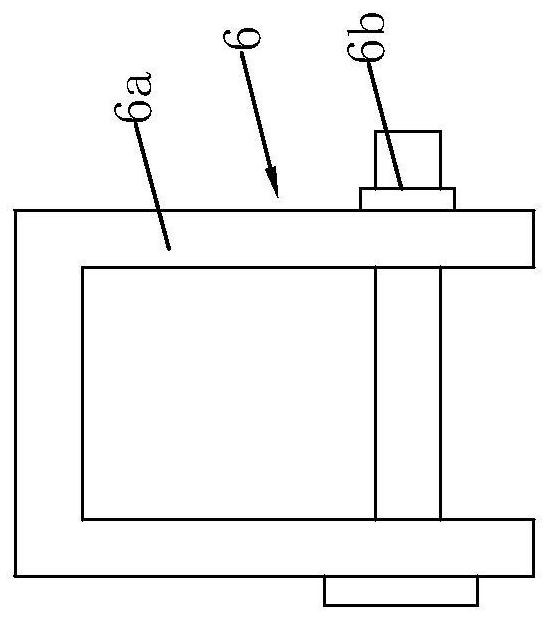

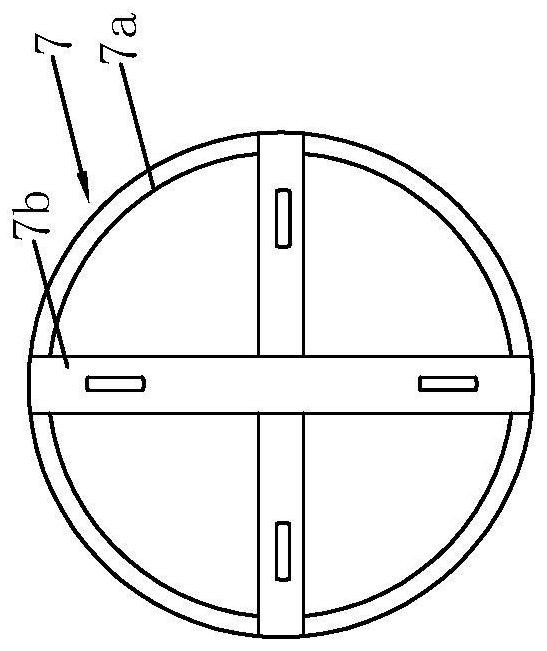

A two-way layered shear model box device and its application method

ActiveCN111024348BMeet the needs of vibration inputLight weightVibration testingVertical vibrationRolling-element bearing

The invention discloses a two-way layered shear model box device and its use method. The device includes a U-shaped layer frame, a rolling body system, a limit device and an inner liner bag. The U-shaped layer frames are vertically and equidistantly arranged in parallel. Through the interlayer rolling body system connection, the limit device is used to limit the plane torsion and vertical vibration deformation of the U-shaped frame, and the bottom frame is fixed on the vibration table. The use method includes a. assembling the rolling body system; b. assembling the model box body and fixing it on the vibrating table; c. assembling the limit device; d. laying a liner bag inside the box body and adding soil in the box body And embed the model structure; e. Vibrate in one direction; f. When the direction of vibration changes, switch the rolling bearing platform from along the direction of vibration to the direction perpendicular to the vibration, and continue the vibration test in the other direction. The invention can vibrate in two directions, has small self-weight, adjustable rigidity, simple operation, wear-resisting and durable, firm structure, and can repeat one-dimensional or two-dimensional shaking table tests.

Owner:JIANGSU UNIV OF SCI & TECH

A Rectangular Air Duct Steel Wire Rope Anti-seismic Support System

ActiveCN111853363BIncrease the force contact areaStable supportPipe supportsPipe elementsMechanicsWire rope

The invention discloses a rectangular air duct steel wire rope anti-seismic support system, which comprises a lower support on which a rectangular air duct is placed, and L-shaped limiting plates are arranged on both sides of the rectangular air duct; A rubber push plate is arranged below, and a damping spring is connected between the rubber push plate and the upper bracket; the upper bracket is symmetrically provided with fixed blocks on both sides of the rubber push plate, and an L-shaped fixed block is arranged in the fixed block. Piston cavity, the side of the second piston plate away from the L-shaped piston cavity is fixedly provided with a second clamping rod; the outer side of the connector is fixedly provided with a ring plate, and the ring plate is provided with a plurality of threaded holes ; The upper bracket is symmetrically threaded with steel wire ropes. The invention provides a rectangular air duct steel wire rope anti-seismic support system with more stable support, which can uniformly limit the allowable shaking range and elastic extrusion state of the rectangular air duct, so multiple anti-seismic supports can evenly disperse the force during an earthquake, which is very It is worth promoting.

Owner:HEFEI YUANKANG ENVIRONMENT SCI & TECH

A swamp rescue device

ActiveCN112642072BStable supportImprove work efficiencyBreathing protectionEngineeringStructural engineering

The invention relates to the technical field of rescue devices, in particular to a swamp rescue device, comprising a first mounting plate, a partition plate, a support plate, an air cushion body and a second mounting plate. A partition plate is fixedly installed in the middle, and a support plate is fixedly installed on the left end faces of the first installation plate and the second installation plate, and an air cushion body is fixedly installed between the first installation plate and the second installation plate. The main body is located on the right side of the partition plate. , a rotating rod is fixedly installed between the two support plates. The invention provides a swamp rescue device, which has a simple structure and is easy to use, greatly improves the rescue efficiency, avoids the risk of the rescuer falling into the quagmire, and does not cause harm to the rescuer, saves time and effort, and saves resources.

Owner:杨梦琳

Anti-collision device for highway vehicles

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Drill bit for penetrating reinforced concrete high wind pressure down-the-hole drilling impactor

Provided is a drill bit used for a high air-pressure down-the-hole drill hammer with the capability of penetrating reinforced concrete. The drill bit comprises a drill bit body, air exhaust holes and slag removing holes. The key point of the structure is characterized in that elongated tooth heads are inlaid on a panel of a head of the drill bit body. The drill bit used for the high air-pressure down-the-hole drill hammer with the capability of penetrating reinforced concrete has following advantages: by changing the distribution of the tooth heads of the drill bit body, the point distribution structure of the tooth heads is changed to be elongated distribution structure for alloy tooth heads; tooth roots are used to be small-diameter blind holes and are changed to be elongated tooth grooves; elongated alloy tooth heads are embedded into the drill bit body so that heat treatment technology becomes easy; welding-on reliability is greatly improved; due to the elongated structure of the alloy tooth heads of the drill bit body, the contact area for acting force is increased; force is applied by lines instead of points; and under effect of high frequency impact, panels of the alloy tooth heads of the drill bit body can operate in the knife-cutting mode in order to generate plastic deformation by force. The drill bit used for the high air-pressure down-the-hole drill hammer with the capability of penetrating reinforced concrete has following beneficial effects: the speed for penetrating reinforced steel bar is 20 times as high as original speed; and the drill bit has 10 or 20-fold service lifetime as compared with an ordinary drill bit.

Owner:SINOHYDRO BUREAU 16 CO LTD

Cable Support Mesh for Long-Span Mesh Ceiling Systems

ActiveCN104763088BAvoid direct forceThe force structure system is clearCeilingsSupporting systemEngineering

Aiming at the problems of the open daylighting roof in the existing public buildings, the exposure of its roof truss and supporting system affects the aesthetic effect of the large space, and the added decorative ceiling is limited by the force of the roof truss supported by the suspenders, a method for large space is disclosed. The steel cable support network of the span mesh ceiling system includes several steel cables and several length-adjustable mechanisms. The steel cables are woven into a net shape, and the ends of the steel cables are arranged between the structural ring beams through the length-adjustable mechanisms. The steel cable support net transfers the gravity of the mesh suspended ceiling to the structural ring beam, replacing the form of transferring the gravity of the mesh suspended ceiling to the roof truss structure in the prior art by using the ceiling and the transfer layer, so as to ensure that the roof truss is not stressed. The steel cables are provided with a number of card connectors for suspending the mesh ceiling, and the weaving direction of the steel cables corresponds to the shape of the mesh ceiling, so that the steel cable support net can be hidden above the mesh ceiling, solving the problem of It solves the problem that the boom cannot be hidden in the traditional scheme.

Owner:SHANGHAI BUILDING DECORATION ENG GRP

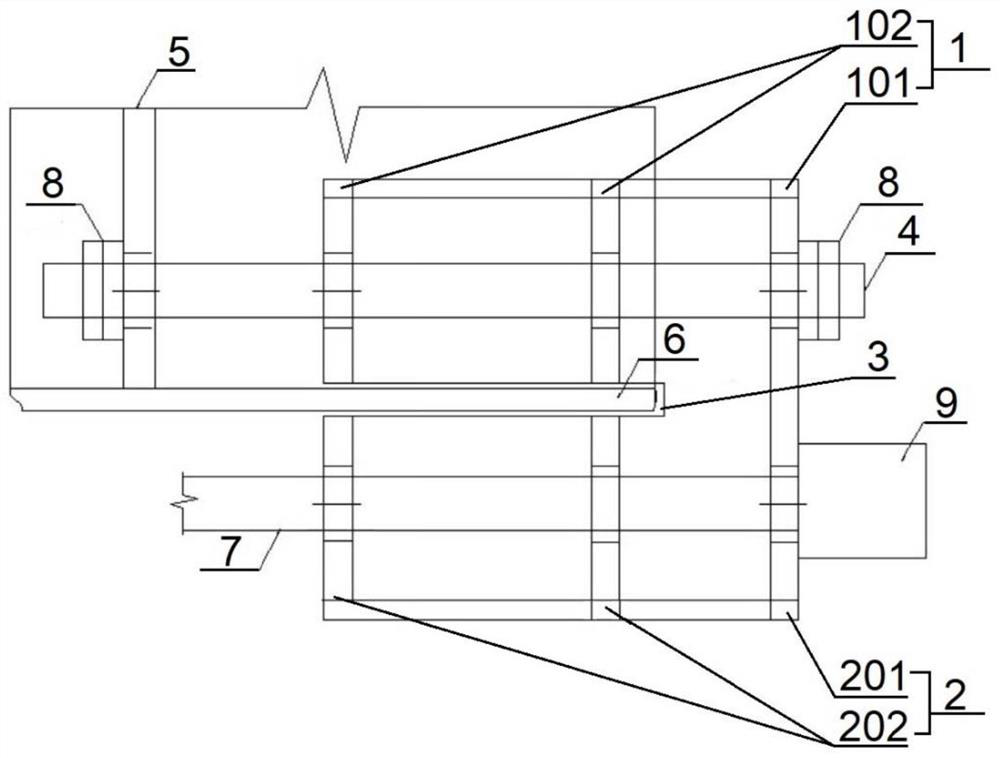

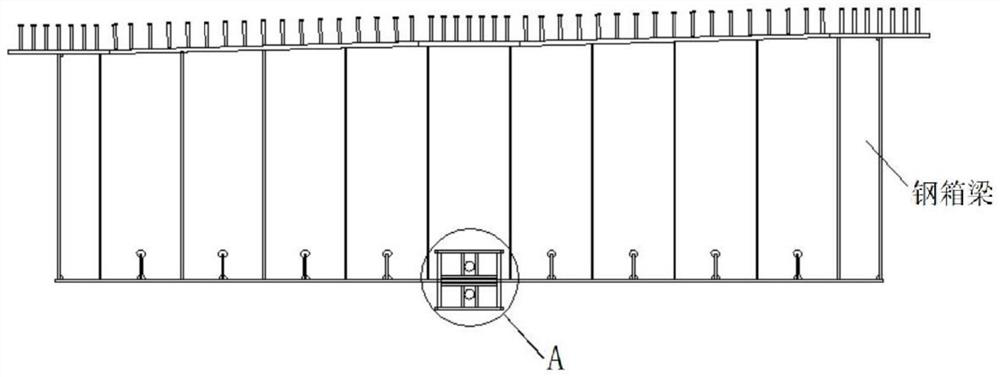

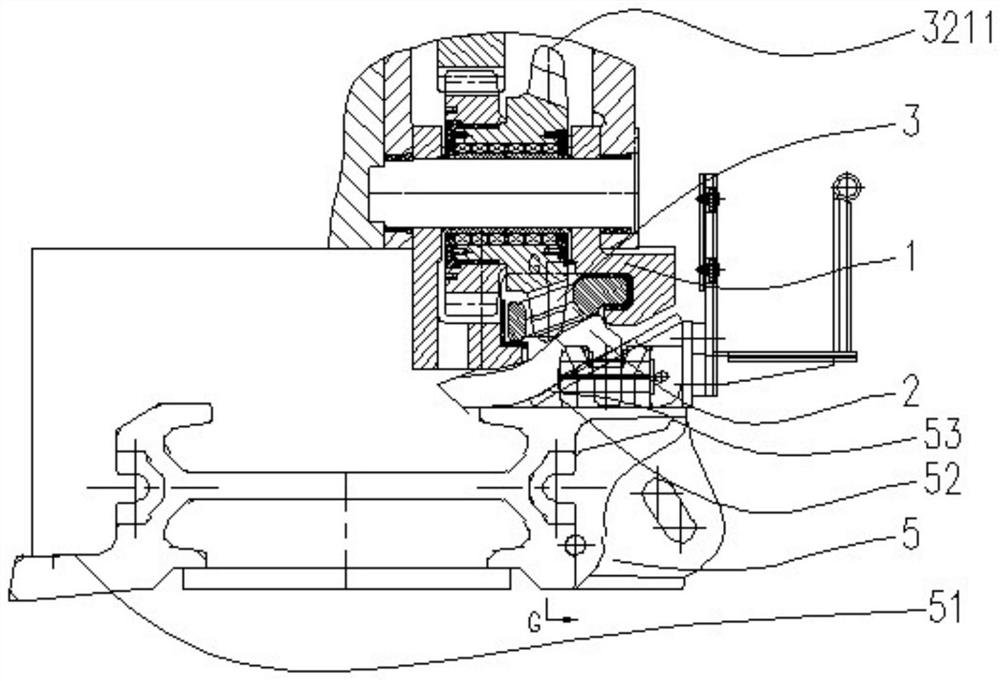

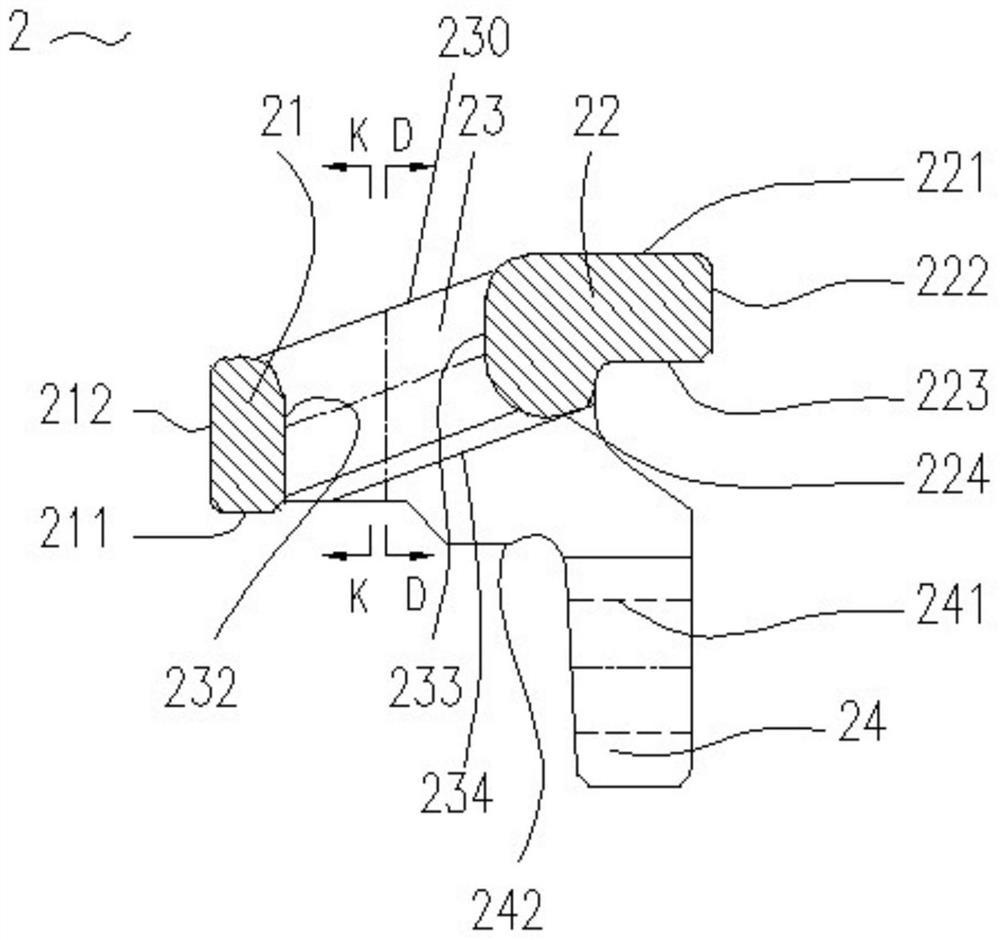

Suspension type anchor puller and its application construction method

ActiveCN111472286BIncrease the force contact areaAvoid deformationBridge erection/assemblyBridge materialsClassical mechanicsEngineering

The application of the invention discloses a suspension type anchor puller and its application and construction method. The suspension type anchor puller includes a first fixing part, which is detachably connected with the transverse diaphragm of the steel box girder through a pull rod, including the first fixing plate; a second fixing part, connected with the steel strand used for pushing construction, including The second fixing plate; the fixing groove, which is arranged between the first fixing piece and the second fixing piece, is used to fix the bottom plate of the steel box girder; the first fixing plate and the steel box girder The partition plate is correspondingly provided with a first structural hole, and the tie rod passes through the first structural hole and penetrates through the transverse partition connecting the first fixed plate and the steel box girder; the second fixed plate is provided with a The second structural hole. The application of the present invention solves the technical problem that the bottom plate is easily deformed due to direct contact with the hoisting equipment during the hoisting process, which leads to the need for time-consuming correction work in the later stage, which increases the overall construction difficulty and lengthens the construction period.

Owner:ROAD & BRIDGE INT +1

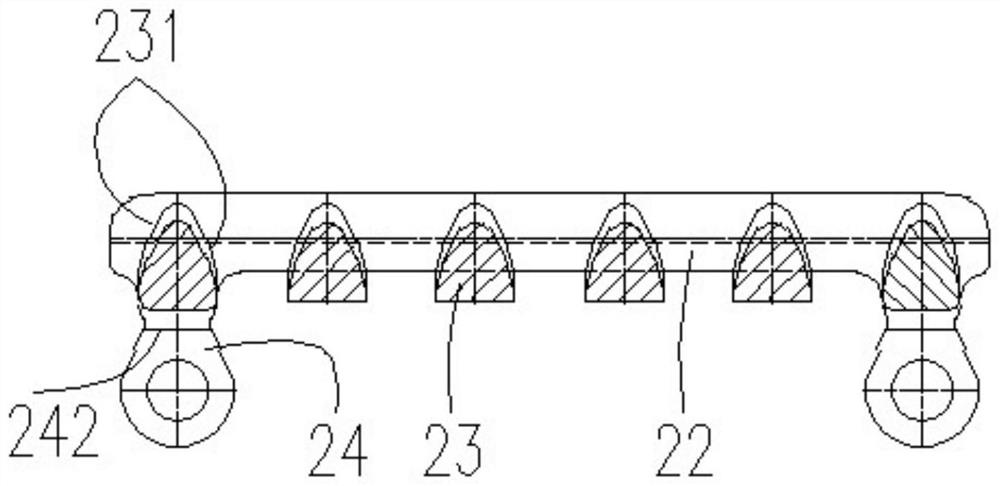

Mining machine walking meshing system with material releasing structure

The invention relates to a mining machine walking meshing system with a material releasing structure. The mining machine walking meshing system comprises a track unit and a guide sliding shoe, whereina front bottom wear-resistant layer, a front side wear-resistant layer, a rear top wear-resistant layer, a rear side wear-resistant layer and a rear bottom wear-resistant layer are arranged on the guide sliding shoe; the track unit comprises a front vertical plate, a rear vertical plate and track teeth; the bottom surface and the front side surface of the front vertical plate are respectively incontact and matched with the front bottom wear-resistant layer and the front side wear-resistant layer; a step which protrudes backwards is arranged at the upper part of the rear vertical plate; the top surface of the rear vertical plate, the rear side surface of the step and the bottom surface of the step are respectively in contact and matched with the rear top wear-resistant layer, the rear side wear-resistant layer and the rear bottom wear-resistant layer; a first material releasing channel is arranged below a track tooth nest between the track teeth; and a second material releasing channel is arranged below the front vertical plate, the rear vertical plate and the track teeth. According to the mining machine walking meshing system, the adaptability of a drum-type mining machine guidesystem to high-hardness and high-lumpiness mineral aggregates can be improved, the guide system is prevented from being quickly worn and crushed, and the fault processing time is short.

Owner:SHANGHAI BRANCH TIANDI SCI&TECH CO LTD +2

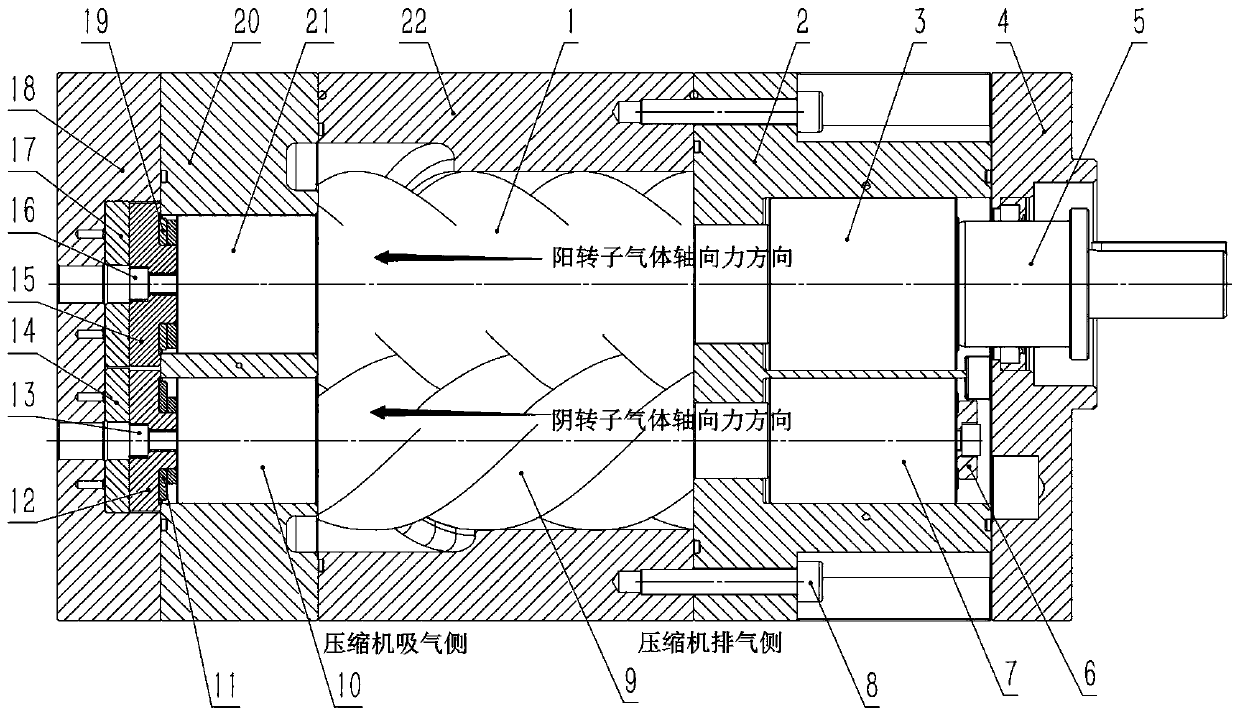

A water-lubricated screw compressor bearing structure

ActiveCN106949059BIncrease the force contact areaImprove cooling conditionsRotary piston pumpsRotary piston liquid enginesThrust bearingTemperature difference

The invention discloses a water lubrication screw rod compressor bearing structure which mainly comprises a female rotor, a male rotor, four water lubrication radial sliding bearings and a thrust sliding bearing. The thrust sliding bearing is located at the shaft end of the female rotor and the male rotor on the air suction side of a compressor. The thrust sliding bearing is located on the air suction side of the compressor, since the whole compression process approximates to constant temperature compression, the air suction and exhaust temperature difference of the compressor is within 10 DEG C, accordingly, the thrust sliding bearing does not affect the rotor exhaust end face gap when installed on the air suction side of the compressor, meanwhile, the stress contact area of the thrust sliding bearing can be greatly enlarged, the thrust bearing face specific pressure is reduced, the service life of the water lubrication thrust sliding bearing is remarkably prolonged, and the reliability of the water lubrication thrust sliding bearing is remarkably improved. The installation gap of the female rotor and the male robot is convenient to adjust, the cooling and lubrication conditions of the thrust sliding bearing are improved, and the whole assembly and later-period maintenance work efficiency of the compressor can be improved.

Owner:SUZHOU ALRBETTER PRECISION MACHINERY

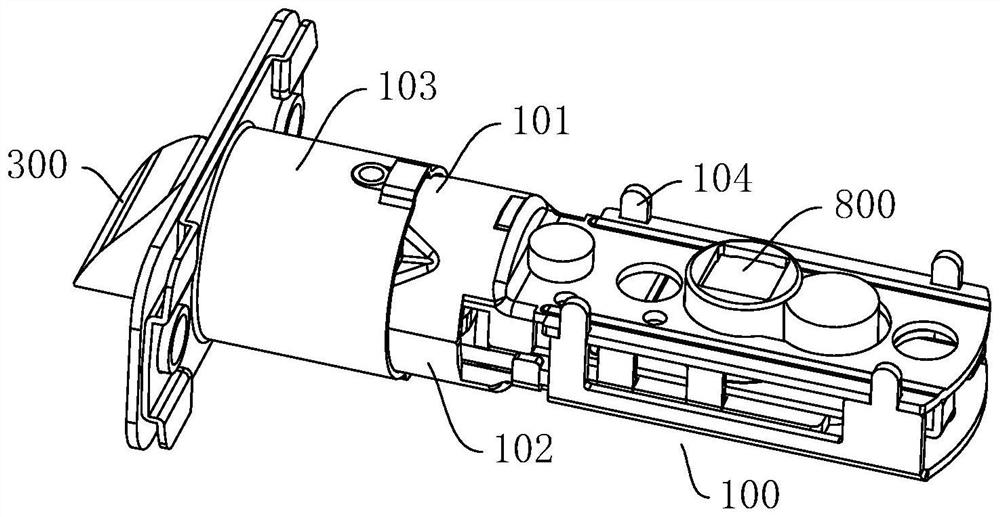

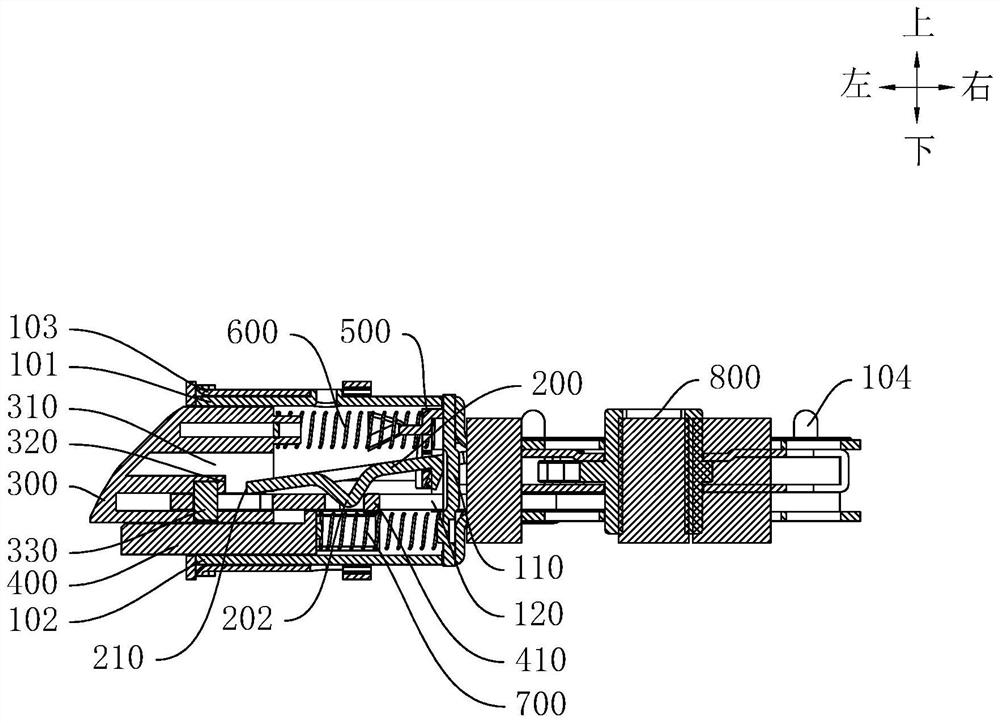

Locking device

PendingCN114876285AGuaranteed service lifeImprove enduranceBuilding locksEngineeringMechanical engineering

The invention discloses a lock bar. The lock bar comprises a main body; the blocking piece is movably arranged in the main body, the blocking piece can swing up and down relative to the main body, and the blocking piece is provided with a first abutting surface; the spring bolt is arranged on the main body in a telescopic mode, the spring bolt is provided with an avoiding part facing the blocking piece and a second abutting face, and the avoiding part is located above the second abutting face; the linkage piece is telescopically arranged on the main body, and the linkage piece is used for driving the blocking piece to swing; after the spring bolt extends out relative to the main body, the linkage piece can be subjected to external force to link the blocking piece to move, so that the first abutting face can swing to be opposite to the second abutting face. According to the lock bar of the structure, the blocking piece can be in plane contact with the spring bolt in the swinging process, the stress contact area of the blocking piece and the spring bolt is increased, then the bearing capacity of the blocking piece for blocking movement of the spring bolt is improved, and the service life of the lock bar is guaranteed.

Owner:中山市摩根金属制品有限公司

Mining machine walking meshing system suitable for blocky mineral aggregate

PendingCN112049636AIncrease the force contact areaForce balancePropulsionMining engineeringStructural engineering

The invention relates to a mining machine walking meshing system suitable for blocky mineral aggregate. The mining machine walking meshing system comprises a track unit and a guide sliding shoe, wherein the guide sliding shoe comprises a sliding shoe body, a sliding shoe bottom plate and a sliding shoe rear plate; the sliding shoe bottom plate and the sliding shoe rear plate are detachably and fixedly connected to the bottoms of the front portion and the rear portion of the sliding shoe body correspondingly; the track unit comprises a front vertical plate, a rear vertical plate and track teeth; the bottom face and the front side face of the front vertical plate make contact with and are matched with an L-shaped groove in the guide sliding shoe, wherein a front groove opening of the L-shaped groove faces the rear upper portion; a step protruding backwards is arranged at the upper portion of the rear vertical plate; the top face of the rear vertical plate, the rear side face of the stepand the bottom face of the step make contact with and are matched with a front double-edge groove in a rear groove opening in the guide sliding shoe; a first material leaking channel is arranged belowa track tooth nest between the track teeth; and a second material leaking channel is arranged below the front vertical plate, the rear vertical plate and the track teeth. According to the mining machine walking meshing system, the adaptability of a drum type mining machine guide system to the high-hardness and high-lumpiness mineral aggregate can be improved, rapid abrasion and crushing of the guide system are avoided, and the fault handling time is short.

Owner:SHANGHAI BRANCH TIANDI SCI&TECH CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com