Large-range fishing spear and fishing method thereof

A fishing spear and a wide range of technology, applied in the direction of earthwork drilling, wellbore/well components, etc., can solve problems such as downhole accidents, affecting the efficiency of accident handling, and unacceptable by customers, achieving fewer accessories, a wide range of fishing, and increased fishing range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

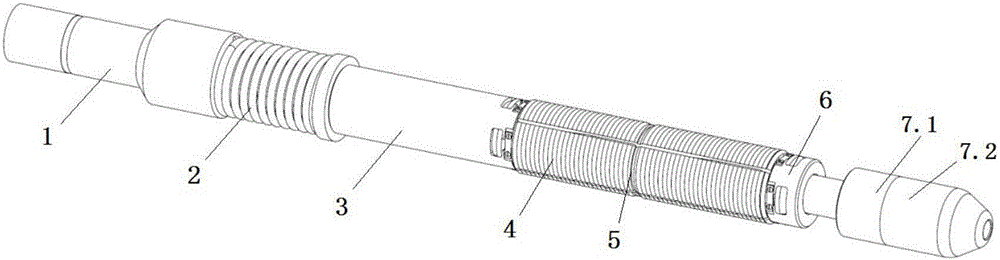

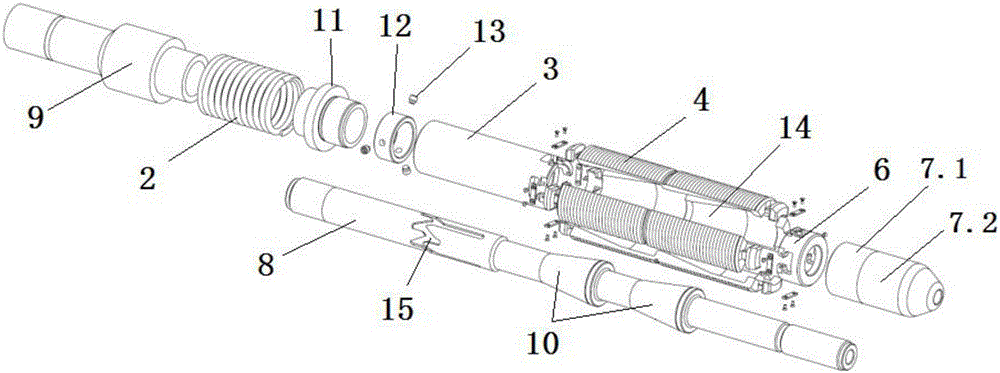

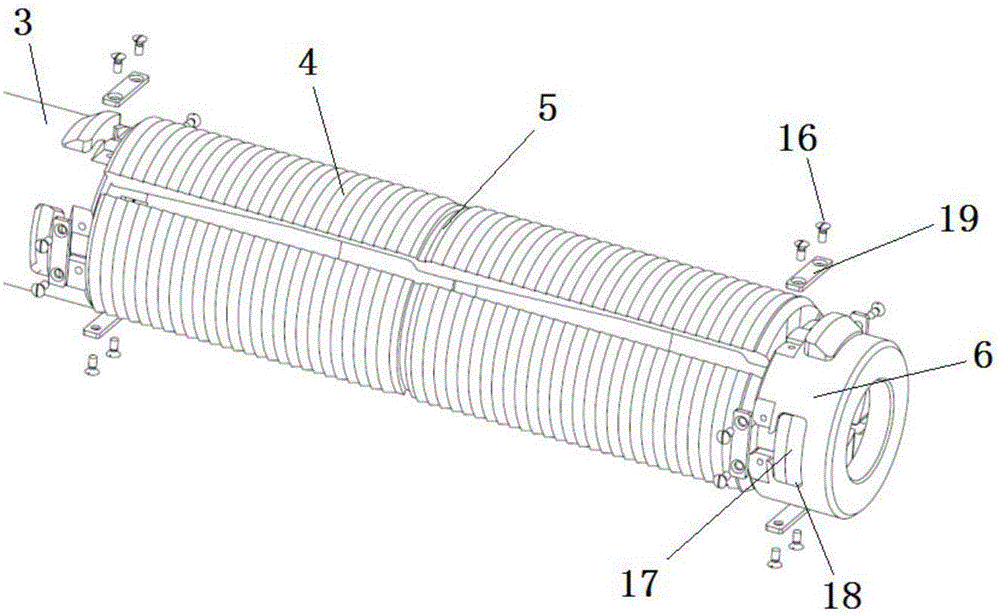

[0032] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0033] Embodiment of the present invention: the structure diagram of large-scale salvage spear is as follows Figure 1~3 As shown, it includes a mandrel 1 and an upper sliding sleeve 3 and a lower sliding sleeve 6 sleeved on the mandrel 1. The mandrel 1 includes a lance 8 and an upper joint 9 and a guide cone respectively connected to the upper and lower ends of the lance 8. 7.2, the adjustment sleeve 7.1 is threadedly connected between the lower sliding sleeve 6 and the leading cone 7.2 on the lance 8, and the stroke of the lower sliding sleeve 6 is limited by the adjustment sleeve 7.1, so as to control the opening range of the split slip 4 . Four split-type slips 4 are connected between the upper sliding sleeve 3 and the lower sliding sleeve 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com