A two-way layered shear model box device and its application method

A shear model box and two-way layer technology, applied in the field of geotechnical engineering, can solve the problems of not considering the spatial effect of the seismic response of complex underground structures, the shear deformation of the model box being difficult to achieve an ideal state, and the insufficient accuracy of vibration test test data. To achieve the effect of adjustable stiffness, good shear deformation and small self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

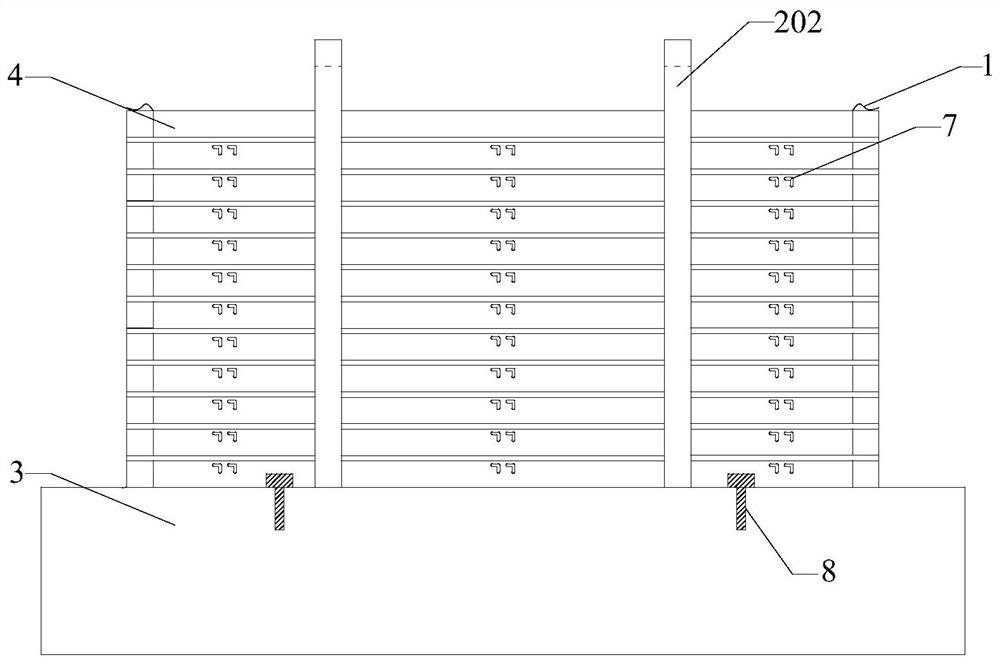

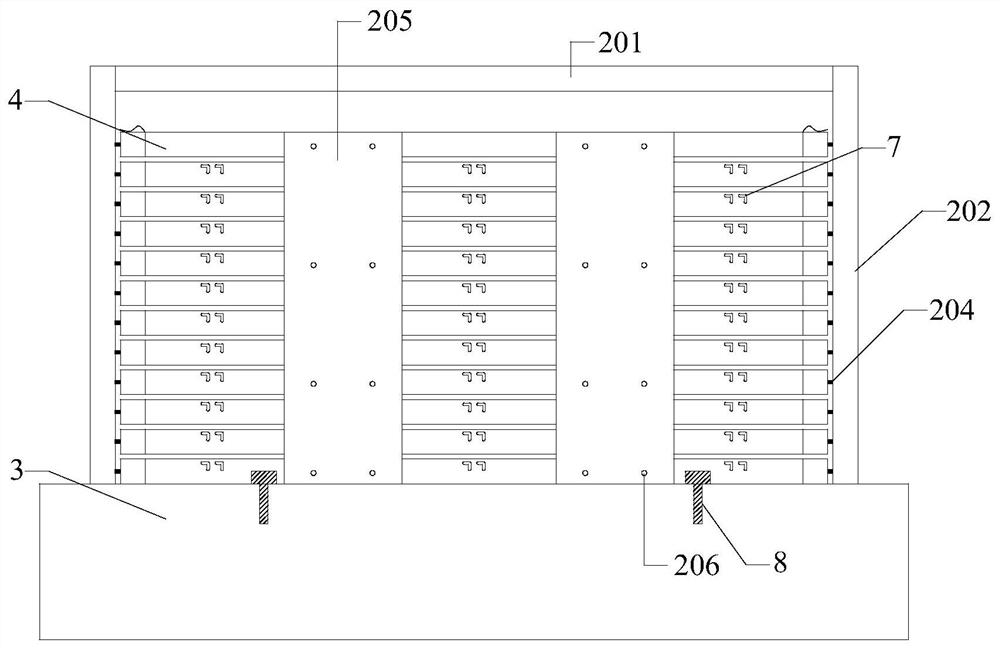

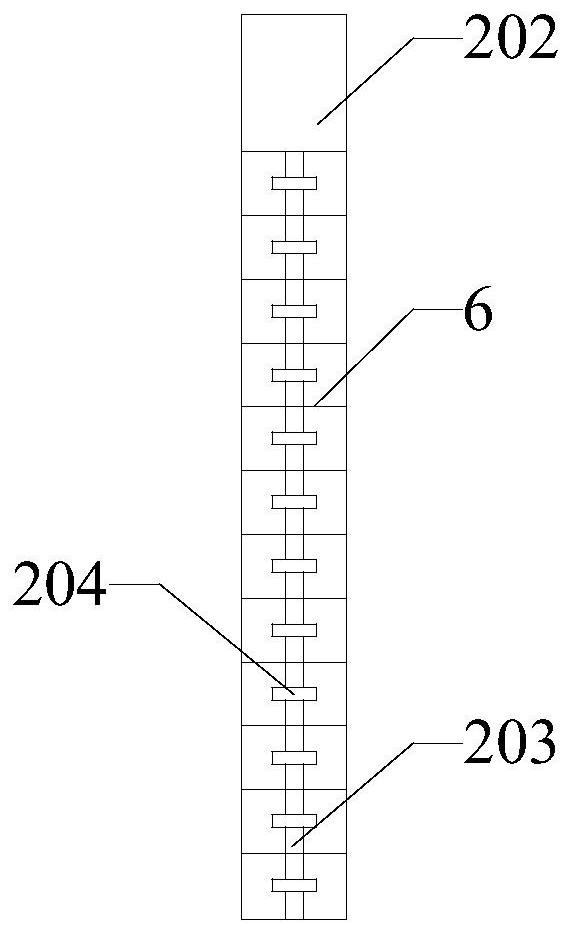

[0036] like Figure 1~3 , there is a vibrating table 3 at the bottom of the two-way layered shear model box device, and the independent multi-layer U-shaped layer frames 4 are vertically and equidistantly arranged in parallel, and are connected by an interlayer rolling body system 5. The cross-section of the U-shaped layer frame 4 The shape is U-shaped and the top and bottom are the same. L-shaped bolt holes 7 are reserved on the side walls of the U-shaped deck frame 4 for connecting with the rolling element bearing platform 501 . Two upper and lower horizontal steel plates 6 are welded to the corresponding positions of the H-shaped steel column 2 web and the U-shaped layer frame 4. The bearing rod 203 of the bearing 204 is fixed on the steel plate 6 by drilling and welding on the steel plate 6. The top of the shaped steel column 202 is connected, the bottom of the H-shaped steel column 202 is welded with a horizontal steel plate 6 and connected to the table top of the vibrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com