Quick connect joint for drill pipe

A quick connection and drill pipe technology, which is applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problems of stress concentration between the drill pipe and the connecting structure, reduce the service life of the drill pipe, increase the cost of exploration work, etc., so as to improve the service life , Compact structure, overcome the effect of stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

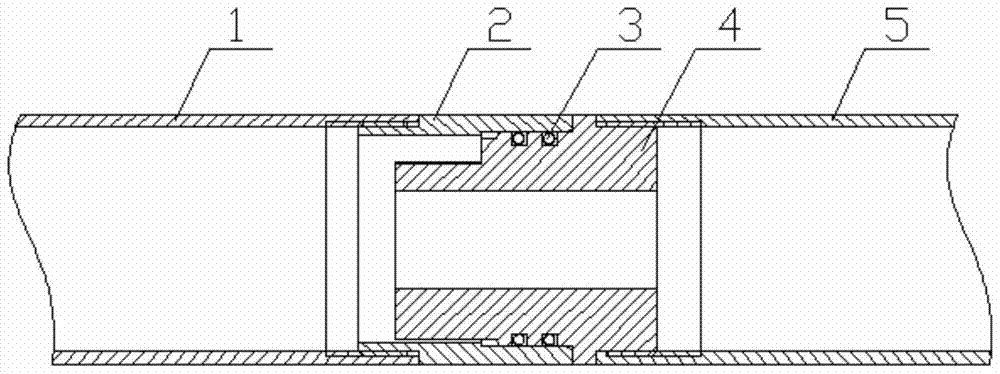

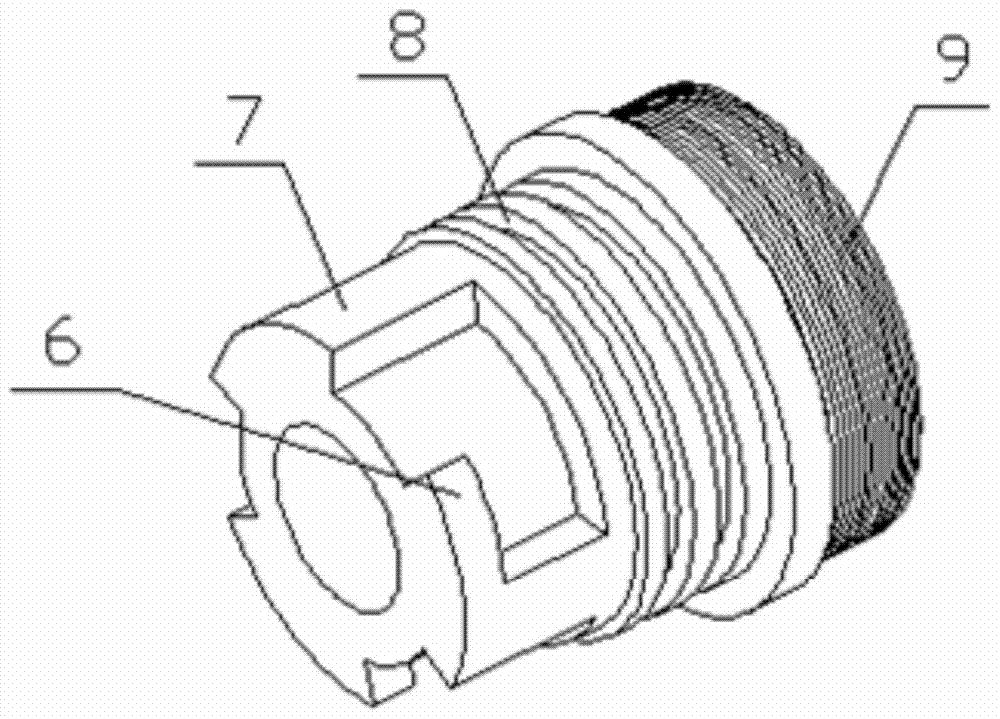

[0016] Embodiment 1: The present invention provides a kind of quick connect joint of drill rod, and its structure is as follows figure 1 As shown, the quick-connect joint of the drill pipe is composed of an outer casing 2, an O-ring 3 and an inner casing 4. The assembly sequence of the drill pipe and the joint is the lower drill pipe 1, the outer casing 2, the inner casing 4 and the upper drill pipe 5, and the O-ring 3 is installed in the sealing groove 8 of the inner casing for the inner casing 4 Sealing with outer casing 2.

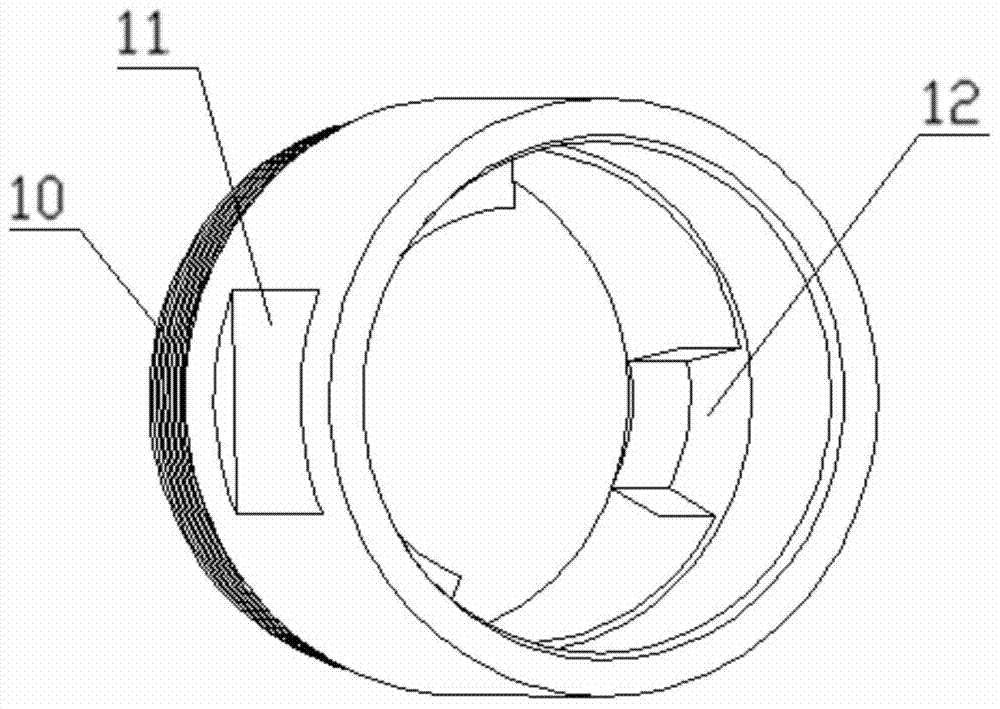

[0017] see image 3 , the inner tube wall of the outer casing 2 is evenly provided with three outer casing stoppers 12, the outer casing stopper is used to transmit torque through the contact surface of the inner and outer casing stoppers when connecting with the inner casing 4; The outer casing thread 10 is provided at the lower end, and the outer casing thread is used for connection with the lower drill pipe; the outer pipe wall in the middle of the...

Embodiment 2

[0020] Embodiment 2: The quick connection joint of the drill pipe provided by the embodiment 1 is used to quickly assemble and disassemble the drill pipe of the drilling rig.

[0021] The specific operation process is as follows: figure 1 shown.

[0022] 1. Connect the inner casing 4 with the upper drill pipe 5 through the inner casing thread 9 .

[0023] 2. Install the O-ring in the sealing groove 8 of the inner casing, insert the inner casing 4 into the outer casing 2 and rotate until the side of the inner casing stopper 7 contacts the side of the outer casing stopper 12, at this time the inner casing The axial stop piece 6 of the pipe should overlap with the end face of the outer casing block 12 in the axial direction, so that the two parts cannot be pulled apart in the axial direction.

[0024] 3. Connect the outer casing to the lower drill pipe 1 through the outer casing thread 10 .

[0025] 4. During the drilling process of the drilling rig, the internal flushing flui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com