Double-deck supporting connection structure of tower drum of wind driven generator and jacket foundation

A technology for connecting structures and jackets, applied in wind turbine components, wind turbines, wind power generation, etc., can solve problems such as stress concentration and point-to-surface contact ratio, and achieve reduced stress concentration, reasonable load transfer, and increased use space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

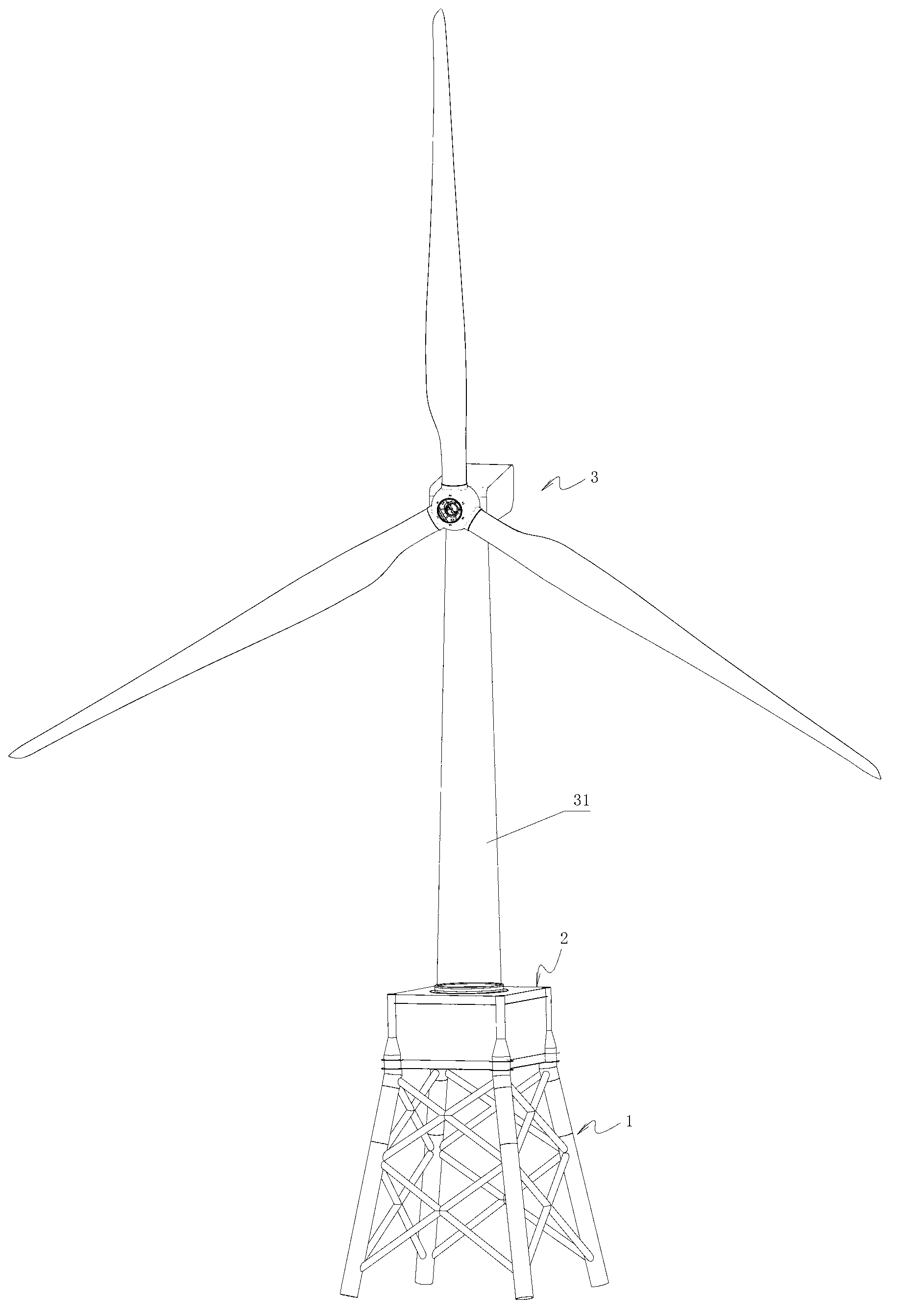

[0021] like figure 1 Shown, a kind of wind power generation equipment, it comprises jacket foundation 1, double deck support structure 2 and wind generator assembly 3, double deck support structure 2 is fixed on the upper end of jacket foundation 1, wind generator assembly 3 is installed on On the tower tube 31 , the tower tube 31 is fixedly installed on the double-deck support structure 2 .

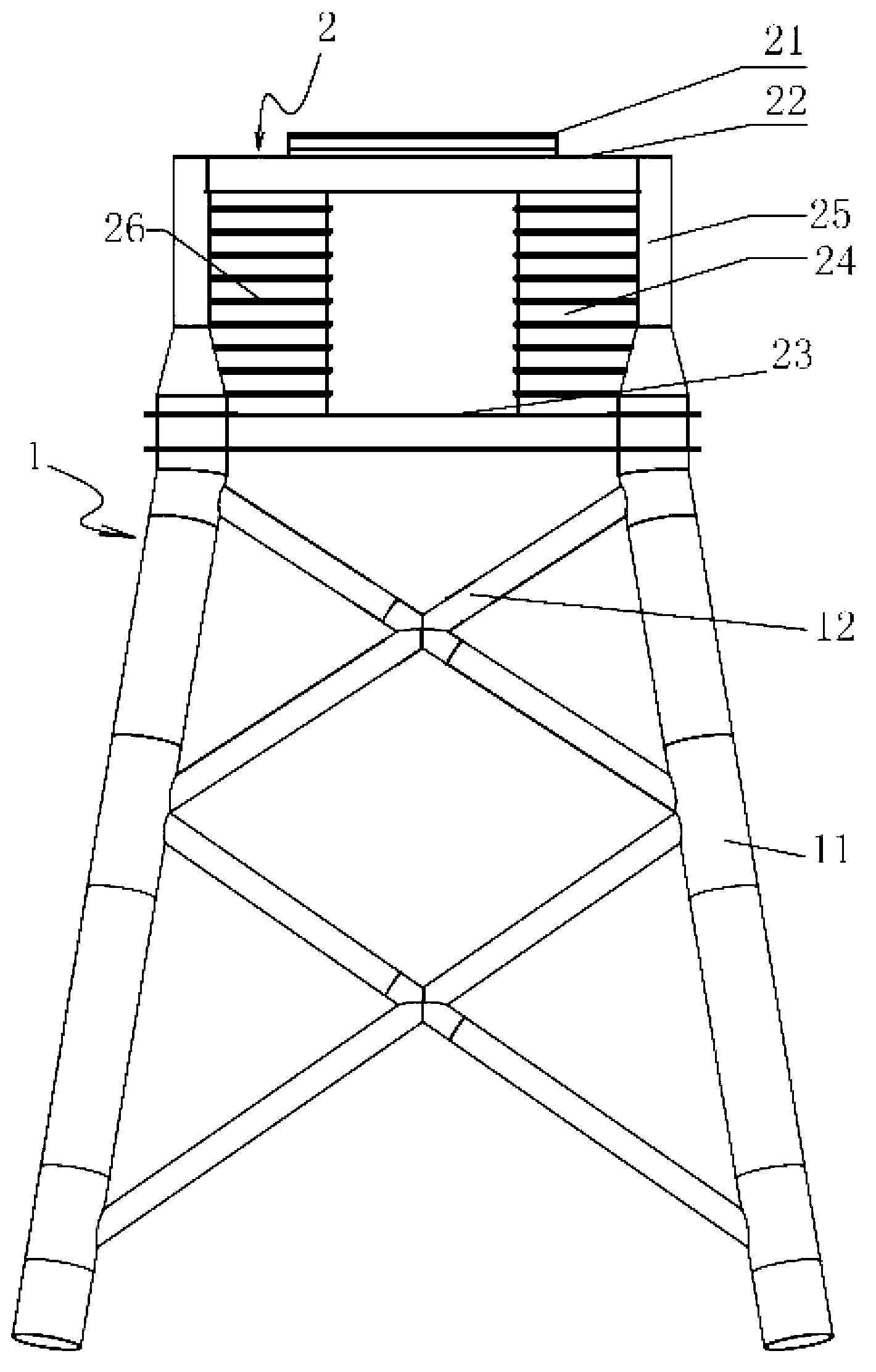

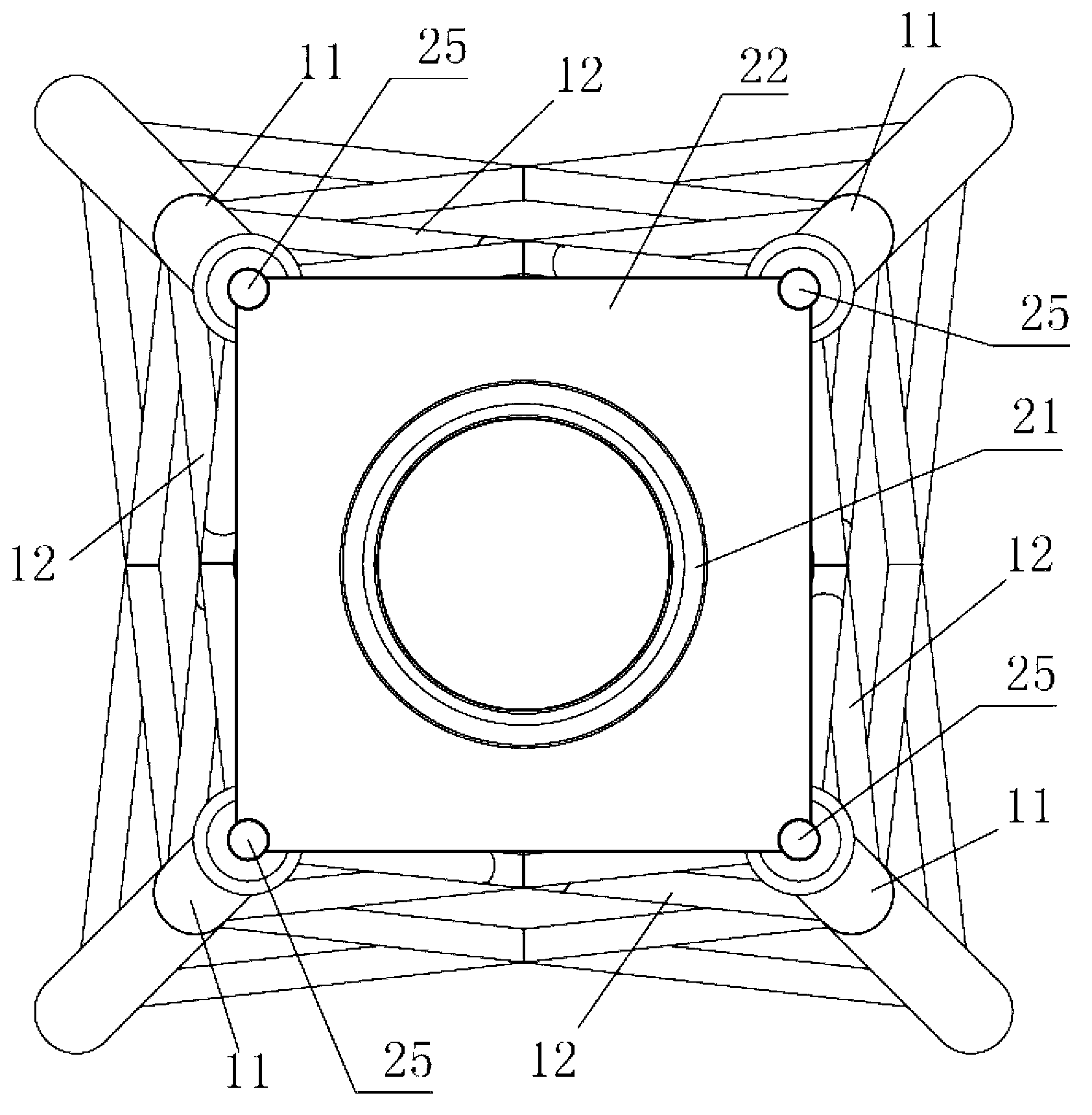

[0022] like figure 2 and image 3 As shown, there is a vertical column 21 in the middle of the double-deck support structure 2, the top and bottom of the double-deck support structure 2 are provided with a deck 22 and a deck 23 with reinforcing ribs, and the column 21 is welded on the deck 22 and the deck 23. A vertical plate 24 containing reinforcing ribs is also arranged between the two decks 22 and 23 .

[0023] In a preferred embodiment of the present invention, the column 21 is a cylindrical steel pipe, the upper and lower ends of the vertical plate 24 are welded to the two deck...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com