Limiting shock attenuation device connecting forklift truck cab with frame

A shock absorbing device and cab technology, which is applied to the upper structure of trucks, vehicle components, transportation and packaging, etc., can solve the problems of poor stability of the cab, unsafe feeling of the driver, and unsatisfactory shock absorption effect, etc. Achieve the effect of improving assembly efficiency, improving driving comfort, improving driving safety and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

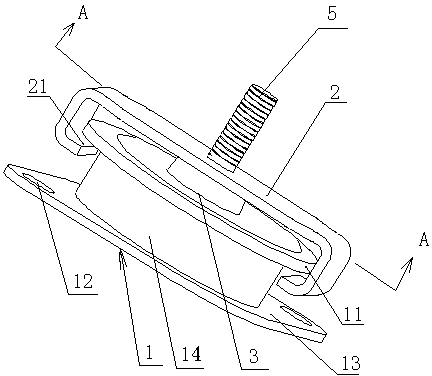

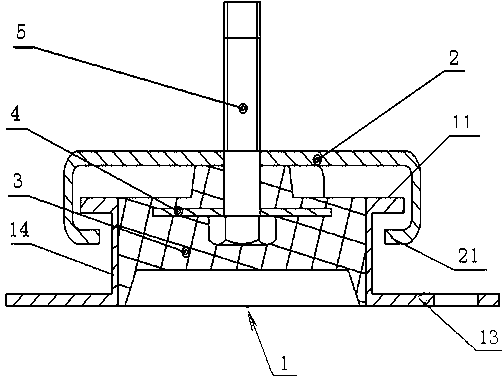

[0025] Such as figure 1 , 2 As shown, a limit damping device for connecting a forklift cab and a vehicle frame includes a base 1, a damping block 3 is provided inside the base 1, and connecting bolts 5 are buried inside the damping block 3 With the damping washer 4, the bottom end of the connecting bolt 5 is vertically connected with the damping washer 4, and the upper end of the connecting bolt 5 passes through the limit block 2 arranged on the top surface of the shock absorber 3 and is riveted with the limit block 2 to connect The top of the bolt 5 is connected with the cab.

[0026] Further, the base 1 includes a base plate 13, the outer side of the base plate 13 is provided with a fixing hole 12 connected with the vehicle frame, a box body 14 for carrying a shock absorber is fixed in the middle of the bottom plate 13, and the box body 14 at the top is The wall is turned outward to form a flange 11;

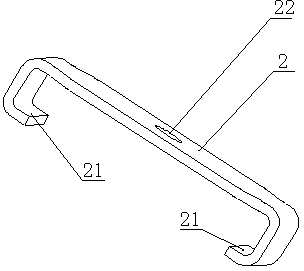

[0027] Such as image 3 As shown, a connecting hole 22 is provided in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com