Cell separation cup with high extraction purity

A separation cup with high purity technology, which is applied in the field of cell separation cups, can solve the problems of reducing the number of use of separation cups, large cell damage, and easy slippage, so as to prevent cells from remaining in the gap, reduce cell damage, and avoid cell damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below with reference to the accompanying drawings.

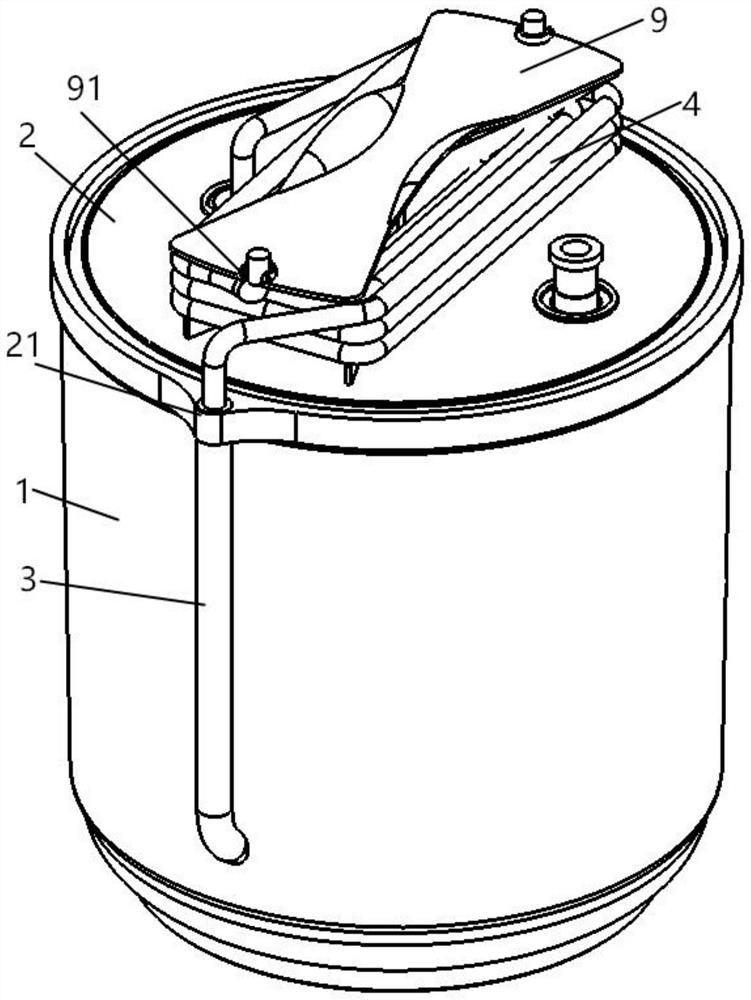

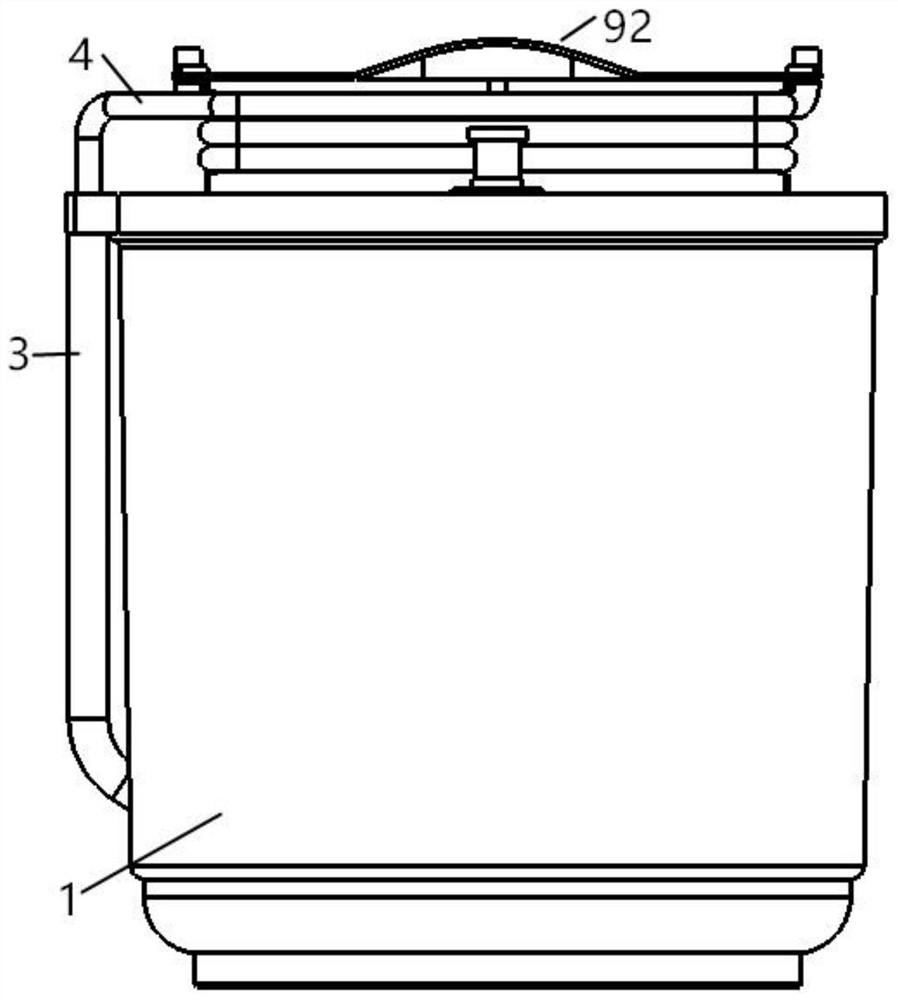

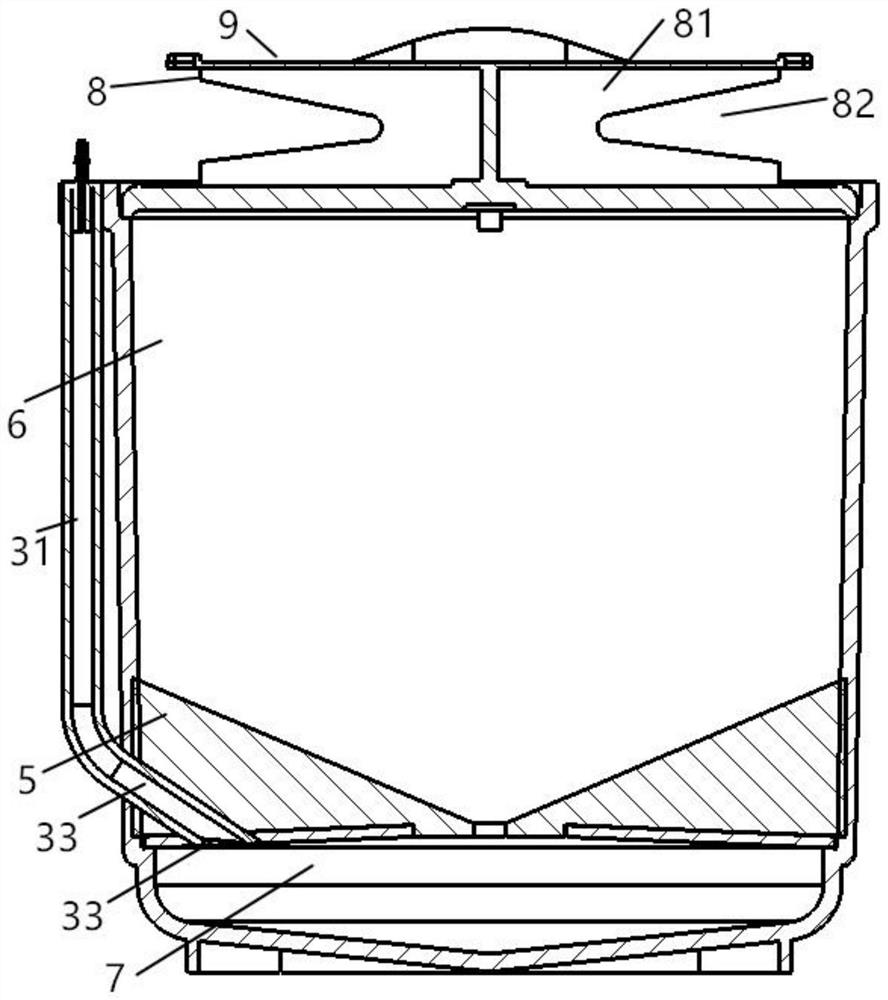

[0021] Such as figure 1 As shown, a cell separation cup extracting high purity, including a cup body 1, a cup cover 2, a straw 3, a sterile tube 4, and a separating body 5 disposed in the cup body 1, the separating body 5 will be a cup body 1 The inner partition is separated into the upper space 6 and the lower space 7, the top of the separating body 5 is welded to the sterile tube 4, the straw 3 includes a vertical section 31 disposed outside the cup body 1 and a wall of the cup and The separation body 5 is passed into the bending section 32 of the lower space 7, and the bottom portion of the flap section 32 is disposed in a bottom portion of the separation body 5.

[0022] Preferably, a circular arc transition structure 33 is disposed on the inner wall at the bottom port of the flap section 32.

[0023] A cell separation cup having a high purity of the present scheme is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com