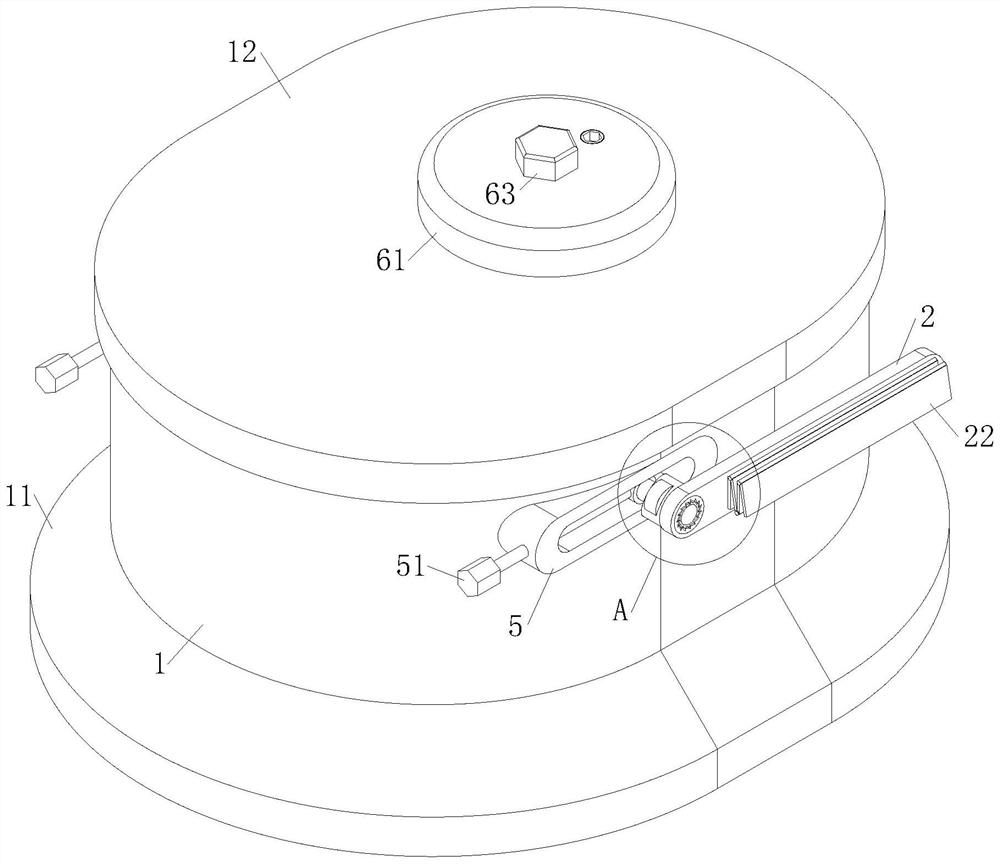

Intelligent portable detector for tooth strength of transmission gear

A technology of transmission gears and detectors, applied in the testing of instruments, measuring devices, mechanical parts, etc., can solve problems such as obstacles and inconvenience for direct detection of plastic gears, and achieve the effect of increasing applicability, reducing influence, and reducing structure size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

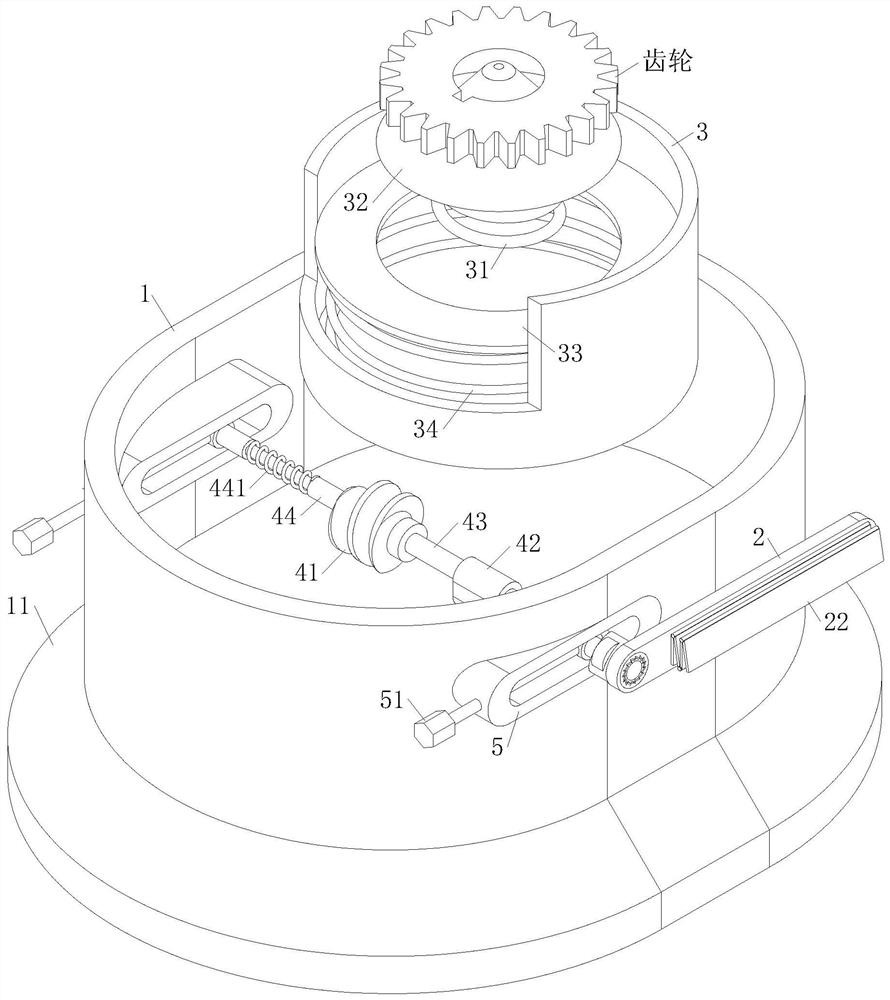

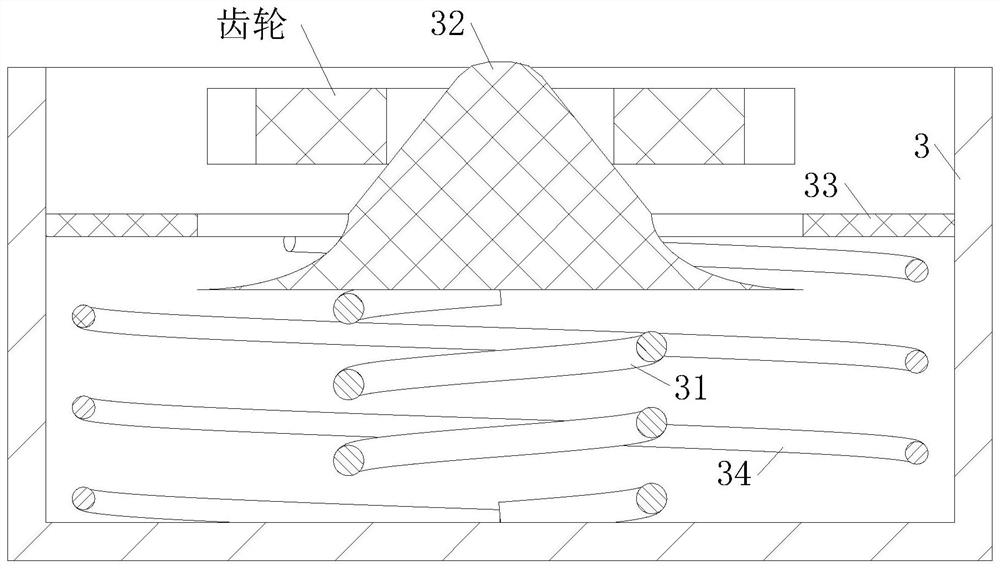

[0030] As an embodiment of the present invention, the center of the clamping cylinder 3 is also provided with a limit shaft 32, and the limit shaft 32 is fixed on the top of the column spring 31; The lower part of the positioning shaft 32 is a concave arc surface; the bottom of the clamping cylinder 3 is also provided with a backing ring 33, the backing ring 33 is located on the outside of the column spring 31 and is parallel to the top of the concave arc surface of the limiting shaft 32 There is also a cylinder spring 34 fixedly connected between the backing ring 33 and the detection platform 1 below, and the rotation direction of the cylinder spring 34 and the column spring 31 is opposite; The limit shaft 32 at the center of the clamping cylinder 3 cooperates with the column spring 31 to adjust the height of the clamping cylinder 3, so that the gear is installed on the limit shaft 32, and the conical surface on the upper part of the limit shaft 32 is convenient for adapting t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com