Rotating connector used for conveying two-phase flow containing solid abrasives

A rotary joint, phase flow technology, applied in grinding/polishing equipment, etc., can solve the problems of easy accumulation of abrasive particles and blockage of pipelines, low service life of rotary joints, limited working time and efficiency, etc., so as to avoid wear and sticking phenomenon. , to ensure flow stability and safety, service life and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereby.

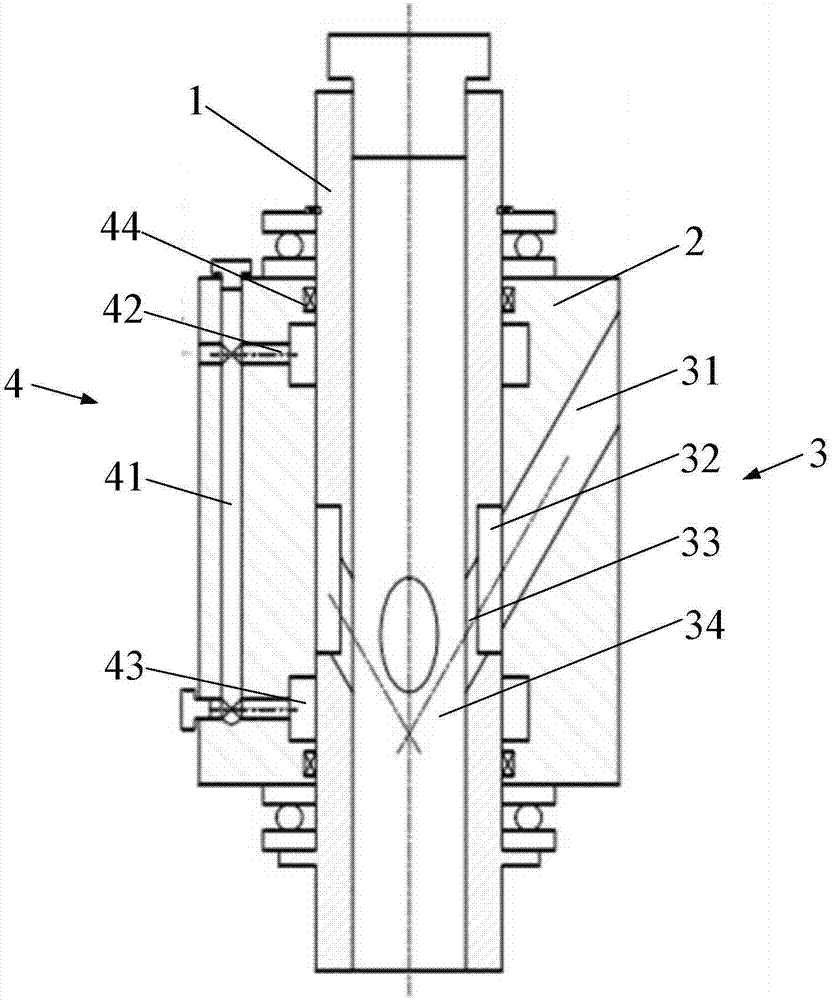

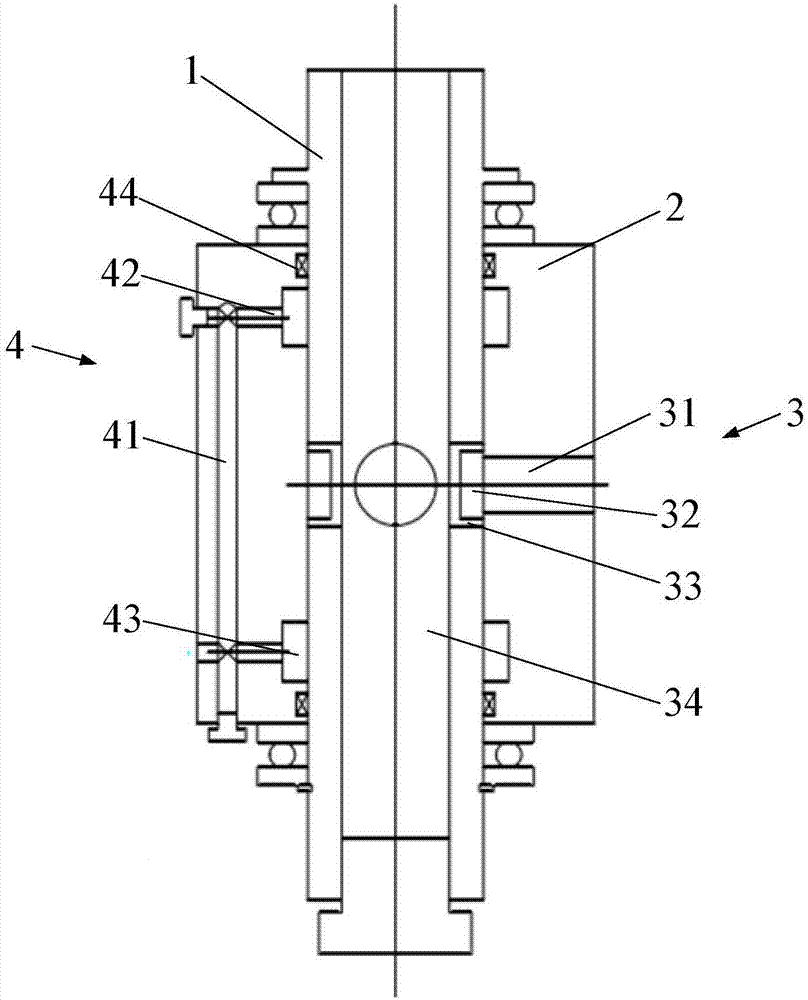

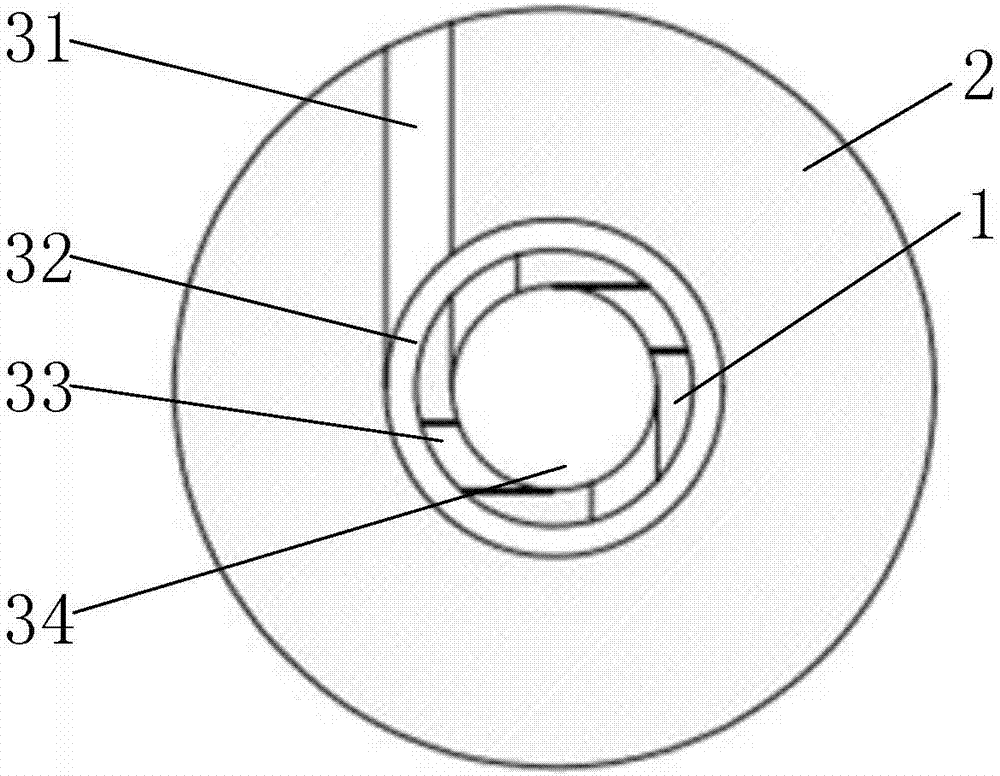

[0027] Such as figure 1 and figure 2 As shown, the rotary joint used to convey the two-phase flow containing solid abrasives in this embodiment includes an inner shaft 1, an outer casing 2 and a feeding assembly 3, the outer casing 2 is sleeved on the inner shaft 1, and the inner shaft 1 and the outer casing 2 Relatively rotatable, the delivery assembly 3 is installed on the inner shaft 1 and the outer jacket 2, and is used to deliver the high-pressure abrasive two-phase flow to the jet nozzle. In this embodiment, the casing 2 is provided with a high-pressure sealing assembly 4, which is used to deliver high-pressure fluid to the gap between the inner shaft 1 and the casing 2. The injection pressure of the high-pressure fluid is greater than the delivery press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com