Patents

Literature

43results about How to "Ensure flow stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

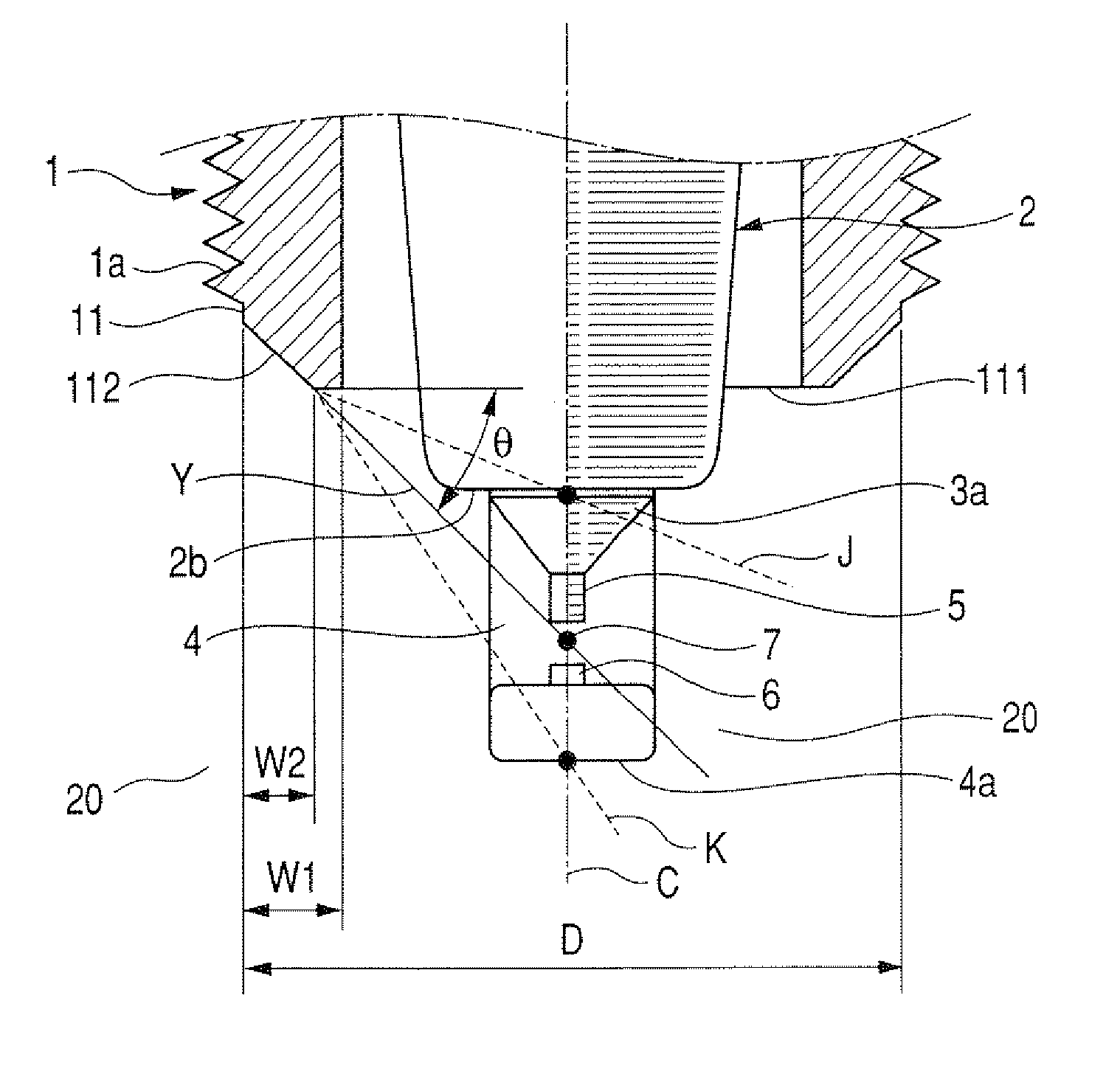

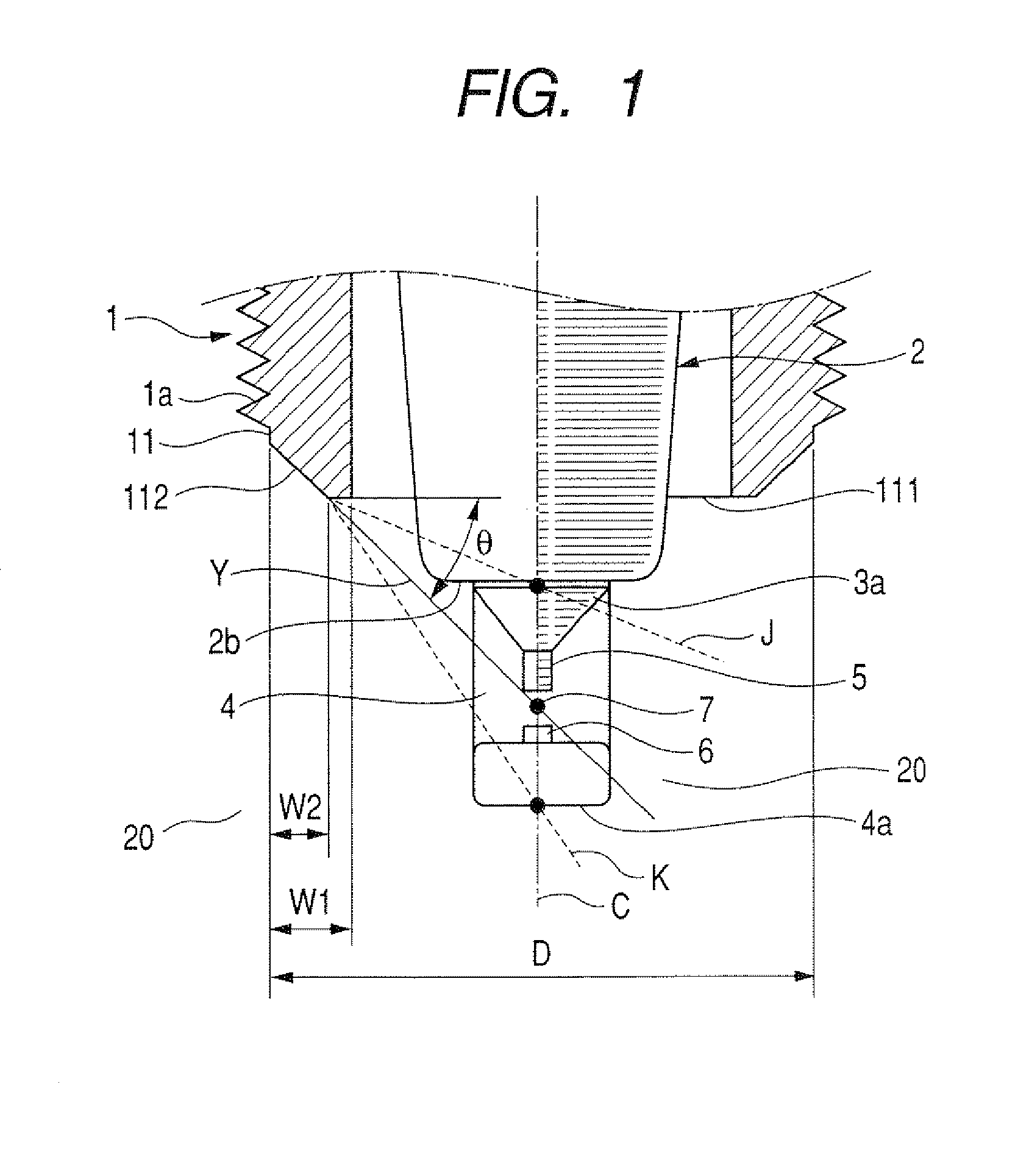

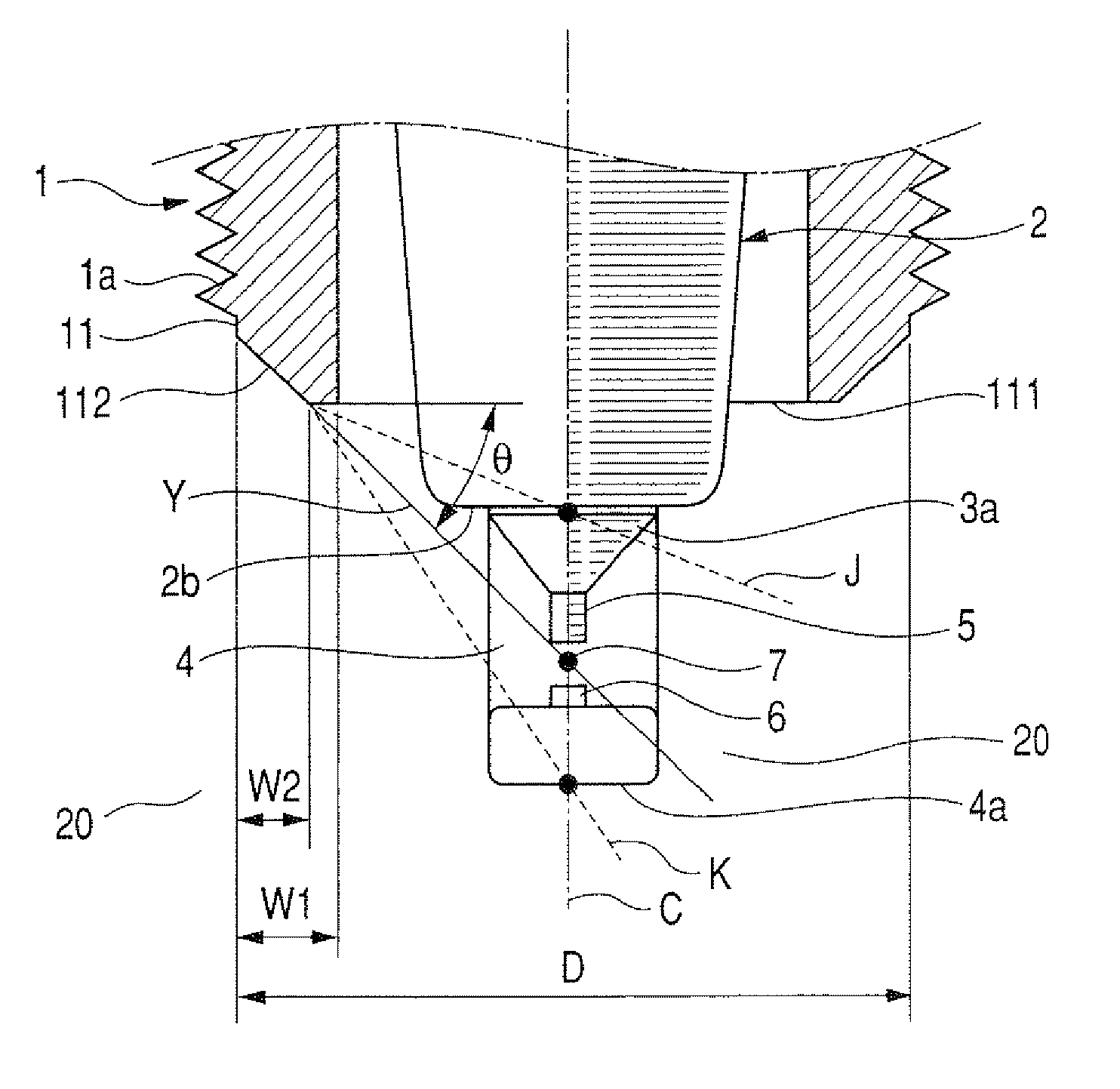

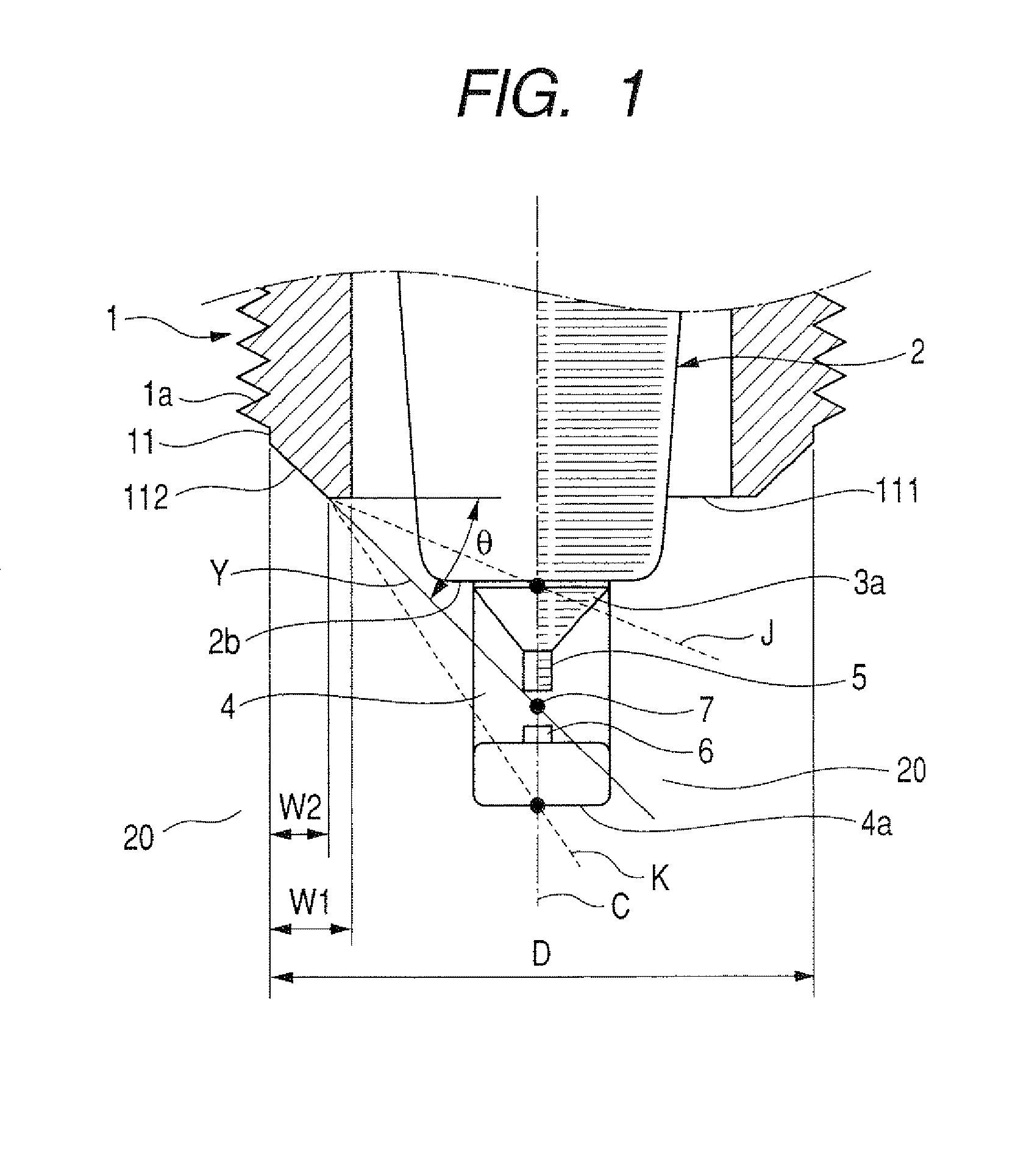

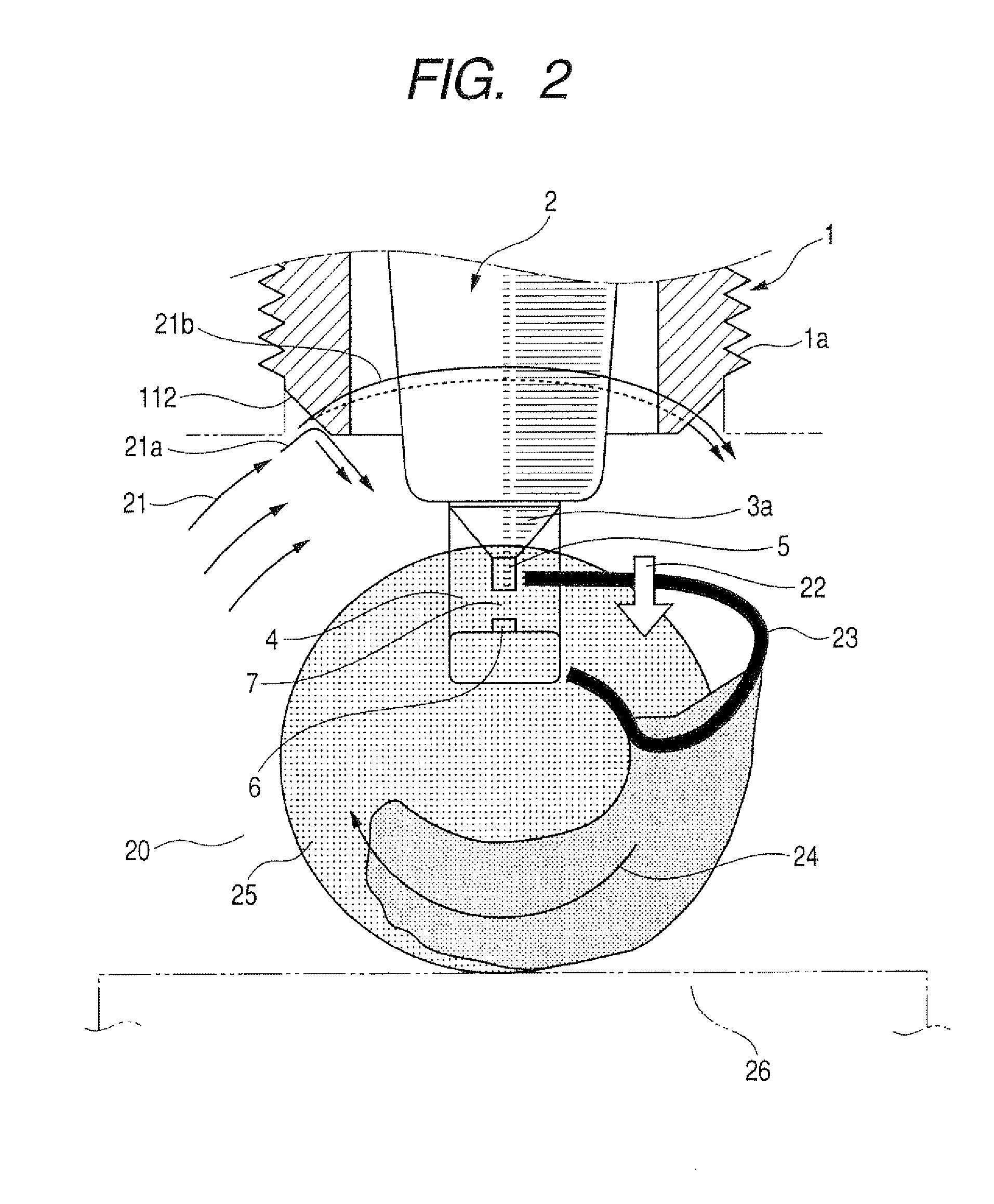

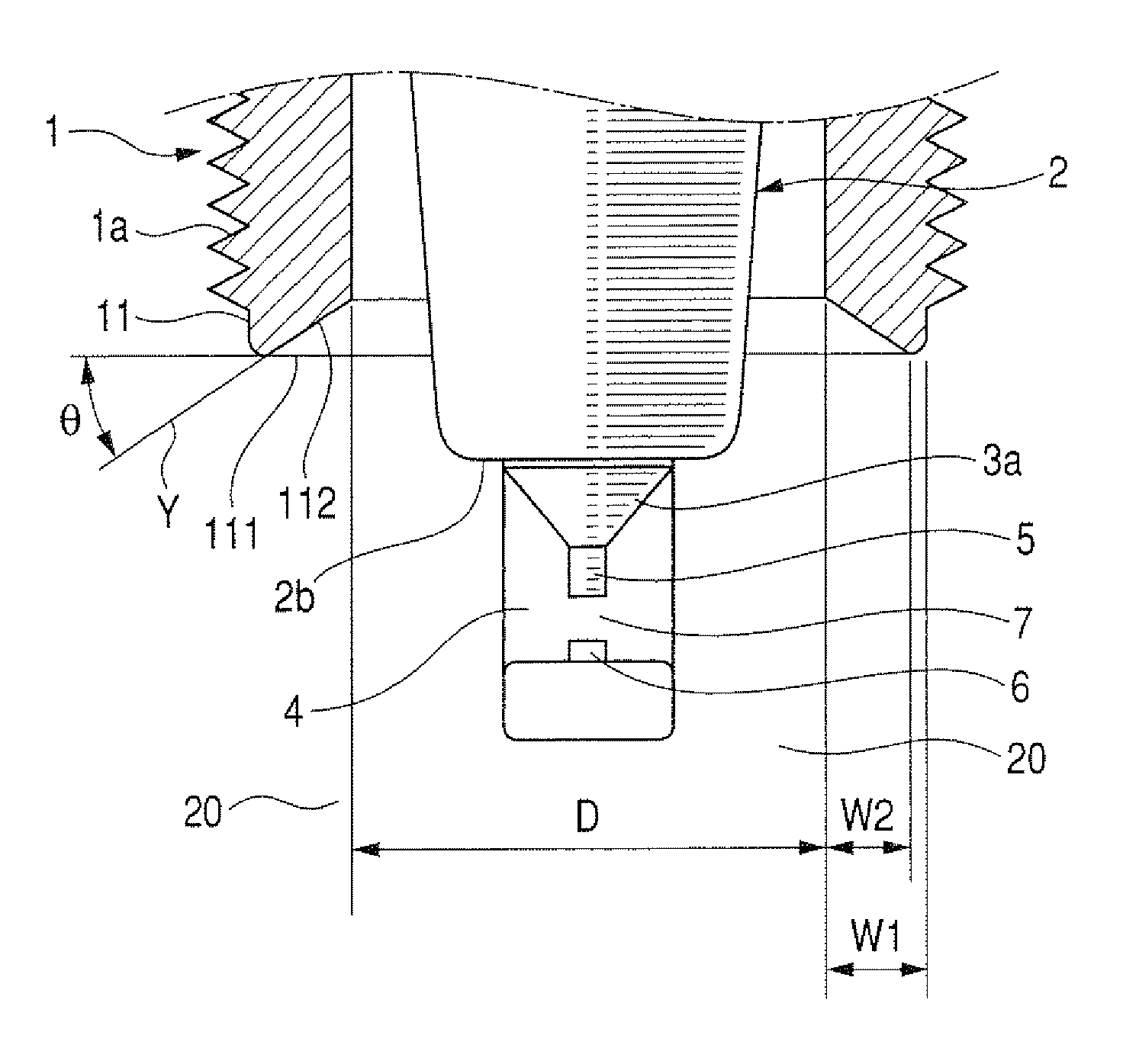

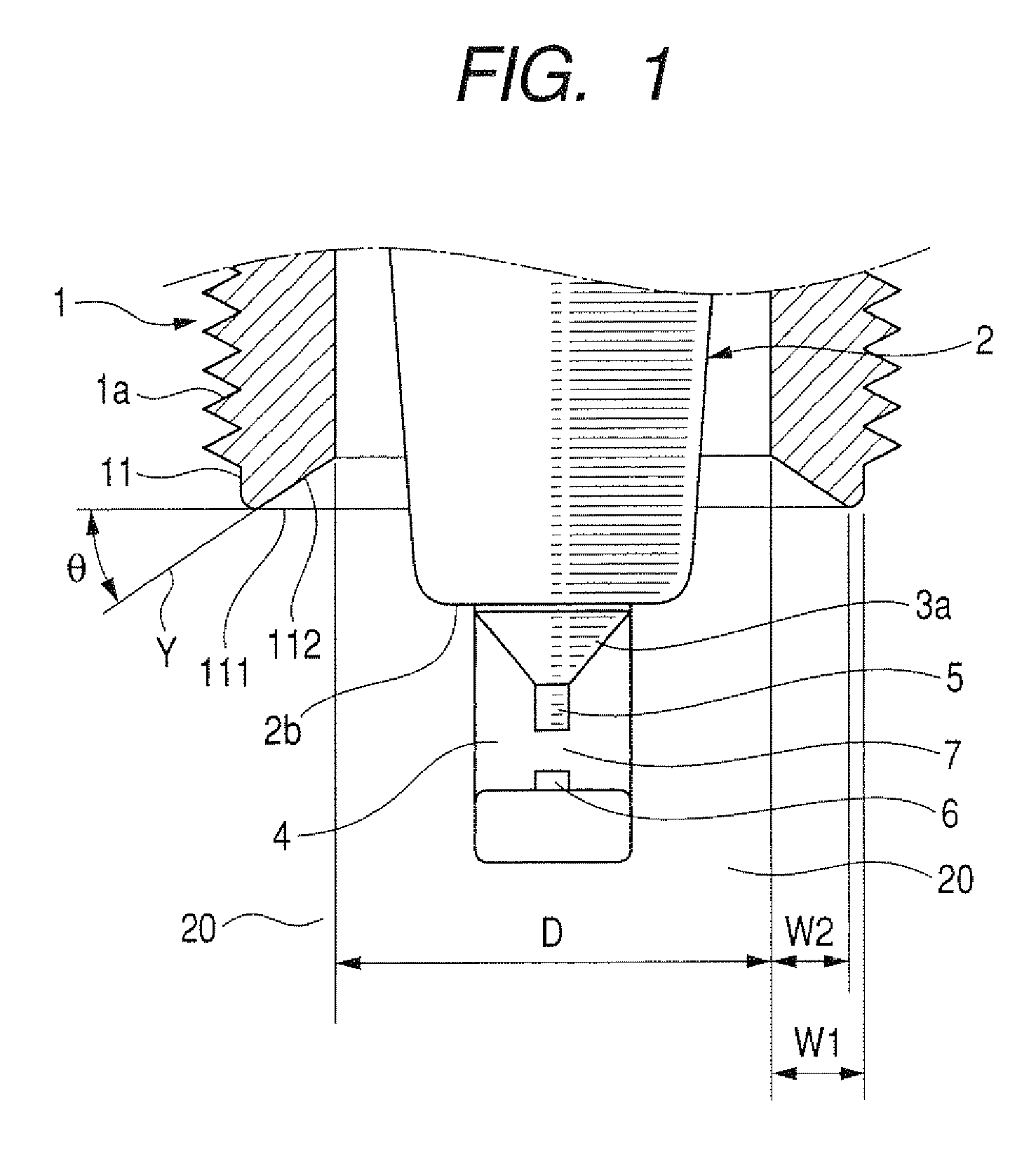

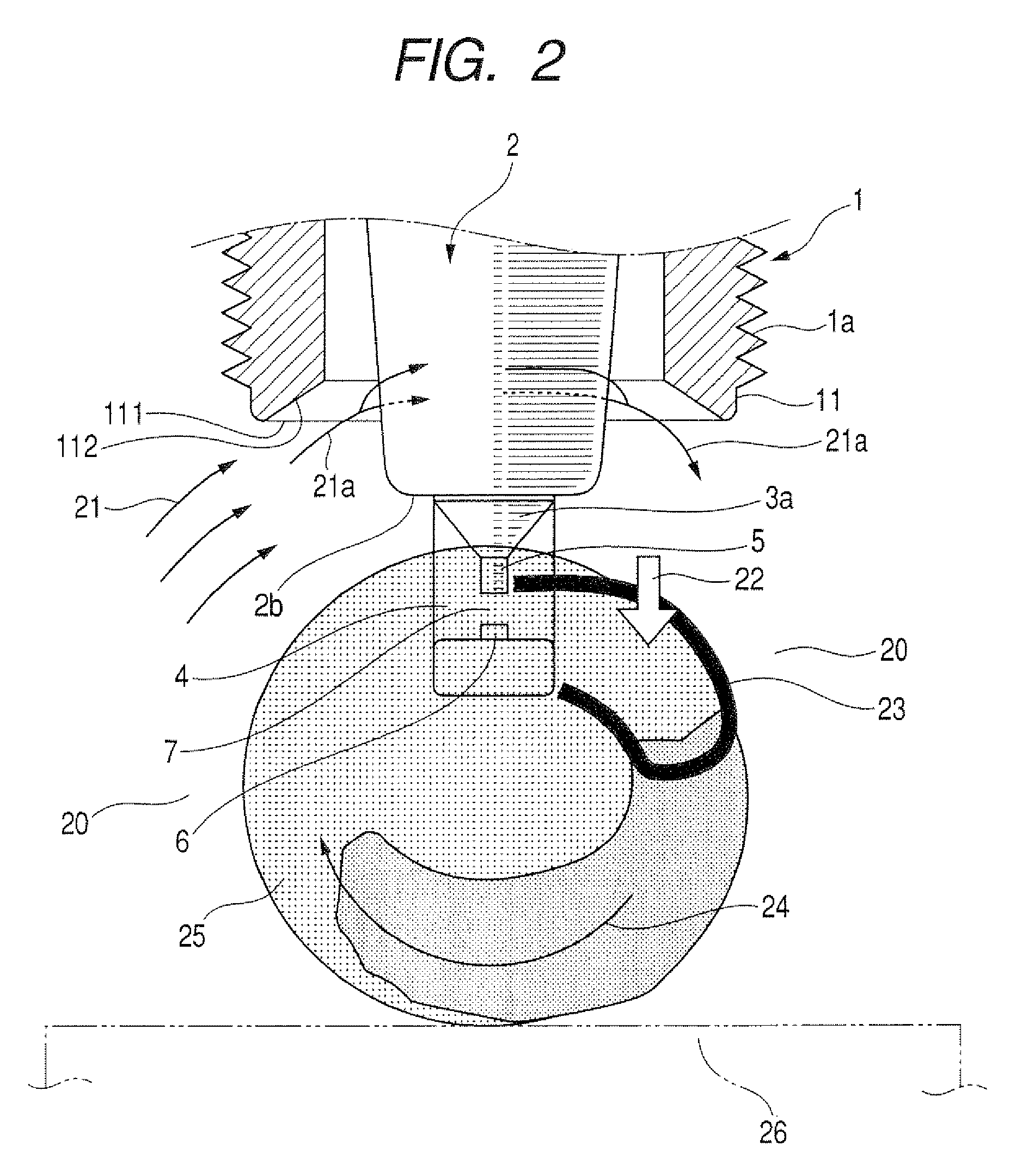

Spark plug with stream shaper to shape tumble vortex into desired stream in combustion chamber

InactiveUS20080092839A1Ensures stability of orientationImprove flammabilitySparking plugsCombustion chamberEngineering

A spark plug for an internal combustion engine is provided which includes a hollow cylindrical metal shell with an open end portion to be exposed to a combustion chamber of the engine, a ground electrode joined to the metal shell, a center electrode disposed in the metal housing to define a spark gap between itself and the ground electrode. The spark plug also includes a stream shaper geometrically formed on an outer periphery of the open end portion of the metal shell to shape tumble vortexes of air-fuel mixture into vortex streams oriented toward a central portion of the combustion chamber. This ensures the stability of orientation of the tumble vortexes to control a flow of sparks, thereby enhancing the ignitability of the air-fuel mixture in the combustion chamber.

Owner:DENSO CORP +1

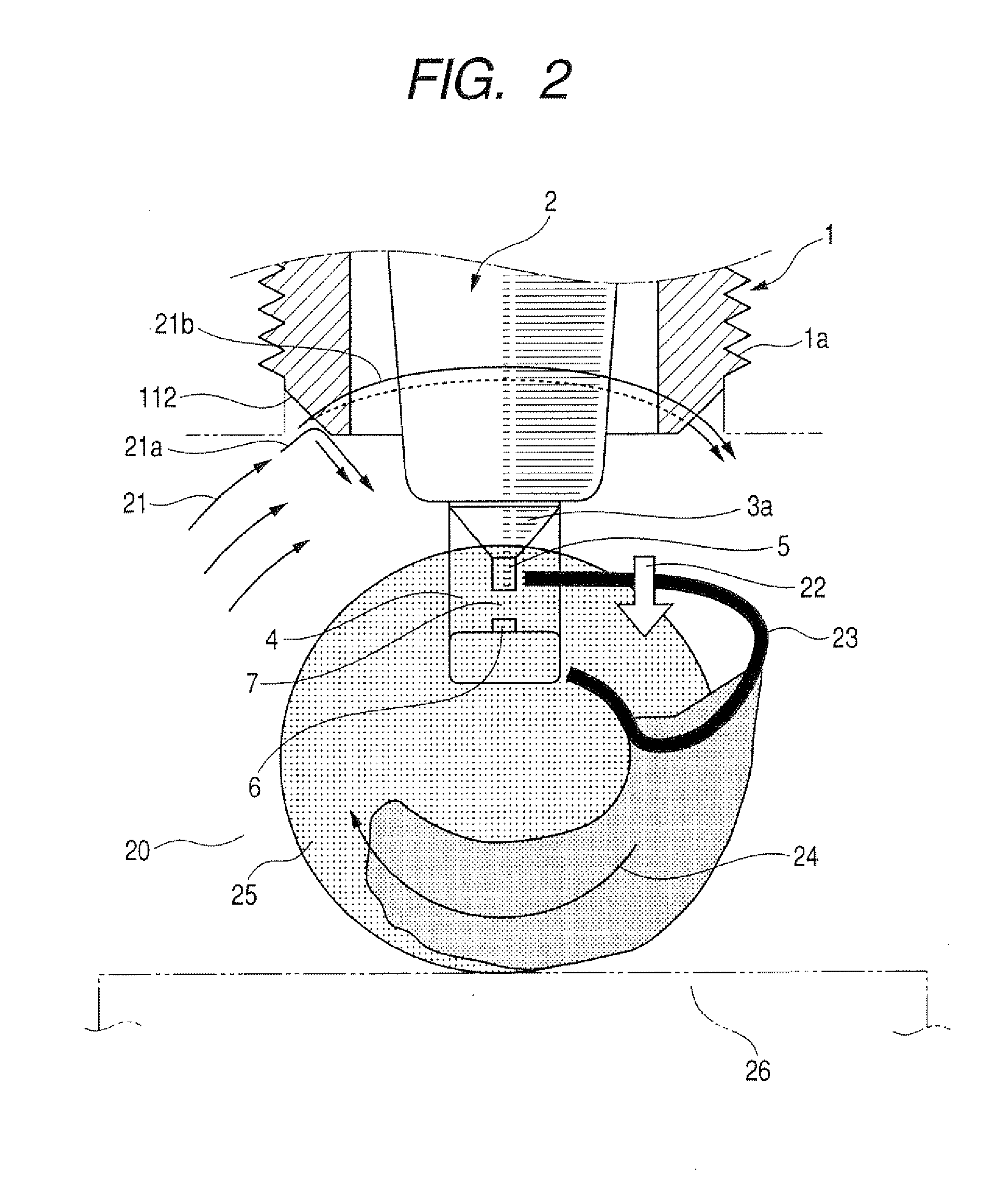

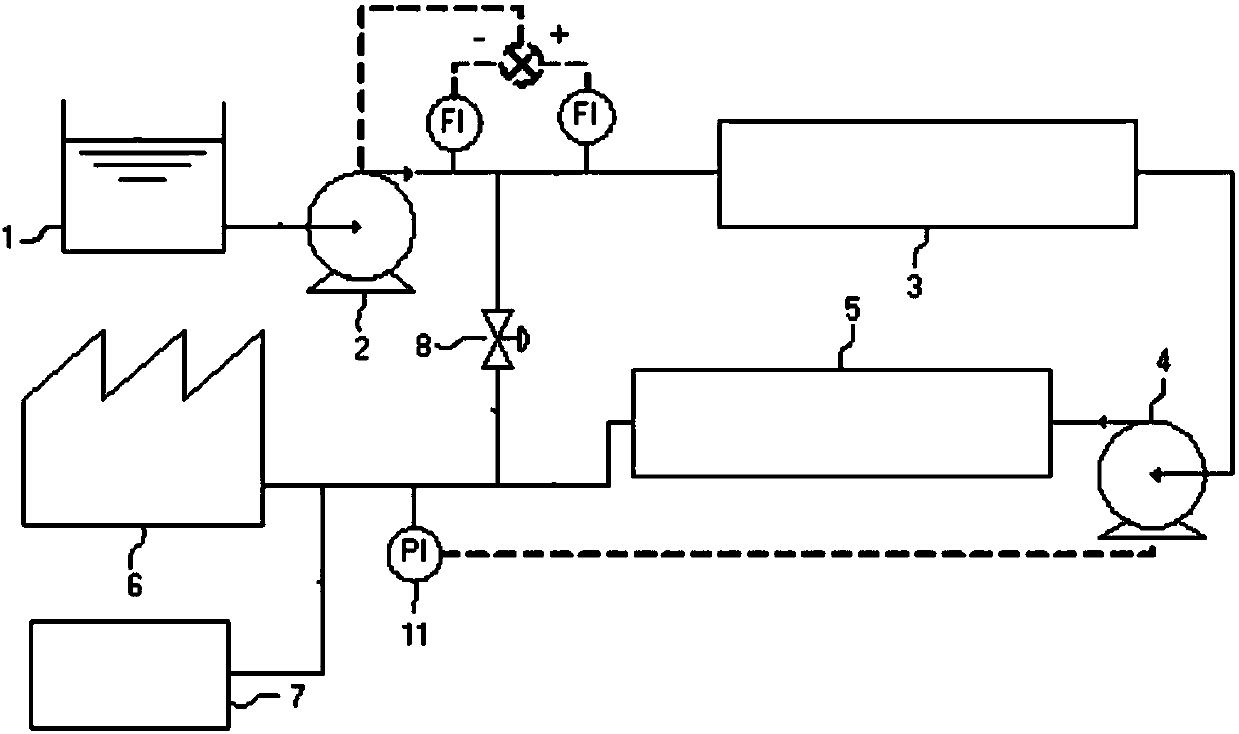

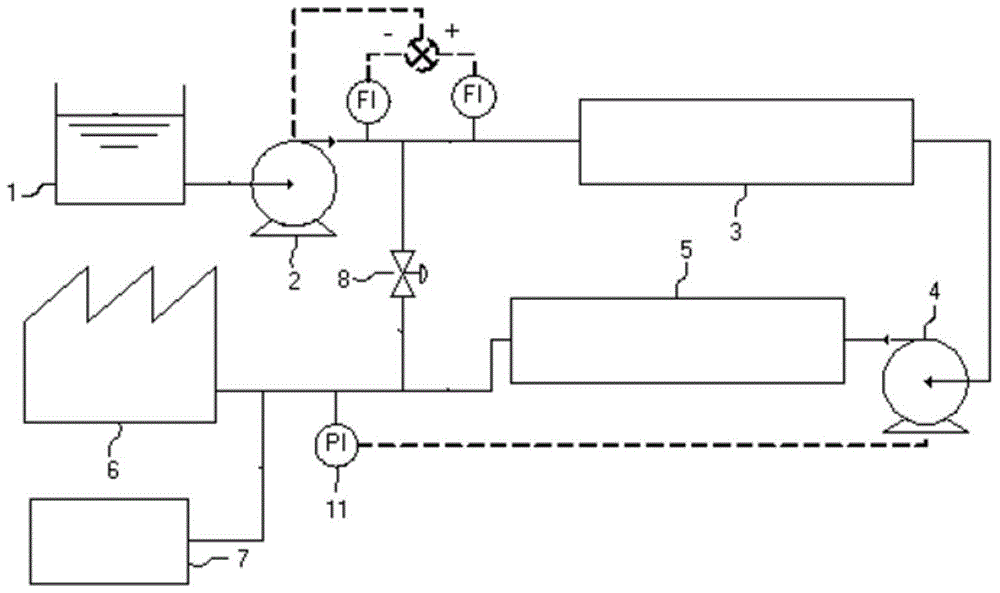

Multi-path liquid temperature regulating device and temperature control method

InactiveCN104199483AAchieve calibrationGuaranteed temperatureTemperatue controlEnergy industryLiquid temperatureWater supply

The invention discloses a multi-path liquid temperature regulating device and a temperature control method thereof and belongs to a liquid temperature regulating device and a temperature control method thereof. The multi-path liquid temperature regulating device can solve the problem that the immersion solution temperature regulating device of the existing mask aligner only has the control ability of one-path output temperature and cannot coordinate to adjust the far-end and near-end water supply temperature. The temperature regulating device comprises a pure water supply part, a liquid injection part and a control system, the pure water supply part is respectively arranged in the far-end pure water device, and the liquid injection part is arranged in the mask aligner; the pure water supply part and the liquid injection part are connected through far transmission pipelines; the control system respectively collects the temperature values of a pure water temperature sensor, a water supply temperature sensor and first-third temperature sensors; heating voltage of first-third heaters and driving current of a cooling water flow servo valve are controlled. In the regulating device, a heat exchanger and a low-power heater are combined, flow is regulated through the flow servo valve and power of multiple low-power heaters is also regulated, such that pure water temperature on multiple output ends reaches the steady value of +1 / -1 degree centigrade.

Owner:HUAZHONG UNIV OF SCI & TECH

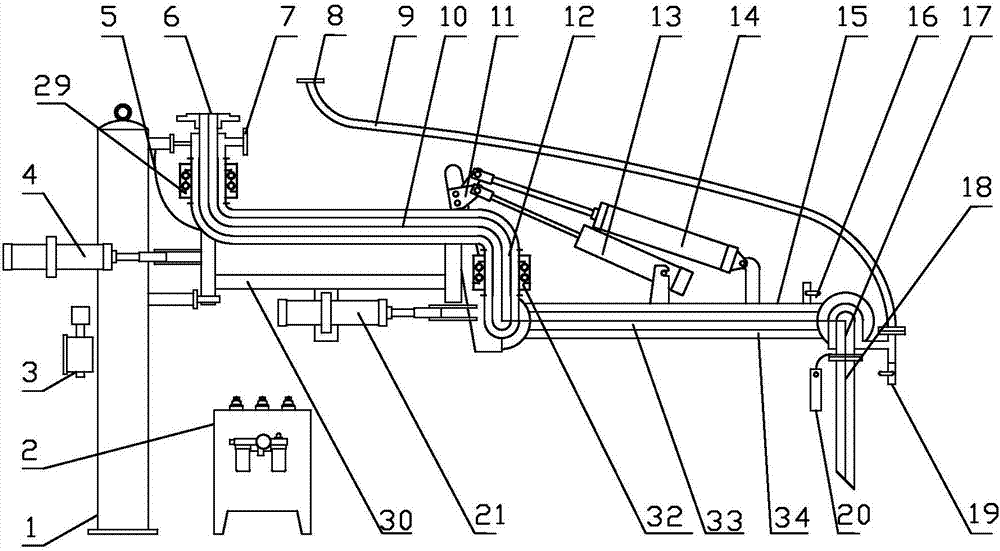

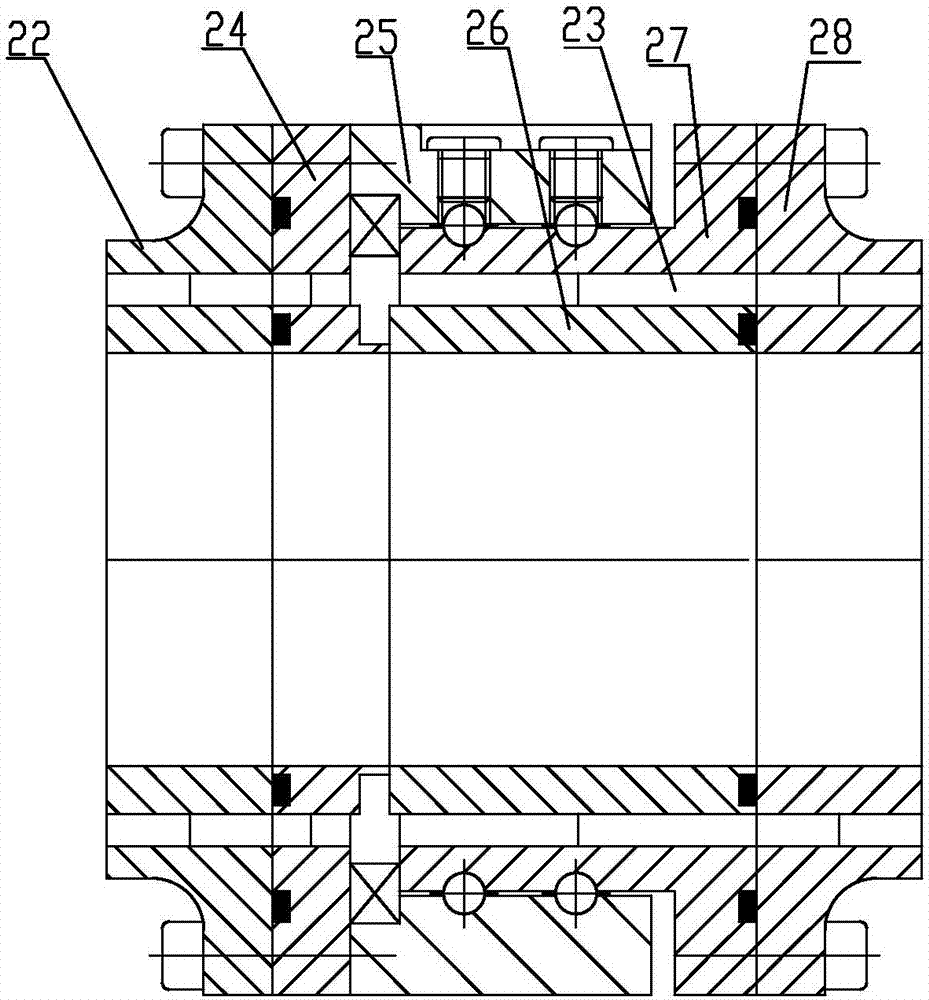

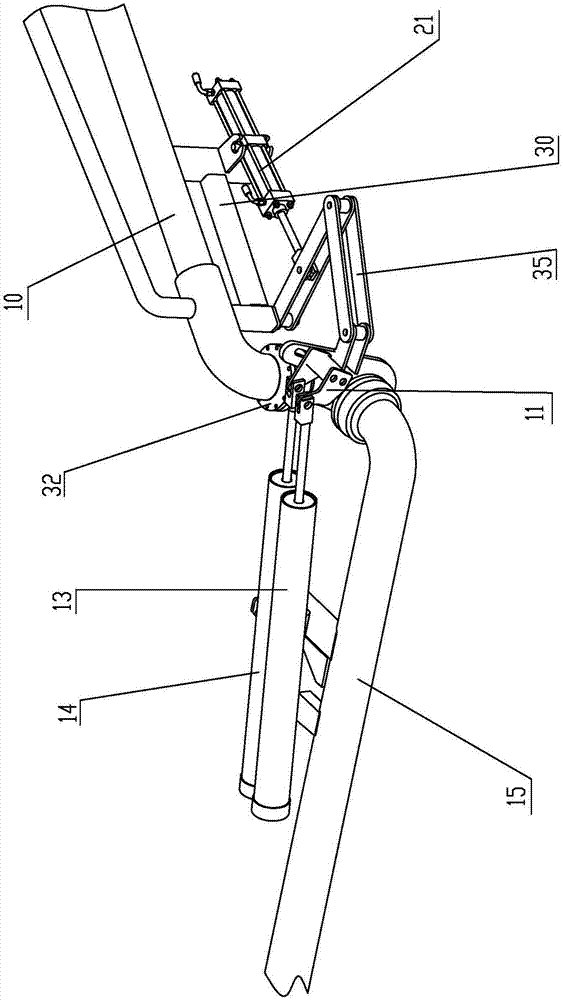

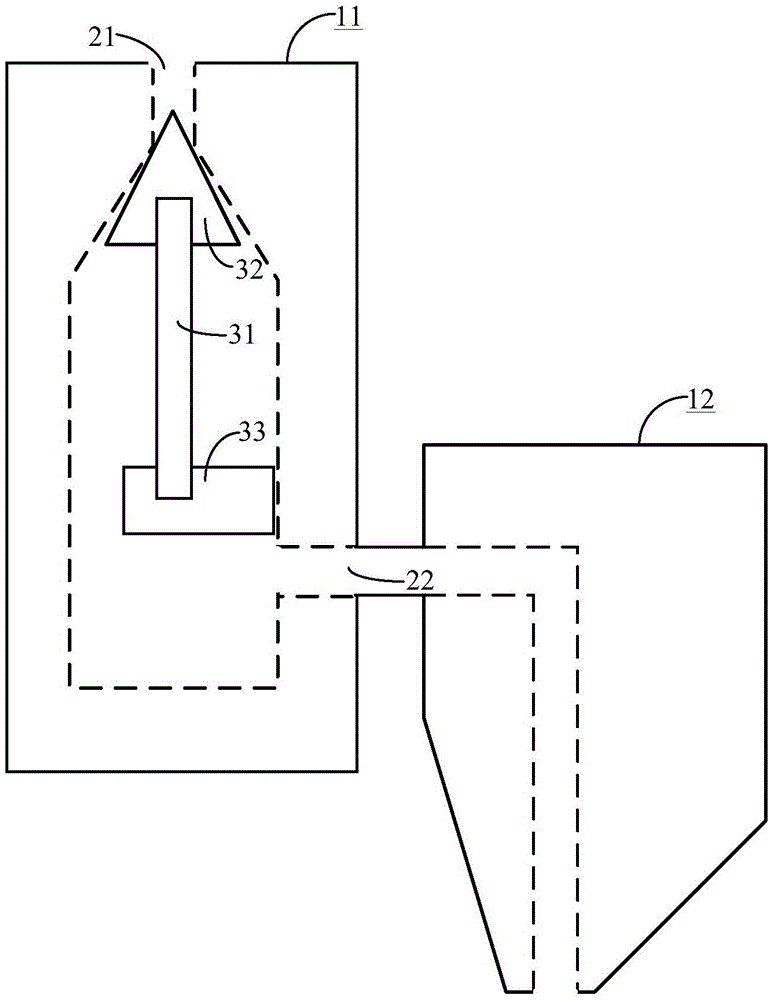

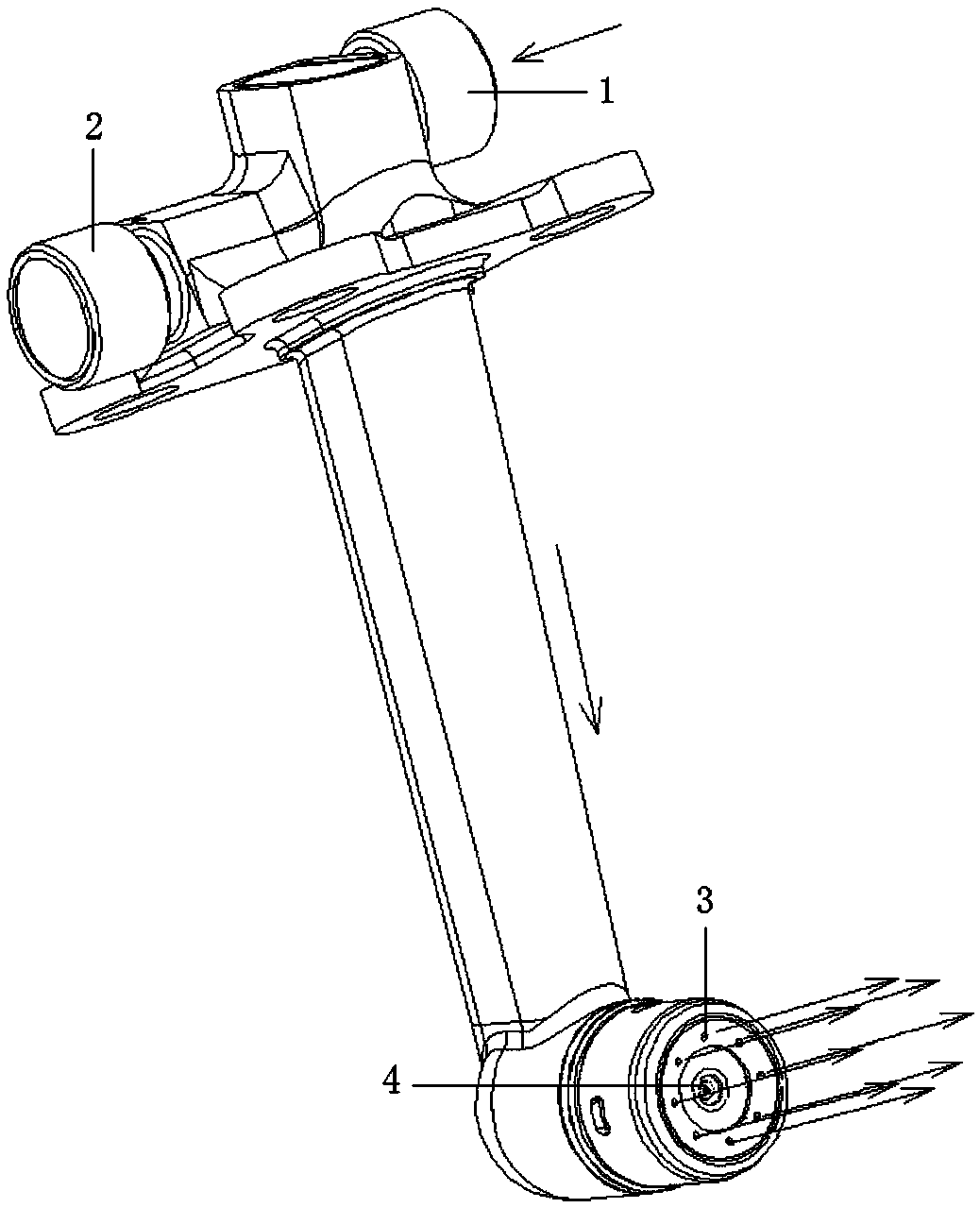

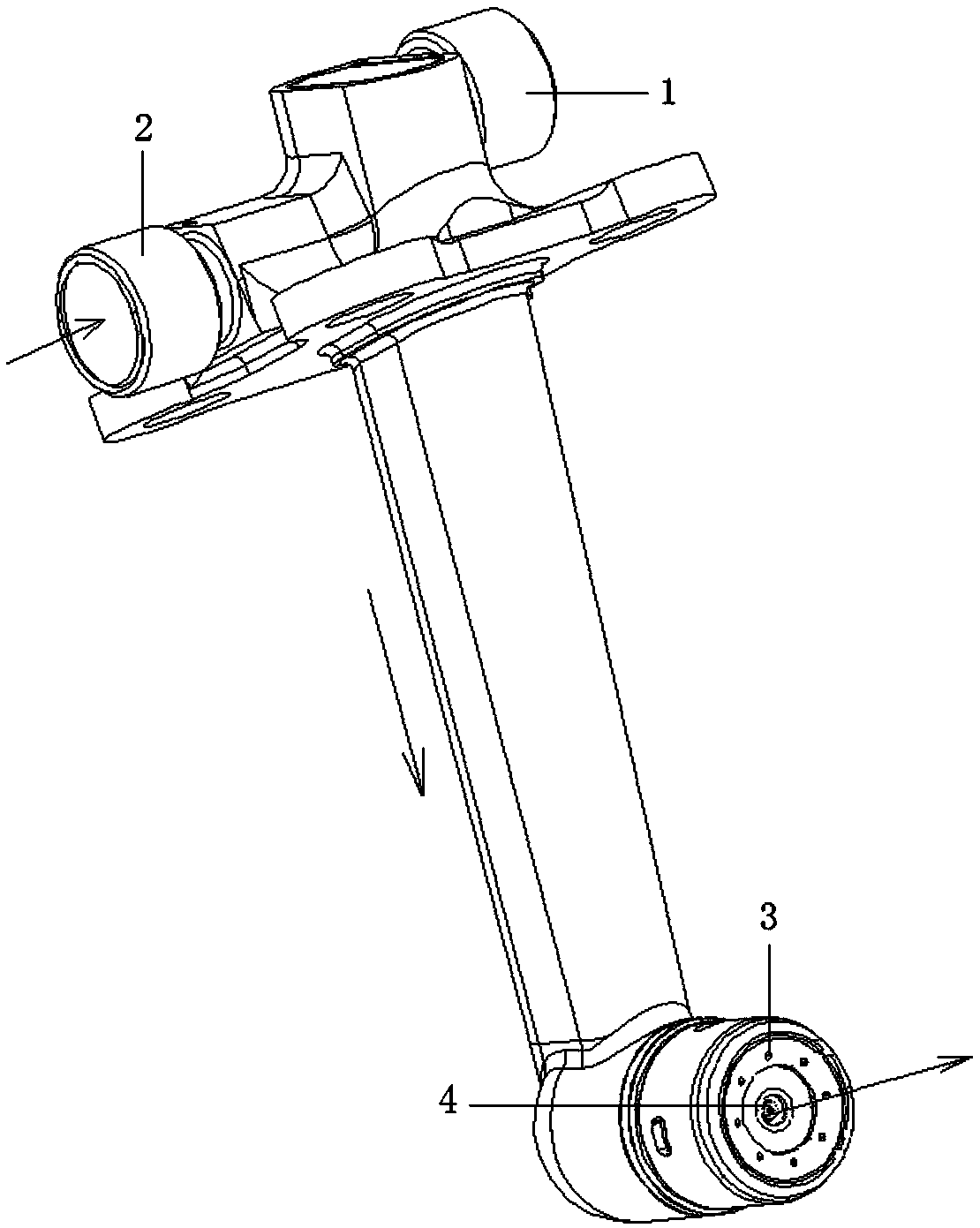

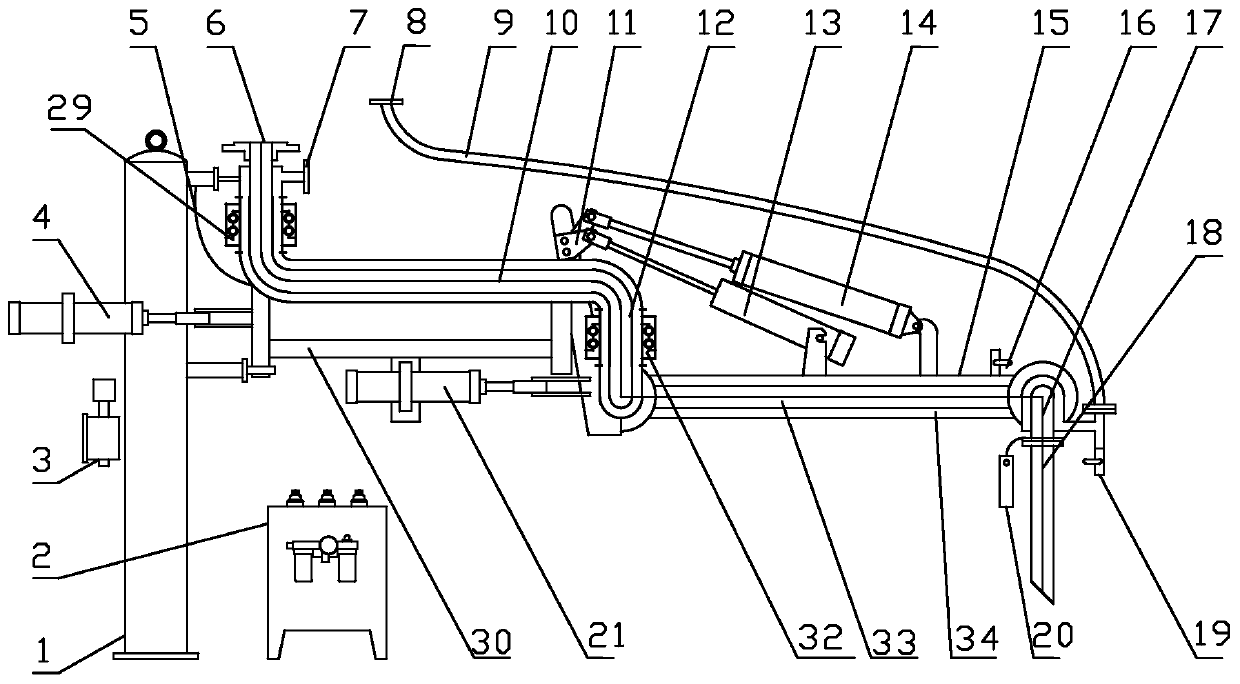

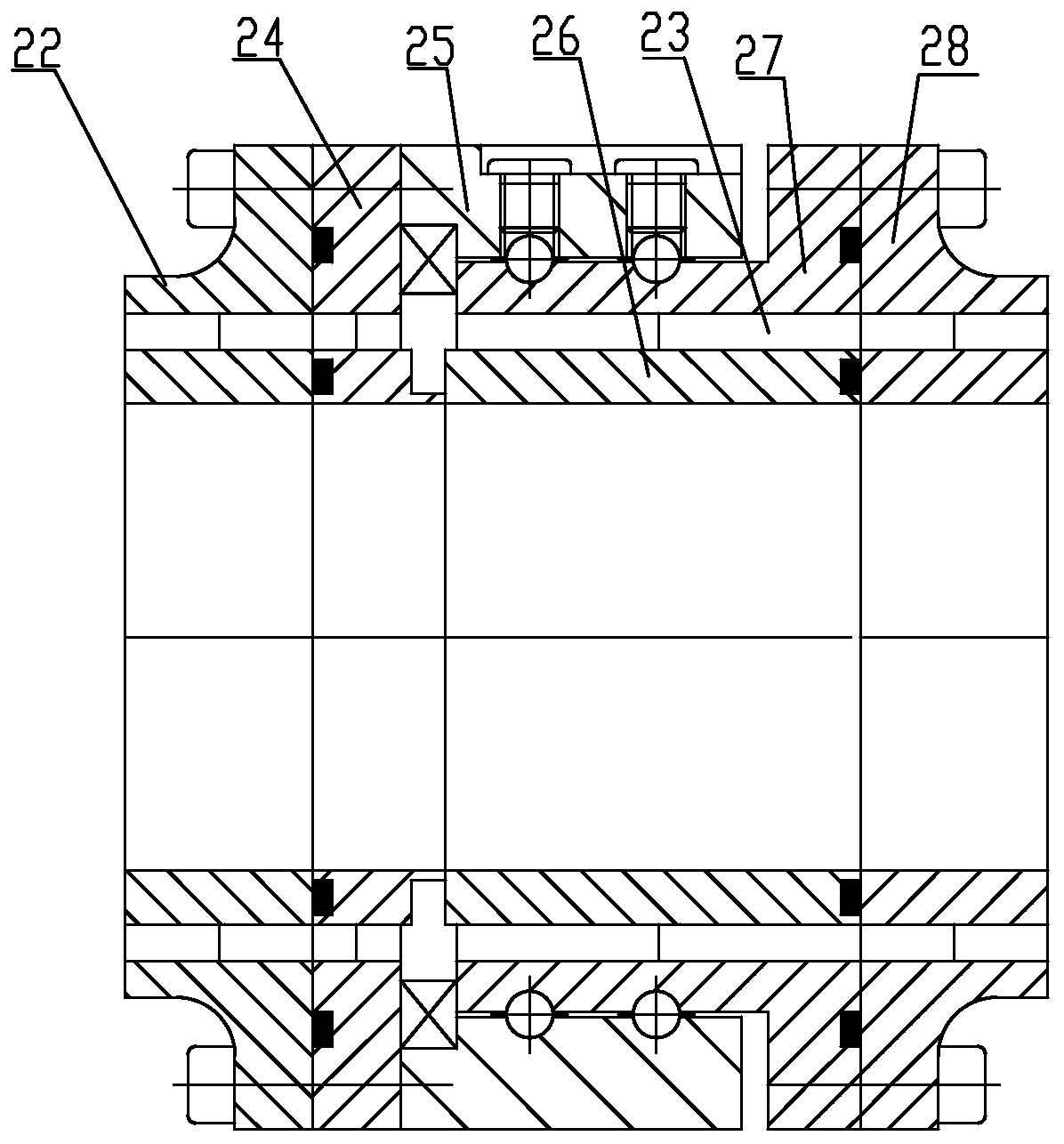

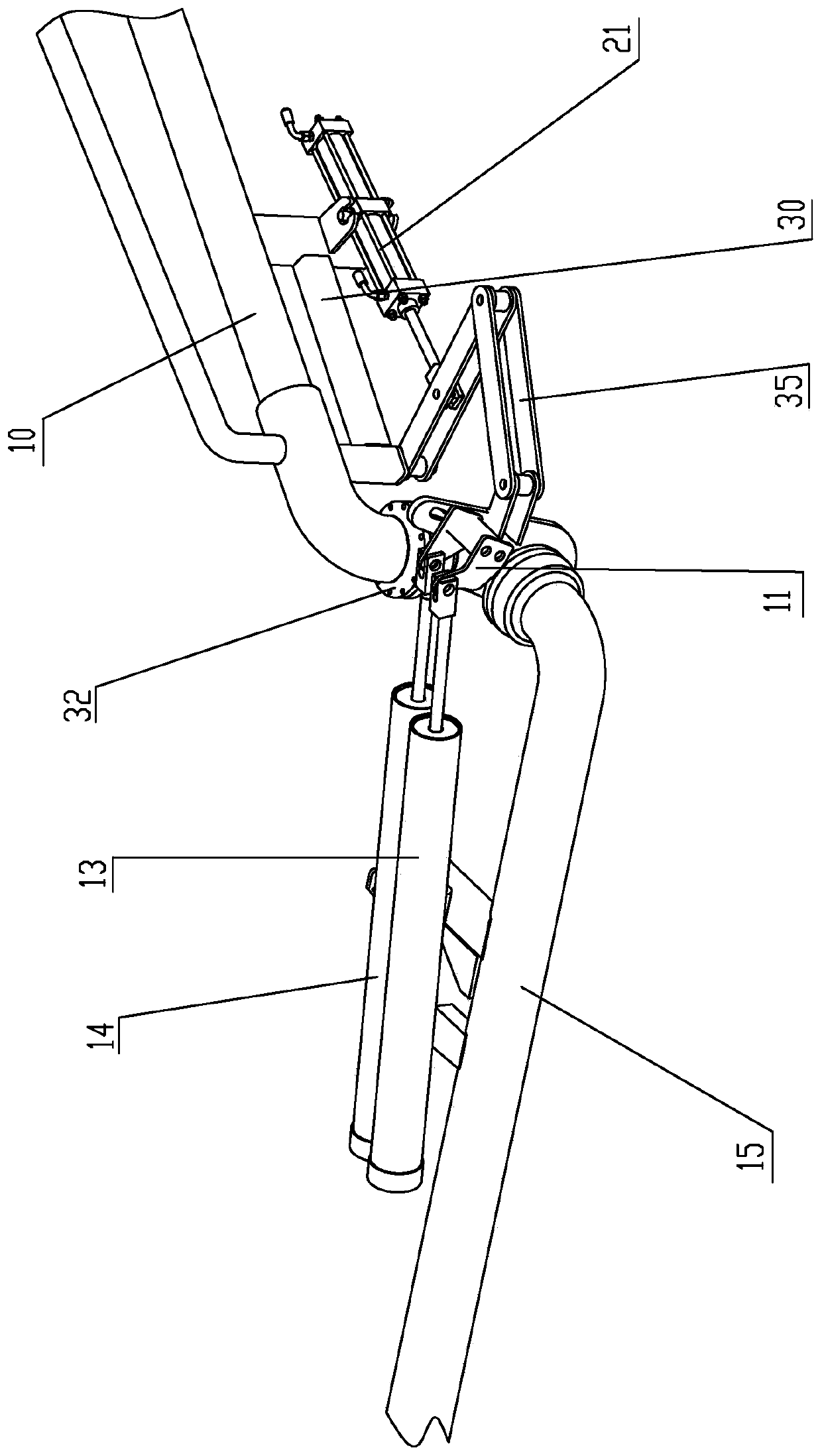

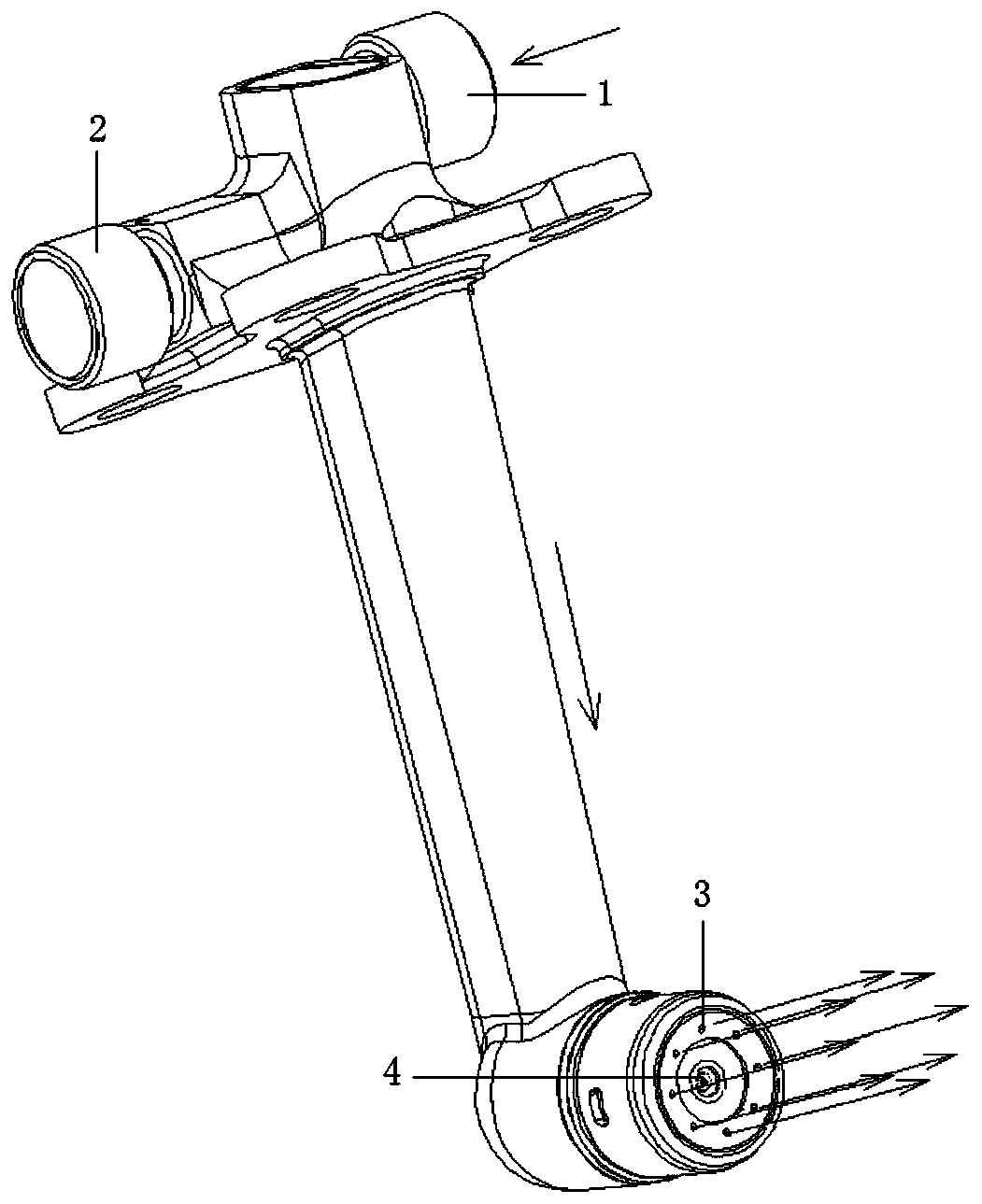

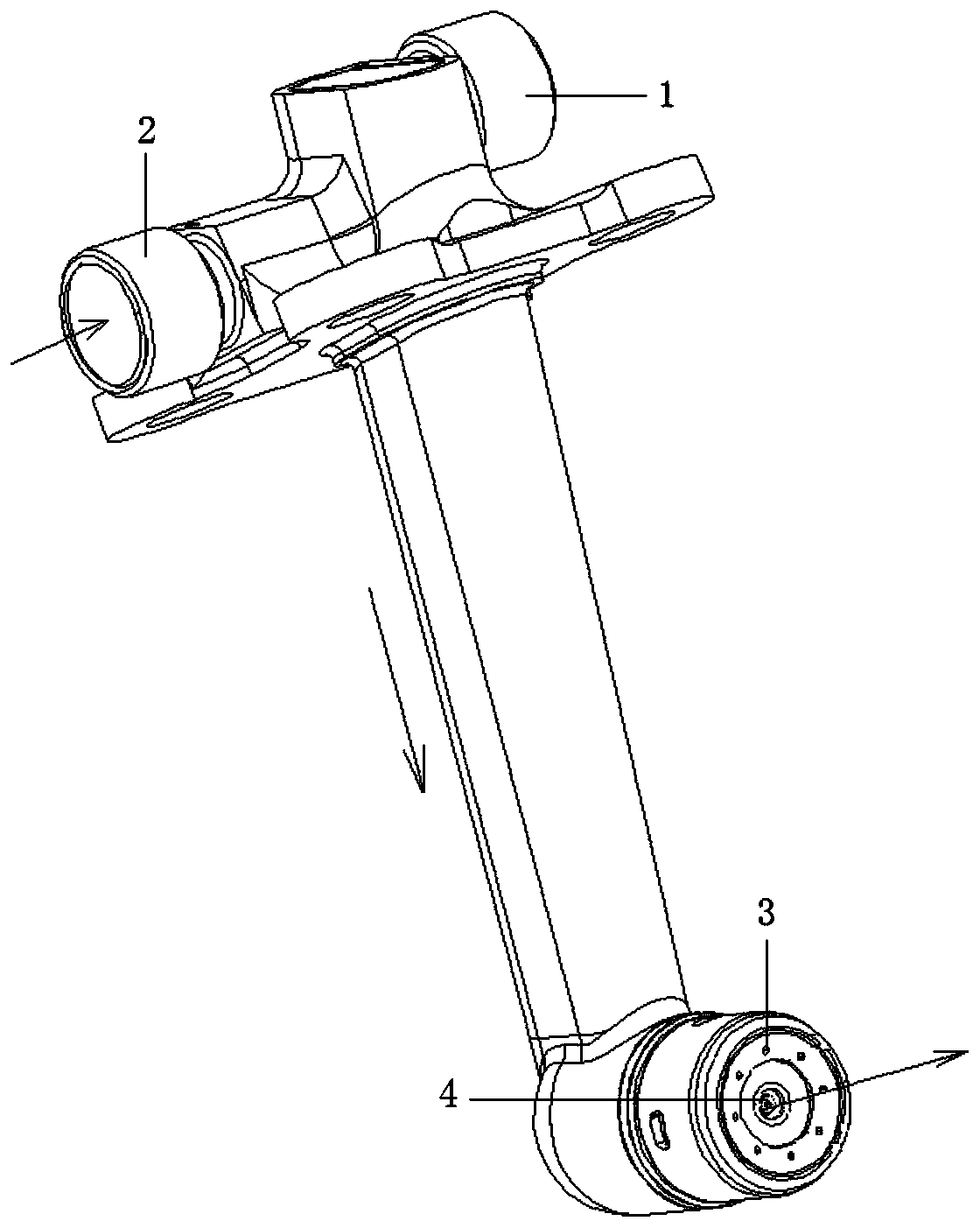

Full-automatic liquid loading crane pipe and application thereof

ActiveCN106966353AEnsure flow stabilityRealize automatic deliveryLiquid transferring devicesEngineeringMechanical engineering

The invention provides a full-automatic liquid loading crane pipe and application thereof, and belongs to the field of liquid conveying equipment. The full-automatic liquid loading crane pipe is uniform in heat tracing, automatic to control, accurate to adjust, safe, reliable, simple and convenient to operate. The full-automatic liquid loading crane pipe comprises a conveying crane pipe, and a heat tracing sleeve which sleeves the conveying crane pipe, wherein a steam hose communicates with the heat tracing sleeve; the conveying crane pipe comprises an inner arm, an outer arm and a vertical arm which are sequentially connected; an elbow assembly is connected between the outer arm and the inner arm; a first driving part and a first transmission rack are connected to the inner arm; the first driving part is connected with the first transmission rack, and the first transmission rack is connected with a second driving part; an angle adjusting rack which is connected to the elbow assembly is connected with the second driving part; a balancing driving part and an adjusting driving part which are connected to the outer arm are connected to the angle adjusting rack; sleeve type rotating joints are connected to the inner arm and the elbow assembly.

Owner:BEIJING MOUNTAIN IND

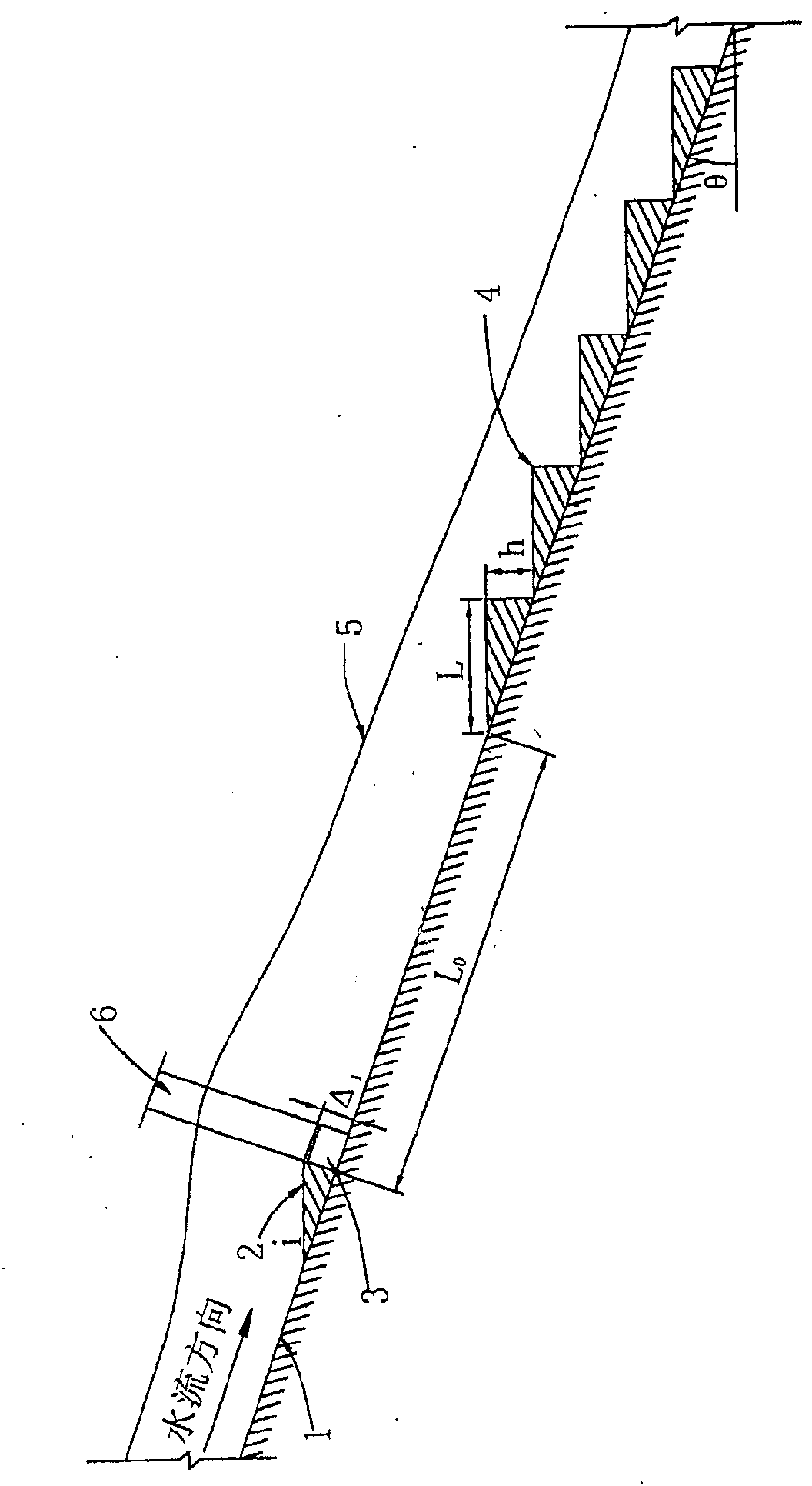

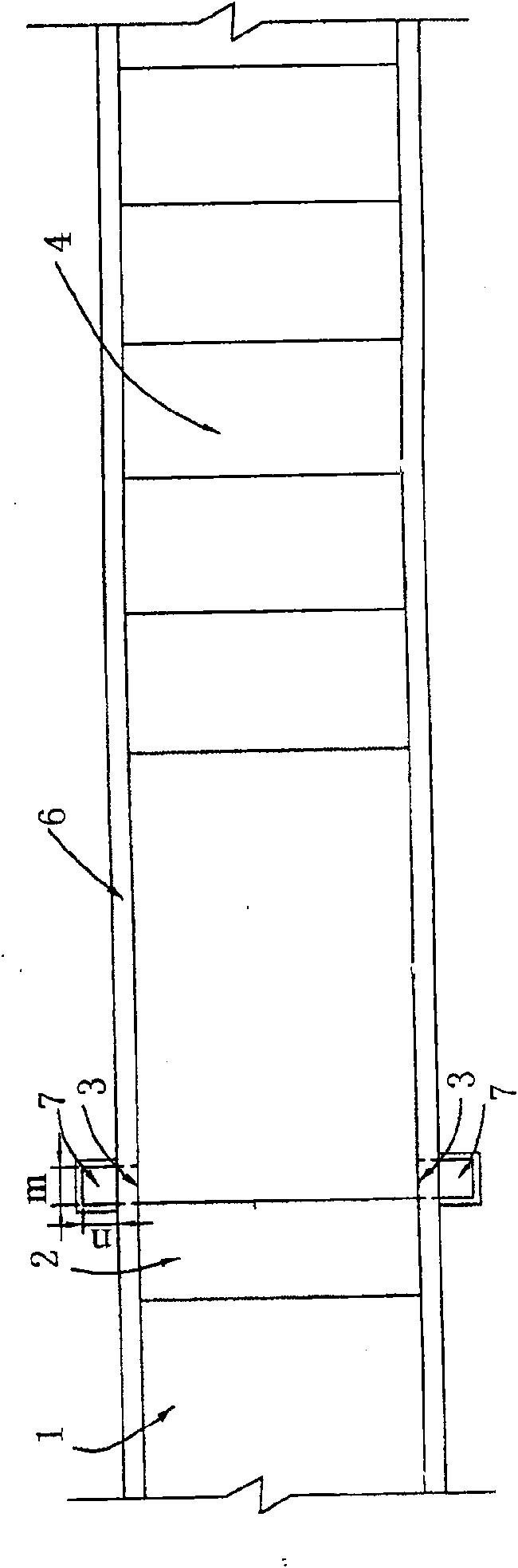

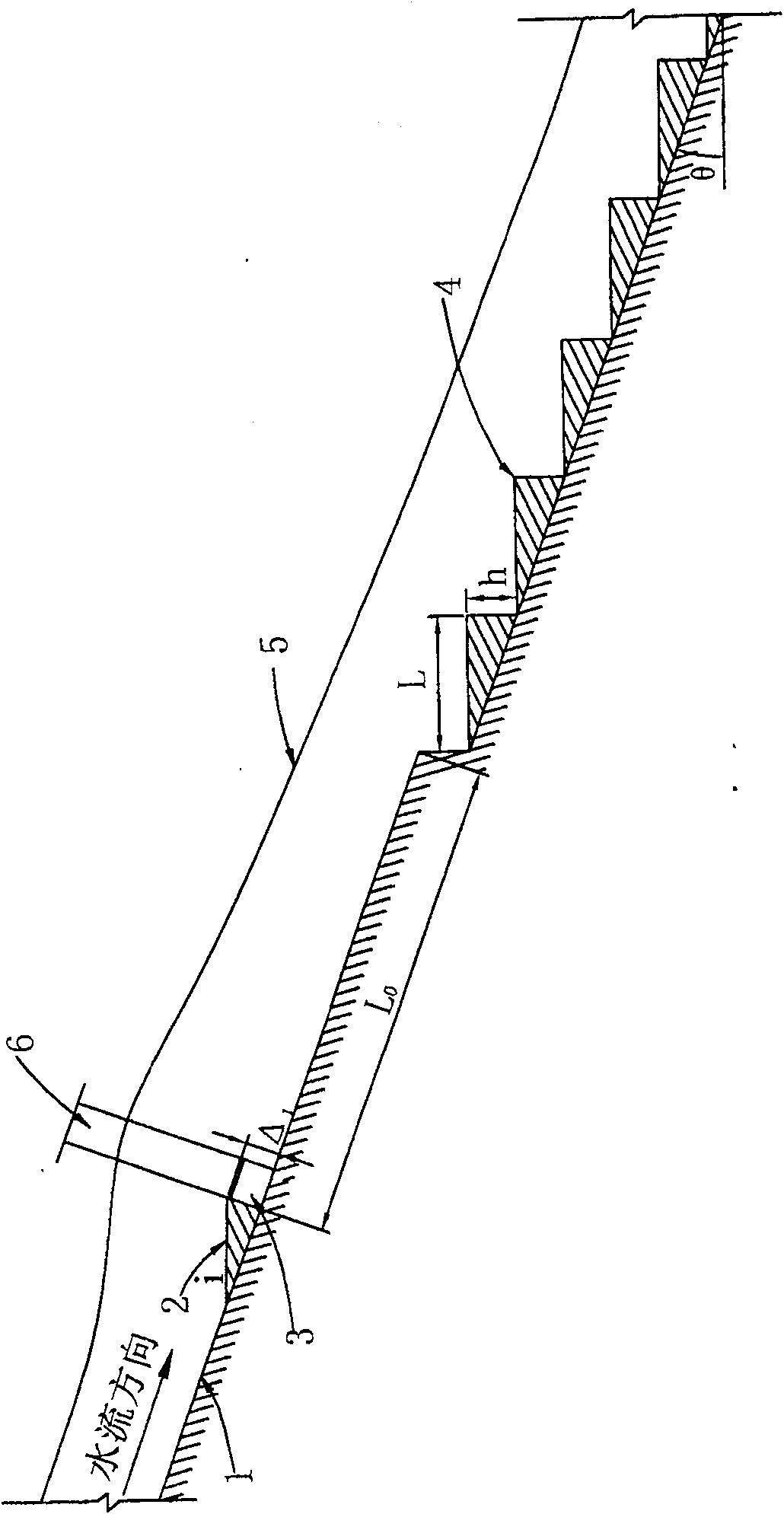

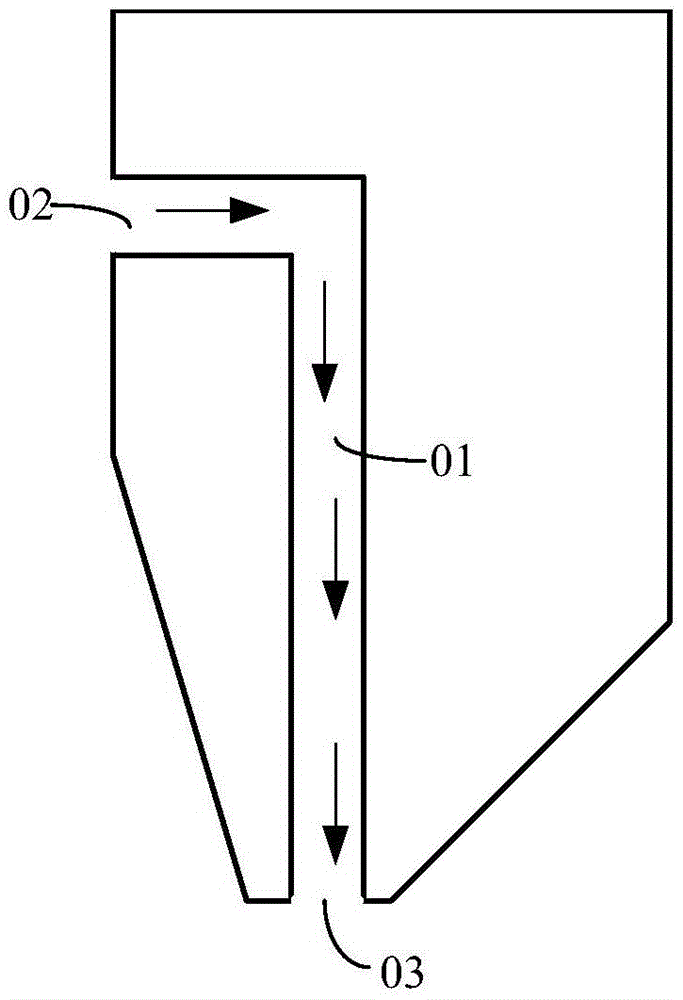

Ladder energy dissipater with doped gas device preposed

InactiveCN100554593CImprove energy dissipation rateMitigate or avoid potential for cavitation damageBarrages/weirsEffective solutionCavitation

A stepped energy dissipator of a pre-aeration device comprises a step arranged on a bottom slope and an aeration device located upstream of the step. The aeration device has four structural forms, the first structural form is composed of a ridge, air holes and air wells, the second structural form is composed of a ridge, aeration grooves, air holes and air wells, and the third The structural form is composed of lifting ridges, falling ridges, air holes and air wells, and the fourth structural form is composed of lifting ridges, falling ridges, aeration grooves, air holes and air wells. This kind of energy dissipator can not only increase the energy dissipation rate of the steps, but also reduce or avoid the possibility of cavitation damage of the steps, and effectively solve the problem of increasing the energy dissipation rate and improving the cavitation resistance when the overflow of the spillway or the dam surface is operated at a large single-width flow rate. There are contradictory problems between erosion and damage.

Owner:SICHUAN UNIV

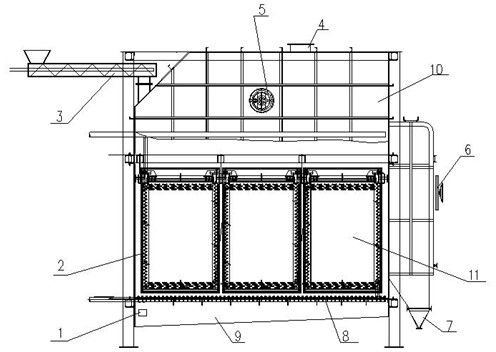

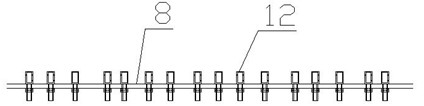

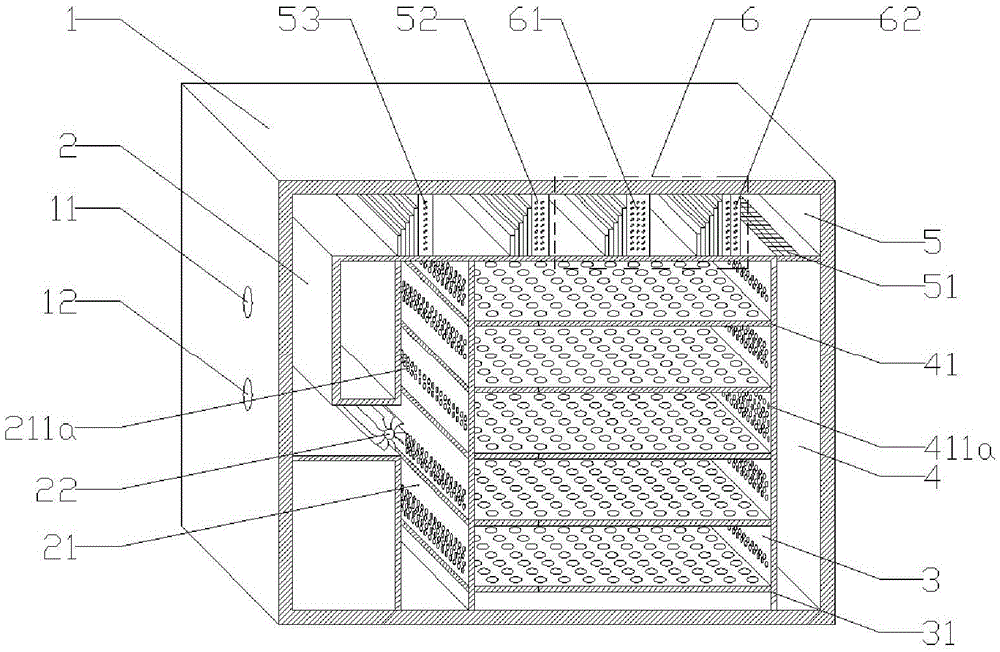

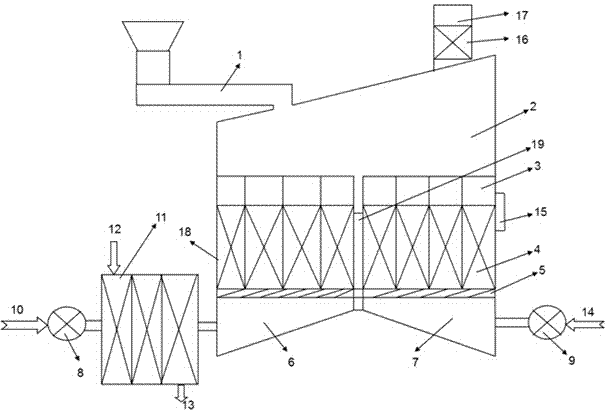

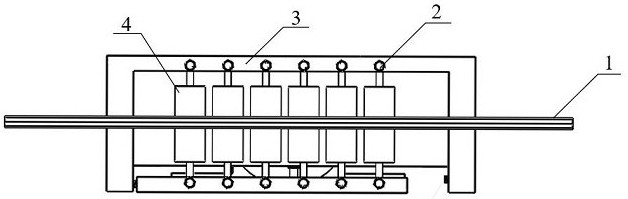

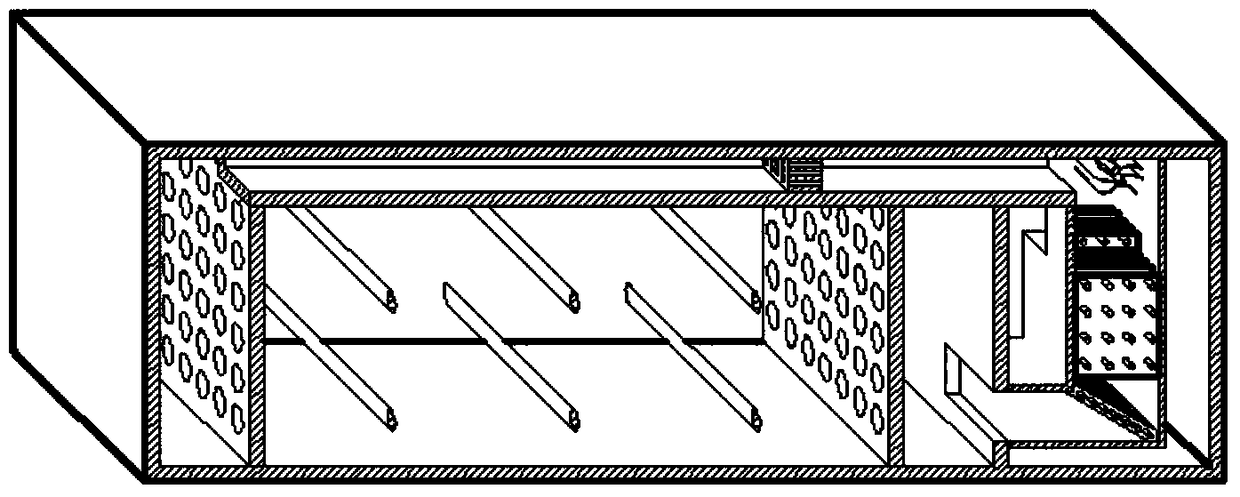

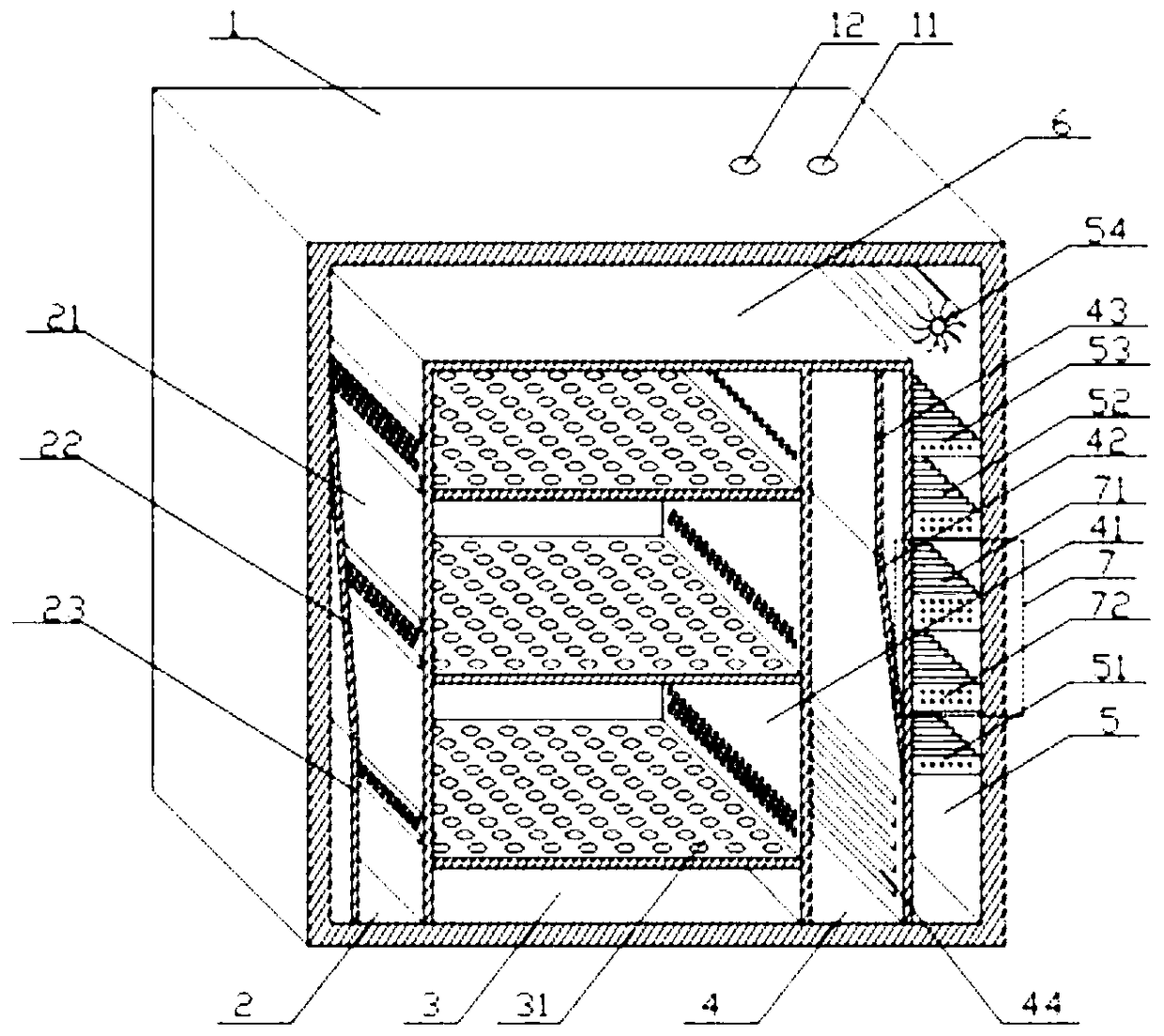

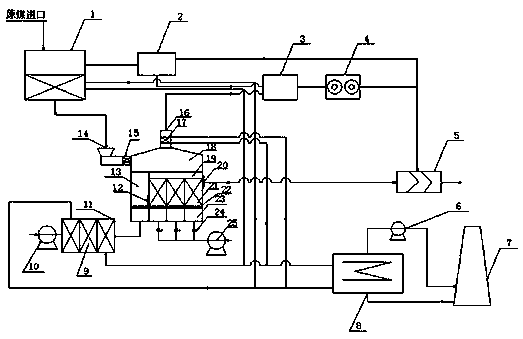

Internal heating type dryer for in-furnace coking coal dehumidification

InactiveCN102533302AImprove heat transfer efficiencyExpand the adjustment rangeDrying solid materials with heatCoke ovensFluidized bed dryingComputer module

The invention discloses an internal heating type dryer for in-furnace coking coal dehumidification, which comprises a dryer outer frame, a drying area on the upper portion in the dryer outer frame, a fluidized bed drying heating area under the drying area and an air distribution area on the lower portion in the dryer outer frame. The drying area is provided with an exhaust space (10) and a heat exchange face, a coil heat exchanger (11) is arranged in the fluidized bed drying heating area, a fluidized air chamber (9), an air distribution plate (8) and a hood (12) are arranged in the air distribution area, and the air distribution plate (8) and the hood (12) form a module structure connected with the fluidized air chamber (9). The internal heating type dryer is simple in structure, good in exchangeability, convenient to overhaul, reliable in operation and reliable and flexible in dehumidification control adjustment, saves energy, is simple in system adjustment and responses quickly to heat adjustment of the heat exchanger. A large drying system can be formed by a plurality of dryers according to the production requirement, and only one backup module is needed to ensure normal production of a humidifying system, so that scale of spare equipment of the existing humidifying system is reduced.

Owner:WUXI YIEN TECH

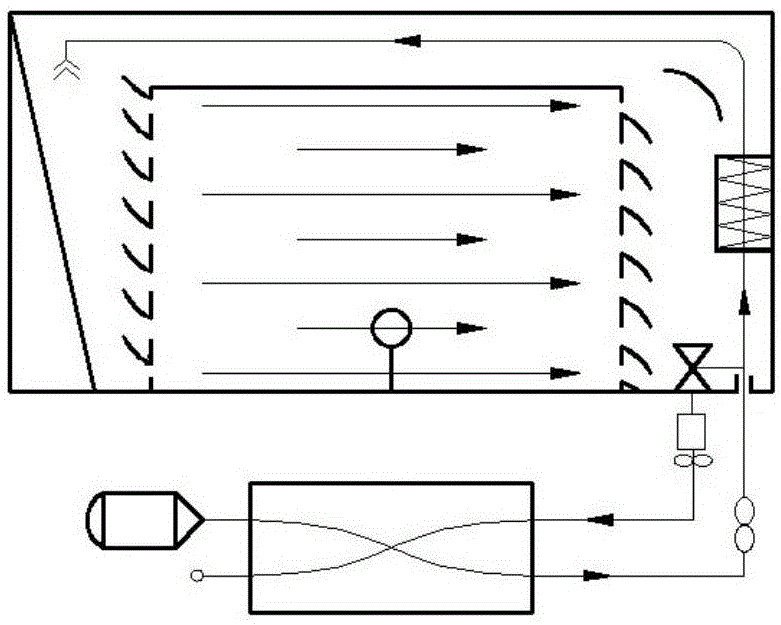

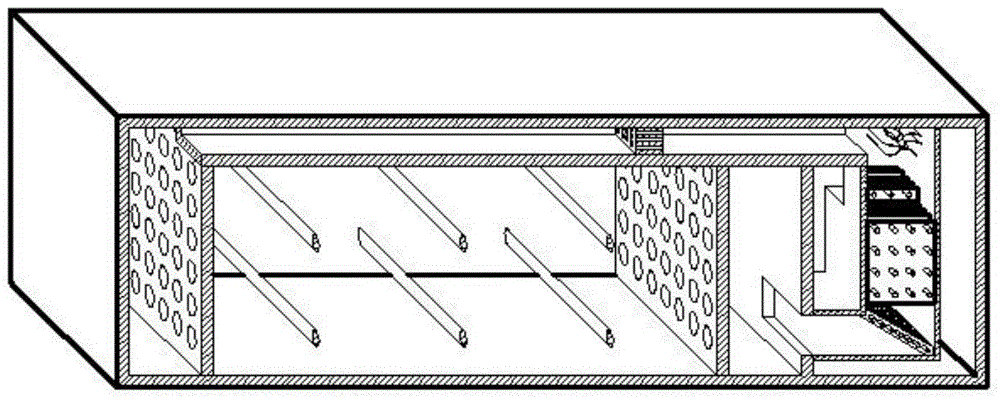

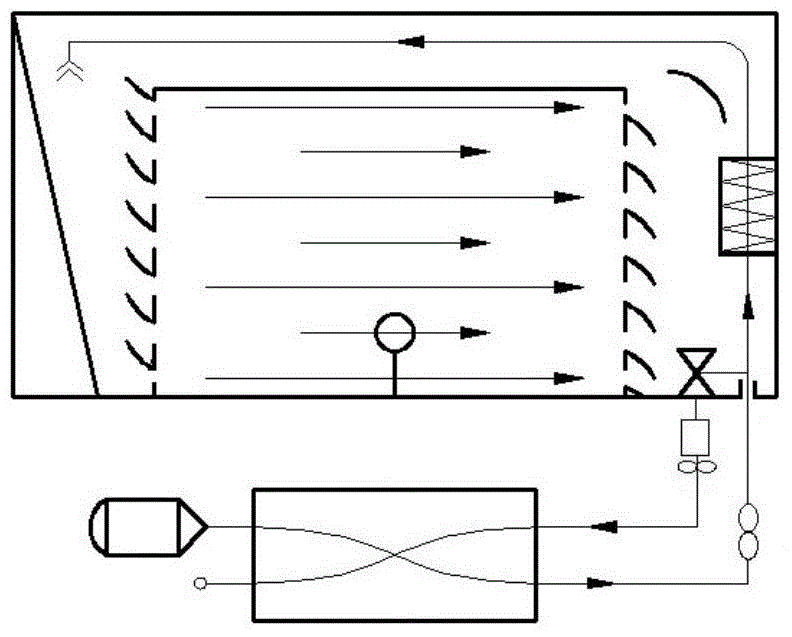

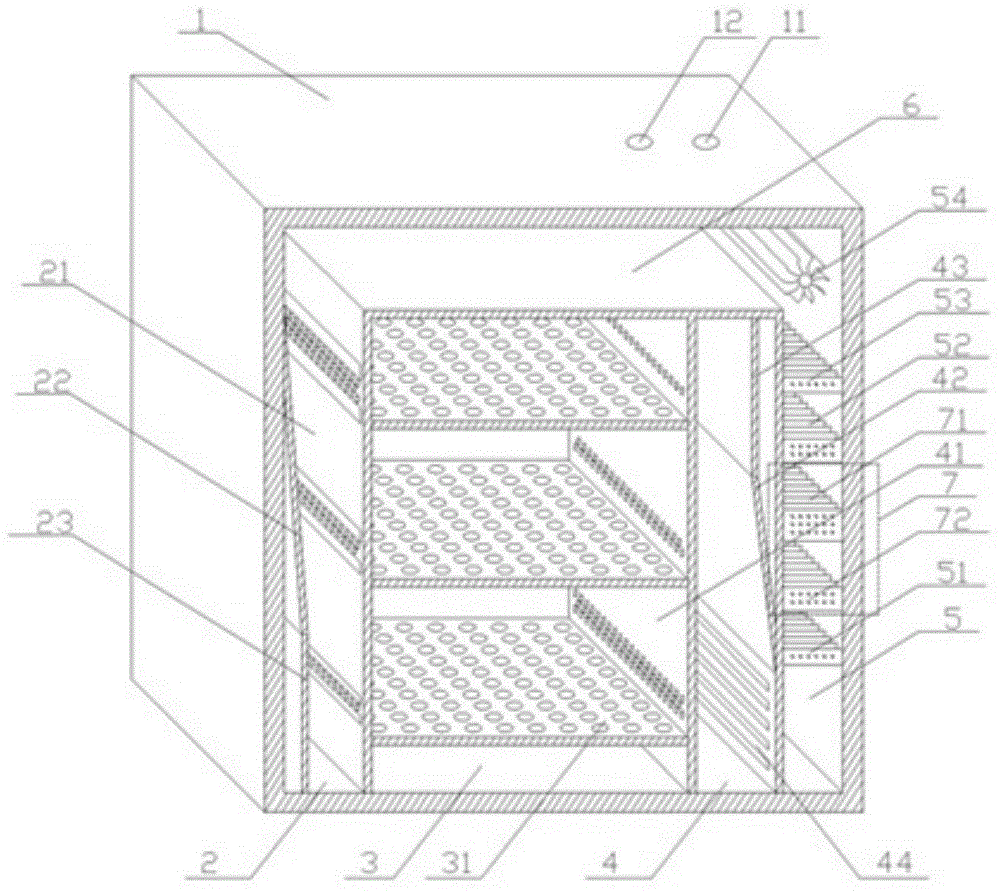

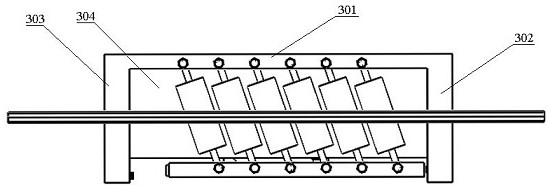

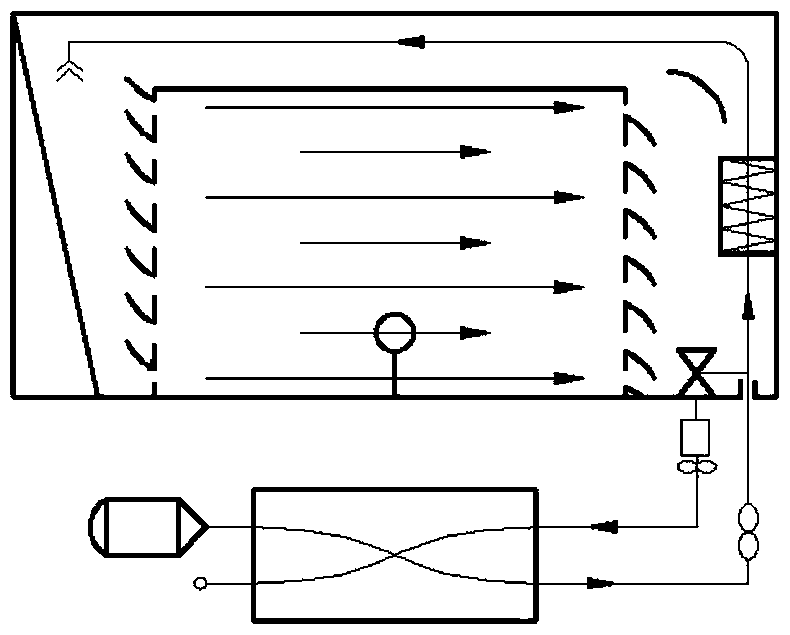

Middle air supply type cyclic edible fungi drying device

ActiveCN105043074AReduce energy consumptionIncrease profitDrying gas arrangementsFruits/vegetable preservation by dehydrationEnergy consumptionWaste management

The invention discloses a middle air supply type cyclic edible fungi drying device which comprises an enclosure structure, a drying region, an air processing device and a main air supply pipe arranged on the left side of the enclosure structure. Vertically-arranged air supply non-uniform pore plates and air return non-uniform pore plates divide the space under the air processing device into the main air supply pipe, the drying region and a main air return pipe in the air flow direction, and the air processing device is communicated with the drying region through the main air supply pipe. A group of air supply holes and a group of air return holes are formed in the left side and the right side of each layer of arrangement plates arranged in the drying region. The middle air supply type cyclic edible fungi drying device improves drying air flow distribution through drying-face middle air supply, ensures that air flows at the drying-face position are uniform and stable, drying efficiency is improved, and energy consumption is reduced.

Owner:NANJING NORMAL UNIVERSITY +1

Spark plug with stream shaper to shape tumble vortex into desired stream in combustion chamber

InactiveUS7768184B2Improve flammabilityEnsure flow stabilitySparking plugsCombustion chamberInternal combustion engine

A spark plug for an internal combustion engine is provided which includes a hollow cylindrical metal shell with an open end portion to be exposed to a combustion chamber of the engine, a ground electrode joined to the metal shell, a center electrode disposed in the metal housing to define a spark gap between itself and the ground electrode. The spark plug also includes a stream shaper geometrically formed on an outer periphery of the open end portion of the metal shell to shape tumble vortexes of air-fuel mixture into vortex streams oriented toward a central portion of the combustion chamber. This ensures the stability of orientation of the tumble vortexes to control a flow of sparks, thereby enhancing the ignitability of the air-fuel mixture in the combustion chamber.

Owner:DENSO CORP +1

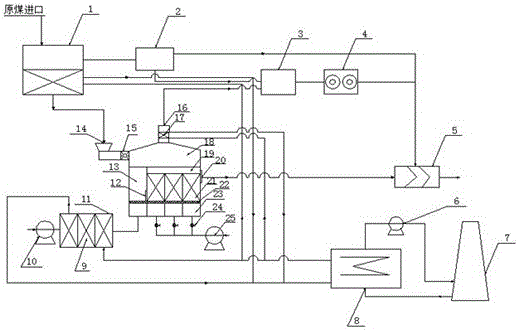

Device for high-humidity charging coking coal humidifying technology

ActiveCN104726121AIncreased load regulation rangeHigh and high humidity coal adaptabilityCoke ovensEnergy inputModular compositionAir preheater

The invention discloses a device for a high-humidity charging coking coal humidifying technology. The device comprises a fluidized bed damping machine, wherein a first fluidized bed type built-in heat humidifying module and a second fluidized bed type built-in heat humidifying module are arranged in the fluidized bed damping machine in parallel; an air preheater and a first fluidized blower are sequentially connected in series outside the first fluidized bed type built-in heat humidifying module to form a first process loop; a second fluidized blower is connected in series outside the second fluidized bed type built-in heat humidifying module form a second process loop; and the first process loop is connected with the second process loop through an adjustable overflow plate. By virtue of a frame structure, the air preheater and the fluidized bed damping machine are in modularized combination; the installation and repairing convenience of the process device is ensured; a plurality of modules can be freely combined into a large process device according to the production requirements; normal production of the humidifying system can be ensured only by reserving a backup module; and the scale of backup equipment for an existing humidifying system is reduced.

Owner:WUXI YIEN TECH

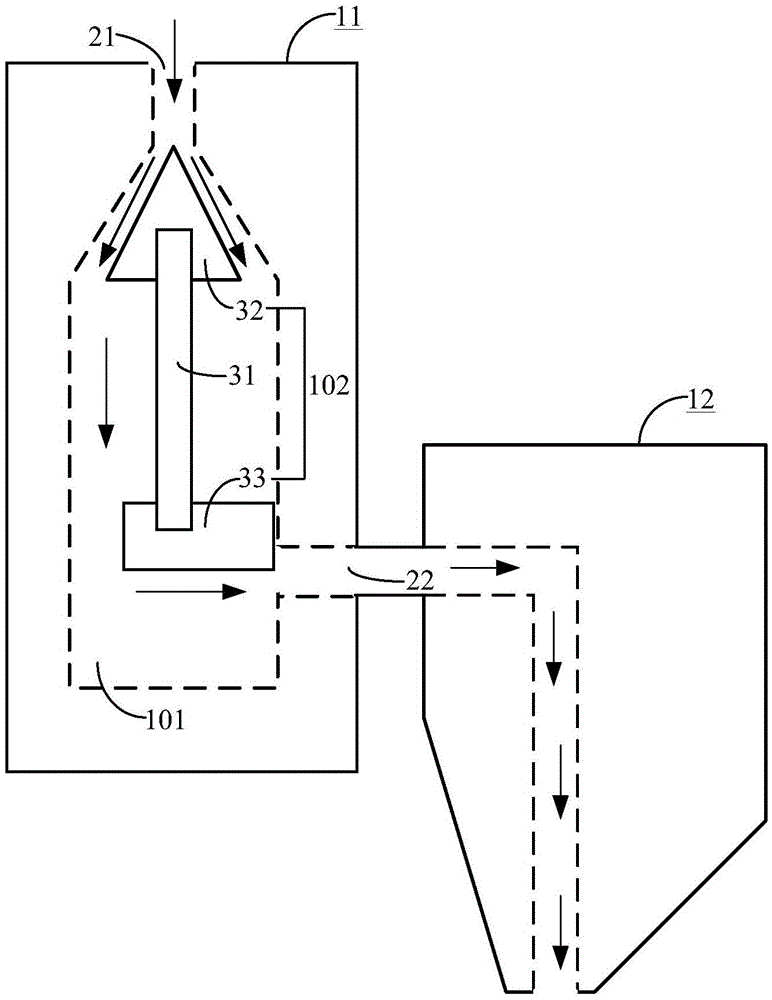

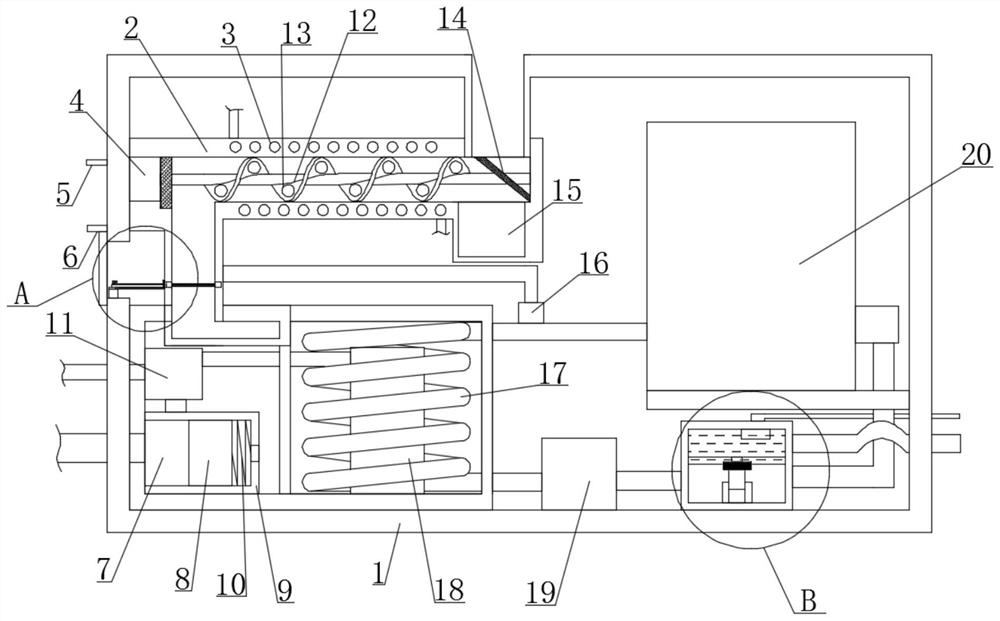

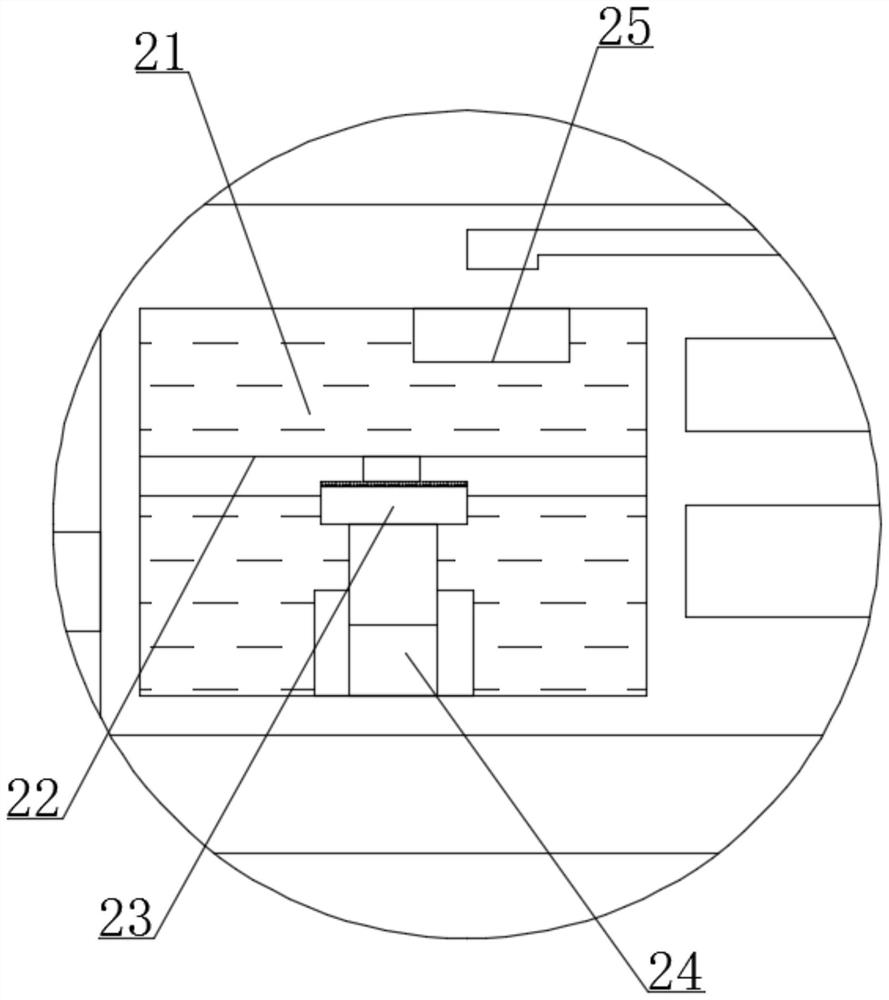

Air curtain device

ActiveCN105575859AEnsure flow stabilityDrying gas arrangementsSemiconductor/solid-state device manufacturingEngineeringAtmospheric pressure

An embodiment of the invention provides an air curtain device and relates to the technical field of display, and thus flow stability of airflow output by the air curtain device can be guaranteed, and yield rate of a prepared array substrate is improved. The air curtain device comprises a pressure limit module and an air curtain main body communicated with the pressure limit module. The pressure limit module is internally provided with a pressure limit cavity. An air inlet of the pressure limit cavity is communicated with the external world; a first air outlet of the pressure limit cavity is communicated with the air curtain main body; the pressure limit cavity is internally provided with an air pressure linkage mechanism; and the air pressure linkage mechanism can change the cross sectional area of the first air outlet with the change of the pressure in the pressure limit cavity to enable the pressure of the airflow output from the first air outlet to be within a preset range. The method can be applied to the manufacturing process of the thin-film transistor array substrate.

Owner:BOE TECH GRP CO LTD +1

Spark plug with stream shaper to shape tumble vortex into desired stream in combustion chamber

ActiveUS7893604B2Improve flammabilityEnsure flow stabilitySpark gapsFuel injection apparatusCombustion chamberEngineering

A spark plug for an internal combustion engine is provided which includes a hollow cylindrical metal shell with an open end portion to be exposed to a combustion chamber of the engine, a ground electrode joined to the metal shell, a center electrode disposed in the metal housing to define a spark gap between itself and the ground electrode. The spark plug also includes a stream shaper geometrically formed on an inner periphery of the open end portion of the metal shell to shape tumble vortexes of air-fuel mixture into vortex streams oriented toward a central portion of the combustion chamber. This ensures the stability of orientation of the tumble vortexes to control a flow of sparks, thereby enhancing the ignitability of the air-fuel mixture in the combustion chamber.

Owner:DENSO CORP +1

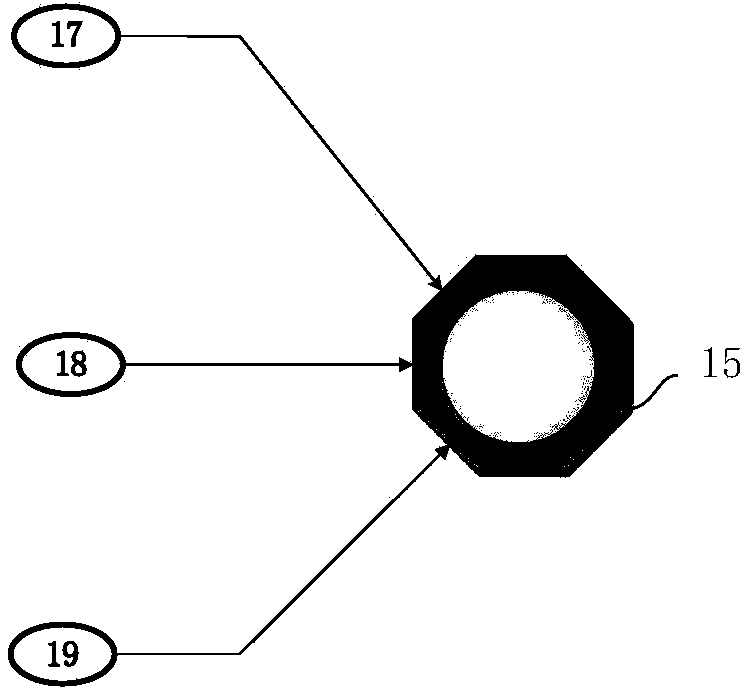

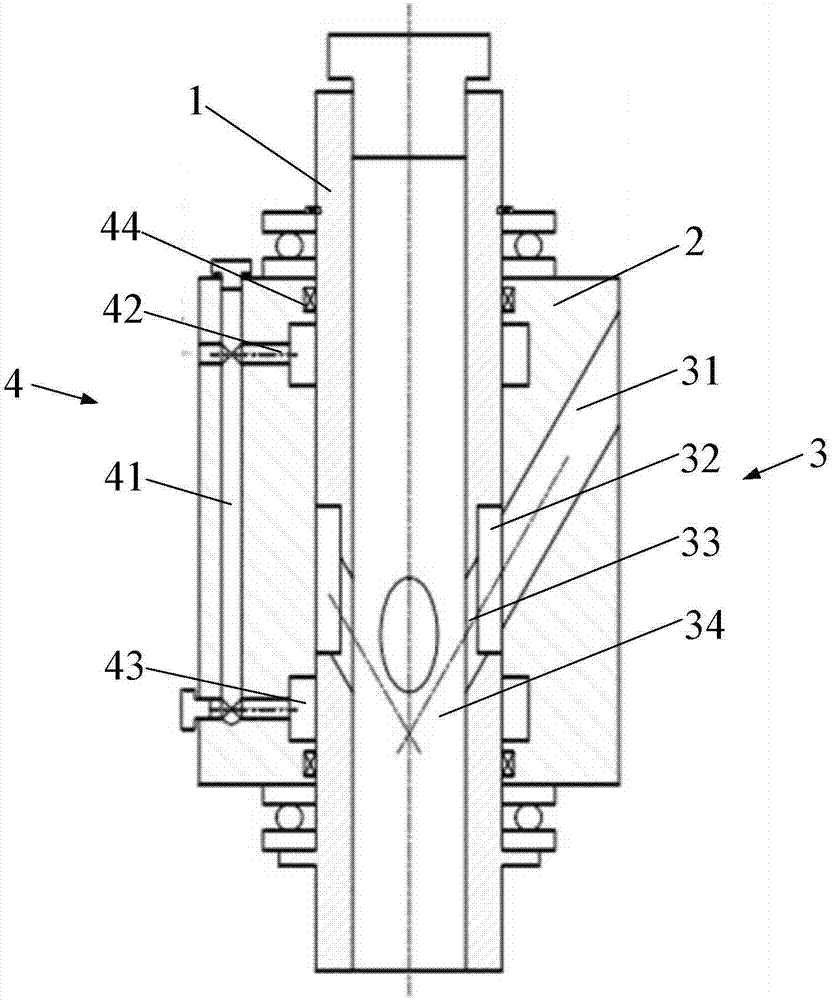

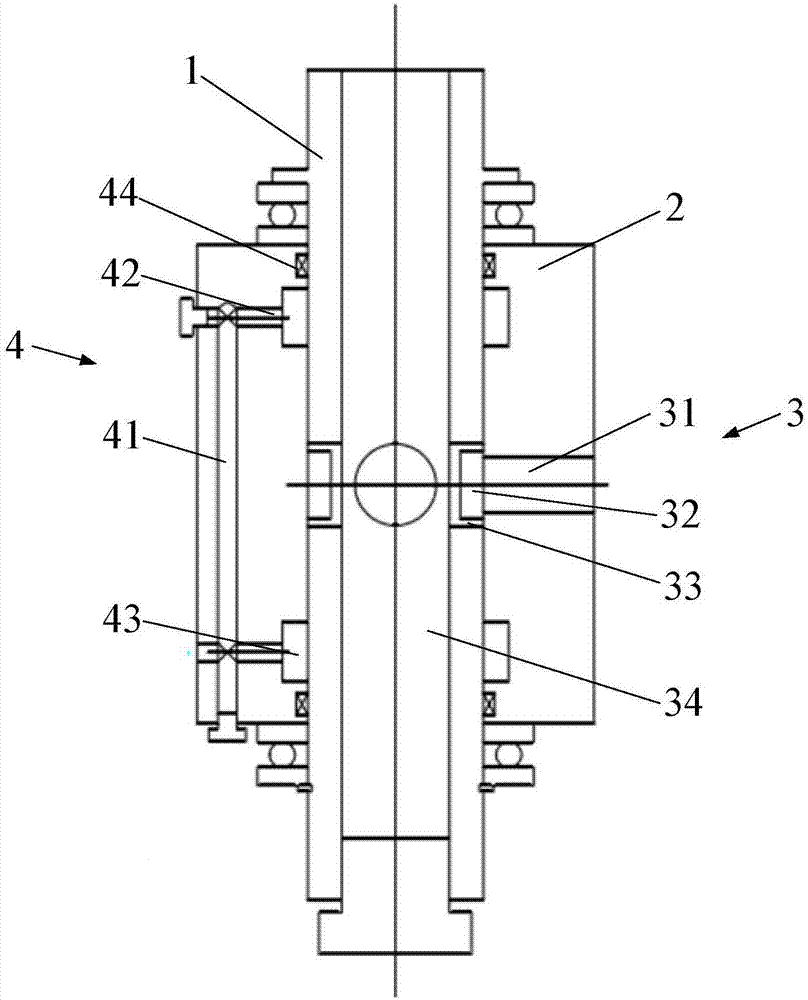

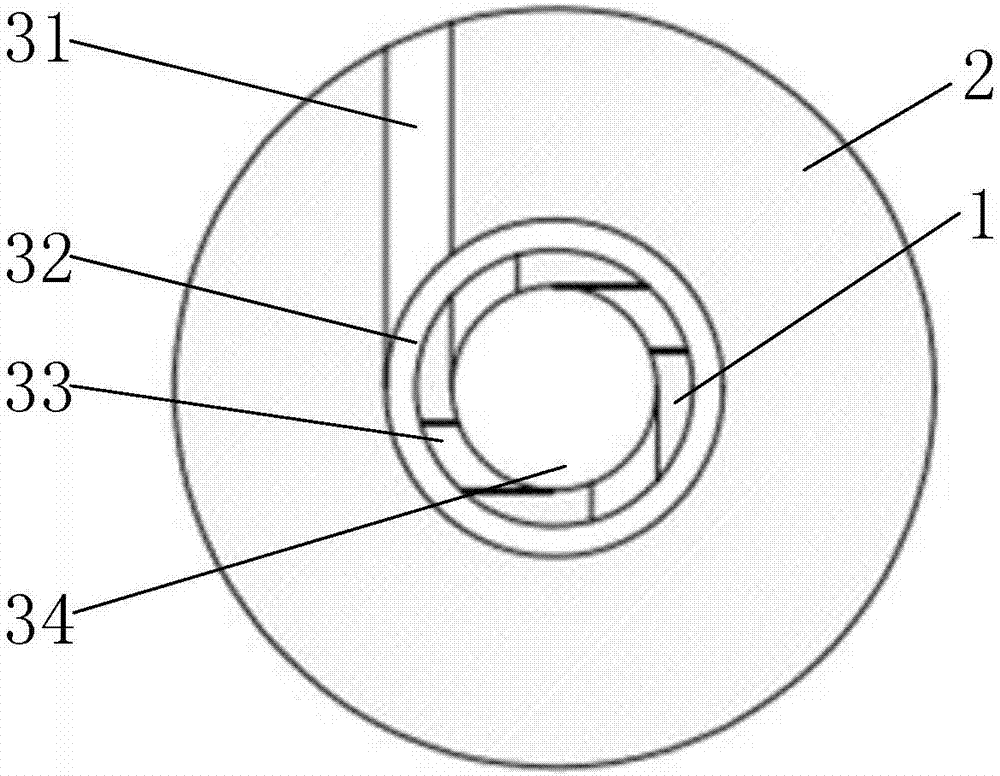

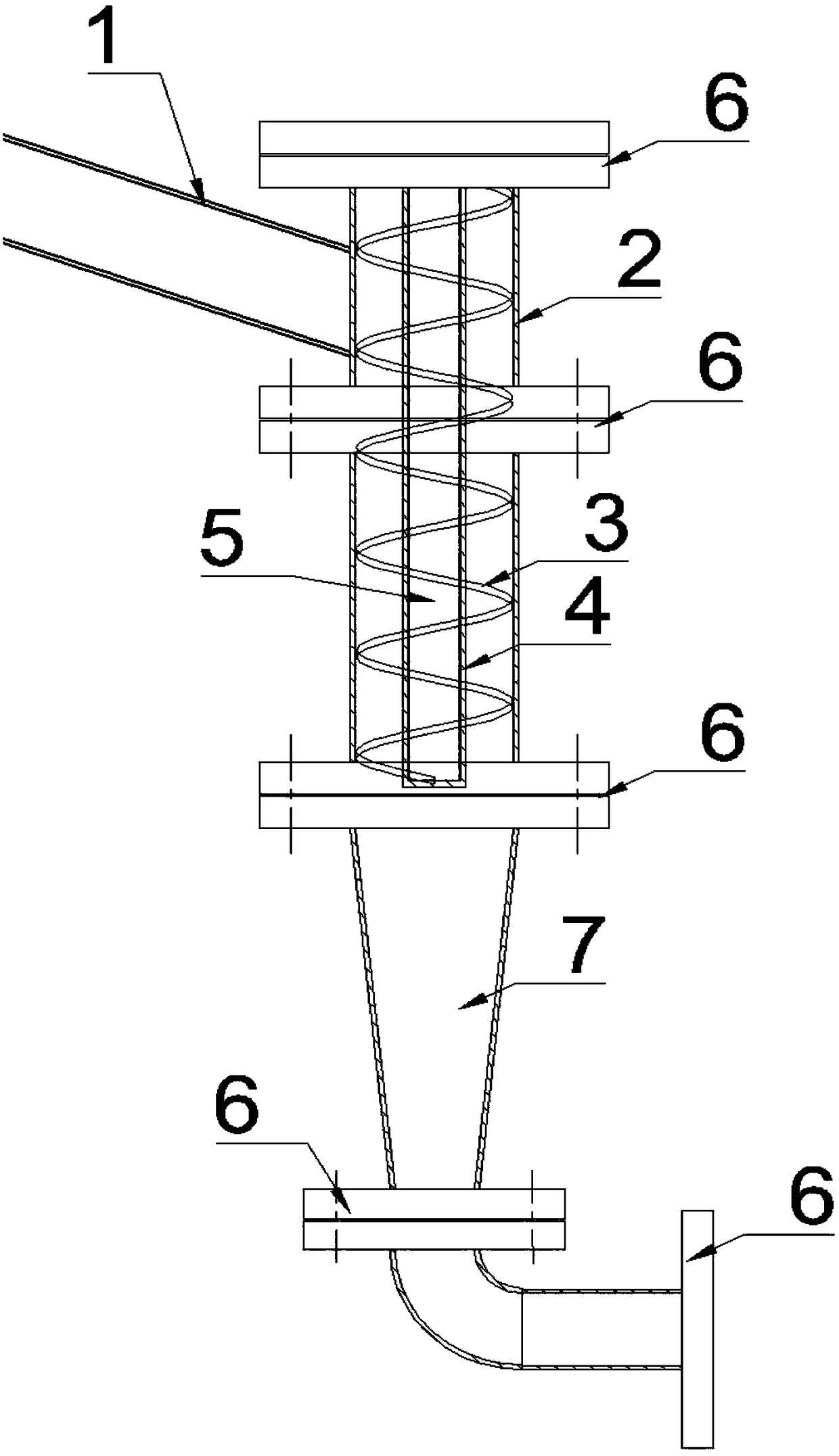

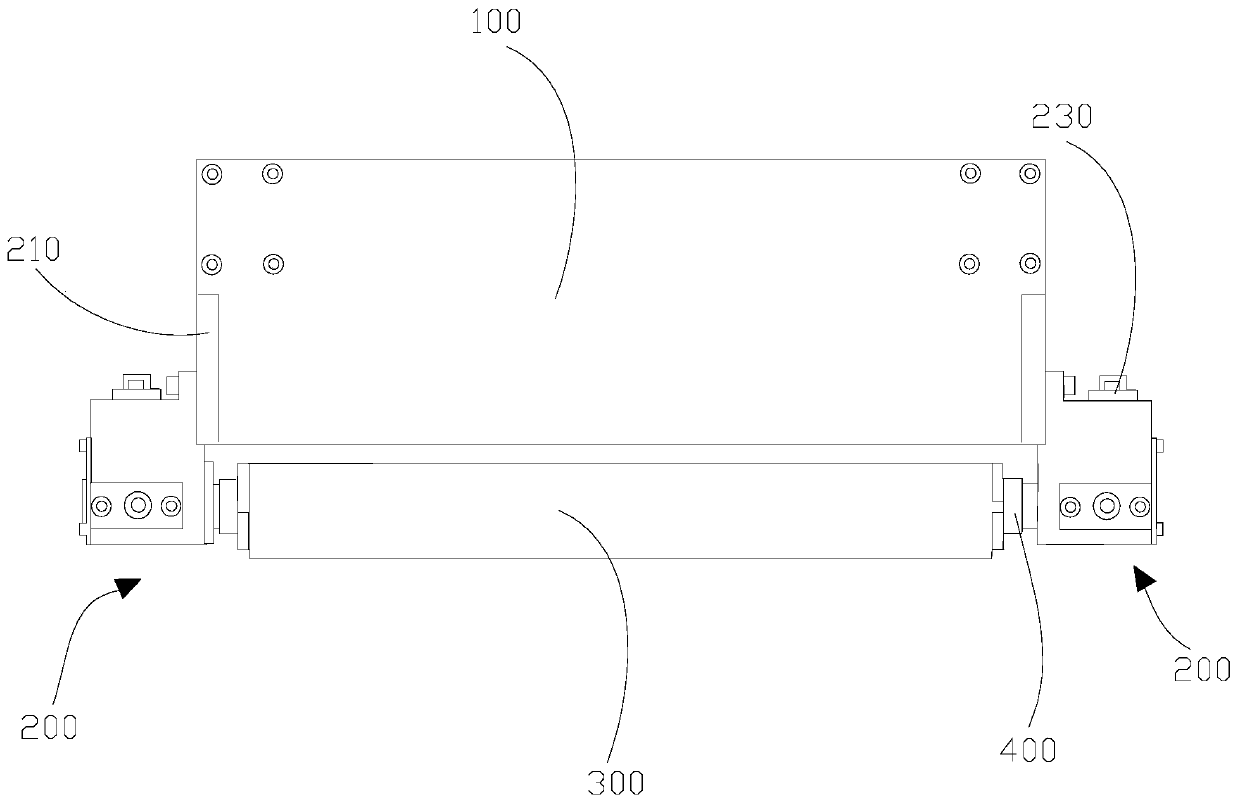

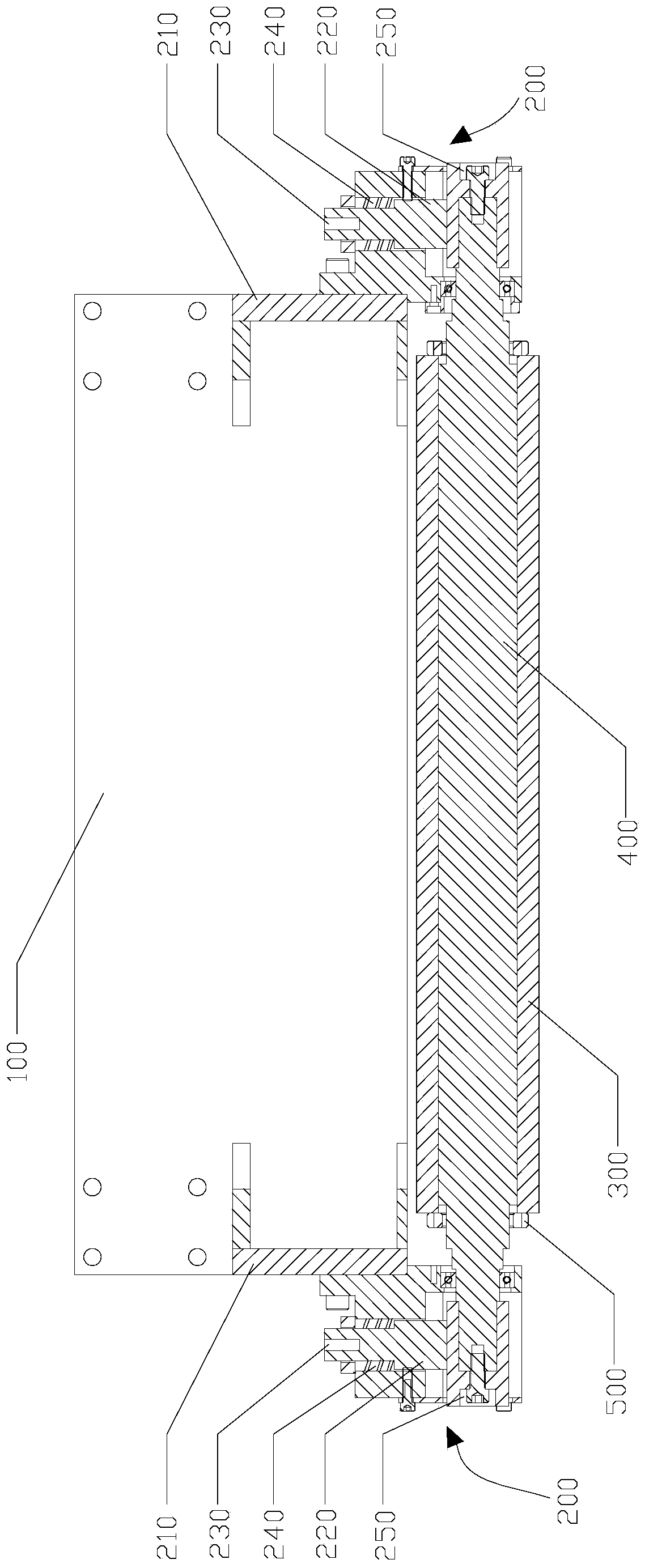

Rotating connector used for conveying two-phase flow containing solid abrasives

ActiveCN107283325AEnsure flow stabilityEnsure safetyGrinding/polishing apparatusMechanical engineeringRotational joint

The invention provides a rotating connector used for conveying a two-phase flow containing solid abrasives. The rotating connector used for conveying the two-phase flow containing the solid abrasives comprises an inner shaft, an outer sleeve arranged on the inner shaft in a sleeving manner, and a material conveying assembly arranged on the inner shaft and the outer sleeve in a penetrating manner; the outer sleeve is provided with a high pressure sealing assembly used for conveying high pressure fluid to a gap between the inner shaft and the outer sleeve; and the injecting pressure of the high pressure fluid is larger than the conveying pressure of the two-phase flow of the high pressure abrasives. The rotating connector used for conveying the two-phase flow containing the solid abrasives is especially used for the work condition of the two-phase flow containing abrasive particles, and has the beneficial effects that abrasion is small and flowing stability is good.

Owner:CHINA RAILWAY CONSTR HEAVY IND

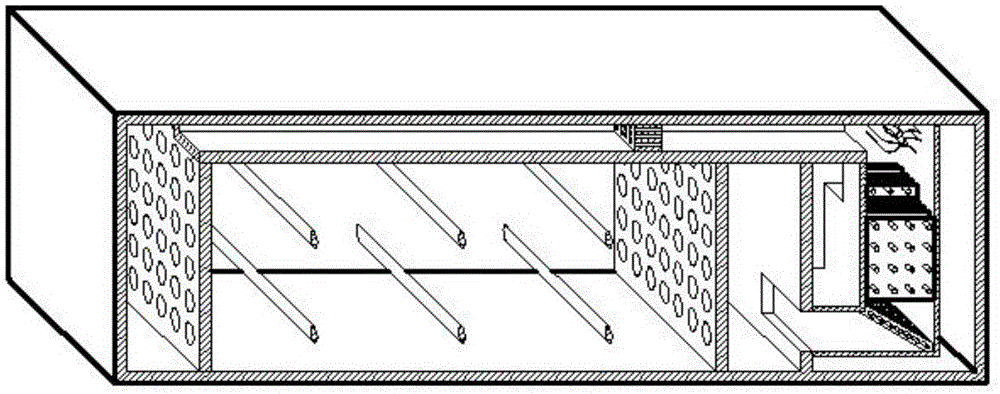

Drying surface parallel air supply type domestic fungus heat pump drying apparatus

ActiveCN105028611AEmission reductionIncrease profitFood processingFruits/vegetable preservation by dehydrationVena contracta diameterAir treatment

The invention discloses a drying surface parallel air supply type domestic fungus heat pump drying apparatus. The apparatus comprises an enclosing structure, a variable cross section air supply static pressure space, a drying area, a variable cross section air return static pressure space, an air treatment device, and an air supply main tube arranged at the upper portion of the enclosing structure, an air supply non-uniform orifice plate and an air return non-uniform orifice plate which are vertically arranged divide a space below the air supply main tube into the variable cross section air supply static pressure space, the drying area and the variable cross section air return static pressure space which are sequentially arranged along the airflow direction, and the air treatment device is arranged at the outer side of the variable cross section air supply static pressure space; and a group of air supply holes and a group of air return holes are arranged above each of layers of storage plates arranged in the drying area. Drying surface parallel air supply is adopted to improve the drying airflow distribution, so the uniformity and the stability of airflow in the drying surface are guaranteed, the drying efficiency is improved, and energy consumption is reduced.

Owner:NANJING NORMAL UNIVERSITY +1

Automatic nozzle deburring and flow adjusting method

ActiveCN109434697ARealize automatic removalFull adjustmentAbrasive feedersAbrasive machine appurtenancesParticle flowWear particle

An automatic nozzle deburring and flow adjusting method comprises the steps that the initial flow value of a main / auxiliary oil spraying port of each nozzle is measured; grinding particle flow equipment is utilized for machining a main / auxiliary oil path of each nozzle, and burrs on each main / auxiliary oil path are removed; cleaning fluid is utilized for cleaning the main / auxiliary oil path of each nozzle; the cleaning fluid is utilized for cleaning the grinding particle flow equipment; the nozzle flow after machining is detected and then compared with the initial flow value, and the grindingparticle flow machining time and flow changing relation under corresponding machining parameters is determined; for nozzles with small flow, secondary grinding particle flow machining is conducted onthe nozzles according to the obtained grinding particle flow machining time and flow changing relation, the nozzle flow is further adjusted till the flow of all the nozzles is consistent, and the flowrequirement is met; the grinding particle flow equipment is cleaned; ultrasonic cleaning equipment is utilized for nozzle cleaning, and residual cleaning fluid is removed; and the weight of each nozzle is measured and compared with the initial weight of the nozzle before grinding particle flow machining, and it is ensured that the nozzle weight changing value does not exceed 50 g.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Automatic Fluid Loading Crane and Its Application

ActiveCN106966353BEnsure flow stabilityRealize automatic deliveryLiquid transferring devicesFluid loadingFully automatic

The invention provides a full-automatic liquid loading crane pipe and application thereof, and belongs to the field of liquid conveying equipment. The full-automatic liquid loading crane pipe is uniform in heat tracing, automatic to control, accurate to adjust, safe, reliable, simple and convenient to operate. The full-automatic liquid loading crane pipe comprises a conveying crane pipe, and a heat tracing sleeve which sleeves the conveying crane pipe, wherein a steam hose communicates with the heat tracing sleeve; the conveying crane pipe comprises an inner arm, an outer arm and a vertical arm which are sequentially connected; an elbow assembly is connected between the outer arm and the inner arm; a first driving part and a first transmission rack are connected to the inner arm; the first driving part is connected with the first transmission rack, and the first transmission rack is connected with a second driving part; an angle adjusting rack which is connected to the elbow assembly is connected with the second driving part; a balancing driving part and an adjusting driving part which are connected to the outer arm are connected to the angle adjusting rack; sleeve type rotating joints are connected to the inner arm and the elbow assembly.

Owner:BEIJING MOUNTAIN IND

Clean and efficient gradient screening internal thermal fluidized bed coal moisture control process

InactiveCN105733635AWide adaptability to humidityReliable operation regulationCoke ovensScreening proceduresHeat carrier

The invention discloses a clean and efficient gradient screening internal thermal fluidized bed coal moisture control process.An internal thermal fluidized bed dryer serves as a main device; in the coal moisture control procedure, a coal particle diameter gradient screening procedure, a selective smashing procedure and a coal fly ash recovering and pelleting procedure are included; step-by-step screening of coal particle diameters is realized in the mode of mechanical screening through a low-temperature variable speed fluidized bed, orderly control over coal particle smashing and drying and coal dust is ensured, repeated processing of coal materials is reduced, and energy is reasonably input in the technological process.Air with strong moisture carrying capacity and high-temperature hot water with high thermal capacity are selected as a fluidizing medium and a heat transfer medium respectively according to the physical properties of the air and the high-temperature hot water.Compared with a traditional fluidized bed coal moisture control process, the functions of a heat carrier, a moisture carrier and the fluidizing medium in the coal moisture control process are separated, flexible control and precise processing can be achieved in terms of control and regulation, and the process is particularly suitable for moisture control over dryness of high-humidity coal materials.

Owner:WUXI YIEN TECH

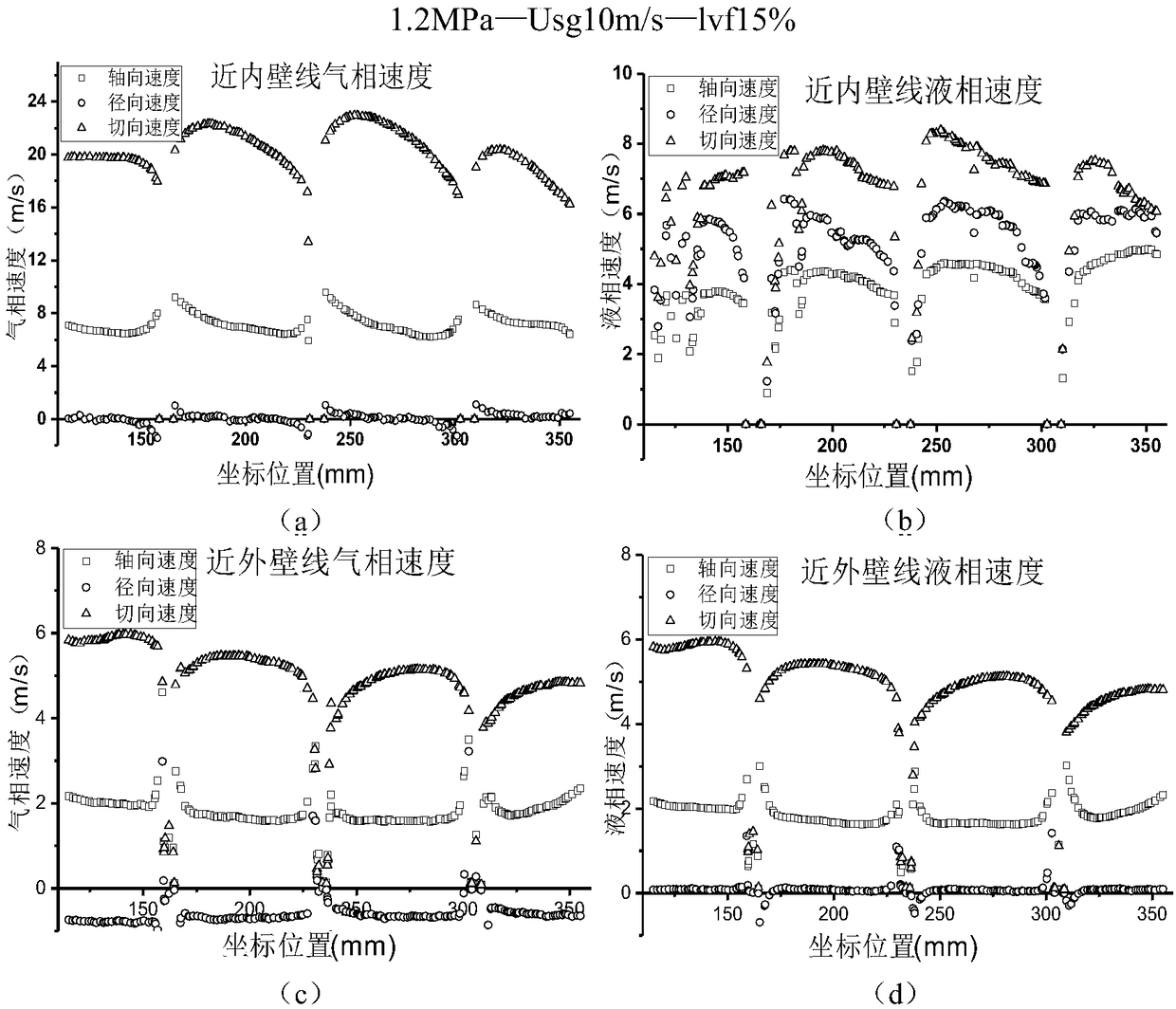

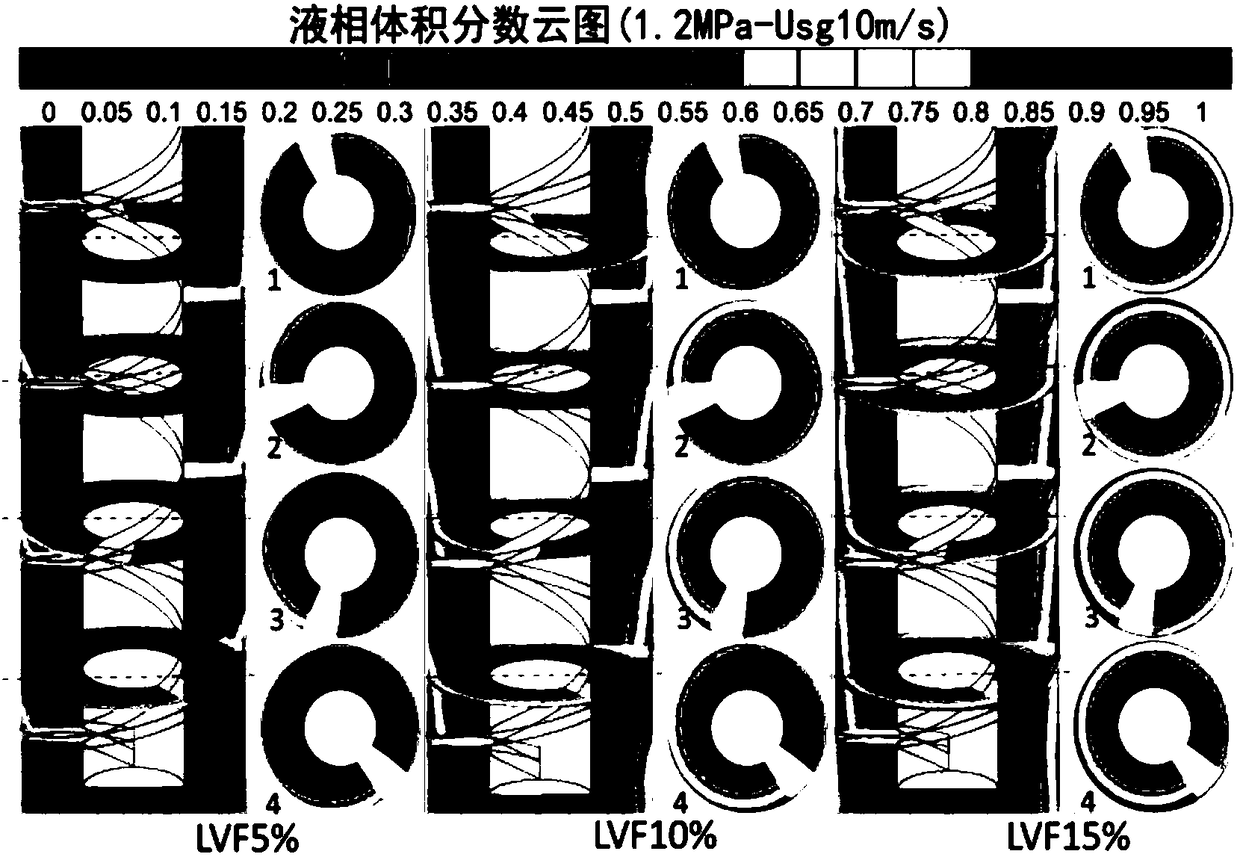

Vertical rotational flow phase-splitting capacitance integrated water content measurement device

ActiveCN108181357AGuaranteed phase distributionShort structure lengthMaterial capacitanceMeasurement devicePhase splitting

The invention relates to a vertical rotational flow phase-splitting capacitance integrated water content measurement device. The vertical rotational flow phase-splitting capacitance integrated water content measurement device comprises an outer pipe wall and an inner electrode, wherein the inner wall of the outer pipe wall is a metal inner wall and serves as an outer electrode, the vertical rotational flow phase-splitting capacitance integrated water content measurement device is characterized in that the metal inner electrode is fixed at the middle part of the outer pipe wall, the metal inner electrode is wrapped with an insulating layer, a helical blade is further fixed at the peripheries of the insulating layer and the metal inner electrode, an inclined inlet is formed in the outer pipe wall, the tangential angle of the inclined inlet and the spiral lead angle of the helical blade are the same, so that a fluid enters a space between the helical blade and the outer pipe wall along the tangential angle, and the length of the inner electrode is the length of a capacitance measurement section.

Owner:TIANJIN UNIV

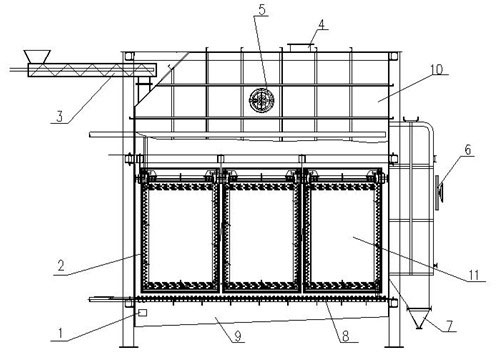

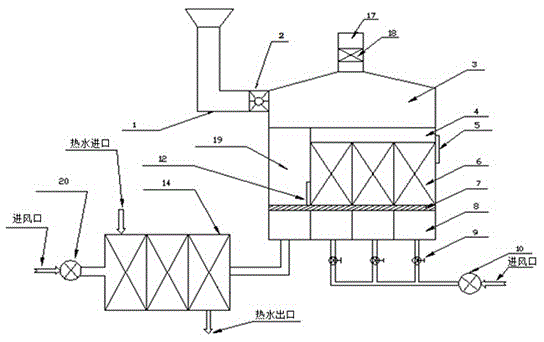

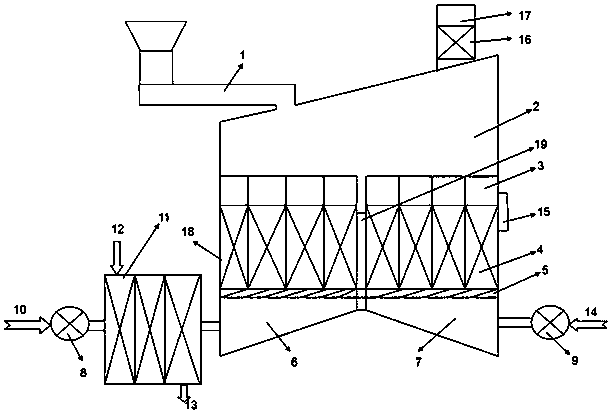

Device for coking coal stage drying step humidify regulating process

ActiveCN105647557AGuaranteed installation and maintenanceGuarantee normal productionDrying solid materials with heatCoke ovensAir preheaterProcess engineering

The invention discloses a device for a coking coal stage drying step humidify regulating process. The device comprises a first-stage humidify regulating process loop and a second-stage humidify regulating process loop, wherein the first-stage humidify regulating process loop comprises a first-stage fluidization air chamber (19), an air preheater (14) and a first fluidization fan (20), wherein no coiled pipe heating module is arranged in the first-stage fluidization air chamber (19), and a layer of bed materials with the thickness being 500 to 600mm is arranged at the bottom; the second-stage humidify regulating process loop comprises a second-stage fluidization air chamber (6) and a second fluidization fan (10); the second-stage fluidization air chamber (6) mainly consists of a plurality of humidify regulating modules; a coiled pipe heater is arranged in each humidify regulating module. The device has the advantages that the stage drying step humidify regulation is realized through two stages of humidify regulating process loops, so that the device has wide coal humidify applicability; the coal dust generation and elutriation can be orderly controlled; energy can be fed in a step way according to the technological process; the system operation regulation is reliable and flexible; the energy saving performance is high.

Owner:WUXI YIEN TECH

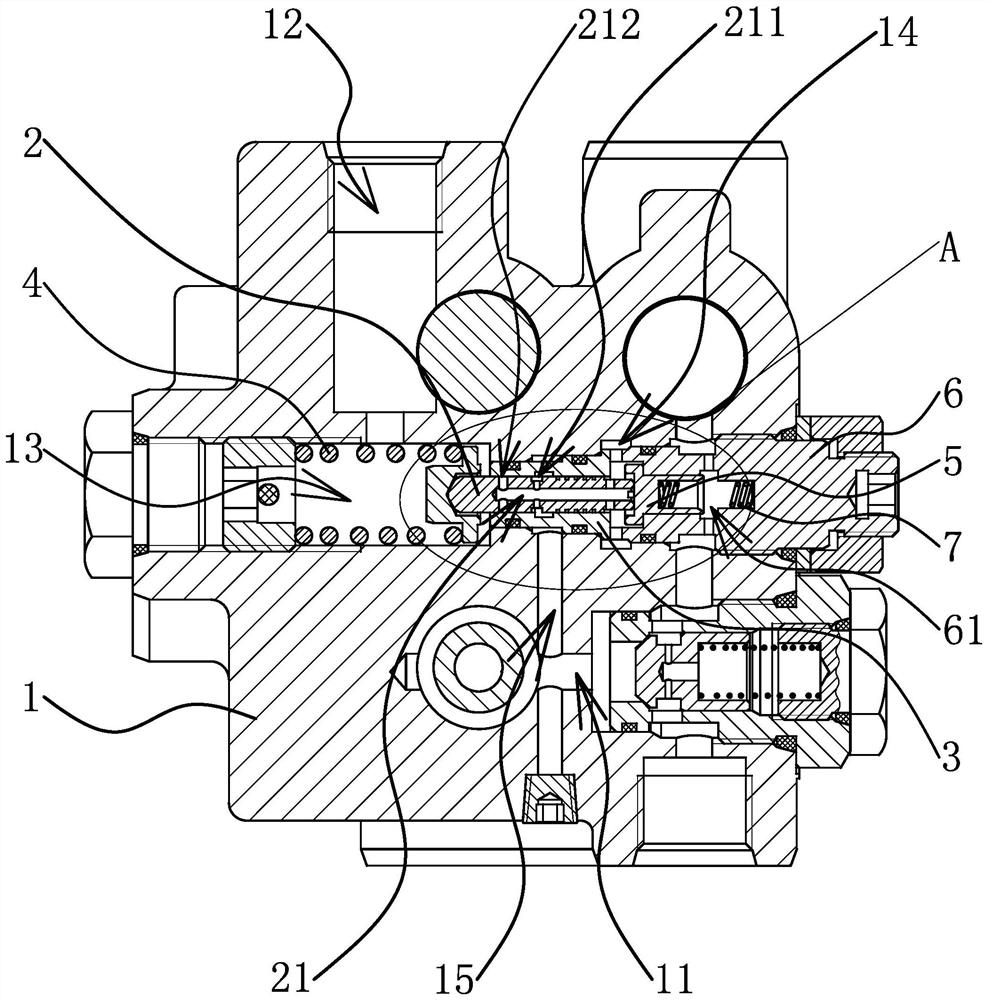

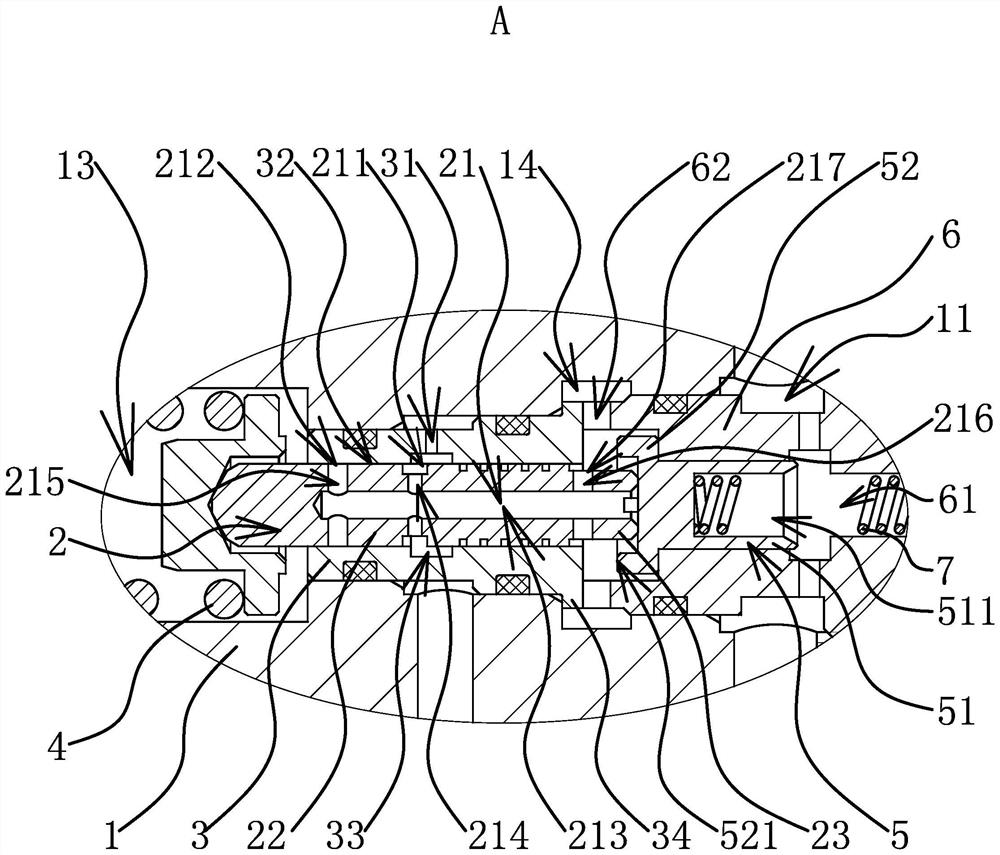

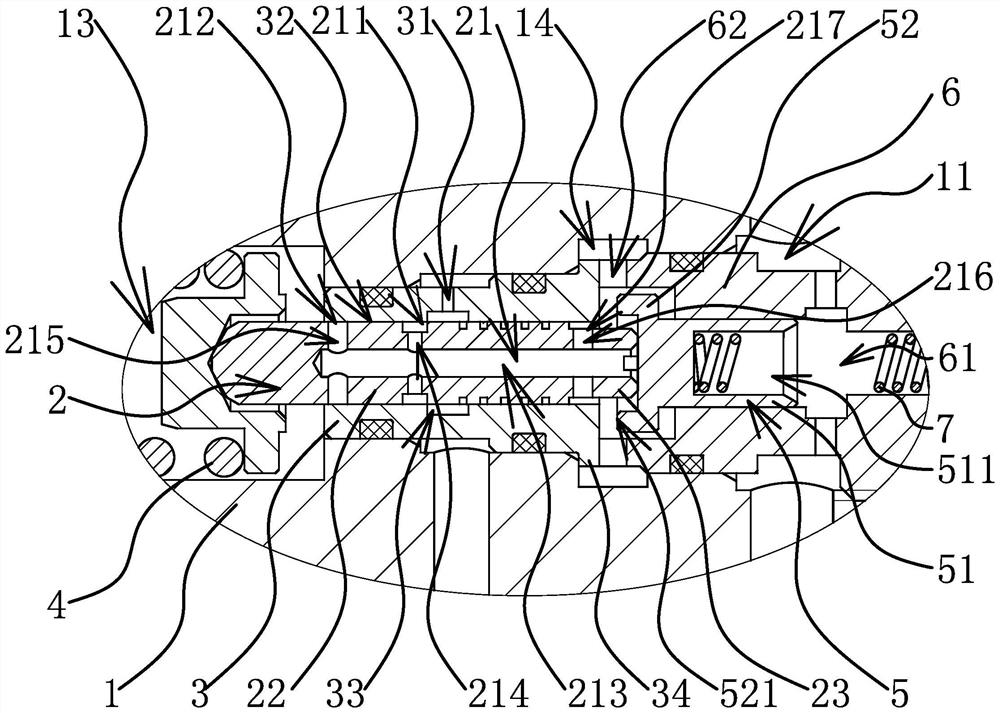

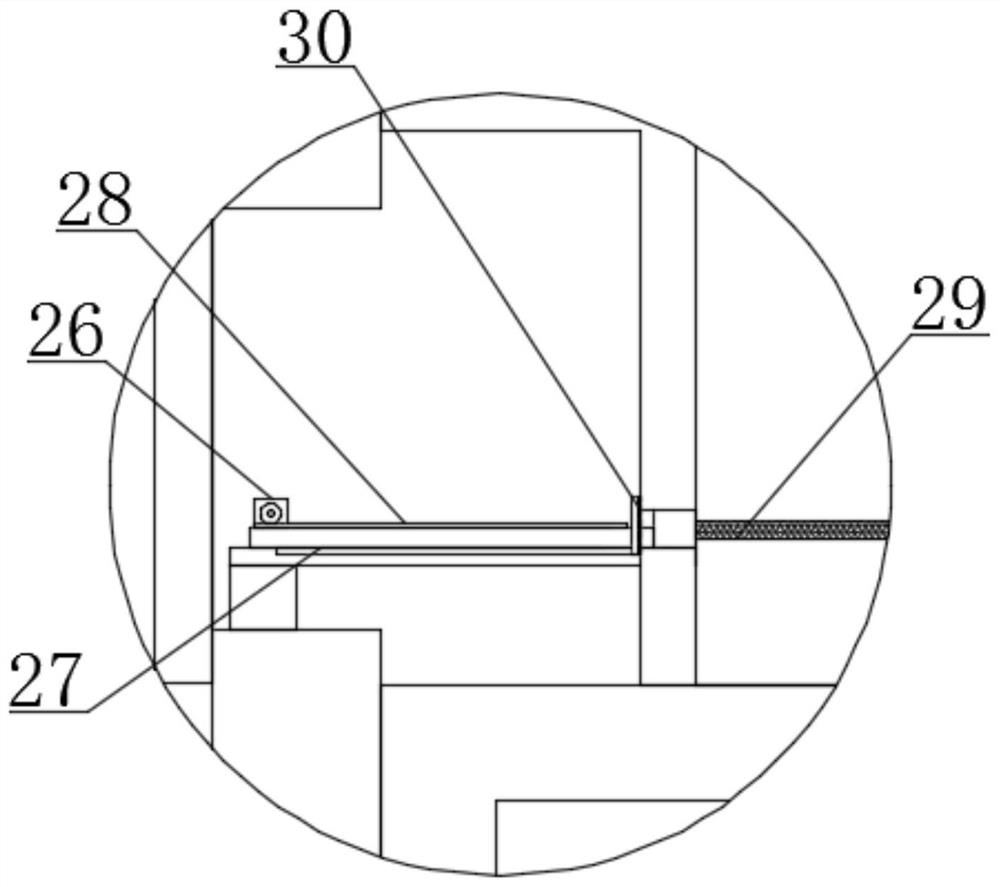

Pressure control structure of prefill valve

ActiveCN114439802AEasy to determineEnsure flow stabilityServomotor componentsEngineeringPressure control

The invention provides a pressure control structure of a prefill valve, and belongs to the technical field of hydraulic pressure. The problem that an existing liquid filling interval is difficult to control is solved. The pressure control structure of the prefill valve comprises a valve body with a prefill oil way, an oil outlet through which oil flows out is formed in the valve body, a valve rod with a control oil way is connected in the valve body in a sliding mode, and a spring cavity located at the left end of the valve rod and communicated with the oil outlet and a pressure cavity located at the right end of the valve rod and communicated with the control oil way are formed in the valve body. The control oil way is provided with an inflow port capable of being communicated with the liquid filling oil way and a pressure relief port capable of being communicated with the spring cavity, a valve sleeve which is arranged outside the valve rod in a sleeving mode and can seal the inflow port and / or the pressure relief port is positioned in the valve body, and a pressure spring which elastically abuts against the left end of the valve rod to enable the inflow port to be communicated with the liquid filling oil way is arranged in the spring cavity. A valve element capable of driving the valve rod to move towards the spring cavity so that the pressure relief opening can be communicated with the spring cavity is arranged in the liquid filling oil way. The pressure control structure of the prefill valve has the advantage of reducing the control difficulty of the prefill interval.

Owner:ZHEJIANG HAIHONG HYDRAULIC TECH

An adaptive variable inclination multi-drum current receiving device for electric locomotives

InactiveCN110816278BReduce wearTake advantage ofPower current collectorsMechanical impactEngineering

The invention discloses an adaptive variable inclination multi-roller current receiving device for an electric locomotive, which includes a plurality of metal rollers and a roller base for placing the metal rollers; includes a bottom plate, a side plate, a first top plate and a second top plate ; It also includes a movable plate opposite to the side plate; the side plate and the movable plate are provided with square holes corresponding to the metal roller one by one; one end of the roller shaft of the metal roller is embedded in the square hole of the side plate, and the other end is embedded in the movable plate inside the square hole; the roller shaft is movably sleeved on the screw through the opening; the metal roller is provided with a brush that is in contact with the roller shaft for receiving current; there is also a sliding device for driving the movable plate to move; the metal roller is in contact with the roller. Line contact receiving current; the invention can adjust the angle between the roller and the contact line according to the change of locomotive speed and traction power, and effectively reduce the wear of the pantograph head and alleviate the mechanical impact with the contact line, and change the contact area to adapt to Variations in traction current.

Owner:SOUTHWEST JIAOTONG UNIV

A heat pump drying device for edible fungus with parallel air supply on the drying surface

ActiveCN105028611BReduce energy consumptionKeep dryFood processingFruits/vegetable preservation by dehydrationVena contracta diameterAir treatment

The invention discloses a drying surface parallel air supply type domestic fungus heat pump drying apparatus. The apparatus comprises an enclosing structure, a variable cross section air supply static pressure space, a drying area, a variable cross section air return static pressure space, an air treatment device, and an air supply main tube arranged at the upper portion of the enclosing structure, an air supply non-uniform orifice plate and an air return non-uniform orifice plate which are vertically arranged divide a space below the air supply main tube into the variable cross section air supply static pressure space, the drying area and the variable cross section air return static pressure space which are sequentially arranged along the airflow direction, and the air treatment device is arranged at the outer side of the variable cross section air supply static pressure space; and a group of air supply holes and a group of air return holes are arranged above each of layers of storage plates arranged in the drying area. Drying surface parallel air supply is adopted to improve the drying airflow distribution, so the uniformity and the stability of airflow in the drying surface are guaranteed, the drying efficiency is improved, and energy consumption is reduced.

Owner:NANJING NORMAL UNIVERSITY +1

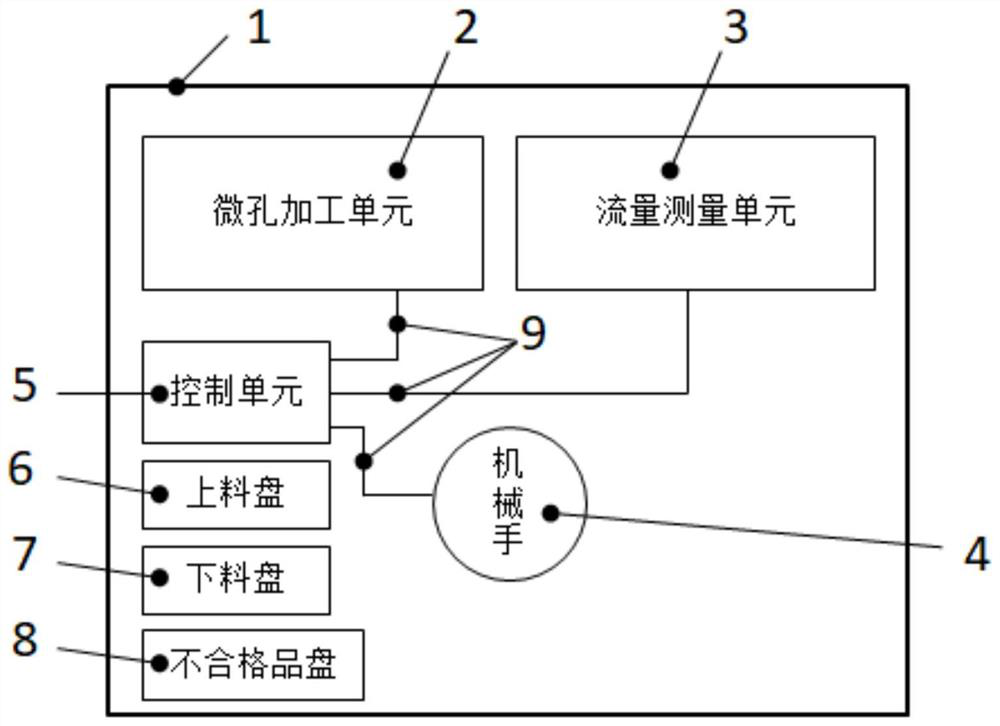

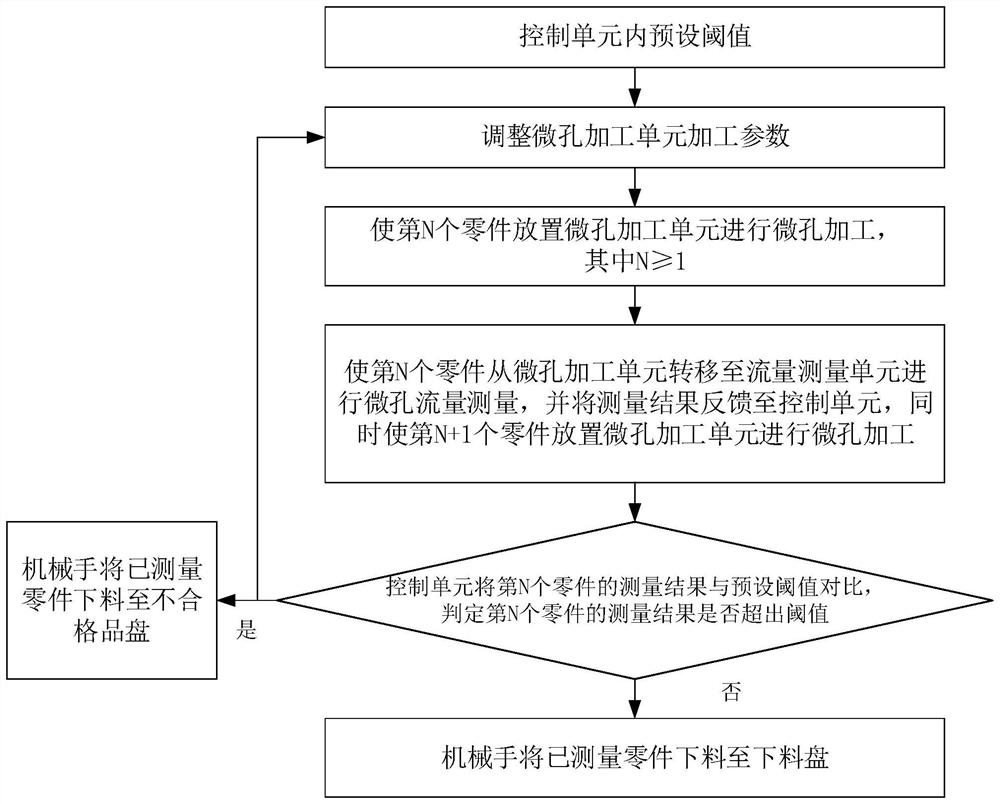

Micropore machining device and method

PendingCN114523167AAvoid quality traceabilityLower skill requirementsElectrical-based auxillary apparatusMachine partsControl cell

The invention belongs to the technical field of micropore machining, and discloses a micropore machining device and method. The micropore machining device comprises a micropore machining unit, a flow measuring unit and a control unit which is in communication connection with the micropore machining unit and the flow measuring unit. The micro-hole machining unit can adjust machining parameters and can conduct micro-hole machining on the part according to preset machining parameters; the flow measuring unit is used for measuring the flow of a micropore of each machined part; the flow measurement unit can feed back the measurement result of the measured micropore flow of the machined part to the control unit, the control unit can judge whether the measurement result meets the requirement or not, when it is judged that the measurement result does not meet the requirement, the control unit can send an adjusting instruction, and the micropore machining unit can correct machining parameters according to the adjusting instruction. According to the micropore machining device and method, the production efficiency is improved, the product quality is guaranteed, and the product percent of pass is increased.

Owner:FAW JIEFANG AUTOMOTIVE CO

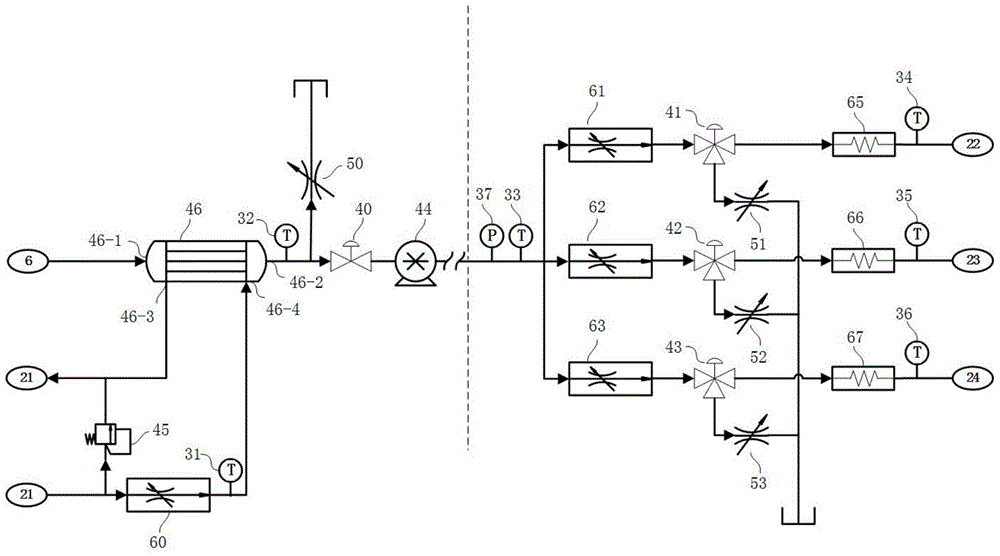

A multi-channel liquid temperature adjustment device and temperature control method

InactiveCN104199483BAchieve calibrationGuaranteed temperatureTemperatue controlEnergy industryLiquid temperatureEngineering

A multi-channel liquid temperature adjustment device and its temperature control method, which belong to the liquid temperature adjustment device and its temperature control method, solve the problem that the existing photolithography machine immersion liquid temperature adjustment control device only has the temperature control capability of one output and cannot coordinately adjust the remote The problem of water supply temperature at the end and near end. The temperature regulating device of the present invention includes a pure water supply part, a liquid injection part and a control system, the pure water supply part is placed in the remote pure water equipment, and the liquid injection part is placed inside the photolithography machine; the pure water supply part and the injection The liquid parts are connected through remote pipelines; the control system collects the temperature values of the pure water temperature sensor, the water supply temperature sensor, and the first to third temperature sensors respectively; and controls the heating voltage of the first to third heaters, At the same time, the driving current of the cooling water flow servo valve is controlled. The invention utilizes the cooperation of the heat exchanger and the low-power heater, adjusts the flow through the flow servo valve and adjusts the power of multiple low-power heaters, so that the pure water temperature at multiple output ends reaches a stable value of ±0.01°C.

Owner:HUAZHONG UNIV OF SCI & TECH

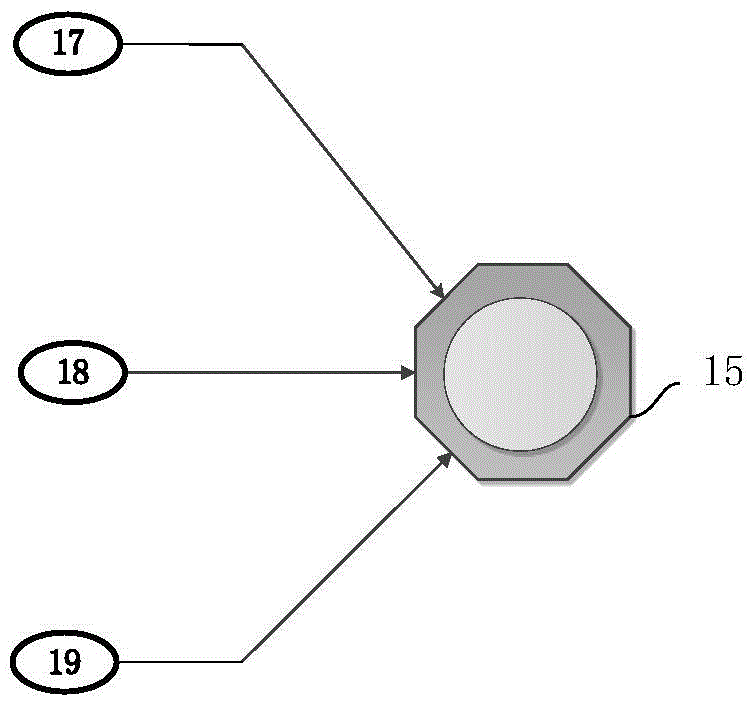

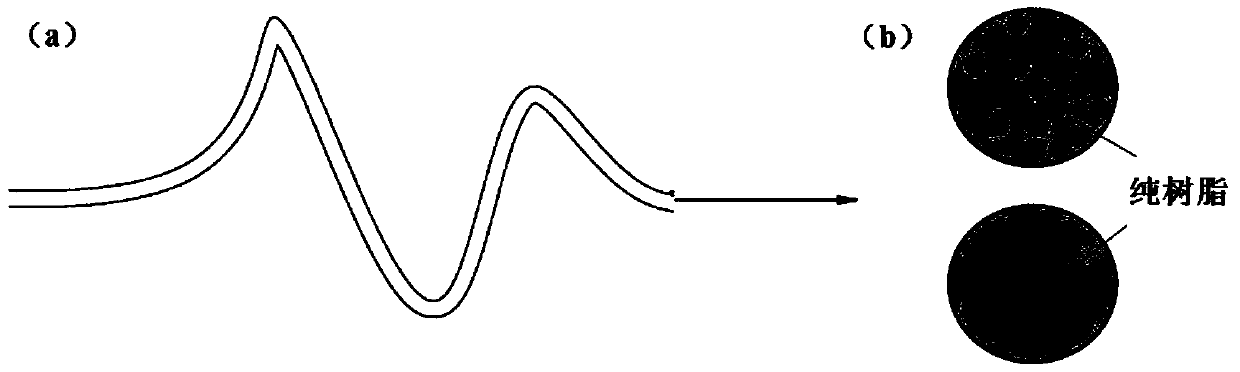

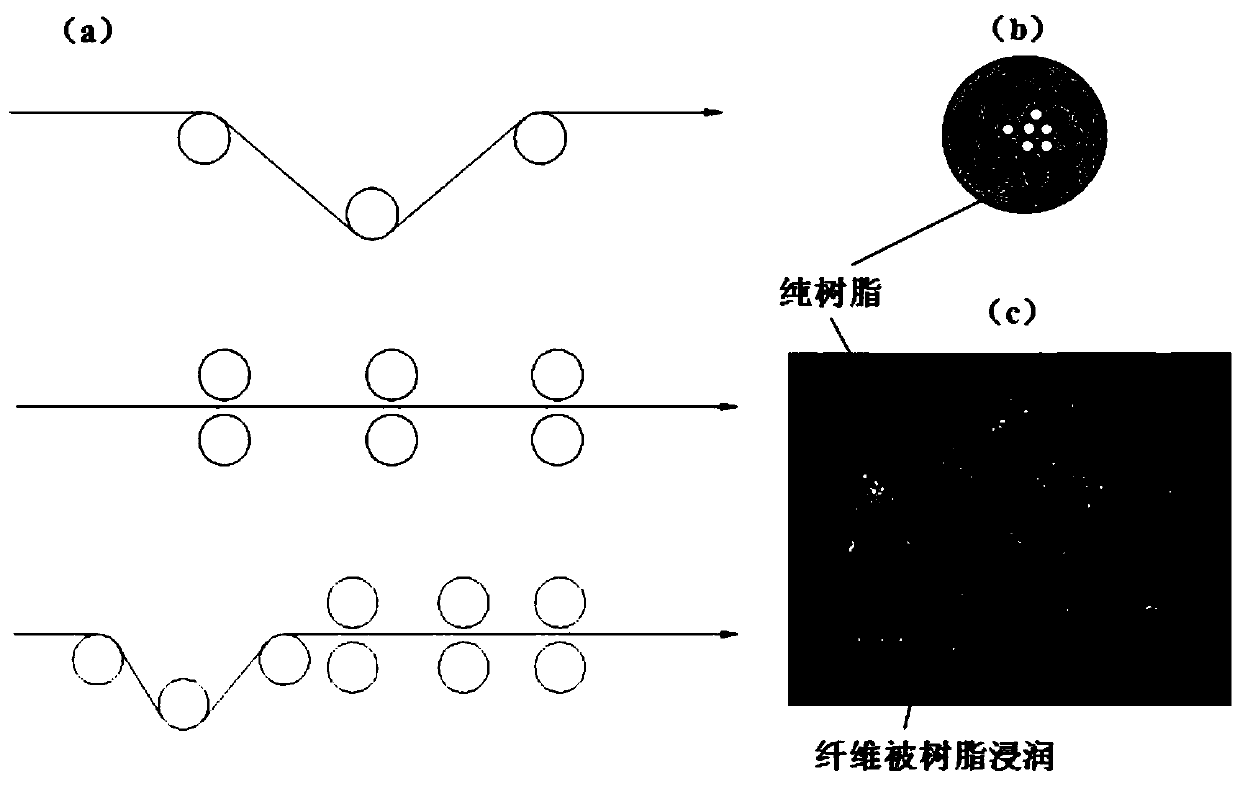

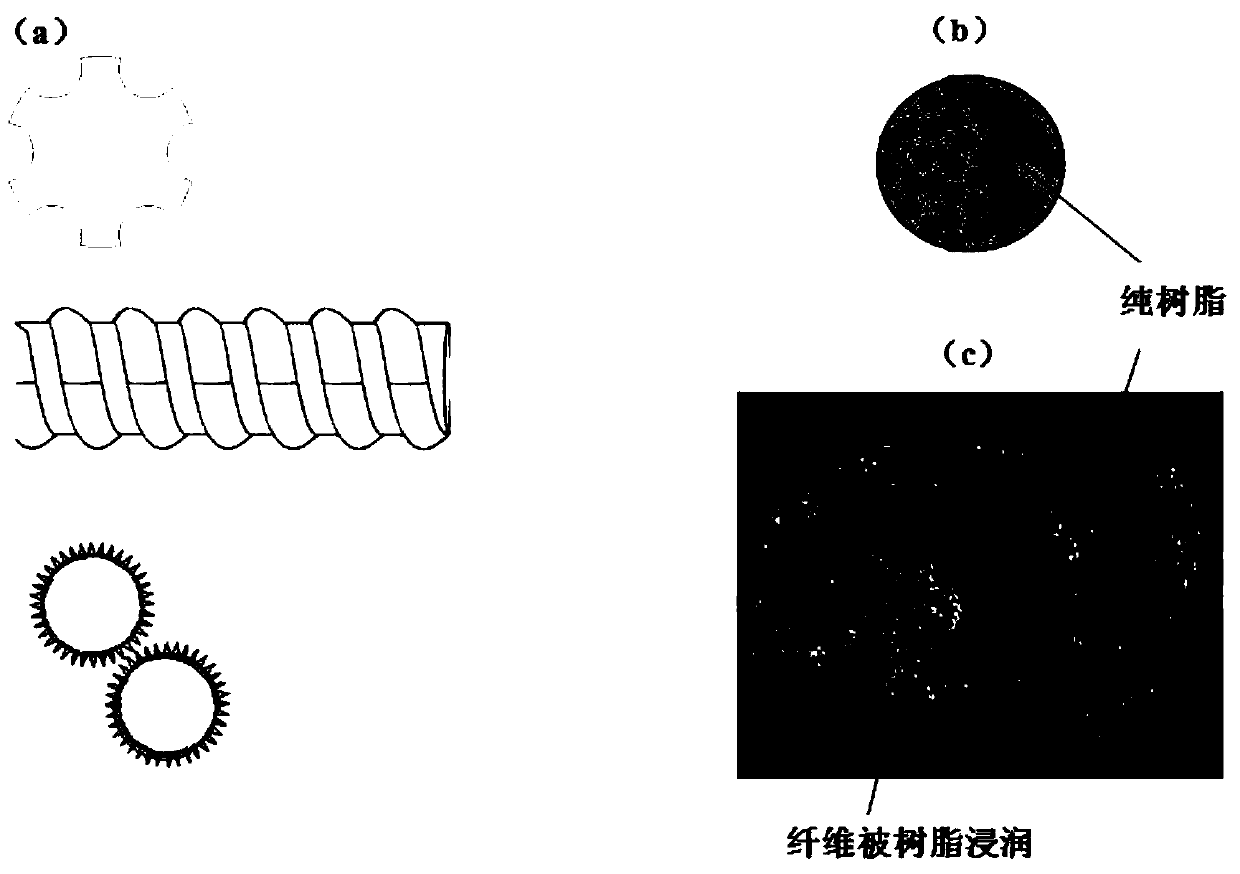

A long fiber bundle melt impregnation system

ActiveCN105538538BEffective dispersionReduce thicknessCoatingsFiber bundleLong-fiber-reinforced thermoplastic

The invention provides a long fiber bundle melt impregnation system. The impregnation system includes a driving unit and at least one group of matched and paired driving covered rolls, the driving unit provides power for the driving covered rolls, the driving covered rolls are composed of a first driving roll and a second driving roll, a slit for a long fiber bundle to go through is left between the first driving roll and the second driving roll, the first driving roll and the second driving roll respectively contact with the long fiber bundle in the slit between the rolls when the first driving roll and the second driving roll rotate, and resultant force generated by mutual chimerism of the first driving roll and the second driving roll promotes the long fiber bundle in the slit between the rolls to move. The long fiber bundle melt impregnation system realizes the purposes of reduction of the thickness of the long fiber bundle in the impregnation process and increase of the filament dispersion uniformity of the long fiber bundle, and reaches less fiber breaking loss, full infiltration, uniform dispersion and high-speed stable production in order to obtain a long fiber reinforced thermoplastic plastic with excellent performances.

Owner:BENSONG ENG PLASTICS HANGZHOU

Device for high humidity charging coking coal humidity control process

ActiveCN104726121BSimple structureImprove interchangeabilityCoke ovensEnergy inputAir preheaterModular composition

The invention discloses a device for high-humidity furnace-loading coking coal humidity control technology, which comprises a fluidized bed type humidity control machine, and a first fluidized bed type built-in heat control device is arranged side by side in the fluidized bed type humidity control machine. The humidity module and the second fluidized bed type built-in heat and humidity control module, the first fluidized bed type built-in heat and humidity control module is connected in series with an air preheater and a first fluidization fan in series to form a first process loop; The second fluidized bed type built-in heat and humidity control module is connected in series with a second fluidization fan to form a second process loop; the first process loop and the second process loop are connected through an adjustable overflow plate. The present invention adopts a frame structure, and the air preheater and the fluidized bed type humidifier are all modularized combinations, which ensures convenient installation and maintenance of the process device, and multiple modules can be arbitrarily combined into a large process device according to production requirements. Only one backup module is needed to ensure the normal production of the humidity control system, which reduces the scale of the backup equipment of the existing humidity control system.

Owner:WUXI YIEN TECH

Efficient dust-free wall-hanging stove

PendingCN112268309ASimple structureReasonable designDispersed particle filtrationSpace heating and ventilation detailsProcess engineeringMechanical engineering

The invention is applicable to the technical field of heating equipment, and particularly relates to an efficient dust-free wall-hanging stove. The efficient dust-free wall-hanging stove comprises a heat exchanger, and further comprises a box body, a smoke heat exchange assembly, a fluid adjusting assembly, a combustion cylinder and a flame heat exchange pipe, wherein the combustion cylinder is fixedly arranged in an incineration cavity in the box body; the flame heat exchange pipe is spirally arranged on the periphery of the combustion cylinder; the two ends of the flame heat exchange pipe are connected to the fluid adjusting assembly and the heat exchanger respectively; the fluid adjusting assembly is used for maintaining the stability of the flow in the flame heat exchange pipe and is further connected to the heat exchanger; and the smoke heat exchange assembly is used for absorbing heat in smoke generated by combustion, and meanwhile, is connected to the fluid adjusting assembly and the heat exchanger. The efficient dust-free wall-hanging stove is reasonable in design; direct heat exchange can be conducted through flames; secondary heat exchange is conducted on smoke through the smoke heat exchange assembly; the energy utilization rate is greatly increased; and in addition, the fluid adjusting assembly is arranged, so that the flowing stability of heat exchange fluid is guaranteed, and the heat exchange effect is guaranteed.

Owner:ZHEJIANG JUYUN PIPE IND CO LTD

Film type wall conductive device

PendingCN111463635AReduce wearWon't pile upRotary current collectorWelding/cutting auxillary devicesSlag (welding)Engineering

The invention discloses a film type wall conductive device and is used for providing electric power for tube bank welding. The film type wall conductive device comprises a conductive mechanism, a barmaterial which can roll on a tube row, and a long shaft which is connected with the conductive mechanism, wherein the bar is mounted on the outer side of the long shaft. Compared with the prior art, the film type wall conductive device is advantaged in that the device is simple in structure and reasonable in design, the abrasion degree of the tube row during welding can be reduced, welding slag accumulation is prevented, that the conductive current on the tube row has stability is guaranteed, and reliability of film type wall tube row welding can be improved.

Owner:POURIN WELDING ENG

A method for automatic nozzle deburring and flow adjustment

ActiveCN109434697BRealize automatic removalFull adjustmentAbrasive feedersAbrasive machine appurtenancesParticle flowProcess engineering

An automatic nozzle deburring and flow adjusting method comprises the steps that the initial flow value of a main / auxiliary oil spraying port of each nozzle is measured; grinding particle flow equipment is utilized for machining a main / auxiliary oil path of each nozzle, and burrs on each main / auxiliary oil path are removed; cleaning fluid is utilized for cleaning the main / auxiliary oil path of each nozzle; the cleaning fluid is utilized for cleaning the grinding particle flow equipment; the nozzle flow after machining is detected and then compared with the initial flow value, and the grindingparticle flow machining time and flow changing relation under corresponding machining parameters is determined; for nozzles with small flow, secondary grinding particle flow machining is conducted onthe nozzles according to the obtained grinding particle flow machining time and flow changing relation, the nozzle flow is further adjusted till the flow of all the nozzles is consistent, and the flowrequirement is met; the grinding particle flow equipment is cleaned; ultrasonic cleaning equipment is utilized for nozzle cleaning, and residual cleaning fluid is removed; and the weight of each nozzle is measured and compared with the initial weight of the nozzle before grinding particle flow machining, and it is ensured that the nozzle weight changing value does not exceed 50 g.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

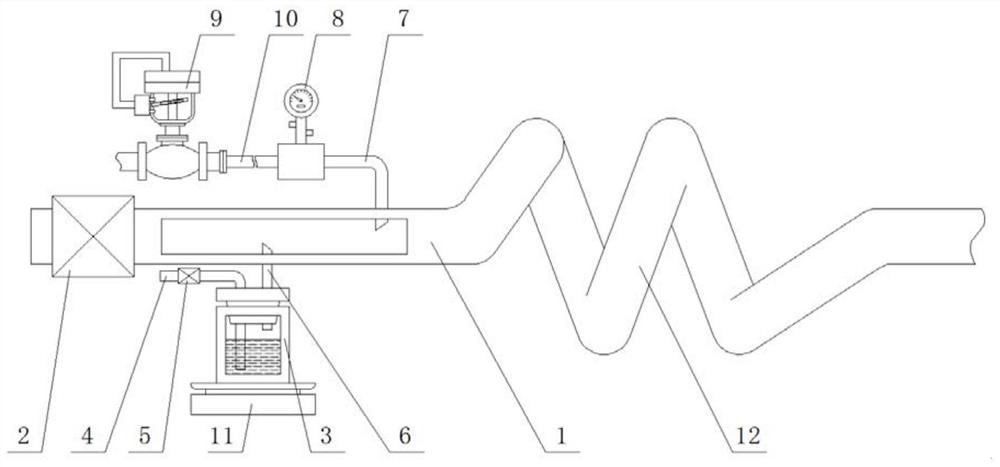

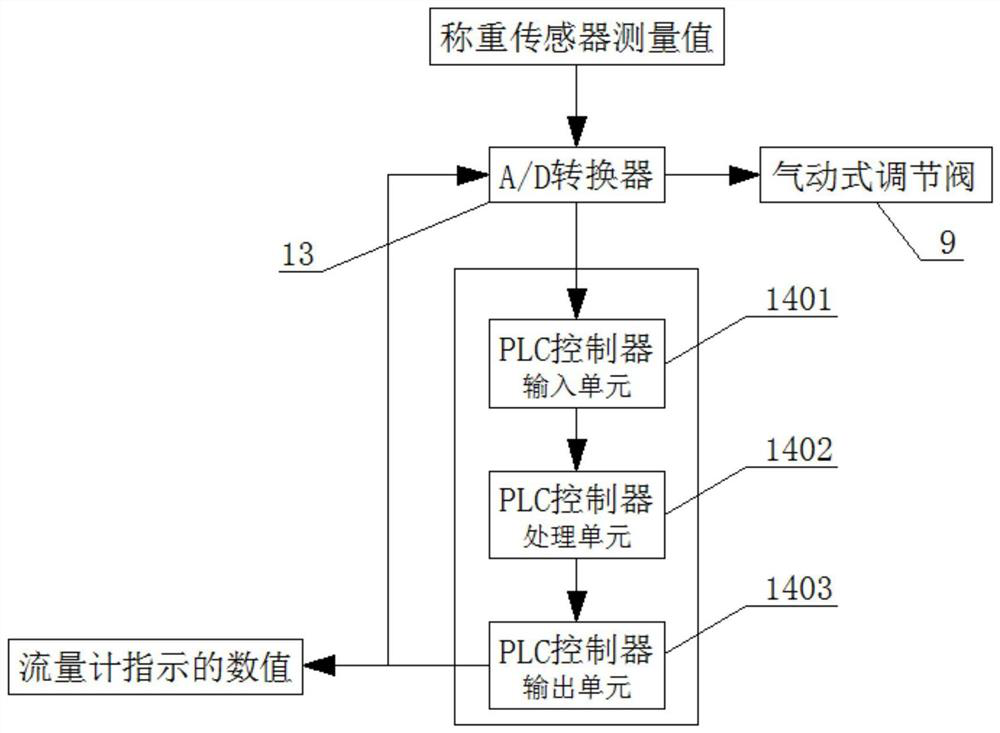

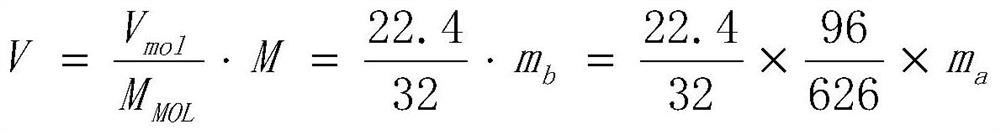

A diffusion furnace air intake device for photovoltaic cell manufacturing and its control method

ActiveCN109355709BImprove effective utilizationReduce load intensityFinal product manufactureDiffusion/dopingTemperature controlData control

The invention relates to the technical field of photovoltaic manufacturing, and discloses a diffusion furnace air inlet device for manufacturing a photovoltaic cell and a control method thereof. The device comprises a main through pipe, a flow control valve I and a constant temperature tank, an inlet end of the main through pipe is provided with a flow rate control valve I, the top end of the constant temperature tank is fixedly sleeved with a current carrying tube and an air inlet tube, and the current carrying tube is located outside the constant temperature tank and is provided with a flowcontrol valve II. The device weighs the constant temperature tank by a weighing sensor to detect the weight change rate of the constant temperature tank which is the weight change rate of a POCl3 carried by a small N2, a PLC controller and a pneumatic regulating valve cooperate with each other, according to the feedback data of the weighing sensor, the O2 content of the main through pipe through an oxygen inlet pipe is controlled to ensure that the O2 is introduced in a ratio required by the process reaction, the inlet amount of the O2 and the unit time supply of POCl3 in the constant temperature tank can achieve real-time dynamic balance according to the ratio required by the process reaction, the resource utilization rate is improved, and the additional load intensity brought by the excessive O2 introduction to the temperature control system is reduced.

Owner:杭州旭菱光伏电力科技有限公司

Clean and efficient cascade screening coal humidity control process with built-in thermal fluidized bed

InactiveCN105733635BWide adaptability to humidityReliable operation regulationCoke ovensHeat carrierHigh humidity

The invention discloses a clean and efficient gradient screening internal thermal fluidized bed coal moisture control process.An internal thermal fluidized bed dryer serves as a main device; in the coal moisture control procedure, a coal particle diameter gradient screening procedure, a selective smashing procedure and a coal fly ash recovering and pelleting procedure are included; step-by-step screening of coal particle diameters is realized in the mode of mechanical screening through a low-temperature variable speed fluidized bed, orderly control over coal particle smashing and drying and coal dust is ensured, repeated processing of coal materials is reduced, and energy is reasonably input in the technological process.Air with strong moisture carrying capacity and high-temperature hot water with high thermal capacity are selected as a fluidizing medium and a heat transfer medium respectively according to the physical properties of the air and the high-temperature hot water.Compared with a traditional fluidized bed coal moisture control process, the functions of a heat carrier, a moisture carrier and the fluidizing medium in the coal moisture control process are separated, flexible control and precise processing can be achieved in terms of control and regulation, and the process is particularly suitable for moisture control over dryness of high-humidity coal materials.

Owner:WUXI YIEN TECH

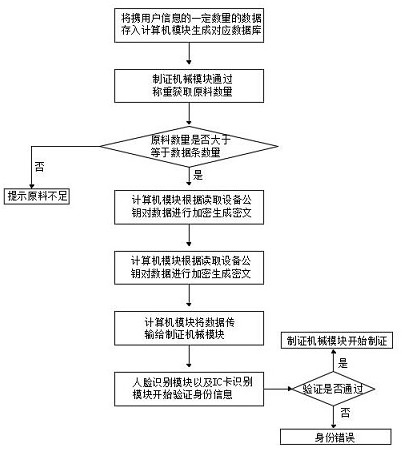

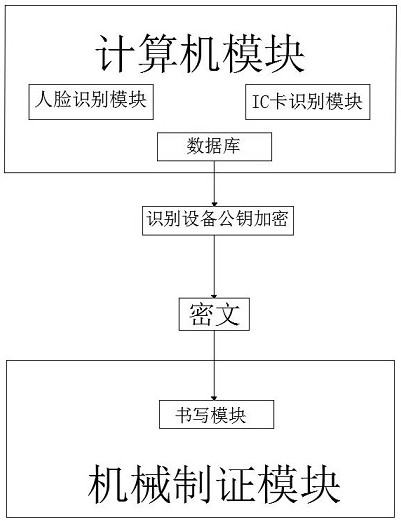

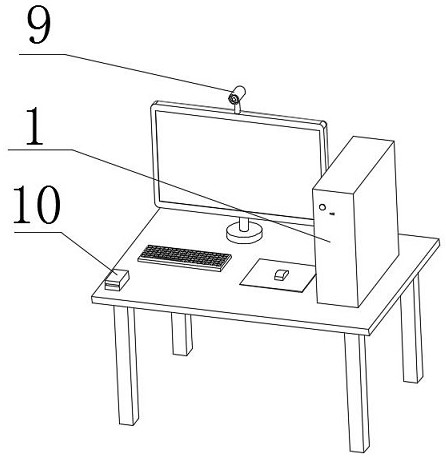

Certificate making control method and device, storage medium and electronic equipment

InactiveCN113836148AImprove securityEnsure safetyKey distribution for secure communicationInternal/peripheral component protectionComputer moduleEngineering

The invention belongs to the technical field of certificate making, and particularly relates to a certificate makingcontrol method and device, a storage medium and electronic equipment. The certificate making control method is a process method for controlling a certificate making module by a computer module. Devices needed by the control method comprise a computer module, a certificate making mechanical module, a material storage table, a feeding inclined rail, a weighing device, a discharging inclined rail, a product box, a grid baffle, a face recognition module, an IC card recognition module and a write-in module, instructions in the process of the certificate making control method are stored in a storage medium, and an electronic equipment is a CPU processor and used for processing an instruction saved in the storage medium. According to the invention, encryption is carried out when the data is written into the chip in the certificate in the certificate making process, the security of information in the certificate is improved in the certificate using process, and malicious change of the information in the certificate and illegal making of a fake certificate are avoided.

Owner:QINGDAO TONGCHAN SOFTWARE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com