Micropore machining device and method

A micro-hole processing and micro-hole technology, which is applied in the direction of accessory devices, metal processing equipment, electric processing equipment, etc., can solve the problems that the micro-hole flow detection cannot be fully covered, the parameter adjustment interval is long, and it is difficult to ensure quality. Quality hidden dangers, reducing human intervention, and improving the effect of processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

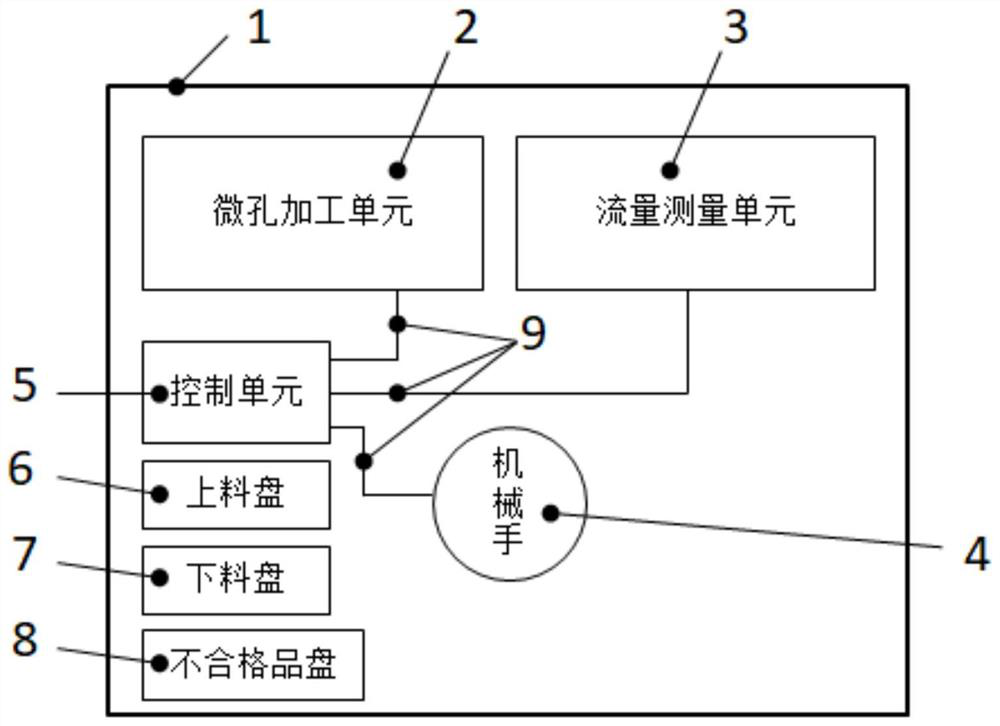

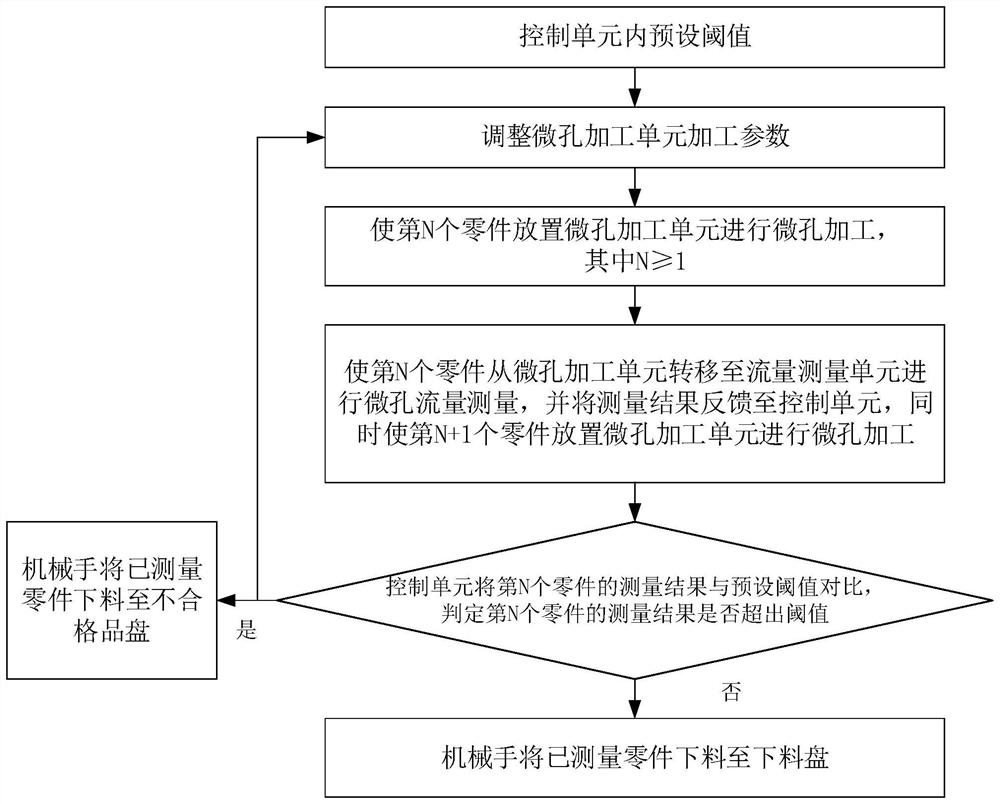

[0053] This embodiment also provides a micro-hole processing method, using the above-mentioned micro-hole processing device, such as figure 2 shown, including the following steps:

[0054] S1: Adjust the processing parameters of the micro-hole processing unit 2, and preset the threshold value in the control unit 5;

[0055] S2: Place the Nth part on the micro-hole machining unit 2 for micro-hole processing, where N≥1;

[0056] S3: Transfer the Nth part from the micropore processing unit 2 to the flow measurement unit 3 for micropore flow measurement, and feed back the measurement results to the control unit 5, and at the same time place the N+1th part in the micropore processing unit 2 for measurement Micro hole processing;

[0057] S4: the control unit 5 compares the measurement result of the Nth part with the preset threshold, and determines whether the measurement result of the Nth part exceeds the threshold;

[0058] S5: when the measurement result exceeds the preset t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com