Automatic Fluid Loading Crane and Its Application

A loading crane tube and fully automatic technology, which is applied in liquid distribution, transportation or transfer devices, packaging, distribution devices, etc., can solve the problems of local heat tracing, affecting liquid sulfur loading, and poor heat tracing effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

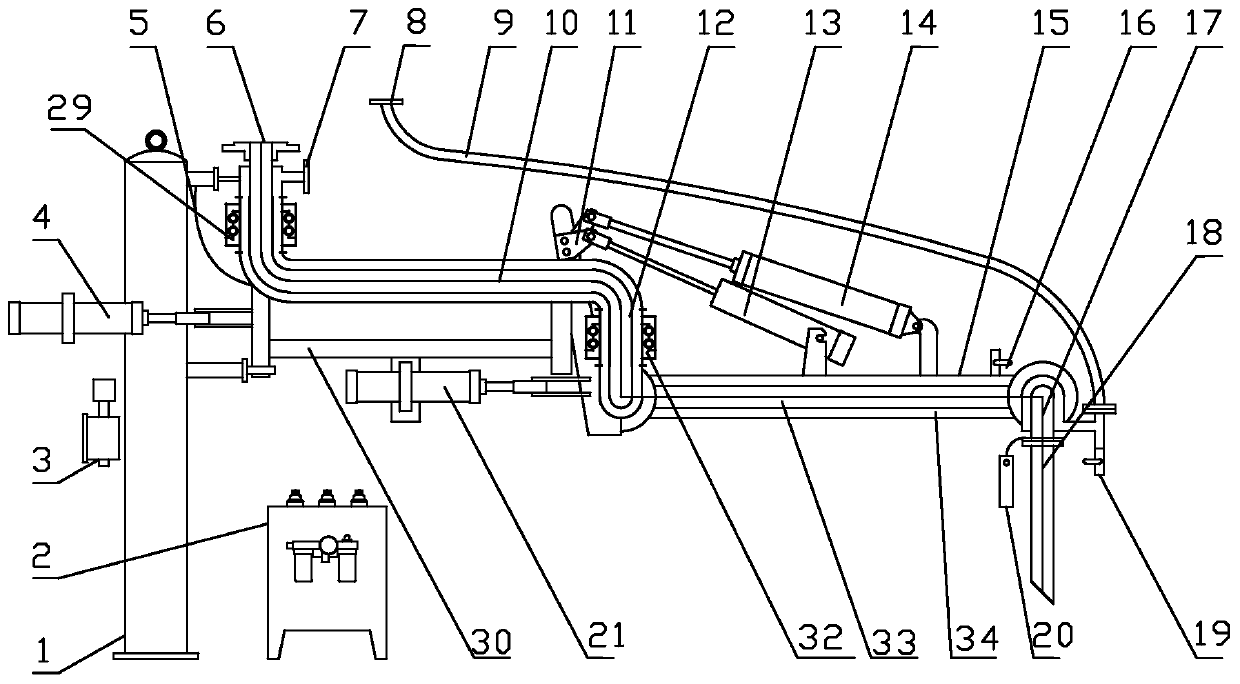

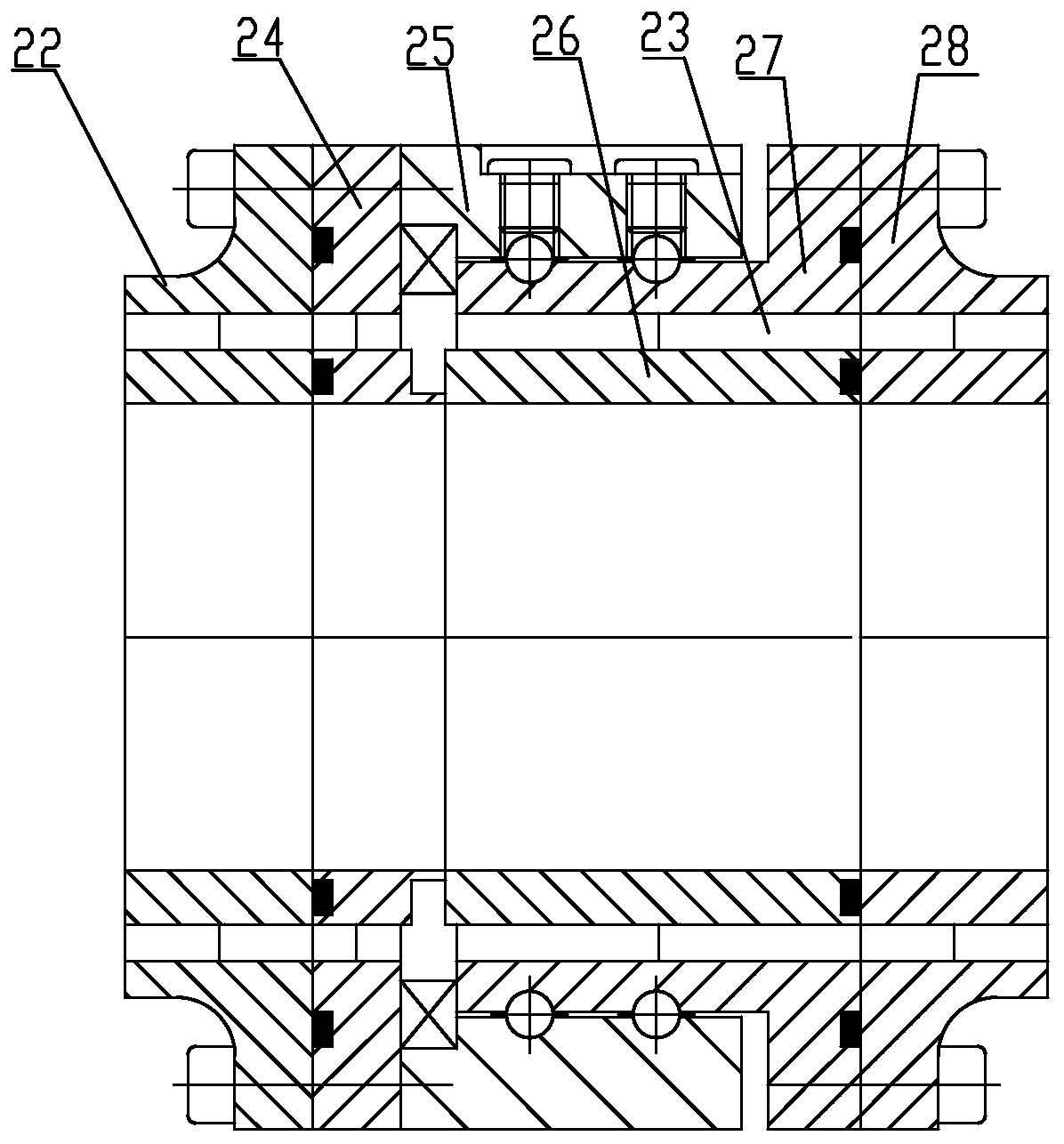

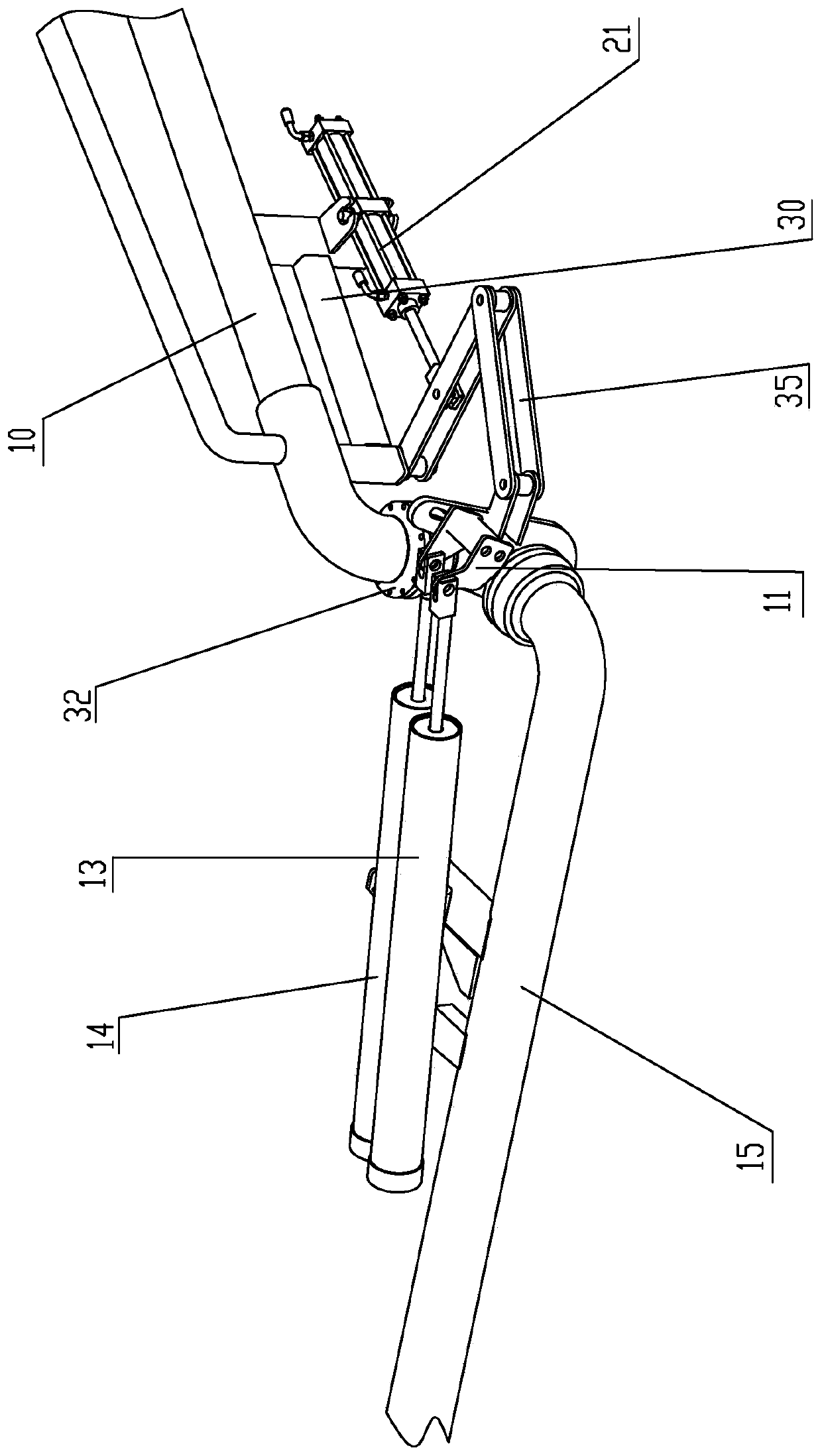

[0022] Such as figure 1 As shown, the automatic fluid loading crane of the present invention includes a conveying crane 33 and a heat tracing sleeve 34 sleeved on the conveying crane 33. The heat tracing sleeve 34 is connected with a steam hose 9, and the conveying crane 33 is connected to the crane tube column 1, the crane tube column 1 supports the delivery crane tube 33, the heat tracing sleeve 34 is set on the delivery crane tube 33, and the space between the heat tracing sleeve 34 and the delivery crane tube 33 transports steam, The steam provides heat for the transporting crane pipe 33 , so that the fluid in the transporting crane pipe 33 can be transported stably, and the steam hose 9 transports heat transfer steam for the heating sleeve 34 .

[0023] The conveying crane pipe 33 includes an inner arm 10, an outer arm 15 and a drop arm 18 connected in sequence, an elbow assembly 12 is connected between the outer arm 15 and the inner arm 10, and a drop arm assembly is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com