Automatic nozzle deburring and flow adjusting method

A flow regulation and deburring technology, applied in used abrasive treatment devices, abrasives, metal processing equipment, etc., can solve problems such as aero-engine safety that affects flow stability, lack of good removal methods, and low efficiency. , to achieve the effect of good consistency, complete burr removal and high flow regulation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0029] A method for automatic nozzle deburring and flow adjustment, comprising the following steps:

[0030] Step 1: Detect the initial flow of the nozzle through the special detection equipment for nozzle flow, and record the initial flow values of the main fuel injection port 3 and the auxiliary fuel injection port 4 respectively;

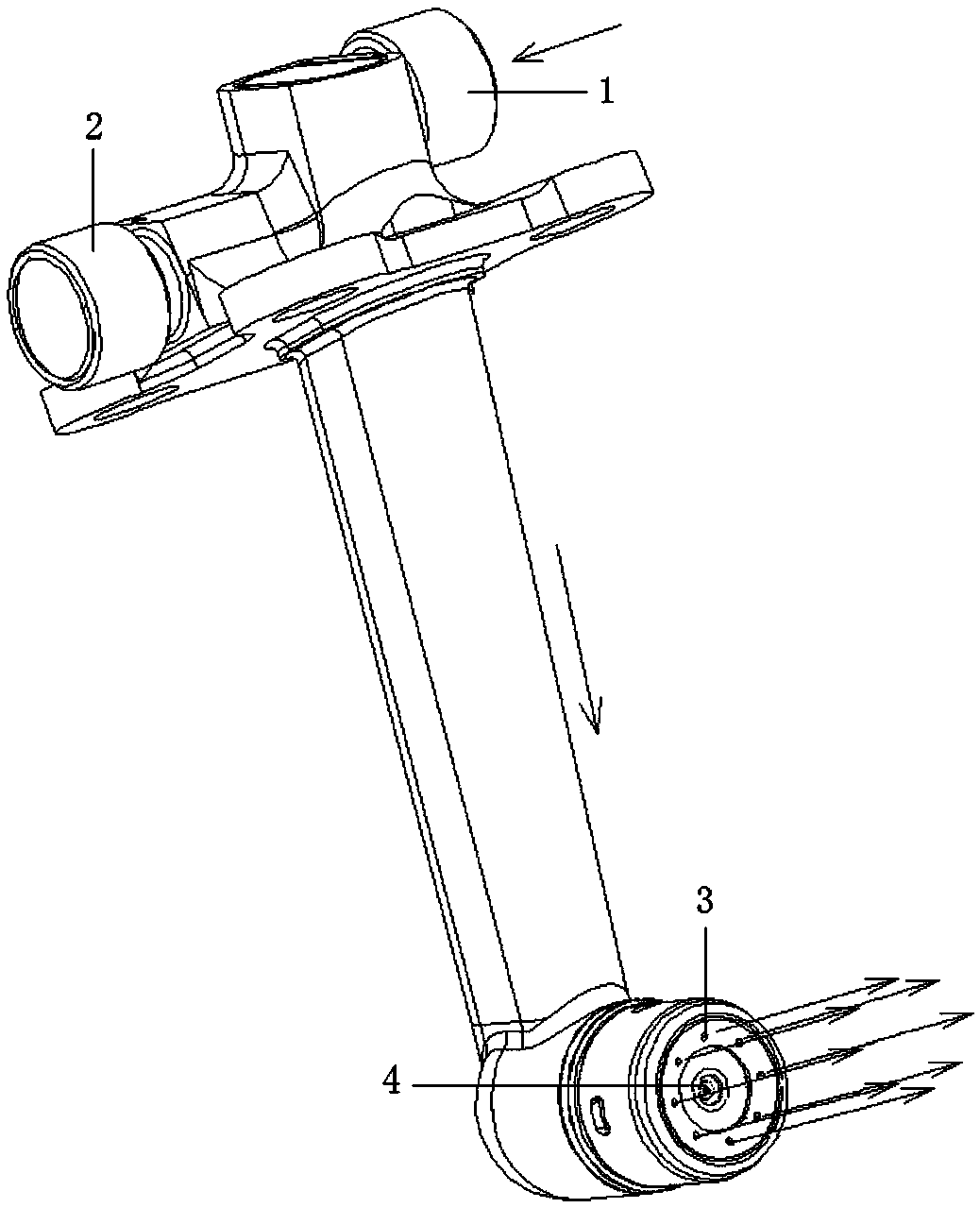

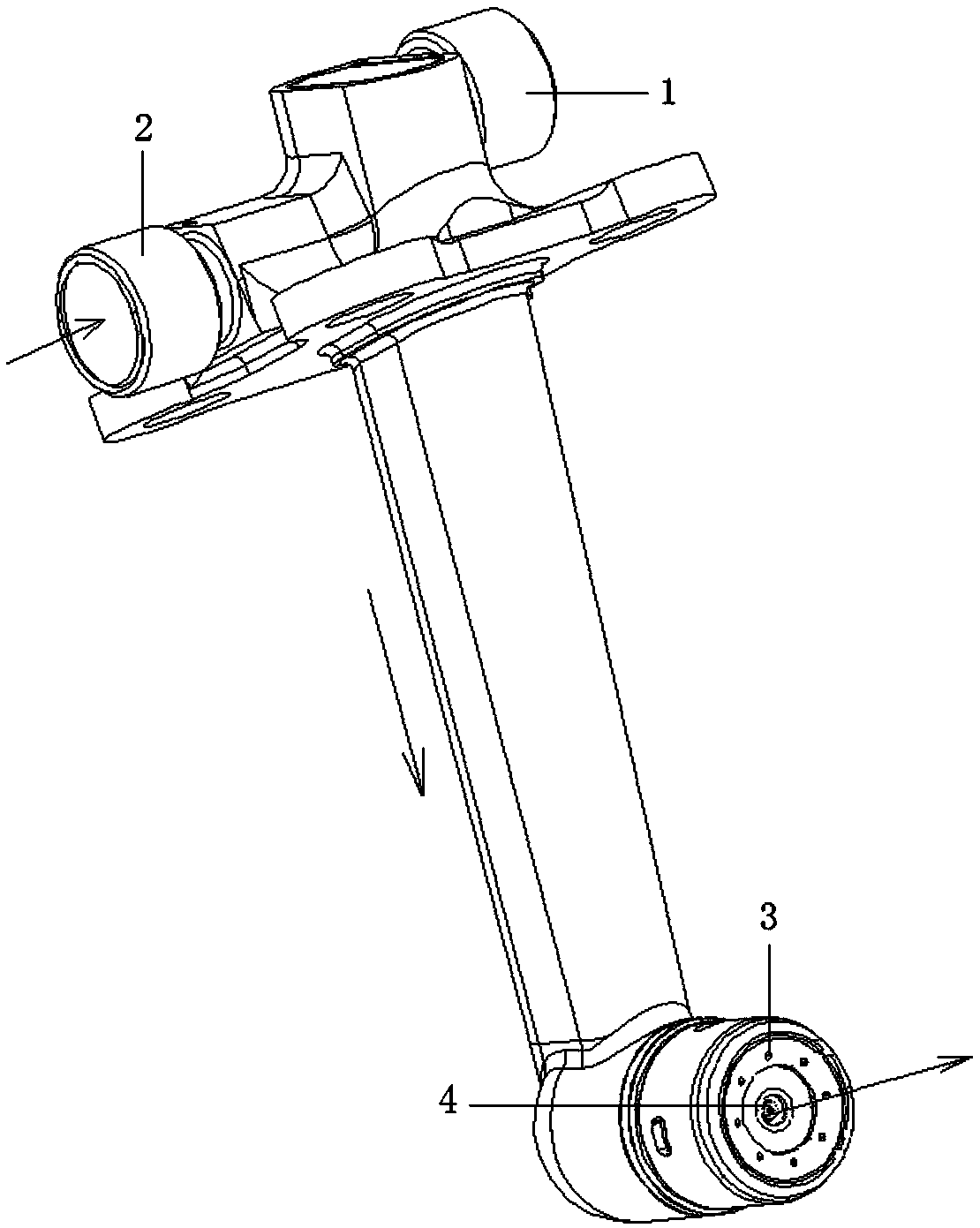

[0031] Step 2: Use abrasive flow equipment to process the main oil circuit of the nozzle, first connect the main oil inlet 1 with the abrasive flow output port of the abrasive flow equipment, and then press figure 1 The flow direction shown is to feed the water-based abrasive flow into the nozzle, and the flow direction of the water-based abrasive flow in the nozzle needs to be consistent in one direction, and the burrs on the main oil road of the nozzle are removed by the water-based abrasive flow; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com