Solenoid valve for automatic transmission

A technology for automatic transmissions and solenoid valves, applied in sliding valves, valve details, valve devices, etc., can solve problems such as increasing the difficulty of structural design and space design, making it difficult to ensure product quality stability, and increasing the response time of oil pressure complementarity, etc. To achieve the effect of convenient structure and space design, compact structure and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

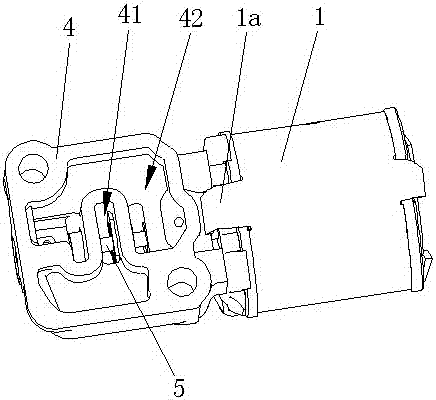

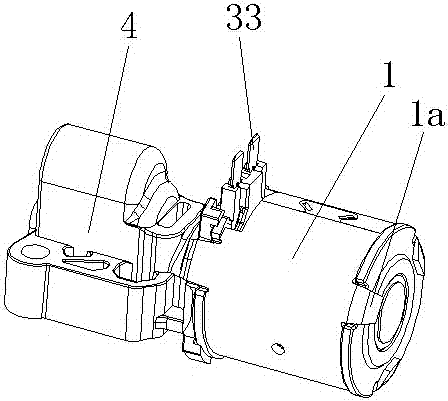

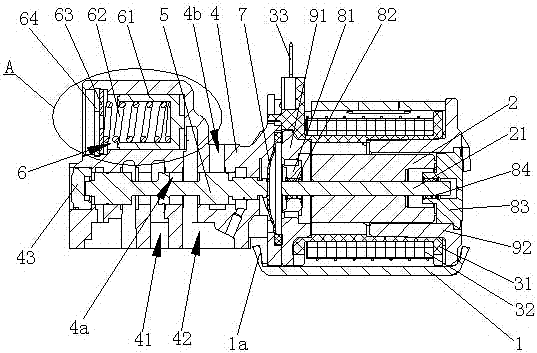

[0031] Such as Figure 1 to Figure 6 Shown is the structural representation of the present invention,

[0032] The reference signs are: shell 1, press button 1a, moving iron core 2, ejector rod 21, electromagnetic coil assembly 3, coil bobbin 31, enameled wire winding 32, electric insert 33, valve body 4, pressure chamber 4a, unloader Pressure port 4b, pressure inlet 41, pressure outlet 42, sealing cover 43, valve core 5, oil film groove 5a, pressure storage chamber 6, piston 61, bump 61a, spring 62, gasket 63, retaining spring 64, rubber pad 7 , Front baffle 81, first bearing 82, rear baffle 83, second bearing 84, front cover 91, rear cover 92.

[0033] Such as Figure 1 to Figure 6 as shown,

[0034] A solenoid valve for an automatic transmission, comprising a casing 1, a moving iron core 2 and an electromagnetic coil assembly assembled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com