Water-leakage-proof upward water adding humidifier

A humidifier and anti-leakage technology, applied in air humidification systems, heating methods, lighting and heating equipment, etc., can solve the problems of large moving distance of the driving mechanism, increased moving distance of the valve body below, and enlarged space, etc., to reduce driving Force requirements, avoid excessive movement, reduce the effect of likelihood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

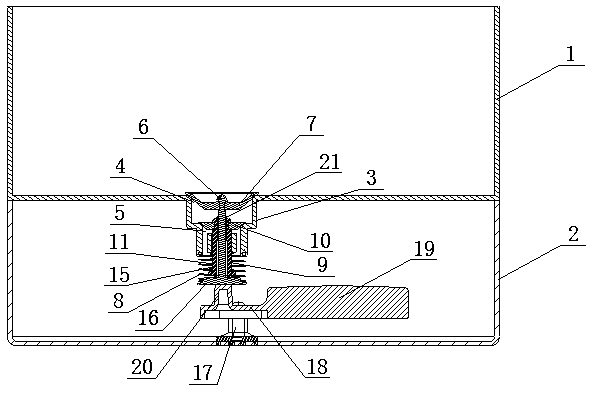

[0031] This embodiment proposes a leak-proof top-fill humidifier. The top-fill humidifier uses double valves to control the opening and closing of the water outlet of the water tank, thereby reducing the possibility of water leakage in the water tank and reducing the space occupied by the double valves. space.

[0032] Such as figure 1 , 2 As shown (the base, the atomizing device, the mist outlet channel, etc. are not shown), the leak-proof top water humidifier of this embodiment includes a base, a water tank 1 erected on the base, and an atomization chamber 2 located on the base And an atomizing device arranged in the atomizing chamber 2, the atomizing chamber 2 is provided with a mist outlet channel for discharging the water mist generated by the atomizing chamber 2. The water tank 1 is provided with a drain part for communicating with the atomization chamber 2, and the drain part is provided with a valve seat 3 having a barrel-like structure. The valve seat 3 has a first ...

Embodiment 2

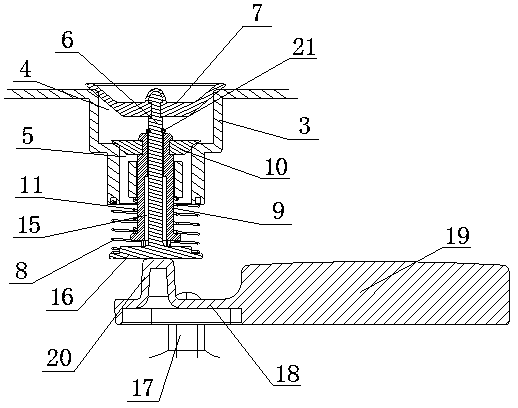

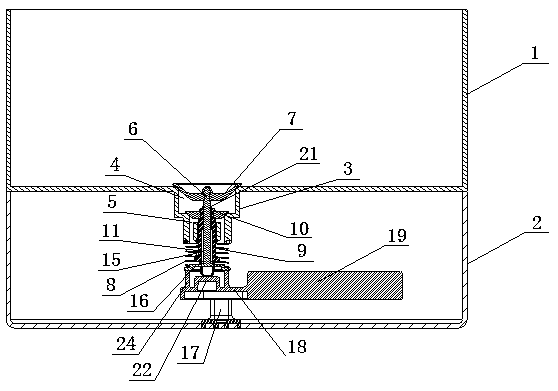

[0045] The cooperative structure of the first valve core 6, the second valve core 9 and the detection and driving mechanism in the humidifier of this embodiment is different from that of Embodiment 1, and other structures are the same, and the structure of the same parts will not be repeated here.

[0046] Such as image 3 , 4 , 5, in this embodiment, the end of the first spool 6 is provided with an avoidance portion 23 for avoiding the second spool 9, and the detection and driving mechanism is connected with the first spool 6 and the second spool respectively. 9 offset. Specifically, the end of the first valve core 6 is provided with an abutment plate 16 , and the escape portion 23 is a through hole provided on the abutment plate 16 . The bottom end of the first valve core 6 passes through the escape portion 23 and is exposed below the abutting plate 16 . The detection and driving mechanism is a lever 18 rotatably installed in the atomization chamber 2 by means of a bracke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com