Adsorption type working platform

A working platform, adsorption technology, applied in the direction of the workbench, manufacturing tools, etc., can solve the problems affecting the accuracy and efficiency of processing, the single function of the forward working platform, and the unstable working process, so as to improve product accuracy and avoid collisions. Wear, improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is described below in conjunction with accompanying drawing.

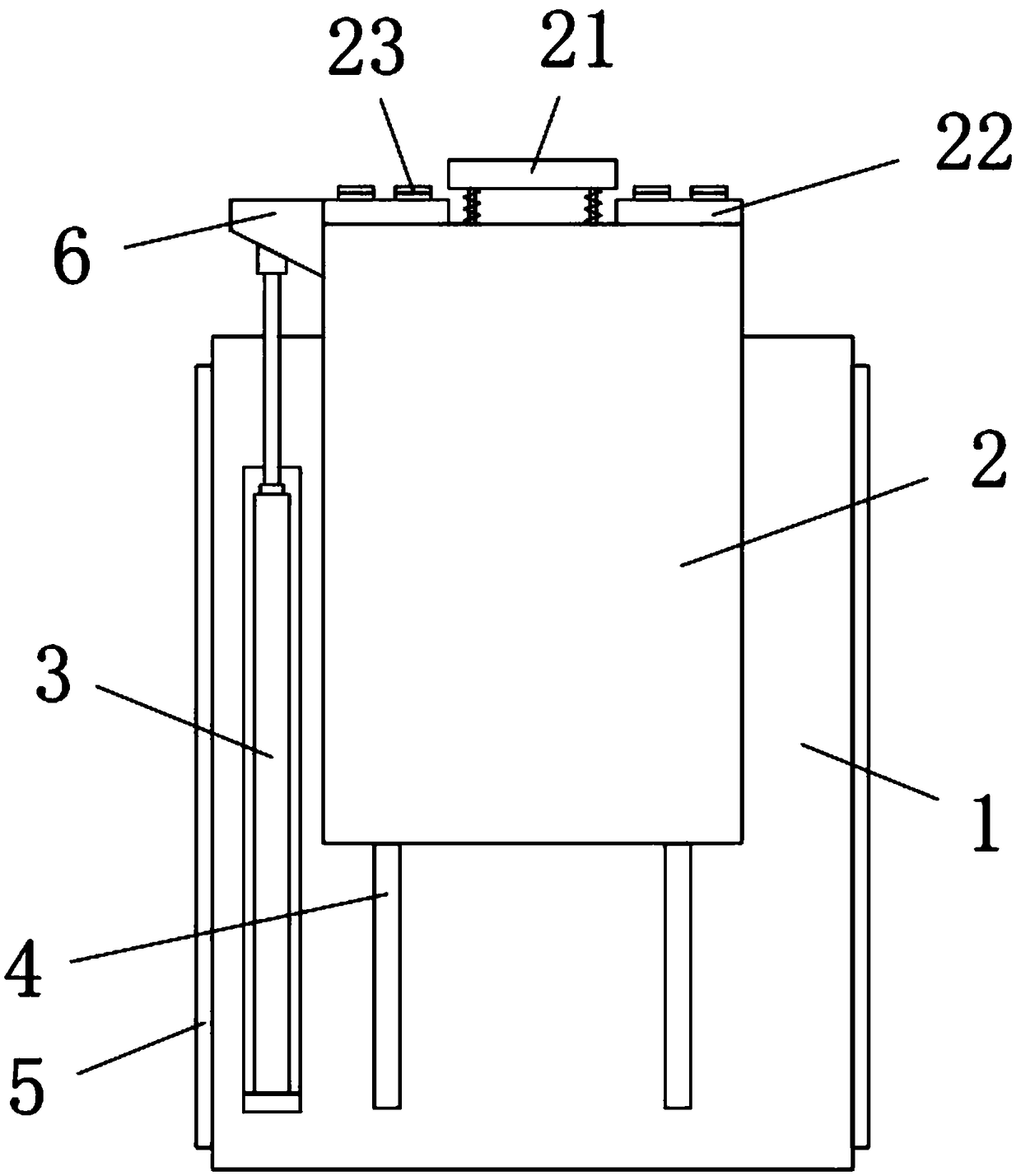

[0012] as attached figure 1 As shown, an adsorption-type working platform according to the present invention includes a fixed table 1, a worktable 2, a moving cylinder 3 and a moving positioning assembly; guard plates 5 are arranged on both sides of the fixed table 1, The fixed platform 1 is provided with a slide rail 4, and the forward cylinder 3 is an oil cylinder. The forward cylinder 3 is arranged on the fixed platform 1 and is located on one side of the workbench 2. The push block 6 and the forward cylinder 3 drive the workbench 2 to slide back and forth along the slide rail 4 .

[0013] The forward positioning assembly includes a buffer plate 21 and a mounting plate 22. The buffer plate 21 is arranged in the middle of the front end of the workbench 2 through a spring guide rod component, and the mounting plate 22 is arranged in two parts at the front end of the workbench 2. The i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com