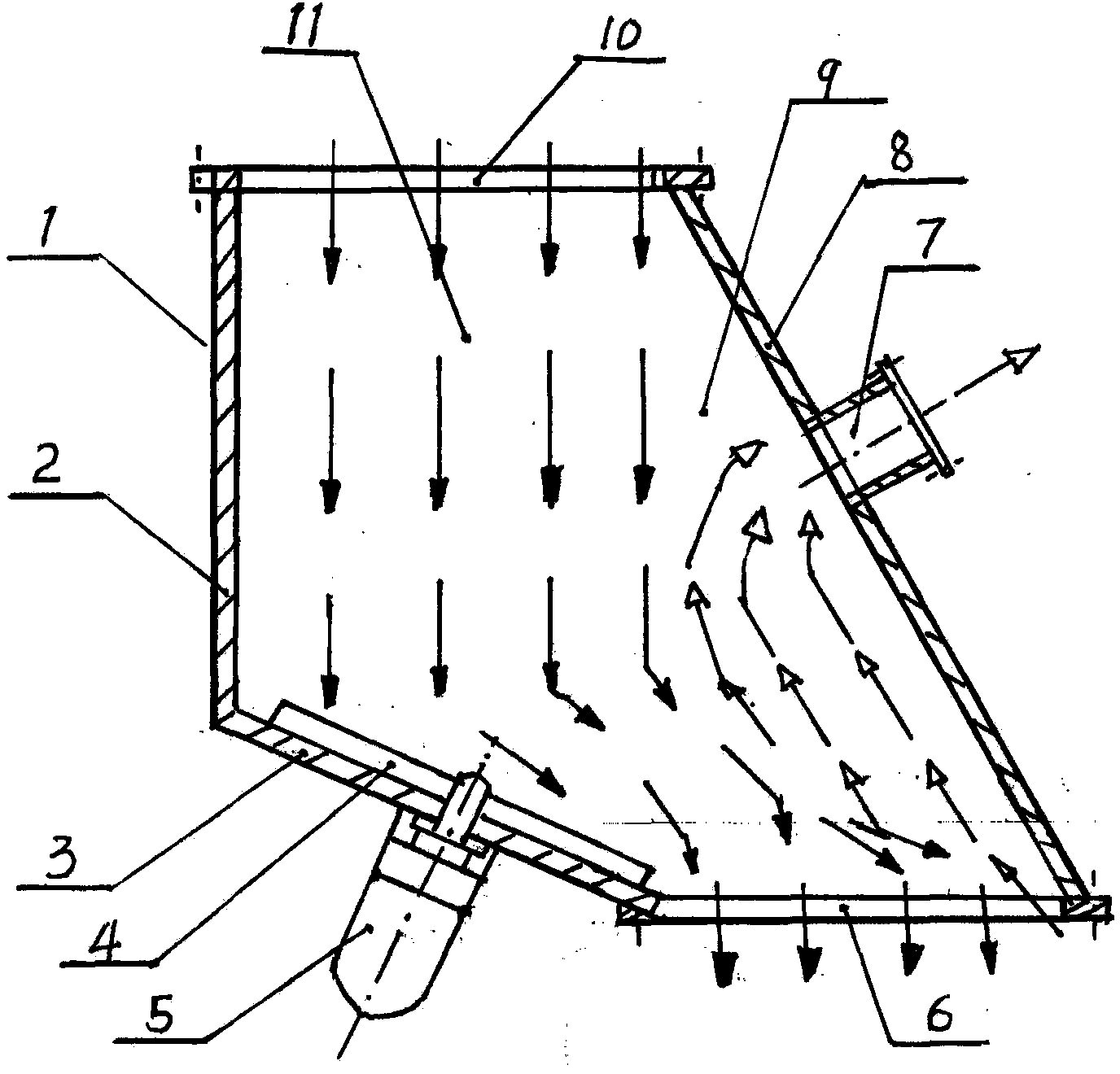

'Three-prevention' blanking pipe

A blanking tube and three-proof technology, which is used in conveyor objects, transportation and packaging, etc., can solve the problems of air pollution, short service life, and the chute is not smooth, so as to prevent material blockage, reduce wear and tear, and achieve a novel structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0016] Embodiment 2 of the "three-defense" drop pipe created by the present invention, its structure includes: In the structure of Embodiment 1, a scale-shaped wear-resistant layer is also arranged on the inner plate surface of the inclined lower plate (not shown in the figure) .

[0017] According to Example 1 of the above-mentioned technical solution, the "three-defense" blanking tube prototype was trial-produced. After the intermediate test was installed and operated, the effect was very satisfactory. It was highly praised by the test participants. It is recommended to mass-produce it as soon as possible and put it on the market to satisfy the majority of users. need.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com