High flame-retardant material for mobile phone shell

A mobile phone shell, high flame-retardant technology, applied in the field of plastic materials, can solve the problems of poor processing fluidity, poor flame retardancy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

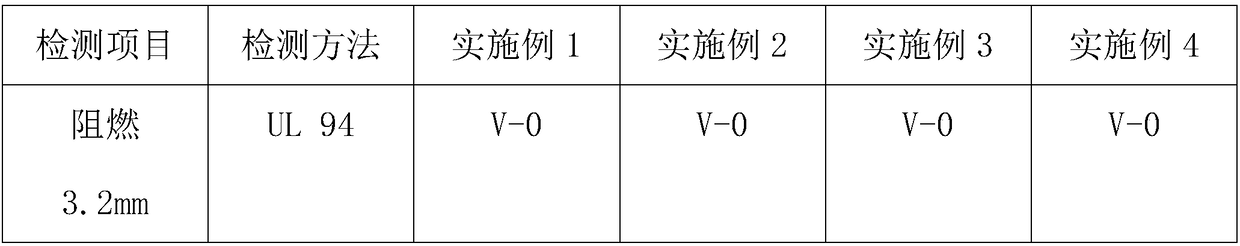

Examples

Embodiment 1

[0019] A high flame-retardant material for mobile phone casings, the raw materials of which include by weight: 65 parts of PC, 33 parts of ABS, 4 parts of composite compatibilizer, 17 parts of composite flame retardant, 0.2 parts of polytetrafluoroethylene, phthalic acid 1.2 parts of diisobutyl ester, 0.3 part of pentaerythritol stearate, 1 part of zinc stearate, 0.2 part of phosphite, and 0.8 part of 2,6-di-tert-butyl-4-methylphenol.

Embodiment 2

[0021] A high flame-retardant material for mobile phone casings, the raw materials of which include by weight: 75 parts of PC, 27 parts of ABS, 7 parts of composite compatibilizer, 13 parts of composite flame retardant, 0.7 parts of polytetrafluoroethylene, phthalic acid 0.5 part of diisobutyl ester, 0.7 part of pentaerythritol stearate, 0.4 part of zinc stearate, 0.8 part of phosphite, and 0.3 part of 2,6-di-tert-butyl-4-methylphenol.

Embodiment 3

[0023] A high flame-retardant material for mobile phone casings, the raw materials of which include by weight: 65 parts of PC, 33 parts of ABS, 4 parts of composite compatibilizer, 17 parts of composite flame retardant, 0.2 parts of polytetrafluoroethylene, phthalic acid 1.2 parts of diisobutyl ester, 0.3 part of pentaerythritol stearate, 1 part of zinc stearate, 0.2 part of phosphite, 0.8 part of 2,6-di-tert-butyl-4-methylphenol; The agent is composed of acrylonitrile-styrene copolymer and its graft and MBS in a weight ratio of 1:3; the composite flame retardant is composed of triphenyl phosphate, nano silicon dioxide, tetraphenyl bisphenol-A-di Phosphate is composed of 13:8:12 by mass ratio;

[0024] The preparation of described high flame retardant material:

[0025] S1. Dry PC at 105°C for 5 hours, and dry ABS at 85°C for 6 hours;

[0026] S2. Weigh PC, ABS, compound compatibilizer, compound flame retardant, polytetrafluoroethylene, diisobutyl phthalate, pentaerythritol ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com