High-efficiency flame-retardant modified melamino-formaldehyde foams and preparation method thereof

A melamine formaldehyde and foam technology is applied in the field of flame retardant modification of melamine formaldehyde foam, which can solve the problems of flame retardant modification failure, flame retardant modification failure, poor adhesion of flame retardant coatings, etc. Improved decomposition temperature and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Soak the melamine formaldehyde foam in a polyethyleneimine aqueous solution with a mass concentration of 0.1% and a pH of 10 for 2 minutes, take out and squeeze the excess polyethyleneimine aqueous solution contained in it, then wash it with water once, remove the water and put it in Dry at 80°C; soak the obtained melamine formaldehyde foam in an aqueous solution of sodium polyphosphate with a mass concentration of 0.1% for 2 minutes, take out and squeeze the excess aqueous solution of sodium polyphosphate contained in it, wash it once with water, and remove the water And drying at 80°C, a modified melamine-formaldehyde foam with a layer of flame-retardant film is formed.

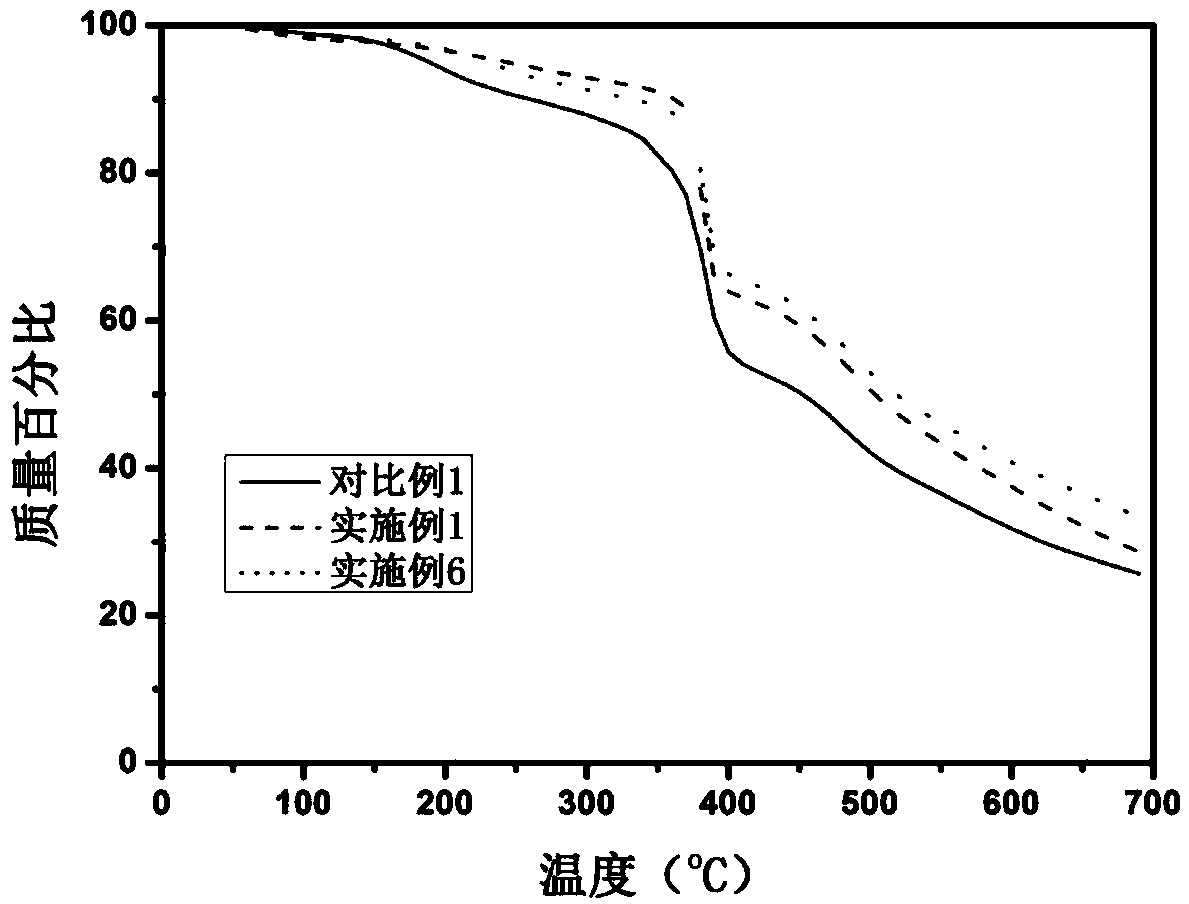

[0039] The limiting oxygen index of the foam is 35.5%; the residual mass of thermogravimetric (TG) in nitrogen atmosphere at 700°C is 26.7%; the foam can be ignited in the cone calorimetry test, and the peak heat release is 78.8kW / m 2 ; Not easy to shrink under continuous high temperature of 750 ℃. ...

Embodiment 2

[0041] First, the polyethyleneimine aqueous solution with a mass concentration of 0.2% and a pH of 10 is directly and evenly sprayed on the melamine formaldehyde foam with a spraying equipment, and dried at 98°C, and then the aqueous solution of potassium polyphosphate with a mass concentration of 0.2% Spray evenly on the melamine-formaldehyde foam to which polyethyleneimine has been attached with spraying equipment, and then dry at 98°C to form a layer of flame-retardant film; repeat the above operation once again to prepare a two-layer flame-retardant Fuel film modified melamine formaldehyde foam.

[0042] The limiting oxygen index of the foam is 39.5%; the residual mass of thermogravimetric (TG) in nitrogen atmosphere at 700°C is 27.7%; the foam can be ignited in the cone calorimetry test, and the peak heat release is 73.8kW / m 2 ; Not easy to shrink under continuous high temperature of 750 ℃.

Embodiment 3

[0044] Soak the melamine formaldehyde foam in an aqueous polyacrylamine solution with a mass concentration of 0.4% and a pH of 7 for 10 minutes, take out and squeeze the excess polyacrylamine aqueous solution contained in it, then wash it twice with water, remove the water and dry it naturally; Soak the obtained melamine formaldehyde foam in an aqueous solution of sodium polyphosphate with a mass concentration of 0.4% for 10 minutes, take out and squeeze the excess aqueous solution of sodium polyphosphate, wash it twice with water, remove the water and dry it naturally to form A layer of flame-retardant film was formed; the above operation was repeated 4 times to prepare a modified melamine-formaldehyde foam with 5 layers of flame-retardant film.

[0045] The limiting oxygen index of the foam is 40.5%; the residual mass of thermogravimetric (TG) in nitrogen atmosphere at 700°C is 28.5%; the foam cannot be ignited in the cone calorimetry test, and the peak heat release is 20.6kW...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com