A kind of mg2al-ls-ldh composite material and its preparation method and application

A composite material and mixed solution technology, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., can solve the problem of low adsorption performance, improve adsorption performance, improve adsorption effect, and improve selection sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

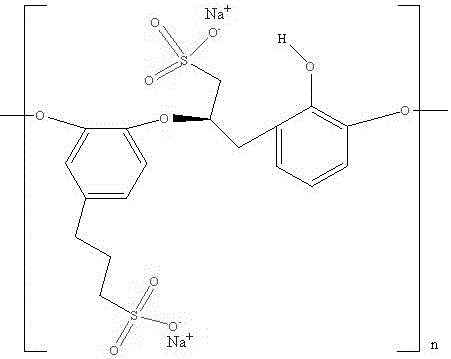

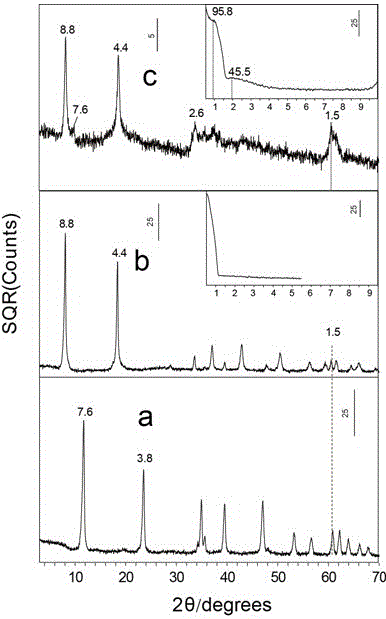

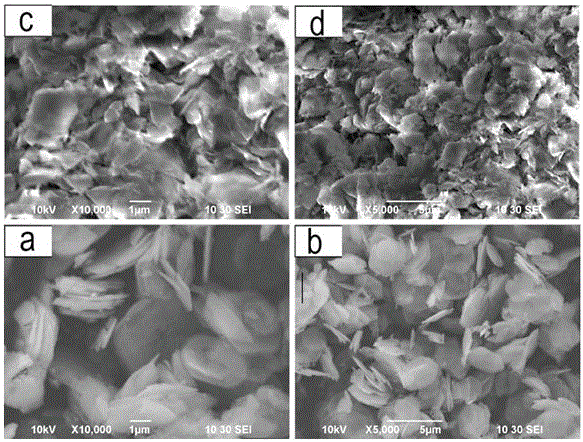

[0029] a kind of Mg 2 The preparation method of Al-LS-LDH composite material, the steps are as follows:

[0030] (1) Precursor Mg 2 Al-CO 3 -Synthesis of LDH: Precursor Mg 2 Al-CO 3 The preparation of -LDH is synthesized by hydrothermal uniform precipitation (urea hydrolysis), and the specific process is as follows: Weigh 12.82gMg(NO 3 ) 2 6H 2 O, 9.38gAl(NO 3 ) 3 9H 2 O, 7.36g urea is dubbed into 500ml mixed solution, shake well and set aside. The concentration of each ion in the mixed solution is: Mg 2+ : 0.1mol / L, Al 3+ : 0.05mol / L, Urea: 0.245mol / L. Measure 50ml of the mixed solution into a 100mL hydrothermal kettle and seal it. The reaction kettle was placed in an environment of 140° C., cooled to room temperature after 24 hours of reaction, and a white precipitate was obtained, which was washed with a large amount of water, suction filtered, and the sample was dried at room temperature in air;

[0031] (2) Mg 2 Al-NO 3 -Synthesis of LDH: Compound Mg 2 Al...

Embodiment 2

[0035] Mg in this example 2 The preparation method of Al-LS-LDH composite material is as follows:

[0036] (1) Add 0.35gMg 2 Al-NO 3 - LDH was added to 1000mL formamide solution to obtain a mixed solution, and the mixed solution was left to stand for 20 hours, and manually shaken 5 times to obtain a nanosheet colloid;

[0037] (2) Add 0.63g of sulfonated lignin to the nanosheet colloid obtained in step (1), then shake it manually to obtain a brown colloidal solution, let it stand for 45 hours, drop the brown colloidal solution into an 800mL drain In gas water, the obtained turbid liquid is centrifuged, washed with exhaust water, and dried in air at room temperature to obtain Mg 2 Al-LS-LDH composites.

Embodiment 3

[0039] Mg in this example 2 The preparation method of Al-LS-LDH composite material is as follows:

[0040] (1) Add 0.45gMg 2 Al-NO 3 - LDH was added to 1000mL formamide solution to obtain a mixed solution, the mixed solution was left to stand for 30 hours, and manually shaken 6 times to obtain a nanosheet colloid;

[0041] (2) Add 0.75g of sulfonated lignin to the nanosheet colloid obtained in step (1), then shake it manually to obtain a brown colloidal solution, let it stand for 50h, drop the brown colloidal solution into a 1000mL drain In gas water, the obtained turbid liquid is centrifuged, washed with exhaust water, and dried in air at room temperature to obtain Mg 2 Al-LS-LDH composites.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com